Batch and Column Adsorption of Phosphorus by Modified Montmorillonite

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material and Chemicals

2.2. Preparation of Modified Montmorillonite

2.3. Preparation of Phosphorus Stock Solution

2.4. The Morphology of MMt and Al13-O-MMt as Characterized by Scanning Electron Microscope (SEM)

2.5. Batch Adsorption of Phosphorus by Al13-O-MMt

2.5.1. Experiment Regarding the Effect of pH on Phosphorus Adsorption

2.5.2. Experiment Regarding the Effect of Concentration on Phosphorus Adsorption at Different Temperatures

2.5.3. Experiment Regarding the Effect of Adsorbent Dosage on Phosphorus Adsorption

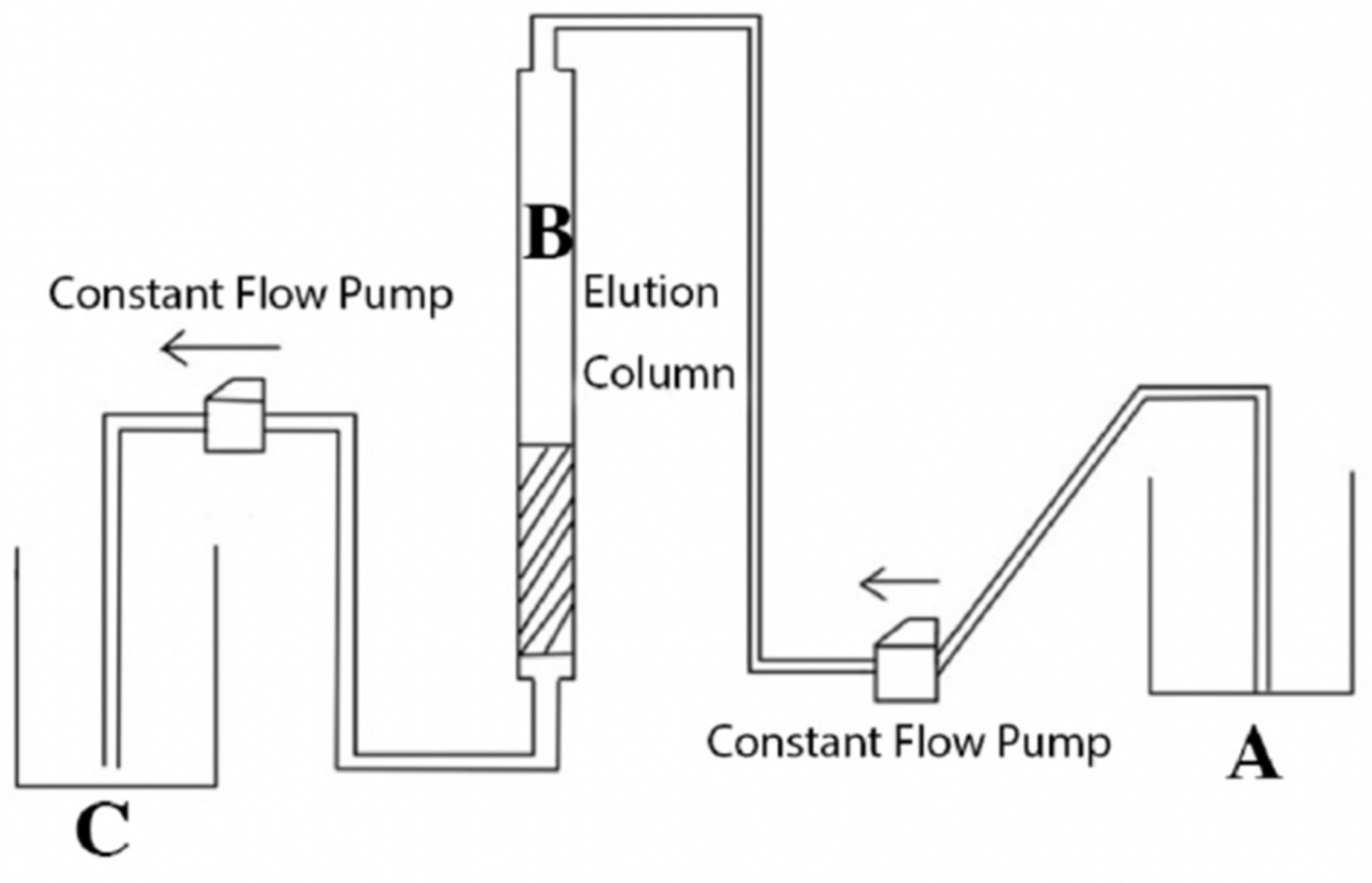

2.6. Column Adsorption Experiment in Elution Column

2.7. Calculation of Breakthrough Time

2.8. Analysis for Further Confirmation of Phosphorus Adsorption

3. Results and Discussion

3.1. The Morphology of MMt and Al13-O-MMt

3.2. The Batch Adsorption of Phosphorus by Al13-O-MMt

3.2.1. Effect of pH on Phosphorus Adsorption by Al13-O-MMt

3.2.2. Effect of Initial Concentration of Phosphorus and Adsorption Temperature on Phosphorus Adsorption by Al13-O-MMt

3.2.3. Effect of the Amount of Al13-O-MMt on Phosphorus Adsorption

3.3. Column Adsorption of Phosphorus by Al13-O-MMt in the Elution Column and Breakthrough Time Analysis

3.4. Further Confirmation of Batch and Column Adsorptions of Phosphorus by XRD Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gutiérrez, G.G. Oxydation of Clay Nanoreinforced Polyolefins; Arts et Métiers ParisTech: Paris, France, 2010. [Google Scholar]

- Uddin, F. Montmorillonite: An Introduction to Properties and Utilization; IntechOpen: London, UK, 2018. [Google Scholar]

- Shao, Y.; Gan, Z.; Epifanovsky, E.; Gilbert, A.T.; Wormit, M.; Kussmann, J.; Lange, A.W.; Behn, A.; Deng, J.; Feng, X. Advances in molecular quantum chemistry contained in the Q-Chem 4 program package. Mol. Phys. 2015, 113, 184–215. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, A.; Chaker, Y.; Belarbi, E.H.; Abbas, O.; Chotard, J.; Abassi, H.; Van Nhien, A.N.; El Hadri, M.; Bresson, S. XRD and ATR/FTIR investigations of various montmorillonite clays modified by monocationic and dicationic imidazolium ionic liquids. J. Mol. Struct. 2018, 1173, 653–664. [Google Scholar] [CrossRef]

- Gu, S.; Kang, X.; Wang, L.; Lichtfouse, E.; Wang, C. Clay mineral adsorbents for heavy metal removal from wastewater: A review. Environ. Chem. Lett. 2019, 17, 629–654. [Google Scholar] [CrossRef]

- Wang, J.; Xu, Y.; Han, Y.; Yan, L.; Wei, Q. Study on Adsorption Properties of modified montmorillonite for organic pollutants. J. Univ. Jinan 2008, 1, 72–76. [Google Scholar] [CrossRef]

- Li, Y.; Narayanan Nair, A.K.; Kadoura, A.; Yang, Y.; Sun, S. Molecular simulation study of montmorillonite in contact with water. Ind. Eng. Chem. Res. 2019, 58, 1396–1403. [Google Scholar] [CrossRef] [Green Version]

- Ilari, R.; Etcheverry, M.; Waiman, C.V.; Zanini, G.P. A simple cation exchange model to assess the competitive adsorption between the herbicide paraquat and the biocide benzalkonium chloride on montmorillonite. Colloids Surf. A Physicochem. Eng. Asp. 2021, 611, 125797. [Google Scholar] [CrossRef]

- Zeng, G.; Liu, Y.; Tang, L.; Yang, G.; Pang, Y.; Zhang, Y. Enhancement of Cd(II) adsorption by polyacrylic acid modified magnetic mesoporous carbon. Chem. Eng. J. 2015, 259, 153–160. [Google Scholar] [CrossRef]

- Jinxu, N.; Wenguang, T.; Mi, L.; Pengjun, Y. Research on preparation of modified bentonite and its removal of ammonia nitrogen and phosphorus from Wastewater. In Proceedings of the 2011 International Conference on Electric Technology and Civil Engineering (ICETCE), Lushan, China, 22–24 April 2011; pp. 6799–6804. [Google Scholar]

- Kalaiselvimary, J.; Selvakumar, K.; Rajendran, S.; Sowmya, G.; Ramesh Prabhu, M. Effect of surface-modified montmorillonite incorporated biopolymer membranes for PEM fuel cell applications. Polym. Compos. 2019, 40, E301–E311. [Google Scholar] [CrossRef]

- Hu, X.; Ke, Y. The influence of organic modified montmorillonite on the solution properties of copolymer containing β-cyclodextrin. J. Polym. Res. 2020, 27, 19. [Google Scholar] [CrossRef]

- Xiao, F.; Yan, B.-Q.; Zou, X.-Y.; Cao, X.-Q.; Dong, L.; Lyu, X.-J.; Li, L.; Qiu, J.; Chen, P.; Hu, S.-G. Study on ionic liquid modified montmorillonite and molecular dynamics simulation. Colloids Surf. A Physicochem. Eng. Asp. 2020, 587, 124311. [Google Scholar] [CrossRef]

- Liu, S.; Chen, M.; Cao, X.; Li, G.; Zhang, D.; Li, M.; Meng, N.; Yin, J.; Yan, B. Chromium (VI) removal from water using cetylpyridinium chloride (CPC)-modified montmorillonite. Sep. Purif. Technol. 2020, 241, 116732. [Google Scholar] [CrossRef]

- Abdel-Karim, A.; El-Naggar, M.E.; Radwan, E.; Mohamed, I.M.; Azaam, M.; Kenawy, E.-R. High-performance mixed-matrix membranes enabled by organically/inorganic modified montmorillonite for the treatment of hazardous textile wastewater. Chem. Eng. J. 2021, 405, 126964. [Google Scholar] [CrossRef]

- Jang, J.; Lee, D.S. Effective phosphorus removal using chitosan/Ca-organically modified montmorillonite beads in batch and fixed-bed column studies. J. Hazard. Mater. 2019, 375, 9–18. [Google Scholar] [CrossRef] [PubMed]

- Ong, L.; Soetaredjo, F.; Kurniawan, A.; Ayucitra, A.; Liu, J.-C.; Ismadji, S. Investigation on the montmorillonite adsorption of biocidal compounds incorporating thermodynamical-based multicomponent adsorption isotherm. Chem. Eng. J. 2014, 241, 9–18. [Google Scholar] [CrossRef] [Green Version]

- Yi, H.; Jia, F.; Zhao, Y.; Wang, W.; Song, S.; Li, H.; Liu, C. Surface wettability of montmorillonite (0 0 1) surface as affected by surface charge and exchangeable cations: A molecular dynamic study. Appl. Surf. Sci. 2018, 459, 148–154. [Google Scholar] [CrossRef]

- Del Mar Orta, M.; Martín, J.; Medina-Carrasco, S.; Santos, J.L.; Aparicio, I.; Alonso, E. Adsorption of propranolol onto montmorillonite: Kinetic, isotherm and pH studies. Appl. Clay Sci. 2019, 173, 107–114. [Google Scholar] [CrossRef]

- Camacho, L.M.; Deng, S.; Parra, R.R. Uranium removal from groundwater by natural clinoptilolite zeolite: Effects of pH and initial feed concentration. J. Hazard. Mater. 2010, 175, 393–398. [Google Scholar] [CrossRef]

- Almasri, D.A.; Rhadfi, T.; Atieh, M.A.; McKay, G.; Ahzi, S. High performance hydroxyiron modified montmorillonite nanoclay adsorbent for arsenite removal. Chem. Eng. J. 2018, 335, 1–12. [Google Scholar] [CrossRef]

- Wang, Y.-Q.; Zheng, Z.-Y.; Zhao, Y.-K.; Huang, J.-H.; Zhang, Z.-B.; Cao, X.-H.; Dai, Y.; Hua, R.; Liu, Y.-H. Adsorption of U (VI) on montmorillonite pillared with hydroxy-aluminum. J. Radioanal. Nucl. Chem. 2018, 317, 69–80. [Google Scholar] [CrossRef]

- Rezala, H.; Douba, H.; Boukhatem, H.; Romero, A. Adsorption of methylene blue by hydroxyl-aluminum pillared montmorillonite. J. Chem. Soc. Pak. 2020, 42, 550–563. [Google Scholar]

- Ruiz, G. Effect of salinity and temperature on the adsorption of Hg(II) from aqueous solutions by a Ca-montmorillonite. Environ. Technol. 2009, 30, 63–68. [Google Scholar] [CrossRef] [PubMed]

- Ma, J.; Lei, Y.; Khan, M.A.; Wang, F.; Chu, Y.; Lei, W.; Xia, M.; Zhu, S. Adsorption properties, kinetics & thermodynamics of tetracycline on carboxymethyl-chitosan reformed montmorillonite. Int. J. Biol. Macromol. 2019, 124, 557–567. [Google Scholar] [PubMed]

- Wu, K.; Ye, Q.; Wu, R.; Dai, H. Alkali metal-promoted aluminum-pillared montmorillonites: High-performance CO2 adsorbents. J. Solid State Chem. 2020, 291, 121585. [Google Scholar] [CrossRef]

- Chauhan, M.; Saini, V.K.; Suthar, S. Removal of pharmaceuticals and personal care products (PPCPs) from water by adsorption on aluminum pillared clay. J. Porous Mater. 2020, 27, 383–393. [Google Scholar] [CrossRef]

- Zou, X.-Y.; Xiao, F.; Liu, S.-R.; Cao, X.-Q.; Li, L.; Chen, M.; Dong, L.; Lyu, X.-J.; Gai, Y.-J. Preparation and application of CPC/Keggin-Al30 modified montmorillonite composite for Cr (VI) removal. J. Water Process Eng. 2020, 37, 101348. [Google Scholar] [CrossRef]

- Wang, M.; Orr, A.A.; He, S.; Dalaijamts, C.; Chiu, W.A.; Tamamis, P.; Phillips, T.D. Montmorillonites can tightly bind glyphosate and paraquat reducing toxin exposures and toxicity. ACS Omega 2019, 4, 17702–17713. [Google Scholar] [CrossRef] [Green Version]

- Manohar, D.M.; Krishnan, K.A.; Anirudhan, T.S. Removal of mercury(II) from aqueous solutions andchlor-alkali industry wastewater using2-mercaptobenzimidazole-clay. Water Res. 2002, 36, 1609–1619. [Google Scholar] [CrossRef]

- Umpuch, C.; Sopasin, S. Adsorption of Malachite Green by Chitosan Modified Montmorillonite. In Proceedings of the International Science and Technology Conference, Paris, France, 18–20 July 2018; p. 53. [Google Scholar]

- França, D.; Oliveira, L.; Nunes Filho, F.; Silva Filho, E.; Osajima, J.; Jaber, M.; Fonseca, M. The Versatility of Montmorillonite in Water Remediation Using Adsorption: Current Studies and Challenges in Drug Removal. J. Environ. Chem. Eng. 2022, 10, 107341. [Google Scholar] [CrossRef]

- Wibulswas, R. Batch and fixed bed sorption of methylene blue on precursor and QACs modified montmorillonite. Sep. Purif. Technol. 2004, 39, 3–12. [Google Scholar] [CrossRef]

- Zelaya Soulé, M.E.; Flores, F.M.; Torres Sánchez, R.M.; Fernández, M.A. Norfloxacin adsorption on montmorillonite and carbon/montmorillonite hybrids: pH effects on the adsorption mechanism, and column assays. J. Environ. Sci. Health Part A 2020, 56, 113–122. [Google Scholar] [CrossRef]

- Yotsuji, K.; Tachi, Y.; Sakuma, H.; Kawamura, K. Effect of interlayer cations on montmorillonite swelling: Comparison between molecular dynamic simulations and experiments. Appl. Clay Sci. 2021, 204, 106034. [Google Scholar] [CrossRef]

- Peng, J.; Yi, H.; Song, S.; Zhan, W.; Zhao, Y. Driving force for the swelling of montmorillonite as affected by surface charge and exchangeable cations: A molecular dynamic study. Results Phys. 2019, 12, 113–117. [Google Scholar] [CrossRef]

- Yang, J.; Wang, S.; Xu, N.; Ye, Z.; Yang, H.; Huangfu, X. Synthesis of montmorillonite-supported nano-zero-valent iron via green tea extract: Enhanced transport and application for hexavalent chromium removal from water and soil. J. Hazard. Mater. 2021, 419, 126461. [Google Scholar] [CrossRef] [PubMed]

- Daňo, M.; Viglašová, E.; Galamboš, M.; Štamberg, K.; Kujan, J. Surface complexation models of pertechnetate on biochar/montmorillonite composite—Batch and dynamic sorption study. Materials 2020, 13, 3108. [Google Scholar] [CrossRef]

- Lawal, I.A.; Moodley, B. Fixed-bed and batch Adsorption of pharmaceuticals from aqueous solutions on ionic liquid-modified montmorillonite. Chem. Eng. Technol. 2018, 41, 983–993. [Google Scholar] [CrossRef]

- Deng, L.; Liu, Y.; Zhuang, G.; Yuan, P.; Liu, D.; Bu, H.; Song, H.; Li, L. Dynamic benzene adsorption performance of microporous TMA+-exchanged montmorillonite: The role of TMA+ cations. Microporous Mesoporous Mater. 2020, 296, 109994. [Google Scholar] [CrossRef]

- Guo, P.; Xu, N.; Li, D.; Huangfu, X.; Li, Z. Aggregation and transport of rutile titanium dioxide nanoparticles with montmorillonite and diatomite in the presence of phosphate in porous sand. Chemosphere 2018, 204, 327–334. [Google Scholar] [CrossRef]

- Tong, Y.; Wang, M.; Peñuelas, J.; Liu, X.; Paerl, H.W.; Elser, J.J.; Sardans, J.; Couture, R.-M.; Larssen, T.; Hu, H. Improvement in municipal wastewater treatment alters lake nitrogen to phosphorus ratios in populated regions. Proc. Natl. Acad. Sci. USA 2020, 117, 11566–11572. [Google Scholar] [CrossRef]

- Zhang, Q.; Yang, W.; Ngo, H.; Guo, W.; Jin, P.; Dzakpasu, M.; Yang, S.; Wang, Q.; Wang, X.; Ao, D. Current status of urban wastewater treatment plants in China. Environ. Int. 2016, 92, 11–22. [Google Scholar] [CrossRef]

- Shi, J.; Xu, C.; Han, Y.; Han, H. Case study on wastewater treatment technology of coal chemical industry in China. Crit. Rev. Environ. Sci. Technol. 2021, 51, 1003–1044. [Google Scholar] [CrossRef]

- Liang, H.; Liu, J.; Wei, Y.; Guo, X. Evaluation of phosphorus removal from wastewater by soils in rural areas in China. J. Environ. Sci. 2010, 22, 15–22. [Google Scholar] [CrossRef]

- Indicators: Phosphorus; Environmental Protection Agency: Washington, DC, USA, 2021.

- Nieder, R.; Benbi, D.K.; Reichl, F.X. Reactive water-soluble forms of nitrogen and phosphorus and their impacts on environment and human health. In Soil Components and Human Health; Springer: Dordrecht, The Netherlands, 2018; pp. 223–255. [Google Scholar]

- D’Haese, P.C.; Douglas, G.; Verhulst, A.; Neven, E.; Behets, G.J.; Vervaet, B.A.; Finsterle, K.; Lürling, M.; Spears, B. Human health risk associated with the management of phosphorus in freshwaters using lanthanum and aluminium. Chemosphere 2019, 220, 286–299. [Google Scholar] [CrossRef] [PubMed]

- Ruan, H.D.; Gilkes, R.J. Accumulation of phosphorus in farm ponds and dams in South-Western Australia. J. Environ. Qual. 2000, 29, 1875–1881. [Google Scholar] [CrossRef]

- Elsheikh, M.A.; Muchaonyerwa, P.; Johan, E.; Matsue, N.; Henmi, T. Mutual adsorption of lead and phosphorus onto selected soil clay minerals. Adv. Chem. Eng. Sci. 2018, 8, 67–81. [Google Scholar] [CrossRef] [Green Version]

- McTaggart, W.S. Characterization of Acid Phosphatase Adsorption to Montmorillonite. FASEB J. 2018, 32, 533.75. [Google Scholar] [CrossRef]

- Soulé, M.Z.; Fernández, M.; Montes, M.L.; Suárez-García, F.; Sánchez, R.T.; Tascón, J. Montmorillonite-hydrothermal carbon nanocomposites: Synthesis, characterization and evaluation of pesticides retention for potential treatment of agricultural wastewater. Colloids Surf. A Physicochem. Eng. Asp. 2020, 586, 124192. [Google Scholar] [CrossRef]

- Ma, L.; Zhu, J.; Xi, Y.; Zhu, R.; He, H.; Liang, X.; Ayoko, G.A. Adsorption of phenol, phosphate and Cd (II) by inorganic–organic montmorillonites: A comparative study of single and multiple solute. Colloids Surf. A Physicochem. Eng. Asp. 2016, 497, 63–71. [Google Scholar] [CrossRef] [Green Version]

- Sahir, A.H.; Kumar, S.; Kumar, S. Modelling of a packed bed solid-state fermentation bioreactor using the N-tanks in series approach. Biochem. Eng. J. 2007, 35, 20–28. [Google Scholar] [CrossRef]

- Mnasri, S.; Frini-Srasra, N. Evolution of Brönsted and Lewis acidity of single and mixed pillared bentonite. Infrared Phys. Technol. 2013, 58, 15–20. [Google Scholar] [CrossRef]

- Chen, J.; Lu, J.; Su, L.; Ruan, H.; Zhao, Y.; Lee, C.; Cai, Z.; Wu, Z.; Jiang, Y. Enhanced Adsorption of Methyl Orange by Mongolian Montmorillonite after Aluminum Pillaring. Appl. Sci. 2022, 12, 3182. [Google Scholar] [CrossRef]

- Ge, Z.; Li, D.; Pinnavaia, T.J. Preparation of alumina-pillared montmorillonites with high thermal stability, regular microporosity and Lewis/Brönsted acidity. Microporous Mater. 1994, 3, 165–175. [Google Scholar] [CrossRef]

- Lin, J.; He, S.; Zhan, Y.; Zhang, Z.; Wu, X.; Yu, Y.; Zhao, Y.; Wang, Y. Assessment of sediment capping with zirconium-modified bentonite to intercept phosphorus release from sediments. Environ. Sci. Pollut. Res. 2019, 26, 3501–3516. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Zhao, F.; Xia, M.; Wang, F. Microscopic adsorption mechanism of montmorillonite for common ciprofloxacin emerging contaminant: Molecular dynamics simulation and Multiwfn wave function analysis. Colloids Surf. A Physicochem. Eng. Asp. 2021, 614, 126186. [Google Scholar] [CrossRef]

- Akram, M.; Bhatti, H.N.; Iqbal, M.; Noreen, S.; Sadaf, S. Biocomposite efficiency for Cr (VI) adsorption: Kinetic, equilibrium and thermodynamics studies. J. Environ. Chem. Eng. 2017, 5, 400–411. [Google Scholar] [CrossRef]

- Wang, D.; Chen, N.; Yu, Y.; Hu, W.; Feng, C. Investigation on the adsorption of phosphorus by Fe-loaded ceramic adsorbent. J. Colloid Interface Sci. 2016, 464, 277–284. [Google Scholar] [CrossRef]

- Zou, Y.; Zhang, R.; Wang, L.; Xue, K.; Chen, J. Strong adsorption of phosphate from aqueous solution by zirconium-loaded Ca-montmorillonite. Appl. Clay Sci. 2020, 192, 105638. [Google Scholar] [CrossRef]

- Al Mesfer, M.K.; Danish, M. Breakthrough adsorption study of activated carbons for CO2 separation from flue gas. J. Environ. Chem. Eng. 2018, 6, 4514–4524. [Google Scholar] [CrossRef]

- Garaga, M.N. Locale Structure around Heteroatoms in Alumino-and Borosilicates for Catalysis. Ph.D. Thesis, Université d’Orléans, Orléans, France, 2013. [Google Scholar]

| Sorbent | Experiment Condition | Sorption Capacity (mg/g) | Reference | ||

|---|---|---|---|---|---|

| Adsorbent Dosage (g) | pH | Phosphorus Concentration (mg/L) | |||

| Chitosan/Ca–organically modified montmorillonite beads | 10 | 7 | 50 | 48.35 | [16]· |

| Fe-loaded ceramic adsorbent (contain montmorillonite) | 10 | 6 | 10 | 45.88 | [61] |

| Zirconium (Zr)-modified calcium-montmorillonite (Zr-CaMs) | 2.5 | 4 | 50 | 22.37 | [62] |

| Keggin Al13 complex–HDTMA-modified montmorillonite (Al13-O-MMt) | 6.667 | 8 | 200 | 60 | This study |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Z.; Chen, J.; Lu, J.; Jiang, S.Y.; Su, L.; Lee, C.H.; Ruan, H.D. Batch and Column Adsorption of Phosphorus by Modified Montmorillonite. Appl. Sci. 2022, 12, 5703. https://doi.org/10.3390/app12115703

He Z, Chen J, Lu J, Jiang SY, Su L, Lee CH, Ruan HD. Batch and Column Adsorption of Phosphorus by Modified Montmorillonite. Applied Sciences. 2022; 12(11):5703. https://doi.org/10.3390/app12115703

Chicago/Turabian StyleHe, Zhonghao, Jiajun Chen, Jianzun Lu, Sabrina Yanan Jiang, Lingcheng Su, Chiu Hong Lee, and Huada Daniel Ruan. 2022. "Batch and Column Adsorption of Phosphorus by Modified Montmorillonite" Applied Sciences 12, no. 11: 5703. https://doi.org/10.3390/app12115703