Dynamic Characteristics of Reconstituted Silt Influenced by Axial Unloading Intensity and Fine Particle Content

Abstract

:1. Introduction

2. Test Program

2.1. Soil

2.2. Parameters of the Cyclic Loading

- Wave form and frequency of the cyclic loading

- 2.

- Amplitude of the cyclic loading

- 3.

- The number of cycles and the failure criterion

2.3. Unloading and Reloading Stress Paths

2.4. Test Procedures

- Sample preparation

- 2.

- Saturation

- 3.

- Consolidation

- 4.

- Unloading and reloading

- 5.

- Cyclic loading

3. Dynamic Response of the Silt Containing Fine Particles under Conventional Triaxial Stress Path

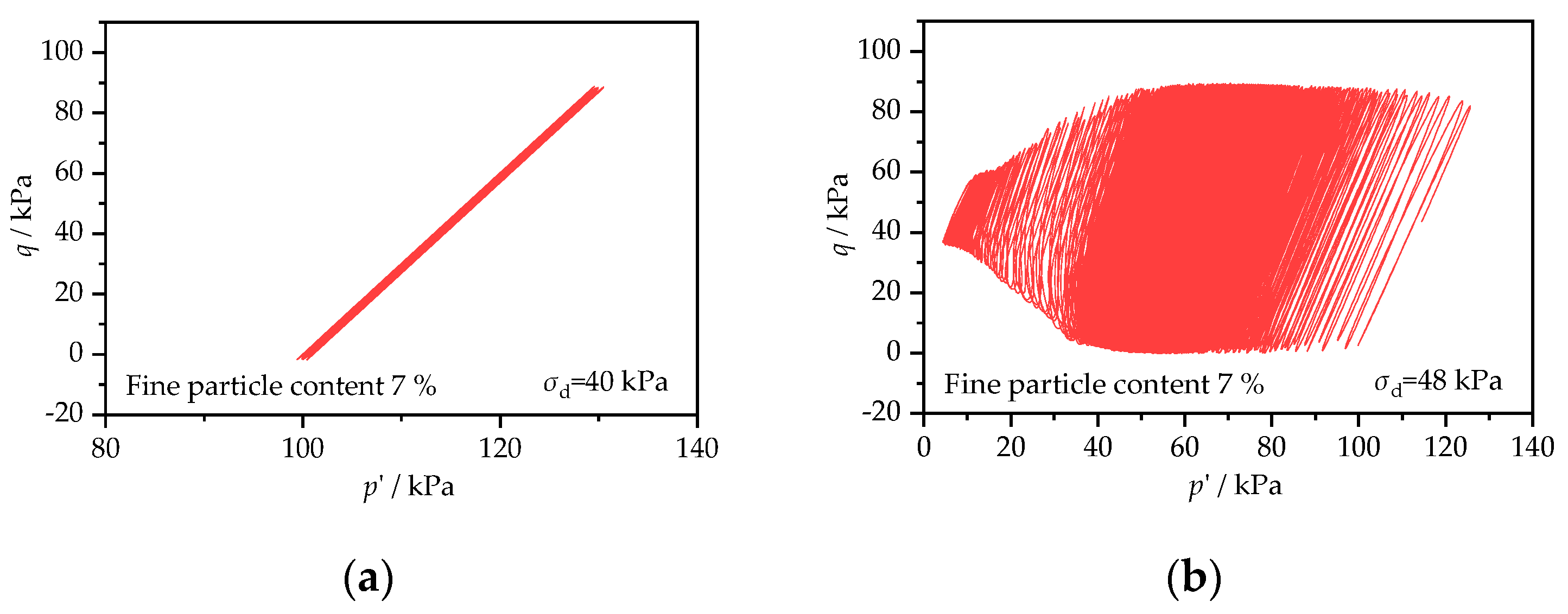

3.1. Undrained Cyclic Tests

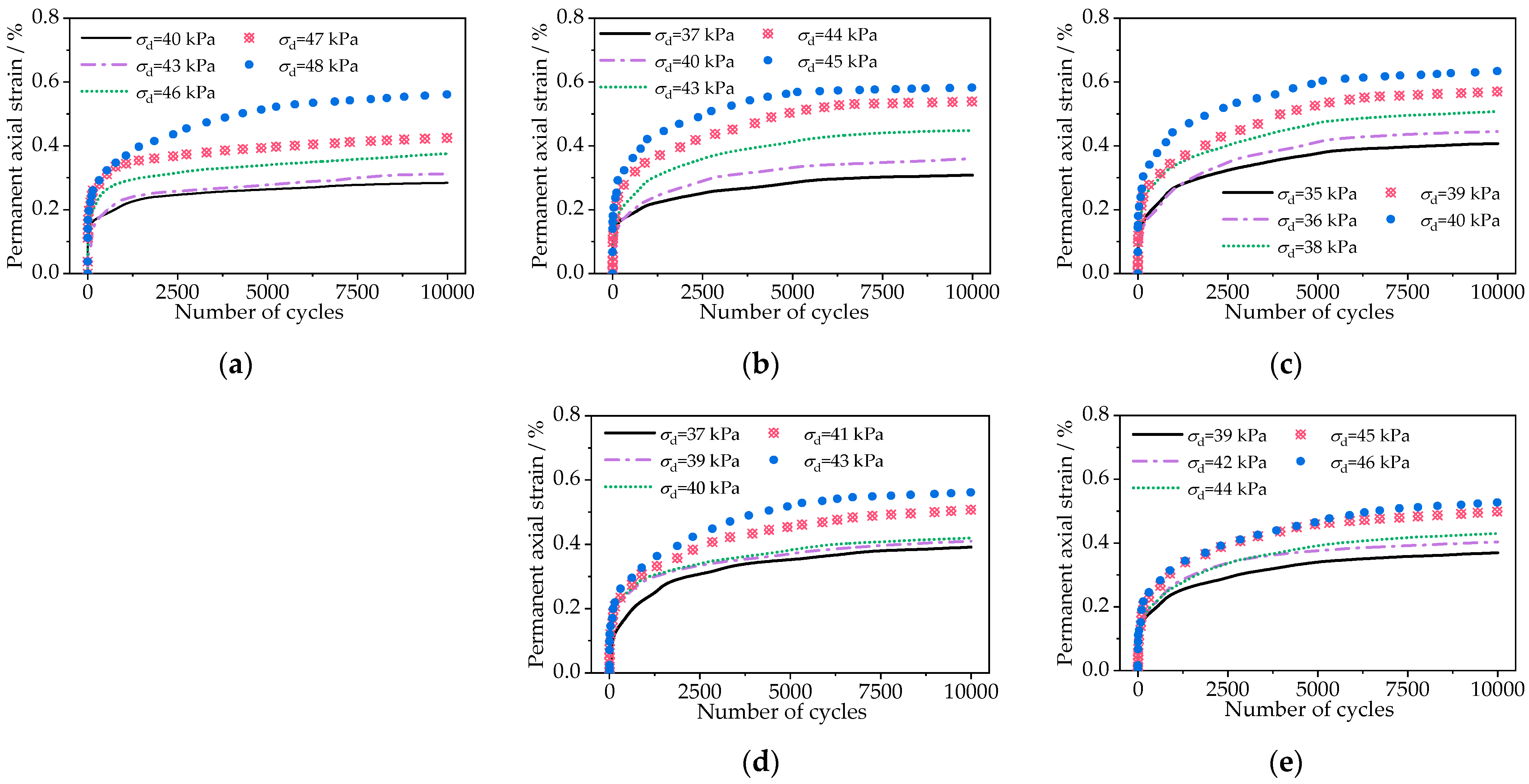

3.2. Drained Cyclic Tests

4. Dynamic Response of the Silt Containing Fine Particles under Unloading Stress Paths

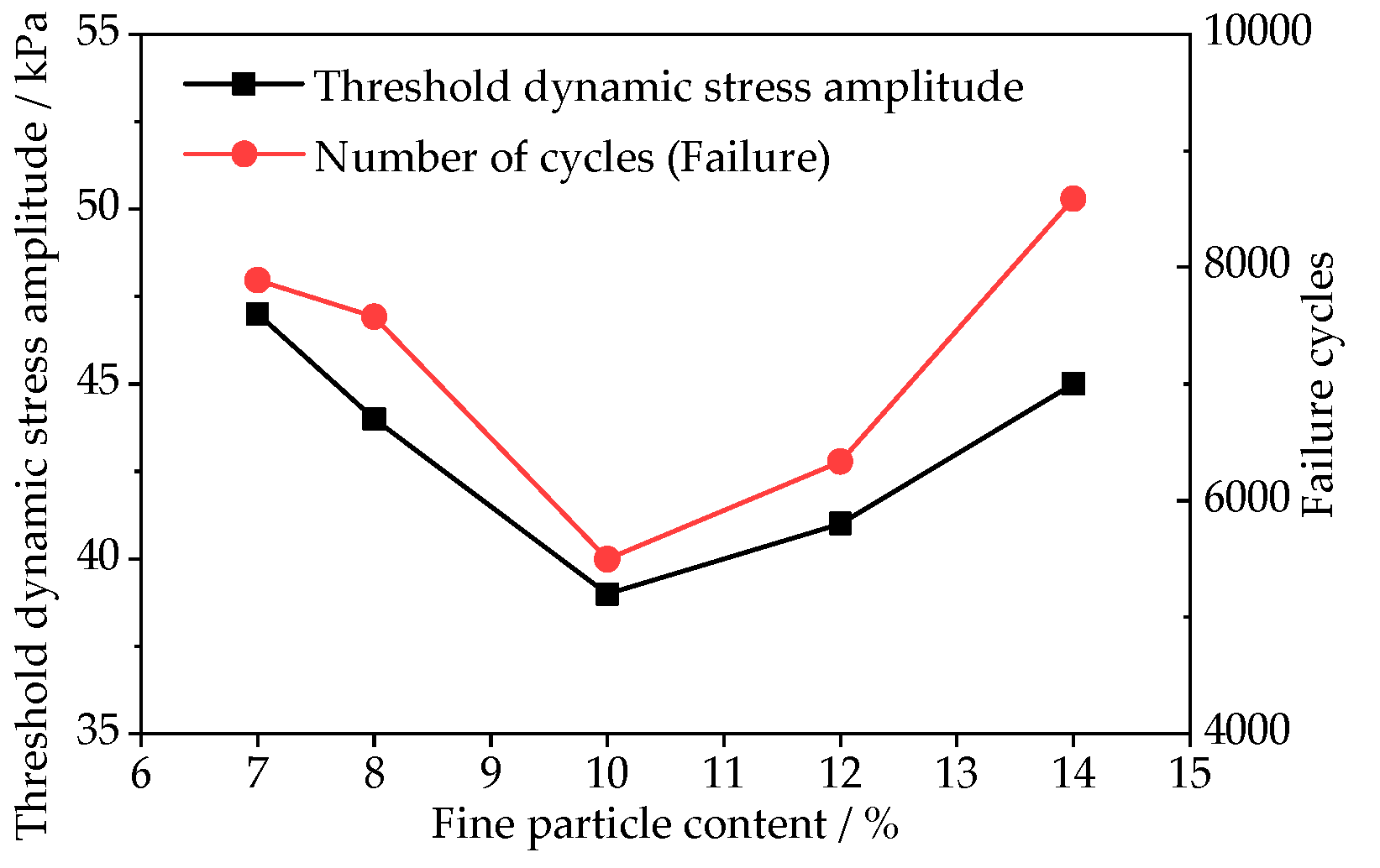

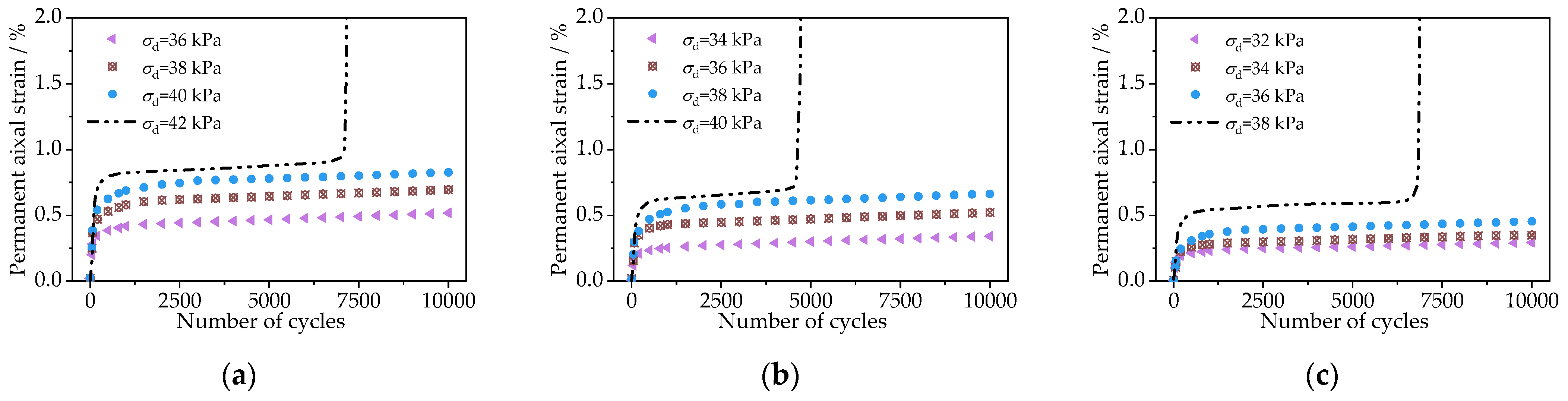

4.1. Pemanent Axial Strain under Different Unloading Intensities

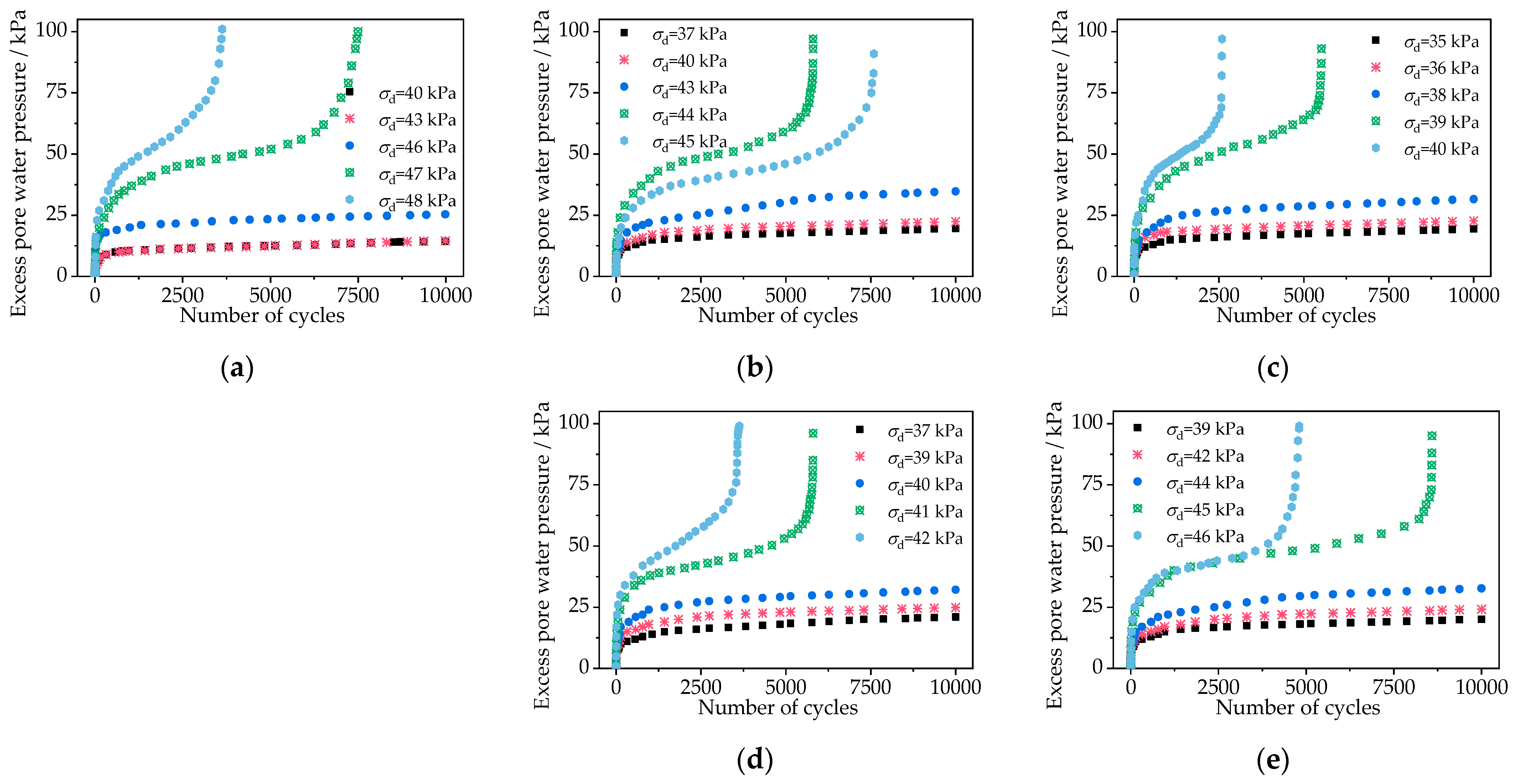

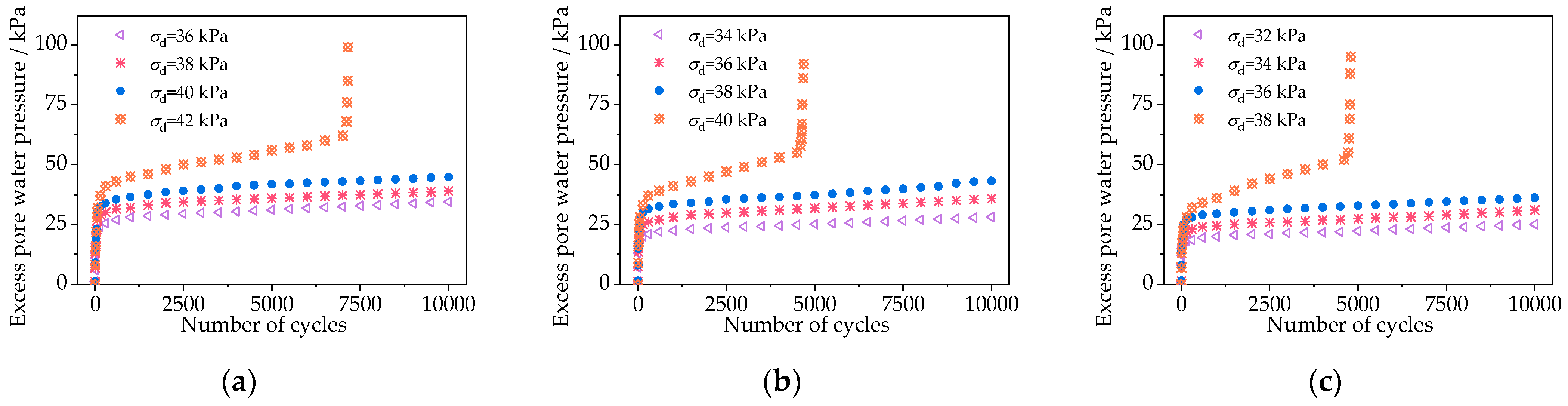

4.2. Excess Pore Water Pressure under Different Unloading Intensities

5. Conclusions

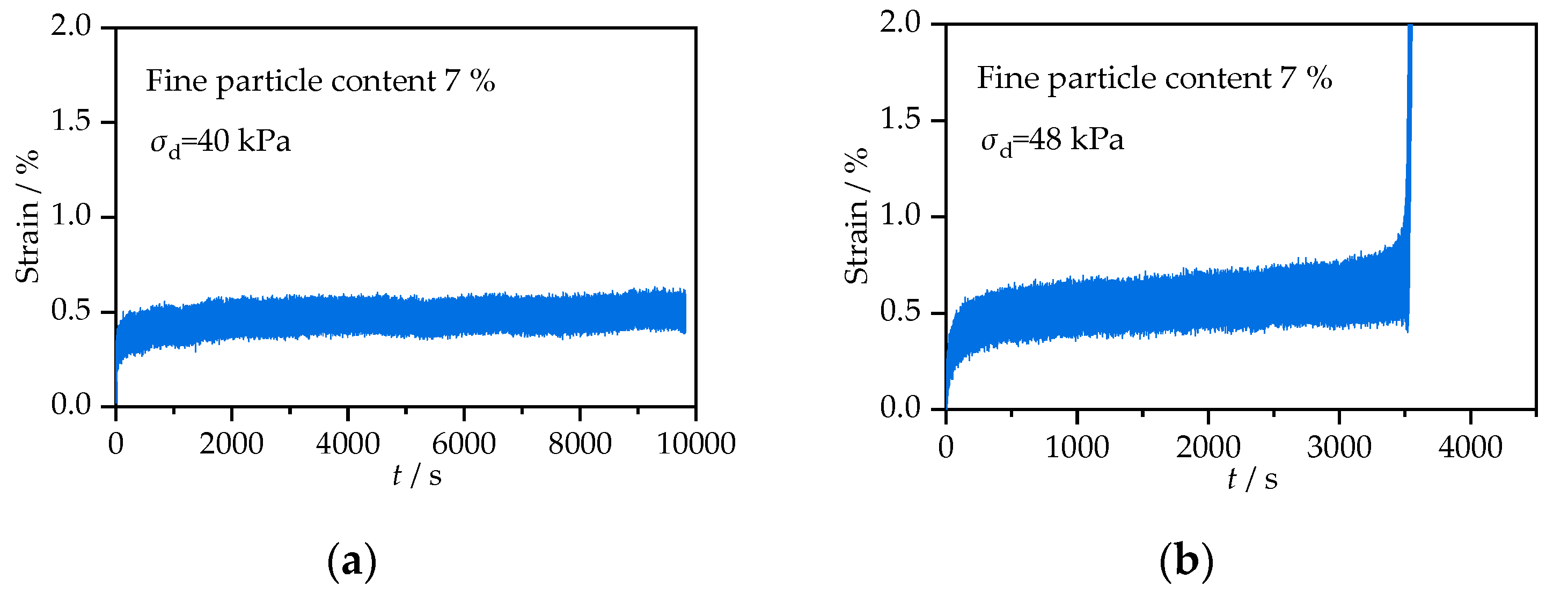

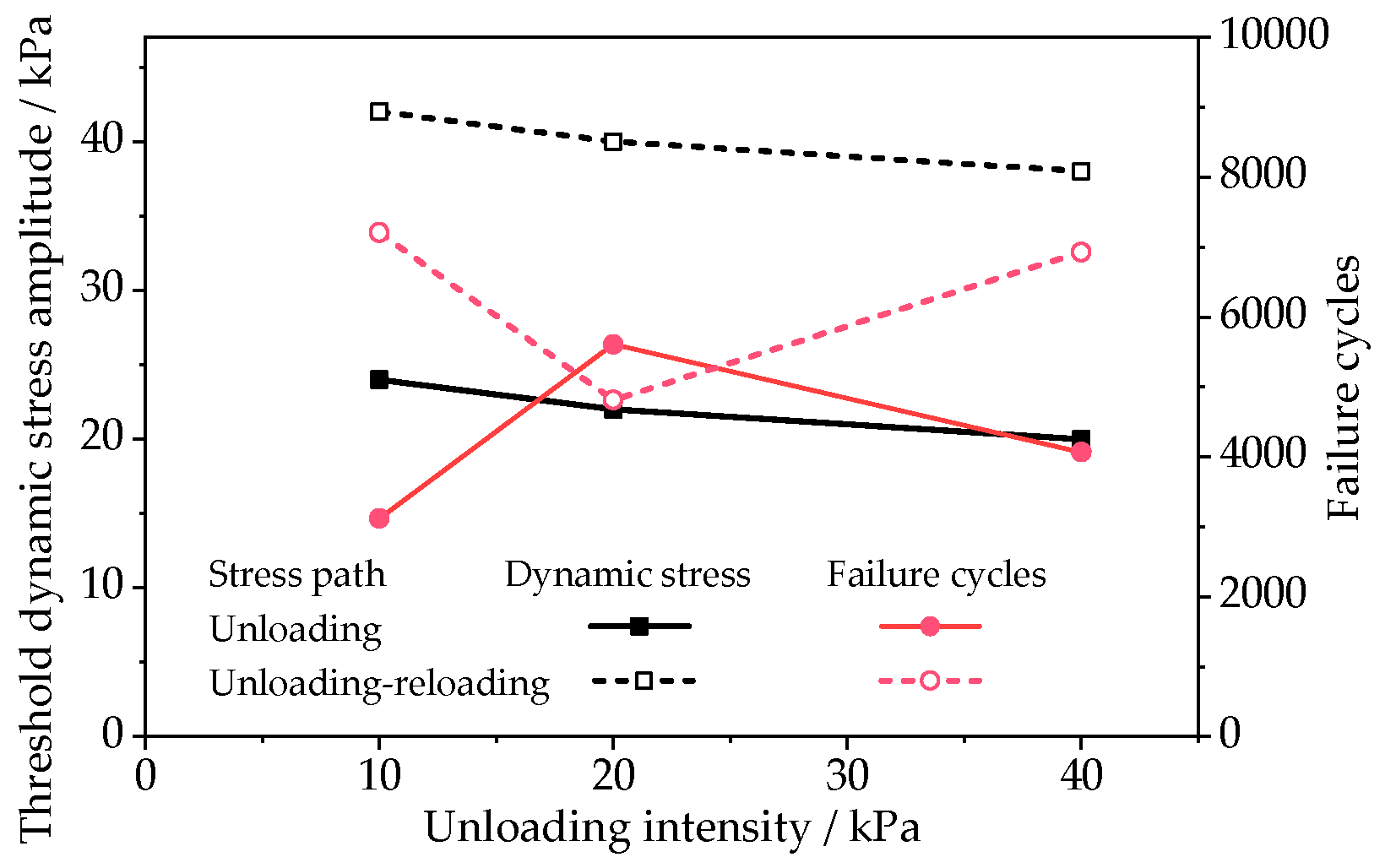

- In cyclic loading tests, there is a dynamic stress amplitude threshold. The permanent axial strain and excess pore water pressure of the silt tend to be stable as the number of cycles increases when the dynamic stress amplitude is less than this value. When the dynamic stress amplitude exceeds this value, the silt will liquefy and fail as the number of cycles increases. With increasing fine particle content, the threshold dynamic stress and failure cycles in silt decrease and then increase, reaching a minimum of 39 kPa and 5495, respectively, at 10% fine particle content.

- For the same fine particle content, the permanent axial strain under drained conditions is greater than that under undrained conditions (when the sample does not fail at 10,000 cycles) because the excess pore pressure under drained conditions is dissipated in time, resulting in the consolidation deformation of soil samples. At the same time, due to higher permeability and lower fine particles of silt, the difference between undrained and drained permanent axial strain is more significant.

- The threshold dynamic stress amplitude and failure cycles of the silt are significantly reduced by axial unloading. The silt is disturbed during the unloading and reloading path, resulting in a slight reduction in the critical dynamic stress amplitude and failure period. The dynamic stress threshold amplitude of a soil sample decreases slightly as unloading strength increases. As a result, the impact of fine particle content and foundation pit unloading on the dynamic characteristics of silt under long-term cyclic loading should be considered.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tang, Y.; Cui, Z.; Zhang, X.; Zhao, S. Dynamic response and pore pressure model of the saturated soft clay around the tunnel under vibration loading of Shanghai subway. Eng. Geol. 2008, 98, 126–132. [Google Scholar] [CrossRef]

- Xiao, J.; Juang, C.; Wei, K.; Xu, S. Effects of Principal Stress Rotation on the Cumulative Deformation of Normally Consolidated Soft Clay under Subway Traffic Loading. J. Geotech. Geoenvironmental Eng. 2014, 140, 4013046. [Google Scholar] [CrossRef]

- Xia, C.; Meng, F.; Zhu, M.; Tang, Y.; Lu, C. Influence of Lateral Multistage Unloading Intensity on Mechanical Properties of Reconstituted Coastal Soils Containing Silty Particles. Appl. Sci. 2022, 12, 3651. [Google Scholar] [CrossRef]

- Liu, J.; Xiao, J. Experimental Study on the Stability of Railroad Silt Subgrade with Increasing Train Speed. J. Geotech. Geoenvironmental Eng. 2010, 136, 833–841. [Google Scholar] [CrossRef]

- Shen, Y.; Zhang, P.; Xu, G.; Liu, H. Dynamic strength characteristics and failure criteria of anisotropically consolidated silt under principal stress rotation. J. Central South Univ. 2013, 20, 2025–2033. [Google Scholar] [CrossRef]

- Ng, C.; Zhou, C. Cyclic behaviour of an unsaturated silt at various suctions and temperatures. Geotechnique 2014, 64, 709–720. [Google Scholar] [CrossRef]

- Juneja, A.; Mohammed-Aslam, A. Post-cyclic undrained response of sand and silt. Soil Dyn. Earthq. Eng. 2020, 133, 106138. [Google Scholar] [CrossRef]

- Cui, X.; Zhang, N.; Zhang, J.; Gao, Z. In situ tests simulating traffic-load-induced settlement of alluvial silt subsoil. Soil Dyn. Earthq. Eng. 2014, 58, 10–20. [Google Scholar] [CrossRef]

- Georgiannou, V.; Hight, D.; Burland, J. Behaviour of clayey sands under undrained cyclic triaxial loading. Geotechnique 1991, 41, 383–393. [Google Scholar] [CrossRef]

- Ansal, A.; Erken, A. Undrained Behavior of Clay Under Cyclic Shear Stresses. J. Geotech. Eng. ASCE 1989, 115, 968–983. [Google Scholar] [CrossRef]

- Mamou, A.; Powrie, W.; Priest, J.; Clayton, C. The effects of drainage on the behaviour of railway track foundation materials during cyclic loading. Geotechnique 2017, 67, 845–854. [Google Scholar] [CrossRef] [Green Version]

- Cavallaro, A.; Capilleri, P.; Grasso, S. Site Characterization by Dynamic In Situ and Laboratory Tests for Liquefaction Potential Evaluation during Emilia Romagna Earthquake. Geosciences 2018, 8, 242. [Google Scholar] [CrossRef] [Green Version]

- Dash, H.; Sitharam, T.; Baudet, B. Influence of Non-Plastic Fines on the Response of a Silty Sand to Cyclic Loading. Soils Found. 2010, 50, 695–704. [Google Scholar] [CrossRef] [Green Version]

- Akhila, M.; Rangaswamy, K.; Sankar, N. Undrained Response and Liquefaction Resistance of Sand–Silt Mixtures. Geotech. Geol. Eng. 2018, 37, 2729–2745. [Google Scholar] [CrossRef]

- Ghani, S.; Kumari, S. Insight into the Effect of Fine Content on Liquefaction Behavior of Soil. Geotech. Geol. Eng. 2020, 39, 1–12. [Google Scholar] [CrossRef]

- Qian, J.; Du, Z.; Lu, X.; Gu, X.; Huang, M. Effects of principal stress rotation on stress–strain behaviors of saturated clay under traffic–load–induced stress path. Soils Found. 2018, 59, 41–55. [Google Scholar] [CrossRef]

- Triantafyllos, P.; Georgiannou, V.; Dafalias, Y.; Georgopoulos, I. Novel findings on the dilatancy and non-coaxiality of sand under generalised loading. Acta Geotech. 2020, 16, 1699–1734. [Google Scholar] [CrossRef]

- Indraratna, B.; Korkitsuntornsan, W.; Nguyen, T. Influence of Kaolin content on the cyclic loading response of railway subgrade. Transp. Geotech. 2020, 22, 100319. [Google Scholar] [CrossRef]

- Shen, S.; Wu, H.; Cui, Y.; Yin, Z. Long-term settlement behaviour of metro tunnels in the soft deposits of Shanghai. Tunn. Undergr. Space Technol. 2014, 40, 309–323. [Google Scholar] [CrossRef]

- Zhu, M.; Gong, X.; Gao, X.; Liu, S.; Yan, J. Remediation of Damaged Shield Tunnel Using Grouting Technique: Serviceability Improvements and Prevention of Potential Risks. J. Perform. Constr. Facil. 2019, 33, 4019062. [Google Scholar] [CrossRef]

- Liu, Z.; Xue, J.; Yaghoubi, M. The effects of unloading on undrained deformation of a kaolin clay under cyclic loading. Soil Dyn. Earthq. Eng. 2020, 140, 106434. [Google Scholar] [CrossRef]

- Liu, Z.; Xue, J.; Mei, G. The impact of stress disturbance on undrained cyclic behaviour of a kaolin clay and settlement of tunnels under cyclic loading. Acta Geotech. 2021, 16, 3947–3961. [Google Scholar] [CrossRef]

- Ding, Z.; Zhang, T.; Wei, X.; Zhang, M. Experimental study on the cyclic loading of metro trains. Chin. Earthq. Eng. J. 2015, 37, 789–793. [Google Scholar]

- Gong, Q.; Xu, Y.; Zhou, S. Dynamic response analysis of tunnel foundation by vehicle vibration in metro. Chin. Railw. Sci. 2005, 26, 47–51. [Google Scholar]

- Seed, H.; Idriss, I.; Arango, I. Evaluation of Liquefaction Potential Using Field Performance Data. J. Geotech. Eng. 1983, 109, 458–482. [Google Scholar] [CrossRef]

| w/% | ρd/g/cm3 | ρ/g/cm3 | Gs | e | wL/% | wP/% | IP |

|---|---|---|---|---|---|---|---|

| 28.91 | 1.49 | 1.94 | 2.69 | 0.79 | 31.3 | 24.70 | 6.74 |

| Particle Size | Silt | Kaolin Clay |

|---|---|---|

| Fine sand (0.25–0.075 mm) (%) | 2.48 | 0 |

| Silt (0.075–0.005 mm) (%) | 90.54 | 49.80 |

| Clay (<0.005 mm) (%) | 6.98 | 50.20 |

| Number | Fine Particle Content/% | Effective Axial Stress Paths/kPa | Drainage Conditions (Cyclic Tests) |

|---|---|---|---|

| AU/AD-1 | 7 | 100 | Undrained/Drained |

| AU/AD-1 | 8 | 100 | Undrained/Drained |

| AU/AD-1 | 10 | 100 | Undrained/Drained |

| AU/AD-1 | 12 | 100 | Undrained/Drained |

| AU/AD-1 | 14 | 100 | Undrained/Drained |

| BU-1 | 8 | 100→90→80→70→60 | Undrained |

| BU-2 | 8 | 100→80→60 | Undrained |

| BU-3 | 8 | 100→60 | Undrained |

| CU-1 | 8 | 100→90→80→70→60→100 | Undrained |

| CU-2 | 8 | 100→80→60→100 | Undrained |

| CU-3 | 8 | 100→60→100 | Undrained |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, F.; Xia, C.; Zhu, M.; Tong, Z.; Lu, C. Dynamic Characteristics of Reconstituted Silt Influenced by Axial Unloading Intensity and Fine Particle Content. Appl. Sci. 2022, 12, 7222. https://doi.org/10.3390/app12147222

Meng F, Xia C, Zhu M, Tong Z, Lu C. Dynamic Characteristics of Reconstituted Silt Influenced by Axial Unloading Intensity and Fine Particle Content. Applied Sciences. 2022; 12(14):7222. https://doi.org/10.3390/app12147222

Chicago/Turabian StyleMeng, Fanli, Changqing Xia, Min Zhu, Zhijun Tong, and Chengyuan Lu. 2022. "Dynamic Characteristics of Reconstituted Silt Influenced by Axial Unloading Intensity and Fine Particle Content" Applied Sciences 12, no. 14: 7222. https://doi.org/10.3390/app12147222

APA StyleMeng, F., Xia, C., Zhu, M., Tong, Z., & Lu, C. (2022). Dynamic Characteristics of Reconstituted Silt Influenced by Axial Unloading Intensity and Fine Particle Content. Applied Sciences, 12(14), 7222. https://doi.org/10.3390/app12147222