Combustion and Emission Characteristics of a Diesel Engine Fueled with Crude Palm Oil Blends at Various Idling Speeds

Abstract

:1. Introduction

2. Materials and Methods

2.1. Test Fuels

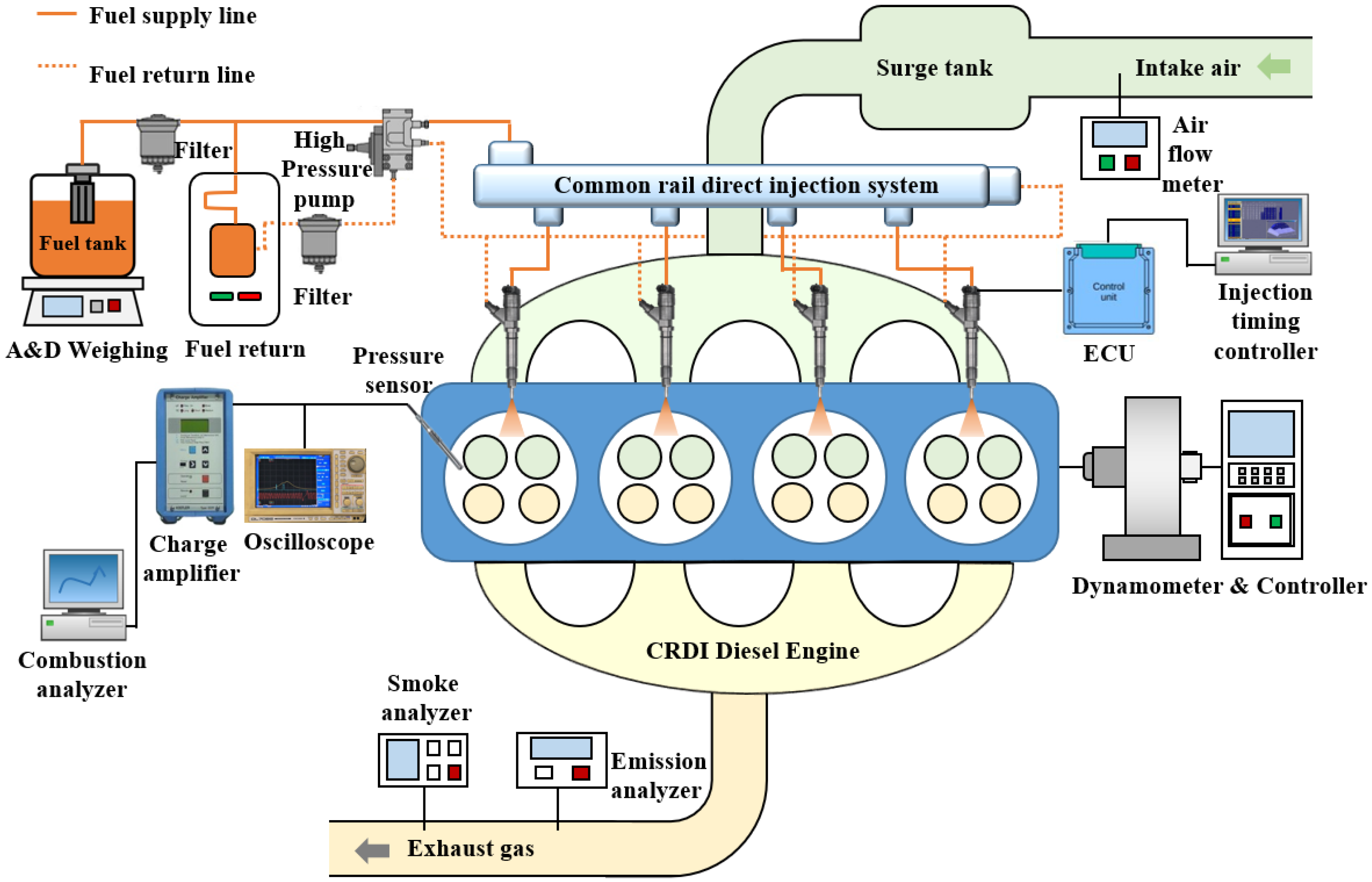

2.2. Engine Test

3. Results and Discussion

3.1. Combustion Characteristics

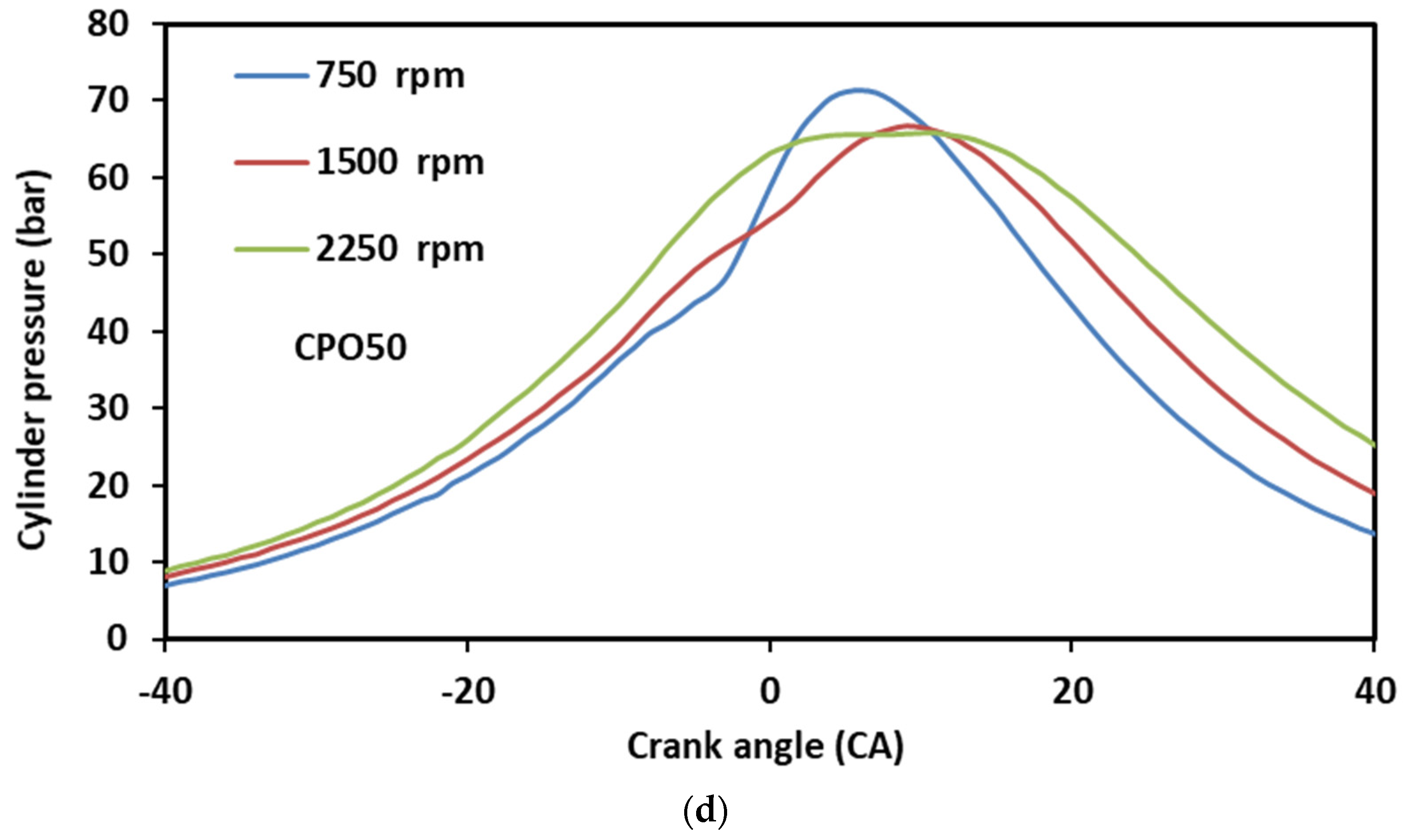

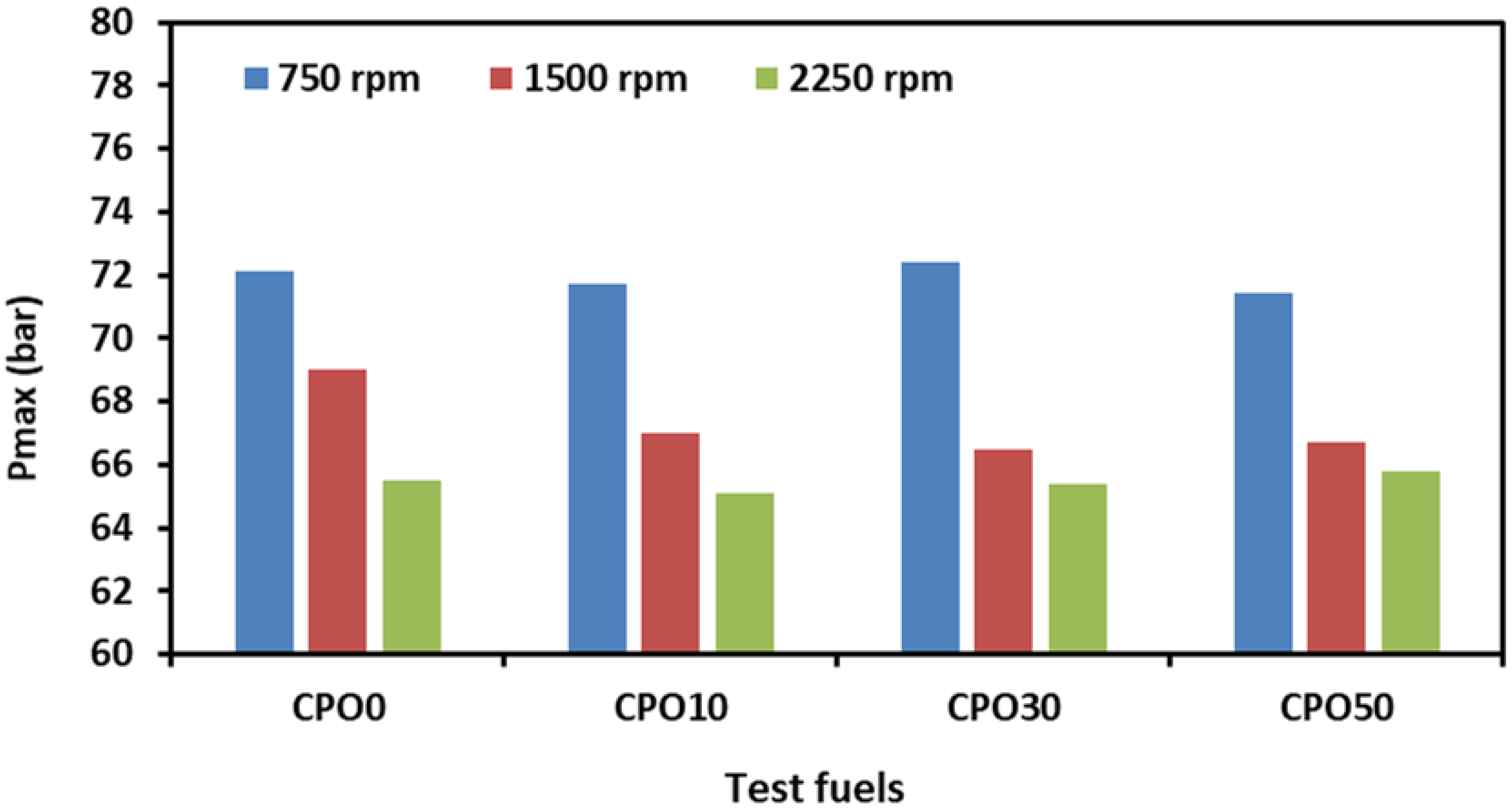

3.1.1. In-Cylinder Pressure

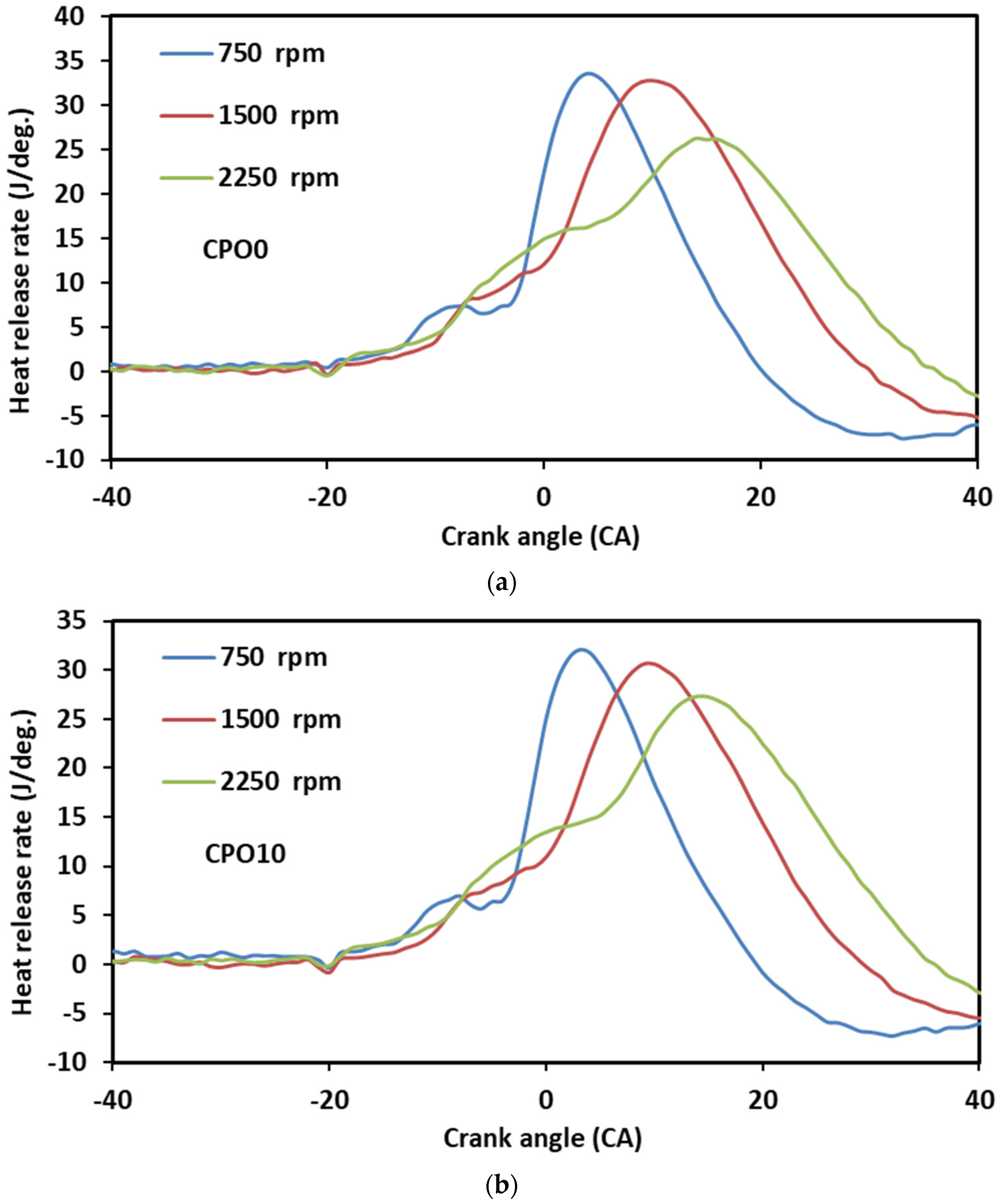

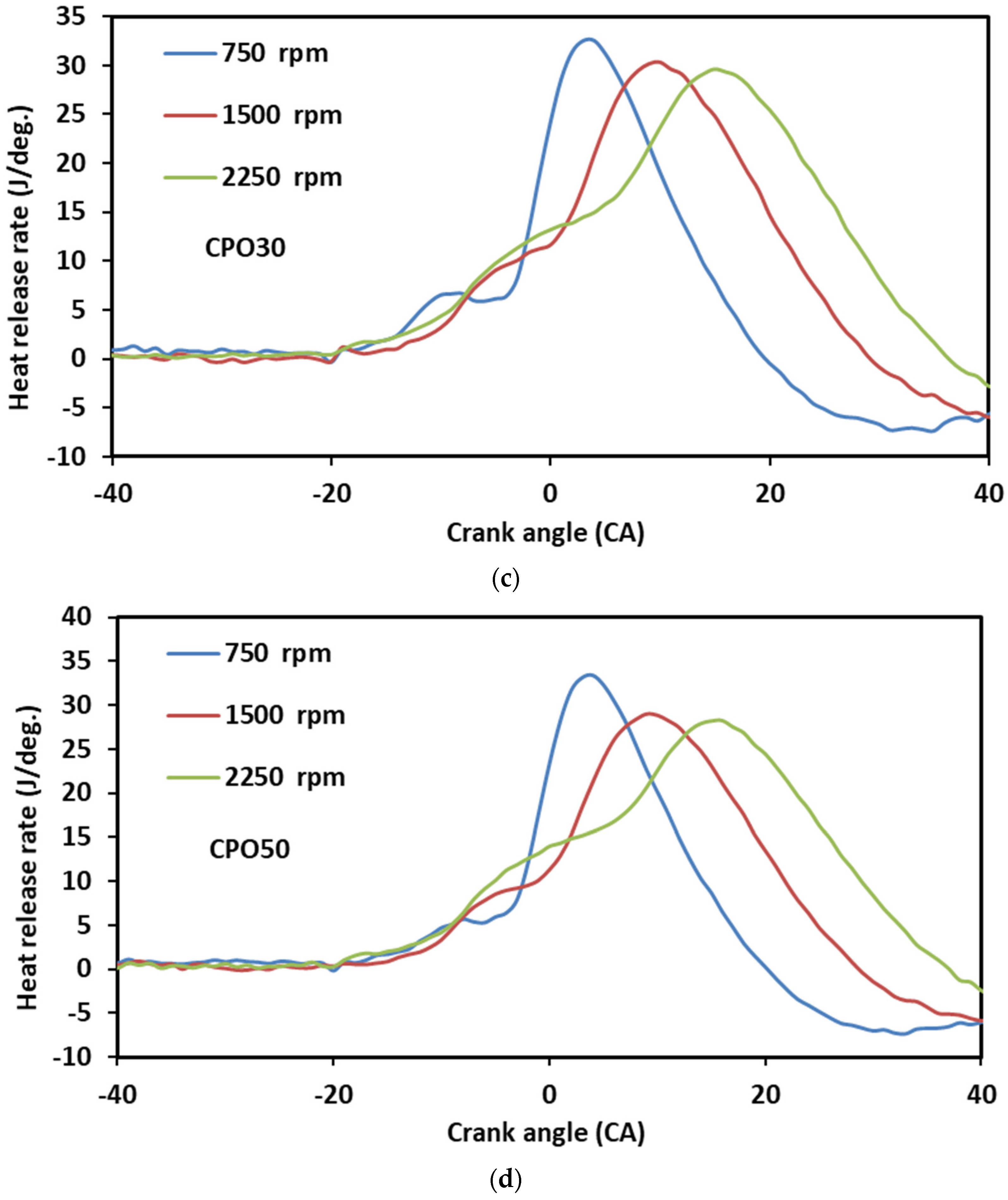

3.1.2. Heat Release Rate

3.2. Engine Performance

3.2.1. Brake Specific Fuel Consumption

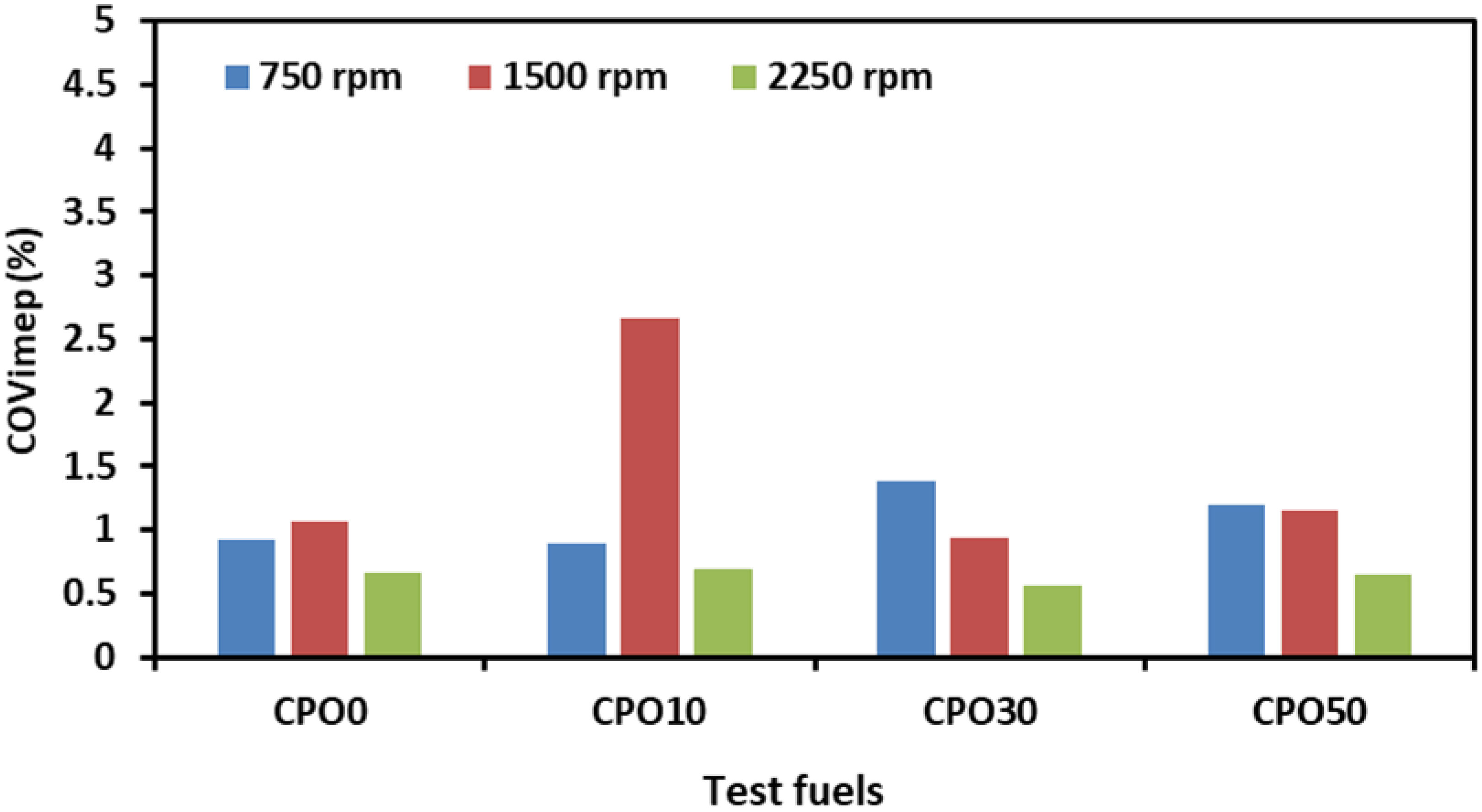

3.2.2. COVimep

3.3. Emission Characteristics

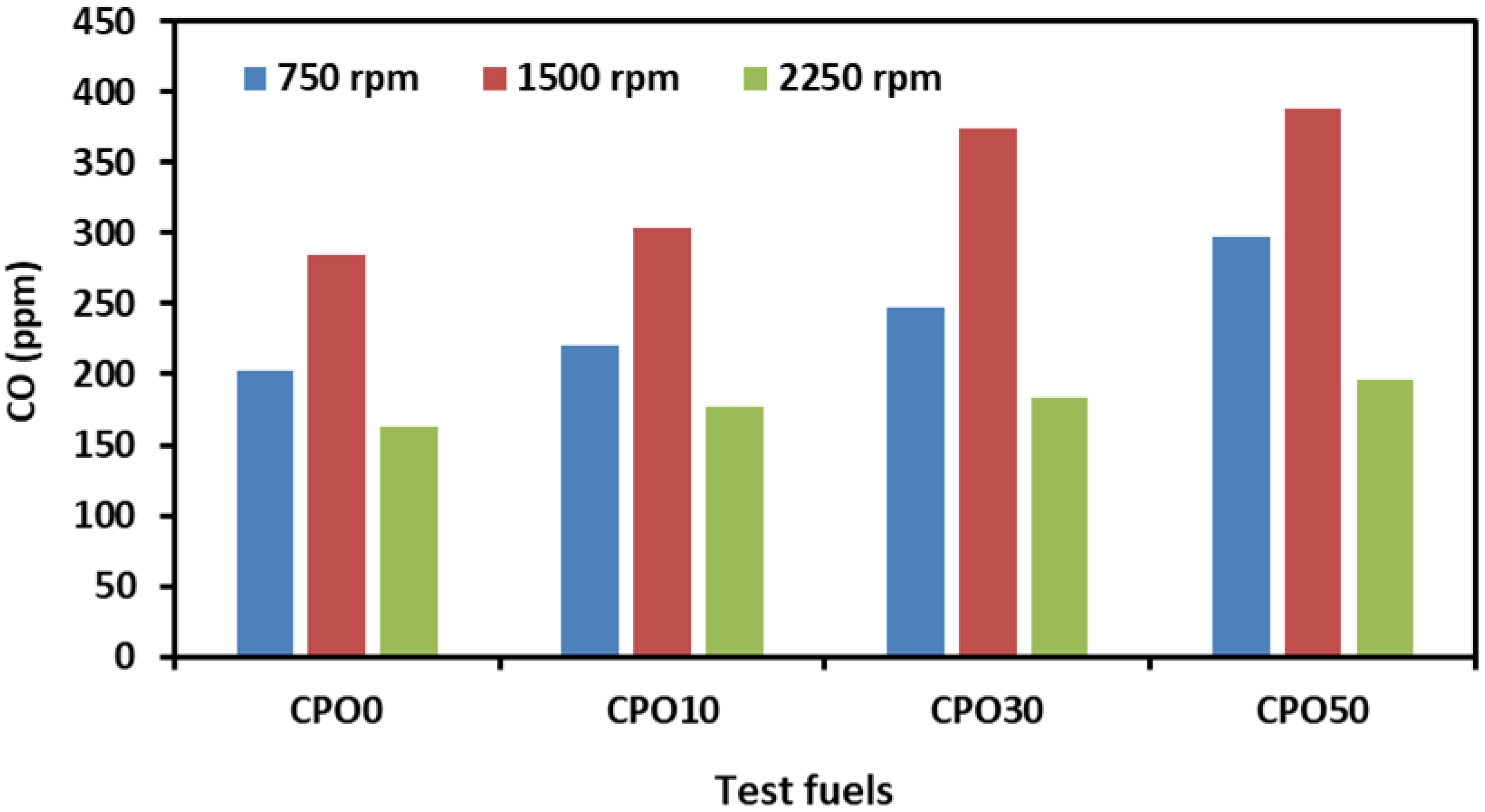

3.3.1. CO Emissions

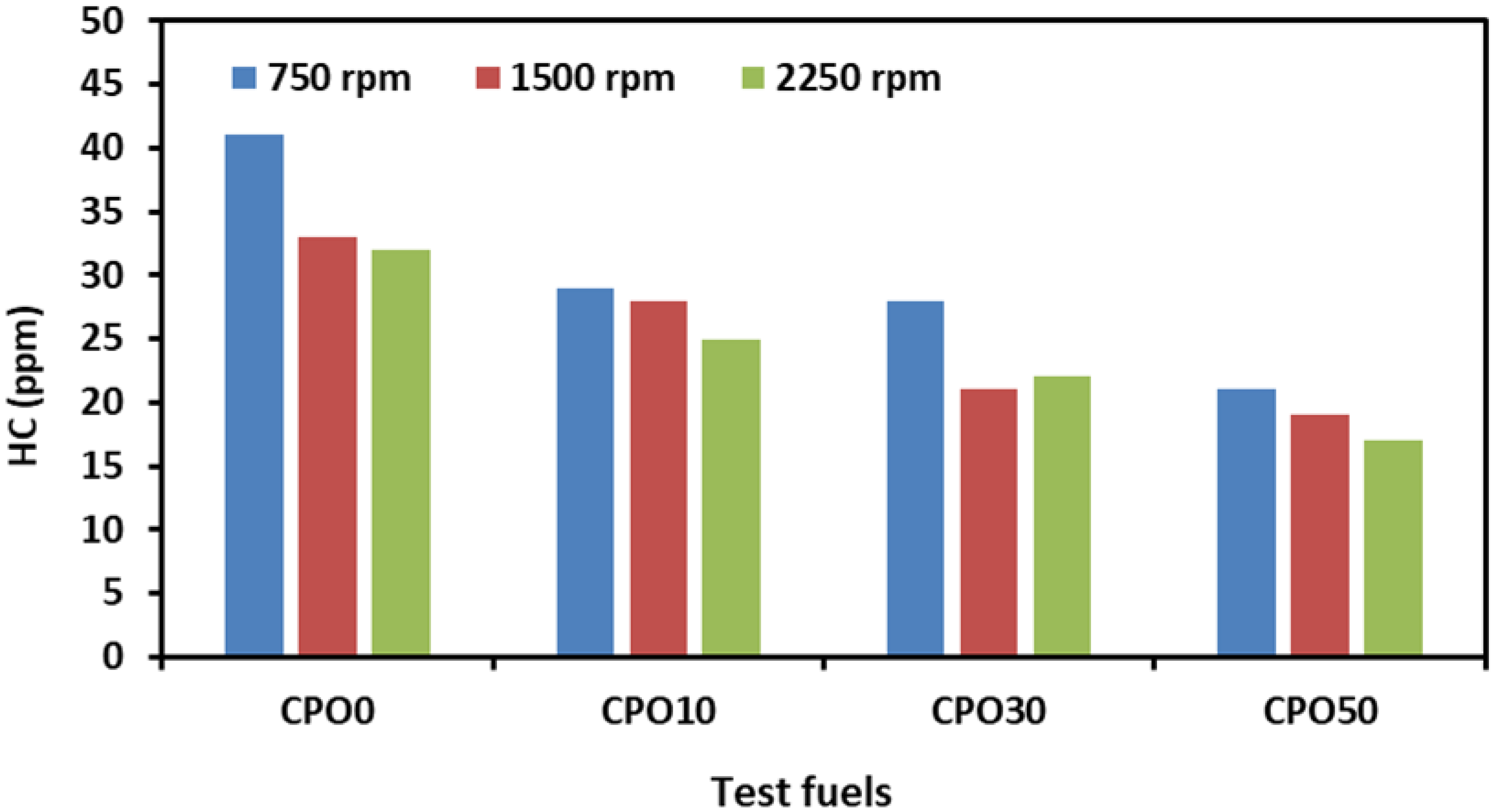

3.3.2. HC Emissions

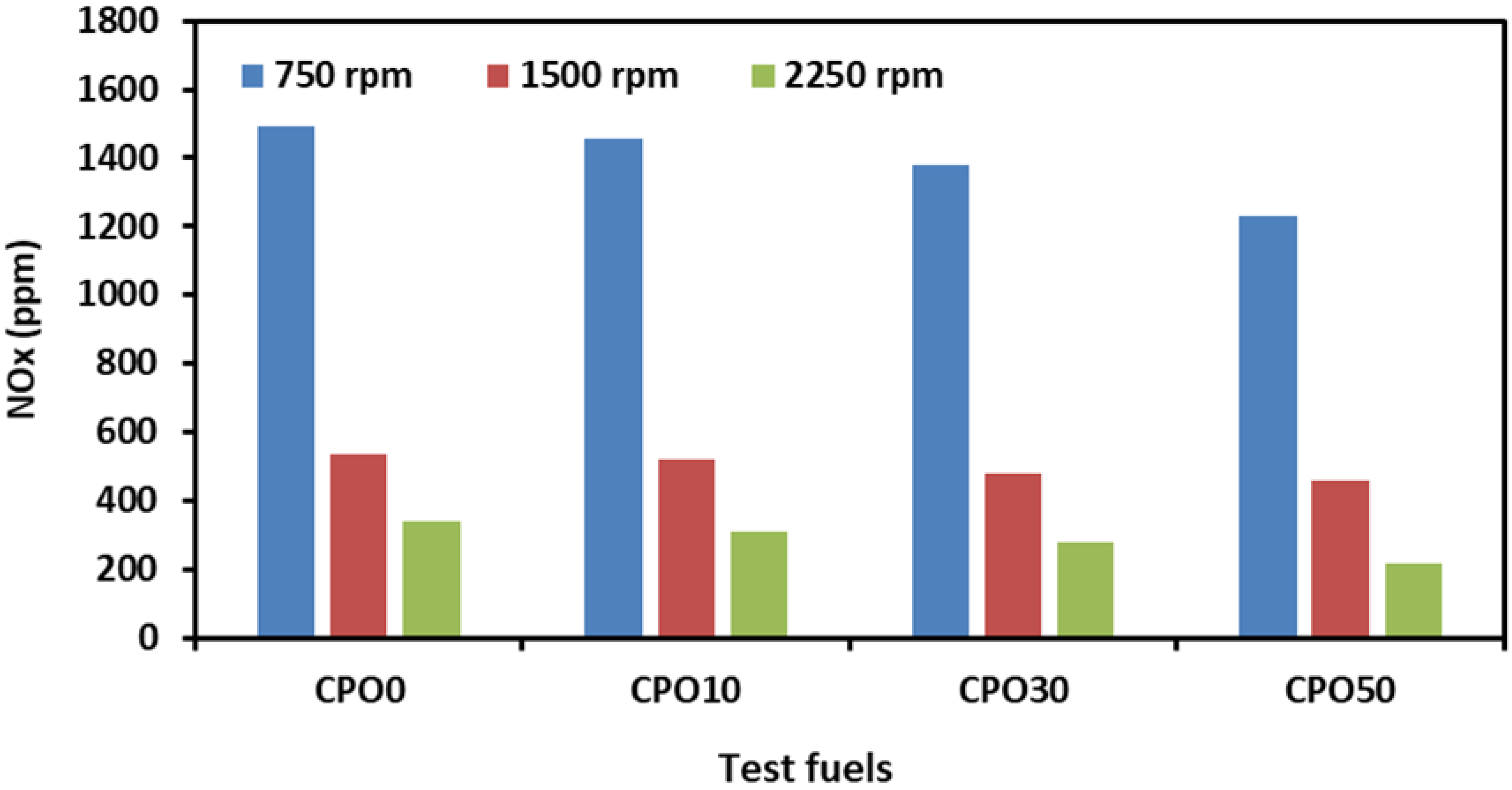

3.3.3. NOx Emissions

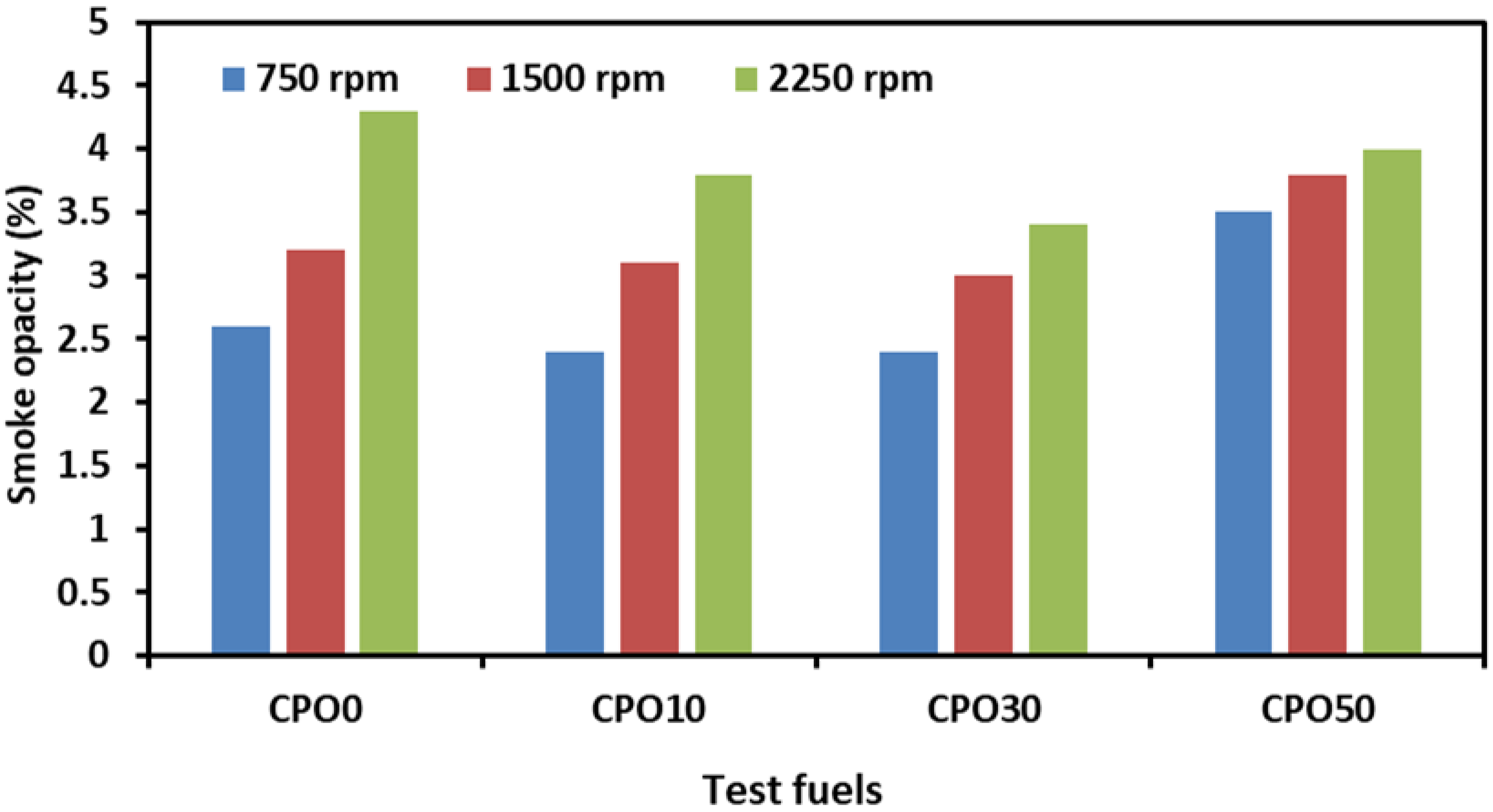

3.3.4. Smoke Emissions

4. Conclusions

- For the combustion characteristics, it is found that the increase in engine speed causes a reduction in the peak in-cylinder pressure and the peak heat release rate. Adding CPO to diesel fuel resulted in a decrease in peak in-cylinder pressure and the peak heat release rate for all test fuels at 750 rpm and 1500 rpm.

- For engine performance, the brake-specific fuel consumption (BSFC) of all tested fuels at 1500 rpm is the lowest, compared with that at 750 rpm and 2250 rpm. In addition, the BSFC of all blended fuels is higher than that of diesel at all idling speeds. The coefficient of variation of the indicated mean effective pressure (COVimep) of all tested fuels is the lowest at 2250 rpm, compared with that at 750 rpm and 1500 rpm. Moreover, the COVimep of all tested fuels at all idling speeds is much lower than 10%, which indicates that this diesel engine does not have the problem of unstable operation even if running with the CPO blended fuel with a mixing ratio of up to 50%.

- For the emission characteristics, the carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx) of all tested fuels at 2250 rpm is the lowest compared with that at 750 rpm and 1500 rpm. The addition of CPO to diesel fuel leads to an increase in CO emission, but it is beneficial to the reduction of HC and NOx emissions. In addition, the smoke emission increases with the increase of engine speed. And adding an appropriate proportion of CPO, such as 10% and 30%, is beneficial to reducing the smoke emission.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Suh, H.K.; Lee, C.S. A review on atomization and exhaust emissions of a biodiesel-fueled compression ignition engine. Renew. Sustain. Energy Rev. 2016, 58, 1601–1620. [Google Scholar] [CrossRef]

- Alptekin, E. Emission, injection and combustion characteristics of biodiesel and oxygenated fuel blends in a common rail diesel engine. Energy 2017, 119, 44–52. [Google Scholar] [CrossRef]

- Buyukkaya, E. Effects of biodiesel on a DI diesel engine performance, emission and combustion characteristics. Fuel 2010, 89, 3099–3105. [Google Scholar] [CrossRef]

- Lapuerta, M.; Armas, O.; Rodriguez-Fernandez, J. Effect of biodiesel fuels on diesel engine emissions. Prog. Energy Combust. Sci. 2008, 34, 198–223. [Google Scholar] [CrossRef]

- Ferrão, M.F.; Viera, M.d.S.; Pazos, R.E.P.; Fachini, D.; Gerbase, A.E.; Marder, L. Simultaneous determination of quality parameters of biodiesel/diesel blends using HATR-FTIR spectra and PLS, iPLS or siPLS regressions. Fuel 2011, 90, 701–706. [Google Scholar] [CrossRef]

- Rojas, N.Y.; Milquez, H.A.; Sarmiento, H. Characterizing priority polycyclic aromatic hydrocarbons (PAH) in particulate matter from diesel and palm oil-based biodiesel B15 combustion. Atmos. Environ. 2011, 45, 6158–6162. [Google Scholar] [CrossRef]

- Dasari, S.R.; Goud, V.V. Simultaneous extraction and transesterification of castor seeds for biodiesel production: Assessment of biodegradability. Process Saf. Environ. Prot. 2017, 107, 373–387. [Google Scholar] [CrossRef]

- Atadashi, I.M.; Aroua, M.K.; Aziz, A.A. High quality biodiesel and its diesel engine application: A review. Renew. Sustain. Energy Rev. 2010, 14, 1999–2008. [Google Scholar] [CrossRef]

- Uyumaz, A. Combustion, performance and emission characteristics of a DI diesel engine fueled with mustard oil biodiesel fuel blends at different engine loads. Fuel 2018, 212, 256–267. [Google Scholar] [CrossRef]

- Gonca, G.; Dobrucali, E. Theoretical and experimental study on the performance of a diesel engine fueled with diesel–biodiesel blends. Renew. Energy 2016, 93, 658–666. [Google Scholar] [CrossRef]

- Uyumaz, A.; Aydoğan, B.; Yılmaz, E.; Solmaz, H.; Aksoy, F.; Mutlu, İ.; İpci, D.; Calam, A. Experimental investigation on the combustion, performance and exhaust emission characteristics of poppy oil biodiesel-diesel dual fuel combustion in a CI engine. Fuel 2020, 280, 118588. [Google Scholar] [CrossRef]

- Gharehghani, A.; Mirsalim, M.; Hosseini, R. Effects of waste fish oil biodiesel on diesel engine combustion characteristics and emission. Renew. Energy 2017, 101, 930–936. [Google Scholar] [CrossRef]

- Nalgundwar, A.; Paul, B.; Sharma, S.K. Comparison of performance and emissions characteristics of DI CI engine fueled with dual biodiesel blends of palm and jatropha. Fuel 2016, 173, 172–179. [Google Scholar] [CrossRef]

- Gebremariam, S.N.; Marchetti, J.M. Economics of biodiesel production: Review. Energy Convers. Manag. 2018, 168, 74–84. [Google Scholar] [CrossRef]

- Senthur Prabu, S.; Asokan, M.A.; Prathiba, S.; Ahmed, S.; Puthean, G. Effect of additives on performance, combustion and emission behavior of preheated palm oil/diesel blends in DI diesel engine. Renew. Energy 2018, 122, 196–205. [Google Scholar] [CrossRef]

- Capuano, D.; Costa, M.; Di Fraia, S.; Massarotti, N.; Vanoli, L. Direct use of waste vegetable oil in internal combustion engines. Renew. Sustain. Energy Rev. 2017, 69, 759–770. [Google Scholar] [CrossRef]

- Roy, M.M.; Wang, W.; Bujold, J. Biodiesel production and comparison of emissions of a DI diesel engine fueled by biodiesel–diesel and canola oil–diesel blends at high idling operations. Appl. Energy 2013, 106, 198–208. [Google Scholar] [CrossRef]

- Rahman, S.A.; Masjuki, H.; Kalam, M.; Abedin, M.; Sanjid, A.; Imtenan, S. Effect of idling on fuel consumption and emissions of a diesel engine fueled by Jatropha biodiesel blends. J. Clean. Prod. 2014, 69, 208–215. [Google Scholar] [CrossRef]

- Rahman, S.M.A.; Masjuki, H.H.; Kalam, M.A.; Abedin, M.J.; Sanjid, A.; Sajjad, H. Production of palm and Calophyllum inophyllum based biodiesel and investigation of blend performance and exhaust emission in an unmodified diesel engine at high idling conditions. Energy Convers. Manag. 2013, 76, 362–367. [Google Scholar] [CrossRef]

- Grupp, D.; Forrest, M.; Mader, P.; Brodrick, C.-J.; Miller, M.; Dwyer, H. Development of a retrofit fuel cell auxiliary power unit for truck idle reduction. SAE Trans. 2004, 113, 237–247. [Google Scholar]

- El-Kasaby, M.; Nemit-allah, M.A. Experimental investigations of ignition delay period and performance of a diesel engine operated with Jatropha oil biodiesel. Alex. Eng. J. 2013, 52, 141–149. [Google Scholar] [CrossRef] [Green Version]

- Kim, M.; Oh, J.; Lee, C. Study on combustion and emission characteristics of marine diesel oil and water-in-oil emulsified marine diesel oil. Energies 2018, 11, 1830. [Google Scholar] [CrossRef] [Green Version]

- Tesfa, B.; Mishra, R.; Gu, F.; Ball, A.D. Water injection effects on the performance and emission characteristics of a CI engine operating with biodiesel. Renew. Energy 2012, 37, 333–344. [Google Scholar] [CrossRef] [Green Version]

- An, H.; Yang, W.M.; Maghbouli, A.; Li, J.; Chou, S.K.; Chua, K.J. Performance, combustion and emission characteristics of biodiesel derived from waste cooking oils. Appl. Energy 2013, 112, 493–499. [Google Scholar] [CrossRef]

- Dhar, A.; Agarwal, A.K. Performance, emissions and combustion characteristics of Karanja biodiesel in a transportation engine. Fuel 2014, 119, 70–80. [Google Scholar] [CrossRef]

- Sharma, A.; Murugan, S. Effect of nozzle opening pressure on the behaviour of a diesel engine running with non-petroleum fuel. Energy 2017, 127, 236–246. [Google Scholar] [CrossRef]

- Sanli, H. An experimental investigation on the usage of waste frying oil-diesel fuel blends with low viscosity in a Common Rail DI-diesel engine. Fuel 2018, 222, 434–443. [Google Scholar] [CrossRef]

- Behçet, R. Performance and emission study of waste anchovy fish biodiesel in a diesel engine. Fuel Process. Technol. 2011, 92, 1187–1194. [Google Scholar] [CrossRef]

- Che Mat, S.; Idroas, M.Y.; Hamid, M.F.; Zainal, Z.A. Performance and emissions of straight vegetable oils and its blends as a fuel in diesel engine: A review. Renew. Sustain. Energy Rev. 2018, 82, 808–823. [Google Scholar] [CrossRef]

- Ghadikolaei, M.A.; Cheung, C.S.; Yung, K.-F. Study of combustion, performance and emissions of diesel engine fueled with diesel/biodiesel/alcohol blends having the same oxygen concentration. Energy 2018, 157, 258–269. [Google Scholar] [CrossRef]

- Ge, J.C.; Kim, H.Y.; Yoon, S.K.; Choi, N.J. Optimization of palm oil biodiesel blends and engine operating parameters to improve performance and PM morphology in a common rail direct injection diesel engine. Fuel 2020, 260, 116326. [Google Scholar] [CrossRef]

- Ge, J.C.; Wu, G.; Choi, N.J. Comparative study of pilot–main injection timings and diesel/ethanol binary blends on combustion, emission and microstructure of particles emitted from diesel engines. Fuel 2022, 313, 122658. [Google Scholar] [CrossRef]

- Ozsezen, A.N.; Canakci, M. Determination of performance and combustion characteristics of a diesel engine fueled with canola and waste palm oil methyl esters. Energy Convers. Manag. 2011, 52, 108–116. [Google Scholar] [CrossRef]

- Ghadikolaei, M.A.; Cheung, C.S.; Yung, K.-F. Comparison between blended mode and fumigation mode on combustion, performance and emissions of a diesel engine fueled with ternary fuel (diesel-biodiesel-ethanol) based on engine speed. J. Energy Inst. 2019, 92, 1233–1250. [Google Scholar] [CrossRef]

- Rahman, S.M.A.; Masjuki, H.H.; Kalam, M.A.; Abedin, M.J.; Sanjid, A.; Rahman, M.M. Assessing idling effects on a compression ignition engine fueled with Jatropha and Palm biodiesel blends. Renew. Energy 2014, 68, 644–650. [Google Scholar] [CrossRef]

- Ge, J.C.; Kim, H.Y.; Yoon, S.K.; Choi, N.J. Reducing volatile organic compound emissions from diesel engines using canola oil biodiesel fuel and blends. Fuel 2018, 218, 266–274. [Google Scholar] [CrossRef]

- Calder, J.; Roy, M.M.; Wang, W. Performance and emissions of a diesel engine fueled by biodiesel-diesel blends with recycled expanded polystyrene and fuel stabilizing additive. Energy 2018, 149, 204–212. [Google Scholar] [CrossRef]

| Properties (Units) | Diesel Fuel | Crude Palm Oil |

|---|---|---|

| Density (kg/m3 at 15 °C) | 836.8 | 903.8 |

| Viscosity (mm2/s at 40 °C) | 2.719 | 42.21 |

| Calorific value (MJ/kg) | 43.96 | 39.34 |

| Cetane index | 55.8 | 49 |

| Flash point (°C) | 55 | 260 |

| Oxygen content (%) | 0 | 11.4 |

| Engine Parameter | Units | Specifications |

|---|---|---|

| Type | - | turbocharged CRDI diesel engine |

| Number of cylinders | - | 4 |

| Bore × stroke | mm | 83 × 92 |

| Injector hole diameter | mm | 0.17 |

| Compression ratio | - | 17.7:1 |

| Max. power | kW/rpm | 82/4000 |

| Parameter | Accuracy |

|---|---|

| CO (ppm) | ±0.62% |

| NOx (ppm) | ±0.25% |

| HC (ppm) | ±5% |

| Smoke opacity (%) | ±1% |

| Load monitoring (Nm) | ±0.2% |

| Speed measuring (rpm) | ±5 |

| Fuel consumption (g) | ±2 |

| Fuel injection pressure (bar) | ±1 |

| Intake air temperature (°C) | ±3 |

| Cooling water temperature (°C) | ±3 |

| Item | Conditions |

|---|---|

| Test fuels | CPO0, CPO10, CPO30, CPO50 |

| Engine load | 30 Nm |

| Engine speed | 750, 1500, 2250 rpm |

| Fuel injection pressure | 45 MPa |

| Pilot injection timing | 22° BTDC |

| Main injection timing | 7° BTDC |

| Intake air temperature | 25 ± 3 °C |

| Cooling water temperature | 85 ± 3 °C |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ge, J.C.; Yoon, S.K.; Song, J.H. Combustion and Emission Characteristics of a Diesel Engine Fueled with Crude Palm Oil Blends at Various Idling Speeds. Appl. Sci. 2022, 12, 6294. https://doi.org/10.3390/app12136294

Ge JC, Yoon SK, Song JH. Combustion and Emission Characteristics of a Diesel Engine Fueled with Crude Palm Oil Blends at Various Idling Speeds. Applied Sciences. 2022; 12(13):6294. https://doi.org/10.3390/app12136294

Chicago/Turabian StyleGe, Jun Cong, Sam Ki Yoon, and Jun Hee Song. 2022. "Combustion and Emission Characteristics of a Diesel Engine Fueled with Crude Palm Oil Blends at Various Idling Speeds" Applied Sciences 12, no. 13: 6294. https://doi.org/10.3390/app12136294

APA StyleGe, J. C., Yoon, S. K., & Song, J. H. (2022). Combustion and Emission Characteristics of a Diesel Engine Fueled with Crude Palm Oil Blends at Various Idling Speeds. Applied Sciences, 12(13), 6294. https://doi.org/10.3390/app12136294