Abstract

In New Zealand (NZ), steel roofing is the most common roofing type for residential buildings. However, the environmental impact of steel roofs are not negligible. Steel roofs account for up to 30% of the upfront embodied carbon for a typical NZ house, highlighting the importance of investigating and reducing the environmental impacts of steel roofs in meeting the net-zero carbon goal of the NZ government. There are several research gaps in investigating the impacts of steel roofs, such as the variation in emissions between local and imported steel coil products, the unavailability of life cycle assessment (LCA) data, and additional impacts from ancillary items. Therefore, this study performed an LCA of a case study roof in NZ to investigate these gaps using GaBi Ts software. It was found that the overall impacts from the steel roofs, including the ancillary items, were 12 kg CO2-eq/m2, where the ancillary items accounted for less than 10% of total emissions. The prepainted steel coils manufactured globally had less than 70% emissions when compared to the emissions of locally manufactured prepainted steel coils. In addition, the roll forming processes had an insignificant effect on overall emissions, whereas the transportation of steel coils had a notable impact.

1. Introduction

Human activities are the primary drivers of change to the Earth’s natural processes, potentially triggering abrupt or irreversible environmental changes that could be disastrous for human well-being, such as climate change []. The construction business emits a substantial amount of carbon dioxide, the leading cause of climate change []. It accounts for one-third of global carbon emissions and over 40% of primary energy consumption []. In New Zealand, the construction sector is responsible for 20% of gross national emissions [], and it has increased by 66% in the last decade []. Approximately half of these building-related emissions are from embodied carbon in the structures [], although this number may be higher in New Zealand []. The manufacture of building materials, such as steel, cement, and glass, is identified as a significant source of these emissions []. Also, building activity contributes to a number of environmental problems, such as eutrophication, acidification, and the depletion of resources [].

In New Zealand, the steel material for housing roofs accounts for more than 75% of the market share []. Steel roofs with timber battens are the most common type of roofing for residential buildings in the country due to their low cost and high performance. With current practice, the great majority (approximately 95%) of the nation’s steel roofs are fabricated from base steel produced by local producers, with the rest generally being imported from South Korea []. Steel roofs in the country typically comprise thin sections of cold-rolled steel coil folded to form profiles such as corrugated, trapezoidal, or standing seam. These profiles can sustain the harsh wind, rain, and snow, as well as the maintenance and access loads exerted over the roof’s lifespan. Research related to steel materials has been widely conducted [,,,], not only for roofing but also for other building components such as columns and beams [,,,,,,]. Several studies analysed the strength of this material [,,,,,] and its ability under certain conditions (e.g., high temperature) [,,,,], as well as proposed the design rules and assessment method of the steel product [,,,,,]. However, despite its good performance and the large market for steel materials in the country, the environmental impact of the steel industry cannot be negligible and needs to be considered [,].

The steel industry accounts for about 8% of global carbon emissions []. Swalec & Shearer [] estimated that 61% of global crude steel is produced using blast furnace-basic oxygen furnaces (BF-BOF). The use of coil in this process results in significant carbon emissions, which are approximately 2.2 tonnes for every tonne of steel produced in a typical BF-BOF. On the other hand, the electric arc furnace (EAF) route, where a natural gas-base can be used for the reduction reaction, can lower emissions to 1.4 tonnes of carbon per tonne of steel. Bhatnaged [] noted several pathways for emissions reduction, such as the use of scrap steel in EAF, biofuels, or carbon capture with BF-BOF and EAF, and blue or green hydrogen for the reduction reaction. The International Energy Agency, through the “Net-zero by 2050” report [], estimated a need for over half of all steel production to be from EAF and approximately 30% of steelmaking to be equipped with hydrogen use and significant carbon capture adoption. It also noted that 40% of the emissions reductions would need to be achieved from material efficiency in design and recycling, requiring a 20% reduction in global steel demand by 2050. Efficiency in steel roof design can reduce the weight of raw material needed in the manufacturing process, which can greatly reduce the embodied carbon emissions of the product. As previously proposed [,,,], structural optimisation techniques can be used to improve the efficiency of steel product design by optimizing form, shape, and topology while not compromising design quality. Therefore, in achieving the emission reduction strategy, an assessment related to environmental impact needs to be conducted to analyse the progress of the emission reduction.

A life cycle assessment (LCA) is the most well-known methodology for quantifying the environmental impact of a product, including building products [,,,]. It can be used to evaluate the expected environmental impacts of a product or service throughout its life cycle, from raw material acquisition through production, distribution, use, maintenance, and disposal []. There are two primary approaches to LCA: process LCA and input-output (IO) LCA, but hybrid combinations of the two are also possible []. IO LCA determines environmental effects from macro-sector-level data of monetary flows combined with statistical environmental impact data []. When assessing the life cycle effects of a specific product with the goal of reducing those impacts, IO LCA is not suitable, and process LCA is typically used. It is because the emissions are assessed according to actual energy and mass flows from process to process []. In addition, ISO standards 14040 [] and 14044 [] outline a framework for LCA methodology that is used globally.

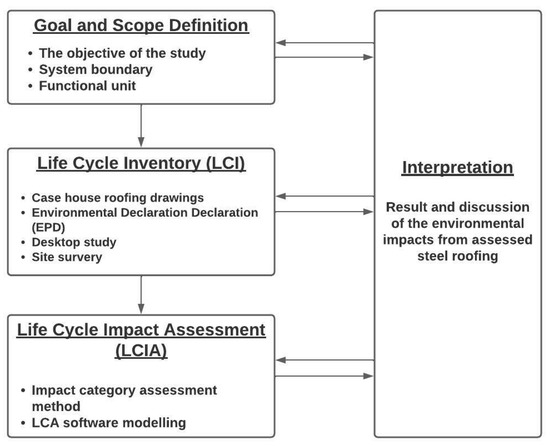

According to ISO 14040:2006 [], there are four steps to conducting LCA: goal and scope definition, life cycle inventory (LCI), life cycle impact assessment (LCIA), and interpretation analysis. The goal and scope definition set the boundaries of the LCA as well as its purpose. The LCI step is a data collection step where an inventory of the materials, energy usage, direct environmental impacts, and waste is compiled from the flows and processes in the supply chain. There is typically a large amount of data in the full supply chain, and it is impractical to collect this data for each LCA. Databases such as ecoinvent and the US Life Cycle Inventory Database have widespread datasets with life cycle inventory background data for various products and processes. However, in order to produce more relevant and transparent results, the LCA study cannot rely solely on generic data from commercial databases. It has to consider more specific data for the assessment, such as an Environmental Product Declaration (EPD) of a specific product []. EPD is a standardized product LCA data that has relatively more accurate and reliable values by using specific foreground data. The LCIA step employs scientific methods such as CML and TRACI to characterize and characterize a large number of different environmental impacts into indicator values that can be interpreted and compared []. The most popular commercial tools for completing product LCA for all sectors, including construction, are GaBi Ts [] and SimaPro [,], but free software like openLCA [] and LCAQuick [] is also gaining popularity in current practice. Using the GaBi Ts, a process-based LCA can be performed, which suits the assessment of specific processes such as steel roofing production processes.

The Worldsteel Association [] completed an LCA of six roofing solutions for a Scandinavian house. The purpose of this LCA was to compare the environmental effects of concrete, steel, and bitumen roofing solutions available in Finland and Sweden, and they found that the steel roofing solutions had the best outcomes for all environmental categories []. Mitchell & Carman [] completed LCA for various building types in NZ (industrial, residential, and office) and found that the building envelopes, including steel roofing, contribute approximately 20–25% of the total embodied carbon. Steel roofing has a more significant proportion of embodied carbon for single-storey structures, and Gamage et al. [] found it could contribute more than 25% of the upfront embodied carbon for a typical New Zealand (NZ) house. However, the choice of database and software may significantly impact the reported results. It should be noted that the result can be varied due to local variations in raw material purity and electric mix. Emami et al. [] used the ReCiPe LCIA methodology for a full building LCA and noted significant variations in all impact category emissions, except climate change, when using the SimaPro software with the ecoinvent database compared with the Gabi software and database. Herrmann and Moltesen [] compared the impact potentials for a single unit process and found that the Gabi software and SimaPro reported significant variations in at least some impact categories for various LCIA methods. Therefore, selecting a database and software for the LCA study is crucial because more specific data may result in better outcomes and accuracy.

Generic data for steel coil used in roofing can be obtained from Worldsteel, a global steel association, which has published a database based on investigations from various global mills, and it is available in most popular LCA software. Alternatively, life cycle effects can be directly extracted from EPDs completed by selected companies. Local companies such as Colorsteel and Colorcote have published EPDs for their finished coil products [,,]. Although imported steel coil products only form a small part of NZ’s roofing market, any notable differences in environmental impacts from production and how to implement this in a simple whole-building life cycle assessment (WBLCA) are not well understood. The impact data from both EPDs and generic data from Worldsteel does not include the final production process to convert steel coil into the finished roofing profile, including transport, storage, and roll forming of the coil. Only a limited number of steel roofing products, such as Tata’s RoofDeck D35 profile available in Europe, have EPDs for the finished profiled roofing product. However, this data is not available for NZ products. Roofing has the largest environmental impact on roof components; other ancillary items such as gutters, flashings, downpipes, underlay, fixings, purlins, and other items could also have a notable effect on overall emissions. Therefore, the calculation of environmental impacts of steel roofs and the ancillary items needs to be quantified throughout their life cycles, and it would be valuable to understand the gaps in environmental impact from the steel roofing products in New Zealand.

The aim of the study was to better understand the nature of gaps for steel roof LCA. The study analyzed the long run roofing profile with five ribs produced by a local manufacturer and used the GaBi Ts software [] in calculating the quantity of environmental impacts from the steel roofing product. The study included ancillary items for the roof installation, such as gutters, flashings, underlay, and other roofing elements. The intention of this investigation was to be able to provide recommendations to improve the accuracy of measurements of the environmental impacts of steel roofs while providing insights for reducing the environmental impacts of roofs in New Zealand.

2. Methods and Life Cycle Assessment Processes

An LCA method was performed to analyze the several environmental impacts of the steel roofing profile and ancillary items in the case housing. A two-storey house located in Kerikeri, New Zealand with a roof area of 270 m2 was used in this study. The selected roof was the long run roofing profile with five ribs, manufactured by local manufacturer in Wiri, Auckland, which was a 5-rib trapezoidal profile. The study referred to ISO 14040:2006 [] in undertaking the LCA process. Figure 1 shows the overall LCA framework undertaken in this study.

Figure 1.

Life cycle assessment framework for the research.

Overall, the study started with defining the goal and scope of the system boundary and functional units of the selected environmental impacts. In the LCI step, data such as material quantities, transport distance, and electricity grid mix were collected from several sources, including quantifying material take off from case house roofing drawings, adopting EPDs, conducting a desktop study, and a site visit to a local manufacturing site. The LCIA step was conducted by selecting environmental impact categories for the study and modelling the LCA of steel roofs and ancillary items using GaBi Ts software. Furthermore, the results obtained from the LCIA were analysed and presented in the interpretation step.

2.1. Goal and Scope of LCA

The primary goal of the study was to complete the LCA of a steel roof, including ancillary items, for a case study house in New Zealand. The results were analyzed to understand the extent of the life cycle impacts of key processes. The analysis focused on the steel coil, the roll forming of roofing from a coil, and the extent of impacts from ancillary items. The functional unit was defined as the “coverage of one square metre of the roof with steel roofing in a very high wind zone and exposure zone B under NZS3604 definitions, while also providing waterproofing in compliance with the NZ Building Code”. The timber roof trusses, ceiling level structure, services, and insulation were outside the scope of the study. The case building lifespan was assumed to be 60 years, which was recommended by IStructE [] as the standard practise for building projects. The selected system boundaries in the study were modules A1–A3 (production stages), A4 (transportation to the site), C2–C4 (from transportation at the end-of-life stages to the disposal process), and D (potential benefits of reuse, recovery, and recycling).

2.2. Life Cycle Inventory (LCI)

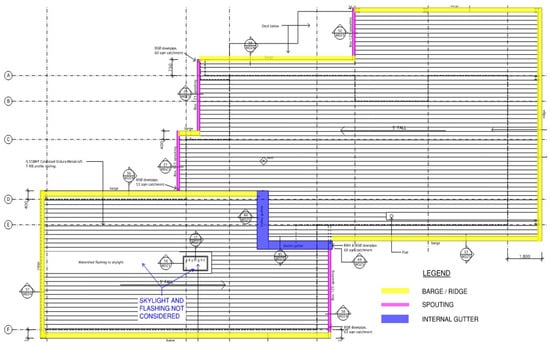

In the LCI step of this study, the data for LCA was gathered from several sources, such as case house roofing drawings, EPDs of steel roofing products, a desktop study, and a site visit to the local manufacturer. The material quantity data was calculated from the roofing plan drawing of the case study. Figure 2 illustrates the case study roof plan drawings, and Table 1 shows the material take-off of the case housing roof.

Figure 2.

Roof level plan of the case study house (all measurements are in millimetres and scaled 1:100).

Table 1.

Bill of materials for case study house.

The study quantified the steel roofs, including the ancillary items from the case building drawing. Some items such as roof trusses and brackets, fixings, and soffit boards were excluded from the calculation. The LCI information by Worldsteel on the GaBi Education database was only available for the organic coated steel coil and not for the full production processes of profile roofing. Therefore, the transport of the steel coil product, energy and resources used at the factory, and intermediate storage facility all need to be considered. Flashing and gutters were also made from steel coil and had an identical gap in available LCI data. In order to gather the unavailable data, a site visit to the local steel roofing factory was completed on 31 May 2021, to understand the full process.

For the transportation data, an ocean container ship with a 43,000-tonne capacity was assumed to transport steel coil from Busan, South Korea, to Auckland, New Zealand. A 9350 km distance was estimated using the portworld.com website, and it had been rounded up to 10,000 km to account for the variability of the shipping routes. For road transport, a 14-tonne truck was assumed for all transport of steel coils, and a smaller 7-tonne truck was used for transport of the finished product. The distance travelled between sites was calculated using Google Maps.

2.3. Life Cycle Impact Assessment (LCIA)

After LCI data was collated, consisting of all the material and energy inputs and outputs in each process of the roof life cycle, all emissions were converted, representing the effect on the mid-point environmental impact categories. Midpoints are recognised to be connections in the cause-effect chain (an environmental mechanism) of the impact group (e.g., ozone depletion and global warming) []. The CML 2001 was used as the LCIA methodology, where it was considered the most popular method in the construction industry []. GaBi Ts software Version 9.1.0.53 [] was used to compile the LCI data and convert the data to environmental impacts using the CML 2001 method. In addition, seven environmental impact categories were quantified, which are outlined below.

- Global warming potential (GWP): greenhouse gasses and global warming—fossil + biogenic

- Ozone depletion potential (ODP): damage to ozone in the upper atmosphere

- Acidification potential (AP): acidification of soil or water

- Eutrophication potential (EP): over-fertilisation and excessive biomass growth

- Photochemical ozone creation potential (POCP): impact of ozone and other oxidants in lower atmosphere

- Abiotic depletion potential—elements (ADPE): elements, minerals and energy consumed

- Abiotic depletion potential—fossil (ADPF): consumption of fossil resources

GaBi Modelling

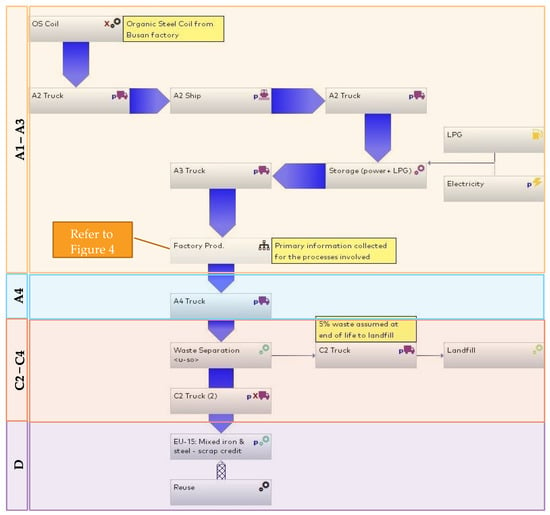

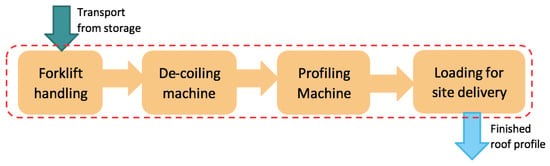

GaBi modelling was conducted to quantify the environmental impacts produced by the steel roof and ancillary items. In the assessment, background LCI data from GaBi’s inbuilt and Worldsteel databases was utilised. The additional information for the steel profile manufacturing in the local factory was estimated from a site visit. Due to the short nature of the study and the limitations in the available LCI data in the GaBi education database, several processes in the manufacturing process of supplementary materials were excluded. Figure 3 shows the overview of GaBi modelling for the steel roof throughout its life cycle stages. The steel coil used by the local manufacturer was supplied by a local supplier, which imported the coil from the Busan factory in South Korea. The data inputs in the coil manufacturing process used global average data. The steel coil was assumed to be shipped to Auckland, where it was transported to the local storage facility by truck. Electricity for lighting and gas for forklift handling were used in the storage site. The coil was delivered to the local steel roof factory, where the steel roof manufacturing process began (see Figure 4). Electricity was consumed during the steel roof production, such as de-coiling, profiling, and cutting workflows. The ratio of overall life cycle impacts to the effects from steel coil production alone was assumed to be identical for the flashings/gutters and the profiled roof. Therefore, the LCI data was only collected for steel-profile roofs, and it was considered similar for gutters and flashings. Transport during the A4 module was assumed to be by truck. For the steel end-of-life (EOL) recycling stage, it was assumed that steel would be transported back to Auckland with the assumption that by the time the building was demolished, a local EAF facility would be set up in Auckland.

Figure 3.

Overview of the case steel roofing aggregate processes in GaBi Ts software.

Figure 4.

Overview of the factory production aggregate process.

The LCI data in GaBi included combustion emissions but did not consider truck production or its EOL emissions. For the timber purlins and fascia used in the study, the data was based on the “pine timber” process, which considered production in Germany using industry data. It included the sawing process but not the timber treatment process. Although a NZ specific data set was not available, the German process was considered suitable as the GaBi Ts software still utilised country-specific situations for electricity and energy modelling. The LCI data for the investigated roofing underlay or its raw material (polyolefin) were not available in GaBi Ts; therefore, polypropylene film was used. In addition, aluminium foil and styrene-butadiene rubber backing were used as the materials of the flashing tape in the assessment due to the unavailability of the data in the GaBi database.

2.4. Other Assumptions

Some additional assumptions were made in the LCA of the steel roof and ancillary items outlined below.

- Assumptions regarding the roll forming and storage facility processes are noted in Appendix A.

- The processes not included in the assessment had a negligible effect on the overall environmental impacts of the roof.

- The generic inventory and LCI data in the software was a reasonably accurate representation of the processes and impacts from the production of the local manufactured long run roofing profile with five ribs.

3. Results

3.1. Life Cycle Assessment of Organic Coated Steel Coil

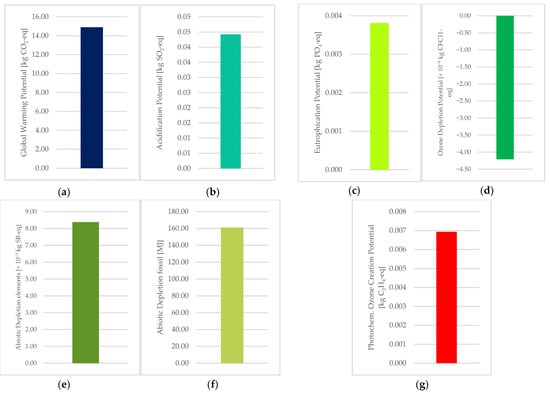

The production of coated steel coil involved the production of steel coil from raw materials, which was then coated to provide the desired finish and durability. The environmental effects of NZ’s popular coated steel coil products were compared to generic Worldsteel data derived from the Gabi Ts software. Colorsteel is the most popular pre-painted steel roofing cladding made from steel coil supplied by a local supplier. The EPD from Colorsteel was used to calculate the locally sourced products’ impacts and compare them with the results of the GaBi modelling using the Worldsteel LCI data. Outputs from the GaBi Ts software for the life cycle impacts of the various categories are shown in Figure 5.

Figure 5.

Outputs from GaBi showing the environmental impacts of organic steel coil production for 1 m2 of roof: (a) GWP; (b) AP; (c) EP; (d) ODP; (e) ADP elements; (f) ADP fossil; (g) POCP.

A comparison of the life cycle impacts of steel coils sourced locally and imported steel coils represented by average Worldsteel global data is presented in Table 2. Although the comparison cannot be made with certainty, the comparison shows that imported steel coils were likely to have lower impacts in all categories than the coils produced locally.

Table 2.

Comparison of the life cycle impacts of the imported and locally sourced organic coated steels.

One of the reasons for the differences in impacts was likely due to the unique processes used in New Zealand to manufacture steel entirely from iron sand found along the west coast. The magnetite ore in the iron-sand was locked in with impurities such as titania and silica, and separating these requires additional heat and processing [], resulting in greater emissions. The average global life cycle impact was also lower because more recycled steel and more electric arc furnace production methods were used in some parts of the world.

The results demonstrated that using imported steel coils results in a lower life cycle impact for a building project. However, care should be taken since generic data was compared with specific data from EPDs in the study. It is possible that a selected batch of imported steel coil purchased from the global market is manufactured with higher emissions than the locally sourced materials.

3.2. Life Cycle Assessment of the Long Run Roofing Profile with Five Ribs

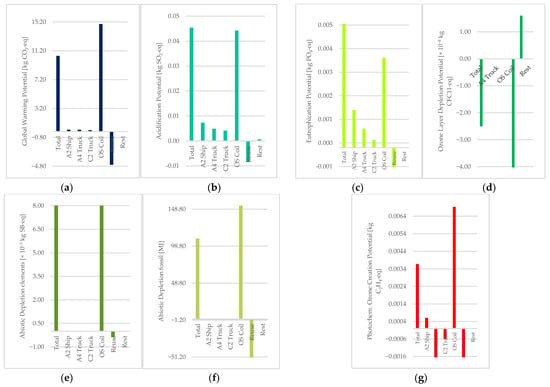

The overall environmental impacts of the long run roofing profile with five ribs included the production of the organic steel coil, transport and storage until arrival at the factory, factory production, transport to the site, and end-of-life disposal and recycling. Outputs from GaBi Ts software for the steel roof profile made from steel coil imported from the factory in Busan, South Korea are shown in Figure 6.

Figure 6.

Outputs from GaBi showing the environmental impacts of a steel roof profile for 1 m2 of the case study house: (a) GWP; (b) AP; (c) EP; (d) ODP; (e) ADP elements; (f) ADP fossil; (g) POCP.

According to Figure 6, it is clear that steel coil production accounts for most of the effects across all impact categories. The processes accounted for essentially 100% of the environmental impacts for ODP, ADPE, and ADPF and 94% for GWP. The proportion of impact was slightly lower for EP (70%) and AP (51%). Therefore, it highlights the huge influence of the steel coil production processes on the overall environmental impacts, and the processes were identified as the hotspots of the study by having contributed over 50% of the total environmental impacts []. The production of roofing from the coil process sat within the “Rest” category for most impact categories due to the small effect on overall emissions. It accounted for less than 0.4% of total effects for all impact categories except acidification potential, which accounted for a negligible 1.4% of total impacts. Similarly, the “landfill” process had a negligible effect on the overall impacts.

The overall transportation, including the road journey to the construction site as well as EOL journeys to the landfill and recycling facility, had a significant effect on some impact categories such as AP (28%), EP (49%), GWP (6%) and POCP (−62%). Transport from the supplier in Busan, South Korea to the factory in Auckland, New Zealand had a notable influence, accounting for 4% of GWP and higher for some other impact categories such as EP, where it was responsible for more than a quarter of the effects. However, the GaBi modelling in the study did not calculate the products’ C3 and C4 emissions due to the availability of the data for the assessment. Therefore, for completeness of the LCA study, EPD for the coil products made by Colorsteel (Maxx 0.55 mm) [] was used to add the missing modules in the assessment by also adjusting the value for 1 m2 of the 5-rib trapezoidal profile. Table 3 shows the overall life cycle impacts for the seven impact categories for 1 m2 of steel roofing.

Table 3.

Overall life cycle impact for the seven impact categories for 1 m2 of case steel roofing.

3.3. Life Cycle Assessment of the Ancillary Items

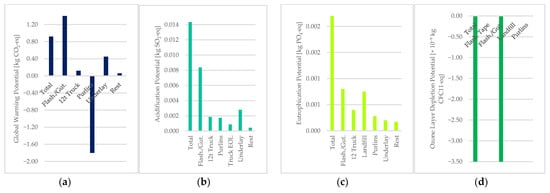

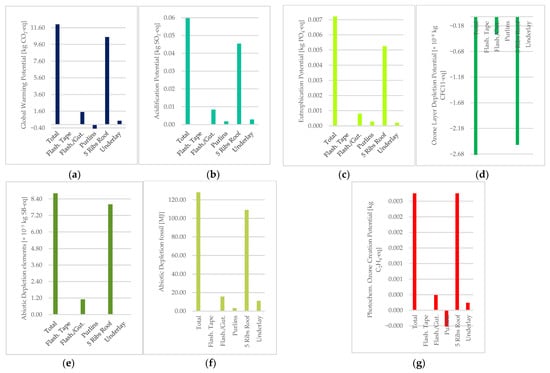

The ancillary items considered for the case roof LCA were steel flashings and gutters, timber purlins and fascia boards, polypropylene underlay, and flashing tape. The LCA results for the seven impact categories are presented for the 1 m2 floor area of the case house, and Figure 7 shows the outcomes of the assessment.

Figure 7.

Outputs from GaBi showing the environmental impacts of ancillary items for 1 m2 of the case study house: (a) GWP; (b) AP; (c) EP; (d) ODP; (e) ADP elements; (f) ADP fossil; (g) POCP.

Based on Figure 7, steel gutters and flashings had the largest effect of all ancillary items for most impact categories considered in the study, except for EP. Most notably, these items comprised more than 150% of the GWP and about 100% of the ODP and ADP elements. The ODP had a positive effect, likely due to the known improvement of the ozone layer from increased carbon dioxide. For the GWP impact category, the overall result was significantly reduced due to the use of timber for the purlins and fascia boards. Timber had negative GWP values when it was assumed to be sourced from sustainably managed forests.

The impact of the EOL landfill had to be considered for the overall effect of using timber purlin as it accounted for approximately 95% of the items disposed in the landfill as applied in the study. Although the GWP impact was still negative, the purlins and their disposal had the largest EP among the ancillary items and a significant POCP. The transportation of materials to the site or landfill at EOL caused between 15–21% of the GWP, AP, and EP but had a positive effect on the POCP. The environmental impacts from transport were directly proportional to the mass and timber from purlins and fascia boards, which accounted for 70% of these transport-related emissions. For timber, the positive sequestered carbon effects were reduced by 45% when transportation and landfill disposal were also considered.

3.4. Life Cycle Assessment of the Case Roof including Ancillary Items

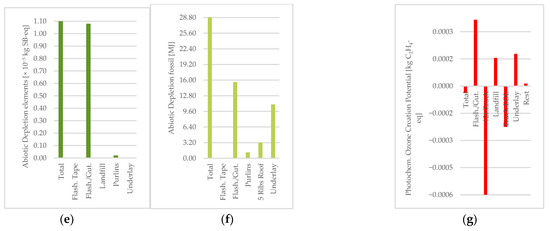

The overall life cycle impacts of the case steel roofing and ancillary items were considered in the study. It included the effects of the transport, disposal, and recycling of each of the individual materials. Figure 8 shows the overall results of the LCA for case steel roofing, including the ancillary items.

Figure 8.

Outputs from GaBi showing the environmental impacts of steel roofing including ancillary items for 1 m2 of the case study house: (a) GWP; (b) AP; (c) EP; (d) ODP; (e) ADP elements; (f) ADP fossil; (g) POCP.

According to Figure 8, steel roofing had the largest environmental effect, accounting for at least 80% of all impact categories, including 92% of the GWP. Steel flashings and gutters were the second most important materials in terms of emissions, which were responsible for 10–13% of the impacts for all categories. There were also notable impacts from both timber (purlins and fascia) and underlay, accounting for −16% to 16% and 0% to 8% of impacts, respectively, for all environmental categories. The impacts from flashing tape were identified as being insignificant. The overall effect from the steel roof was 12 kg CO2-eq for every 1 m2 of floor area. For the 270 m2 case study house, it equated to global warming emissions of approximately 3.2 tonnes of CO2 equivalent.

4. Discussion and Recommendations

4.1. Importance of Source of Steel Coil for Roofing in LCA

Simple software tools such as LCAQuick and OneClick LCA are becoming commonplace in the industry and use generic environmental impact data for simplicity. However, LCAQuick only allowed data from typical NZ products to be used for steel roofing, while OneClick LCA typically used generic data with some additional options for the input of recycled steel content, such as EPD, but was not widely available for New Zealand products. Therefore, the GaBi Ts were used in the study using the process LCA method to quantify the environmental impacts of the long run roofing profile with five ribs from the local producer attached to the house roof.

The study found significant variations in the environmental effects of similar products due to the source of the materials, location, transportation, and manufacturing processes. These factors were discovered to have a significant impact on the assessment’s outcomes. When completing an LCA, there is a potential for the result to be misleading if the generic data does not match the product used. It could become even more important as state-of-the-art sustainable steel technologies, such as hydrogen-based iron reduction, are adopted globally and the difference in environmental effects from different producers is exacerbated.

Steel roofing has a significant effect on the overall environmental impact. Developers with resources and know-how would likely engage in detailed LCA to benefit from the improved performance of imported steel roofing. However, it could be fairer to provide all developers with the opportunity to achieve their sustainability targets by considering steel coil manufacturers, even in a simplified LCA. Given the small number of dominant market players in the steel coil industry that is used for roofing, this could be easily achieved by providing guidance on how steel coil from each manufacturer is assessed.

According to the findings, steel coil production was the most significant process that produced environmental impacts in the majority of indicators. In terms of the GWP values, this production process emitted 14.9 kg CO2eq/m2. In order to check the validity of the result, the results from previous studies were considered. The range of GWP values of the production processes of the steel roofing products in New Zealand by Thinkstep ANZ ranged between 14.6 and 18.1 kg CO2eq/m2 for the 0.55 mm base metal thickness (BMT) []. A study by Le et al. [] found that the production process of the steel roofing sheets (including raw material acquisition and manufacturing process) was responsible for 98% of the total carbon emissions during the product’s life cycle. In addition, in investigating each process during the production of the steel roofing products, the effects of roll forming were negligible due to its low environmental impacts compared to the other processes studied. Therefore, the outcome of the assessment of steel roofing in the study can be used for other roof profiles created by local producers using the 0.55 mm coil. However, the data would need to be adjusted for the weight of the coil used per square metre of roof. Future research should be completed on the 0.44 mm BMT steel coil, which is also used by the same local producer. It would also be prudent to investigate the life cycle impacts of regular imported steel coils suppliers instead of global average data.

In addition, in an ideal system, users would purchase steel with different environmental gradings at different price points to achieve their targets and project needs. Ultimately, it could result in an improved business case for steel mills by improving the environmental performance of their processes. However, in a local context, the scale of investment required to reduce emissions from steel manufacturing may mean that the desirability of imported steel is increasing, and this is only harming local business. It would further inhibit the ability to invest in sustainable technologies. Therefore, to solve the issue, LCA, as the environmental impact assessment method, should attempt to provide accurate outputs of emissions data, including the steel coil source. Support is required to encourage innovation in the local industry, and it should be provided outside of the LCA framework. One of the largest improvements in the sustainability of buildings will come from the improved environmental performance of steel products, and research into the effective use of LCA to assist the transition should be studied further.

4.2. Consideration of Ancillary Items in LCA

Besides the main steel roof or the long run roofing profile with five ribs as the object of the study, the LCA of the ancillary items was also conducted to quantify their effect on the environment. The result demonstrates that the roof sheeting accounted for most of the environmental impacts of a steel roof (excluding the main structure). It was acceptable to ignore some ancillary items such as flashing tape in a simplified LCA. For other ancillary items that need to be considered, it is desirable to have a straightforward approach in simplified LCA. It could simply involve multiplying the emissions from the roof sheeting by a factor to account for additional emissions from ancillary items. Although the ratio of steel roofing to underlay will remain constant for all houses, the ratio of roofing to purlins, flashings, gutters, or fascia boards will vary with some factors, such as the shape of the house, materials used, and wind zone of the house. However, since all ancillary items are provided by the same supplier and roofing has the most significant environmental effects, additional efforts to calculate the impacts of ancillary items will have a negligible effect on product selection and sustainability outcomes.

The percentage increase of each impact category based on the findings in the study is noted in Table 4. It is noted that the percentage change will be different when using locally produced roofing, which would have higher environmental impacts. Further research into a range of house layouts and different ancillary items would be useful to establish the percentage increase with a greater level of certainty.

Table 4.

Recommended percentage increase in environmental impacts from roofing only to include ancillary items.

4.3. Recommendation for Improving the Sustainability of Steel Roofing Products

The study conducted the LCA of steel roofing products from the production to the EOL stages, including the potential benefits after the life stages (module D). The LCA study was intended to analyse each process during the steel roof product’s life cycle, which in this assessment is the long run roofing profile with five ribs. By considering each process that occurred during the product’s life cycle, identifying the most significant process in terms of the environmental impacts produced was possible. Therefore, it enabled the study to identify key processes during the life of steel roofing products that need improvement in environmental performance.

- There was a large part of the environmental impact from the steel roof product’s raw materials and manufacturing processes. The processes were identified as the hotspots of the steel roofing product by having more than 50% environmental impact across all indicators. In addition, when including the ancillary items, the steel roofing production processes also had the biggest environmental impact, accounting for more than 80% of the total impact in most categories. Therefore, this highlights the potential room for improvement in the steel roofing product’s environmental performance by reducing the effects of the product’s manufacturing processes. Optimising the steel roof design can be one of the solutions for reducing the impacts of the manufacturing processes. Reducing the weight of steel used can potentially reduce the amount of raw material and also the amount of energy used during the manufacturing process.

- Although the roll forming process had lower environmental impacts than others, identifying the highest impacts from the components during the process was performed. The machine used in the study to press and cut the steel coil into the final long run roofing profile with five ribs had the largest impact on the environment, which is 69% of the total impacts, in comparison with other activities in the processes. One of the other contributing factors was the direct electricity consumption used by the machine. According to 2019 national electricity supply data [], most of the electricity supply in New Zealand is primarily from renewable energy sources. However, 17.5% of the energy generated is from burning fossil fuels []. Thus, improving renewable energy production, such as using photovoltaic (PV) panels in manufacturing sites, can reduce the effects of fossil fuel consumption during the roll forming process.

- It was found that the recycling of steel products at the EOL stages had a significant positive influence on the environmental impacts for all impact categories. There was a significant recovery of the life cycle impacts after the recycling process, which could reduce the impact values by up to 45% of the total impacts in GWP, POCP, and ADP fossil indicators. Therefore, it highlights the importance of the reuse and recycling processes of the steel roofing product in improving its environmental performance.

In addition, some recommendations are made to improve the accuracy of steel roof environmental effects in simple life cycle assessments, which would eventually assist in reducing overall emissions from steel roofing.

- LCA should consider the source of the steel coil used in roofing. When the final guidance for completing a simple LCA is released, it should include data to consider all major brands of steel coil used for roofing. EPDs are available for NZ products, and data for roofing made from an imported coil is presented in the study.

- Roll forming processes to convert steel coil to roofing are negligible and can be ignored. However, the transportation of the coil to the roll forming site should be considered if the steel coil is imported.

- Ancillary items should be considered in LCA; however, a simple increase in emissions from steel roofing is considered suitable for simplified LCA. The data for the factor of increase for each impact category is provided in the study.

Future research should consider the 0.44 mm coil and the suppliers of uncoated steel coil to the steel coil producer in detail to get a more accurate assessment of the life cycle impacts of coil imported from South Korea. The range of environmental effects from ancillary items for various houses could also be investigated to better understand their effect on overall environmental impacts. Future research should also investigate the effective use of LCA to assist the transition to more sustainable steel manufacturing.

5. Conclusions

A life cycle assessment of a case study roof in Kerikeri, New Zealand, was completed to investigate the gaps and challenges for the steel roof life cycle assessment using simple procedures. The GaBi Ts software was used, and primary data was collected from the roll forming factory in Wiri, New Zealand. The study came to some initial conclusions, which are outlined below.

- It was found that for all impact categories, on average, coated steel coil manufactured globally had less than 70% of the impact of the New Zealand product.

- The roll forming process to convert coated steel coil to steel roofing had an insignificant effect on overall emissions, less than 0.5% of the total impacts for six out of the seven impact categories. On the other hand, transportation of steel coil was responsible for a significant proportion of impacts, accounting for 49% of the eutrophication potential and 6% of the global warming potential for steel coil imported from South Korea.

- Ancillary items accounted for less than 30% of total roof emissions for all impact categories except eutrophication (40%). Gutter and flashings accounted for at least 10% of total emissions for all impact categories, and there were also notable emissions from underlay and timber purlins or fascia boards.

- The overall global warming impact from the steel roof was 12 kg CO2-eq for every 1 m2 of floor area.

Author Contributions

Conceptualization, K.R., A.A.D., H.I. and J.B.P.L.; methodology, K.R., A.A.D., H.I. and Z.F.; software, K.R. and H.I.; formal analysis, A.A.D., H.I. and Z.F.; investigation, A.A.D. and H.I.; resources, K.R. and H.I.; writing—original draft preparation, K.R. and A.A.D.; writing—review and editing, Z.F. and J.B.P.L.; visualization, K.R., A.A.D. and H.I.; supervision, J.B.P.L.; project administration, K.R. and Z.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare that they have no conflict of interest.

Appendix A

Assumptions regarding the roll forming and storage facility processes were calculated based on the data collected during the site visit to the local factory on 31 May 2021. Only one visit could be completed to the roll forming facility in Wiri, New Zealand, to understand the production process. An additional visit to measure the specifications of the machines and forklifts, as well as the time taken for handling, could not be completed due to COVID-19 restrictions in the country. The following assumptions were made and are outlined below.

Appendix A.1. De-Coiler

- De-coiler model: Haixing HX.

- Output: 1 m of roofing/5 s based on speed of roll forming machine.

- Power usage: 3 kW assumed continuously for operation resulting in an estimated power use of 0.0066 kWh/m2 of roofing.

Appendix A.2. Roll Forming (and Cutting) Machine

- Roll forming model: Xianfa XF42.

- Machine output: Based on a YouTube video of the operating machine, an output of approximately 1 m of roofing per 5 s was determined.

- Power usage: 7.5 kW assumed to be used continuously during the machine’s operation resulting in an estimated power use of 0.016 kWh/m2 of roofing.

Appendix A.3. Forklift

- Length of steel in one coil: 500 m.

- Gas use by forklift: 2.75 kg/h.

- Handling time per coil prior to profiling in factory: 10 min → 0.012 kg/m2-roofing.

- Handling time per coil in storage: 10 min → 0.012 kg/m2-roofing.

Appendix A.4. Other Power Usage

Based on the factory floor plan, the factory floor area is 5050 m2, with approximately 750 m2 used for the long run roofing profile with five ribs operations. According to the department of energy’s “Energy Benchmarking Report:” in an average manufacturing facility, approximately 96 kWh/m2 of power is used for lighting. Assuming a factory output of 50,000 m2 results in power use of 0.002 kWh/m2. The storage facility details are not known, but the same power usage was assumed in the study.

References

- Rockström, J.; Steffen, W.; Noone, K.; Persson, Å.; Chapin, F.S., III; Lambin, E.; Lenton, T.M.; Scheffer, M.; Folke, C.; Schellnhuber, H.J.; et al. Planetary Boundaries: Exploring the Safe Operating Space for Humanity. Ecol. Soc. 2009, 14, 32. Available online: https://www.jstor.org/stable/26268316 (accessed on 25 February 2022). [CrossRef]

- Ministry of Business, Innovation & Employment. Building for Climate Change: Transforming the Building and Construction Sector to Reduce Emissions and Improve Climate Resilience; MBIE: Wellington, New Zealand, 2020; p. 10. Available online: https://www.mbie.govt.nz/dmsdocument/11522-building-for-climate-change (accessed on 25 February 2022).

- UNEP. Buildings and Climate Change: Summary for Decision Makers; United Nations Environment Programme: Paris, France, 2009. [Google Scholar]

- Ministry of Business, Innovation & Employment. Whole-of-Life Embodied Carbon Emissions Reduction Framework; MBIE: Wellington, New Zealand, 2020; p. 24. Available online: https://www.mbie.govt.nz/dmsdocument/11794-whole-of-life-embodied-carbon-emissions-reduction-framework (accessed on 25 February 2022).

- NZGBC. Climate Change and Building Pollution. 2020. Available online: https://www.nzgbc.org.nz/climate-change-and-building-pollution (accessed on 24 February 2022).

- Gibbons, O.P.; Orr, J.J. How to Calculate Embodied Carbon; The Institution of Structural Engineers: London, UK, 2020. [Google Scholar]

- Mitchell, O.; Carman, N. An Introduction to Embodied Carbon Associated with Building Design in Aotearoa—New Zealand [Paper Presentation]. SESOC 2-21: A New Beginning, Hamilton, New Zealand; 5–6 July 2021. Available online: https://2021conf.sesoc.org.nz/PDFs/S3A%20P3%20-%20Mitchell_Carman.pdf (accessed on 25 February 2022).

- Hu, M.; Esram, N.W. The Status of Embodied Carbon in Building Practice and Research in the United States: A Systematic Investigation. Sustainability 2021, 13, 12961. [Google Scholar] [CrossRef]

- Park, W.-J.; Kim, R.; Roh, S.; Ban, H. Identifying the Major Construction Wastes in the Building Construction Phase Based on Life Cycle Assessments. Sustainability 2020, 12, 8096. [Google Scholar] [CrossRef]

- Gamage, G.; Vickers, J.; Fisher, B.; Nebel, B. Under Construction: Hidden Emissions and Untapped Potential of Buildings for New Zealand’s 2050 Zero Carbon Goal; Thinkstep ANZ: Pukerua Bay, New Zealand, 2019; p. 55. Available online: https://www.thinkstep-anz.com/resrc/reports/hidden-emissions-and-untapped-potential-of-buildings-for-new-zealands-2050-zero-carbon-goal/ (accessed on 26 February 2022).

- McElroy, S. Notice Seeking Clearance for IKO to Acquire All of the Shares of Ross Roof Group Limited; IKO: Wellington, New Zealand, 2021. Available online: https://comcom.govt.nz/__data/assets/pdf_file/0030/255918/IKO-Industries-Ltd-clearance-application-27-May.pdf (accessed on 27 February 2022).

- Chen, B.; Roy, K.; Fang, Z.; Uzzaman, A.; Chi, Y.; Lim, J. Web crippling capacity of fastened cold-formed steel channels with edge-stiffened web holes, un-stiffened web holes and plain webs under two-flange loading. Thin-Walled Struct. 2021, 163, 107666. [Google Scholar] [CrossRef]

- Ananthi, G.B.G.; Roy, K.; Chen, B.; Lim, J.B.P. Testing, simulation and design of back-to-back built-up cold-formed steel unequal angle sections under axial compression. Steel Compos. Struct. 2019, 33, 595–614. [Google Scholar] [CrossRef]

- Roy, K.; Lau, H.H.; Lim, J.B.P. Finite element modelling of back-to-back built-up cold-formed stainless-steel lipped channels under axial compression. Steel Compos. Struct. 2019, 33, 37–66. [Google Scholar] [CrossRef]

- Mathieson, C.; Roy, K.; Clifton, G.; Ahmadi, A.; Lim, J. Failure mechanism and bearing capacity of cold-formed steel trusses with HRC connectors. Eng. Struct. 2019, 201, 109741. [Google Scholar] [CrossRef]

- Fang, Z.; Roy, K.; Chen, B.; Xie, Z.; Ingham, J.; Lim, J. Effect of the web hole size on the axial capacity of back-to-back aluminium alloy channel section columns. Eng. Struct. 2022, 260, 114238. [Google Scholar] [CrossRef]

- Roy, K.; Chen, B.; Fang, Z.; Uzzaman, A.; Lim, J.B.P. Axial Capacity of Back-to-Back Built-Up Aluminum Alloy Channel Section Columns. J. Struct. Eng. 2022, 148, 04021265. [Google Scholar] [CrossRef]

- Roy, K.; Lau, H.H.; Ting, T.C.H.; Chen, B.; Lim, J.B. Flexural behaviour of back-to-back built-up cold-formed steel channel beams: Experiments and finite element modelling. Structures 2020, 29, 235–253. [Google Scholar] [CrossRef]

- Lowe, D.; Roy, K.; Das, R.; Clifton, G.C.; Lim, J.B. Full scale experiments on splitting behaviour of concrete slabs in steel concrete composite beams with shear stud connection. Structures 2019, 23, 126–138. [Google Scholar] [CrossRef]

- Wang, J.; Wang, W.; Zhang, R.; Zhao, P.; Cheng, J. A calculation model and time-history analysis of semi-rigid steel frame-cfs inflled wall structures. Prog. Steel Build. Struct. 2021, 23, 115–124. [Google Scholar]

- Roy, K.; Chen, B.; Fang, Z.; Uzzaman, A.; Chen, X.; Lim, J.B. Local and distortional buckling behaviour of back-to-back built-up aluminium alloy channel section columns. Thin-Walled Struct. 2021, 163, 107713. [Google Scholar] [CrossRef]

- Chen, B.; Roy, K.; Uzzaman, A.; Lim, J.B. Moment capacity of cold-formed channel beams with edge-stiffened web holes, un-stiffened web holes and plain webs. Thin-Walled Struct. 2020, 157, 107070. [Google Scholar] [CrossRef]

- Fang, Z.; Roy, K.; Ma, Q.; Uzzaman, A.; Lim, J.B. Application of deep learning method in web crippling strength prediction of cold-formed stainless steel channel sections under end-two-flange loading. Structures 2021, 33, 2903–2942. [Google Scholar] [CrossRef]

- Roy, K.; Lau, H.H.; Fang, Z.; Ahmed, A.M.M.; Lim, J.B.P. Axial capacity of back-to-back built-up cold-formed stainless steel unlipped channels-Numerical investigation and parametric study. Steel Compos. Struct. 2021, 40, 761–780. [Google Scholar] [CrossRef]

- Fang, Z.; Roy, K.; Mares, J.; Sham, C.-W.; Chen, B.; Lim, J.B. Deep learning-based axial capacity prediction for cold-formed steel channel sections using Deep Belief Network. Structures 2021, 33, 2792–2802. [Google Scholar] [CrossRef]

- Dar, M.A.; Subramanian, N.; Rather, A.I.; Dar, A.R.; Lim, J.B.P.; Anbarasu, M.; Roy, K. Effect of angle stiffeners on the flexural strength and stiffness of cold-formed steel beams. Steel Compos. Struct. 2019, 33, 225–243. [Google Scholar]

- Fang, Z.; Roy, K.; Chen, B.; Xie, Z.; Lim, J.B. Local and distortional buckling behaviour of aluminium alloy back-to-back channels with web holes under axial compression. J. Build. Eng. 2022, 47, 103837. [Google Scholar] [CrossRef]

- Chen, B.; Roy, K.; Fang, Z.; Uzzaman, A.; Raftery, G.; Lim, J.B. Moment capacity of back-to-back cold-formed steel channels with edge-stiffened holes, un-stiffened holes, and plain webs. Eng. Struct. 2021, 235, 112042. [Google Scholar] [CrossRef]

- Chi, Y.; Roy, K.; Chen, B.; Fang, Z.; Uzzaman, A.; Ananthi, G.B.G.; Lim, J.B.P. Effect of web hole spacing on axial capacity of back-to-back cold-formed steel channels with edge-stiffened holes. Steel Compos. Struct. 2021, 40, 287–305. [Google Scholar] [CrossRef]

- Roy, K.; Lau, H.H.; Fang, Z.; Masood, R.; Ting, T.C.H.; Lim, J.B.; Lee, V.C.C. Effects of corrosion on the strength of self-drilling screw connections in cold-formed steel structures-experiments and finite element modeling. Structures 2022, 36, 1080–1096. [Google Scholar] [CrossRef]

- Roy, K.; Ting, T.; Lau, H.H.; Lim, J. Experimental Investigation into the Behaviour of Back-to-Back Gapped Built-Up Cold-Formed Steel Channel Sections under Compression. In Proceedings of the International Specialty Conference on Cold-Formed Steel Structures 2018—Recent Research and Developments in Cold-Formed Steel Design and Construction, St. Louis, MO, USA, 7–8 November 2018; pp. 283–297. [Google Scholar]

- Roy, K.; Lau, H.H.; Lim, J.B. Numerical investigations on the axial capacity of back-to-back gapped built-up cold-formed stainless steel channels. Adv. Struct. Eng. 2019, 22, 2289–2310. [Google Scholar] [CrossRef]

- Fang, Z.; Roy, K.; Lakshmanan, D.; Pranomrum, P.; Li, F.; Lau, H.H.; Lim, J.B. Structural behaviour of back-to-back cold-formed steel channel sections with web openings under axial compression at elevated temperatures. J. Build. Eng. 2022, 54, 104512. [Google Scholar] [CrossRef]

- Fang, Z.; Roy, K.; Xu, J.; Dai, Y.; Paul, B.; Lim, J.B. A novel machine learning method to investigate the web crippling behaviour of perforated roll-formed aluminium alloy unlipped channels under interior-two flange loading. J. Build. Eng. 2022, 51, 104261. [Google Scholar] [CrossRef]

- Dai, Y.; Roy, K.; Fang, Z.; Chen, B.; Raftery, G.M.; Lim, J.B. A novel machine learning model to predict the moment capacity of cold-formed steel channel beams with edge-stiffened and un-stiffened web holes. J. Build. Eng. 2022, 53, 104592. [Google Scholar] [CrossRef]

- Fang, Z.; Roy, K.; Chen, B.; Sham, C.-W.; Hajirasouliha, I.; Lim, J.B. Deep learning-based procedure for structural design of cold-formed steel channel sections with edge-stiffened and un-stiffened holes under axial compression. Thin-Walled Struct. 2021, 166, 108076. [Google Scholar] [CrossRef]

- Fang, Z.; Roy, K.; Chi, Y.; Chen, B.; Lim, J.B. Finite element analysis and proposed design rules for cold-formed stainless steel channels with web holes under end-one-flange loading. Structures 2021, 34, 2876–2899. [Google Scholar] [CrossRef]

- Fang, Z.; Roy, K.; Liang, H.; Poologanathan, K.; Ghosh, K.; Mohamed, A.M.; Lim, J.B.P. Numerical Simulation and Design Recommendations for Web Crippling Strength of Cold-Formed Steel Channels with Web Holes under Interior-One-Flange Loading at Elevated Temperatures. Buildings 2021, 11, 666. [Google Scholar] [CrossRef]

- Fang, Z.; Roy, K.; Uzzaman, A.; Lim, J.B. Numerical simulation and proposed design rules of cold-formed stainless steel channels with web holes under interior-one-flange loading. Eng. Struct. 2021, 252, 113566. [Google Scholar] [CrossRef]

- Dani, A.A.; Roy, K.; Masood, R.; Fang, Z.; Lim, J.B.P. A Comparative Study on the Life Cycle Assessment of New Zealand Residential Buildings. Buildings 2022, 12, 50. [Google Scholar] [CrossRef]

- Liang, H.; Roy, K.; Fang, Z.; Lim, J.B.P. A Critical Review on Optimization of Cold-Formed Steel Members for Better Structural and Thermal Performances. Buildings 2022, 12, 34. [Google Scholar] [CrossRef]

- Hoffmann, C.; van Hoey, M.; Zeumer, B. Decarbonization Challenge for Steel; McKinsey & Company: New York, NY, USA, 2020; Available online: https://www.mckinsey.com/~/media/McKinsey/Industries/Metals%20and%20Mining/Our%20Insights/Decarbonization%20challenge%20for%20steel/Decarbonization-challenge-for-steel.pdf (accessed on 27 February 2022).

- Swalec, C.; Shearer, C. Pedal to the Metal 2021: No Time to Delay Decarbonizing the Global Steel Sector; Global Energy Monitor: San Francisco, CA, USA, 2021; p. 36. Available online: https://globalenergymonitor.org/wp-content/uploads/2021/06/Pedal-to-the-Metal.pdf (accessed on 27 February 2022).

- Bhatnagar, S. Five Actions to Improve the Sustainability of Steel. 2021. Available online: https://www.ey.com/en_jo/mining-metals/five-actions-to-improve-the-sustainability-of-steel (accessed on 28 February 2022).

- International Energy Agency. Net Zero by 2050—A Roadmap for the Global Energy Sector; International Energy Agency: Paris, France, 2021; p. 224. Available online: https://iea.blob.core.windows.net/assets/deebef5d-0c34-4539-9d0c-10b13d840027/NetZeroby2050-ARoadmapfortheGlobalEnergySector_CORR.pdf (accessed on 28 February 2022).

- Grande, E.; Imbimbo, M.; Tomei, V. Structural Optimization of Grid Shells: Design Parameters and Combined Strategies. J. Arch. Eng. 2018, 24, 04017027. [Google Scholar] [CrossRef]

- Grande, E.; Imbimbo, M.; Tomei, V. Optimization Strategies for Grid Shells: The Role of Joints. J. Arch. Eng. 2020, 26, 04019028. [Google Scholar] [CrossRef]

- Rombouts, J.; Lombaert, G.; de Laet, L.; Schevenels, M. A novel shape optimization approach for strained gridshells: Design and construction of a simply supported gridshell. Eng. Struct. 2019, 192, 166–180. [Google Scholar] [CrossRef]

- Richardson, J.N.; Adriaenssens, S.; Coelho, R.F.; Bouillard, P. Coupled form-finding and grid optimization approach for single layer grid shells. Eng. Struct. 2013, 52, 230–239. [Google Scholar] [CrossRef]

- Ortiz-Rodríguez, O.; Castells, F.; Sonnemann, G. Life cycle assessment of two dwellings: One in Spain, a developed country, and one in Colombia, a country under development. Sci. Total Environ. 2010, 408, 2435–2443. [Google Scholar] [CrossRef]

- Rebitzer, G.; Ekvall, T.; Frischknecht, R.; Hunkeler, D.; Norris, G.; Rydberg, T.; Schmidt, W.-P.; Suh, S.; Weidema, B.P.; Pennington, D.W. Life cycle assessment: Part 1: Framework, goal and scope definition, inventory analysis, and applications. Environ. Int. 2004, 30, 701–720. [Google Scholar] [CrossRef]

- Olsen, S.I.; Christensen, F.M.; Hauschild, H.; Pedersen, F.; Larsen, H.F.; Torslov, J. Life cycle impact assessment and risk assessment of chemicals in a methodological comparison. Environ. Impact Assess. Rev. 2001, 21, 385–404. [Google Scholar] [CrossRef]

- Vilches, A.; Martinez, A.; Montanes, B. Life cycle assessment (LCA) of building refurbishment: A literature review. Energy Build. 2017, 135, 286–301. [Google Scholar] [CrossRef]

- Johnston, R.P.; McGrath, T.; Nanukuttan, S.; Lim, J.B.; Soutsos, M.; Chiang, M.C.; Masood, R.; Rahman, M.A. Sustainability of Cold-formed Steel Portal Frames in Developing Countries in the Context of Life Cycle Assessment and Life Cycle Costs. Structures 2018, 13, 79–87. [Google Scholar] [CrossRef]

- Emami, N.; Heinonen, J.; Marteinsson, B.; Säynäjoki, A.; Junnonen, J.-M.; Laine, J.; Junnila, S. A Life Cycle Assessment of Two Residential Buildings Using Two Different LCA Database-Software Combinations: Recognizing Uniformities and Inconsistencies. Buildings 2019, 9, 20. [Google Scholar] [CrossRef]

- SimaPro. What is an Input-Output Database for LCA? SimaPro: Amersfoort, The Netherlands, 2017; Available online: https://simapro.com/2017/what-is-an-input-output-io-database/ (accessed on 27 February 2022).

- Säynäjoki, A.; Heinonen, J.; Junnila, S.; Horvath, A. Can life-cycle assessment produce reliable policy guidelines in the building sector? Environ. Res. Lett. 2017, 12, 013001. [Google Scholar] [CrossRef]

- ISO Standard, No. 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva Switzerland, 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 27 February 2022).

- Rangelov, M.; Dylla, H.; Mukherjee, A.; Sivaneswaran, N. Use of environmental product declarations (EPDs) of pavement materials in the United States of America (U.S.A.) to ensure environmental impact reductions. J. Clean. Prod. 2021, 283, 124619. [Google Scholar] [CrossRef]

- Pagnon, F.; Mathern, A.; Ek, K. A Review of Online Sources of Open-Access Life Cycle Assessment Data for the Construction Sector. In IOP Conference Series Earth and Environmental Science; IOP Publishing: Bristol, UK, 2020; Volume 588, p. 042051. [Google Scholar] [CrossRef]

- Sphera. GaBi ts, Version 9.1.0.53; Computer Software; Sphera: Berlin, Germany, 2020. Available online: https://gabi.sphera.com/software/gabi-universities/gabi-education-free/(accessed on 25 February 2022).

- PRé Sustainability. SimaPro, Version 9.1.1; Computer Software; PRé Sustainability: Amersfoort, The Netherlands, 2020. Available online: https://simapro.com/licences/#/education(accessed on 25 February 2022).

- GreenDelta. OpenLCA, Version 1.11.0; Computer Software; GreenDelta: Berlin, Germany, 2022. Available online: https://www.openlca.org/download/(accessed on 25 February 2022).

- BRANZ. LCAQuick, Version 3.4.3; Computer Software; BRANZ: Judgeford, New Zealand, 2020. Available online: https://www.branz.co.nz/environment-zero-carbon-research/framework/lcaquick/(accessed on 25 February 2022).

- WorldSteel Association. Life Cycle Assessment: Environmental Assessment of Roofing Systems; WorldSteel Association: Brussels, Belgium, 2020; p. 47. Available online: https://worldsteel.org/wp-content/uploads/Life-cycle-assessment-Environmental-assessment-of-roofing-systems.pdf (accessed on 17 February 2022).

- Herrmann, I.T.; Moltesen, A. Does it matter which Life Cycle Assessment (LCA) tool you choose?—A comparative assessment of SimaPro and GaBi. J. Clean. Prod. 2015, 86, 163–169. [Google Scholar] [CrossRef]

- Colorsteel. Environmental Product Declaration; EPD Australasia: Nelson, New Zealand, 2018; p. 20. Available online: https://epd-australasia.com/wp-content/uploads/2018/11/NZS0028-EPD-document-COLORSTEEL.pdf (accessed on 18 January 2022).

- Colorsteel. Environmental Product Declaration: Addendum—Rollforming Data; Colorsteel: Glenbrook, New Zealand, 2018; p. 8. Available online: https://www.colorsteel.co.nz/assets/Brochures/COLORSTEEL_EDP_Document_Supplement_2019_Nocrops.pdf (accessed on 18 January 2022).

- Colorcote. Environmental Product Declaration; Colorcote: Auckland, New Zealand, 2019; p. 15. Available online: https://www.colorcote.co.nz/wp-content/uploads/2019/04/Colorcote-EPD-Document.pdf (accessed on 18 January 2022).

- Bare, J.C.; Hofstetter, P.; Pennington, D.W.; de Haes, H.A.U. Midpoints versus endpoints: The sacrifices and benefits. Int. J. Life Cycle Assess. 2000, 5, 319. [Google Scholar] [CrossRef]

- Sartori, T.; Drogemuller, R.; Omrani, S.; Lamari, F. A schematic framework for Life Cycle Assessment (LCA) and Green Building Rating System (GBRS). J. Build. Eng. 2021, 38, 102180. [Google Scholar] [CrossRef]

- New Zealand Steel. The Ironmaking Process|New Zealand Steel. 2015. Available online: https://www.nzsteel.co.nz/.https://www.nzsteel.co.nz/new-zealand-steel/the-story-of-steel/the-science-of-steel/the-ironmaking-process/ (accessed on 21 February 2022).

- Zampori, L.; Saouter, E.; Schau, E.; Cristobal Garcia, J.; Castellani, V.; Sala, S. Guide for Interpreting Life Cycle Assessment Result; EUR 28266 EN; Publications Office of the European Union: Luxembourg, 2016. [Google Scholar]

- Love, S. Steel Product Carbon Offset Programme; Thinkstep ANZ: Wellington, New Zealand, 2020; p. 47. Available online: https://www.hera.org.nz/wp-content/uploads/Steel-Sector-Carbon-Offset-Programme-Instructions-v4-28-10-2020.pdf (accessed on 22 May 2022).

- Le, A.B.D.; Whyte, A.; Biswas, W.K. Carbon footprint and embodied energy assessment of roof-covering materials. Clean Technol. Environ. Policy 2019, 21, 1913–1923. [Google Scholar] [CrossRef]

- Ministry for the Environment. New Zealand’s Greenhouse Gas Inventory 1990–2019; Ministry for the Environment: Wellington, New Zealand, 2021. Available online: https://environment.govt.nz/assets/Publications/New-Zealands-Greenhouse-Gas-Inventory-1990-2019Volume-1-Chapters-1-15.pdf (accessed on 20 May 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).