CO2 Distribution under CO2 Enrichment Using Computational Fluid Dynamics Considering Photosynthesis in a Tomato Greenhouse

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Set-Up

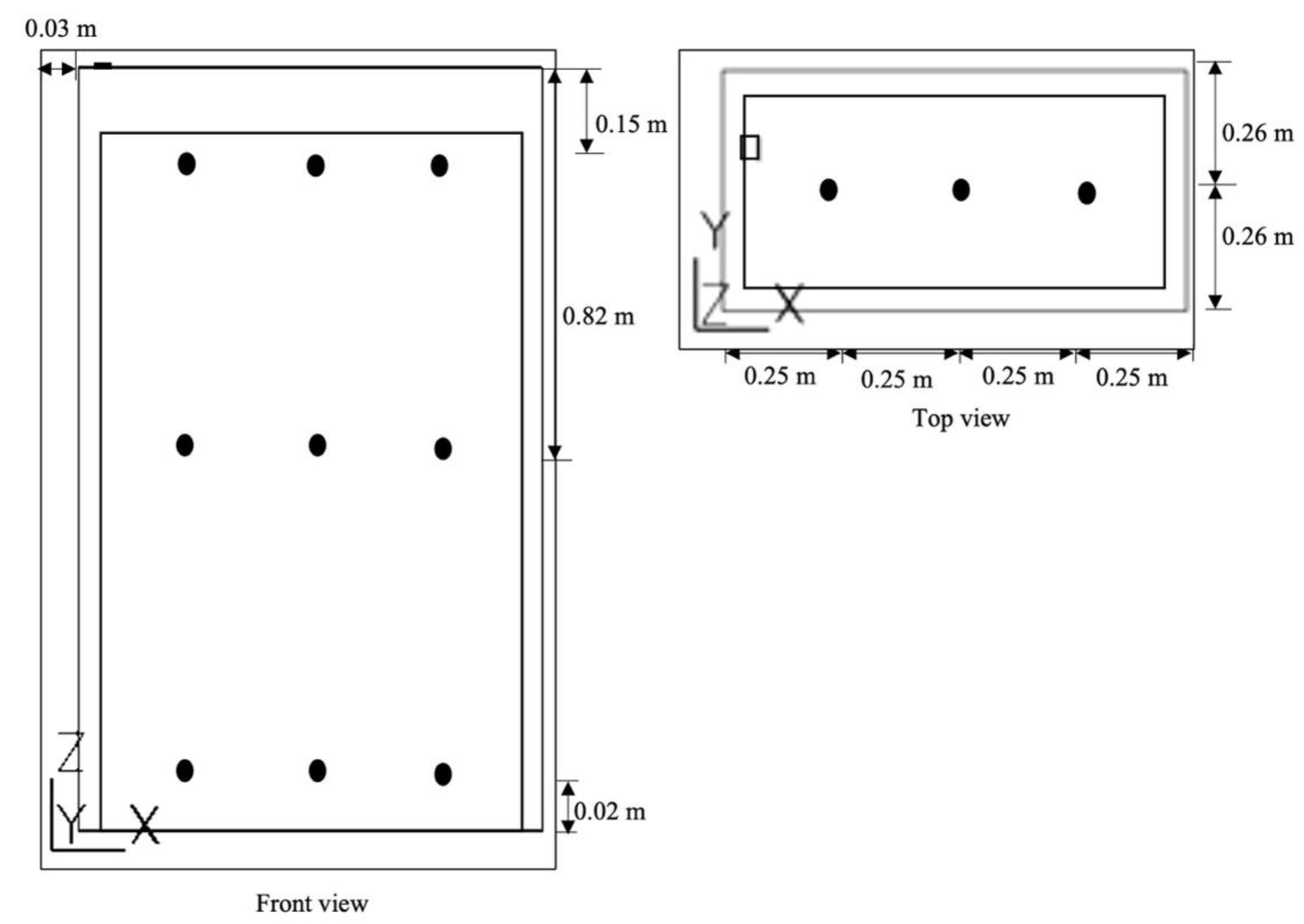

2.1.1. Chamber Description

2.1.2. CO2 Distribution Measurement in the Chamber

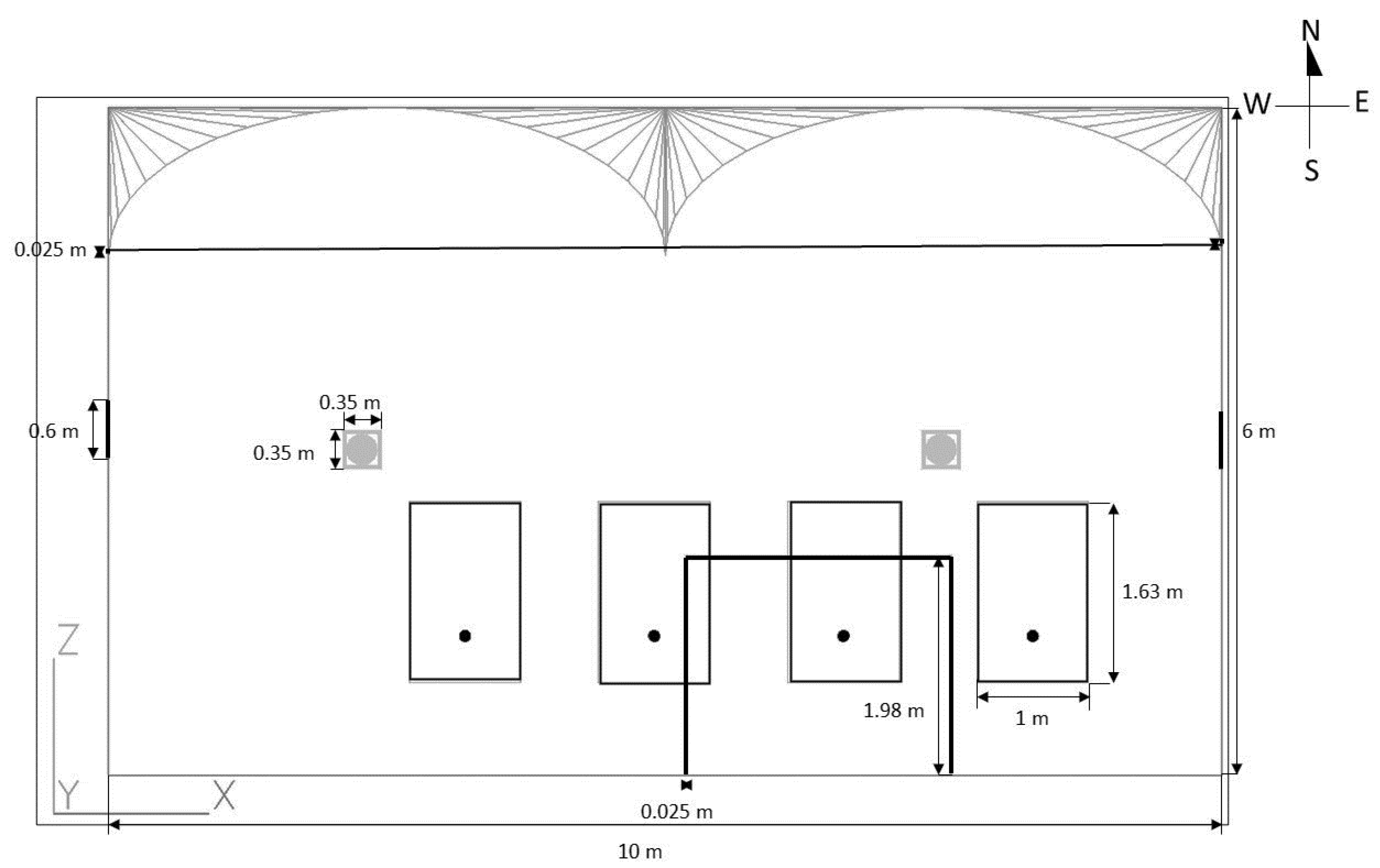

2.1.3. Greenhouse Description

2.1.4. Measurement of CO2 Concentration in Greenhouse

2.1.5. Brief Description of CO2 Enrichment on CO2 Distribution in a Greenhouse

2.2. Numerical Modelling

2.2.1. Governing Equations

2.2.2. Photosynthesis Model

2.3. Model Settings and Validation

2.3.1. Chamber Model

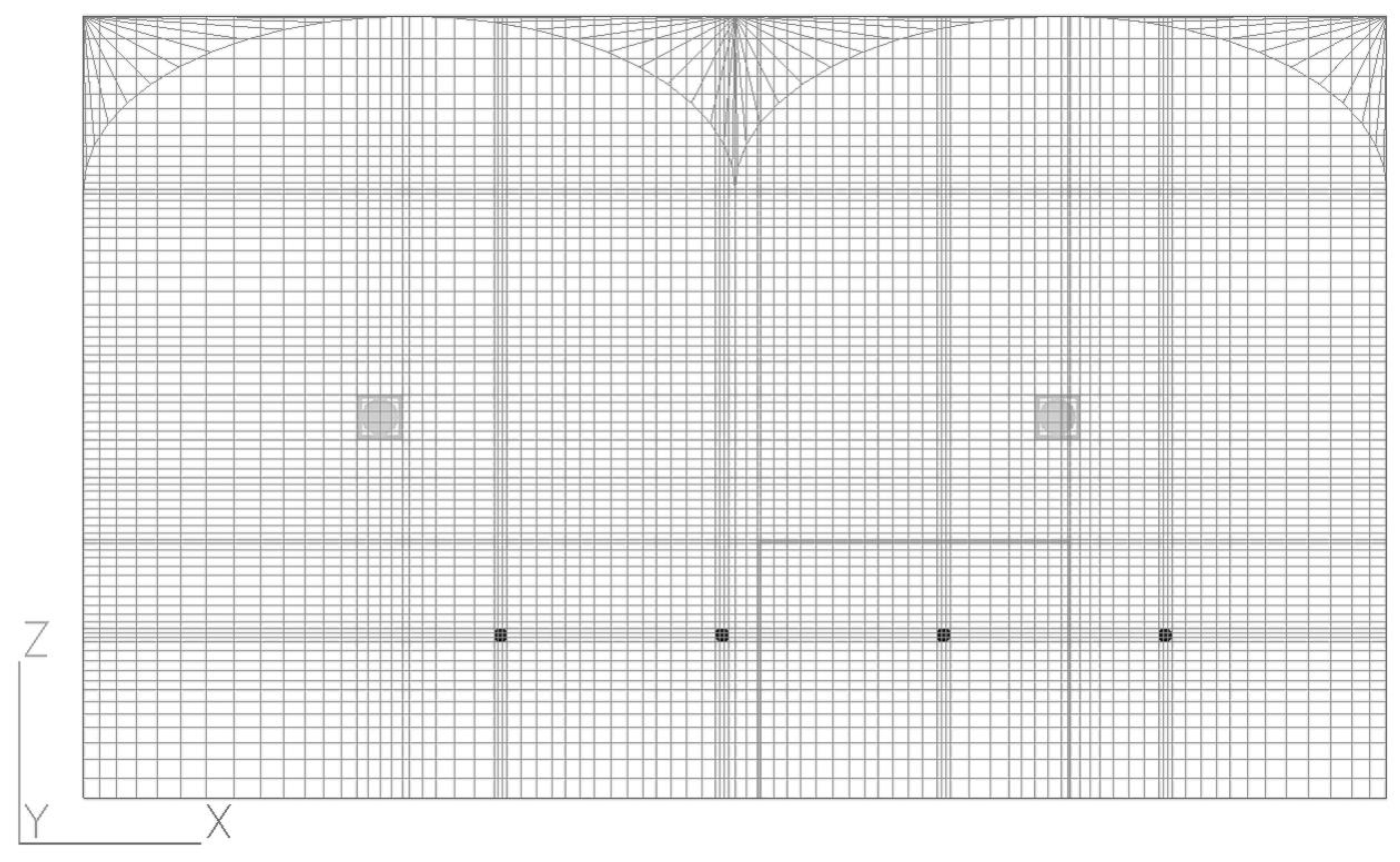

2.3.2. Validation Chamber Model

2.3.3. Greenhouse Model

2.3.4. Validation of the Greenhouse Model

3. Results and Discussion

3.1. Model Validation

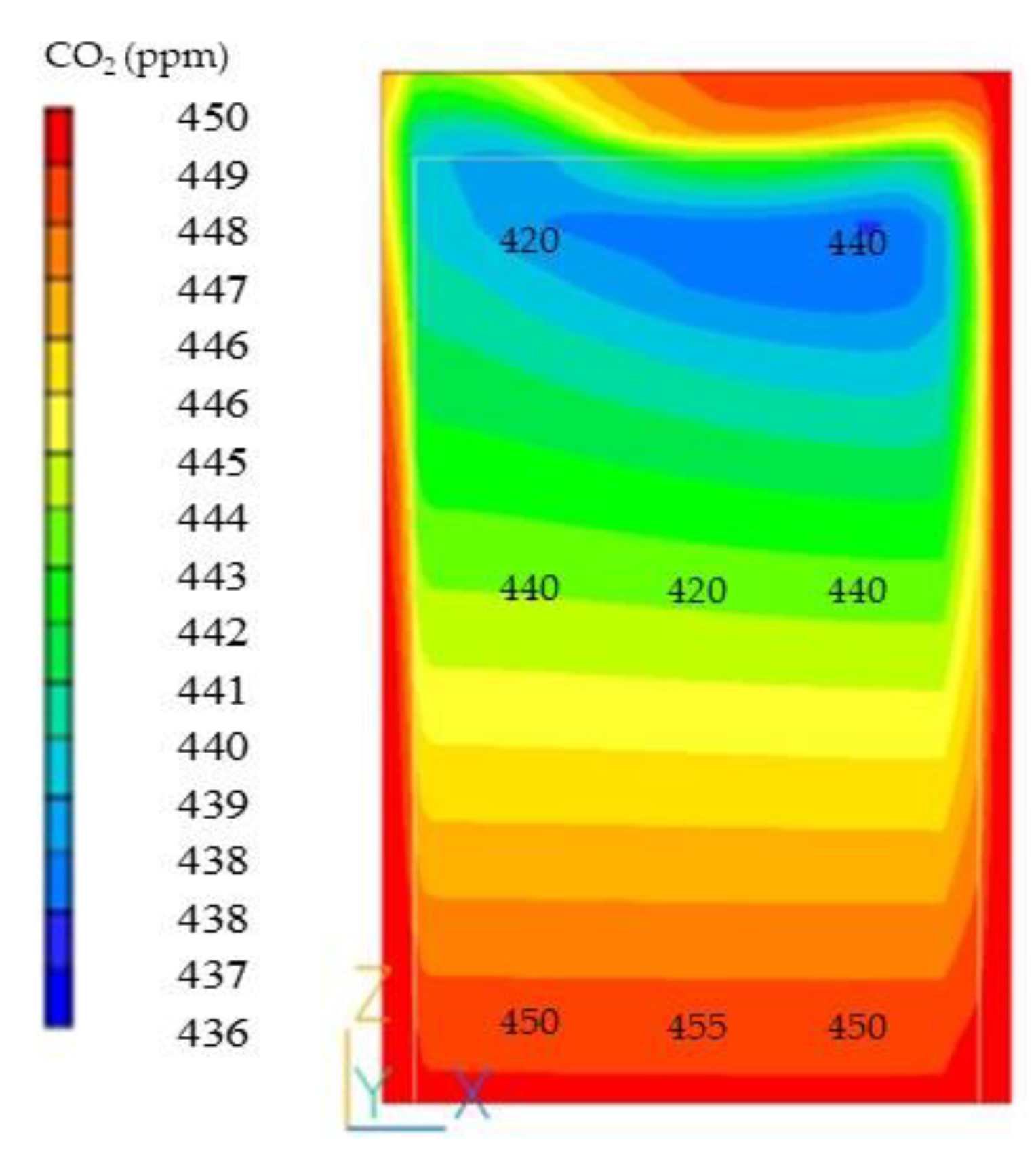

3.1.1. CO2 Distribution Inside the Chamber

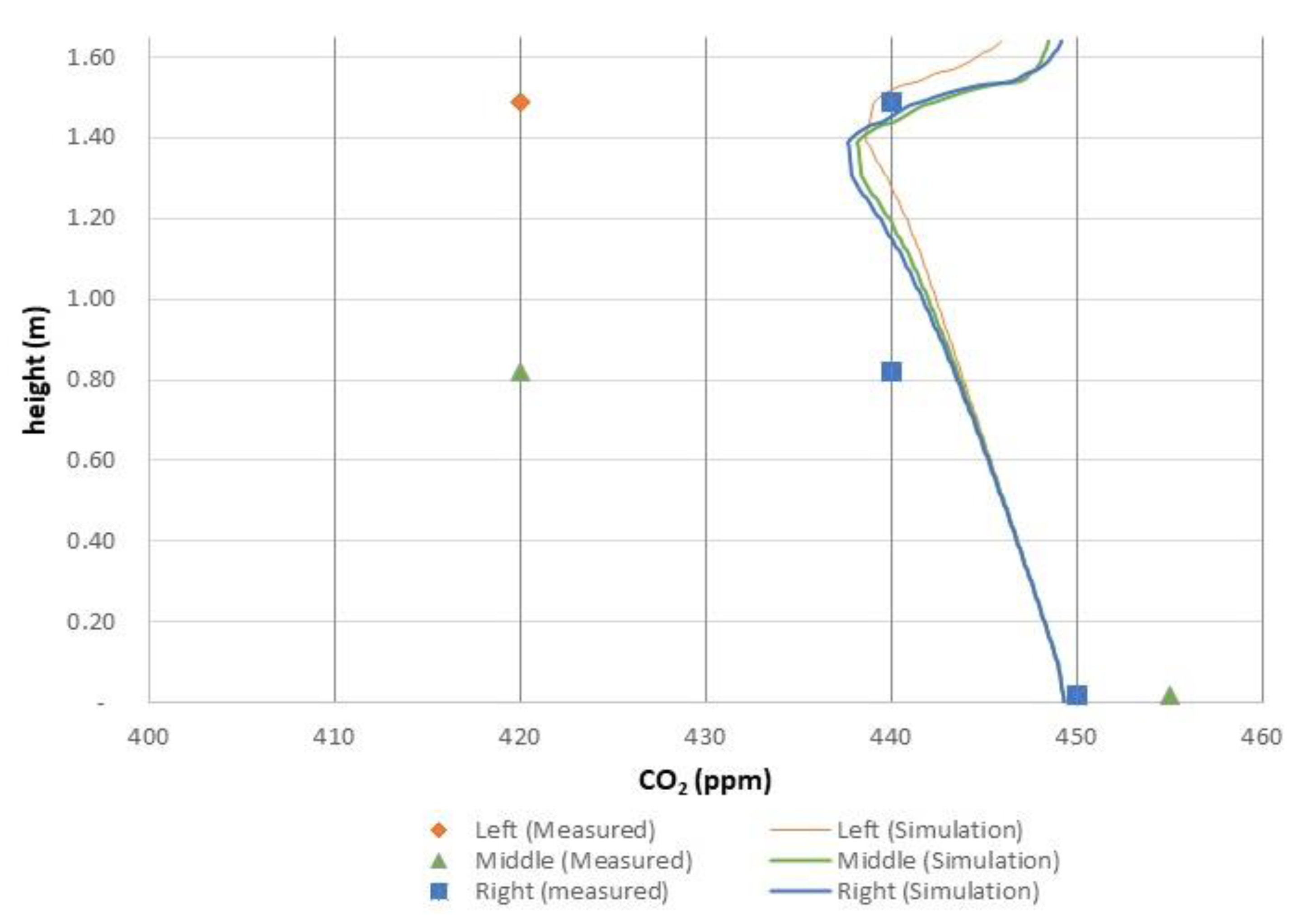

3.1.2. CO2 Distribution Inside the Greenhouse

3.2. Simulation Cases for Greenhouse Model

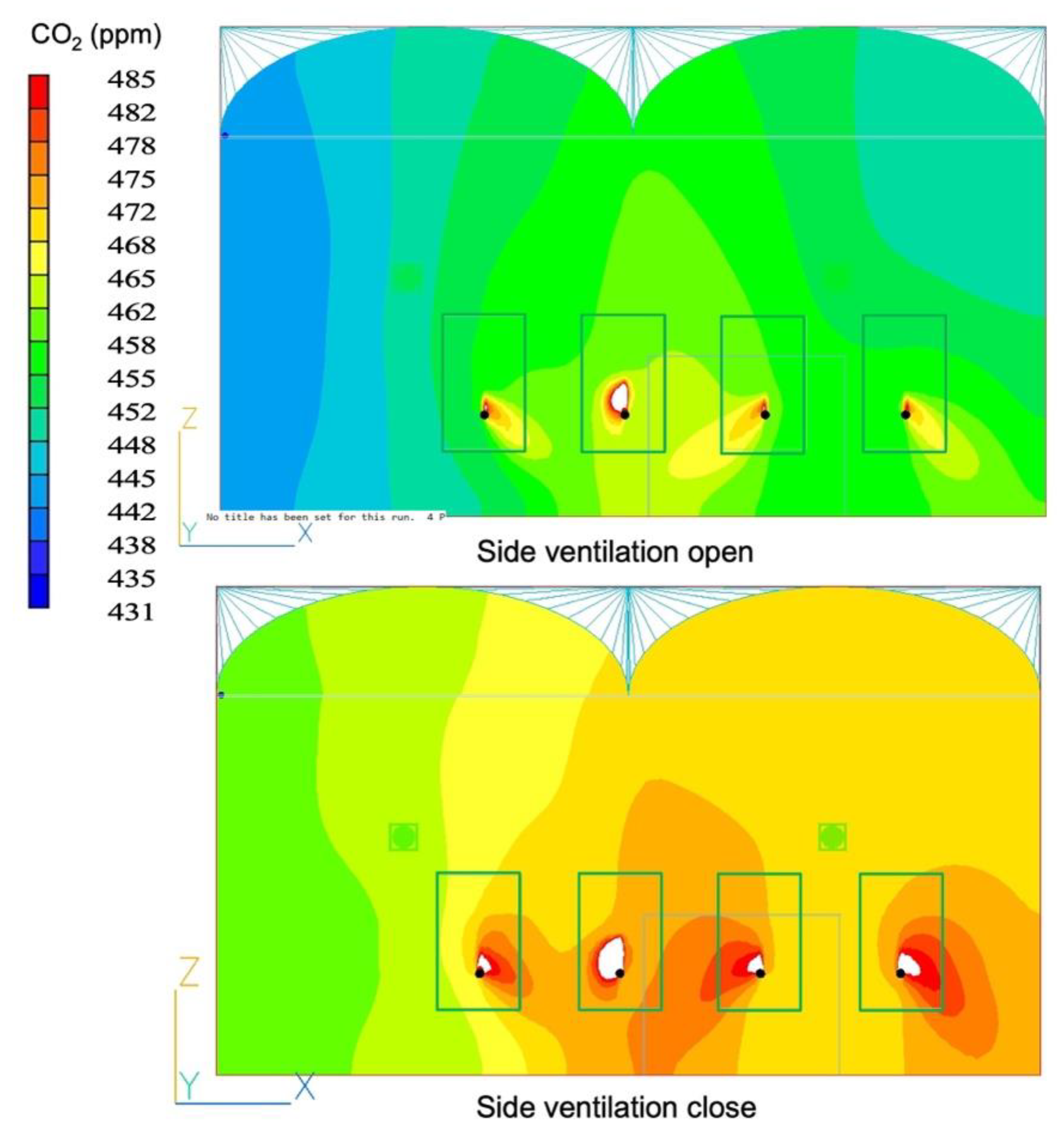

3.2.1. CO2 Distribution toward Open and Closed Side Ventilation Inside the Greenhouse

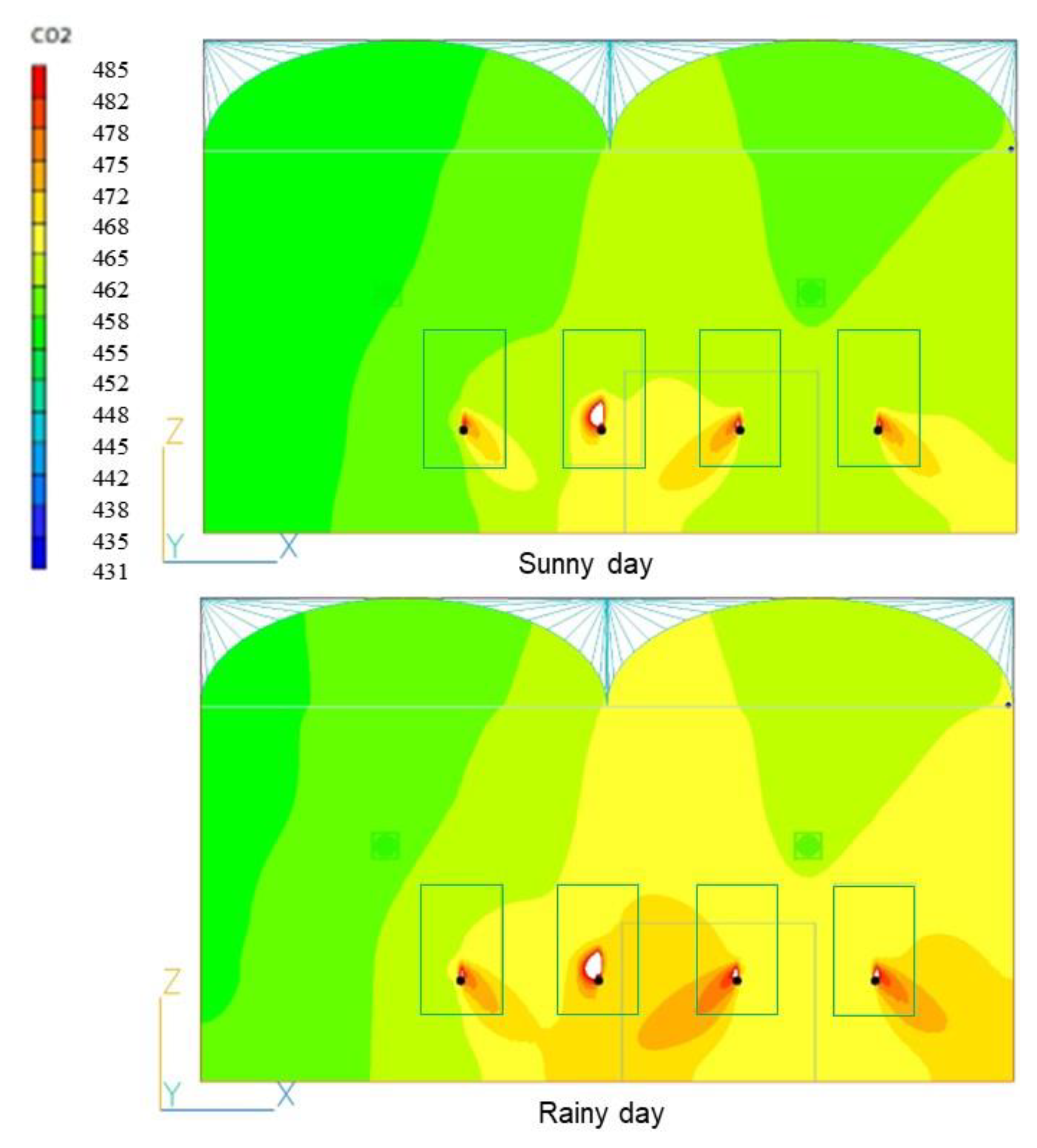

3.2.2. CO2 Distribution toward on Sunny and Rainy Day Inside the Greenhouse

3.3. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Y.; Kacira, M.; An, L. A CFD study on improving air flow uniformity in indoor plant factory system. Biosyst. Eng. 2016, 147, 193–205. [Google Scholar] [CrossRef]

- Benni, S.; Tassinari, P.; Bonora, F.; Barbaresi, A.; Torreggiani, D. Efficacy of greenhouse natural ventilation: Environmental monitoring and CFD simulations of a study case. Energy Build. 2016, 125, 276–286. [Google Scholar] [CrossRef]

- Santolini, E.; Pulvirenti, B.; Benni, S.; Barbaresi, L.; Torreggiani, D.; Tassinari, P. Numerical study of wind-driven natural ventilation in a greenhouse with screens. Comput. Electron. Agric. 2018, 149, 41–53. [Google Scholar] [CrossRef]

- Roy, J.C.; Boulard, T.; Kittas, C.; Wang, S. Convective and ventilation transfers in greenhouses, part 1: The greenhouse considered as a perfectly stirred tank. Biosyst. Eng. 2002, 83, 1–20. [Google Scholar] [CrossRef] [Green Version]

- Kim, R.W.; Lee, I.B.; Kwon, K.S. Evaluation of wind pressure acting on multi-span greenhouses using CFD technique, Part 1: Development of the CFD model. Biosyst. Eng. 2017, 164, 235–256. [Google Scholar] [CrossRef]

- Kichah, A.; Bournet, P.E.; Migeon, C.; Boulard, T. Measurement and CFD simulation of microclimate characteristics and transpiration of an Impatiens pot plant crop in a greenhouse. Biosyst. Eng. 2012, 112, 22–34. [Google Scholar] [CrossRef]

- Fang, H.; Li, K.; Wu, G.; Cheng, R.; Zhang, Y.; Yang, Q. A CFD analysis on improving lettuce canopy airflow distribution in a plant factory considering the crop resistance and LEDs heat dissipation. Biosyst. Eng. 2020, 200, 1–12. [Google Scholar] [CrossRef]

- Roy, J.C.; Pouillard, J.B.; Boulard, T.; Fatnassi, H.; Grisey, A. Experimental and CFD results on the CO2 distribution in a semi closed greenhouse. Acta Hortic. 2014, 1037, 993–1000. [Google Scholar] [CrossRef]

- Molina-Aiz, F.D.; Norton, T.; López, A.; Reyes-Rosas, A.; Moreno, M.A.; Marín, P.; Espinoza, K.; Valera, D.L. Using computational fluid dynamics to analyse the CO2 transfer in naturally ventilat0ed greenhouses. Acta Hortic. 2017, 1182, 283–292. [Google Scholar] [CrossRef]

- Niam, A.G.; Muharam, T.R.; Widodo, S.; Solahudin, M.; Sucahyo, L. CFD simulation approach in determining air conditioners position in the mini plant factory for shallot seed production. In Proceedings of the 10th International Meeting of Advances in Thermofluids, Bali, Indonesia, 16–17 November 2018. [Google Scholar] [CrossRef]

- Zhang, Y.; Yasutake, D.; Hidaka, K.; Kitano, M.; Okayasu, T. CFD analysis for evaluating and optimizing spatial distribution of CO2 concentration in a strawberry greenhouse under different CO2 enrichment methods. Comput. Electron. Agric. 2020, 179, 105811. [Google Scholar] [CrossRef]

- Li, Y.; Ding, Y.; Li, D.; Miao, Z. Automatic carbon dioxide enrichment strategies in the greenhouse: A review. Biosyst. Eng. 2018, 171, 101–119. [Google Scholar] [CrossRef]

- Kuroyanagi, T.; Yasuba, K.; Higashide, T.; Iwasaki, Y.; Takaichi, M. Efficiency of carbon dioxide enrichment in an unventilated greenhouse. Biosyst. Eng. 2014, 119, 58–68. [Google Scholar] [CrossRef]

- Kim, C.H.; Kim, M.H.; Choi, E.G.; Jin, B.O.; Baek, G.Y.; Yoon, Y.C.; Kim, H.T. CO2 distribution due to thermal buoyancy in the greenhouse. In Proceedings of the 5th International Federation of Automatic Control on Biorobotics, Sakai, Japan, 27–29 March 2013. [Google Scholar] [CrossRef]

- Shimomoto, K.; Takayama, K.; Takahashi, N.; Nishina, H.; Inaba, K.; Isoyama, Y.; Oh, S.C. Real-time monitoring of photosynthesis and transpiration of a fully-grown tomato plant in greenhouse. Environ. Control Biol. 2020, 58, 65–70. [Google Scholar] [CrossRef]

- Campen, J.B. Greenhouse design applying CFD for Indonesian conditions. Acta Hortic. 2005, 691, 419–424. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.W.; Luo, J.Y.; Li, X.P. CFD based study of heterogeneous microclimate in a typical chinese greenhouse in central China. J. Integr. Agric. 2013, 12, 914–923. [Google Scholar] [CrossRef]

- Boulard, T.; Roy, J.C.; Pouillard, J.B.; Fatnassi, H.; Grisey, A. Modelling of micrometeorology, canopy transpiration and photosynthesis in a closed greenhouse using computational fluid dynamics. Biosyst. Eng. 2017, 158, 110–133. [Google Scholar] [CrossRef]

- Kuroyanagi, T. Prediction of leakage rate of a greenhouse using computational fluid dynamics. Acta Hortic. 2017, 1170, 87–94. [Google Scholar] [CrossRef]

- Hong, S.W.; Exadaktylos, V.; Lee, I.B.; Amon, T.; Youssef, A.; Norton, T.; Berckmans, D. Validation of an open source CFD code to simulate natural ventilation for agricultural buildings. Comput. Electron. Agric. 2017, 138, 80–91. [Google Scholar] [CrossRef]

- Saberian, A.; Sajadiye, S.M. The effect of dynamic solar heat load on the greenhouse microclimate using CFD simulation. Renew. Energy. 2019, 138, 722–737. [Google Scholar] [CrossRef]

- Bouhoun, A.H.; Bournet, P.E.; Cannavo, P.; Chantoiseau, E. Development of a CFD crop submodel for simulating microclimate and transpiration of ornamental plants grown in a greenhouse under water restriction. Comput. Electron. Agric. 2018, 149, 26–40. [Google Scholar] [CrossRef]

- Boulard, T.; Wang, S. Experimental and numerical studies on the heterogeneity of crop transpiration in a plastic tunnel. Comput. Electron. Agric. 2002, 34, 173–190. [Google Scholar] [CrossRef]

- Majdoubi, H.; Boulard, T.; Fatnassi, H.; Bouirden, L. Airflow and microclimate patterns in a one-hectare Canary type greenhouse: An experimental and CFD assisted study. Agric. For. Meteorol. 2009, 149, 1050–1062. [Google Scholar] [CrossRef]

- Zhang, Y.; Wei, Z.; Xu, J.; Wang, H.; Zhu, H.; Lv, H. Numerical simulation and application of micro-nano bubble releaser for irrigation. Mater. Express 2021, 11, 1007–1015. [Google Scholar] [CrossRef]

- Kumazaki, T.; Ikeuchi, Y.; Tokairin, T. Relationship between positions of CO2 supply in a canopy of tomato grown by high-wire system and distribution of CO2 concentration in a greenhouse. Clim. Biosph. 2021, 21, 54–59. [Google Scholar] [CrossRef]

- PHOENICS User Manual. The Mathematical Basis of PHOENICS. Available online: https://www.cham.co.uk/phoenics/d_polis/d_lecs/general/maths.htm (accessed on 18 February 2022).

- Stathopoulou, O.I.; Assimakopoulos, V.D. Numerical study of the indoor environmental conditions of a large athletic hall using the CFD code PHOENICS. Environ. Model. Assess. 2008, 13, 449–458. [Google Scholar] [CrossRef]

- Nederhoff, E.M.; Vegter, J.G. Canopy photosynthesis of tomato, cucumber, and sweet pepper in greenhouses: Measurements compared to models. Ann. Bot. 1994, 73, 421–427. [Google Scholar] [CrossRef]

- Nurmalisa, M.; Tokairin, T.; Takayama, K.; Inoue, T. Numerical simulation of detailed airflow distribution in newly developed photosynthesis chamber. In Proceedings of the 2nd International Conference on Environment, Sustainability Issues, and Community Development (Virtual Conference), Semarang, Indonesia, 21 October 2020. [Google Scholar] [CrossRef]

- Kuroyanagi, T. Investigating air leakage and wind pressure coefficients of single-span plastic greenhouses using computational fluid dynamics. Biosyst. Eng. 2017, 163, 15–27. [Google Scholar] [CrossRef]

- Velázquez, J.F.; Gea, G.D.T.; Garcia, E.R.; Cruz, I.L.L.; Aguilar, A.R. Advances in Computational Fluid Dynamics Applied to the Greenhouse Environment. In Applied Computational Fluid Dynamics; Oh, H.W., Ed.; IntechOpen: London, UK, 2012; pp. 35–62. [Google Scholar] [CrossRef] [Green Version]

- PHOENICS User Manual. VR Object Types and Attributes. Available online: https://www.cham.co.uk/phoenics/d_polis/d_docs/tr326/obj-type.htm (accessed on 20 February 2022).

- Nederhoff, E.M.; Vegter, J.G. Photosynthesis of stands of tomato, cucumber, and sweet pepper measured in greenhouses under various CO2 concentrations. Ann. Bot. 1994, 73, 353–361. [Google Scholar] [CrossRef]

- Kim, H.T.; Kim, C.H.; Choi, E.G.; Jin, B.O.; Yoon, Y.C.; Kim, H.T. The effect of thermal conditions on CO2 distribution in a greenhouse. Trop. Agric. Res. 2015, 26, 714. [Google Scholar] [CrossRef] [Green Version]

- Romdhonah, Y.; Fujiuchi, N.; Shimomoto, K.; Takahashi, N.; Nishina, H.; Takayama, K. Averaging techniques in processing the high time-resolution photosynthesis data of cherry tomato plants for model development. Environ. Control Biol. 2021, 59, 107–115. [Google Scholar] [CrossRef]

- Xu, S.; Zhu, X.; Li, C.; Ye, Q. Effects of CO2 enrichment on photosynthesis and growth in Gerbera jamesonii. Sci. Hortic. 2014, 177, 77–84. [Google Scholar] [CrossRef]

- Reichrath, S.; Ferioli, F.; Davies, T.W. A simple computational fluid dynamics (CFD) model of a tomato glasshouse. Acta Hortic. 2000, 534, 197–202. [Google Scholar] [CrossRef]

). The rectangular shapes inside of the chamber represent the plants.

). The rectangular shapes inside of the chamber represent the plants.

). The rectangular shapes inside of the chamber represent the plants.

). The rectangular shapes inside of the chamber represent the plants.

| Parameter | Symbol | Unit | Value |

|---|---|---|---|

| Canopy photosynthesis rate | Pcg | g CO2 h−1 m−2ground area | |

| CO2 density | Cc | g m−3 | 1839 |

| Conductance of CO2 | τc | m s−1 | 12.168 × 10−4 |

| Crop respiration | R` | g h−1m−2 | 2.84 × 10−2 |

| Initial CO2 | - | ppm | 450 |

| Leaf area density | m2leaf m−3row | 2.67 | |

| Leaf area index | LAI | m2 m−2 | 4 |

| The light use efficiency of the plant canopy | αc | g CO2 J−1 | 3.705 × 10−6 |

| The incident light flux PAR | Jo | W m−2leaf | 379.9 |

| Parameter | Symbol | Unit | Value |

|---|---|---|---|

| Canopy photosynthesis rate | Pcg | g CO2 h−1 m−2ground area | |

| CO2 density | Cc | g m−3 | 1839 |

| Conductance of CO2 | τc | m s−1 | 12.168 × 10−4 |

| Crop respiration | R` | g h−1 m−2 | 2.84 × 10−2 |

| Initial CO2 | - | ppm | 450 |

| Leaf area density | m2leaf m−3row | 0.67 | |

| Leaf area index | LAI | m2 m−2 | 1.1 |

| The light use efficiency of the plant canopy | αc | g CO2 J−1 | 3.705 × 10−6 |

| The incident light flux PAR | Jo | W m−2leaf | 355 |

| Canopy Layer | Measured | Simulation | Percentage error (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Left | Middle | Right | Left | Middle | Right | Left | Middle | Right | |

| Top | 420 | ─ | 440 | 439 | 442 | 442 | 4.53 | ─ | 0.36 |

| Middle | 440 | 420 | 440 | 444 | 443 | 443 | 0.84 | 5.59 | 0.76 |

| Bottom | 450 | 455 | 450 | 449 | 449 | 449 | 0.17 | 1.27 | 0.17 |

| MAPE (%) | 1.85 | 3.43 | 0.43 | ||||||

| RMSE (ppm) | 11.20 | 16.99 | 2.17 | ||||||

| Height (m) | Measured (ppm) | Simulation (ppm) | Percentage Error (%) | |||

|---|---|---|---|---|---|---|

| North | South | North | South | North | South | |

| 4.2 | 391 | 418 | 435 | 435 | 11.15 | 3.96 |

| 2.4 | 411 | 439 | 433 | 432 | 5.28 | 1.53 |

| 1.8 | 418 | 431 | 432 | 432 | 3.34 | 0.14 |

| 1.2 | 432 | 443 | 432 | 432 | 0.03 | 2.55 |

| MAPE (%) | 4.95 | 2.04 | ||||

| RMSE (ppm) | 25.33 | 10.57 | ||||

| Parameter | Greenhouse | Plants | ||

|---|---|---|---|---|

| Side Vent | ||||

| Open | Closed | Open | Closed | |

| SD (ppm) 1 | 80 | 71 | 41 | 41 |

| Mean (ppm) | 438 | 457 | 464 | 476 |

| CV (%) 2 | 18.2 | 15.6 | 8.8 | 8.7 |

| Parameter | Greenhouse | Plants | ||

|---|---|---|---|---|

| Weather | ||||

| Sunny | Rainy | Sunny | Rainy | |

| SD (ppm) | 81 | 71 | 38 | 41 |

| Mean (ppm) | 446 | 457 | 467 | 476 |

| CV (%) | 18.1 | 15.6 | 8.1 | 8.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nurmalisa, M.; Tokairin, T.; Kumazaki, T.; Takayama, K.; Inoue, T. CO2 Distribution under CO2 Enrichment Using Computational Fluid Dynamics Considering Photosynthesis in a Tomato Greenhouse. Appl. Sci. 2022, 12, 7756. https://doi.org/10.3390/app12157756

Nurmalisa M, Tokairin T, Kumazaki T, Takayama K, Inoue T. CO2 Distribution under CO2 Enrichment Using Computational Fluid Dynamics Considering Photosynthesis in a Tomato Greenhouse. Applied Sciences. 2022; 12(15):7756. https://doi.org/10.3390/app12157756

Chicago/Turabian StyleNurmalisa, Moliya, Takayuki Tokairin, Tadashi Kumazaki, Kotaro Takayama, and Takanobu Inoue. 2022. "CO2 Distribution under CO2 Enrichment Using Computational Fluid Dynamics Considering Photosynthesis in a Tomato Greenhouse" Applied Sciences 12, no. 15: 7756. https://doi.org/10.3390/app12157756

APA StyleNurmalisa, M., Tokairin, T., Kumazaki, T., Takayama, K., & Inoue, T. (2022). CO2 Distribution under CO2 Enrichment Using Computational Fluid Dynamics Considering Photosynthesis in a Tomato Greenhouse. Applied Sciences, 12(15), 7756. https://doi.org/10.3390/app12157756