Abstract

The development of inland terminals helps seaports mitigate inevitable storage capacity problems, extending their gravitational field and strengthening their competitive advantage. Optimizing the container storage, efficiency, and productivity of seaports and inland terminals is becoming increasingly important. The present paper develops a network-based mathematical model to optimize the location assignment of inbound containers at inland terminals. The model’s assumptions are based on the analysis of criteria at representative European inland terminals, and the model aims to reduce unproductive manipulations. The present study is one of the few to develop a single model that integrates all important criteria for container location assignment, including a container’s dimensions, its occupancy, cargo type, the container’s owner, and distance to the final user. These criteria are important for the terminal operator so that they can determine container locations in a way that minimizes unproductive manipulations. Data from a single inland terminal were used to validate the model within the FlexSim CT simulation environment. Our results suggest that the model can reduce unproductive manipulations and associated costs at inland terminals.

1. Introduction

As international trade develops, an increasing number of large container ships arrive at container seaports, creating storage problems. The limited yard space at container seaports and pressure from shippers to deliver goods to end users as quickly as possible have led many seaports to connect with inland terminals [1]. Seaports are attractive not only because of their reliability and nautical qualities, but also because of their hinterland connectivity and capacity [2].

Container storage is one of the most important operations at any terminal, including container seaports and inland terminals. Optimal storage means proper management, rapid retrieval time, and a minimum number of unproductive manipulations, defined as manipulations (e.g., to access a specific container among many others) that do not bring the container closer to its final destination. Such manipulations generate significant additional costs and take time. The challenge of optimal storage is known as the “location assignment (stacking) problem” because it involves the allocation of containers to stacks [3].

Reducing the number of unproductive manipulations becomes more complex when different types of containers are involved (e.g., different dimensions, weights, cargo type), as well as when the departure time of the containers is unknown [4]. Reducing these manipulations and optimizing container location assignment and storage space allocation have been studied thoroughly at seaports. In Section 2 a literature review on container allocation at seaports and inland terminals has been presented. Most studies have aimed to minimize transportation costs and maximize space utilization. In contrast, studies of the container location assignment problem at inland terminals are lacking.

Optimizing methods to allocate and collect containers depends on the storage surface available, the degree of mechanization, and the management policies [5]. Whatever storage allocation methods at inland terminals are applied, they should be harmonized with technological processes at seaports in order to ensure optimal container processing.

The present study developed a new network-based mathematical model for determining the order of inbound container storage and their allocation, according to the retention time estimated from container parameters, which were identified after the analysis of European inland terminals (Section 4). The purpose of the model is to reduce unproductive inbound manipulations and their associated costs at inland terminals. The model assigns container locations in a way that minimizes container handling costs related to unproductive manipulations, while taking into account the spatial and operational constraints of inbound operations. The assumptions in the network are based on the analysis of technological processes involving inbound containers at representative European inland terminals. For the model proposed, first we analyzed the parameters (criteria) for container location assignment at the representative inland terminals (Section 3). The resulting parameters were used to evaluate the hierarchy of container location assignment criteria by calculating the parameter potentials defined for container storage determination. The proposed model determines the inbound container assignment location according to criterion potentials and ranks based on the consistent approximation preference stream for the case when container departure time is unknown. To determine the hierarchy of parameter potentials for optimizing container storage, we implemented a novel potential method. We validated the model on one of the analyzed inland terminals using the FlexSim simulation environment (Section 5 and Section 6). Our results suggest that the model can determine exact container locations at inland terminals in a way that minimizes unproductive manipulations and reduces operating costs.

2. Literature Review

At the beginning of the 1980s, inland terminals were mentioned as being an object that could serve as a solution for container storage congestion at seaports, accelerating intermodal transport and reducing total transport costs [6]. Inland terminals for international shipping are becoming extremely important worldwide. Numerous studies have documented the advantages and benefits of intermodal transport implementation in reducing transport costs between ports and inland terminals or final users [7,8,9,10,11,12,13,14,15]. Studies on inland terminals have generally focused either on the problem of where to locate inland terminals, or on the problem of connecting inland terminals with seaports for efficient intermodal transport [16]. Numerous quantitative models have been proposed for optimizing the position of inland terminals within transport networks [17,18,19,20,21,22,23,24,25,26]. Similarly, several models of intermodal transport involving seaports and inland terminals have been described [27,28,29,30,31,32,33,34].

Few studies have examined how to optimize container location assignment at inland terminals, in contrast to the extensive literature on this question at seaports.

2.1. Container Allocation at Seaports

Studies on seaports have focused on improving quay-side efficiency to speed up the processing of container vessels, but faster quay-side operations will not lead to greater overall productivity without effective storage yard strategies [35]. To address this, the authors of [36] proposed a model to increase seaport productivity by preventing subsystem overcapacity. The authors of [37] developed an analytical model to simultaneously determine the optimal storage space and number of yard cranes for inbound containers that could minimize total cost. Paper [38] investigated container yard congestion issues and proposed a physics-based model for truck interruptions that could minimize the total time spent in moving containers in the container yard. The concept of yard template regeneration was proposed [39]. In that approach, a multiple-objective mixed-integer programming model was formulated that considers the minimum transportation cost, minimum template disturbance, and maximum space utilization for container terminals. The authors of [40] developed a model to determine the numbers of bays, rows, and tiers in a seaport container yard block that maximize throughput and storage capacities.

To improve storage yard management at seaports, several studies have tackled the problems of container storage space allocation and location assignment (stacking). A model for predicting the number of relocation steps to access a required container from the seaport container yard was proposed by the authors of [41]. A mathematical model for the solution of the block relocation problem in order to minimize the number of relocations required to retrieve the blocks in the specified order was presented [42]. In that approach, a binary linear program was used for block relocation, while a simple heuristic was used to define relocation rules for shifting containers located on top of the one to be retrieved. Based on the model of [42], the author of [43] developed a mathematical solution for the block relocation problem. In the paper [44], the authors used a genetic algorithm and a tabu search algorithm, on their own and together, to integrate a container-transfer model with a container-location model to optimize seaport container location and handling. Paper [45] defined a dynamic generalized assignment problem to allocate containers in port storage yards.

A consignment strategy with a static yard template to reduce the level of relocations in the yard for outbound containers and improve operation efficiency and land productivity was proposed in paper [35]. To implement their strategy, the researchers allocated yard storage within the sections. To make yard allocation more efficient, two space-sharing approaches were proposed in which storage space was dynamically reserved for different vessels during different shifts. To improve storage yard management at seaports, paper [46] presented an integer linear programming model that integrates the two interrelated decision problems, space allocation and yard crane deployment. The main goal was to minimize the costs of yard crane operation and interblock movements. A heuristic approach, based on a divide-and-conquer strategy, was used to solve the integrated problem efficiently; a harmony search algorithm and constraint satisfaction techniques were used to solve subproblems within the heuristic approach.

In paper [47], the authors considered the restricted container relocation problem and analyzed the selection of appropriate slots for relocated outbound containers during the retrieval process in order to minimize the total number of container relocations. A beam search algorithm was employed to solve this problem, while heuristics were used to ensure efficient beam search node selection.

In paper [4], the authors developed a fuzzy knowledge-based system for container yard management with the aim of lowering unproductive manipulations. Fuzzy theory was introduced to solve multi-dimensional problems with multiple objectives. A heuristic algorithm called “neighbourhood” was developed to model re-handling operations of containers. The discrete event simulation approach was used to mimic container arrival, storage, and retrieval. The model considered several factors, including the number of containers in each stack, the similarity between the containers in each stack (e.g., containers belonging to the same customer), and the residence time of the topmost container in each stack. The constraints considered in this system were weight (full and empty), size, and type. Based on these factors and constraints, stacks for container storage were allocated according to the hierarchy of constraints.

Paper [48] studied the operational problem of sequencing container storage and retrieval requests for a single block of containers at a seaport, such that multiple locations were available for each storage container. The researchers proposed a method to store containers that would minimize the travel time of a single automated stacking crane. They adopted a three-phase solution method as well as a heuristic approach to solve the generalized asymmetric traveling salesman problem. The authors of [49] compared random and category stacking in simulations, which suggested that category stacking according to expected container departure time can reduce container relocations.

2.2. Container Allocation at Inland Terminals

In contrast to this substantial exploration of container positioning and storage at seaports, few studies have examined the same questions at inland terminals. This may be partly due to the fact that, although the technological processes for positioning and storing containers are similar between inland terminals and container seaports, container layout and yard space at inland terminals are subject to specific constraints. For example, inland terminals are usually smaller than seaports, creating more severe space constraints on container storage. Most studies of inland terminals, rather than deal directly with these constraints, have focused on the most efficient ways to transport containers to such terminals. Dynamic programming and genetic algorithms have been used to route vehicles and optimize container delivery to inland terminals [31,50]. A system for accelerating container documentation and transport to its storage location has been developed [51], and a mathematical model has been proposed to allocate a group of containers at an inland terminal, after their delivery by rail, in a way that minimizes unproductive manipulations and overall storage costs [52]. A mathematical model for optimizing the configuration and operation of terminal equipment to improve the efficiency and sustainability of an inland waterway terminal has been implemented by the authors of [53]. The authors of [16] used a bilevel programming approach to address the problem of how to price storage for outbound containers.

In order to overcome the disadvantages and “blind spots” of previous models, the present study was undertaken to develop a mathematical model to determine the inbound container assignment location according to empirically determined potentials and ranks of parameters (criteria) that affect the storage allocation of containers at inland terminals when the container’s departure time is unknown. Relatively few studies have aimed to develop a single model that integrates all important parameters (criteria), including the container’s dimensions, its occupancy, cargo type, container owner, and distance to the final user. These parameters are important for the terminal operator so that they can determine container locations in a way that minimizes unproductive manipulations.

3. Criteria for Optimizing Container Storage at Inland Terminals

To develop the model in the present study, criteria for container storage were identified after an analysis of 11 inland terminals in Europe whose total turnover is up to 50,000 TEU annually and whose storage area is up to 100,000 m2, with storage capacity of 1000–5000 containers. All 11 terminals receive inbound containers of 20, 30, 40, and 45 feet, which are stored on three tiers using reach stackers and on four tiers using rail-mounted gantries. In all cases, containers are stored on a “first-in, first-out” basis, and containers are stored for 5–10 business days. Logistic processes and data for train arrivals and departures to seaports were analyzed during model validation.

At the observed terminals, 45–60% of all manipulations are unproductive, because container retention times are not known in advance. Terminal operators position the containers based on the likely retention time predicted by experienced staff, without any predefined model.

Interviews with terminal operators indicated that containers are positioned within the inbound zone according to the criteria defined in Table 1. (Container storage in the outbound zone was not considered in the present study.) During the 12-month observation period, the average storage capacity of the terminals was 2400 TEU, and an average of 75% of storage space was occupied by containers. Inbound trains spent an average of 312 min at the terminals, and unloading lasted an average of 174 min.

Table 1.

Storage criteria for containers in the inbound zone at the 11 European inland terminals analyzed.

Table 2 shows the observed daily average number and retention time of containers, categorized by dimension, for the entire 12-month observation period.

Table 2.

Average daily number of inbound containers and their average retention time at the 11 European inland terminals, according to container dimension.

The average retention time was calculated to be the weighted harmonious mean of the individual retention times

Unknown retention time increases the number of unproductive manipulations. The new mathematical container storage model system proposed here is based on the expected retention time, estimated after ranking the criteria according to the preferences expressed by terminal operators.

4. Mathematical Model

The criteria from Table 1 are the nodes in the graph for the mathematical model proposed. Generally, the non-oriented complete graph is a pair consisting of the final set of nodes and a set of all possible pairs . Each pair of incidental nodes admits one of two possible replacements, or . Replacement shows an advantage of criterion over criterion [54]. The nodes and are incidental nodes. Replacements are defined by inland terminal operators, and their intensities are inputs into the mathematical model’s graph.

Each non-oriented complete graph becomes directed by selecting only one replacement by a pair. This complete directed graph is now a pair , consisting of criteria as the nodes and replacements as oriented arches of asymmetric relation . Concatenation of the criteria occurs when their incident replacements , and are arches of the same asymmetric relation .

4.1. Criteria Preferences and Potentials

All terms, relations, and notations defined below have been described previously [54]. The decision maker (inland terminal manager) subjectively defines the preference intensities as values of each replacement on a 5-point scale, where 0 means indifference; 1, weak preference; 2, strong preference; 3, distinct preference; and 4, absolute preference. The intensity of the replacement preference is a skew-symmetric function

A value is a gain if criterion prevails over criterion , which was determined based on interviews with inland terminal operators.

All preferences together create the preference stream . The stream is consistent if the following statement is valid for all three concatenated criteria

The preference stream defines the preference relation on the set

Preference intensities define the potential criterion function , such that

4.2. Graph Preference Replacement Criteria

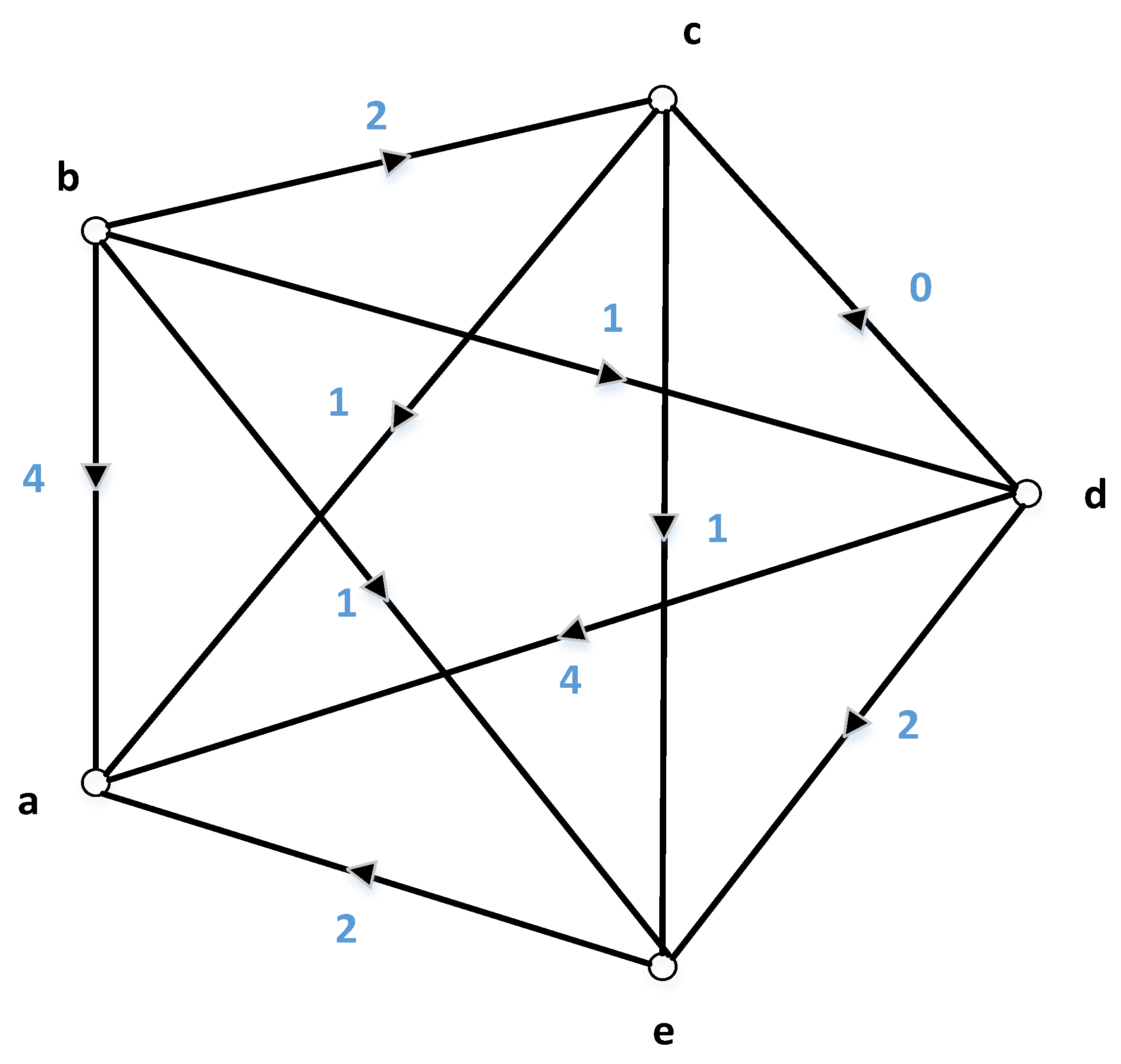

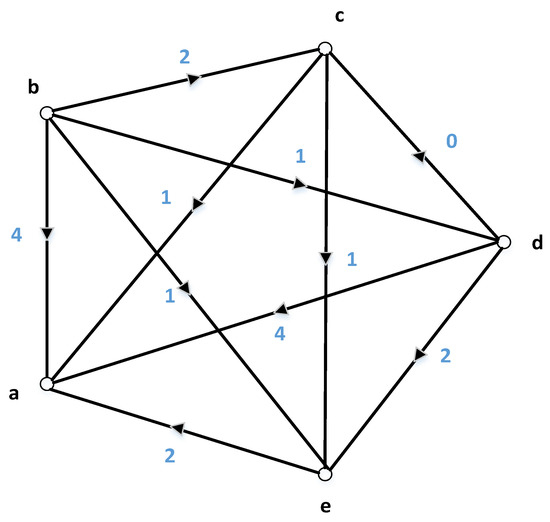

Figure 1 shows the preference values from an interview with one representative decision maker (inland terminal operator) for the set of criteria in Table 1.

Figure 1.

Preferences of the criteria for locating a container in the inbound zone of an inland terminal. The letters refer to criteria, and the numbers on the connecting lines refer to preferences (see Section 4.1).

The preference stream in Figure 1 is not consistent since there is a concatenation

After determining the preferences of all replacements, the criterion potential is calculated as the sum of all replacement preference intensities incident with criterion

Taking into account the skew-symmetry (Equation (2)), the criterion potential of is negative

The criterion rank is provided by an arbitrary and criterion potentials [54]

Table 3.

Potential of inconsistent flow.

4.3. Consistent Approximation Based on an Interview

For each inconsistency stream , at least one consistent approximation stream could be obtained that satisfied Equation (3). A deflection of approximation is the ratio

where the square of the absolute flow value, , is given by

Analogously, it follows that

Application of Equation (8) leads to

To create the stream with minimal , we respect the maximal potentials together with maximal preferences of . The maximal potential of , given in Table 3, is . Thus, the new potential appears in . Maximal preferences incident to criterion are . Then the new potentials of consistent approximation are and criterion , , and have new potentials.

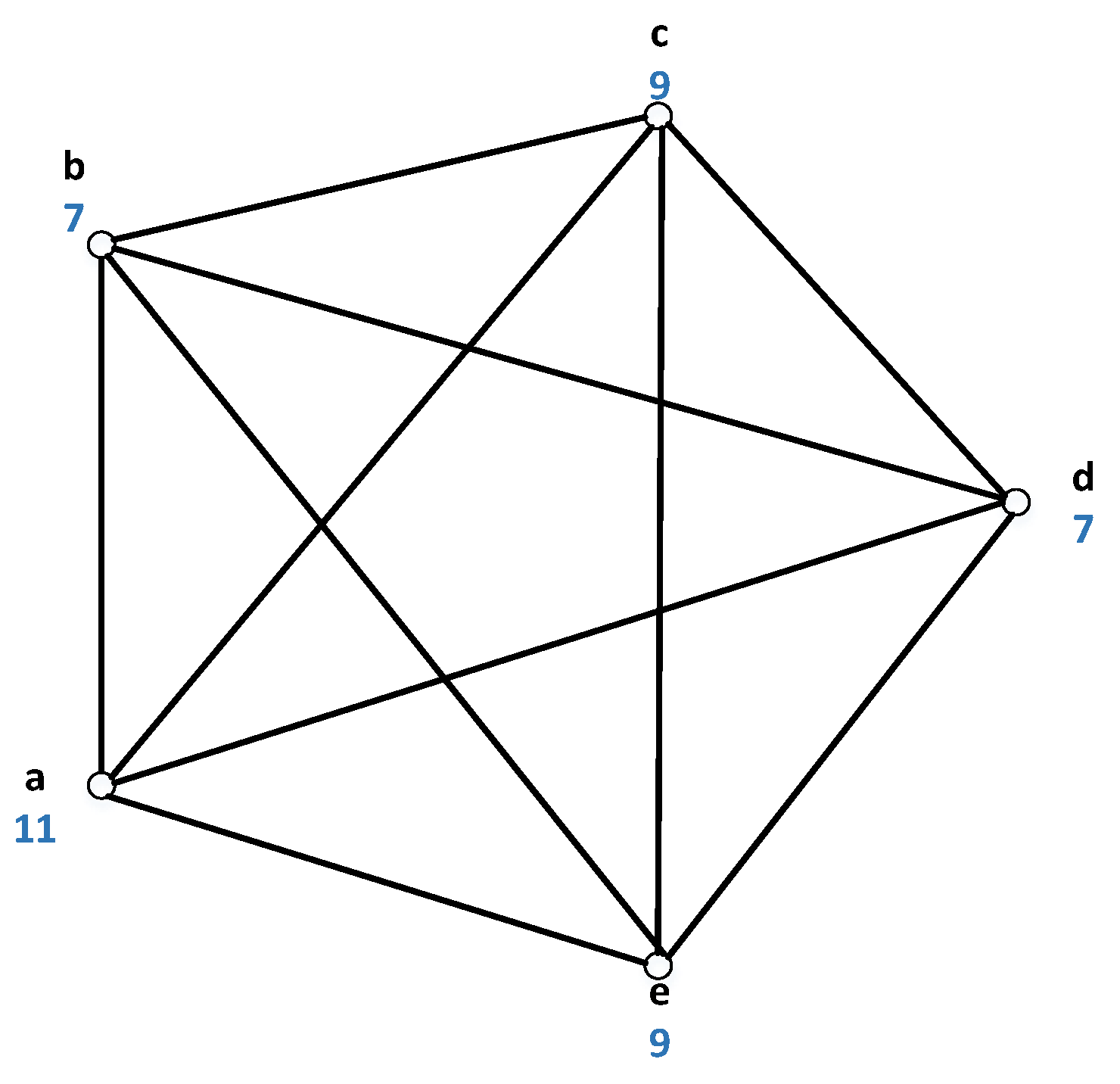

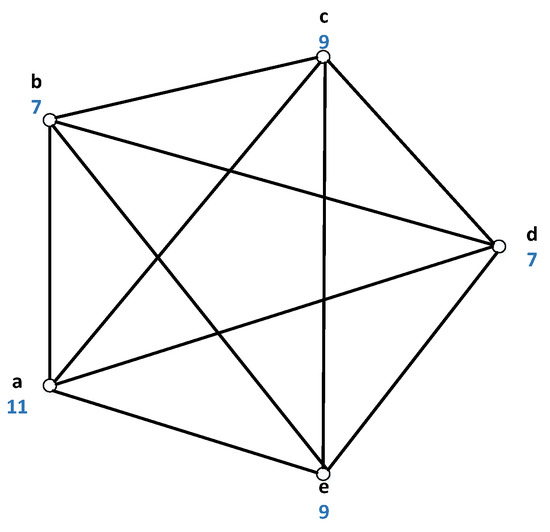

The maximum preferences of replacements incident to the criteria with new potentials are . Because , then the new potential . By analogy, . The undirected complete graph with new potentials is shown in Figure 2.

Figure 2.

An unoriented complete graph with new potentials.

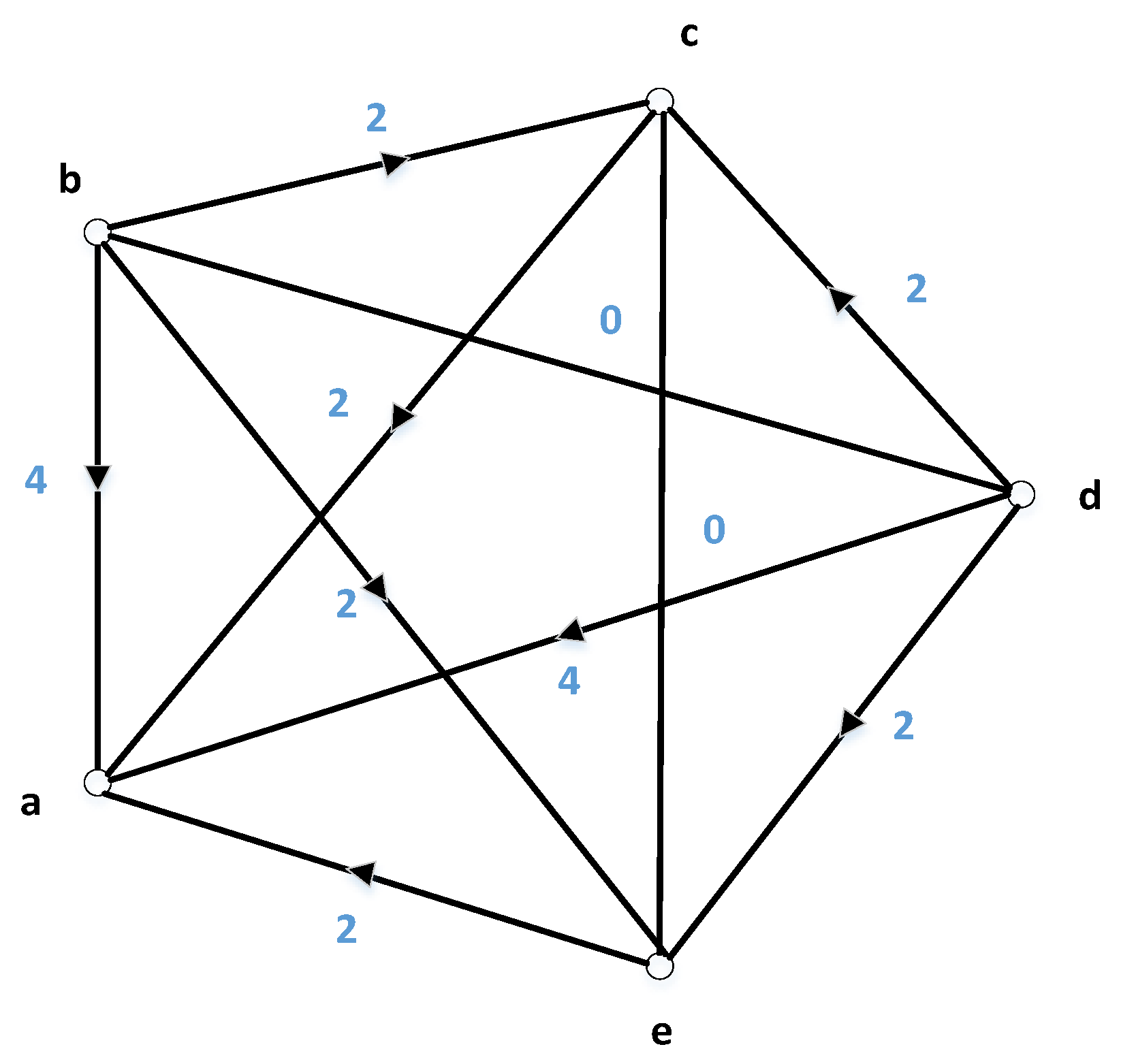

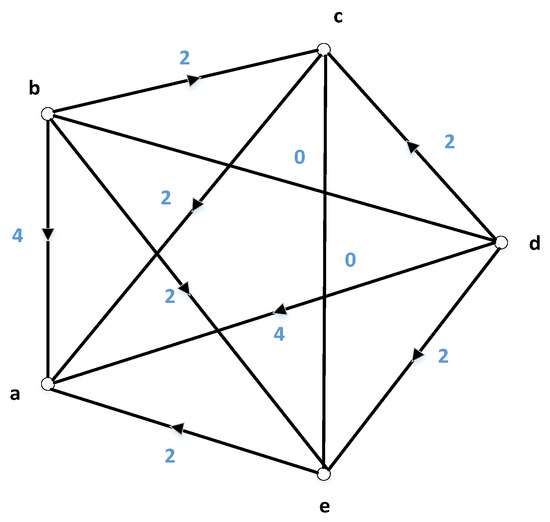

The new replacement preferences are calculated by considering the new potentials as a tool. The consistent stream is obtained and presented in Figure 3.

Figure 3.

Consistent approximation preference stream.

Plugging the relevant values into Equations (9) and (7) leads to and .

The potentials calculated by consistent approximation preferences created in Figure 3 change the ordinal scale at the lowest preferred potentials. The criteria were ranked according to Equation (6), where was defined arbitrarily in order to obtain a suitable range of criterion ranks [54]. Potentials and ranks are shown in Table 4.

Table 4.

Criterion potentials and ranks based on the consistent approximation preference stream.

5. Container Storage According to the Model

During interviews, operators (decision makers) at the 11 inland terminals indicated their preference stream for criterion replacements. For each subjective preference stream, the consistent approximation preference stream with minimal deflection was determined. For each consistent approximation preference stream, the potentials of criteria and categories were calculated separately. From this point, the average potentials of each determined criteria and categories were calculated and ranked according to Equation (6), with (Table 5, Table 6, Table 7, Table 8, Table 9 and Table 10).

Table 5.

Ranking of container storage criteria according to their importance based on decision maker preferences.

Table 6.

Ranking of the container dimension categories according to retention time.

Table 7.

Ranking of the categories of distance to the container’s final destination according to retention time.

Table 8.

Ranking of the cargo type in a container according to retention time.

Table 9.

Ranking of container owner according to retention time.

Table 10.

Ranking of container occupancy according to retention time.

Our analysis indicates that the ranking of container storage tiers according to retention time is necessary to reduce unproductive manipulations in container storage and shipping (Table 11). Higher ranking implies better availability for faster shipping.

Table 11.

Ranking of container storage tiers according to retention time.

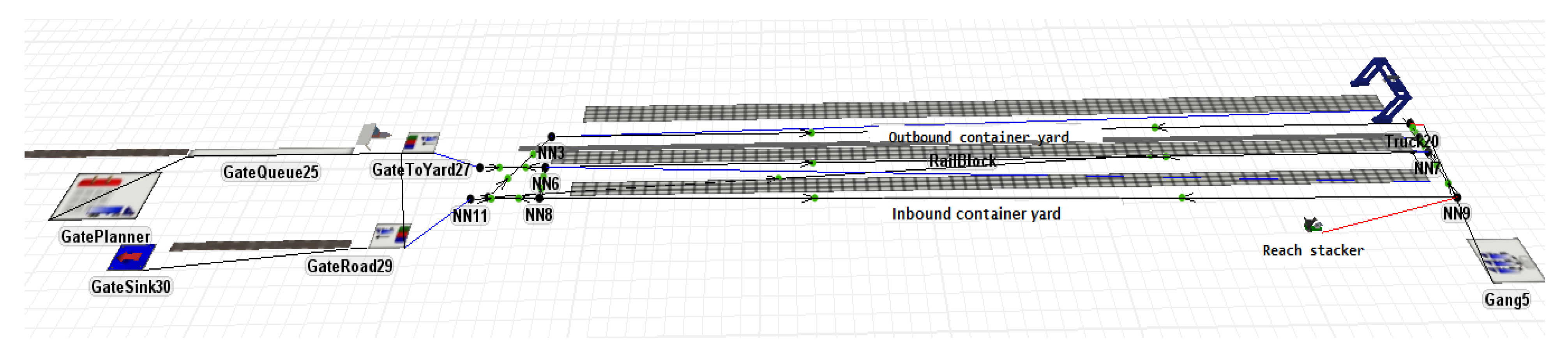

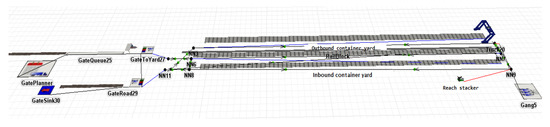

6. Validation of the Mathematical Model

To validate the mathematical model developed in Section 3, a simulation was carried out based on the data on technological processes collected at an inland terminal randomly selected from among the 11 European terminals. The observed inland terminal was modeled in the FlexSim CT simulation tool (Figure 4). The observed inland terminal consists of inbound and outbound container yards. The first inbound container yard had four tiers and was located along the rail track, with 648 positions for storing 40′ containers. The second yard had three storage tiers and was located 12 m away from the first outbound container yard, with 634 positions for storing 40′ containers.

Figure 4.

Layout of the inland terminal in the FlexSim CT simulation to validate the mathematical model for inbound container placement.

Containers arrived at the inland terminal by rail and were positioned within the inbound container yard according to the criteria in Table 1 and an empirically observed delivery of 24–36 full containers five times per day every weekday. Container unloading and loading each took an average of 150 min, or 300 min for both operations. A rail-mounted gantry crane is used for container loading and unloading from/to trains, while each container yard is equipped with one reach stacker that is used for container storage in the inbound and outbound container yards. Capacity for the rail-mounted gantry crane was 20–25 TEU/h, and the capacity of the reach stacker was 15 TEU/h. Containers of dimension 45′ were stored on the edge of the container yard block; 40′ containers, on tiers 2–3; and 20′ containers, on tiers 2–4.

6.1. Simulating Container Storage Using the Mathematical Model

The simulation suggested that the criteria of container owner, dimension, and final destination are decisive in determining the container’s storage location (Table 5).

The random numbers in Table 12 were adapted from statistics given in Table 2. The random numbers in Table 13 and Table 14 were adapted from statistical analysis of the 11 European inland terminals.

Table 12.

Simulation of container retention according to container dimension.

Table 13.

Simulation of container retention according to container owner.

Table 14.

Simulation of container retention according to the distance to the container’s final destination.

Table 15 shows the storage tier locations based on tier ranking for 32 inbound containers arriving daily in the inland terminal. The aim of defining the storage tier was to shorten the number of unproductive manipulations at the inland terminal and to lower overall terminal costs related to container storage.

Table 15.

Modeling the retention time and storage tier of inbound containers at the simulated inland terminal.

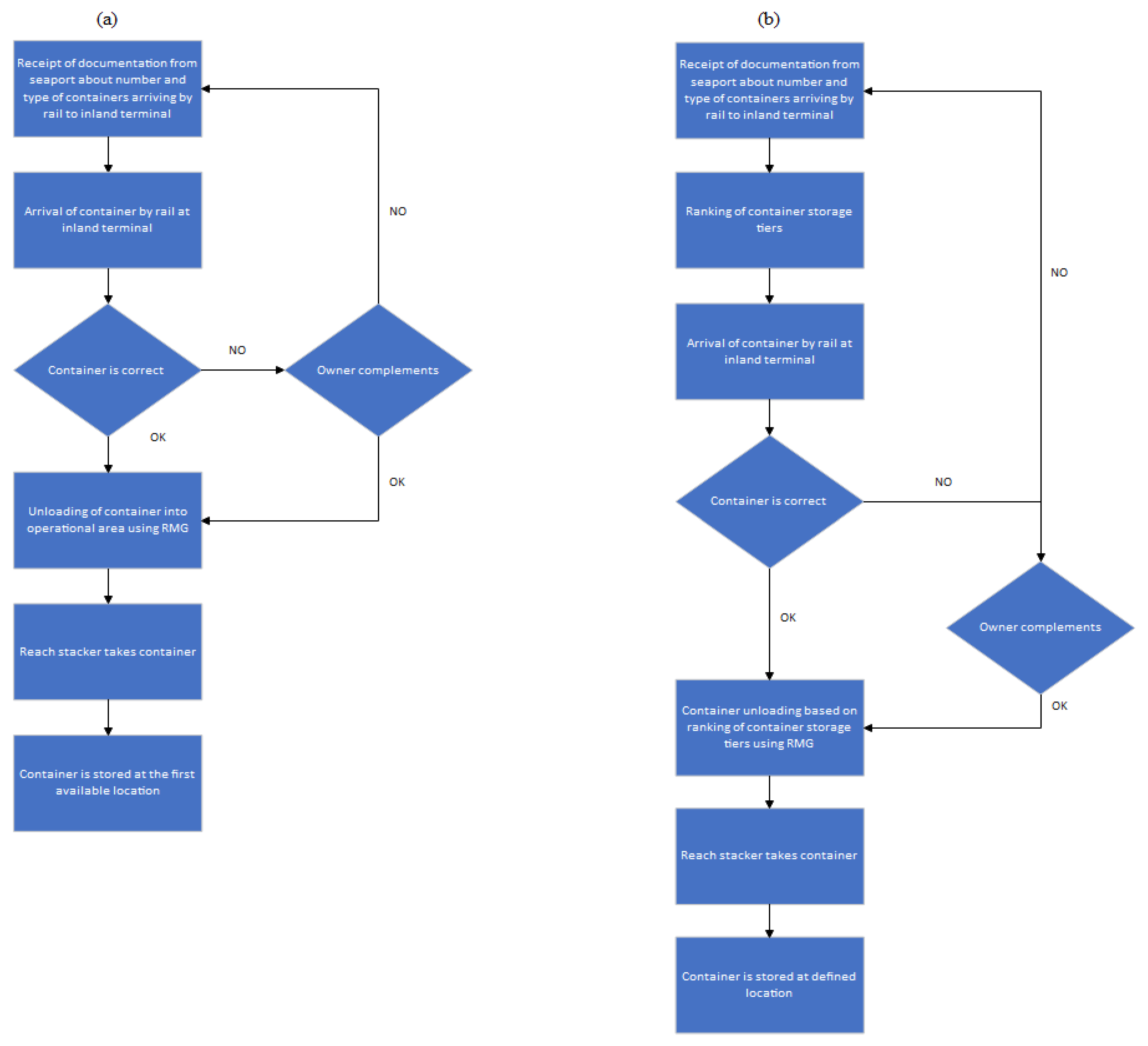

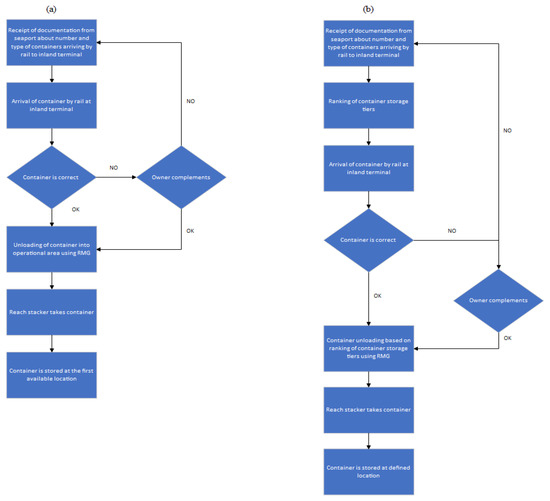

The proposed model suggested a different ranking of criteria for container storage at the simulated inland terminal than what was empirically observed at the inland terminal whose data were used in the simulation (Figure 5). In this way, the model was validated by a simulation of container storage processes at an inland terminal representative of many European inland terminals.

Figure 5.

Container storage processes at the simulated inland terminal (a) as observed or (b) according to the proposed mathematical model.

6.2. Assessing Model Performance

The proposed model was validated by comparing the number of manipulations between the simulated inland terminal and the actual data collected for the one terminal used to set up the simulation.

For the inland terminal used to set up the validation simulation, approximately 60% of container manipulations were unproductive, corresponding to 2.5 unproductive manipulations per container. Among all containers arriving at the inland terminal, 18.4% were 20′, 79.9% were 40′, and 1.7% were 45′. No 30′ containers arrived at the terminal. The retention times of certain types of containers are shown in Table 12, Table 13 and Table 14. The retention times of criterion categories were unknown for the used terminal, so we used average values for the retention times from our analysis of 11 inland terminals. The occupancy of the terminal was approximately 60%.

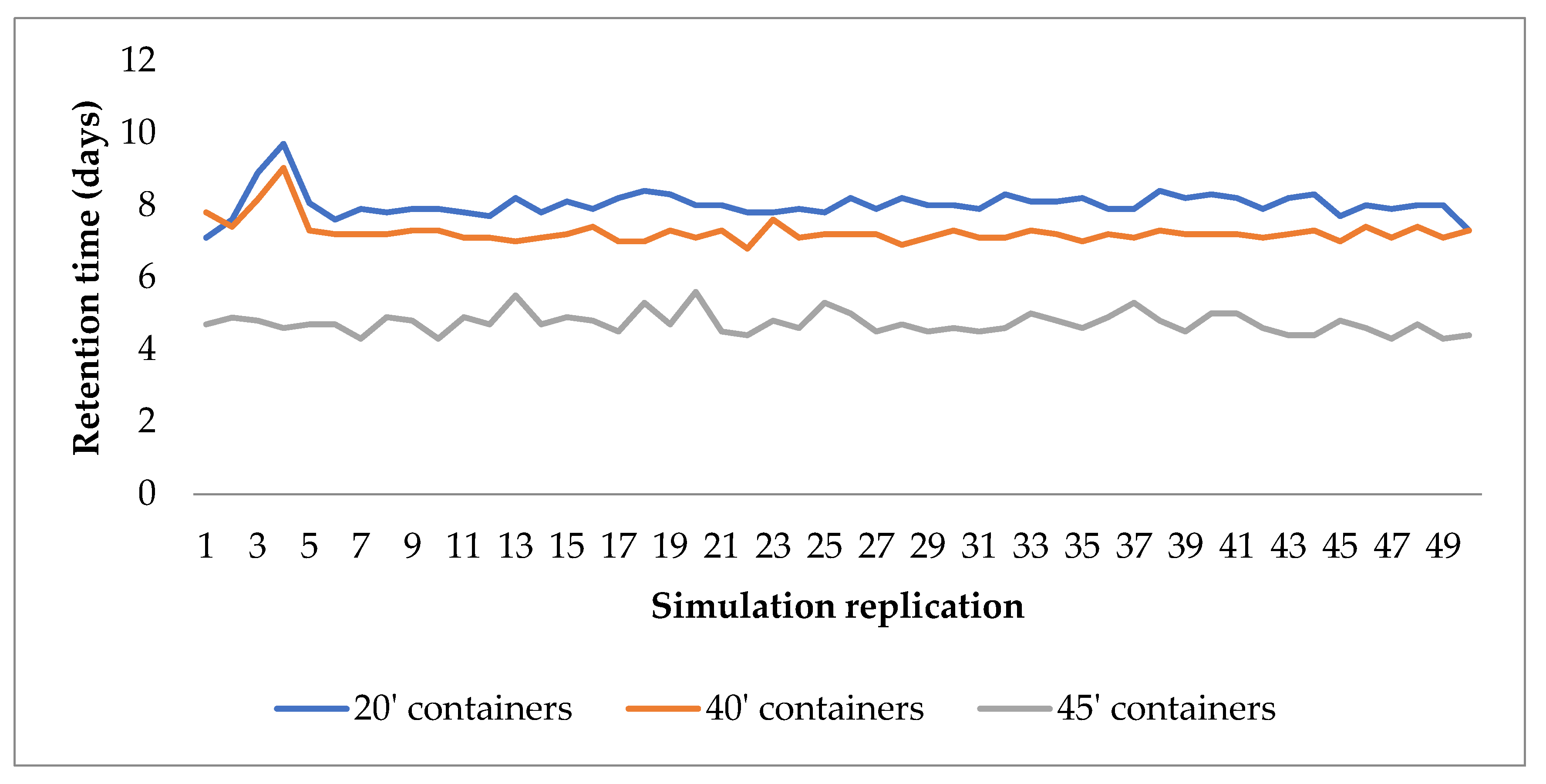

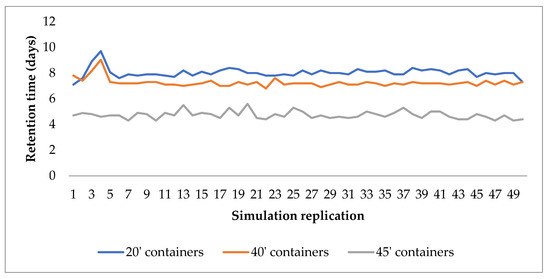

A simulation with these input data and model applications was performed for 50 parallel replications, with each replication lasting 720 h. Of all containers, 23.3% were 20′, 74.4% were 40′, and 2.3% were 45′. The average terminal occupancy was 55.6%. The simulated retention times (Figure 6) were lower than the average for the 11 European inland terminals (Table 2) by 17.95% (1.75 days) in the case of 20′ containers, 8.75% (0.7 day) in the case of 40′ containers, and 1.05% (0.5 day) in the case of 45′ containers.

Figure 6.

Simulated container retention times as a function of simulation replication.

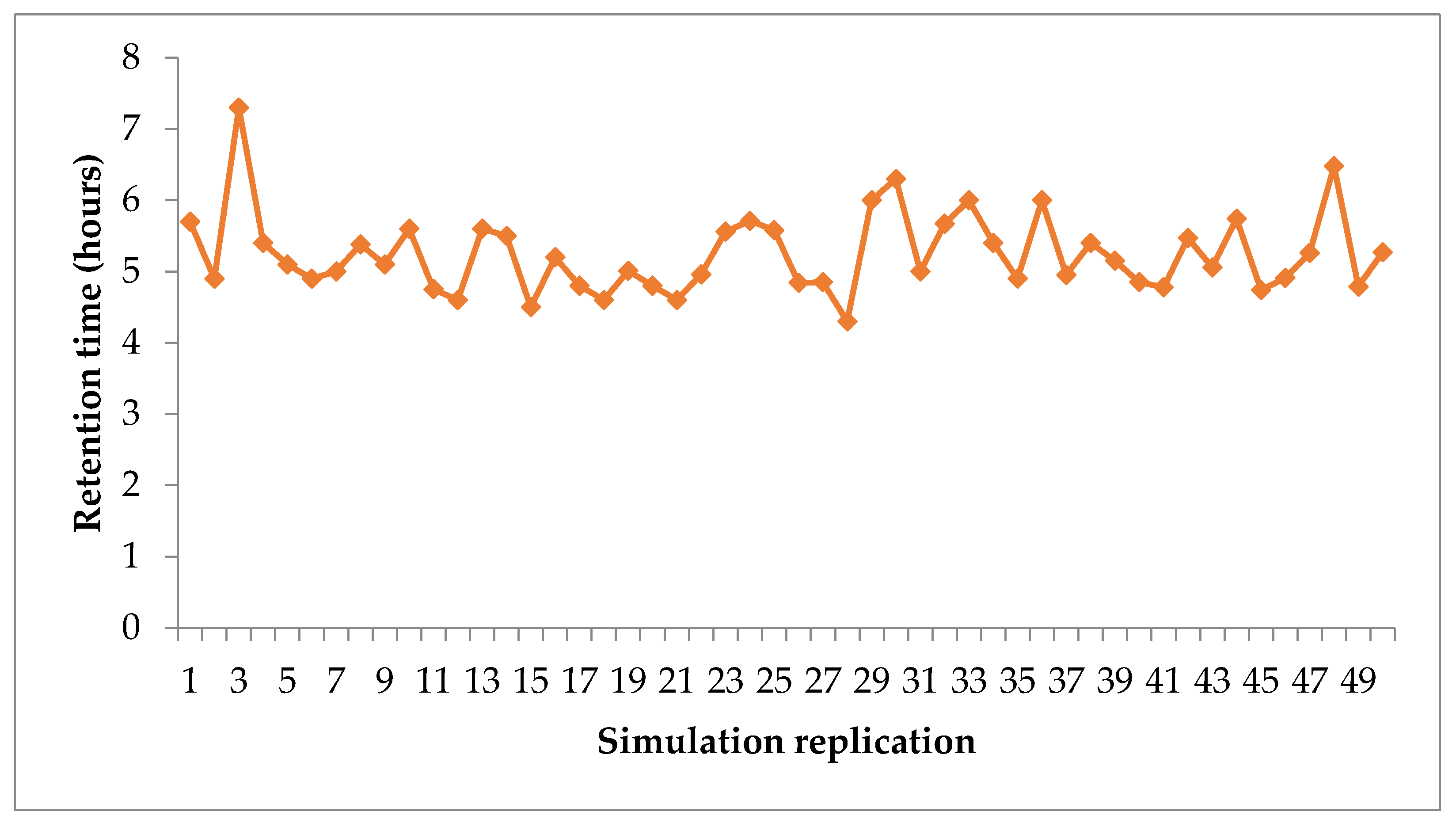

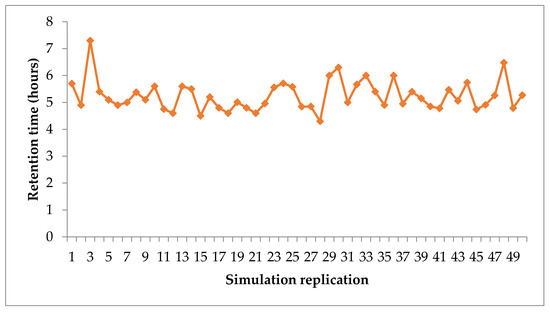

The simulated average number of inbound containers in simulation replications was 29.6 full containers per train per day (Figure 7), similar to what was actually observed. The average simulated retention time of each train was 1.89% (12 min) longer than what was observed for the actual inland terminal, where containers are stored based on the “first-in, first-out” principle. Conversely, the model results led to an unloading time that was 8% (12 min) shorter than the time observed for the inland terminal used in the simulation, and 20% (36 min) shorter than the average time across all 11 European inland terminals.

Figure 7.

Average train retention time.

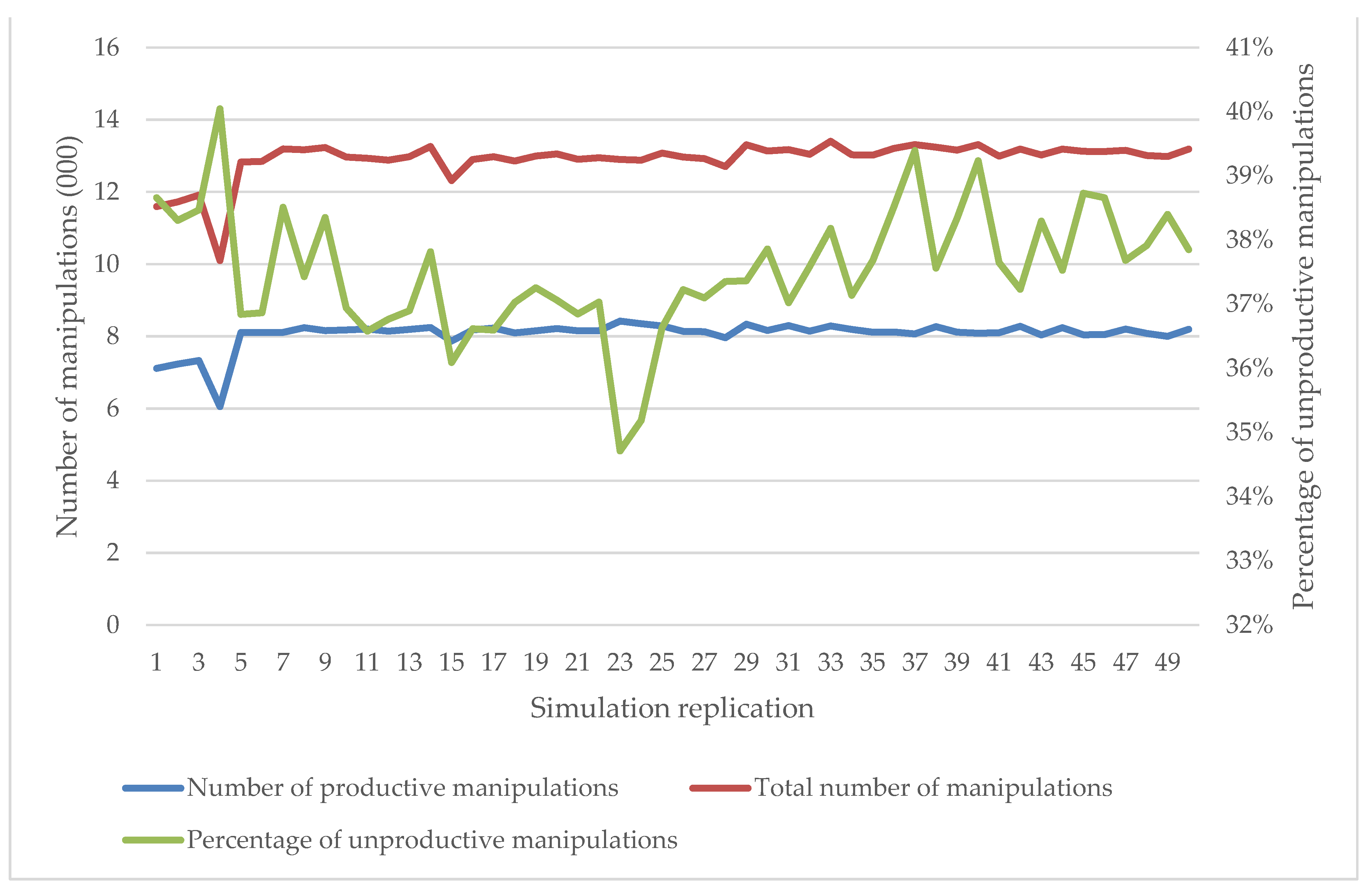

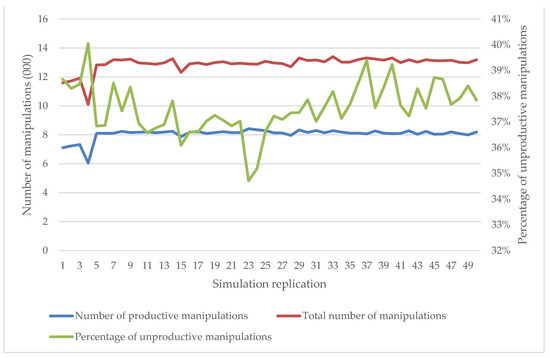

The average number of container manipulations was 12,908 in the simulation, of which 3845 (38%) were unproductive (Figure 7). This corresponded to 22% fewer unproductive manipulations than observed at the actual inland terminal, and 37% fewer than observed across all 11 European inland terminals (Figure 8). These results suggest that the proposed model can improve container storage processes at inland terminals.

Figure 8.

Numbers of total and productive manipulations as well as the percentage of unproductive manipulations in the simulation.

7. Discussion

Few studies have examined container assignment location at inland terminals. Here we develop a new network-based mathematical model that integrates the most important criteria for inbound container location assignment (container dimension, its occupancy, cargo type, container owner, and distance to final user) under conditions when the container’s departure time is unknown. The model determines the locations of inbound containers based on the retention time estimated according to the container criterion and category. The ranking of container storage tiers according to retention time is necessary to reduce unproductive manipulations in container storage and shipping. A higher ranking implies better availability for faster shipping.

To develop our model, inland terminal operators (decision makers) were asked to indicate their preference stream for criterion replacements. For each subjective preference stream, the consistent approximation preference stream with minimal deflection was determined. For each consistent approximation preference stream, the potentials of the criteria and categories were calculated separately. We implemented a novel method to determine the hierarchy of parameter potentials for optimizing container storage. Implementation of the final model showed that the most important criteria for container assignment location were the container’s dimensions, the container’s final destination, and cargo type. Other criteria were less important, including the container’s owner, container’s occupancy, and distance to the final user.

The proposed model determines a feasible sequence of stacking operations that minimize the costs associated with the storage of containers while taking into account the spatial and operational constraints. Its implementation can optimize the storage of inbound containers, reducing unproductive manipulations as well as the costs associated with the use of the inland terminal. The model was validated against data from one of the observed inland terminals, and the model was able to significantly reduce unproductive manipulations.

Thus, the presented model may help optimize technological processes. It may also harmonize technological processes between seaports and inland terminals, which in turn may increase productivity and reduce operating costs at both nodes in cargo distribution.

Future research should examine whether determining the statistical distributions of retention times can improve the estimation of container retention time and the ranking of criteria. It may be possible to reduce even further the number of unproductive manipulations and thereby further improve inland terminal productivity.

8. Conclusions

This paper defines and analyzes criterion categories for container storage optimization at inland terminals that, when integrated into an appropriate model, can decrease the number of unproductive manipulations and thereby reduce the time and cost of container management. The criteria and model were developed using inland container data for 11 European inland terminals, one of which further served as the basis for a simulation to validate the proposed model. The model estimates the retention time based on ranking criteria developed through interviews with terminal operators (decision makers), and in the validation simulation, it reduced unproductive manipulations by 37%. The model reduced inbound container unloading time as well as container storage time at the terminal. This should translate to lower handling costs and higher inland terminal productivity.

The presented model requires analysis of the container retention time statistics for each criterion category. This enables containers to be stored in tiers ranked according to average container retention time. Such an approach reduces the number of unproductive manipulations and speeds up container shipping from the terminal. Although the model may lead to longer train retention than under the conventional storage principle of “first-in, first-out”, the simulation suggests that this prolongation is negligible compared to the increase in inland terminal productivity.

Author Contributions

Conceptualization, M.S.; Formal analysis, I.B.; Investigation, T.R.; Supervision, I.B.; Validation, B.I.; Writing — original draft, T.R.; Writing — review & editing, B.I. and M.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rožić, T.; Rogić, K.; Bajor, I. Research Trends of Inland Terminals: A Literature Review. Promet Traffic Transp. 2016, 28, 539–548. [Google Scholar] [CrossRef]

- Abourraja, M.-N.; Oudani, M.; Samiri, M.-Y.; Boukachour, J.; Elfazziki, A.; Bouain, A.; Najib, M. An improving agent-based engineering strategy for minimizing unproductive situations of cranes in a rail–rail transshipment yard. Simulation 2018, 94, 681–705. [Google Scholar] [CrossRef]

- Zhen, L.; Jiang, X.; Lee, L.H.; Chew, E.P. A review on yard management in container terminals. Ind. Eng. Manag. Syst. 2013, 12, 289–304. [Google Scholar] [CrossRef]

- Abbas, A.; Al-Baz, A.; Palade, V. A Constrained Fuzzy Knowledge-Based System for the Management of Container Yard Operations. Int. J. Fuzzy Syst. 2018, 20, 1205–1223. [Google Scholar] [CrossRef]

- Ayaci, I.; Kammarti, R.; Ksouri, M.; Borne, P. A genetic algorithm to solve the container storage space allocation problem. In Proceedings of the International Conference on Computational Intelligence and Vehicular System (CIVS), Seoul, Korea, 22–23 September 2010; Available online: http://arxiv.org/ftp/arxiv/papers/1303/1303.1051.pdf (accessed on 4 January 2022).

- Munford, C. Buenos Aires—Congestion and the dry port solution. Cargo Syst. Int. J. ICHCA 1980, 7, 26–27. [Google Scholar]

- Notteboom, T.E. Concentration and load centre development in the European container port system. J. Transp. Geogr. 1997, 5, 99–115. [Google Scholar] [CrossRef]

- Van Klink, H.A.; van den Berg, G. Gateways and intermodalism. J. Transp. Geogr. 1998, 6, 1–9. [Google Scholar] [CrossRef]

- Roso, V.; Woxenius, J.; Lumsden, K. The dry port concept: Connecting container seaports with the hinterland. J. Transp. Geogr. 2009, 27, 338–345. [Google Scholar] [CrossRef]

- Frémont, A.; Franc, P. Hinterland transportation in Europe: Combined transport versus road transport. J. Transp. Geogr. 2010, 18, 548–556. [Google Scholar] [CrossRef]

- Rodrigue, J.P.; De Brie, J.; Fremont, A. Functions and actors of inland ports: European and North American dynamics. J. Transp. Geogr. 2010, 18, 519–529. [Google Scholar] [CrossRef]

- Wilmsmeier, M.; Monios, J.; Lambert, B. The directional development of intermodal freight corridors in relation to inland terminals. J. Transp. Geogr. 2011, 19, 1379–1386. [Google Scholar] [CrossRef]

- Monios, J. The role of inland terminal development in the hinterland access strategies of Spanish ports. Res. Transp. Econ. 2011, 33, 59–66. [Google Scholar] [CrossRef]

- Ng, A.K.Y.; Padilha, F.; Pallis, A.A. Institutions, bureaucratic and logistical roles of dry ports: The Brazilian experiences. J. Transp. Geogr. 2013, 27, 46–55. [Google Scholar] [CrossRef]

- Agamez-Arias, A.d.M.; Moyano-Fuentes, J. Intermodal transport in freight distribution: A literature review. Transp. Rev. 2017, 37, 782–807. [Google Scholar] [CrossRef]

- Qui, H.; Siu Lee Lam, J.; Huang, G.Q. A bilevel storage pricing model for outbound containers in a dry port system. Transp. Res. Part E 2015, 75, 65–83. [Google Scholar] [CrossRef]

- Abacoumkin, C.; Ballis, A. Development of an expert system for the evaluation of conventional and innovative technologies in the intermodal transport area. Eur. J. Oper. Res. 2004, 152, 410–419. [Google Scholar] [CrossRef]

- Racunica, I.; Wynter, L. Optimal location of intermodal freight hubs. Transp. Res. Part B 2005, 39, 453–477. [Google Scholar] [CrossRef]

- Sirikijpanichkul, A.; Van Dam, H.K.; Ferreira, L.; Lukszo, Z. Optimizing the Location of Intermodal Freight Hubs: An Overview of the Agent Based Modelling Approach. J. Transp. Syst. Eng. Inf. Technol. 2007, 7, 71–81. [Google Scholar] [CrossRef]

- Limbourg, S.; Jourquin, B. Optimal rail-road container terminal locations on the European network. Transp. Res. Part E Logist. Transp. Rev. 2009, 45, 551–563. [Google Scholar] [CrossRef]

- Kayikci, Y. A conceptual model for intermodal freight logistics centre location decisions. The Sixth International Conference on City Logistics. Procedia-Soc. Behav. Sci. 2010, 2, 6297–6311. [Google Scholar] [CrossRef]

- Da Silva Portugal, L.; Vaz Morgado, A.; Lima Júnior, O. Location of cargo terminals in metropolitan areas of developing countries: The Brazilian case. J. Transp. Geogr. 2011, 19, 900–910. [Google Scholar] [CrossRef]

- Sörensen, K.; Vanovermeire, C.; Busschaert, S. Efficient metaheuristics to solve the intermodal terminal location problem. Comput. Oper. Res. 2012, 39, 2079–2090. [Google Scholar] [CrossRef]

- Ambrosino, D.; Sciomachen, A. Location of Mid-range Dry Ports in Multimodal Logistic Networks. Procedia-Soc. Behav. Sci. 2014, 108, 118–128. [Google Scholar] [CrossRef]

- Wadhwa, S.S.; Farahmand, K.; Vachal, K. A deterministic mathematical model to support future investment decisions for developing inland container terminals. Res. Transp. Econ. 2019, 80, 100799. [Google Scholar] [CrossRef]

- Rožić, T.; Rogić, K.; Ivanković, B. Modelling inland terminal locations based on transport cost optimization. Int. J. Shipp. Transp. Logist. 2020, 12, 487–503. [Google Scholar] [CrossRef]

- Crainic, T.G. Service network design in freight transportation. Eur. J. Oper. Res. 2000, 122, 272–288. [Google Scholar] [CrossRef]

- Chang, T.S. Best routes selection in international intermodal networks. Comput. Oper. Res. 2008, 35, 2877–2891. [Google Scholar] [CrossRef]

- Caris, A.; Janssens, G.K. A local search heuristic for the pre-and end-haulage of intermodal container terminals. Comput. Oper. Res. 2009, 36, 2763–2772. [Google Scholar] [CrossRef]

- Ferrari, C.; Parola, F.; Gattorna, E. Measuring the quality of port hinterland accessibility: The Ligurian case. Transp. Policy 2011, 18, 382–391. [Google Scholar] [CrossRef]

- Wang, W.F.; Yun, W.Y. Scheduling for inland container truck and train transportation. Int. J. Prod. Econ. 2013, 143, 349–356. [Google Scholar] [CrossRef]

- Braekers, K.; Caris, A.; Janssens, G.K. Bi-objective optimization of drayage operations in the service area of intermodal terminals. Transp. Res. Part E 2014, 65, 50–69. [Google Scholar] [CrossRef]

- Fazi, S.; Fransoo, J.C.; Van Woensel, T.; Dong, J.H. A variant of the split vehicle routing problem with simultaneous deliveries and pickups for inland container shipping in dry-port based systems. Transp. Res. Part E 2020, 142, 102057. [Google Scholar] [CrossRef]

- Shan, W.; Peng, Z.; Liu, J.; Yao, B.; Yu, B. An exact algorithm for inland container transportation network design. Transp. Res. Part B Methodol. 2020, 135, 41–82. [Google Scholar] [CrossRef]

- Jiang, X.; Lee, L.H.; Chew, E.P.; Han, Y.; Tan, K.C. A container yard storage strategy for improving land utilization and operation efficiency in a transshipment hub port. Eur. J. Oper. Res. 2012, 221, 64–73. [Google Scholar] [CrossRef]

- Beškovnik, B.; Twrdy, E.; Bauk, S. Developing Higher Berth Productivity: Comparison of Eastern Adriatic Container Terminals. Promet-Traffic Transp. 2019, 31, 397–405. [Google Scholar] [CrossRef]

- Kim, K.H.; Kim, H.B. The optimal sizing of the storage space and handling facilities for import containers. Transp. Res. Part B 2002, 36, 821–835. [Google Scholar] [CrossRef]

- Zhen, L. Modeling of yard congestion and optimization of yard template in container ports. Transp. Res. Part B 2016, 36, 821–835. [Google Scholar] [CrossRef]

- Tan, C.; He, J.; Yu, H. Mathematical modeling of yard template regeneration for multiple container terminals. Adv. Eng. Inform. 2019, 40, 58–68. [Google Scholar] [CrossRef]

- Lee, K.B.; Kim, H.W. Optimizing the block size in container yards. Transp. Res. Part E 2010, 46, 120–135. [Google Scholar] [CrossRef]

- Kim, K.H. Evaluation of the number of rehandles in container yards. Comput. Ind. Eng. 1997, 32, 701–711. [Google Scholar] [CrossRef]

- Caserta, M.; Schwarze, S.; Voß, S. A mathematical formulation and complexity considerations for the blocks relocation problem. Eur. J. Oper. Res. 2012, 219, 96–104. [Google Scholar] [CrossRef]

- Zehendner, E.; Caserta, M.; Feillet, D.; Schwarze, S.; Voß, S. An improved mathematical formulation for the blocks relocation problem. Eur. J. Oper. Res. 2015, 245, 415–422. [Google Scholar] [CrossRef]

- Kozan, E.; Preston, P. Mathematical modelling of container transfers and storage locations at seaport terminals. OR Spectr. 2006, 28, 519–537. [Google Scholar] [CrossRef]

- Moccia, L.; Cordeau, J.P.; Monaco, M.F.; Sammarra, M. Operations Research for the management of a transhipment container terminal: The Gioia Tauro case. Marit. Econ. Logist. 2009, 11, 7–35. [Google Scholar] [CrossRef]

- Jin, J.G.; Lee, D.H.; Cao, J.X. Storage Yard Management in Maritime Container Terminals. Transp. Sci. 2016, 50, 1300–1313. [Google Scholar] [CrossRef]

- Ting, C.J.; Wu, K.C. Optimizing container relocation operations at container yards with beam search. Transp. Res. Part E Logist. Transp. Rev. 2017, 103, 17–31. [Google Scholar] [CrossRef]

- Gharehgozli, A.; Yu, Y.; Koster, R.; Du, S. Sequencing storage and retrieval requests in a container block with multiple open locations. Transp. Res. Part E Logist. Transp. Rev. 2019, 125, 261–284. [Google Scholar] [CrossRef]

- Dekker, R.; Voogd, P.; van Asperen, E. Advanced methods for container stacking. OR Spectr. 2006, 28, 563–586. [Google Scholar] [CrossRef]

- Imai, A.; Nishimura, E.; Current, J. A Lagrangian relaxation-based heuristic for the vehicle routing with full container load. Eur. J. Oper. Res. 2007, 176, 87–105. [Google Scholar] [CrossRef]

- Jarašūniene, A. Optimisation of technological processes in terminals. Transport 2004, 19, 207–213. [Google Scholar] [CrossRef][Green Version]

- Carrese, S.; Tatarelli, L. Optimizing the stacking of the Intermodal Transport Units in an inland terminal: An heuristic procedure. Procedia Soc. Behav. Sci. 2011, 20, 994–1003. [Google Scholar] [CrossRef][Green Version]

- Wiercx, M.; van Kalmthout, M.; Wiegmans, B. Inland waterway terminal yard configuration contributing to sustainability: Modeling yard operations. Res. Transp. Econ. 2019, 73, 4–16. [Google Scholar] [CrossRef]

- Čaklović, L. Teorija Vrednovanja s Naglaskom na Metodu Potencijala, Principi, Metode, Primjene; Prirodoslovno-Matematički Fakultet: Zagreb, Croatia, 2014. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).