Quantum Dot-Based White Organic Light-Emitting Diodes Excited by a Blue OLED

Abstract

:1. Introduction

2. Experimental Details

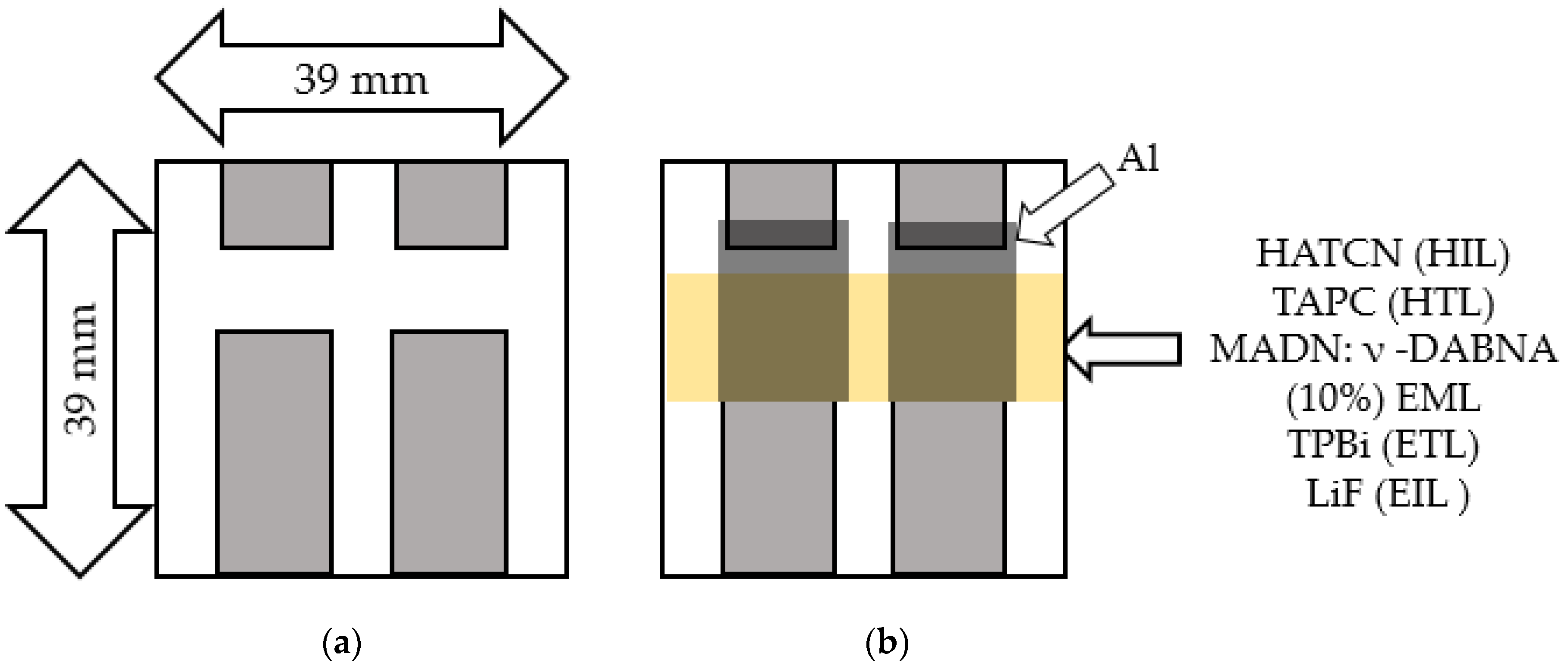

2.1. Blue OLED Device Fabrication

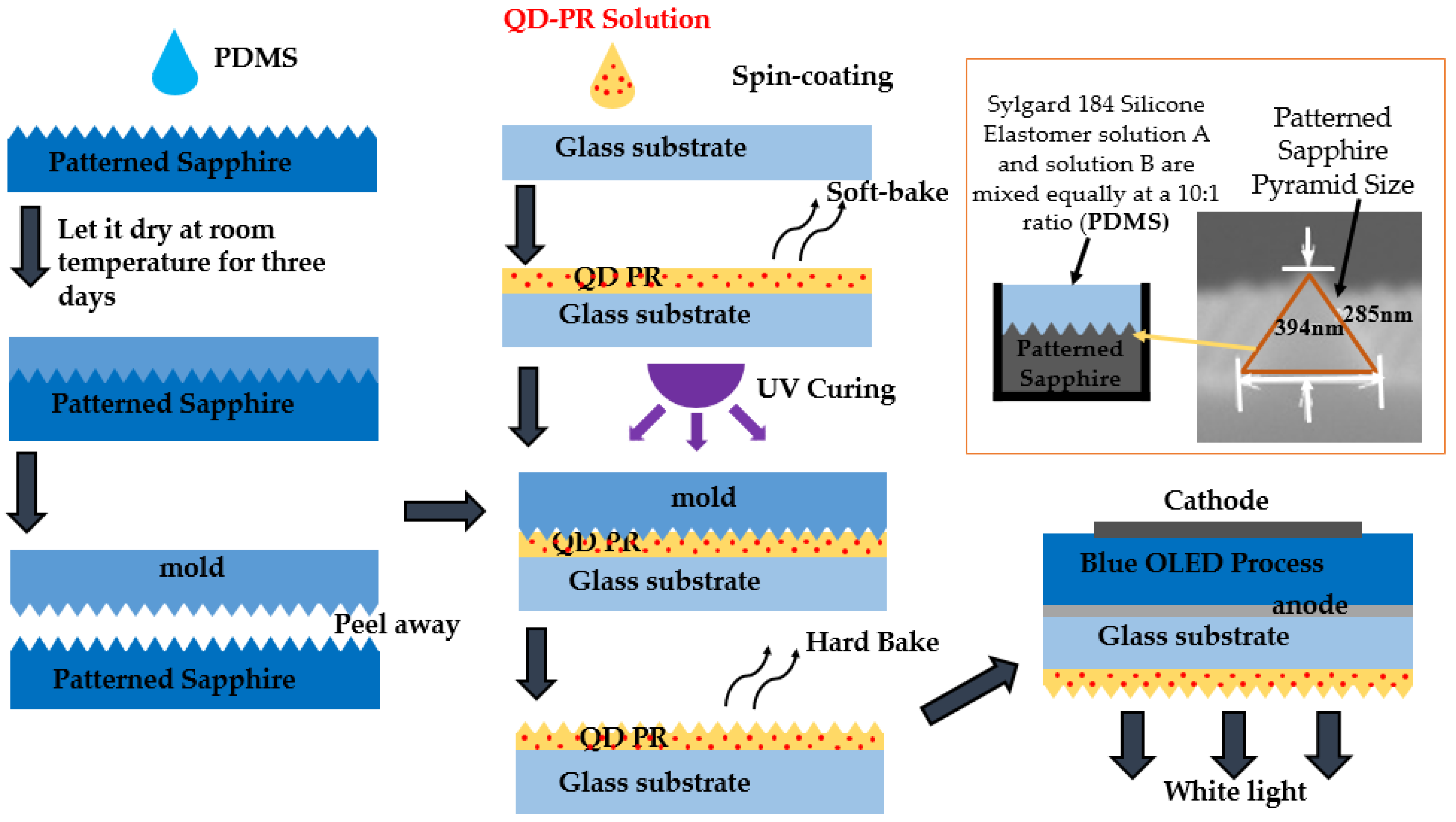

2.2. White OLED Device Fabrication

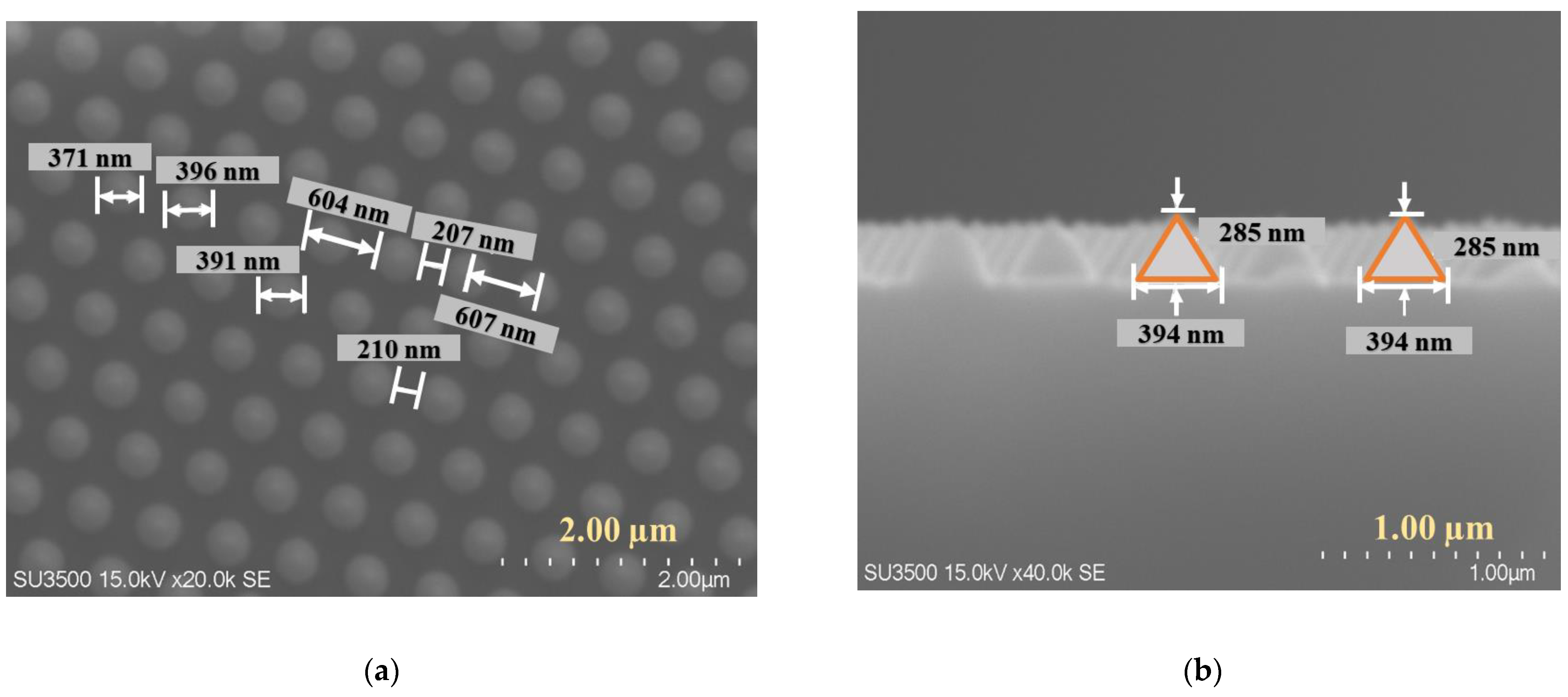

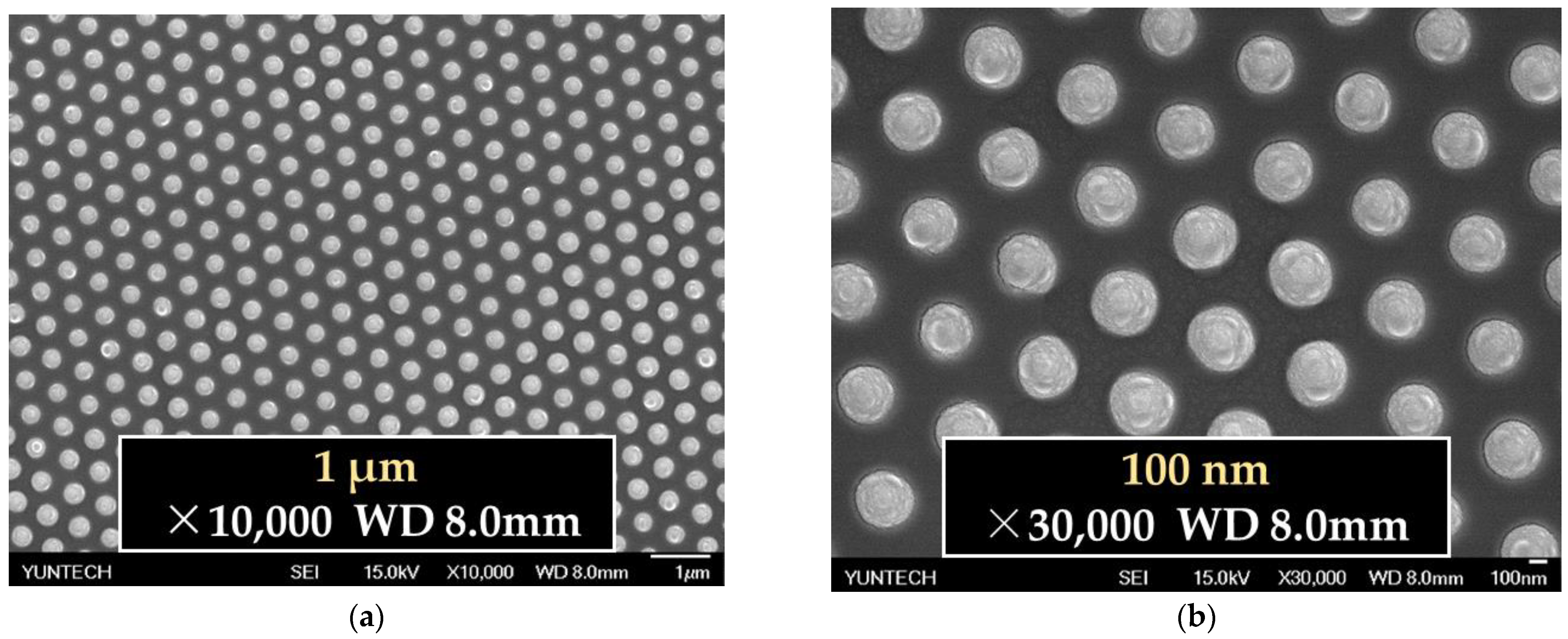

2.3. Nanoimprinting on QD Photoresists

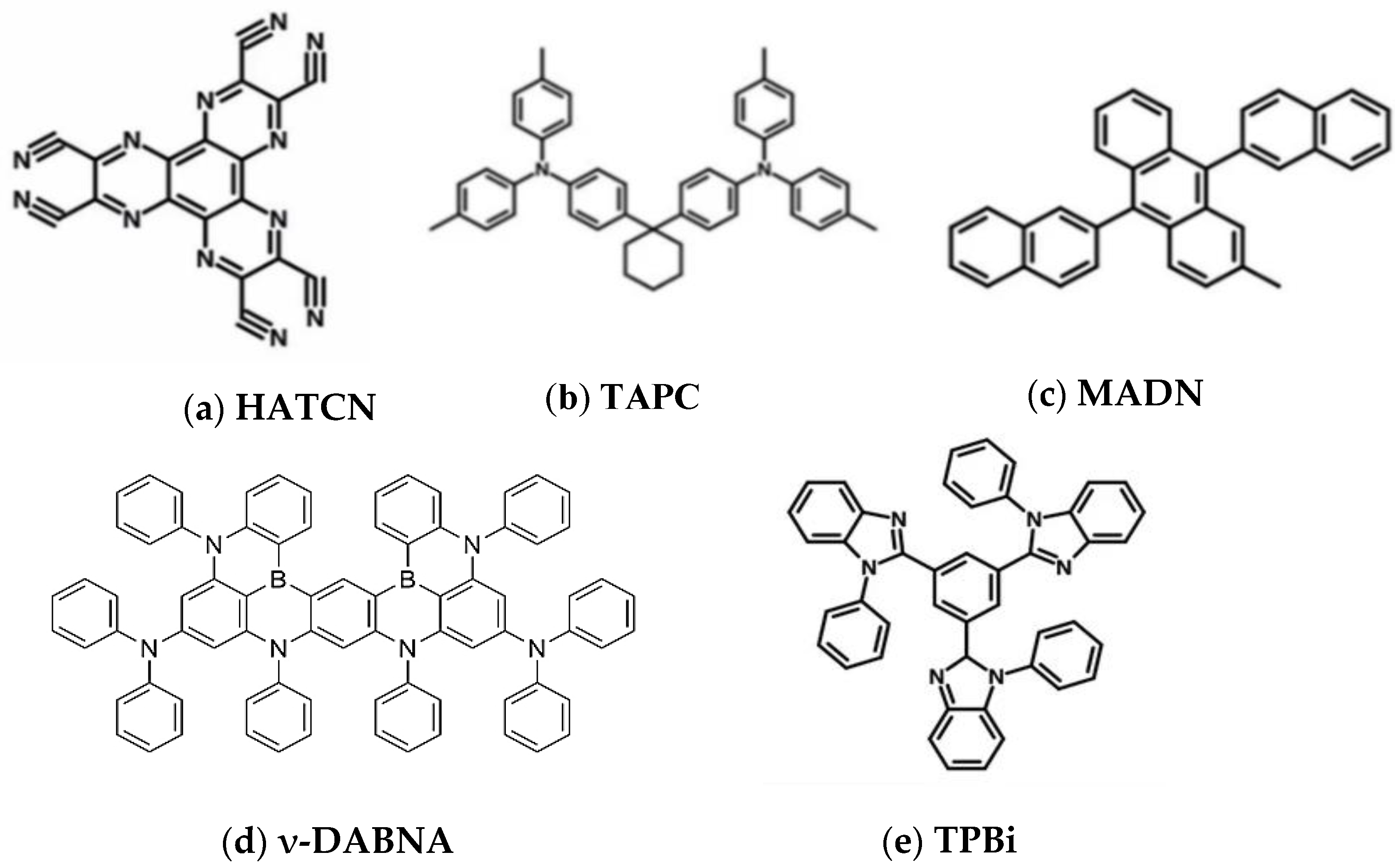

2.4. Material Details

3. Results and Discussion

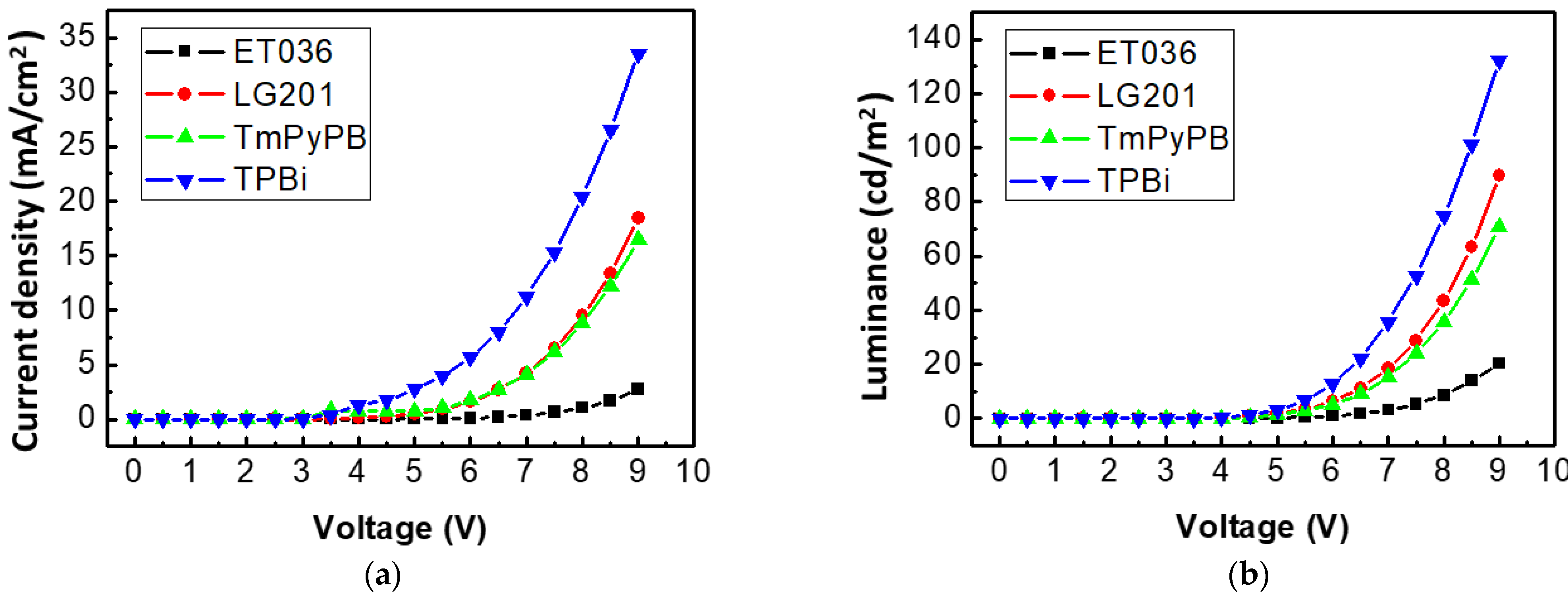

3.1. The Comparison of Electron Transport Layer Materials

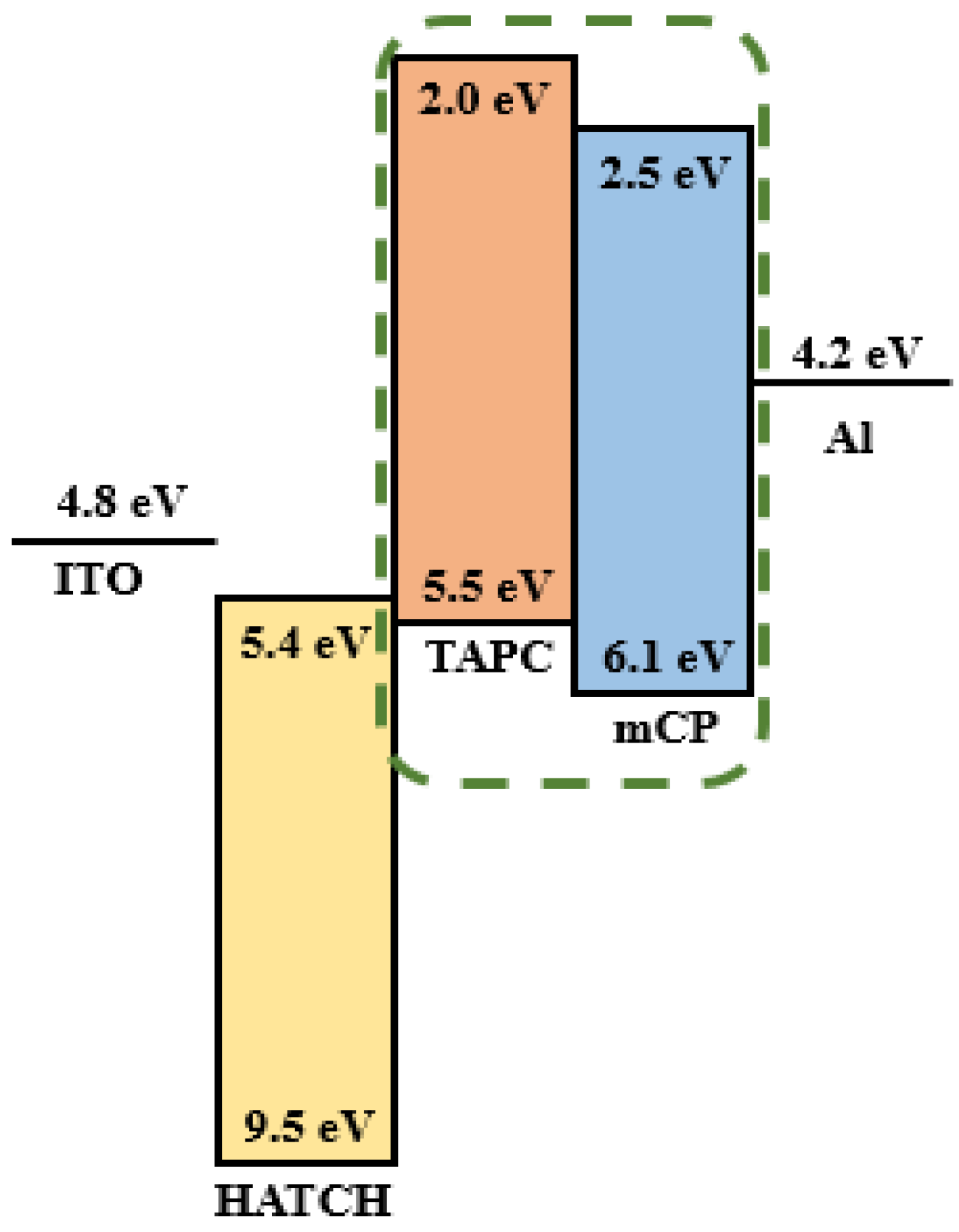

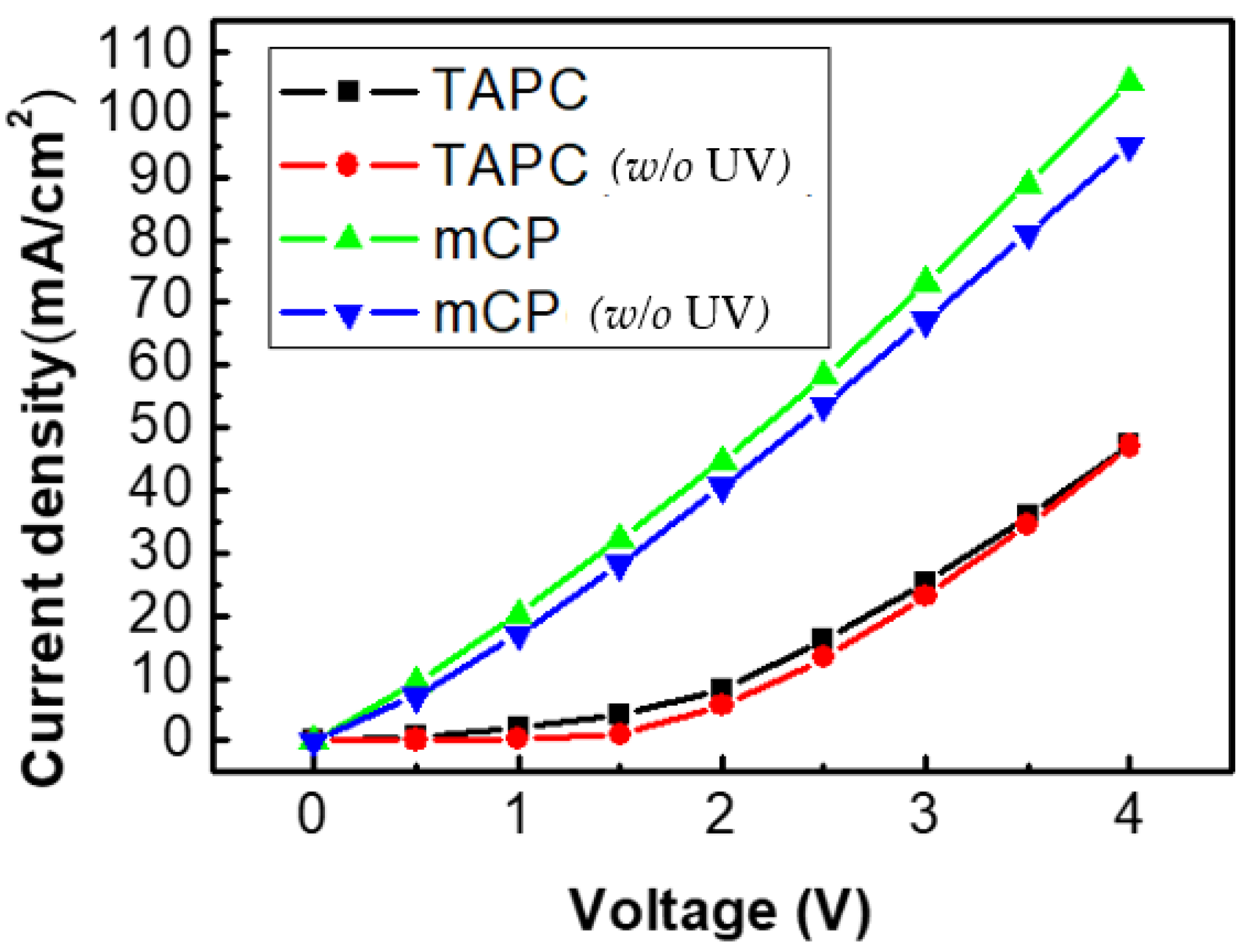

3.2. The Comparison of Hole Transport Layer Materials

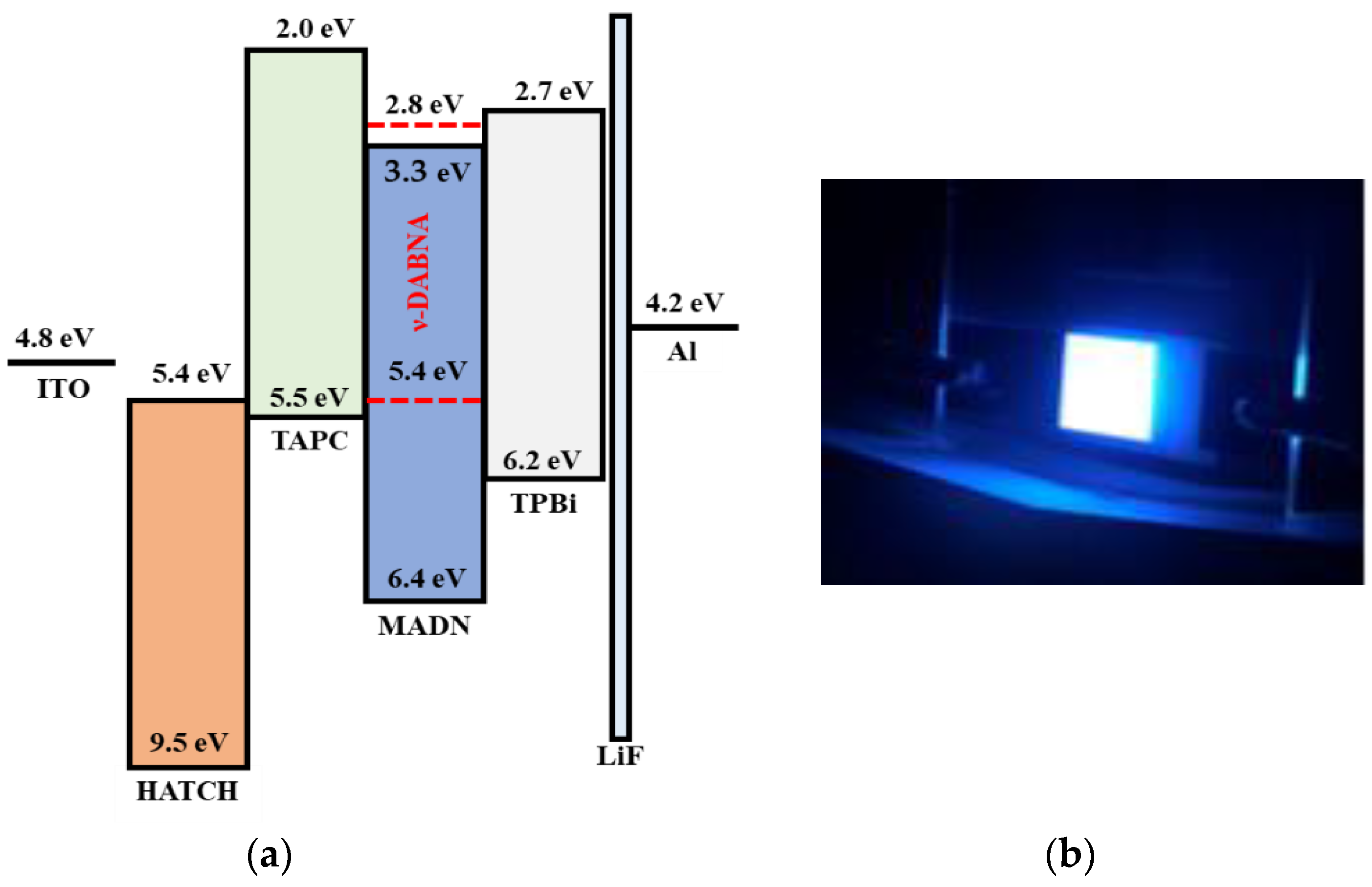

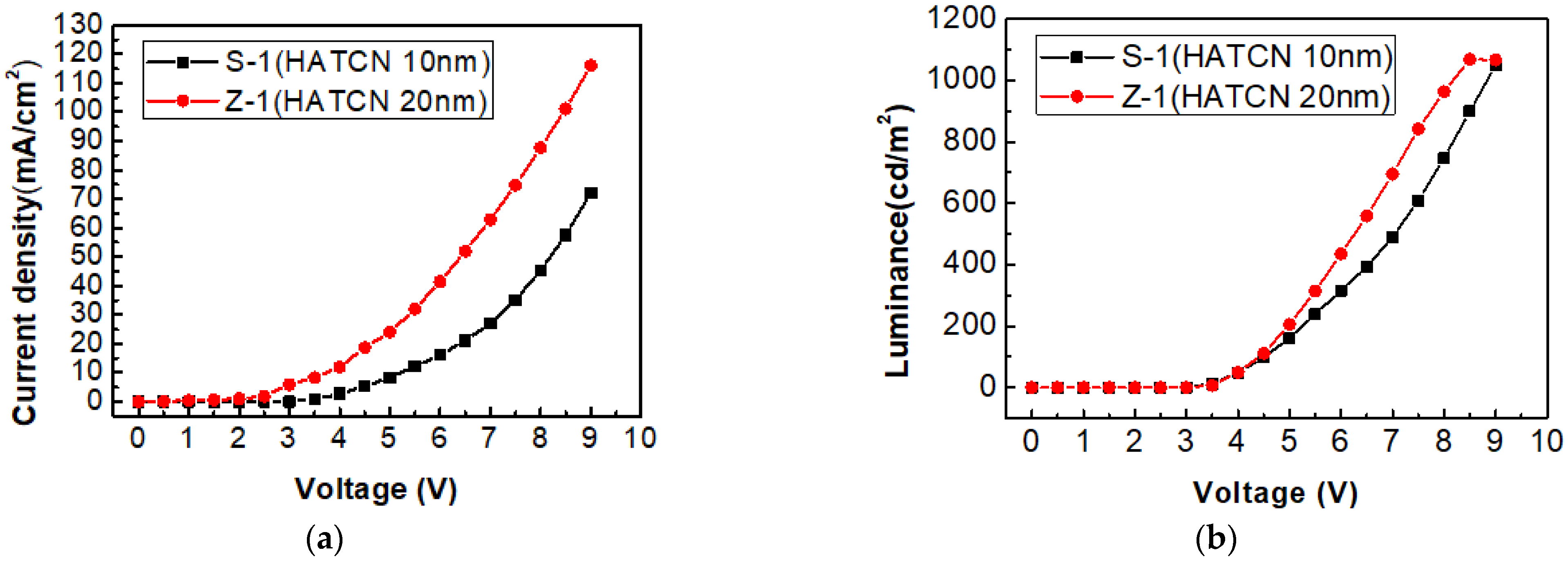

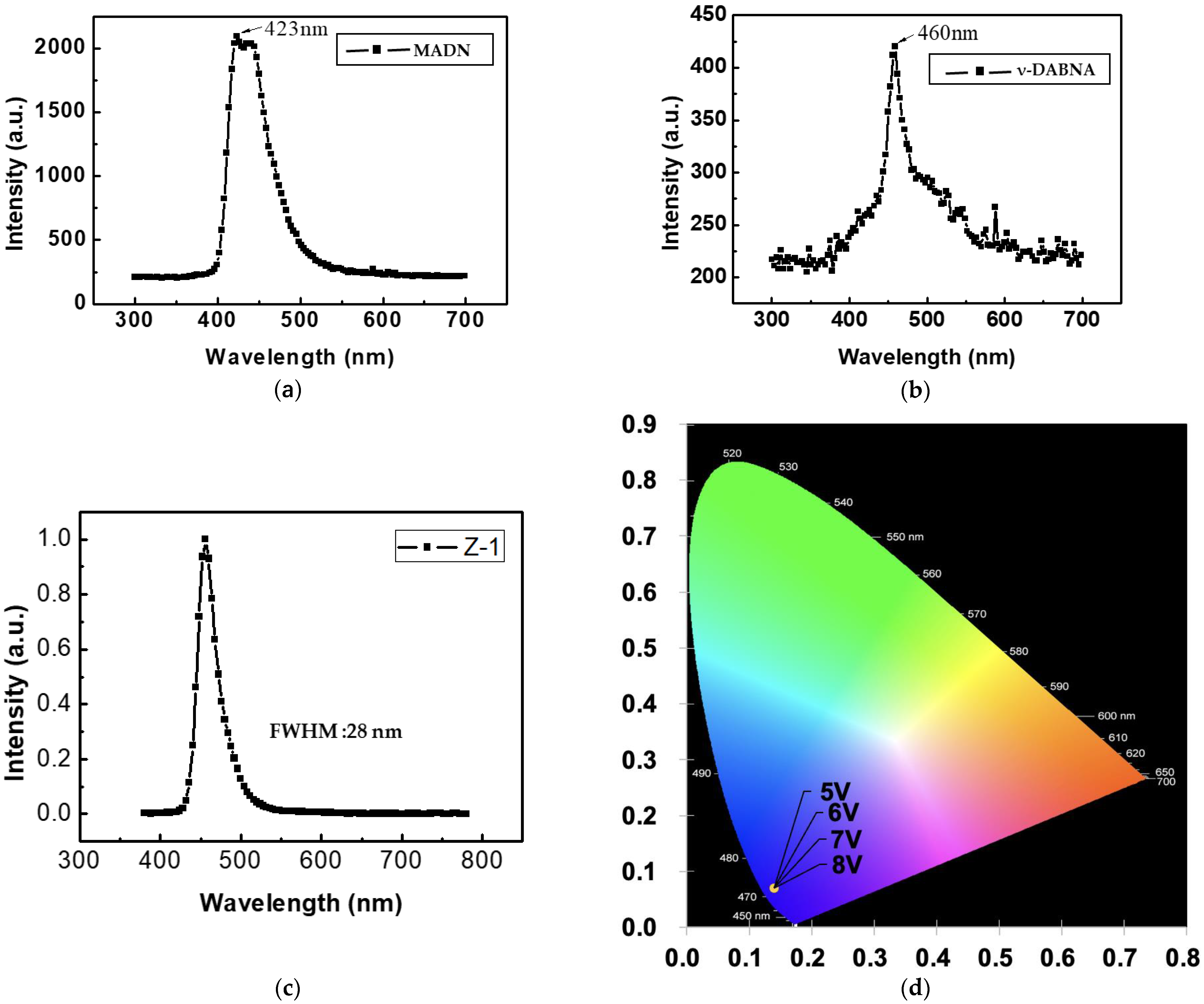

3.3. Blue OLED (BOLED) Devices

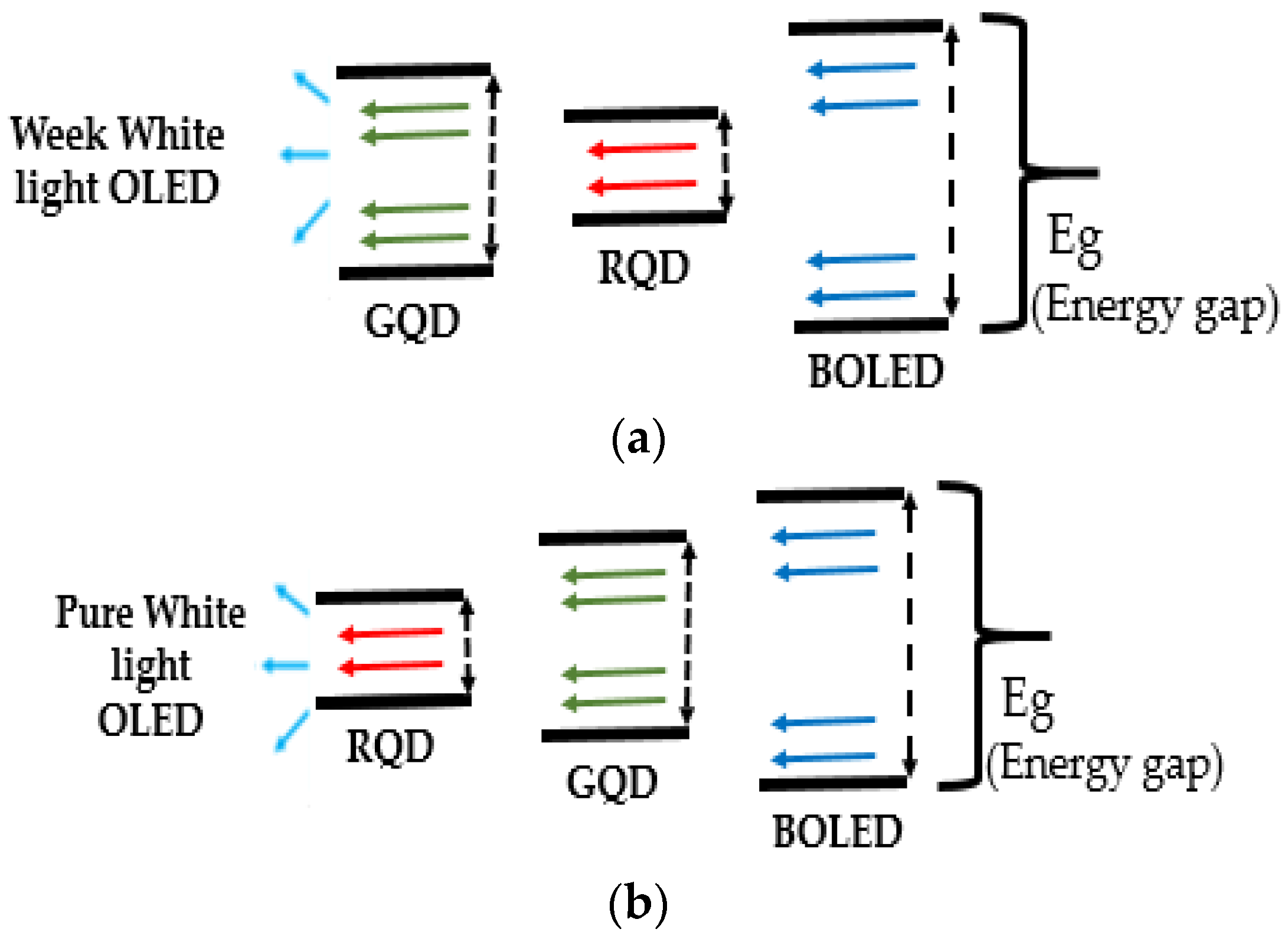

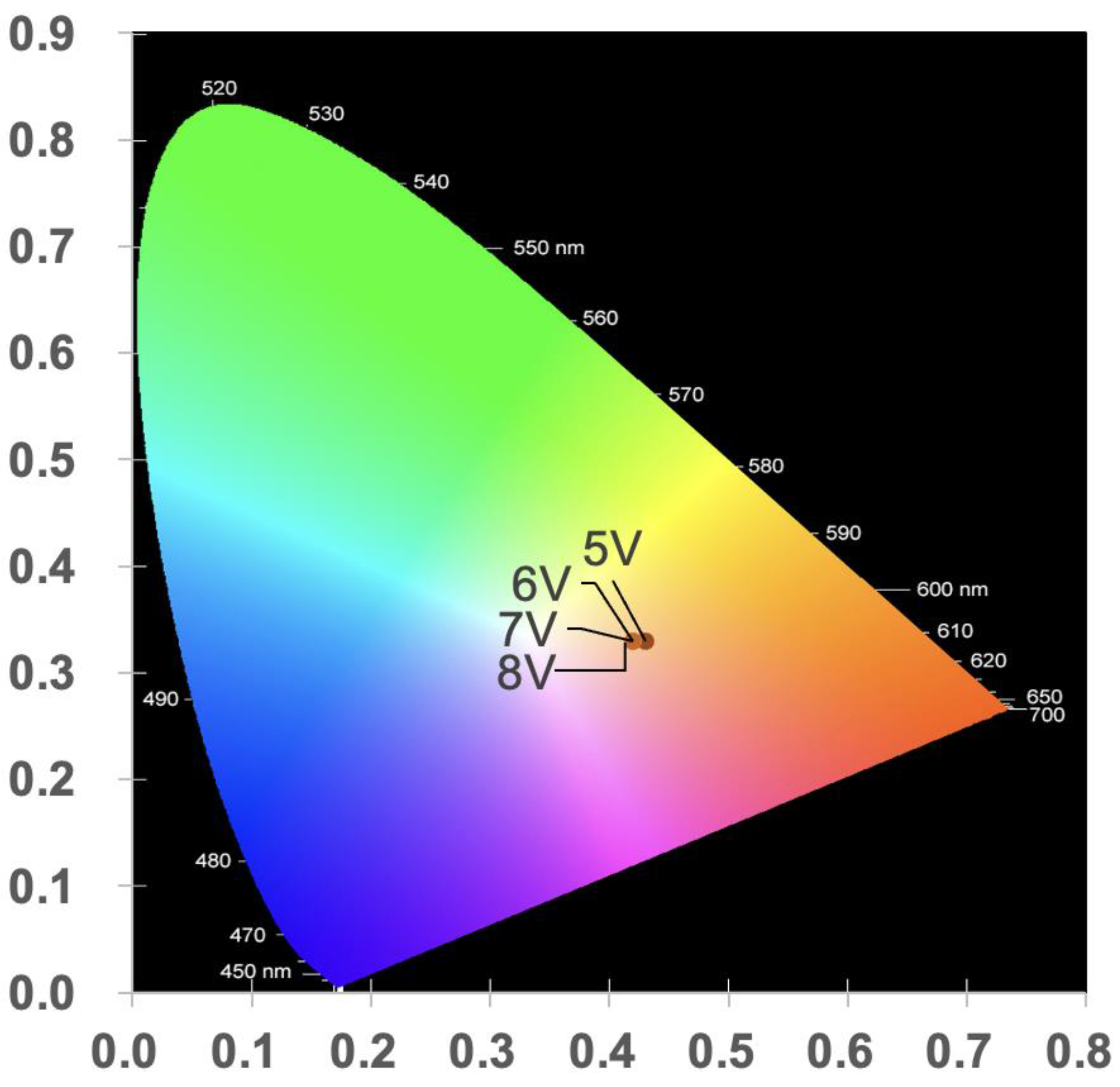

3.4. White OLED (WOLED) Devices

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Leem, D.-S.; Kim, J.W.; Jung, S.O.; Kim, S.O.; Kim, S.H.; Kim, K.Y.; Kim, J.-J. Efficient and colour-stable hybrid white organic light-emitting diodes utilizing electron–hole balanced spacers. J. Phys. D Appl. Phys. 2010, 43, 405102. [Google Scholar] [CrossRef]

- Jeong, B.S. Device Modeling of Quantum Dot–Organic Light Emitting Diodes for High Green Color Purity. Appl. Sci. 2021, 11, 2828. [Google Scholar] [CrossRef]

- Yoon, C.; Kim, T.; Shin, M.H.; Song, Y.G.; Shin, K.; Kim, Y.J.; Lee, K. Highly luminescent and stable white light-emitting diodes created by direct incorporation of Cd-free quantum dots in silicone resins using the thiol group. J. Mater. Chem. C 2015, 3, 6908–6915. [Google Scholar] [CrossRef]

- Choi, M.K.; Yang, J.; Hyeon, T.; Kim, D.H. Flexible quantum dot light-emitting diodes for next-generation displays. Npj Flex. Electron. 2018, 2, 10. [Google Scholar] [CrossRef]

- Hu, Z.; Yin, Y.; Ali, M.U.; Peng, W.; Zhang, S.; Li, D.; Zhou, H. Inkjet printed uniform quantum dots as color conversion layers for full-color OLED displays. Nanoscale 2020, 12, 2103–2110. [Google Scholar] [CrossRef]

- Huang, Y.M.; Singh, K.J.; Liu, A.C.; Lin, C.C.; Chen, Z.; Wang, K.; Lin, Y.; Liu, Z.; Wu, T.; Kuo, H.C. Advances in Quantum-Dot-Based Displays. Nanomaterials 2020, 10, 1327. [Google Scholar] [CrossRef]

- Han, H.V.; Lin, C.C.; Tsai, Y.L.; Chen, H.C.; Chen, K.J.; Yeh, Y.L.; Yu, P. A Highly Efficient Hybrid GaAs Solar Cell Based on Colloidal-Quantum-Dot-Sensitization. Sci. Rep. 2014, 4, 5734. [Google Scholar] [CrossRef] [Green Version]

- Konstantatos, G.; Sargent, E.H. Solution-Processed Quantum Dot Photodetectors. Proc. IEEE 2009, 97, 1666–1683. [Google Scholar] [CrossRef]

- Pal, B.N.; Robel, I.; Mohite, A.; Laocharoensuk, R.; Werder, D.J.; Klimov, V.I. High-Sensitivity p–n Junction Photodiodes based on PbS nanocrystal quantum dots. Adv. Funct. Mater. 2012, 22, 1741–1748. [Google Scholar] [CrossRef]

- Koh, W.K.; Saudari, S.R.; Fafarman, A.T.; Kagan, C.R.; Murray, C.B. Thiocyanate-Capped PbS nanocubes: Ambipolar transport enables quantum dot based circuits on a flexible substrate. Nano Lett. 2011, 11, 4764–4767. [Google Scholar] [CrossRef]

- Algar, W.R.; Krull, U.J. Quantum dots as donors in fluorescence resonance energy transfer for the bioanalysis of nucleic acids, proteins, and other biological molecules. Anal. Bioanal. Chem. 2008, 391, 1609–1618. [Google Scholar] [CrossRef] [PubMed]

- Chen, K.J.; Lin, C.C.; Han, H.V.; Lee, C.Y.; Chien, S.H.; Wang, K.Y.; Chiu, S.H.; Tu, Z.Y.; Li, J.R.; Chen, T.M.; et al. Wide-Range correlated color temperature light generation from resonant cavity hybrid quantum dot light-emitting diodes. IEEE J. Sel. Top. Quantum Electron. 2015, 21, 23–29. [Google Scholar] [CrossRef]

- Armăşelu, A. Recent Developments in Applications of Quantum-Dot Based Light-Emitting Diodes. In Quantum-Dot Based Light-Emitting Diodes; IntechOpen: London, UK, 2017; pp. 7–24. [Google Scholar] [CrossRef] [Green Version]

- Kim, K.; Jung, H.; Bae, W.; Lee, C. Effect of Solvents and Pressure on the Performance of Quantum Dot light Emitting Diodes Fabricated with Soft-Contact Transfer Printing. SID Dig. 2018, 49, 1643–1646. [Google Scholar] [CrossRef]

- Yin, M.; Yu, Z.; Pan, T.; Peng, X.; Zhang, X.; Zhang, L.; Xie, W. Efficient and angle-stable white top-emitting organic light emitting devices with patterned quantum dots down-conversion films. Org. Electron. 2018, 56, 46–50. [Google Scholar] [CrossRef]

- Kim, H.-J.; Shin, M.H.; Kim, J.S.; Kim, S.E.; Kim, Y.J. High efficient OLED displays prepared with the air-gapped bridges on quantum dot patterns for optical recycling. Sci. Rep. 2017, 7, 43063. [Google Scholar] [CrossRef] [Green Version]

- Im, J.H.; Kang, K.T.; Choi, J.S.; Cho, K.H. Strong microcavity effects in hybrid quantum dot/blue organic light-emitting diodes using Ag based electrode. J. Lumin. 2018, 203, 540–545. [Google Scholar] [CrossRef]

- Lee, K.-H.; Han, C.Y.; Kang, H.D.; Ko, H.; Lee, C.; Lee, J.; Yang, H. Highly Efficient, Color-Reproducible Full-Color Electroluminescent Devices Based on Red/Green/Blue Quantum Dot-Mixed Multilayer. ACS Nano. 2015, 9, 10941–10949. [Google Scholar] [CrossRef]

- Li, Y.; Rizzo, A.; Mazzeo, M.; Carbone, L.; Manna, L.; Cingolani, R.; Gigli, G. White organic light-emitting devices with CdSe/ZnS quantum dots as a red emitter. J. Appl. Phys. 2005, 97, 113501. [Google Scholar] [CrossRef]

- Hao, J.; Liu, H.; Miao, J.; Lu, R.; Zhou, Z.; Zhao, B.; Xie, B.; Cheng, J.; Wang, k.; Delville, M.H. A facile route to synthesize CdSe/ZnS thick-shell quantum dots with precisely controlled green emission properties: Towards QDs based LED applications. Sci. Rep. 2019, 9, 12048. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, H.T.; Pham, T.N.; Koh, K.H.; Lee, S. Fabrication and characterization of CdSe/ZnS quantum-dot LEDs. Phys. Status Solidi (A) 2012, 209, 1163–1167. [Google Scholar] [CrossRef]

- Heydari, N.; Ghorashi, S.M.B.; Han, W.; Park, H.H. Quantum Dot-Based Light Emitting Diodes (QDLEDs). New Progress. In Quantum-Dot Based Light-Emitting Diodes; IntechOpen: London, UK, 2017; pp. 25–45. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.-J.; Shin, M.-H.; Hong, H.-G.; Song, B.-S.; Kim, S.-K.; Koo, W.-H.; Kim, Y.-J. Enhancement of Optical Efficiency in White OLED Display Using the Patterned Photoresist Film Dispersed with Quantum Dot Nanocrystals. J. Disp. Technol. 2016, 12, 526–531. [Google Scholar] [CrossRef]

- Dayneko, S.; Lypenko, D.; Linkov, P.; Sannikova, N.; Samokhvalov, P.; Nikitenko, V.; Chistyakov, A. Application of CdSe/ZnS/CdS/ZnS Core–multishell Quantum Dots to Modern OLED Technology. Mater. Today Proc. 2016, 3, 211–215. [Google Scholar] [CrossRef]

- Jeon, Y.P.; Park, S.J.; Kim, T.W. Electrical and optical properties of blue organic light-emitting devices fabricated utilizing color conversion CdSe and CdSe/ZnS quantum dots embedded in a poly(N-vibyl carbazole) hole transport layer. Opt. Mater. Express 2012, 2, 663. [Google Scholar] [CrossRef]

- Uoyama, H.; Goushi, K.; Shizu, K.; Nomura, H.; Adachi, C. Highly efficient organic light-emitting diodes from delayed fluorescence. Nature 2012, 492, 234–238. [Google Scholar] [CrossRef] [PubMed]

- Miwa, T.; Kubo, S.; Shizu, K.; Komino, T.; Adachi, C.; Kaji, H. Blue organic light-emitting diodes realizing external quantum efficiency over 25% using thermally activated delayed fluorescence emitters. Sci. Rep. 2017, 7, 284. [Google Scholar] [CrossRef] [Green Version]

- Rodella, F.; Saxena, R.; Bagnich, S.; Banevičius, D.; Kreiza, G.; Athanasopoulos, S.; Juršėnas, s.; Kazlauskas, K.; Köhler, A.; Strohriegl, P. Low efficiency roll-off blue TADF OLEDs employing a novel acridine–pyrimidine based high triplet energy host. J. Mater. Chem. C 2021, 9, 17471–17482. [Google Scholar] [CrossRef]

- Yin, X.; He, Y.; Wang, X.; Wu, Z.; Pang, E.; Xu, J.; Wang, J. Recent Advances in Thermally Activated Delayed Fluorescent Polymer—Molecular Designing Strategies. Front. Chem. 2020, 8, 725. [Google Scholar] [CrossRef]

- Ma, D. White OLED Devices. In Handbook of Advanced Lighting Technology; Springer: Cham, Switzerland, 2017; pp. 321–361. [Google Scholar] [CrossRef]

- Lee, J.H. QD Display: A Game-Changing Technology for the Display Industry. Inf. Disp. 2020, 36, 9–13. [Google Scholar] [CrossRef]

- Springer, R.; Kang, B.Y.; Lampande, R.; Ahn, D.H.; Lenk, S.; Reineke, S.; Kwon, J.H. Cool white light-emitting three stack OLED structures for AMOLED display applications. Opt. Express 2016, 24, 28131. [Google Scholar] [CrossRef]

- Kim, H.-J.; Shin, M.-H.; Kim, Y.-J. Optical efficiency enhancement in white organic light-emitting diode display with high color gamut using patterned quantum dot film and long pass filter. Jpn. J. Appl. Phys. 2016, 55, 08RF01. [Google Scholar] [CrossRef]

| Device | HIL | HTL-1 | HTL-2 | EML | ETL | EIL | Cathode |

|---|---|---|---|---|---|---|---|

| PEDOT: PSS (Spin) | Poly-TPD(Spin) | mCP | MADN(90%): ν-DABNA (10%) | X | LiF | Al | |

| ET036 | Three layers | One layer | 15 | 50 | 20 | 0.8 | 150 |

| LG201 | |||||||

| TmPyPB | |||||||

| TPBi |

| Device | ITO | HIL | HTL | EIL | Cathode |

|---|---|---|---|---|---|

| UV Treatment | HATCN | X | LiF | Al | |

| TAPC | Yes | 10 | 30 | 0.8 | 150 |

| TAPC (w/o UV) | w/o | ||||

| mCP | Yes | 15 | |||

| mCP (w/o UV) | w/o |

| HIL | HTL | EML | ETL | EIL | Cathode | |

|---|---|---|---|---|---|---|

| NO | HATCN | TAPC | MADN: ν-DABNA (10%) | TPBi | LiF | Al |

| S-1 | 10 | 30 | 40 | 30 | 0.8 | 150 |

| Z-1 | 20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patel, K.D.; Juang, F.-S.; Wang, H.-X.; Jian, C.-Z.; Chen, J.-Y. Quantum Dot-Based White Organic Light-Emitting Diodes Excited by a Blue OLED. Appl. Sci. 2022, 12, 6365. https://doi.org/10.3390/app12136365

Patel KD, Juang F-S, Wang H-X, Jian C-Z, Chen J-Y. Quantum Dot-Based White Organic Light-Emitting Diodes Excited by a Blue OLED. Applied Sciences. 2022; 12(13):6365. https://doi.org/10.3390/app12136365

Chicago/Turabian StylePatel, Krishn Das, Fuh-Shyang Juang, Hao-Xuan Wang, Chong-Zhe Jian, and Jia-You Chen. 2022. "Quantum Dot-Based White Organic Light-Emitting Diodes Excited by a Blue OLED" Applied Sciences 12, no. 13: 6365. https://doi.org/10.3390/app12136365