A Control Method for the Differential Steering of Tracked Vehicles Driven Independently by a Dual Hydraulic Motor

Abstract

:1. Introduction

2. Materials and Methods

2.1. Operating Principle and Modeling of the Dual-Sided Independent Drive System of a Tracked Vehicle

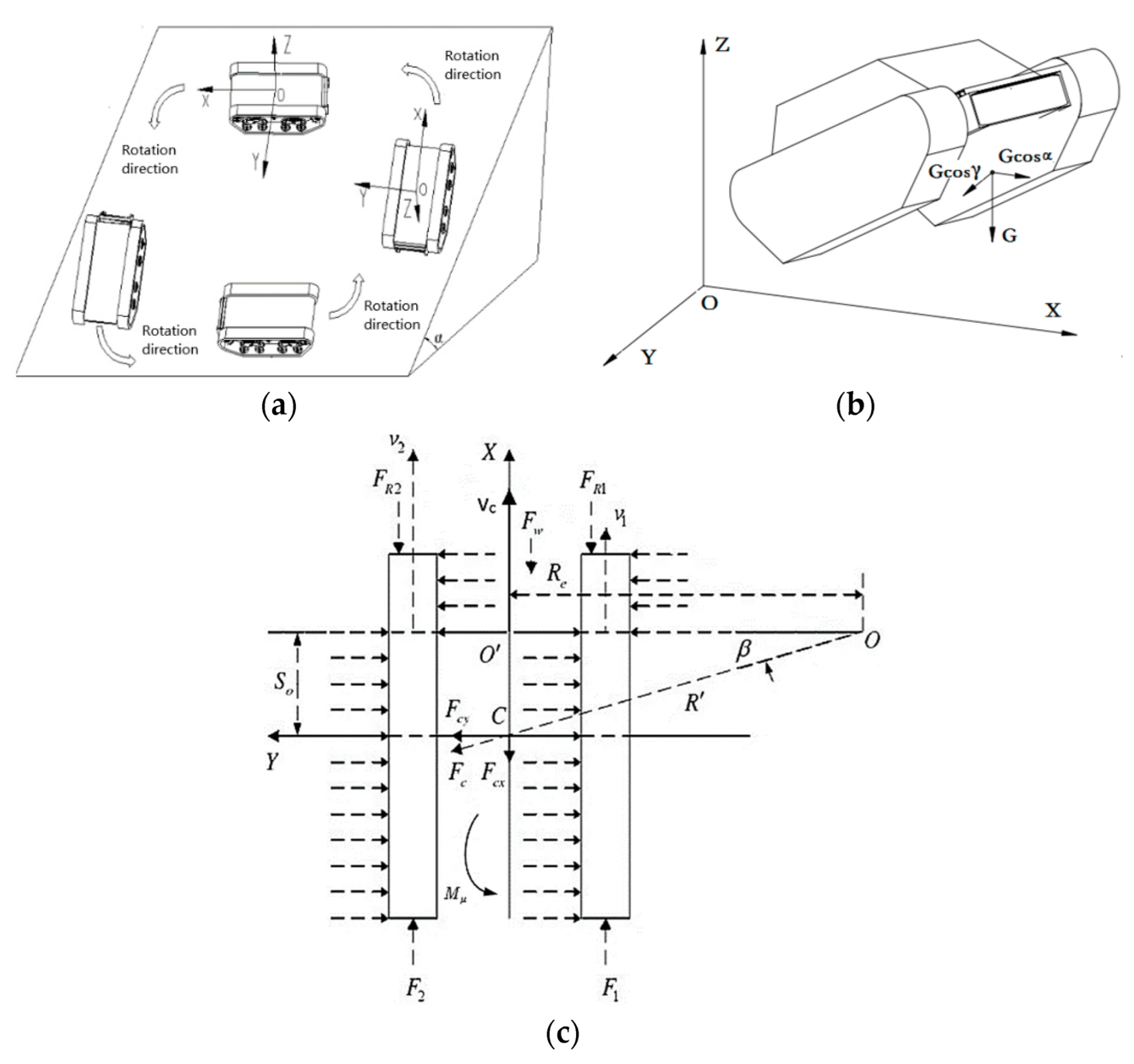

2.2. Differential Steering Model of a Tracked Vehicle

Kinematic Analysis of Differential Steering

2.3. Dynamics Analysis of Slope Steering

3. Modeling and Results Analysis

3.1. Analysis of the Control System

3.2. Simulation Model Building

4. Analysis of Control Strategy Based on Steering Stability

4.1. Analysis of Skid Conditions

4.2. Analysis of the Rollover Condition

4.3. Development of an Integrated Control Strategy Considering Steering Safety

5. Discussion

- (1)

- The simulation conditions are: the initial vehicle speed is 3 m/s, when t = 10 s, the steering angle speed input by the driver is 2.5 rad/s. If the angle sensor detects , According to Formula (19), the maximum steering angular speed corresponding to the vehicle speed of 3 m/s is 1.96 rad/s, which does not achieve the target steering angular speed of 2.5 rad/s. Therefore, to achieve the desired steering command, the vehicle speed needs to be adjusted automatically. Figure 9a shows the curve of the steering control signal, the inside and outside speed of the track, and the central vehicle speed under this condition. Figure 9b shows the pressure change curve of the hydraulic motors on both sides during steering.

- (2)

- The simulation conditions are: Initial speed is 2.8 m/s, when t = 10 s, the steering angle speed input by the driver is 2.2 rad/s. If the angle sensor detects for uphill driving steering, according to Formula (19), the maximum steering angular speed corresponding to the vehicle speed of 2.8 m/s is 1.82 rad/s, which does not achieve the target steering angular speed of 2.2 rad/s. Therefore, to perform the desired steering command, the vehicle speed needs to be adjusted automatically. Figure 10a is the curve of the steering control signal, the inside and outside speeds of the track, and the central vehicle speed in this condition. Figure 10b shows the pressure change curve of the hydraulic motors on both sides during steering.

- (3)

- The simulation conditions are: Initial vehicle speed is 1m/s, when t = 10 s, driver inputs a steering control signal of 0.5 rad/s. If the angle sensor detects , and when driving along the slope contour and turning upward, according to Formula (19), the maximum steering angular speed corresponding to the vehicle speed of 1m/s is 0.2 rad/s, which does not achieve the target steering angular speed of 0.5 rad/s. To perform the desired steering command, the vehicle speed needs to be adjusted automatically.

- (4)

- The simulation conditions were: At an initial speed of 3.3 m/s and t = 10 s, the driver inputs a steering angular velocity control signal as the steering intention, the value of which increases from 0 to 3.2 rad/s within 0.5 s. If the angle sensor detects for steering downhill along the contour line, according to Formula (19), the maximum steering angular speed corresponding to the vehicle speed of 3.3 m/s is 3 rad/s, which does not achieve the target steering angular speed of 3.2 rad/s. To achieve the target steering, the vehicle speed needs to be adjusted automatically.

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Symbol | Meaning |

| Variable pump displacement | |

| Motor displacement | |

| Pump input speed | |

| Motor rotation angle | |

| Pump internal leakage coefficient | |

| Pump external leakage coefficient | |

| Motor internal leakage coefficient | |

| Motor external leakage coefficient | |

| Total volume of high-pressure side | |

| Hydraulic oil bulk modulus of elasticity | |

| Total rotational inertia of motor and load | |

| Total viscous damping factor of motor and load | |

| External load torque acting on the motor shaft | |

| Rotation angular velocities of the inner and outer driving wheels | |

| Theoretical speed of inner and outer tracks relative to the ground | |

| Driving wheel radius | |

| Actual speed of inner and outer tracks relative to the ground | |

| Actual turning radius | |

| Actual steering angular velocity of tracked vehicle | |

| Track gauge of both sides | |

| Driving forces of the tracks on both sides | |

| Rolling resistance of the tracks | |

| Steering resistance moment | |

| Distance from the steering center to the vehicle centerline | |

| Distance from the center of the vehicle plane | |

| Longitudinal offset of the steering center | |

| Ground shear deformation coefficient | |

| Vehicle deflection angle | |

| Vehicle weight | |

| Angle with Y-axis | |

| Angle with X-axis | |

| Height of the mass center | |

| Motor torque on both sides | |

| Ground adhesion coefficient | |

| Side transmission ratio | |

| Transmission efficiency from motor to track | |

| Rolling resistance coefficient | |

| Track grounding length | |

| Relative steering radius | |

| Lateral adhesion coefficient |

References

- Mao, Z.L.; Jiang, J.D.; Zhang, S.Q. Design and Test of Hydraulic Control Differential Steering System for Crawler Tractor. J. Agric. Mech. Res. 2022, 44, 253–258+263. [Google Scholar]

- Wang, Y.; Zhang, Y.L.; Qin, X.Q.; Xu, M. Research Status and Development Trend on vehicle Hydrostatic Transmission Hydraulic System. Mach. Tool Hydraul. 2015, 43, 149–155. [Google Scholar]

- MA, K.; Cao, F.Y.; Wang, H.R. Fuzzy PID Control of Tracked Vehicle Steering Based on Hydro-mechanical Differential Steering. Agric. Equip. Veh. Eng. 2020, 58, 25–29. [Google Scholar]

- Zhai, L.; Sun, T.M.; Wang, Q.N.; Wang, J. Lateral stability control of dynamic steering for dual motor drive high speed tracked vehicle. Int. J. Automot. Technol. 2016, 17, 1079–1090. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, C. Control strategy based on BP neutral network plus PID algorithm for dual electric tracked vehicle steering. In Proceedings of the 2nd International Conference on Advanced Computer Control, Shenyang, China, 27–29 March 2010; Volume 2, pp. 584–587. [Google Scholar]

- Morimoto, T.; Hirata, N.; Ono, K.; Mizutani, N.; Matsui, H.; Yano, K.I. Turning Control on a Slope Based on a Vehicle Posture for a Tracked Vehicle. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Tampa, FL, USA, 3–9 November 2017; American Society of Mechanical Engineers: New York, NY, USA, 2017; p. 58370. [Google Scholar]

- Park, W.Y.; Chang, Y.C.; Lee, S.S.; Hong, J.H.; Park, J.G.; Lee, K.S. Prediction of the tractive performance of a flexible tracked vehicle. J. Terramech. 2008, 45, 13–23. [Google Scholar] [CrossRef]

- Li, G.; Zhao, H. Analysis of High-speed Steering Drift for Track Vehicles. Constr. Mach. Equip. 2019, 50, 7, 38–42. [Google Scholar]

- Liu, Y.; Gai, J.; Chen, Y.; Wan, F. Self-adaptive Steering Control of Electric Drive for Tracked Vehicles. Veh. Power Technol. 2015, 137, 5–10. [Google Scholar]

- Gai, J.; Liu, C. Steering Control of Electric Drive Tracked Vehicle Considering Tracks’ Skid and Slip. Acta Armamentarii 2021, 42, 2092–2101. [Google Scholar]

- Su, Y.; Xue, N.; Zhang, H.; Ku, G. Dynamics Simulationof High-Speed Tracked Vehiclesin Steering Processon Ramp. Mach. Des. Manuf. 2016, 2, 157–160. [Google Scholar]

- Sun, F.; Shi, Q.; Guo, F.; Zhai, L. Characteristics of Dynamics of Tracked Vehicles Steering on Ramp. China Mech. Eng. 2007, 22, 2766–2771. [Google Scholar]

- Zhang, Y.; Liu, X.; Qiu, M.; Li, J.; Song, H. Characteristics of ramp steering for the motion planning of unmanned tracked vehicle. J. Nanjing Univ. Sci. Technol. 2020, 44, 536–542. [Google Scholar]

- Zeng, G.; Wang, W.D.; Gai, J.T. Steering on Ramp Control Strategy of Double Motor Coupling Drive Transmission for Tracked Vehicle. Acta Armamentarii 2021, 42, 2189–2195. [Google Scholar]

- Zhang, S. Research on Steering Control Strategy of Double Pump Driving Motor System in Tracked Vehicle. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2016. [Google Scholar]

- Zou, Y.; Sun, F.; Zhang, C. Electric Tracked Vehicle Real-Time Simulation of Dual-Motor Driving Control with Driver-Glogal Controller In-loop. Chin. J. Mech. Eng. 2007, 43, 193–198. [Google Scholar] [CrossRef]

- Chi, Y. Technology and Theory of Differential Steering for Tracked Vehicles; Chemical Industry Press: Shanghai, China, 2013; Volume 7, pp. 34–38. [Google Scholar]

- Yang, L.; Ma, B.; Li, H. Steering safety control strategy of hydrostatic driving tracked vehicle on icy-snowy road. J. Jilin Univ. (Eng. Technol. Ed.) 2011, 41, 904–909. [Google Scholar]

- Xing, P.; Guo, Z.; Qi, D.; Shi, J. An Evaluation Method of Differential Steering Performance of Crawler Tractor. Tract. Farm Transp. 2018, 45, 32–35+39. [Google Scholar]

| Parameters | Value | Unit |

|---|---|---|

| Tracked vehicle overall mass G | 2800 | kg |

| High quality core h | 1.15 | m |

| Track center distance B | 1.25 | m |

| Crawler ground length L | 1.56 | m |

| Drive wheel radius r | 0.18 | m |

| Variable Pump Displacement | 0–71 | mL/r |

| Hydraulic system pressure | 30 | Mpa |

| Motor Displacement | 514 | mL/r |

| Maximum pressure of fixed motor | 31.5 | Mpa |

| Parameters | Value |

|---|---|

| Rolling resistance coefficient f | 0.1 |

| Steering resistance coefficient | 0.8 |

| Lateral adhesion coefficient ψ | 0.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, J.; Wang, F.; Wang, Y. A Control Method for the Differential Steering of Tracked Vehicles Driven Independently by a Dual Hydraulic Motor. Appl. Sci. 2022, 12, 6355. https://doi.org/10.3390/app12136355

Han J, Wang F, Wang Y. A Control Method for the Differential Steering of Tracked Vehicles Driven Independently by a Dual Hydraulic Motor. Applied Sciences. 2022; 12(13):6355. https://doi.org/10.3390/app12136355

Chicago/Turabian StyleHan, Jiangyi, Fan Wang, and Yuhang Wang. 2022. "A Control Method for the Differential Steering of Tracked Vehicles Driven Independently by a Dual Hydraulic Motor" Applied Sciences 12, no. 13: 6355. https://doi.org/10.3390/app12136355