1. Introduction

Laser-engineered net shaping (LENS) is a metal additive manufacturing technique that enables laser repair (LR) of industrial components, in which metallic powders are melted by high energy laser, and consecutive layers are additively deposited. LENS has become one of the most important repairing methods for damaged components, considering its advantages in free forming, automation and high efficiency [

1,

2,

3,

4,

5,

6].

The laser-repaired components generally consist of the repair zone (containing the cladding and fusion zones), the heat-affected zone and the substrate. The defects and their distribution characteristics in the repaired components differ significantly from those using conventional metal forming processes, especially in the repair zone, where multiple types of defects may exist [

1,

5]. It has been shown that the repaired components are prone to generate surface cracks, which can seriously affect the repair quality and even leads to the mechanical failure of the repaired components. Therefore, the nondestructive testing of surface cracks is required to guarantee the quality and structural integrity of repaired components, a challenge which receives much attention from industry and academia [

7,

8,

9,

10]. In the detection of surface cracks, thermography methods show great potential due to their advantages of being non-contact and full-field [

11,

12,

13,

14,

15,

16].

Compared with traditional active thermography techniques, laser thermography retains the characteristics of being non-contact and full-field, and also has the advantage of high detection accuracy. It has a good application potential in nondestructive testing and evaluation of surface cracks [

17,

18,

19,

20,

21]. Pech-May et al. obtained semi-analytical expression of surface temperature for a model with a semi-infinite crack under laser pulse and lock-in excitation, and verified the validity of the model by lock-in thermography of stainless steel and glass carbon samples [

22,

23,

24]. Based on the analytical results under laser pulse excitation, González et al. obtained the temperature response under laser scanning excitation by convolution of time, providing a reliable theoretical basis for the optimization of thermographic process parameters of laser scanning thermography (LST) [

25]. To reduce the detection time, Li et al. adopted the line laser scanning thermography method, which could realize the rapid detection of cracks on smooth titanium specimens [

26]. In order to improve the identification efficiency and accuracy, Jiao et al. proposed a laser multi-mode scanning thermography (SMLT) method combining fast scanning of line laser and fine scanning of point laser, which has a large detection range, detection speed and sensitivity, and can effectively detect the position and shape of cracks on the surface of TBC material [

10]. According to the existing research results, the laser thermography method generally determines key thermographic process parameters such as laser scanning speed and power through comparative experiments, and this method has high requirements on the surface flatness of the test piece [

27]. However, the surface state of the LR components is complex, e.g., the surface is rough and there are periodic cladding tracks, which poses challenge to the detection of crack defects. It is imperative to optimize the thermal image processing algorithm to improve the efficiency and accuracy of detection [

20].

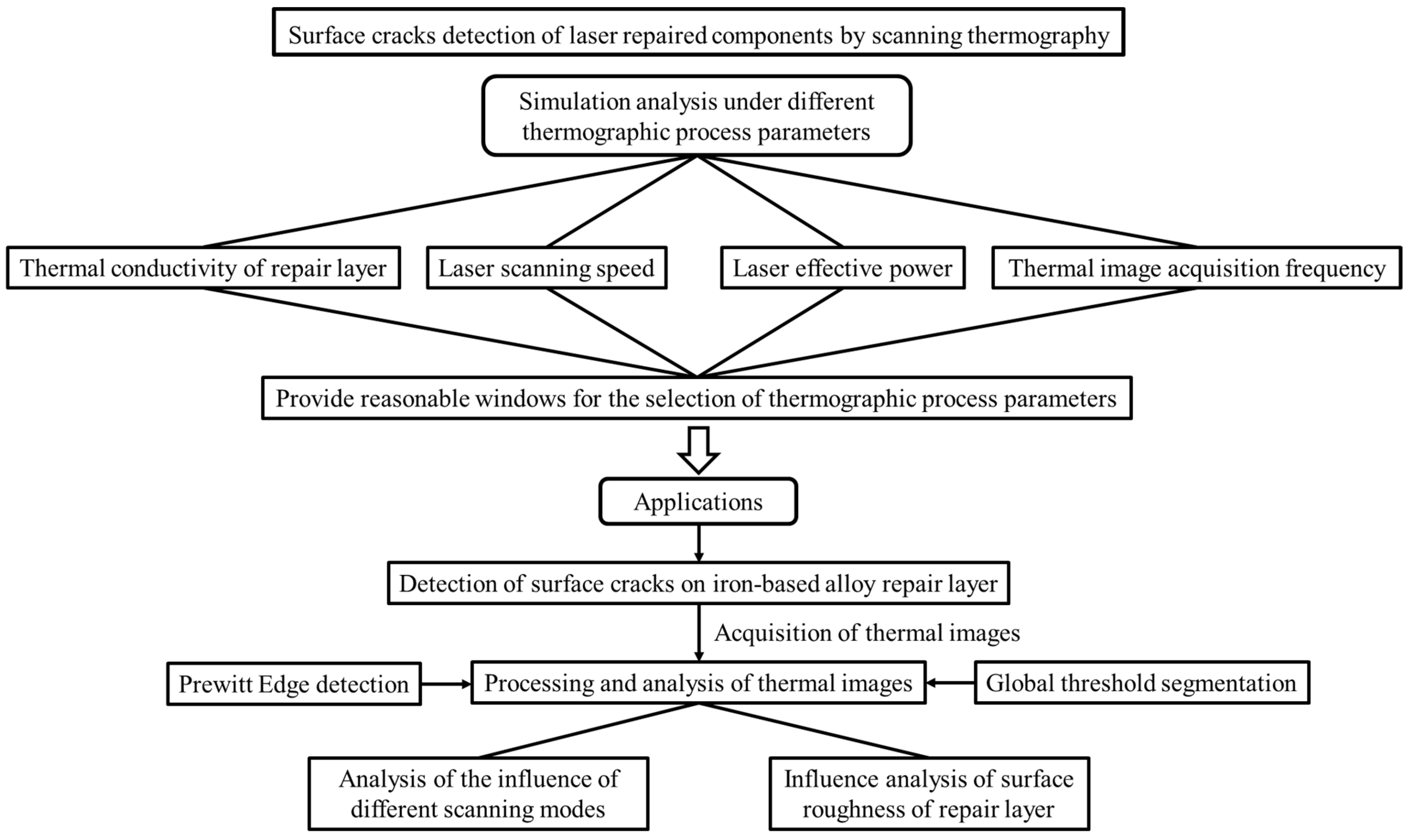

Laser spot thermography is an important way to realize laser thermography. In this paper, in order to improve the detection accuracy and efficiency of laser spot thermography, the optimization of thermographic process parameters and the development of thermal image processing algorithm are studied. Firstly, a simulation model with a vertical surface crack was established based on the finite element method, and the surface temperature response of the model under different heat source parameters was calculated. Based on the simulation results, the influences of material properties, laser power and laser scanning speed, thermal image acquisition frequency on the temperature gradient at the crack were analyzed, and the windows for selecting laser scanning parameters were proposed for iron-based and nickel-based alloy materials. The optimized thermographic process parameters were applied to the surface crack detection of real repaired components, and the thermal image sequence based on laser scanning was used for post-processing. Then, the processing results of the one-order gradient algorithm, the second-order gradient algorithm and the edge detection algorithms were compared. The results show that the edge detection algorithm based on Prewitt operator has high precision in locating crack edges, and can achieve fast crack extraction with high signal-to-noise ratio (SNR). The detection sensitivity of crack width can reach 10 μm. To further study the influence of surface roughness on thermographic detection, repair layer with and without polishing process are detected. The results show that the periodic temperature distribution is caused by the periodic cladding tracks. When the amplitude of surface fluctuation is small, the global threshold segmentation algorithm can effectively eliminate the cladding track noise. When the amplitude of surface fluctuation is large, cladding noise has a great influence on crack identification results. The framework and technical route are shown in

Figure 1.

2. Detection Principle

In order to perform theoretical analyses of laser spot thermography, a semi-infinite model is used with heat excitation on the surface by a circular Gaussian heat source, and the resultant heat conduction follows Fourier’s law. Ignoring the effects of heat convection and external radiation, Fourier’s law of heat conduction can be expressed as [

26]:

where

is the thermal diffusivity,

,

is the material density, and

is the specific heat capacity.

is the temperature distribution of the model under thermal excitation, the temperature change rate

of each point after being heated is proportional to

is the heat input per unit time, and if the effect of thermal excitation is removed, then

.

For the semi-infinite model without crack, the surface temperature distribution along the

y-axis direction under the excitation of gaussian pulse heat source is [

22]:

Consider the semi-infinite model, which contains infinite surface vertical cracks. On the model surface,

axis is perpendicular to the crack direction and

axis is parallel to the crack direction, and circular Gaussian pulse heat source excitation is applied at a distance of d from the crack, as shown in

Figure 2. The total energy obtained by the model is

, and based on the heat conduction Equation (2) and the boundary conditions, the temperature distribution along

y-axis can be obtained [

22]:

where

is the interference term of the crack on the temperature distribution,

is the radius of the laser spot (at

of the intensity),

is the thermal diffusion length, and

is the thermal effusivity. Air is the main filling medium inside the crack; its thermal conductivity is

, and the width of the crack contained in the model is

, so the thermal resistance coefficient of the crack is expressed as

.

reflects the resisting effect of the crack, and with the increase in

, the blocking effect on heat conduction becomes more significant.

is the heat absorption energy fraction of the model, which denotes the energy absorption efficiency. Then,

, where

is the

y-axis coordinate of the laser spot center [

22].

Based on Equations (3) and (4), we perform the calculations by MATLAB, and the thermal response of the cracked model under pulse excitation is obtained, as shown in

Figure 3. Thus, the influence of material properties and laser power on the distribution of surface temperature and temperature gradient can be analyzed, which provides reference for the simulation and experiment. Several commonly used materials are selected, and their thermodynamic parameters are shown in

Table 1. The distance between the circular Gaussian heat source and the crack is set as

= 1 mm, the spot radius of the heat source is set as

= 1 mm (at

of the intensity), the total energy of the pulse heat source is set as

= 300 mJ, and the excitation time is set as 0.3 s. The crack width is set as 40 μm and the thermal resistance coefficient at the crack is

. At 0.05 s after excitation, the surface temperature distribution and temperature gradient of the model along

y-axis are shown in

Figure 3a,b, where the surface temperature gradient

is defined as:

It can be seen from the results that there are significant temperature changes at the crack, so the temperature gradient can be used as the characteristic quantity to describe the shape and geometric distribution of the crack. The thermal conductivity has a significant effect on the temperature field amplitude and gradient. Note that the thermal gradient amplitude of titanium alloy material is the largest, and the crack characteristics are easier to be extracted. When studying the influence of laser power, a nickel-based alloy is selected as the model material and the total energy using the model is set as

= 100~600 mJ, and other parameters remain unchanged. As shown in

Figure 3d, the temperature abruptness at the crack is sharper with the increase in laser power.

We can see that the temperature gradient can be used as an important indicator to evaluate the detection quality, which will be further analyzed by the temperature gradient results in the following section.

3. Simulation Analysis of Factors Affecting Detection Effect

In laser thermography methods, key parameters, such as laser power and scanning speed, have an important influence on the detection quality [

29,

30]. In order to guide the selection of experimental parameters of laser thermography, based on finite element method, a simulation model with a vertical surface crack is established. Circular Gaussian heat source is used to simulate the point laser, and the surface temperature response of the model under different heat source parameters is calculated. According to the simulation results, the effects of material properties, laser power and laser scanning speed, thermal image acquisition frequency on the temperature gradient at the crack are analyzed.

3.1. Establishment of Simulation Model

The simulation model is established using ABAQUS as shown in

Figure 4 [

31]. The size of the model is 40 mm × 10 mm × 5 mm, and the model includes a vertical surface crack with a length of 6 mm, a width of L and a depth of 1 mm. In order to improve the accuracy of calculation and reduce the calculation time, more dense mesh is only set at the crack and near the crack. A point laser is scanning and exciting along the horizontal centerline

of the model surface, and the heat flux density of the point laser satisfies a Gaussian distribution [

24,

32]:

where

is the effective power of the laser, which indicates the thermal effect caused by the heat flux to the model surface, without considering the heat dissipation,

is the radius of the laser (at

of the intensity), and

is the distance from the center of the laser heat source.

The scanning speed of laser spot is set as 10 mm/s, the total scanning time is 4 s, the acquisition frequency of thermal images is 50 Hz, the total number of thermal images is 200, the radius of the heat source is 1 mm, and the effective power of the laser is 1200 mW. Taking nickel-based alloy K438 as the model material, and the thermodynamic parameters of the material are shown in

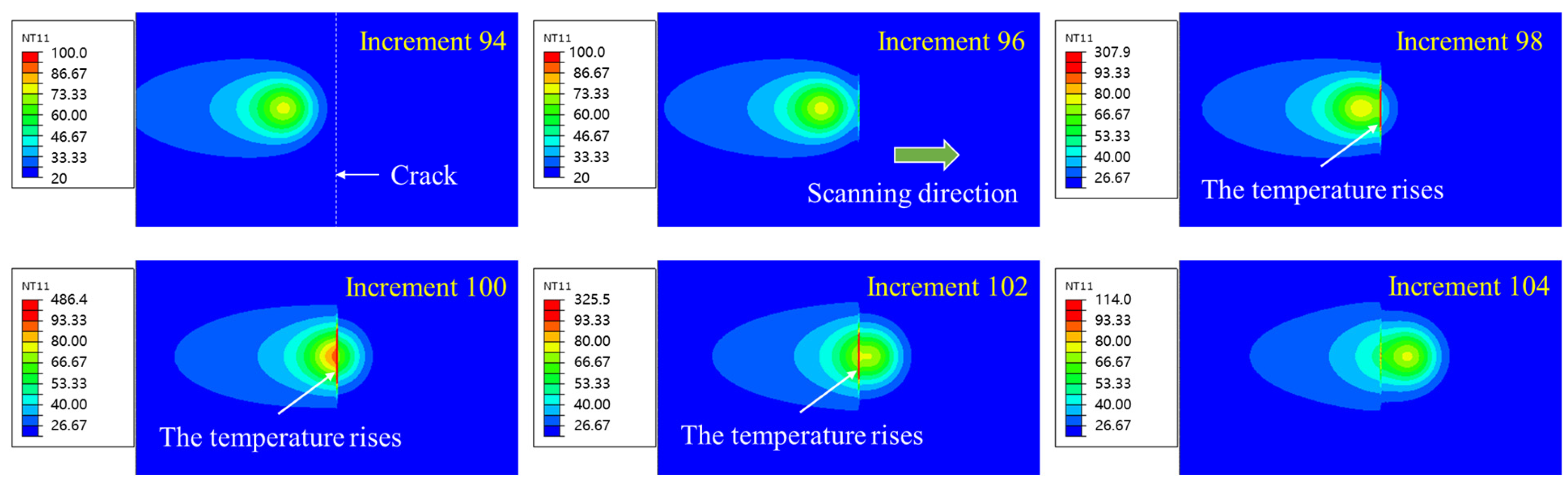

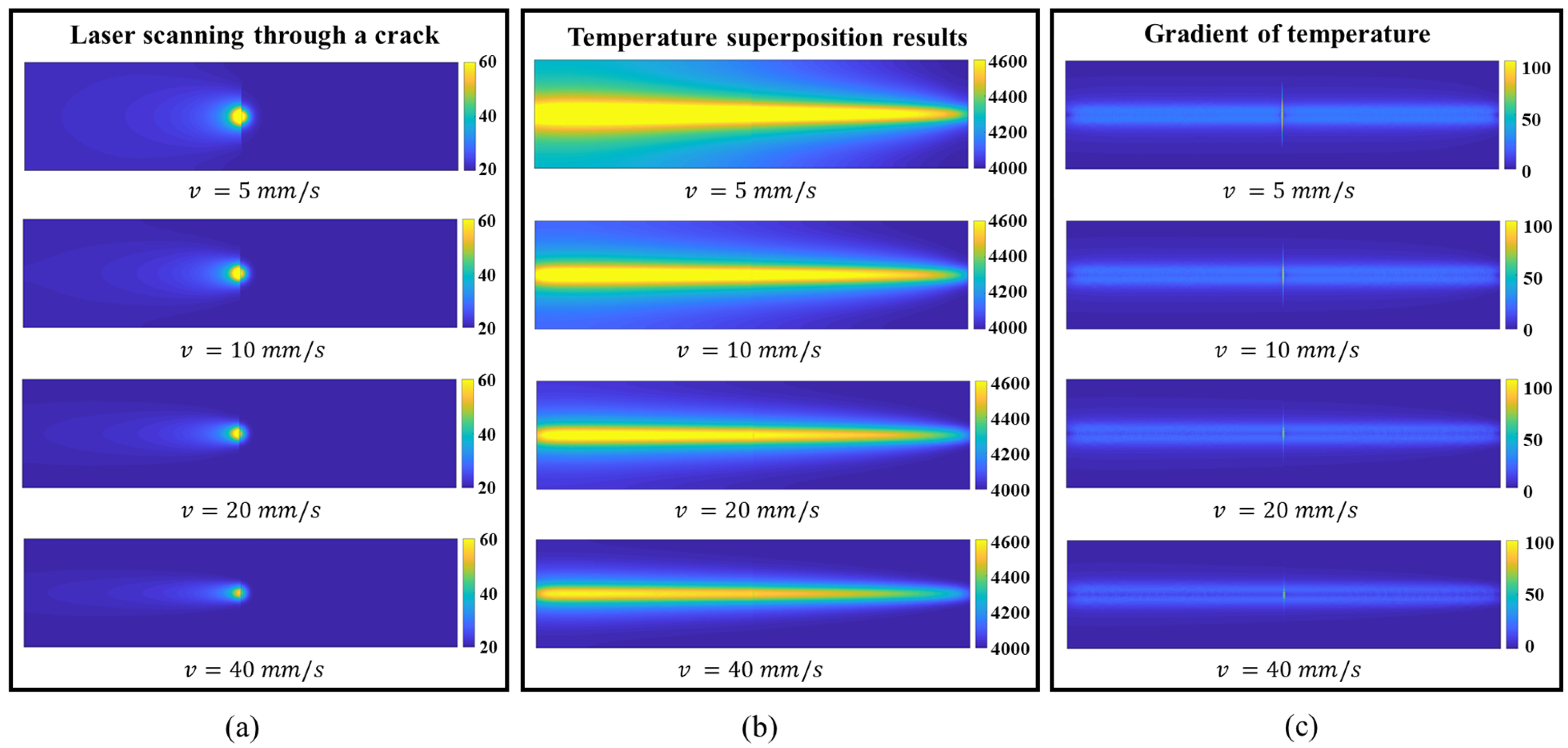

Table 1. When the laser spot scans in the direction perpendicular to the crack and approaches the crack, as shown in

Figure 5, the conduction of heat wave will be hindered by the crack boundary, so there is an obvious temperature rise at the crack edge. The surface temperature gradient can reflect the shape and geometric distribution of the crack. When the laser gets closer to the crack, the range of the thermal barrier influence expands and the temperature rise increases, and the temperature rise is the largest when the center of the point laser overlaps with the crack.

The temperature field under laser excitation contains two parts of temperature information: the background temperature without thermal excitation and the temperature change under laser excitation. Taking the temperature image of the initial moment as the background temperature field, and the background is removed for the temperature field of other times to obtain the temperature change field . Based on this, the post-processing analyses are carried out.

3.2. Crack Width

Due to the difference in LR processes, materials and service conditions, the size and distribution of the surface cracks generated in the repair layer are different, which results in a distinct detection difficulty of laser thermography [

29,

33]. Therefore, the temperature and temperature gradient value

of different crack widths under laser excitation are studied, so as to reflect the sensitivity of crack width to laser point excitation. A nickel-based alloy K348 is used as the repair layer material. The simulation model is shown in

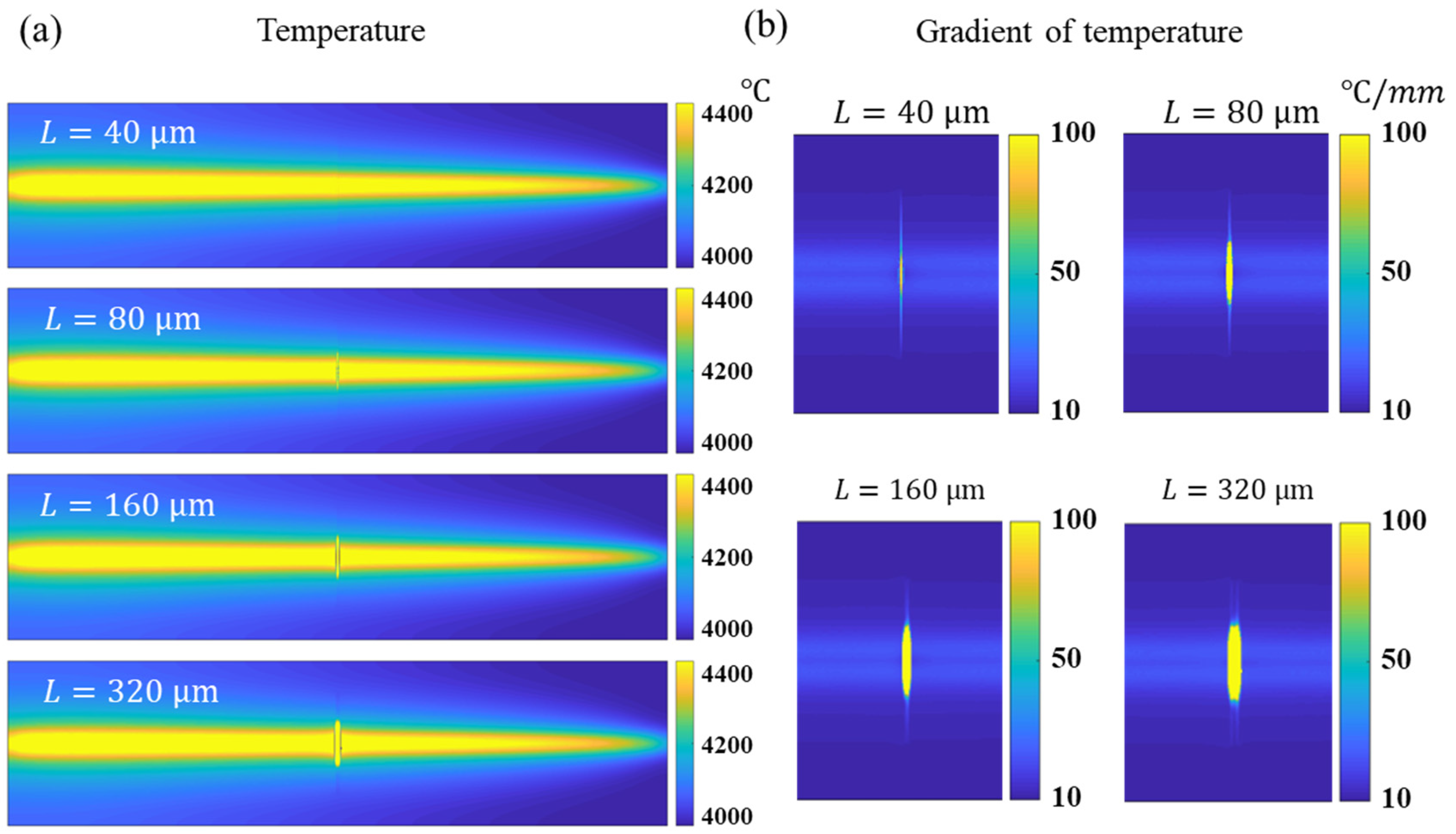

Figure 4. The effective power of the heat source is 1200 mW, the scanning speed of the heat source is 10 mm/s, the frequency of thermal image acquisition is 50 Hz, and the scanning time is 2 s. The crack widths

are set as 40 μm, 80 μm, 160 μm, and 320 μm.

Figure 6 shows the distribution of the temperature change field

and temperature gradient field

under the given crack width.

Figure 6 shows the simulation results which indicate that the temperature gradient at the crack increases rapidly with the increase in the crack width. When the crack width is larger than 80 μm, the location and geometry of the crack can be clearly observed from the temperature change field without image enhancement, as shown in

Figure 6a, which makes it easier to detect the crack. When the crack width is larger than 160 μm, the two sides of the crack boundary gradually separate. However, when the width of the crack is 40 μm, the temperature rise at the crack is difficult to be identified from the temperature change field, and the crack characteristics need to be enhanced. A good identification result can be obtained by gradient calculation, as shown in

Figure 6b.

3.3. Thermodynamic Properties of Materials

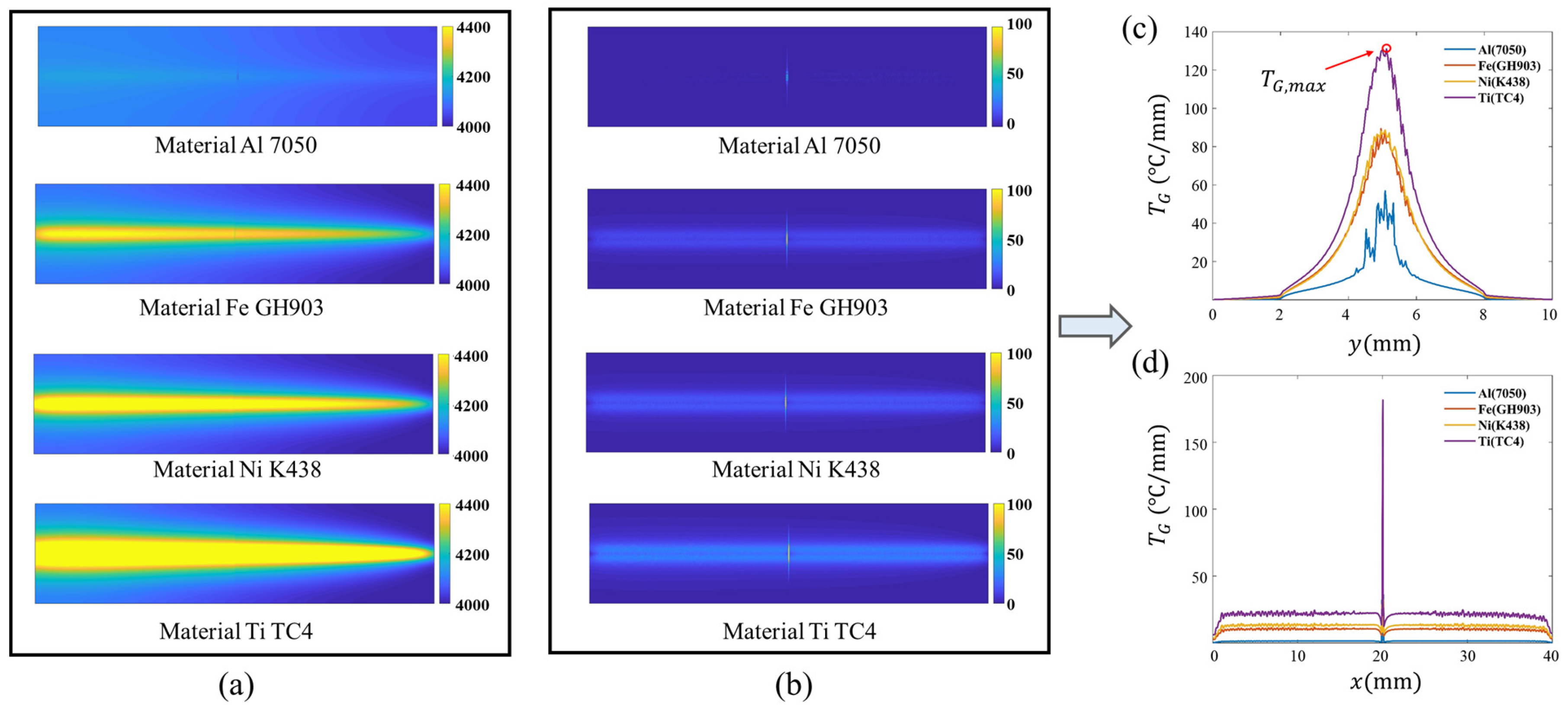

When using laser scanning thermography to detect cracks, the difference in material thermodynamic parameters will affect the detection effect, so it is necessary to explore the influence of thermodynamic parameters. Aluminum, titanium, nickel-based and iron-based alloys are used as model materials for the simulation analyses, and the width of crack is set to be 40 μm. The laser effective power is 1200 mW, the laser scanning speed is 10 mm/s, and the thermal image acquisition frequency is 50 Hz.

Figure 7a shows the superposition results of temperature change images of four materials under laser excitation.

Figure 7b shows the superposition results of temperature gradient field of temperature change images, from which the geometric characteristics of cracks can be clearly observed.

represents the gradient value of the temperature change field. Due to the scanning excitation of the circular Gaussian heat source,

at the crack also satisfies the Gaussian distribution. For several materials with different thermodynamic parameters, the distribution and amplitude of

are obviously different.

The results show that the thermal conductivity

is the main thermodynamic parameter that affects the thermal response [

34]. Among the four materials, aluminum alloy has the largest thermal conductivity, so it has the fastest thermal diffusion under heat excitation, and the smallest surface temperature and temperature gradient amplitude. Although this is not conducive to highlighting the edge features of cracks, it is conducive to expanding the detection range of cracks. Titanium alloy material has the minimum thermal conductivity

, the diffusion rate of thermal wave is slow, and the amplitude of surface temperature rise and thermal gradient caused by heat source excitation is the largest, but the heat affected zone is small, so it is necessary to reduce the scan line spacing to ensure the integrity of defect detection. Due to the similar thermal diffusivity of nickel-based and iron-based alloys [

35], the characteristics of temperature change field of the two materials are similar under circular Gaussian heat source excitation, and the difference in crack detection is small [

36].

3.4. Thermographic Process Parameters

The selection of laser parameters directly determines the quality of surface crack detection, so the optimization of thermographic process parameters is crucial. Based on the simulation model shown in

Figure 4, the influences of laser effective power

, scanning speed

and thermal image acquisition frequency

on the detection results are studied. A nickel-based alloy is selected as the repair material, the crack width

is 40 μm, and the laser spot radius is 1 mm. The setting of parameters to be discussed is shown in

Table 2.

Figure 8 shows the calculation results of

field under different laser effective powers, and the results of the display range with fixed temperature are shown in

Figure 8a. With the increase in laser effective power, the heat input per unit time of the model increases, and the thermal resistance effect of the crack on the heat wave increases, so does the amplitude of the temperature gradient.

Figure 8c shows that there is a linear relationship between the amplitude of

and the effective power

of the heat source. The increase in effective laser effective power will increase the heat affected zone, accordingly, for materials with low thermal conductivity, the increase in laser effective power is generally used to expand the heat affected zone and improve the quality of detection. However, excessively high laser effective power will cause damage to the specimen surface, so the appropriate laser effective power should be selected under the premise of considering the material properties.

Laser scanning speed is one of the important parameters which determines the detection efficiency and quality. With the increase in laser scanning speed , the following phenomena can be observed:

- (1)

Due to the rapid movement of the laser, the heat input to the model decreases, and the amplitude of the surface temperature field decreases;

- (2)

The trailing phenomenon is more significant in the laser scanning process (

Figure 9a), the temperature field contour gradually becomes flat, the heat-affected zone decreases, and the crack characteristics are weakened;

- (3)

When the heat source scans through the crack, the maximum thermal gradient on the specimen surface decreases due to the weakening of the thermal blocking phenomenon, as shown in

Figure 9c.

When selecting the laser scanning speed, the detection quality should be mainly considered, which is reflected by the thermal gradient . Secondly, the detection time should also be considered, which is determined by the scanning speed and the scanning line spacing. On the one hand, when the scanning speed of laser is too low, especially below 10 mm/s, the scanning time is too long and the amount of data obtained is large, the time for processing costs longer time. Besides, the thermal diffusion range will become limited, which may lead to an incomplete detection of defects. On the other hand, when the speed of laser scanning is too high, the thermal resistance phenomenon is cut down, and resolution for detecting crack will be lower. For the detection of iron-based alloy and nickel-based alloy repair layer, the scanning speed should not be too large. It is recommended to select 10–20 mm/s in the experiment, and it should still be properly adjusted in combination with the specimen size.

Figure 10 shows the crack shape and geometric distribution characteristics under different thermal image acquisition frequencies, which is reflected by the temperature gradient field. Based on this, it can be seen that at the laser scanning speed of 10 mm/s, when the acquisition frequency is 20 Hz, there is almost no information missing along the scanning path. At this time, two frames of thermal images are collected within the laser moving distance of 1 mm. The laser radius is 1 mm, reflecting the size of the heat-affected area, so the minimum thermal image acquisition frequency should be

, where

is the laser scanning speed and

is the laser spot radius. When the thermal image acquisition frequency is lower than

the detection information is easy to be lost. Consequently, a better characterization of the crack characteristics, i.e., a better detection quality can be obtained by increasing the acquisition frequency.

Considering the performance of infrared camera and laser scanning speed commonly used at present, the acquisition frequency of thermal image is generally set in the range of 20~50 Hz. If the laser scanning speed is higher, a higher-speed infrared camera is needed. For example, the maximum acquisition frequency of Vari oCAM® HD series camera developed by InfraTec in Germany can reach 240 Hz, and the number of pixels in thermal images reaches 2048 × 1536 pixels. However, its price is relatively expensive, so its application in the field of nondestructive testing is limited. Therefore, in order to improve the detection quality, we mainly focus on the more controllable parameters, such as laser scanning speed and laser power.

3.5. A Scheme for Selecting Laser Thermography Parameters

Considering the influence of laser power, laser scanning speed and thermal image acquisition frequency on the temperature gradient at the crack, we give the selection window for the following thermographic process parameters:

- (1)

For materials with low thermal conductivity, such as nickel-based alloys and iron-based alloys with similar thermodynamic properties, considering the detection time and quality, in the detection process of cracks with a width within 40~80 μm, the laser scanning speed is set to be 10–20 mm/s. Considering the thermal influence range under this scanning speed, the scanning line spacing can be selected as 1~3 mm. Additionally, considering the diffusion of heat, the laser power should be controlled at 3000 mW.

- (2)

For components with cracks less than 40 μm in width, the scanning speed and scanning line spacing should be reduced, and a higher frequency of thermal image acquisition should be used to achieve more accurate detection. If the detection area is large, the laser scanning speed should be appropriately increased.

4. Scanning Thermography for Crack Detection of Repair Component

In order to achieve higher quality detection of surface cracks on the repaired components, we adopt the laser point scanning thermography technique to detect cracks on the real components repaired using iron-based alloy powders. The optimization window of laser thermography parameters is verified by experiments. Meanwhile, the thermal image processing algorithm is optimized to improve the accuracy and efficiency of surface crack detection.

4.1. Experimental Setup System and Detection Scheme

The system adopted in the experiment is shown in

Figure 11 and

Figure 12a, which mainly includes laser transmitter, image acquisition device, infrared camera and tested components [

18]. VarioCam HR infrared camera produced by Infratec in Germany is used, with a resolution of 1024 × 768 pixels, the measurable temperature range is −40~1200 °C, the measurement accuracy is ±1 °C or ±1%, the temperature resolution (30 °C) is up to 0.02 K, and the maximum thermal image acquisition frequency is 30 Hz.

Fiber Laser Marking Machine (XQFL-G50 W) is used as the laser transmitter, and its maximum laser power is 50 W. Based on the parameter analyses in the simulation, we set the laser scanning speed in the experiment to be 15 mm/s, and the laser power 3 W to ensure no damage to the specimen surface. Set the image acquisition frequency to be 30 Hz to obtain enough thermal image data and reduce the loss of information.

The edge area of the plate-like specimen shown in

Figure 12b is repaired using LENS technique. The repair layer is made of iron-based alloy, and the surface cracks are formed in the process of manufacturing. The repair layer is divided into three main areas: Area-1, Area-2 and Area-3, where the area of Area-1 is 8.4 × 2.2 cm

2. Area-1 was detected by a combination of various scanning modes. As shown in

Figure 12c, assuming that the direction perpendicular to the molten pool is 0°, and the angle between the scanning direction and the 0° direction is

, The scanning combination modes are shown in

Table 3. The line spacing of the laser scanning path is set to be 3 mm to improve the detection efficiency.

The other two areas (Area-2 and Area-3) are detected by scanning in the four directions of 0°, 45°, 90° and 135°. To ensure the detection quality, the line spacing of area-2 and area-3 is set to be 2 mm and 1 mm to achieve more precise scanning.

4.2. Experimental Results and Analysis

The thermal image processing and analyses are at the core of crack detection quality. Therefore, we take thermal images scanned along the direction of 0° as an example to show the process of thermal image processing, as shown in

Figure 13. Firstly, the infrared camera is used to collect the n-frame thermal image in the laser scanning process,

n = 1550. Then, MATLAB is used to digitize the thermal image sequence, as shown in

Figure 13b. Further analysis is conducted based on digital image processing technique. The first image is taken as the reference image, representing the background temperature field without thermal excitation. The temperature change sequence is obtained by subtracting the reference image from other frames, and the post-processing analysis is conducted on this basis. In the post-processing process, the shape and geometric distribution of cracks are extracted by the enhancement and segmentation algorithms of temperature change images. The commonly used post-processing algorithms include first-order and second-order gradient algorithms, edge detection algorithms, etc., and the detection quality is different to some extent [

10,

38,

39,

40,

41].

In

Figure 13c, we compare and analyze the detection effects of the traditional gradient algorithm and several commonly used edge detection algorithms. In

Table 4, we compare the number of parameters and calculation time of several algorithms. The processor type used for calculation is Intel (R) Core (TM) i7-10870H CPU. The results show that the traditional first-order and second-order gradient algorithms require more parameters, the parameter adjustment process is relatively tedious and the calculation time is long.

The edge detection algorithms based on Prewitt, Robert and Sobel operators can achieve higher SNR detection results, and the crack edge positioning is more accurate, the detection precision can be improved to be 1 pixel, and the calculation time is reduced. Among them, edge detection based on Prewitt has the shortest computation time, and has significant detection capability for horizontal and vertical cracks.

For the thermographic detection of the surface crack of laser-repaired components, the SNR and calculation time of the detection results are taken into consideration, and the edge detection based on Prewitt operator is selected for post-processing of the temperature change image sequence. By calculating the edge information of the temperature change image, the high-precision and rapid detection of the crack shape and geometric position is achieved.

Figure 14 shows the scanning and detection results of laser spot along the four directions: 0°, 45°, 90° and 135°. The edge detection algorithm based on Prewitt operator is used to process the temperature change image sequence. As can be seen that when scanning along a certain direction, the crack parallel to the laser scanning direction can be clearly detected, while not the case for the perpendicular cracks. When scanning in a single direction, it is impossible to detect all the crack information, so the combination of scanning in multiple directions must be used [

10].

Therefore, several combinations of laser scanning modes are considered to achieve comprehensive crack detection. After the collection and processing of thermal image, the detection results are obtained as shown in

Figure 15. When the scanning combination along 0° and 90° is adopted, the horizontal and numerical crack detection can be achieved, but the detection effect along oblique crack is not good. When the scanning combination of 0°, 45°, 90° and 135° is adopted, better detection effect can be obtained, and the resulting image contains more crack details. When six or more scanning directions are used for detection, the detection effect is not significantly improved and the detection efficiency is low. Therefore, it is recommended to use the scanning combination of 0°, 45°, 90° and 135° to ensure the detection effect and efficiency.

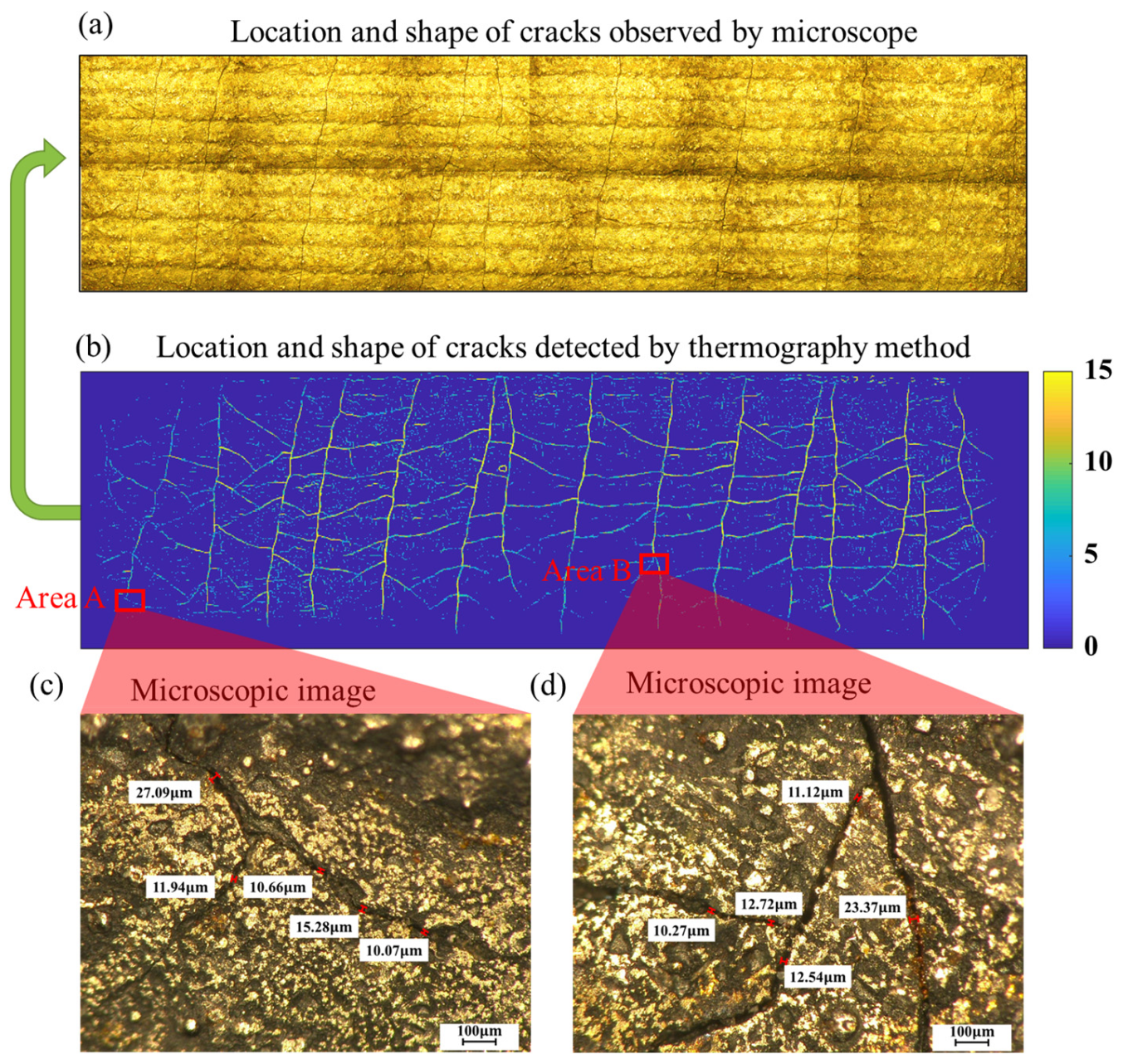

Thermography method has good detection results in different repair areas. As shown in

Figure 16, in the detection of the other two areas, the edge detection algorithm based on Prewitt operator is used to process the temperature change image sequence by combining the four-direction scanning combination mode. Clear crack shape and geometric distribution can be obtained. Therefore, it can be seen that laser scanning thermography has good applicability in the detection of different areas. By using laser scanning thermography in three areas, we can obtain the crack shape and geometric distribution in each part of the repair layer, as shown in

Figure 17.

From the detection results shown in

Figure 17, obvious cracks exist in the tested area with a dendritic distribution. The main cracks are distributed along the direction of 0°, and the angle between the secondary cracks and the main cracks is mostly 45~90°. By observing Area-1 with a 50× microscope, a clear crack shape and geometric distribution can be obtained as shown in

Figure 18a, which is in good agreement with the results of thermographic detection as shown in

Figure 18b. Based on the laser spot scanning thermography, a crack with a minimum width of 10.07 μm can be detected, which proves that the thermography method has good applicability and high detection sensitivity for the detection of irregular surface cracks.