Compressive-Strength Analysis of High-Strength Cementitious Composites Mixed with Red and Green Pigments

Abstract

:1. Introduction

2. Experimental Design and Methodology

2.1. Specimens

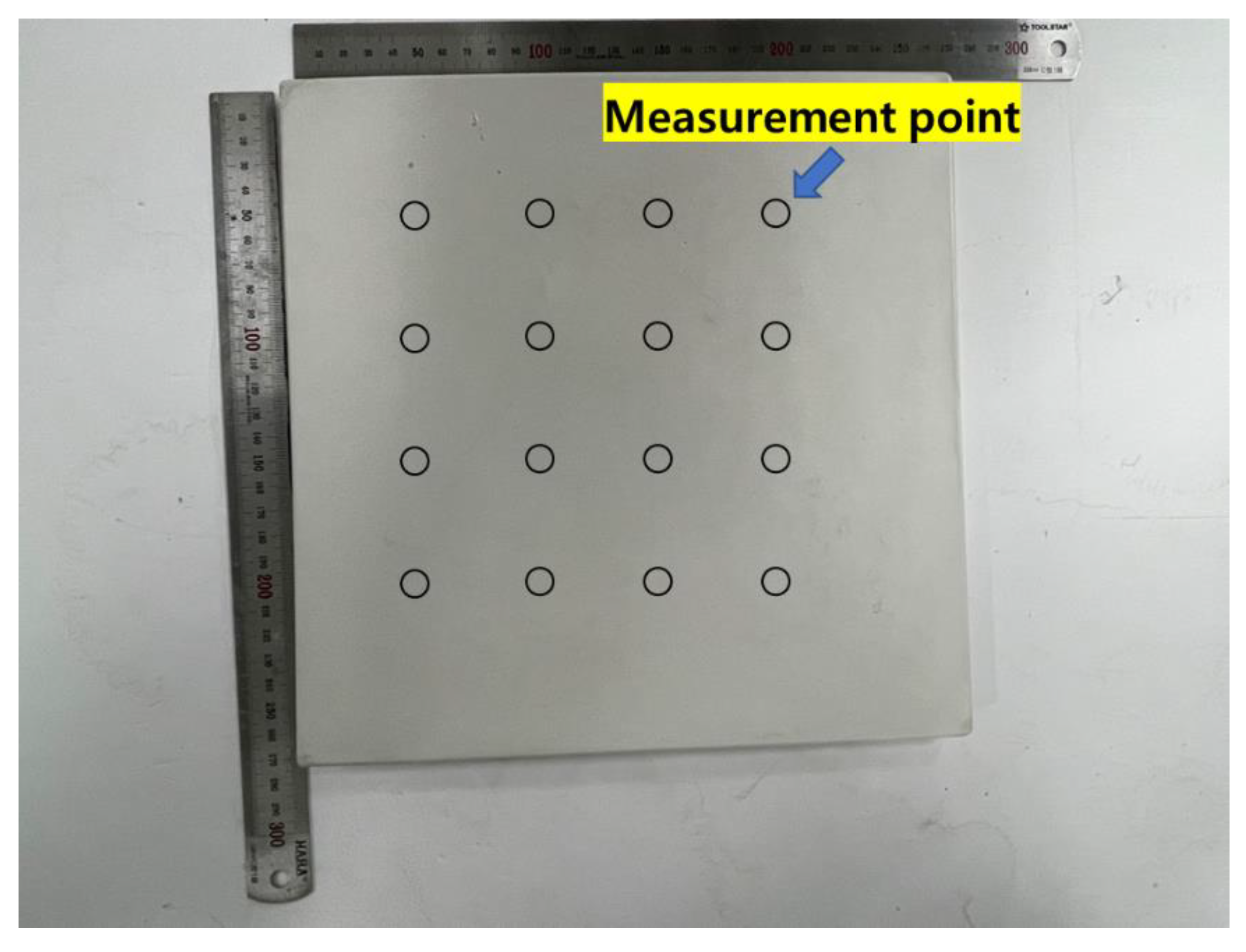

2.2. Test Methodology

3. Results and Discussion

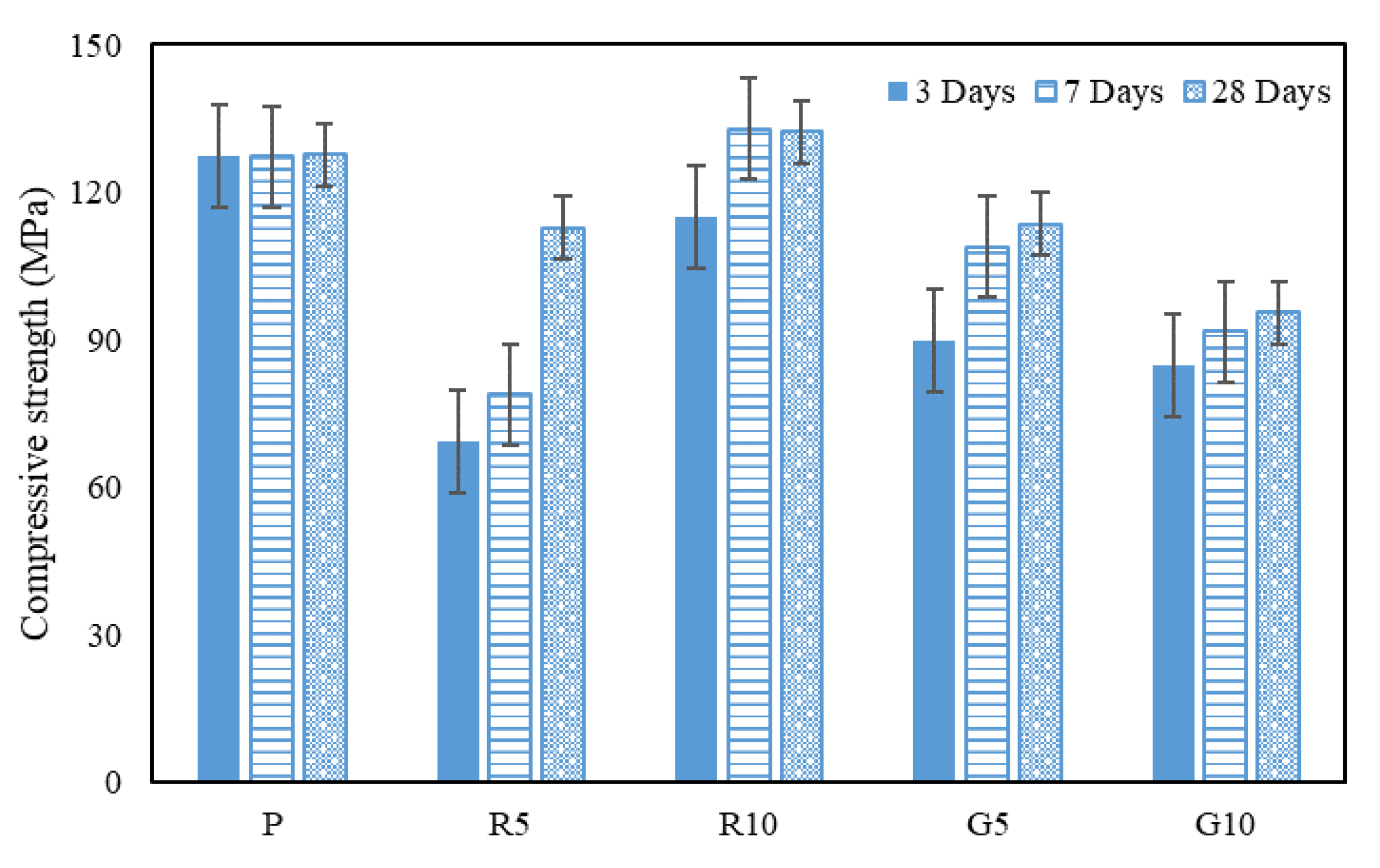

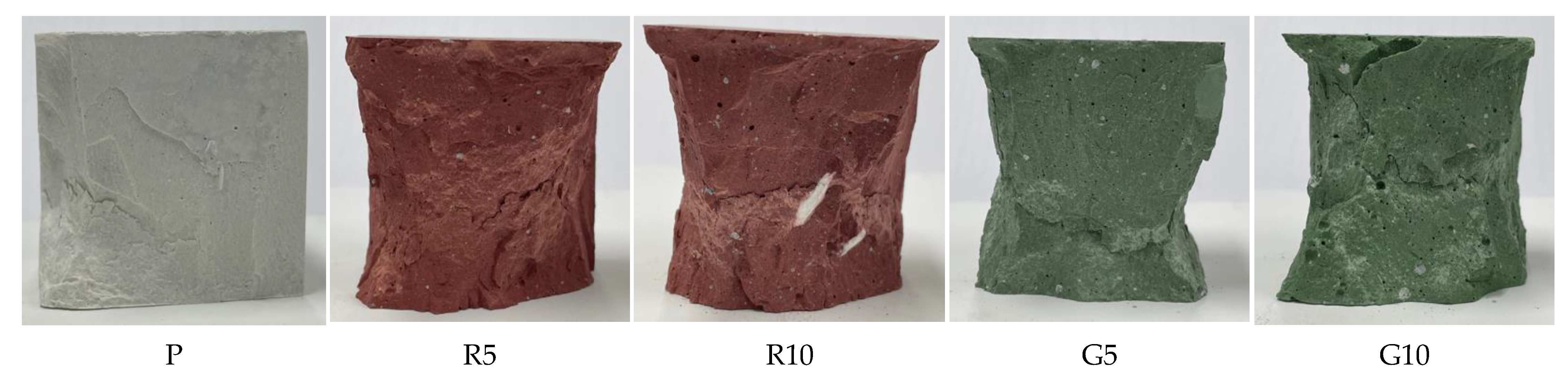

3.1. Compressive Strength

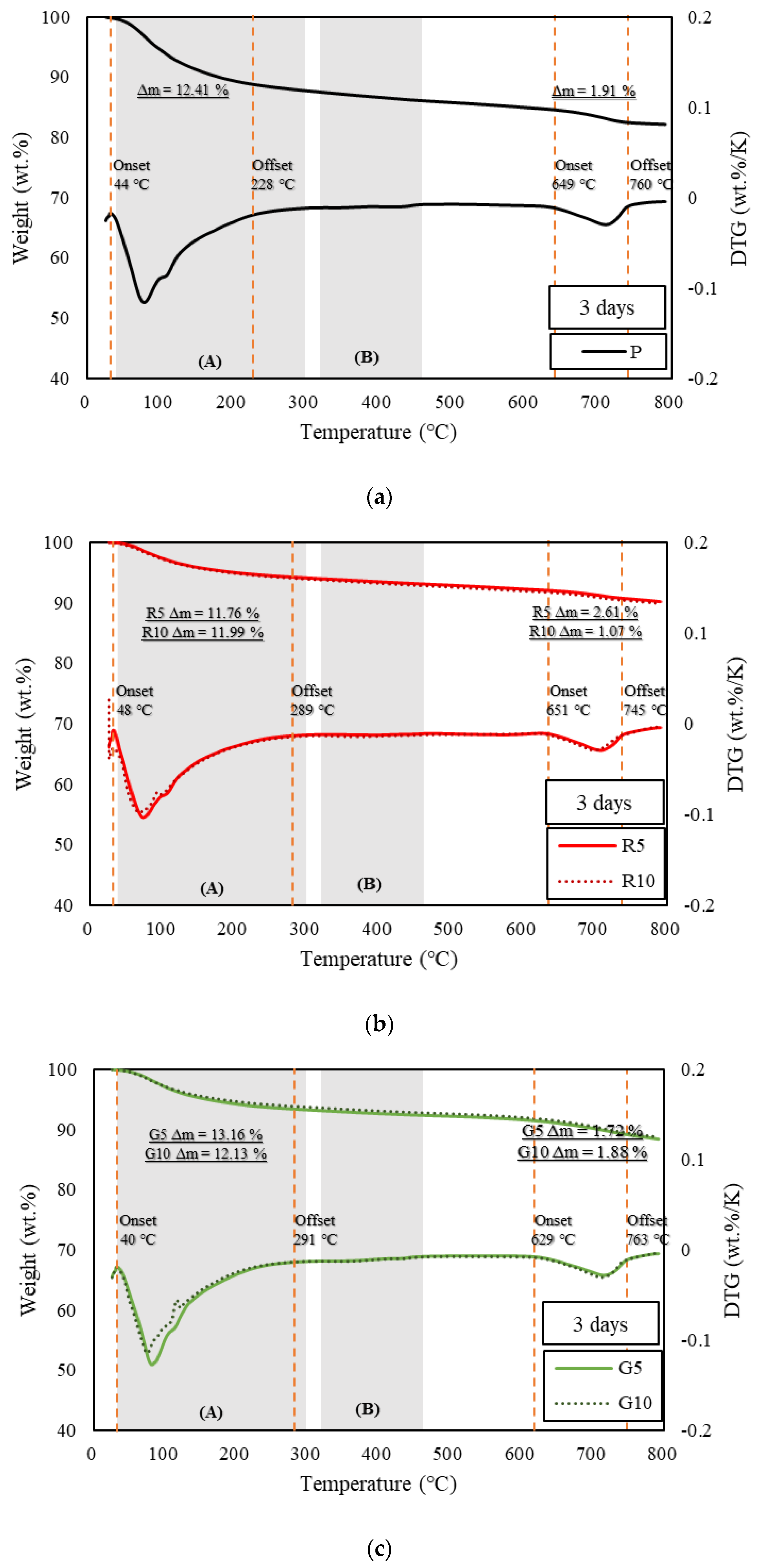

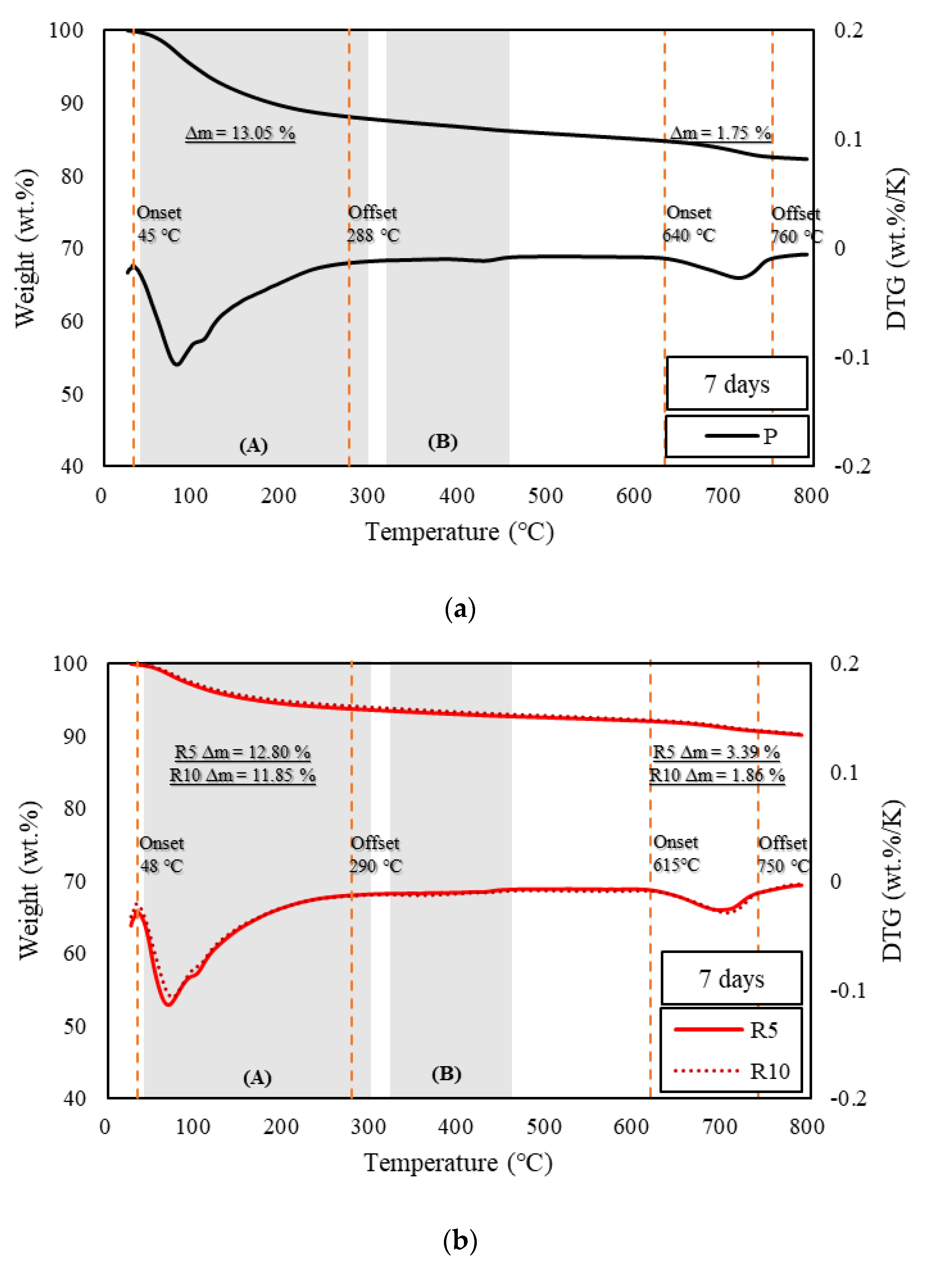

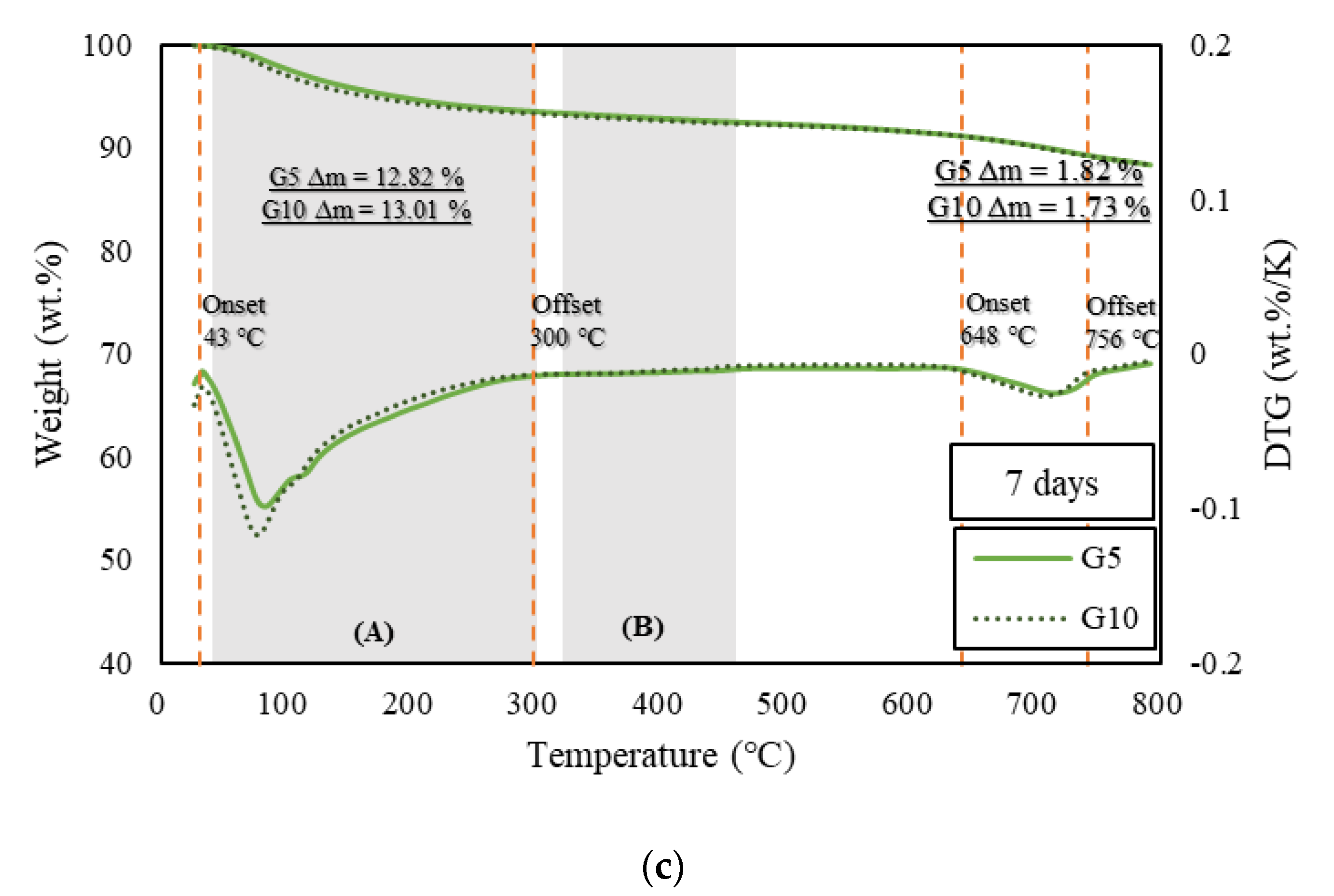

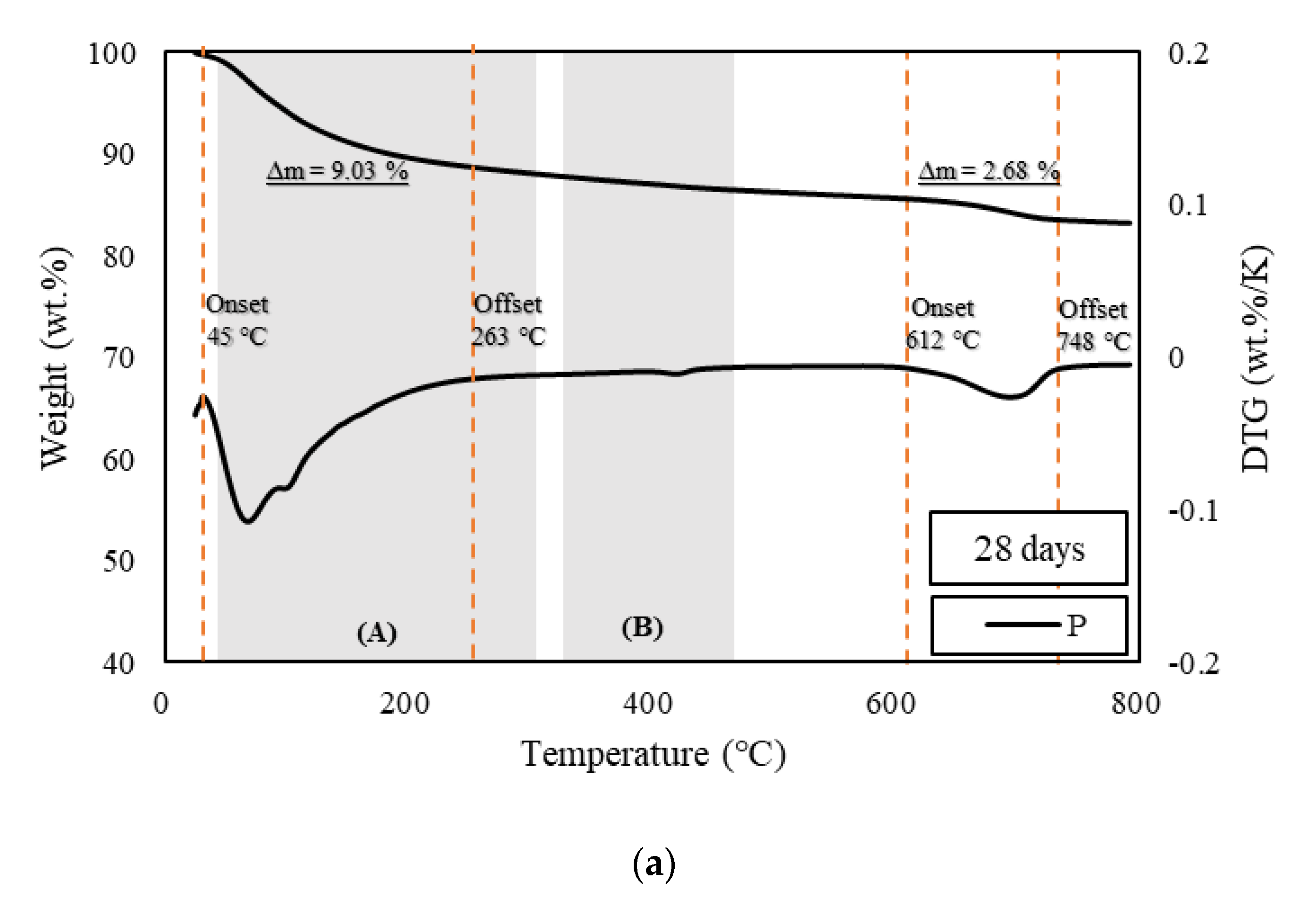

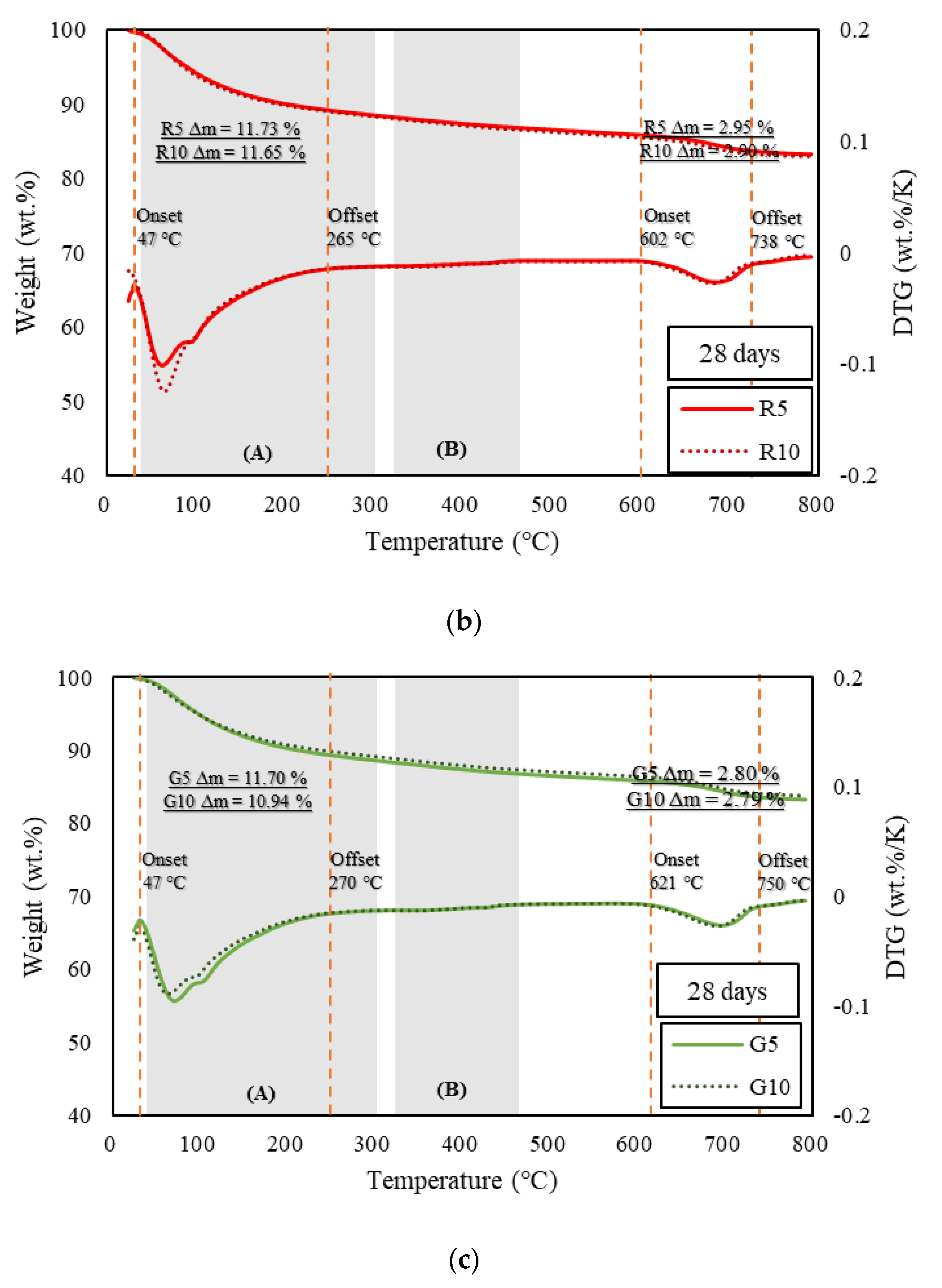

3.2. Thermogravimetry

3.3. Analysis and Verification of Hydration Dynamics via TGA

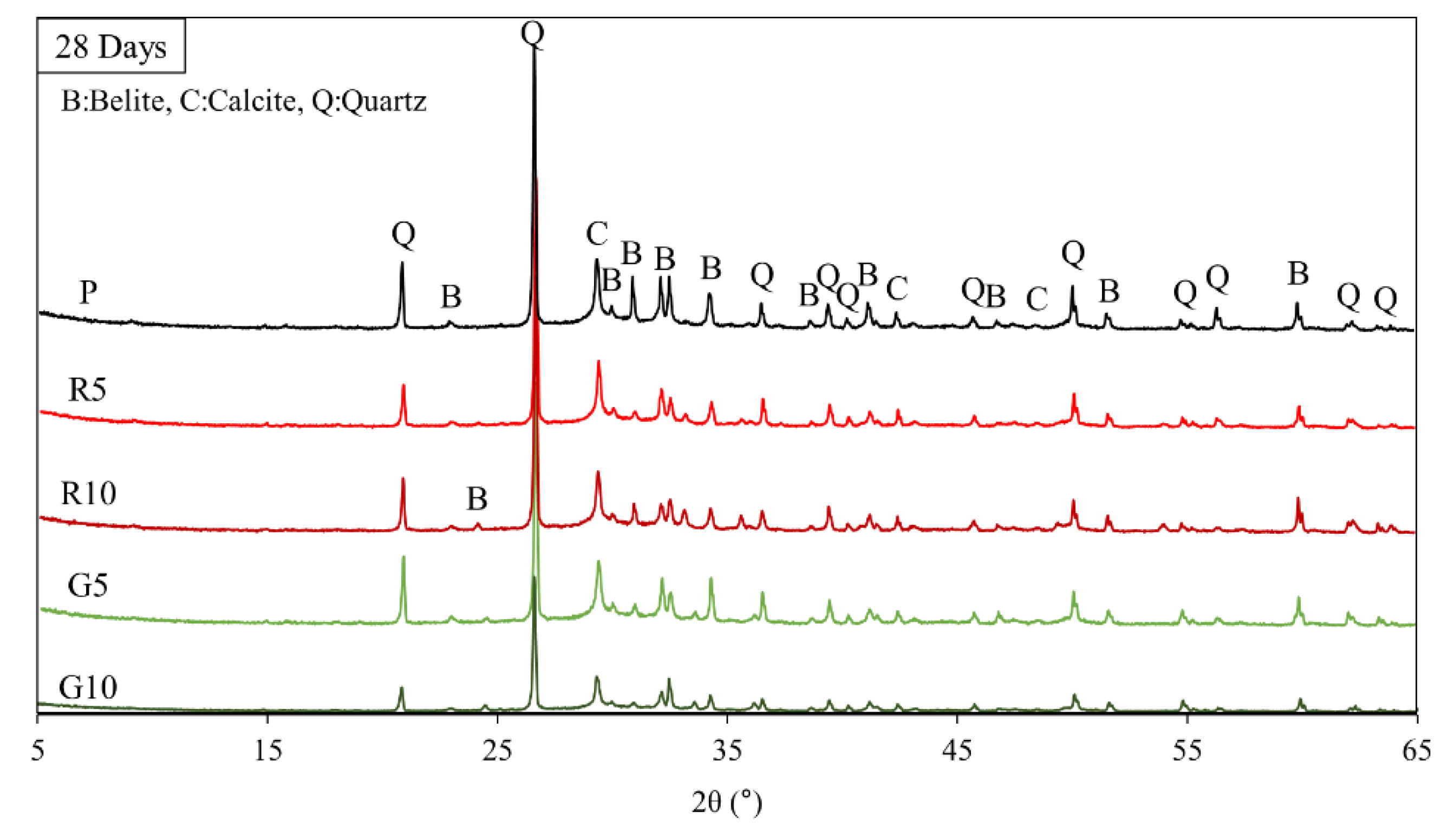

3.4. XRD Analysis

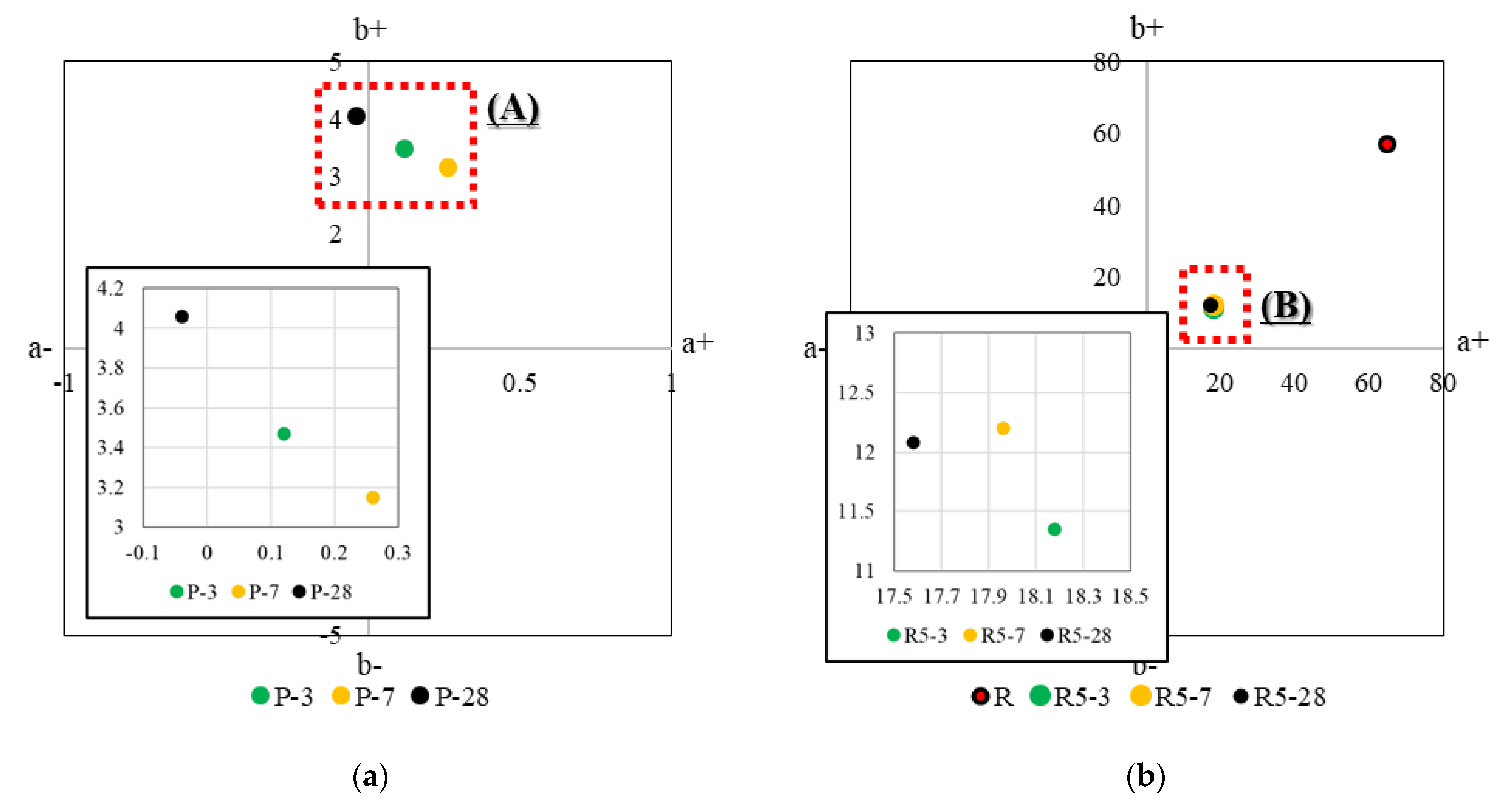

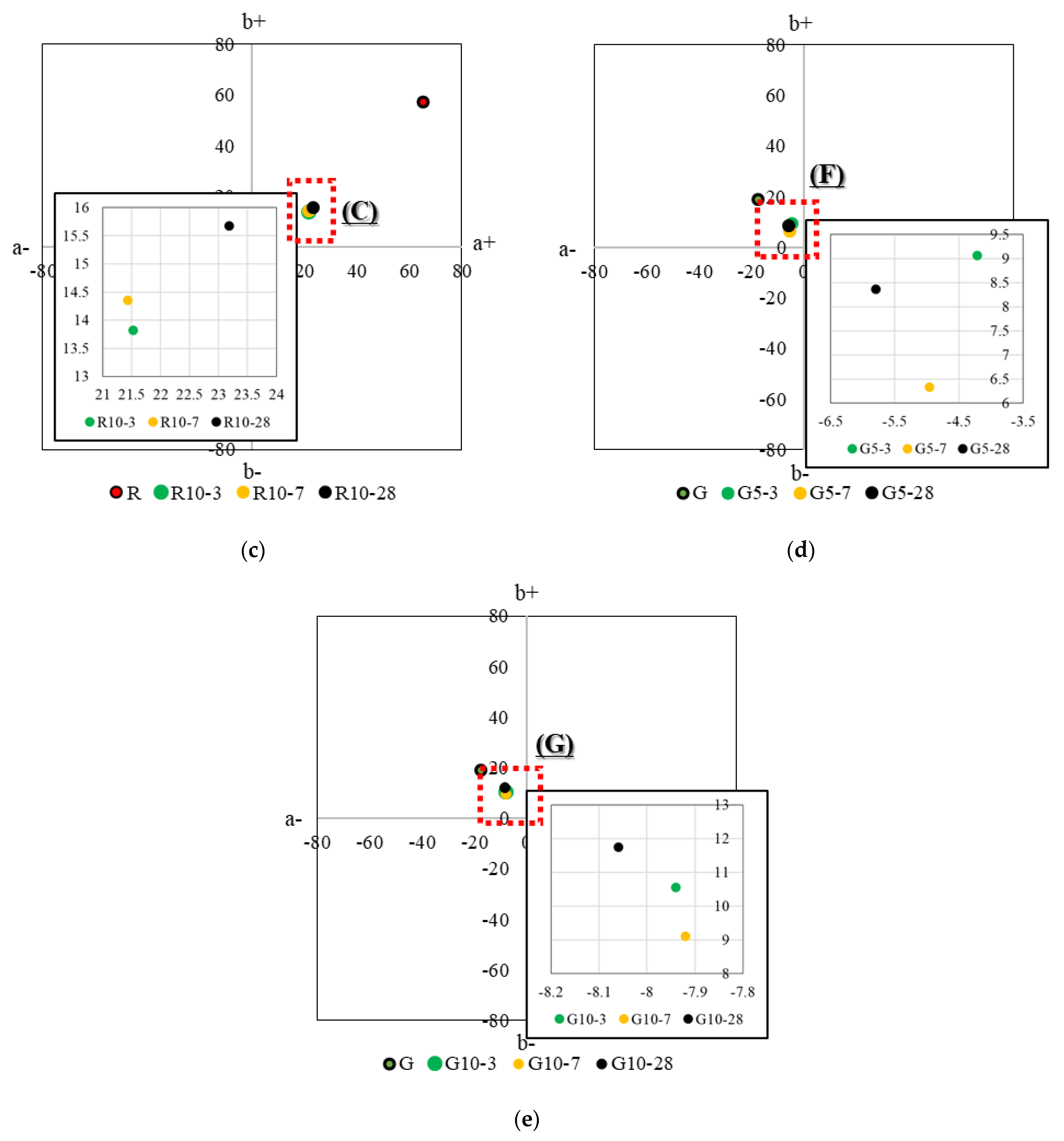

3.5. CIELAB Analysis

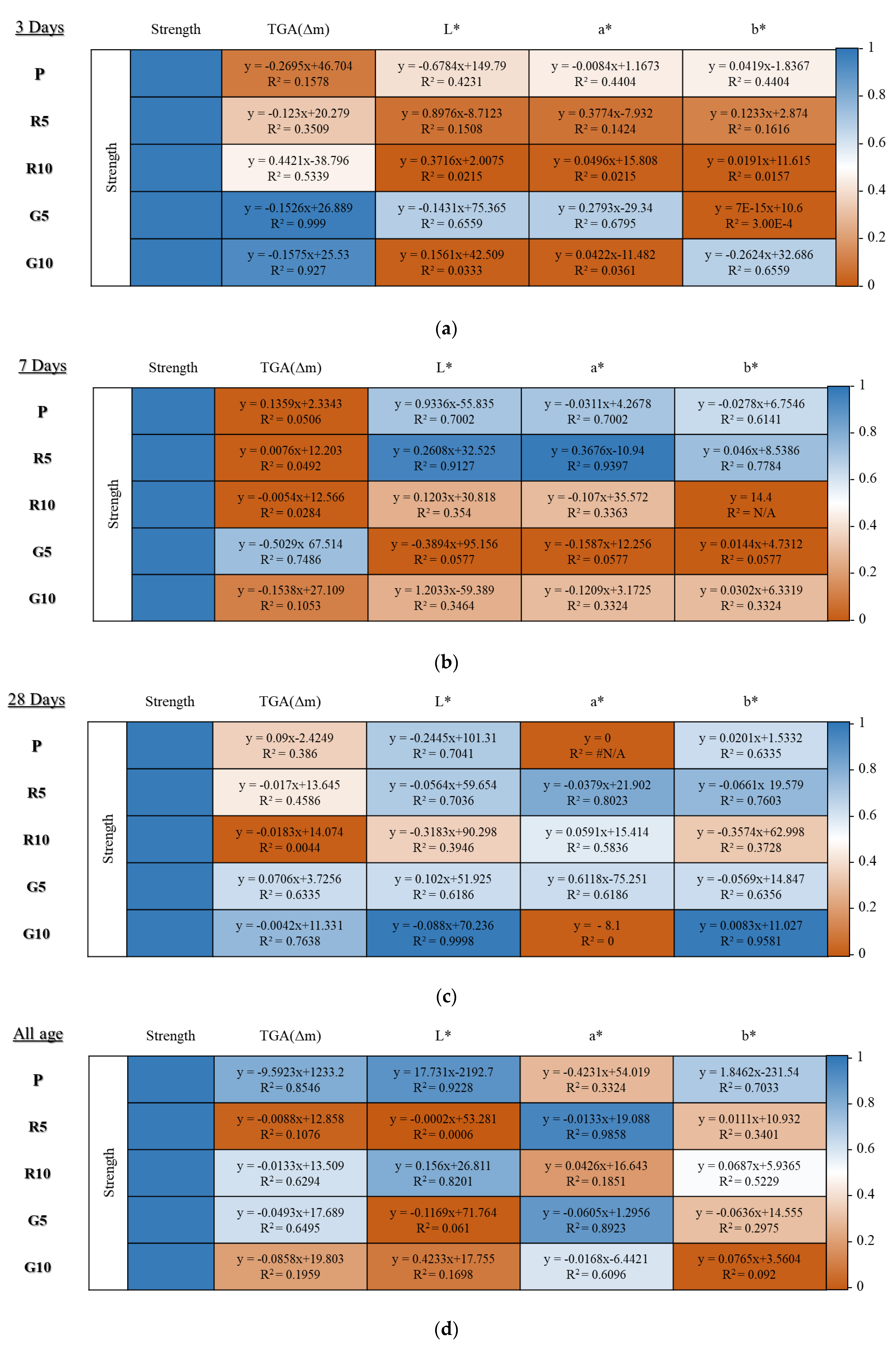

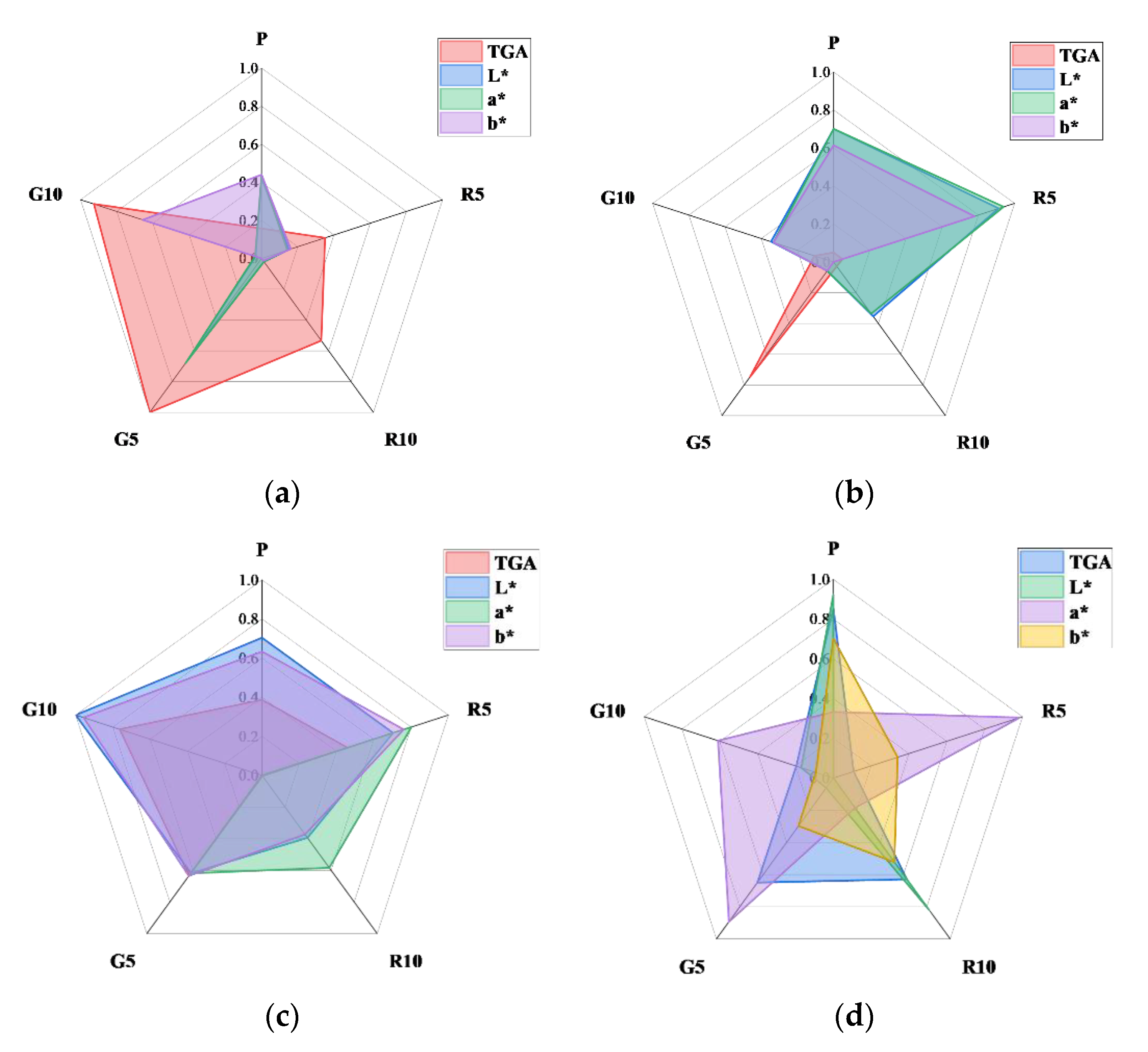

3.6. Coefficient of Determination Analysis of Strength with TGA and Color Difference

4. Conclusions

- The initial strengths of the specimens mixed with pigments were lower than those of the specimens without a pigment in a steam-curing environment. However, the strength development accelerated with specimen age. The highest strength development was observed in the specimens mixed with 10% red pigment. Specimens containing the red pigment exhibited higher strengths than specimen P (without pigments) because of the presence of nano-Fe2O3 particles in the former. This result shows the pore-filling effect of nano-Fe2O3 particles.

- Because of the high internal density of HSCCs, the specimens mixed with pigments, except for R10, exhibited a lower shrinkage rate than specimen P. After the steam-curing process, the shrinkage of specimen R10 increased to 0.55% because of the accelerated internal hydration caused by the higher Fe2O3 content in the red pigment compared to that of the R5 specimen.

- The results of the differential thermal analysis using the stepwise method revealed that most of the hydration was completed during the initial steam-curing process. Specimen G10 exhibited the highest combustion rate at approximately 300 °C because residual hydrates (Afm) were generated by the initial hydration delay. Furthermore, the hydration characteristics of the specimens that completed the steam-curing process were determined by calculating the residual mass (Δm) of calcium hydroxide.

- In the analysis of the chromaticity and color difference of the specimens, the red-pigmented samples exhibited differences in chromaticity with increasing age, regardless of the pigment content, and the color difference exhibited a similar trend. For the green-pigmented specimens, the chromaticity remained constant with increasing pigment content, irrespective of the specimen age, but the color difference was considerable when the pigment content was approximately 5%.

- The correlation of strength with the thermogravimetry, shrinkage, and color analysis results of C-UHSCC at different ages was analyzed, and R2 tended to increase as the total TGA (Δm) decreased. This was because strength developed at the initial stages of aging. The correlation between the TGA intensity (Δm) and color components tended to increase with age. From the R2 analysis at all ages, we observed the following. The lower the mixing rate, the higher the correlation between the intensity and L* in the R series. Furthermore, the higher the mixing rate, the higher the correlation between intensity and a*. The G series exhibited a high correlation with a* regardless of the incorporation rate.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Seo, S.G.; Yeon, G.W.; Jeon, C.G.; Kim, J.; Kim, J.B. Fundamental study on the engineering properties of colored concrete. J. Archit. Inst. Korea-Struct. Syst. 2009, 25, 107–114. [Google Scholar]

- Hatami, L.; Jamshidi, M. Influence of pigment content and cement type on appearance and performance of colored self-compacting mortars (C-SCMs). Int. J. Civ. Eng. 2017, 15, 727–736. [Google Scholar] [CrossRef]

- Oh, Y.H.; Lim, O.Y. Influence of inorganic pigments on physical properties and chromaticity of color concretes. J. Kor. Soc. Color Stud. 2014, 28, 133–142. [Google Scholar] [CrossRef]

- Lee, S.R.; Kim, J.S. The effects of coloring admixture on the material properties of color. Concrete 2000, 10, 157–168. [Google Scholar]

- Lee, H.-S.; Lee, J.-Y.; Yu, M.-Y. Influence of iron oxide pigments on the properties of concrete interlocking blocks. Cem. Concr. Res. 2003, 33, 1889–1896. [Google Scholar] [CrossRef]

- Kim, T.C.; Kim, J.; Jeon, C.G.; Yeon, G.W.; Shin, D.A.; Ryu, H.G. The study on the fundamental properties of the colored concrete according to the kinds of coloring agents and the variation of their admixture ratio. J. Reg. Assoc. Architect. Inst. Kor. 2010, 1, 509–512. [Google Scholar] [CrossRef] [Green Version]

- Jung, G.-H.; Im, N.-K.; Jung, J.-Y.; Jung, S.-J. Manufacturing and construction method of precast concrete. J. Kor. Inst. Build. Constr. 2002, 2, 67–74. [Google Scholar]

- Zurita Ares, M.C.; Villa González, E.; Torres Gómez, A.I.; Fernández, J.M. An easy method to estimate the concentration of mineral pigments in colored mortars. Dyes. Pig. 2014, 101, 29–337. [Google Scholar] [CrossRef]

- López, A.; Tobes, J.M.; Giaccio, G.; Zerbino, R. Advantages of mortar-based design for coloured self-compacting concrete. Cem. Concr. Compos. 2009, 31, 754–761. [Google Scholar] [CrossRef]

- Park, J.H.; Kim, J.B.; Jeong, Y. An experimental study on properties of color concrete with types and addition ratio of pigment. In Proceedings of the Korea Concrete Institute Conference, Korea Concrete Institute, Seoul, Korea, 16–19 October 2018; pp. 673–676. [Google Scholar]

- Chalangaran, N.; Farzampour, A.; Paslar, N. Nano silica and metakaolin effects on the behavior of concrete containing rubber crumbs. CivilEng 2020, 1, 264–274. [Google Scholar] [CrossRef]

- Mansouri, I.; Shahheidari, F.S.; Hashemi, S.M.A.; Farzampour, A. Investigation of steel fiber effects on concrete abrasion resistance. Adv. Concr. Constr. 2020, 9, 367–374. [Google Scholar] [CrossRef]

- Zhang, J.; Yu, R.; Shui, Z.; Liu, K. Hydration kinetics and microstructure development of ultra-high performance concrete (UHPC) subjected to microwave pre-curing. Cem. Concr. Compos. 2022, 129, 104484. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Silani, M.; Weinberg, K. Fracture studies of ultra-high performance concrete using dynamic Brazilian tests. Theor. Appl. Fract. Mech. 2018, 93, 302–310. [Google Scholar] [CrossRef]

- Kazemian, M.; Shafei, B. Internal curing capabilities of natural zeolite to improve the hydration of ultra-high performance concrete. Constr. Build. Mater. 2022, 340, 127452. [Google Scholar] [CrossRef]

- Chen, Q.; Ma, R.; Li, H.; Jiang, Z.; Zhu, H.; Yan, Z. Effect of chloride attack on the bonded concrete system repaired by UHPC. Constr. Build. Mater. 2021, 272, 121971. [Google Scholar] [CrossRef]

- Gopinath, S.; Mouli, P.C.; Murthy, A.R.; Iyer, N.R.; Maheswaran, S. Effect of nano silica on mechanical properties and durability of normal strength concrete. Arch. Civ. Eng. 2012, 58, 433–444. [Google Scholar] [CrossRef]

- Schmidt, M.; Amrhein, K.; Braun, T.; Glotzbach, C.; Kamaruddin, S.; Tänzer, R. Nanotechnological improvement of structural materials–Impact on material performance and structural design. Cem. Concr. Compos. 2013, 36, 3–7. [Google Scholar] [CrossRef]

- Nazari, A.; Riahi, S. Computer-aided design of the effects of Fe2O3 nanoparticles on split tensile strength and water permeability of high strength concrete. Mater. Des. 2011, 32, 3966–3979. [Google Scholar] [CrossRef]

- Uysal, M. The use of waste maroon marble powder and iron oxide pigment in the production of coloured self-compacting concrete. Adv. Civ. Eng. 2018, 2018, 8093576. [Google Scholar] [CrossRef] [Green Version]

- Alcantara, P.S.X.; Nóbrega, A.C. Colored concrete interlocking blocks with addition of red ceramic waste for iron oxide pigments reduction. Proc. Constr. Sustain. Mater. Technol. Nocmat. 2015, 2015, 1–11. [Google Scholar]

- Lee, H.-S.; Lee, J.-Y.; Yu, M.-Y. Influence of inorganic pigments on the fluidity of cement mortars. Cem. Concr. Res. 2005, 35, 703–710. [Google Scholar] [CrossRef]

- Anwar, A.; Mohammed, B.S.; Wahab, M.A.; Liew, M.S. Enhanced properties of cementitious composite tailored with graphene oxide nanomaterial—A review. Dev. Built Environ. 2020, 1, 100002. [Google Scholar] [CrossRef]

- C109/C109M-16a; Standard Test Method for Compressive Strength Hydraulic Cement Mortars (Using 2-in, Or [50-mm] Cube Specimens). ASTM: West Conshohocken, PA, USA, 2021.

- Yoon, H.N.; Seo, J.; Kim, S.; Lee, H.K.; Park, S. Hydration of calcium sulfoaluminate cement blended with blast-furnace slag. Constr. Build. Mater. 2021, 268, 121214. [Google Scholar] [CrossRef]

- Seo, J.; Kim, S.; Park, S.; Yoon, H.N.; Lee, H.K. Carbonation of calcium sulfoaluminate cement blended with blast furnace slag. Cem. Concr. Compos. 2021, 118, 103918. [Google Scholar] [CrossRef]

- Park, S.; Jeong, Y.; Moon, J.; Lee, N. Hydration characteristics of calcium sulfoaluminate (CSA) cement/Portland cement blended pastes. J. Build. Eng. 2021, 34, 101880. [Google Scholar] [CrossRef]

- Park, S.M.; Jang, J.G.; Lee, N.K.; Lee, H.K. Physicochemical properties of binder gel in alkali-activated fly ash/slag exposed to high temperatures. Cem. Concr. Res. 2016, 89, 72–79. [Google Scholar] [CrossRef]

- Nurse, R.W. Steam curing of concrete. Mag. Concr. Res. 1949, 1, 79–88. [Google Scholar] [CrossRef]

- Du, J.; Meng, W.; Khayat, K.H.; Bao, Y.; Guo, P.; Lyu, Z.; Abu-obeidah, A.; Nassif, H.; Wang, H. New development of ultra-high-performance concrete (UHPC). Compos. B Eng. 2021, 224, 109220. [Google Scholar] [CrossRef]

- Baoju, L.; Youjun, X.; Shiqiong, Z.; Jian, L. Some factors affecting early compressive strength of steam-curing concrete with ultrafine fly ash. Cem. Concr. Res. 2001, 31, 1455–1458. [Google Scholar] [CrossRef]

- Liu, B.; Jiang, J.; Shen, S.; Zhou, F.; Shi, J.; He, Z. Effects of curing methods of concrete after steam curing on mechanical strength and permeability. Constr. Build. Mater. 2020, 256, 119441. [Google Scholar] [CrossRef]

- Zeyad, A.M.; Tayeh, B.A.; Adesina, A.; de Azevedo, A.R.; Amin, M.; Hadzima-Nyarko, M.; Agwa, I.S. Review on effect of steam curing on behavior of concrete. Clean. Mater. 2022, 3, 100042. [Google Scholar] [CrossRef]

- Farzampour, A. Temperature and humidity effects on behavior of grouts. Adv. Concr. Constr. 2017, 5, 659. [Google Scholar] [CrossRef]

- Nazari, A.; Riahi, S.; Riahi, S.; Shamekhi, S.F.; Khademno, A. Benefits of Fe2O3 nanoparticles in concrete mixing matrix. J. Am. Sci. 2010, 6, 102–106. [Google Scholar]

- Khoshakhlagh, A.; Nazari, A.; Khalaj, G. Effects of Fe2O3 nanoparticles on water permeability and strength assessments of high strength self-compacting concrete. J. Mater. Sci. Technol. 2012, 28, 73–82. [Google Scholar] [CrossRef]

- Seo, J.H.; Park, S.M.; Lee, H.K. Evolution of the binder gel in carbonation-cured Portland cement in an acidic medium. Cem. Concr. Res. 2018, 109, 81–89. [Google Scholar] [CrossRef]

- Wang, D.; Shi, C.; Wu, Z.; Xiao, J.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part II. Hydration, microstructure and properties. Constr. Build. Mater. 2015, 96, 368–377. [Google Scholar] [CrossRef]

- Shi, Z.; Geiker, M.R.; Lothenbach, B.; De Weerdt, K.; Garzón, S.F.; Enemark-Rasmussen, K.; Skibsted, J. Friedel’s salt profiles from thermogravimetric analysis and thermodynamic modelling of Portland cement-based mortars exposed to sodium chloride solution. Cem. Concr. Compos. 2017, 78, 73–83. [Google Scholar] [CrossRef]

- Song, K.; Lee, B.Y.; Hong, G.H.; Gong, M.H.; Song, J.G. Effects of basicity on the carbonation characteristics of alkali-activated slag mortar. J. Korea Concr. Inst. 2012, 24, 577–584. [Google Scholar] [CrossRef]

- Scrivener, K.; Snellings, R.; Lothenbach, B. A Practical Guide to Microstructural Analysis of Cementitious Materials; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Criado, Y.A.; Alonso, M.; Abanades, J.C. Kinetics of the CaO/Ca (OH)2 hydration/dehydration reaction for thermochemical energy storage applications. Ind. Eng. Chem. Res. 2014, 53, 12594–12601. [Google Scholar] [CrossRef] [Green Version]

- Mo, Z.; Gao, X.; Su, A. Mechanical performances and microstructures of metakaolin contained UHPC matrix under steam curing conditions. Constr. Build. Mater. 2021, 268, 121112. [Google Scholar] [CrossRef]

- Huang, W.; Kazemi-Kamyab, H.; Sun, W.; Scrivener, K. Effect of cement substitution by limestone on the hydration and microstructural development of ultra-high performance concrete (UHPC). Cem. Concr. Compos. 2017, 77, 86–101. [Google Scholar] [CrossRef]

- Kang, S.H.; Moon, J.H.; Hong, S.G. Effect of internal curing by super-absorbent polymer (SAP) on hydration, autogenous shrinkage, durability and mechanical characteristics of ultra-high performance concrete (UHPC). J. Korea Concr. Inst. 2016, 28, 317–328. [Google Scholar] [CrossRef] [Green Version]

- Lemaire, G.; Escadeillas, G.; Ringot, E. Evaluating concrete surfaces using an image analysis process. Constr. Build. Mater. 2005, 19, 604–611. [Google Scholar] [CrossRef]

- Schanda, J. Colorimetry: Understanding the CIE Systems; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Hirschler, R.; Zwinkels, J. Use of CIE colorimetry in the pulp, paper, and textile industries. In Colorimetry: Understanding the CIE System; Wiley: New York, NY, USA, 2007; pp. 427–428. [Google Scholar]

- Ford, A.; Roberts, A. Colour Space Conversions; Westminster University: London, UK, 1998; pp. 1–31. [Google Scholar]

- Stone, M. A Field Guide to Digital Color; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Lee, J.Y.; Go, S.S. Effect Analysis of Inorganic Pigment on the Colors of Colored Cement Mortars Applying CIE L*a*b* Color System. J. Archit. Inst. Korea Struct. Constr. 2003, 19, 125–132. [Google Scholar]

- Shao, L.; Rehman, A.U. Image demosaicing using content and colour-correlation analysis. Sig. Process. 2014, 103, 84–91. [Google Scholar] [CrossRef]

| Binder (wt. %) | CaO | SiO2 | Al2O3 | MgO | Na2O | K2O | SO3 | Fe2O3 | TiO2 |

| White cement | 66.79 | 16.14 | 4.40 | 2.47 | 0.08 | 1.18 | 3.23 | 3.83 | 0.34 |

| Silica fume | 0.02 | 99.0 | 0.30 | 0.01 | 0.05 | 0.02 | 0.05 | 0.05 | 0.06 |

| Silica powder | 0.05 | 99.0 | 0.30 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.06 |

| Pigment (wt. %) | Al | Ca | Ti | Cr | Fe | Co | Zn | As | Sb |

| Red | 0.00 | 0.03 | 0.00 | 0.00 | 26.40 | 0.00 | 0.01 | 0.02 | 0.05 |

| Green | 0.00 | 0.00 | 0.00 | 21.26 | 0.00 | 0.01 | 0.01 | 0.02 | 0.01 |

| Mixture ID. | Cement | Silica Fume | Silica Powder | Water | SP Admixture | Pigment |

|---|---|---|---|---|---|---|

| P | 1 | 0.23 | 0.33 | 0.26 | 0.04 | 0 |

| R5 | 0.05 | |||||

| R10 | 0.1 | |||||

| G5 | 0.05 | |||||

| G10 | 0.1 |

| ID | Curing Times (Days) | X | Y | Z | ΔX | ΔY | ΔZ | ΔE | L* | a* | b* | ΔL* | Δa* | Δb* |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P | 3 | 30.6 | 32.2 | 32.0 | 0.0 | 0.0 | 0.0 | 0.0 | 63.5 | 0.1 | 3.5 | 0.0 | 0.0 | 0.0 |

| 7 | 30.2 | 31.8 | 31.8 | −0.4 | −0.4 | −0.2 | 0.5 | 63.2 | 0.3 | 3.2 | −0.4 | 0.2 | −0.3 | |

| 28 | 38.7 | 40.8 | 40.3 | 8.1 | 8.6 | 8.3 | 6.6 | 70.0 | 0.0 | 4.1 | 6.5 | −0.2 | 0.6 | |

| R5 | 3 | 24.2 | 21.4 | 17.0 | −6.3 | −10.8 | −15.0 | 22.2 | 53.4 | 18.2 | 11.4 | −10.1 | 18.1 | 7.9 |

| 7 | 23.9 | 21.1 | 16.4 | −6.7 | −11.1 | −15.6 | 22.4 | 53.1 | 18.0 | 12.2 | −10.4 | 17.8 | 8.7 | |

| 28 | 26.0 | 23.2 | 18.2 | −4.6 | −9.0 | −13.8 | 21.1 | 53.3 | 17.6 | 12.1 | −8.3 | 17.5 | 8.6 | |

| R10 | 3 | 17.2 | 14.3 | 10.0 | −13.4 | −17.9 | −22.0 | 30.3 | 44.7 | 21.5 | 13.8 | −18.8 | 21.4 | 10.4 |

| 7 | 18.9 | 15.9 | 11.1 | −11.7 | −16.3 | −20.9 | 29.2 | 46.8 | 21.4 | 14.4 | −16.7 | 21.3 | 10.9 | |

| 28 | 20.5 | 17.0 | 11.5 | −10.1 | −15.2 | −20.5 | 30.3 | 48.2 | 23.2 | 15.7 | −15.3 | 23.1 | 12.2 | |

| G5 | 3 | 28.2 | 30.9 | 27.0 | −2.3 | −2.3 | −5.1 | 7.2 | 62.5 | −4.2 | 9.1 | −1.1 | −4.3 | 5.6 |

| 7 | 18.8 | 20.9 | 19.0 | −11.8 | −11.8 | −13.0 | 12.2 | 52.8 | −5.0 | 6.3 | −10.7 | −5.1 | 2.9 | |

| 28 | 29.4 | 32.6 | 29.0 | −1.2 | −1.2 | −3.0 | 7.7 | 63.5 | −5.8 | 8.4 | 0.3 | −5.9 | 4.9 | |

| G10 | 3 | 20.8 | 23.7 | 19.5 | −9.8 | −9.8 | −12.5 | 13.2 | 55.8 | −7.9 | 10.6 | −7.7 | −8.1 | 7.1 |

| 7 | 16.6 | 19.1 | 16.0 | −14.0 | −14.0 | −16.0 | 16.1 | 50.8 | −7.9 | 9.1 | −12.8 | −8.0 | 5.6 | |

| 28 | 26.6 | 30.2 | 24.6 | −4.0 | −4.0 | −7.4 | 11.8 | 61.8 | −8.1 | 11.8 | −1.7 | −8.2 | 8.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pyeon, S.; Kim, G.; Choe, G.; Park, N.; Jeong, D.; Choi, B.; Kim, M.; Nam, J. Compressive-Strength Analysis of High-Strength Cementitious Composites Mixed with Red and Green Pigments. Appl. Sci. 2022, 12, 7667. https://doi.org/10.3390/app12157667

Pyeon S, Kim G, Choe G, Park N, Jeong D, Choi B, Kim M, Nam J. Compressive-Strength Analysis of High-Strength Cementitious Composites Mixed with Red and Green Pigments. Applied Sciences. 2022; 12(15):7667. https://doi.org/10.3390/app12157667

Chicago/Turabian StylePyeon, Sujeong, Gyuyong Kim, Gyeongcheol Choe, Namgyu Park, Donggeun Jeong, Byungcheol Choi, Moonkyu Kim, and Jeongsoo Nam. 2022. "Compressive-Strength Analysis of High-Strength Cementitious Composites Mixed with Red and Green Pigments" Applied Sciences 12, no. 15: 7667. https://doi.org/10.3390/app12157667

APA StylePyeon, S., Kim, G., Choe, G., Park, N., Jeong, D., Choi, B., Kim, M., & Nam, J. (2022). Compressive-Strength Analysis of High-Strength Cementitious Composites Mixed with Red and Green Pigments. Applied Sciences, 12(15), 7667. https://doi.org/10.3390/app12157667