Effect of Considering Wave Angles on the Motion Response of Oversized Floating Bodies in Offshore Airports under Irregular Wind and Wave Loads

Abstract

:1. Introduction

2. Materials and Methods

2.1. Wind and Wave Field Characteristic Parameters

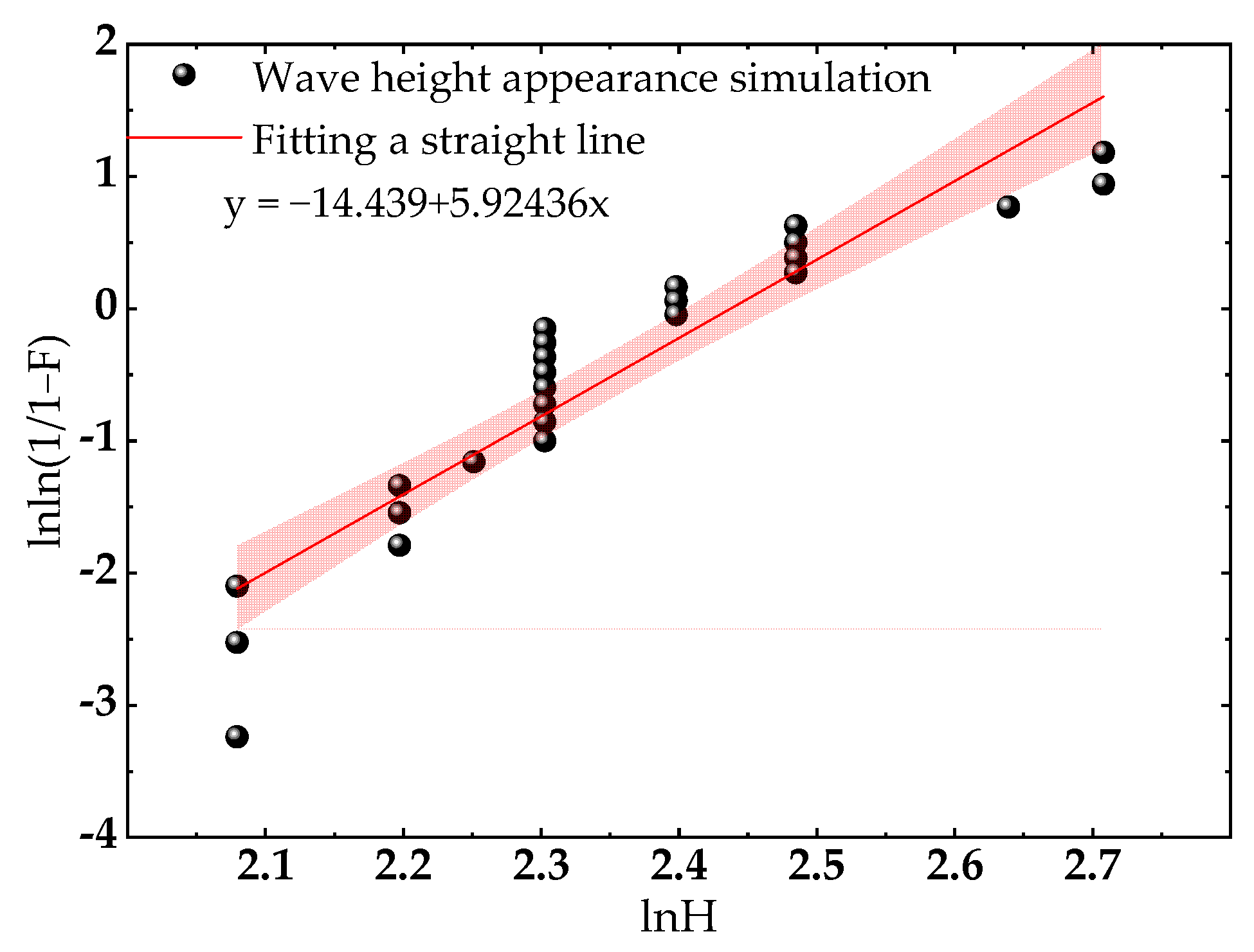

2.1.1. Non-Operational Sea State

2.1.2. Random Wind and Waves

2.2. Numerical Simulation

2.2.1. Control Equations

2.2.2. Model Parameters

2.2.3. Mesh Division

2.2.4. Power Characteristics Analysis

3. Results

3.1. Single Module Strength Analysis of Offshore Airports

3.2. Single Module Motion Response Analysis of Offshore Airports

3.2.1. Hydrodynamic Response

3.2.2. Vertical Displacement

4. Discussion

- The location where the column is connected to the upper and lower pontoons, and the location where the lower cross brace is connected to the lower pontoon have large stresses. Therefore, it is necessary to design to increase the strength of the structure at these locations to ensure the safety of the floating airport.

- The dynamic response of the offshore airport under wind and wave fields shows significant nonlinearity; for both regular and irregular waves, vertical shock is dominant. The difference between the two pendulum response curves is large. The hydroelastic response of floating bodies under irregular wave conditions is more sensitive to the wave direction angle than that of regular waves; when the wave direction angle is 90°, the stabilization trend of the droop response is not obvious. The difference in the hydroelastic response of the offshore airport along the length of the floating body varies less under different wave angles. The stress concentration in the floating body at 50 m in the direction of incoming waves is triangularly distributed and extremely unfavorable. At wave angles of 22.5, 67.5, and 86.25°, the floating body shows a large stress, and at an angle of ±3.75° the stress symmetrically decreases in distribution. For this reason, the strength of the suspension line can be strengthened in the design and the rotation angle can be reasonably set to adapt to the influence of different wave angles on the sea airport.

- The total vertical displacement amplitude of the marine airport cannot be regarded as a simple superposition of the vertical displacement amplitude of the rigid body and the elastic deformation amplitude, because the two often cannot reach the maximum value at the same time.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Weng, Z.P. Research and Development Direction of Green Ultra-large Floating Structures. In Proceedings of the 2010 Academic Conference of China Steel Structure Association Marine Steel Structure Branch and the Third Meeting of the Sixth Council, Luoyang, China, 8–10 September 2010. [Google Scholar]

- Daokun, L. Structural Design of Offshore Floating Airports; China University of Petroleum (East China): Shandong, China, 2016. [Google Scholar]

- Yonggang, S.; Jianqun, S.; Fei, G.; Shixiao, F.; Gang, Z. Characterization of multi-segment beam model for ultra-large floating bodiesof T. J. PLA Univ. Echnology 2015, 16, 456–464. [Google Scholar]

- Mansheng, H. Plate Model Analysis of Hydroelastic Response of Very Large Floating Structures. Master’s Thesis, Ocean University of China, Qingdao, China, 2005. [Google Scholar]

- Hu, J. Analysis of Beam-Slab Model for Hydro-Elastic Response of Super-Large Floating Body Structure. Master’s Thesis, Hohai University, Nanjing, China, 2007. [Google Scholar]

- Paulling, J.R.; Tyagi, S. Multi-module floating ocean structures. Mar. Struct. 1993, 6, 187–205. [Google Scholar] [CrossRef]

- Wu, Y.; Du, S. Fluid-structure interaction analysis of very large floating structures. Ship Sci. Technol. 1995, 1, 1–9. (In Chinese) [Google Scholar]

- Bishop, R.E.D.; Price, W.G. Hydroelasticity of Ships; Cambridge University Press: Cambridge, UK, 1979. [Google Scholar]

- Kashiwagi, M. Research on hydroelastic responses of VLFS: Recentprogress and future work. Int. J. Shore Po-Lar Eng. 2000, 10, 1053–5381. [Google Scholar]

- Watanabe, E.; Utsunomiya, T.; Wang, C.M. Hydroelastic analysis ofpontoon-type VLFS: A literature survey. Eng. Struct. 2004, 26, 245–256. [Google Scholar] [CrossRef]

- Heller, S.R. Hydroelasticity, Advances in Hydrody-Namics; Academic Press: New York, NY, USA, 1964. [Google Scholar]

- Yousheng, W. Hydroelasticity of Floating Bodies; University of Brunel: London, UK, 1984. [Google Scholar]

- Watanabe, E.; Utsunomiya, T.; Wang, C.M. Benchmark hydroelastic responses of a circular VLFS under wave action. Eng. Struct. 2006, 28, 423–430. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhai, G.; Ou, J. Time-domain numerical and experimental analysis of hydroelastic response of a very large floating structure edged with a pair of submerged horizontal plates. Mar. Struct. 2014, 39, 198–224. [Google Scholar] [CrossRef]

- Cheng, Y.; Ji, C.; Zhai, G.; Oleg, G. Fully nonlinear numerical investigation on hydroelastic responses of floating elastic plate over variable depth sea-bottom. Mar. Struct. 2017, 55, 37–61. [Google Scholar] [CrossRef]

- Ding, J.; Tian, C.; Wu, Y.S.; Wang, X.F.; Liu, X.L.; Zhang, K. A simplified method to estimate the hydroelastic responses of VLFS in the inhomogeneous waves. Ocean. Eng. 2019, 172, 434–445. [Google Scholar] [CrossRef]

- Xu, D.-L.; Lu, C.; Zhang, H. Mechanical modeling and nonlinear dynamic response characteristics of offshore floating airports. J. Mech. 2015, 47, 289–300. [Google Scholar]

- Feng, Y.; Weibing, F.; Haijin, C. Analysis of wave spatial and temporal characteristics in the South China Sea based on ERA-Interim data for the past 37 years. Ocean. Forecast. 2018, 35, 44–51. [Google Scholar]

- Mei, Y.; Song, S.; Zhou, L. Interannual variability of wave and wind fields in the North Indian Ocean-South China Sea. Ocean. Forecast. 2010, 27, 27–33. [Google Scholar]

- Sun, Z.; Tian, C.; Ding, J. Hydroelastic response analysis of an oversized floating body on an island reef under wind and wave environment. Ship Mech. 2020, 24, 1024–1035. [Google Scholar]

- Bo, Z.; Qianqing, C.; Chunhui, Z. Study on the dynamic characteristics of multi-module MOB connectors. Ship Sci. Technol. 2017, 39, 77–81+87. [Google Scholar]

- Hongxian, L.; Yanmao, C.; Qixian, L. Analysis of hydrodynamic response of multi-floating offshore platform. Ship Sci. Technol. 2017, 39, 75–78. [Google Scholar]

| Conditions | Wind Speed | Wind Height | Wind Period |

|---|---|---|---|

| Operating sea conditions | 11.4 m/s | 6.4 m | 7.4 s |

| Rule Waves | 11.4 m/s | 3 m | 10 s |

| irregular waves | 40 m/s | 6 m | 10 s |

| Parameters | Unit | Numerical |

|---|---|---|

| Module length | m | 300 |

| Module Width | m | 100 |

| Module Height | m | 27 |

| Module depth in the water | m | 14 |

| Column height | m | 16 |

| Column diameter | m | 18 |

| Drainage capacity | t | 852,136 |

| Transverse moment of inertia | kg/m2 | 2.37 × 1012 |

| Longitudinal moment of inertia | kg/m2 | 1.62 × 1013 |

| Vertical moment of inertia | kg/m2 | 1.81 × 1013 |

| Module density | kg/m3 | 327.3 |

| Elastic modulus | pa | 2.1 × 1011 |

| Mass | kg | 9.3614 × 107 |

| Centre of Gravity | m, m, m | [0.0,0.0,4.0] |

| Poisson factor | 0.3 |

| Parameters | Unit | Numerical |

|---|---|---|

| Sink length | m | 800 |

| Sink width | m | 200 |

| Sink height | m | 100 |

| Mass per unit length of suspension chain line | kg/m | 400 |

| Stiffness of suspension chain line | N/m | 3 × 106 |

| Relaxation length of suspension chain line | m | 270 |

| Vibration Type | Steps | Rate/Hz |

| 7 | 0.017 |

| 8 | 0.046 |

| 9 | 0.091 |

| 10 | 0.148 |

| 11 | 0.182 |

| 13 | 0.275 |

| 16 | 0.491 |

| 18 | 0.835 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Ke, S.; Li, W.; Chen, J. Effect of Considering Wave Angles on the Motion Response of Oversized Floating Bodies in Offshore Airports under Irregular Wind and Wave Loads. Appl. Sci. 2022, 12, 7651. https://doi.org/10.3390/app12157651

Wang L, Ke S, Li W, Chen J. Effect of Considering Wave Angles on the Motion Response of Oversized Floating Bodies in Offshore Airports under Irregular Wind and Wave Loads. Applied Sciences. 2022; 12(15):7651. https://doi.org/10.3390/app12157651

Chicago/Turabian StyleWang, Lijun, Shitang Ke, Wenjie Li, and Jing Chen. 2022. "Effect of Considering Wave Angles on the Motion Response of Oversized Floating Bodies in Offshore Airports under Irregular Wind and Wave Loads" Applied Sciences 12, no. 15: 7651. https://doi.org/10.3390/app12157651