Investigation of Quadrate Fresnel Zone Plates Fabricated by Femtosecond Laser Direct Writing

Abstract

:1. Introduction

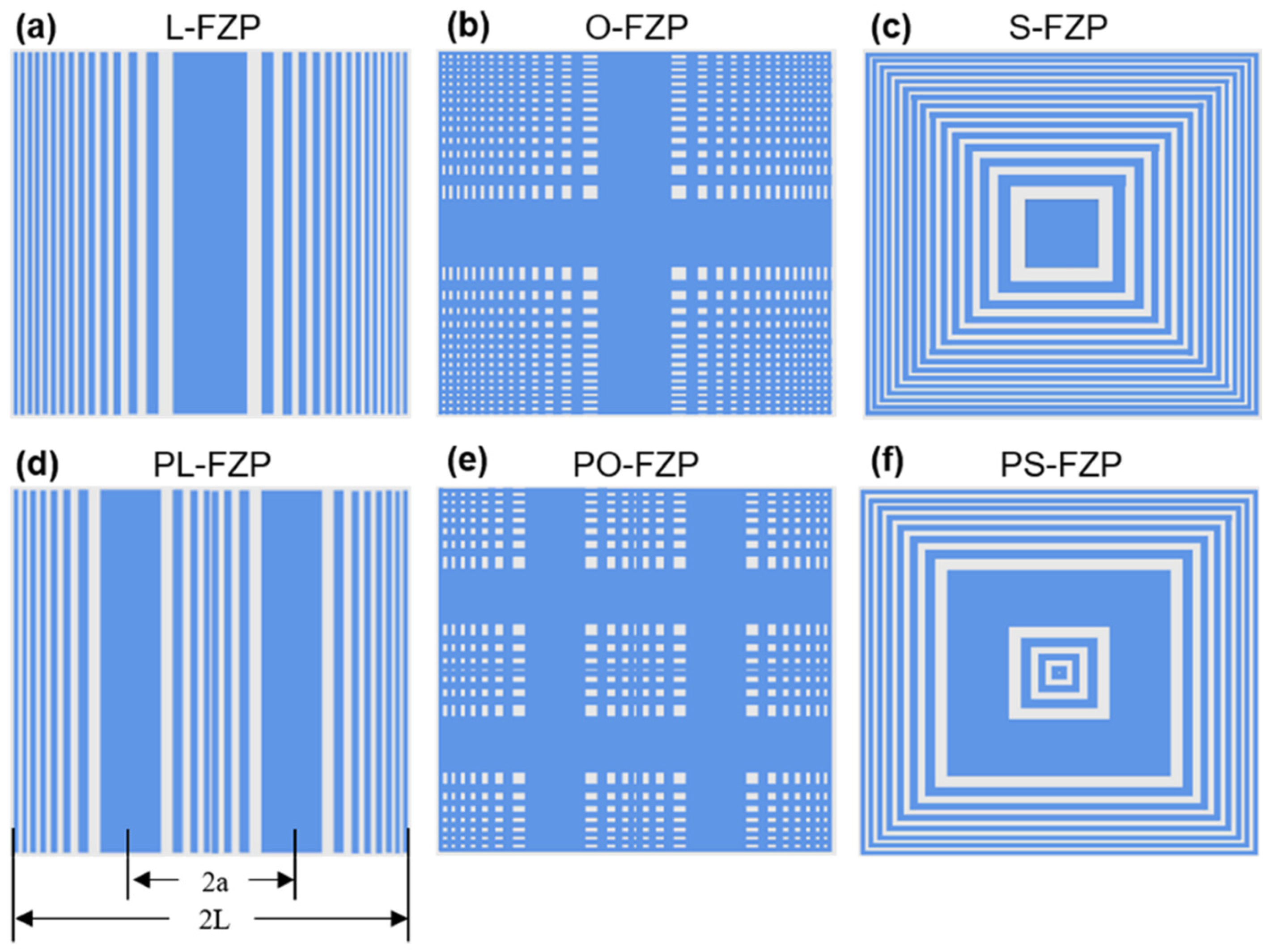

2. Theoretical and Experimental Methods

2.1. Theoretical Approach

2.2. Experimental Methods

3. Results and Discussion

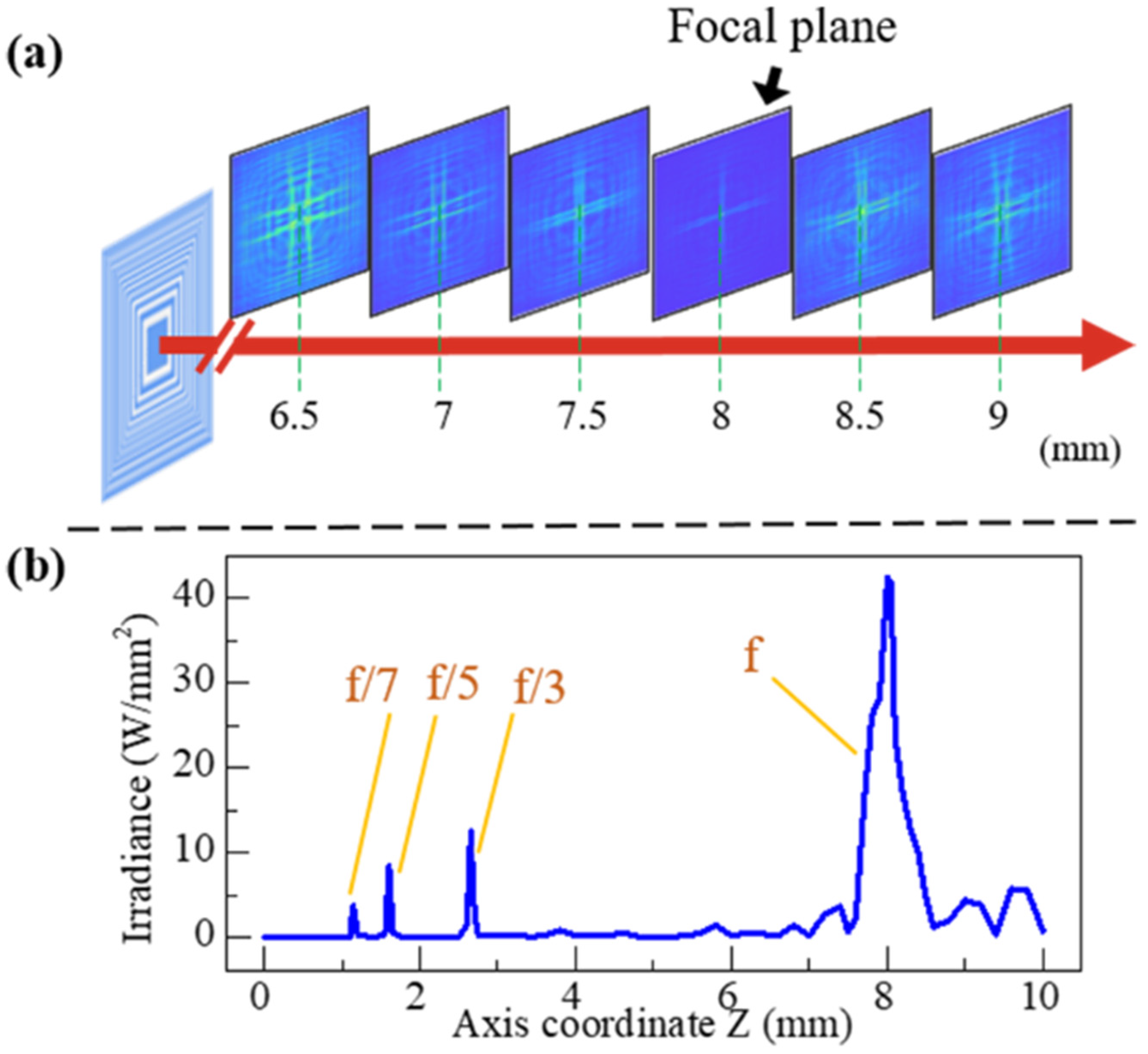

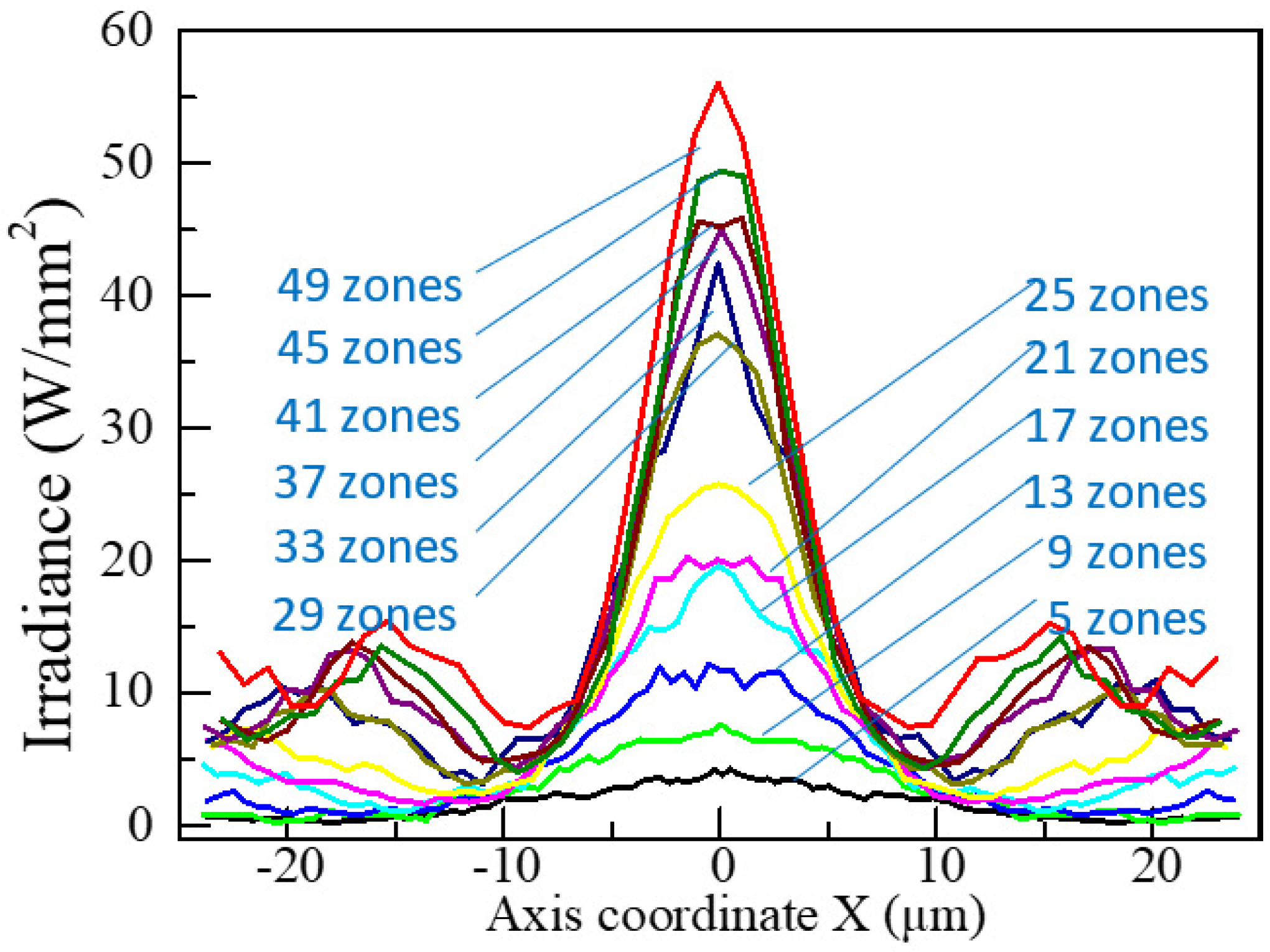

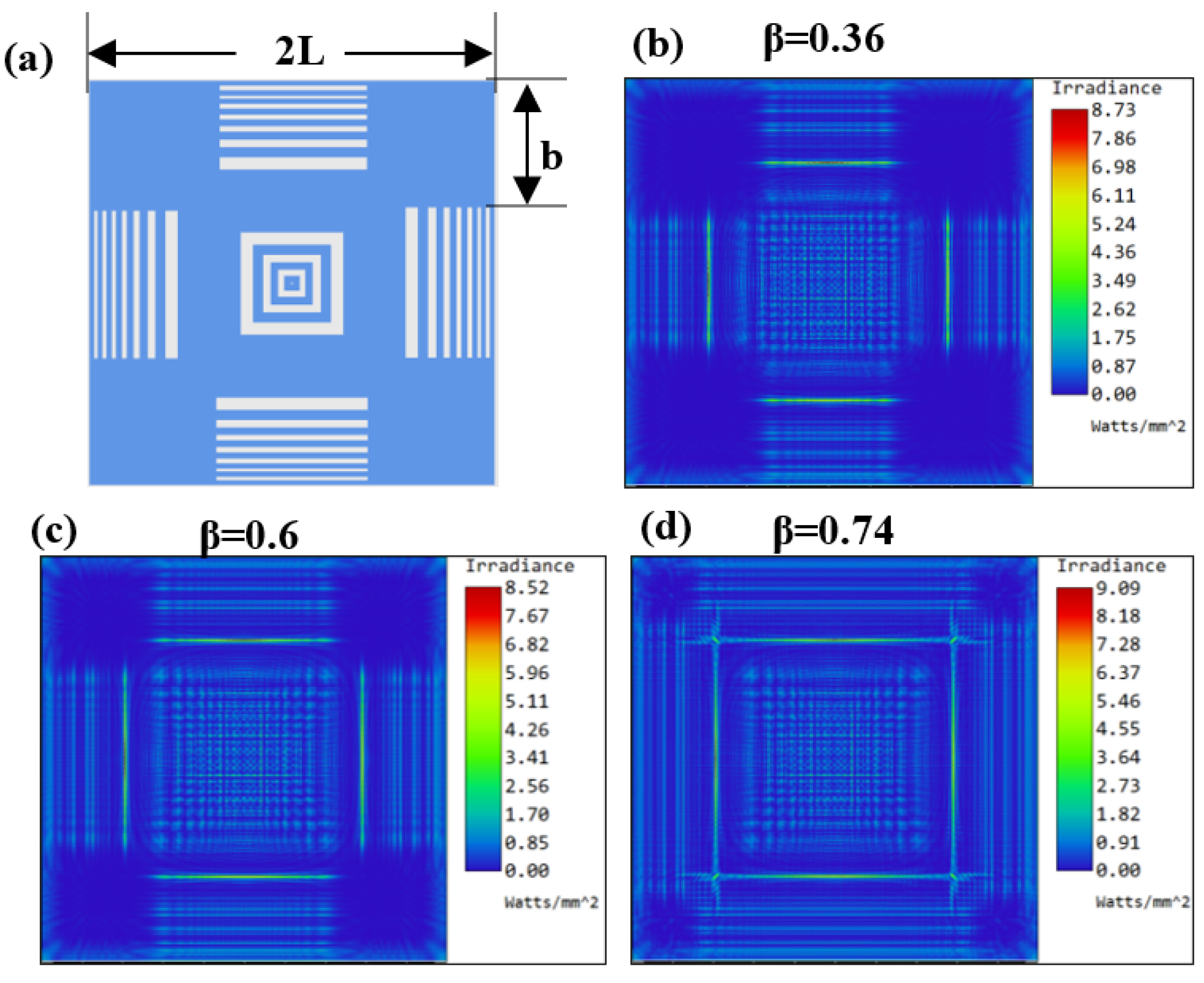

3.1. Simulation Study on Diffraction Process of S-FZP

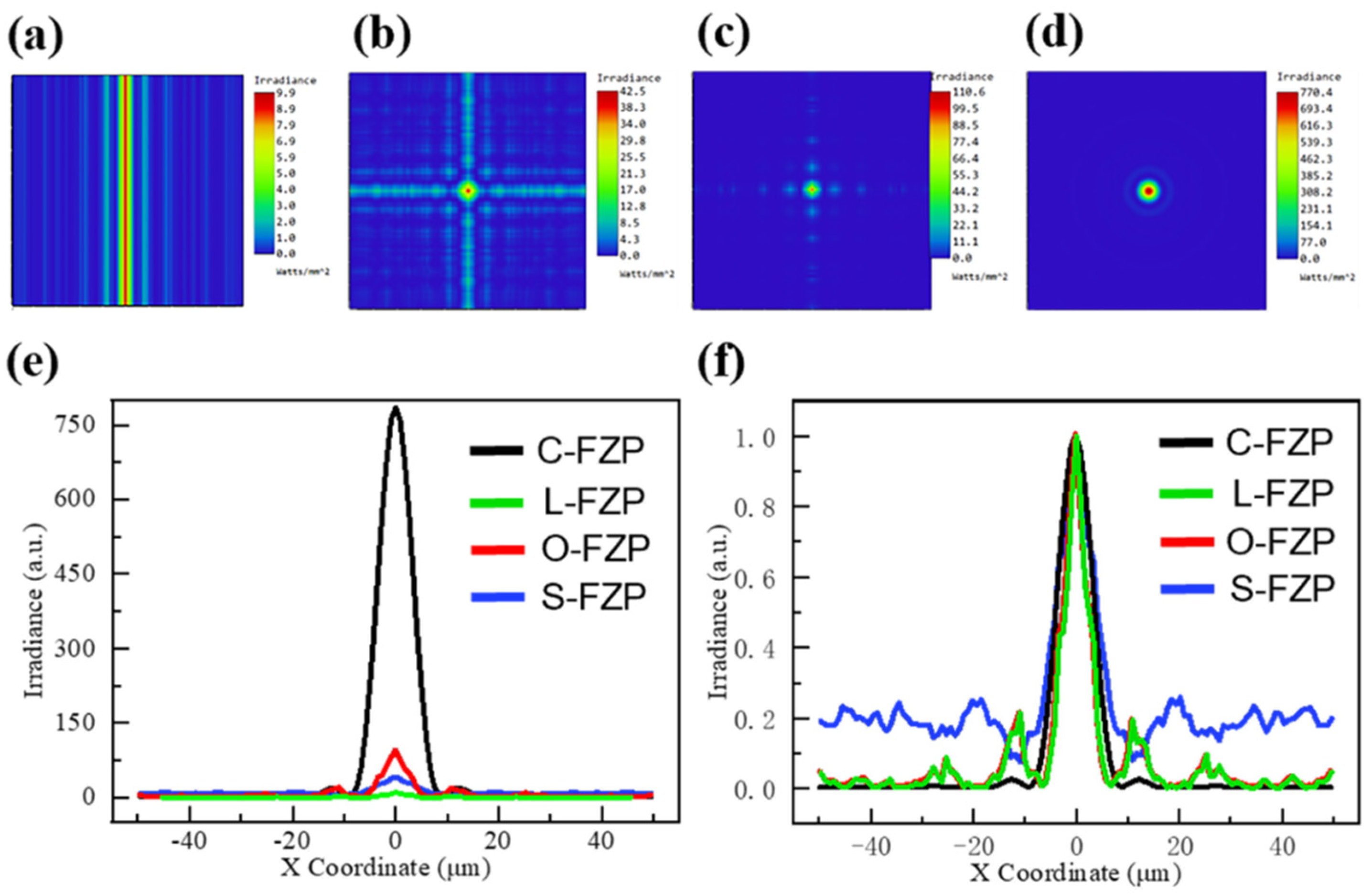

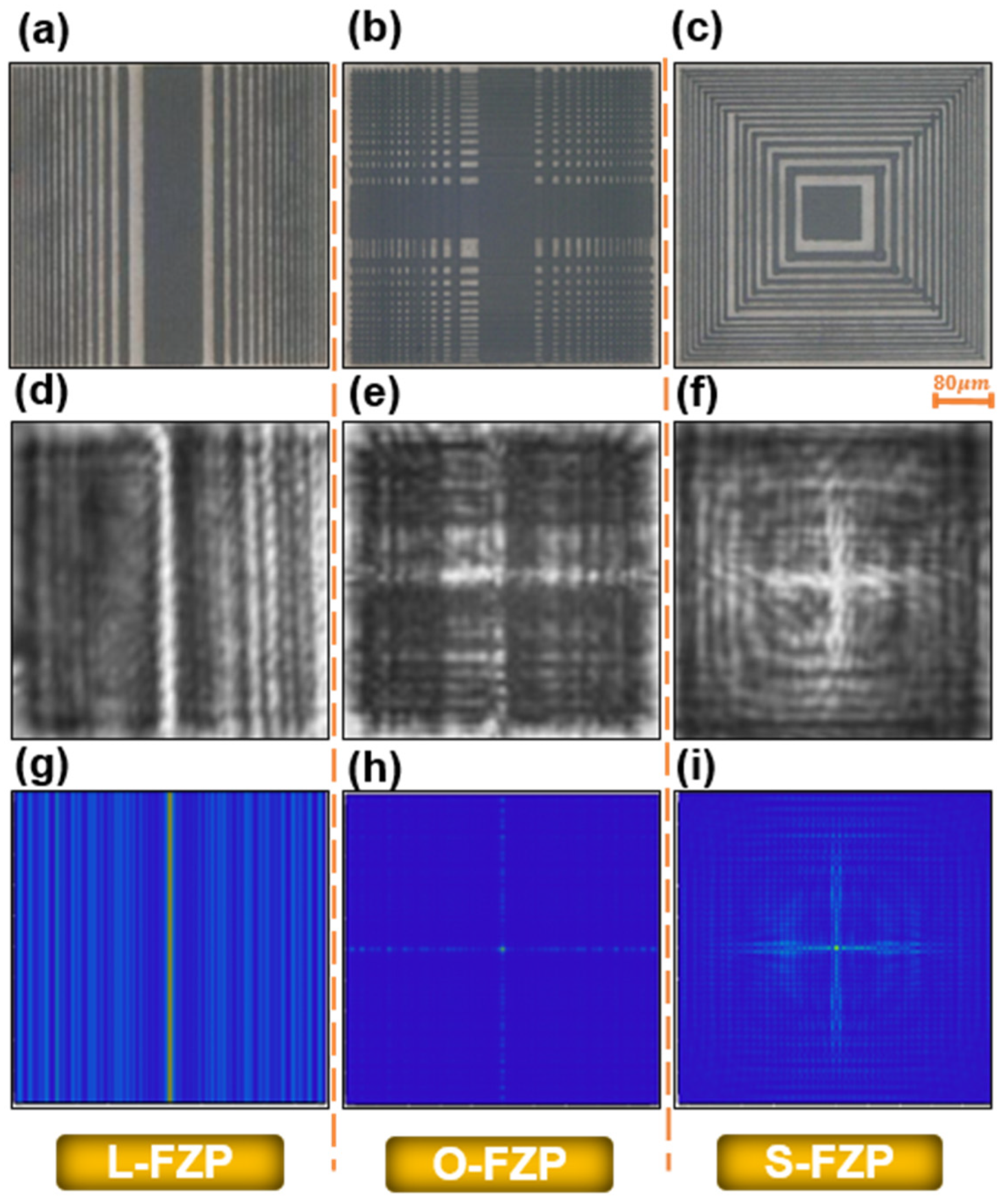

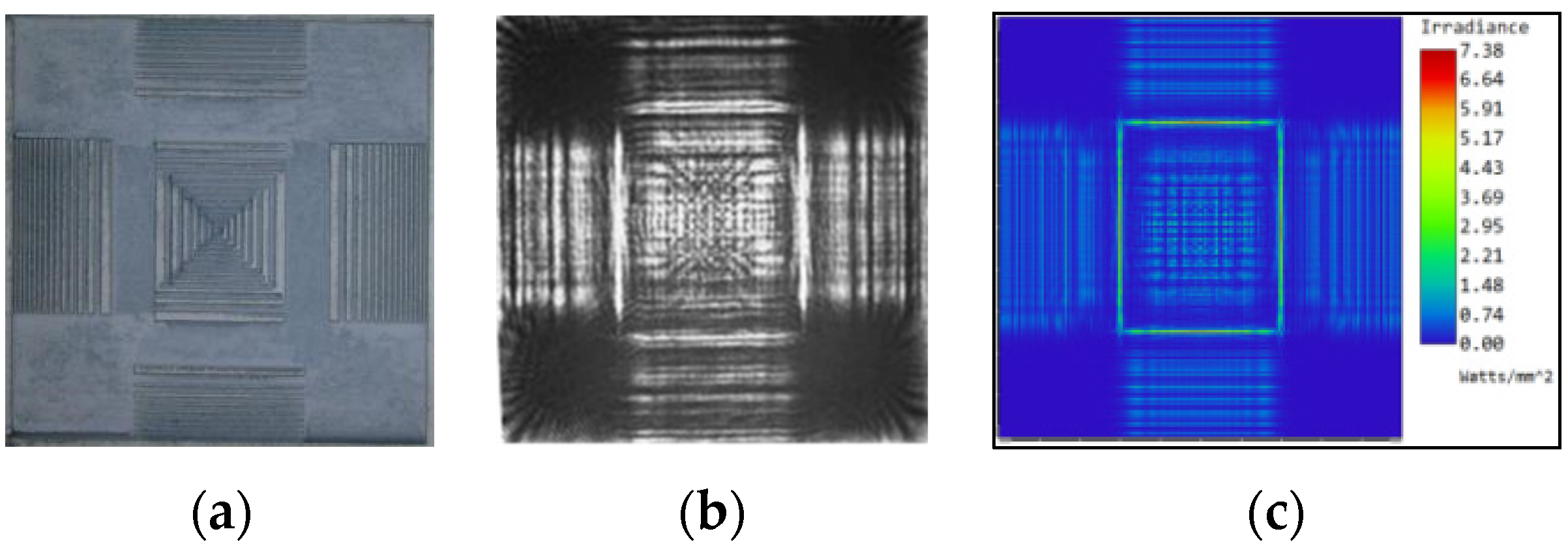

3.2. Simulation and Experimental Study on L-FZPs, O-FZPs and S-FZPs

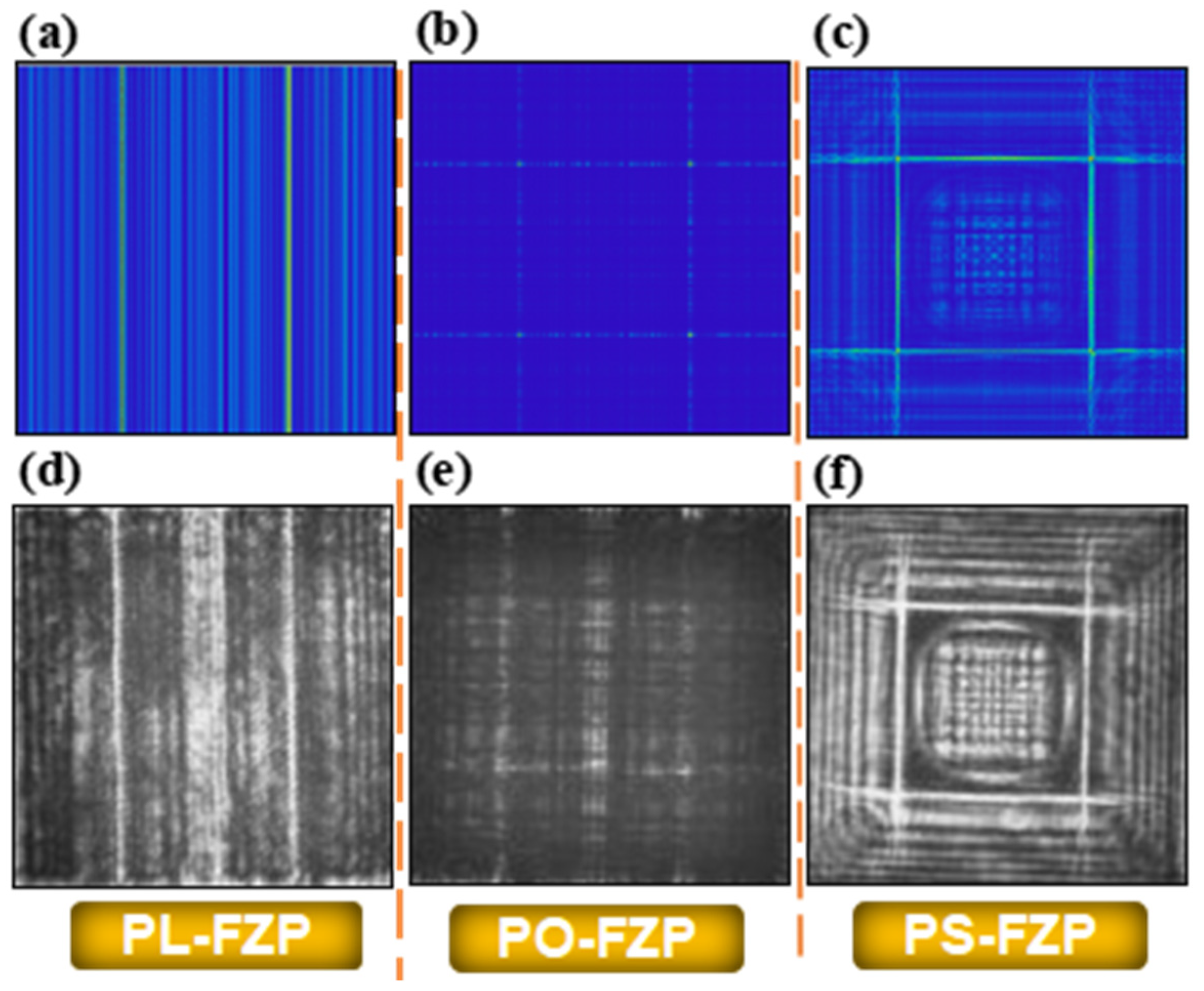

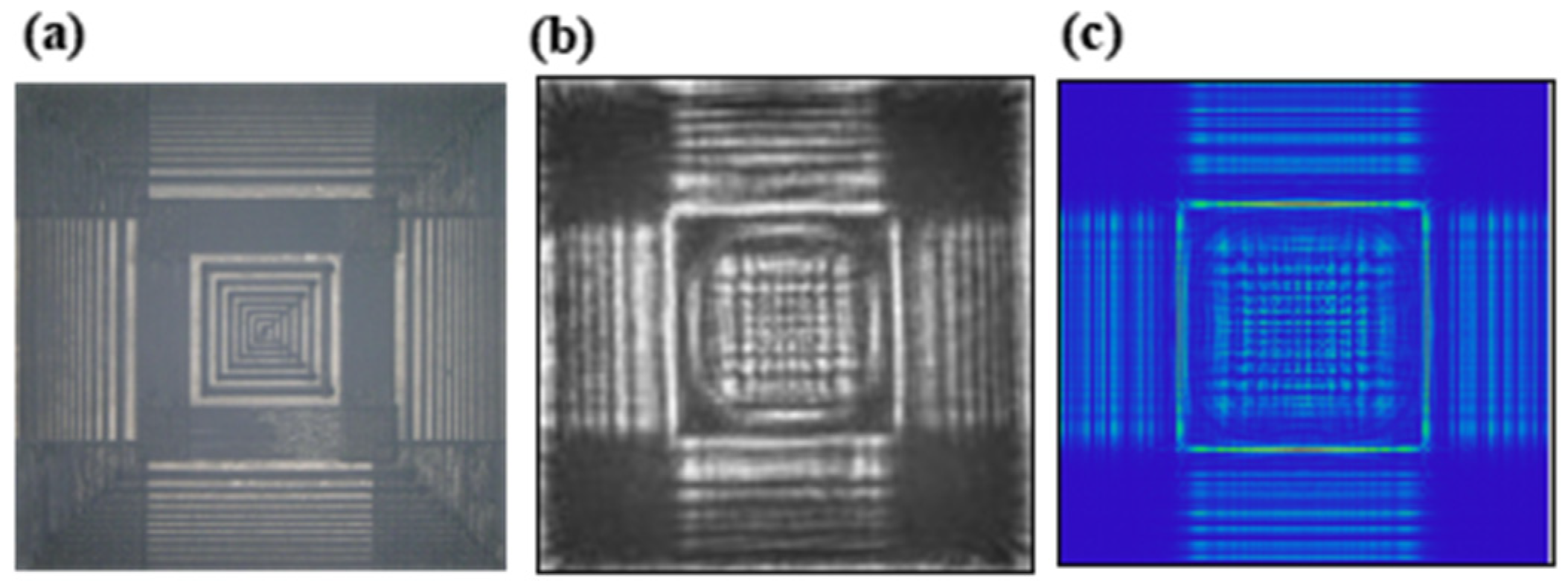

3.3. Simulation and Experimental Study on PS-FZPs

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Qing, C.; Jürgen, J. Comprehensive focusing analysis of various Fresnel zone plates. J. Opt. Soc. Am. A 2004, 21, 561–571. [Google Scholar]

- Kim, J.; Ha, W.; Park, J.; Kim, J.K.; Sohn, I.B.; Shin, W.; Oh, K. Micro Fresnel Zone Plate Lens Inscribed on a Hard Polymer Clad Fiber Using Femtosecond Pulsed Laser. IEEE Photonic Technol. Lett. 2013, 25, 761–763. [Google Scholar] [CrossRef]

- Zhou, F.; Sun, X.Y.; Zhong, H.M.; Duan, L.; Hu, Y.W.; Duan, J.; Li, M. Optimization of the focusing characteristics of Fresnel zone plates fabricated with a femtosecond laser. J. Mod. Opt. 2021, 68, 100–107. [Google Scholar] [CrossRef]

- Wang, J.H.; Zhang, W.; Cui, Y.W.; Teng, S.Y. Fresnel diffraction by a square aperture with rough edge. Optik 2015, 126, 3066–3071. [Google Scholar] [CrossRef]

- Arash, S.; Shima, G. Generation of double line focus and 1D non-diffractive beams using phase shifted linear Fresnel zone plate. Opt. Laser Technol. 2015, 69, 65–70. [Google Scholar]

- Zhang, B.Z.; Zhao, D.M. Square Fresnel zone plate with spiral phase for generating zero axial irradiance. Opt. Lett. 2010, 35, 1488–1490. [Google Scholar] [CrossRef]

- Gonzalez, F.J.; Alda, J.; Ilic, B.; Boreman, G.D. Infrared antennas coupled to lithographic Fresnel zone plate lenses. Appl. Opt. 2004, 33, 6067–6073. [Google Scholar] [CrossRef]

- Minin, I.V.; Minin, O.V.; Petosa, A.; Thirakoune, S. Improved zoning rule for designing square Fresnel zone plate lenses. Microw. Opt. Technol. Lett. 2007, 49, 276–278. [Google Scholar] [CrossRef]

- Sabatyan, A.; Rafighdoost, J. Considerable diversity in generation light-arm beams using multi-twisted phase structure zone plate. Opt. Laser Technol. 2018, 107, 24–31. [Google Scholar] [CrossRef]

- Sabatyan, A.; Fathi, B. High-efficiency arrays of any desired optical beams using modified grating-based elements. Opt. Quantum Electron. 2018, 50, 338. [Google Scholar] [CrossRef]

- Sabatyan, A.; Behjat, Z. Radial phase modulated spiral zone plate for generation and manipulation of optical perfect vortex. Opt. Quantum Electron. 2017, 49, 371. [Google Scholar] [CrossRef]

- Anne, S.; Yanwei, L. Phase contrast soft x-ray microscopy using Zernike zone plates. Opt. Express 2008, 16, 1559–1564. [Google Scholar]

- Sun, X.Y.; Zhou, F.; Dong, X.R.; Zhang, F.; Liang, C.; Duan, L.; Hu, Y.W.; Duan, J. Fabrication of GaAs micro-optical components using wet etching assisted femtosecond laser ablation. J. Mod. Optic. 2021, 67, 1516–1523. [Google Scholar] [CrossRef]

- Lim, K.-D.; Choi, H.-K.; Sohn, I.-B.; Lee, B.-H.; Kim, J.-T. Fabrication of Lensed Optical Fibers for Biosensing Probes Using CO2 and Femtosecond Lasers. Appl. Sci. 2021, 11, 3738. [Google Scholar] [CrossRef]

- Low, M.J.; Lee, H.; Lim, C.H.J.; Sandeep, C.S.S.; Murukeshan, V.M.; Kim, S.W.; KIm, Y.J. Laser-induced reduced-graphene-oxide micro-optics patterned by femtosecond laser direct writing. Appl. Surf. Sci. 2020, 526, 146647. [Google Scholar] [CrossRef]

- Xu, C.; Zhang, F.; Lu, S.Q.; Zhong, S.S.; Chu, D.K.; Duan, J. Gold filled in Fresnel zone plate fabricated by femtosecond laser on fiber tip. Opt. Fiber Technol. 2021, 64, 102572. [Google Scholar] [CrossRef]

- Delullier, P.; Druart, G.; De La Barrière, F.; Calvez, L.; Lancry, M. Femtosecond Laser Direct Writing of Gradient Index Fresnel Lens in GeS2-Based Chalcogenide Glass for Imaging Applications. Appl. Sci. 2022, 12, 4490. [Google Scholar] [CrossRef]

- Jiang, Z.; Du, H.P.; Ruan, Y.Z. On the adaptive beam forming performance of a multi-beam antenna. Chin. J. Electron. 2004, 13, 724–727. [Google Scholar]

- Rico-Garcia, J.M.; Salgado-Remacha, F.J.; Sanchez-Brea, L.M.; Alda, J. Optimized square Fresnel zone plates for microoptics applications. Model. Asp. Opt. Metrol. II 2009, 7390, 739011. [Google Scholar]

- Kim, J.; Kim, H.; Lee, G.Y.; Kim, J.; Lee, B.; Jeong, Y. Numerical and Experimental Study on Multi-Focal Metallic Fresnel Zone Plates Designed by the Phase Selection Rule via Virtual Point Sources. Appl. Sci. 2018, 8, 449. [Google Scholar] [CrossRef] [Green Version]

- Alda, J.; Rico-Garcia, J.M.; Lopez-Alonso, J.M.; Lail, B.; Boreman, G. Design of Fresnel lenses and binary-staircase kinoforms of low value of the aperture number. Opt. Commun. 2006, 260, 454–461. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Zheng, C. Axial intensity distribution behind a Fresnel zone plate. Opt. Laser Technol. 2005, 37, 77–80. [Google Scholar] [CrossRef]

| Number of zones | 5 | 9 | 13 | 17 | 21 | 25 | 29 | 33 | 37 | 41 | 45 | 49 |

| Focal depth (mm) | 3 | 3 | 2.8 | 2.4 | 1.6 | 1.4 | 1.1 | 1.1 | 0.9 | 0.7 | 0.7 | 0.7 |

| Peak power (W/mm2) | 3.8 | 7.7 | 11.7 | 19.7 | 20.0 | 25.9 | 42.5 | 37.2 | 45.2 | 45.2 | 49.5 | 56.0 |

| Focus radius (μm) | 18.2 | 14.1 | 14.1 | 14.8 | 13.6 | 12.5 | 10.9 | 10.8 | 9.5 | 10.0 | 9.4 | 8.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, X.; Zhou, F.; Duan, L.; Duan, J.-a. Investigation of Quadrate Fresnel Zone Plates Fabricated by Femtosecond Laser Direct Writing. Appl. Sci. 2022, 12, 7788. https://doi.org/10.3390/app12157788

Sun X, Zhou F, Duan L, Duan J-a. Investigation of Quadrate Fresnel Zone Plates Fabricated by Femtosecond Laser Direct Writing. Applied Sciences. 2022; 12(15):7788. https://doi.org/10.3390/app12157788

Chicago/Turabian StyleSun, Xiaoyan, Fang Zhou, Lian Duan, and Ji-an Duan. 2022. "Investigation of Quadrate Fresnel Zone Plates Fabricated by Femtosecond Laser Direct Writing" Applied Sciences 12, no. 15: 7788. https://doi.org/10.3390/app12157788