Self-Assembly at a Macroscale Using Aerodynamics

Abstract

:1. Introduction

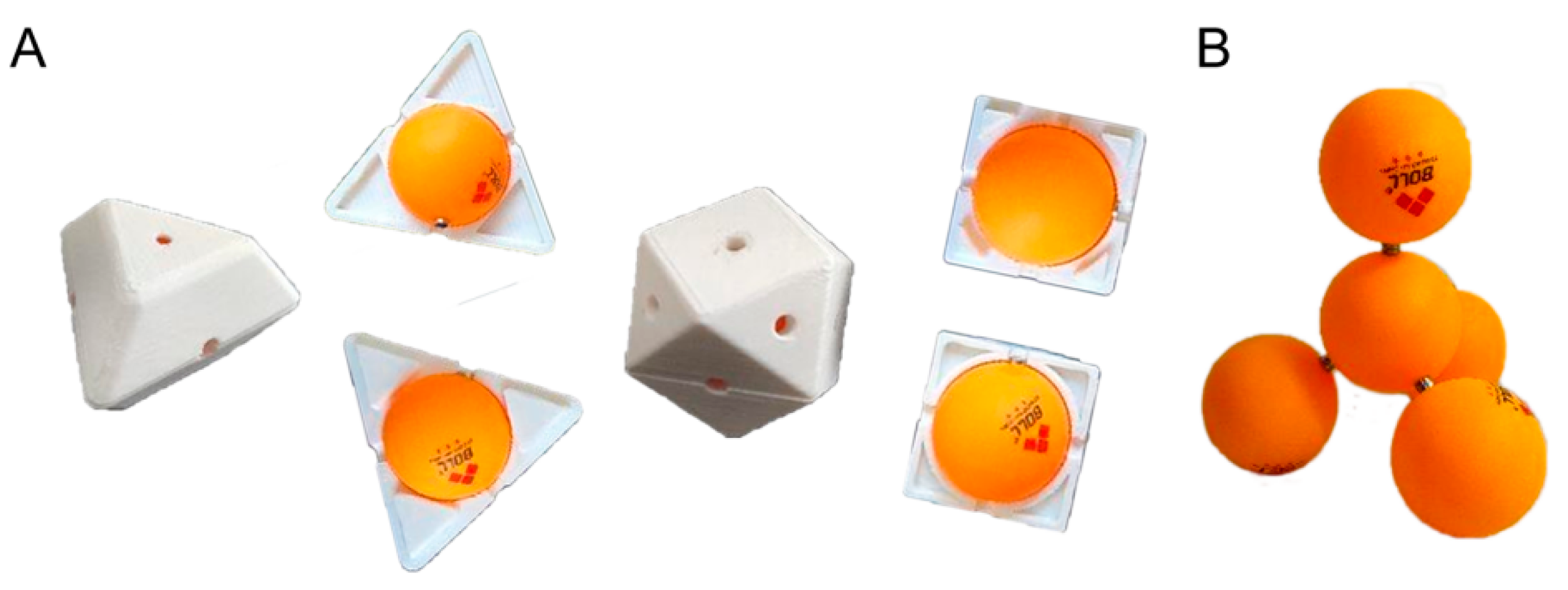

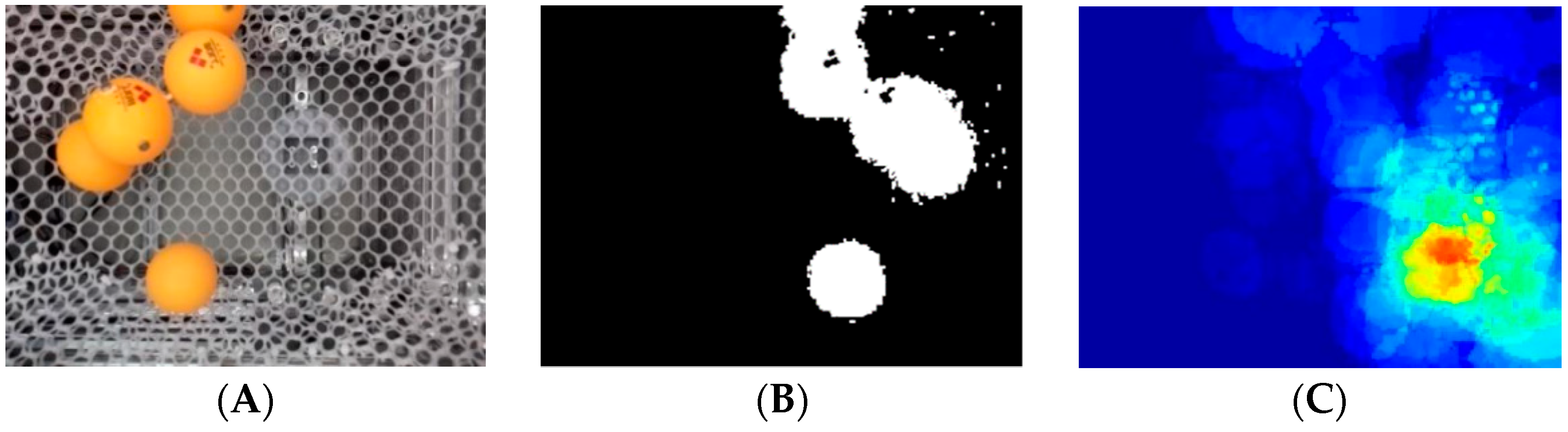

2. Design of the Self-Assemble Device

3. Experiments

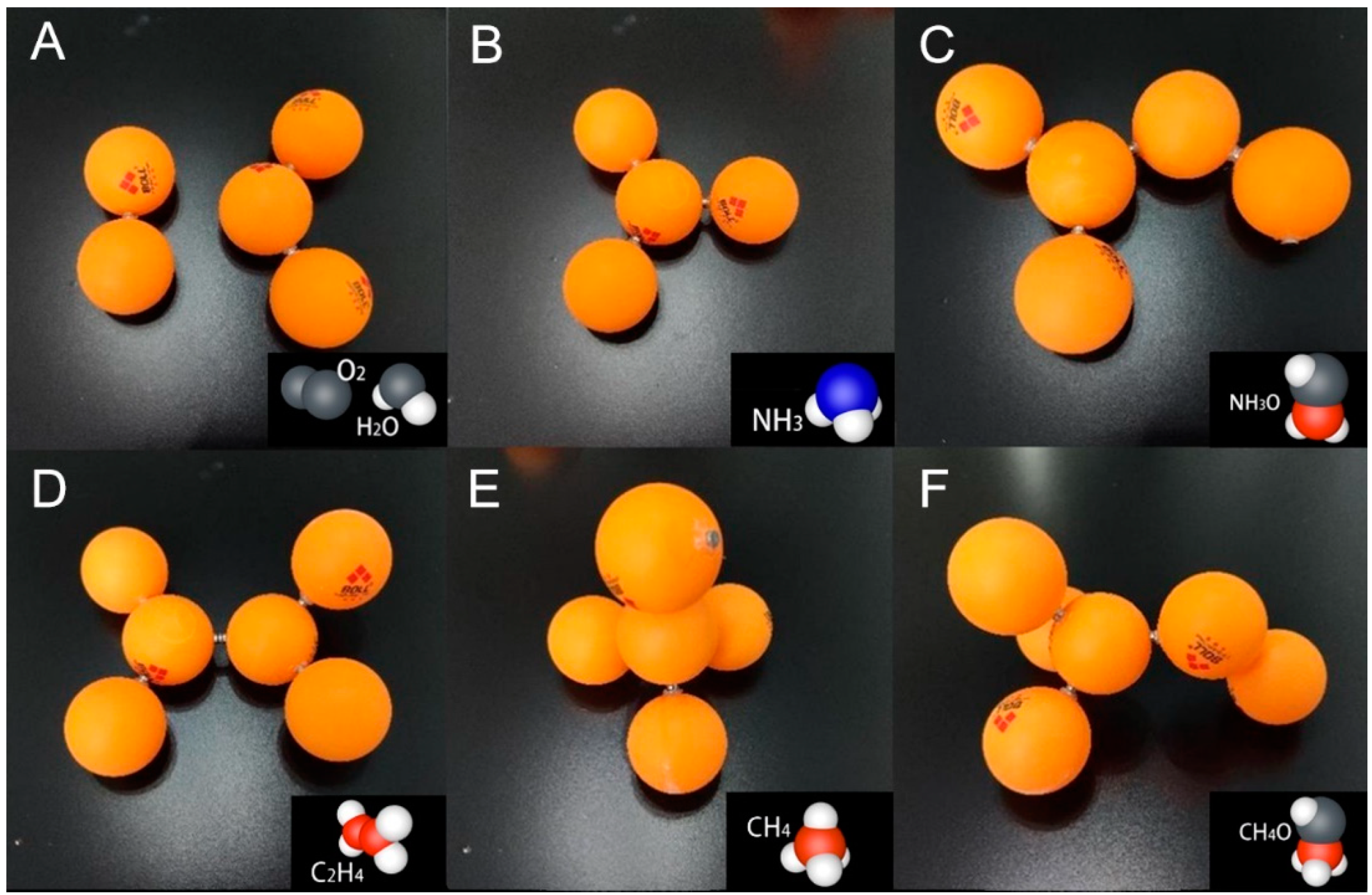

3.1. The Directed Assembly Experiment

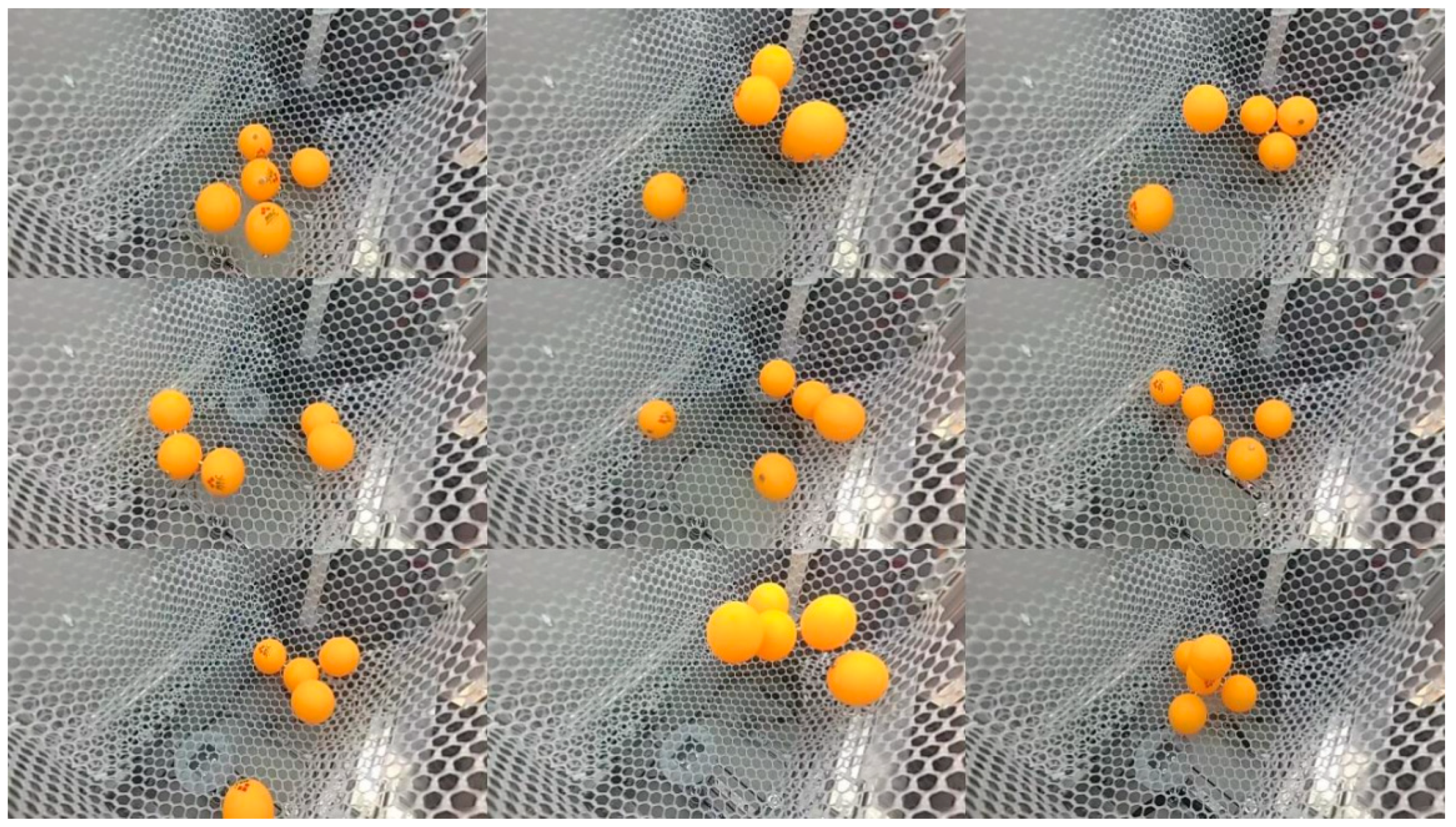

3.2. The Disordered Assembly Experiment

4. Results and Discussions

4.1. Results and Discussions of the Directed Assembly Experiment

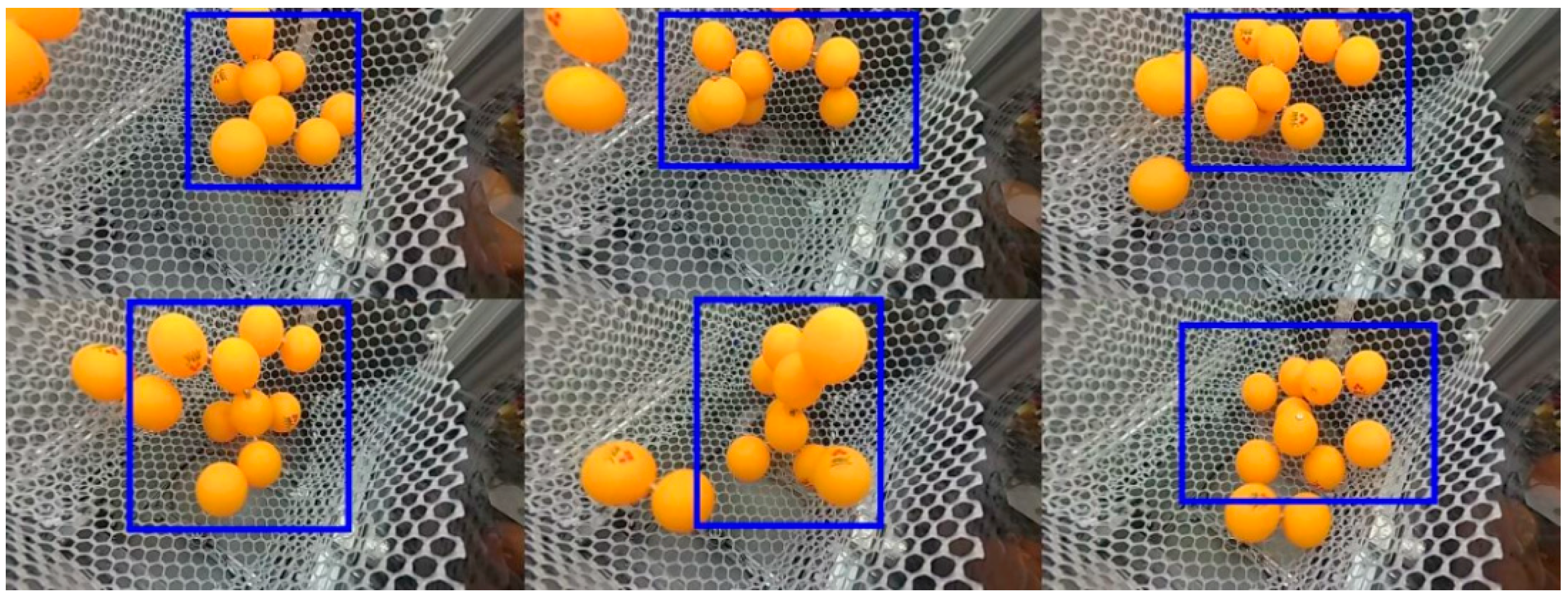

4.2. Results and Discussions of the Indirect Assembly Experiment

4.3. Other Results and Discussions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Grzybowski, B.A.; Wilmer, C.E.; Kim, J.; Browne, K.P.; Bishop, K.J. Self-assembly: From crystals to cells. Soft Matter. 2009, 5, 1110–1128. [Google Scholar] [CrossRef]

- Bowden, N.; Terfort, A.; Carbeck, J.; Whitesides, G.M. Self-assembly of mesoscale objects into ordered two-dimensional arrays. Science 1997, 276, 233–235. [Google Scholar] [CrossRef] [PubMed]

- Denkov, N.D.; Velev, O.D.; Kralchevsky, P.A.; Ivanov, I.B.; Yoshimura, H.; Nagayama, K. Two-dimensional crystallization. Nature 1993, 361, 26. [Google Scholar] [CrossRef]

- Furst, E.M. Directed self-assembly. Soft Matter 2013, 9, 9039–9045. [Google Scholar] [CrossRef]

- Trimmer, W.S. Microrobots and micromechanical systems. Sens. Actuators 1989, 19, 267–287. [Google Scholar] [CrossRef]

- Hu, Y.; Lao, Z.; Cumming, B.P.; Wu, D.; Li, J.; Liang, H.; Chu, J.; Huang, W.; Gu, M. Laser printing hierarchical structures with the aid of controlled capillary-driven self-assembly. Proc. Natl. Acad. Sci. USA 2015, 112, 6876–6881. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bhatt, K.H.; Grego, S.; Velev, O.D. An AC electrokinetic technique for collection and concentration of particles and cells on patterned electrodes. Langmuir 2005, 21, 6603–6612. [Google Scholar] [CrossRef] [PubMed]

- Neelakandan, P.P.; Pan, Z.; Hariharan, M.; Zheng, Y.; Weissman, H.; Rybtchinski, B.; Lewis, F.D. Hydrophobic Self-Assembly of a Perylenediimide-Linked DNA Dumbbell into Supramolecular Polymers. Am. Chem. Soc. 2010, 132, 15808–15813. [Google Scholar] [CrossRef]

- Wang, M.; He, L.; Yin, Y. Magnetic field guided colloidal assembly. Mater. Today 2013, 16, 110–116. [Google Scholar] [CrossRef]

- Destgeer, G.; Hashmi, A.; Park, J.; Ahmed, H.; Afzal, M.; Sung, H.J. Microparticle self-assembly induced by travelling surface acoustic waves. RSC Adv. 2019, 9, 7916–7921. [Google Scholar] [CrossRef] [Green Version]

- Radu, M.; Pfleiderer, P.; Schilling, T. Solid-solid phase transition in hard ellipsoids. J. Chem. Phys. 2009, 131, 164513. [Google Scholar] [CrossRef] [Green Version]

- Love, J.C.; Estroff, L.A.; Kriebel, J.K.; Nuzzo, R.G.; Whitesides, G.M. Self-assembled monolayers of thiolates on metals as a form of nanotechnology. Chem. Rev. 2005, 105, 1103–1170. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Glotzer, S.C. Self-assembly of patchy particles. Nano Lett. 2004, 4, 1407–1413. [Google Scholar] [CrossRef] [PubMed]

- Damasceno, P.F.; Engel, M.; Glotzer, S.C. Predictive self-assembly of polyhedra into complex structures. Science 2012, 337, 453–457. [Google Scholar] [CrossRef] [PubMed]

- Dong, B.; Zhou, T.; Zhang, H.; Li, C.Y. Directed self-assembly of nanoparticles for nanomotors. ACS Nano 2013, 7, 5192–5198. [Google Scholar] [CrossRef]

- Hynninen, A.-P.; Dijkstra, M. Phase behavior of dipolar hard and soft spheres. Phys. Rev. E 2005, 72, 051402. [Google Scholar] [CrossRef] [Green Version]

- Kahraman, C.; Tolga, E.; Ulukan, Z. Using triangular fuzzy numbers in the tests of control charts for unnatural patterns. In Proceedings of the 1995 INRIA/IEEE Symposium on Emerging Technologies and Factory Automation ETFA’95, Paris, France, 10–13 October 1995; pp. 291–298. [Google Scholar]

- Tibbits, S. Design to Self-Assembly. Archit. Des. 2012, 82, 68–73. [Google Scholar] [CrossRef]

- Rubenstein, M.; Cornejo, A.; Nagpal, R. Programmable self-assembly in a thousand-robot swarm. Science 2014, 345, 795–799. [Google Scholar] [CrossRef]

- Suzuki, R.; Yamaoka, J.; Leithinger, D.; Yeh, T.; Gross, M.D.; Kawahara, Y.; Kakehi, Y. Dynablock: Dynamic 3d printing for instant and reconstructable shape formation. In Proceedings of the 31st Annual ACM Symposium on User Interface Software and Technology, Berlin, Germany, 14–17 October 2018; pp. 99–111. [Google Scholar]

- Tibbits, S. From automated to autonomous assembly. Archit. Des. 2017, 87, 6–15. [Google Scholar] [CrossRef]

- Tibbits, S. Autonomous Assembly: Designing for a New Era of Collective Construction; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Falvello, A.; Tibbits, S. Biomolecular, Chiral and Irregular Self-Assemblies. In Proceedings of the Association for Computer Aided Design in Architecture 2013: Adaptive Architecture, Cambridge, ON, Canada, 24–26 October 2013. [Google Scholar]

- Tibbits, S. The Self-Assembly Line. In Proceedings of the 32nd Annual Conference of the Association for Computer Aided Design in Architecture (ACADIA), ACADIA 12: Synthetic Digital Ecologies, San Francisco, CA, USA, 18–21 October 2012; pp. 365–372, ISBN 978-1-62407-267-3. Available online: http://papers.cumincad.org/cgi-bin/works/Show?acadia12_365 (accessed on 22 April 2021).

- Papadopoulou, A.; Laucks, J.; Tibbits, S. From Self-Assembly to Evolutionary Structures. Archit. Des. 2017, 87, 28–37. [Google Scholar] [CrossRef]

- Bearman, P.W.; Harvey, J.K. Golf ball aerodynamics. Aeronaut. Q. 1976, 27, 112–122. [Google Scholar] [CrossRef]

- Batchelor, C.K.; Batchelor, G.K. An Introduction to Fluid Dynamics; Cambridge University Press: Cambridge, UK, 2000. [Google Scholar]

| Environmental Variables | Changing Airspeed with a Moving Shutter (s) | Constant Airspeed with a Moving Shutter (s) | Changing Airspeed with a Stationary Shutter (s) | |

|---|---|---|---|---|

| Number of Sub-Balls | ||||

| 4 | 72 | 82 | 98 | |

| 5 | 59 | >150 | 125 | |

| 6 | 53 | >150 | 91 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Chen, Y.; Jiang, X.; Ni, Q.; Liu, C.; Shang, F.; Xia, Q.; Zhang, S. Self-Assembly at a Macroscale Using Aerodynamics. Appl. Sci. 2022, 12, 7676. https://doi.org/10.3390/app12157676

Liu Y, Chen Y, Jiang X, Ni Q, Liu C, Shang F, Xia Q, Zhang S. Self-Assembly at a Macroscale Using Aerodynamics. Applied Sciences. 2022; 12(15):7676. https://doi.org/10.3390/app12157676

Chicago/Turabian StyleLiu, Yi, Yuting Chen, Xiaowu Jiang, Qianying Ni, Chen Liu, Fangfang Shang, Qingchao Xia, and Sheng Zhang. 2022. "Self-Assembly at a Macroscale Using Aerodynamics" Applied Sciences 12, no. 15: 7676. https://doi.org/10.3390/app12157676