Experimental Investigation on OBD Signal and PN Emission Characteristics by Damaged-DPF Types of 2.0 L Diesel Vehicle

Abstract

:1. Introduction

- Frequent short journeys where the engine doesn’t reach optimum operating temperature

- EGR valve problems, such as stuck or fouled EGR components

- Faulty fuel injectors sending too much fuel to the air/fuel mixture

- The use of the wrong engine oil—low ash, low sulfur oil must be used on DPF equipped vehicles.

- Turbo failure with oil dripping into the DPF: oil passes through turbo seals into the exhaust housing and the burnt oily residue enters the DPF, causing excessive dense soot loading.

- High mileage vehicle that will find regeneration harder

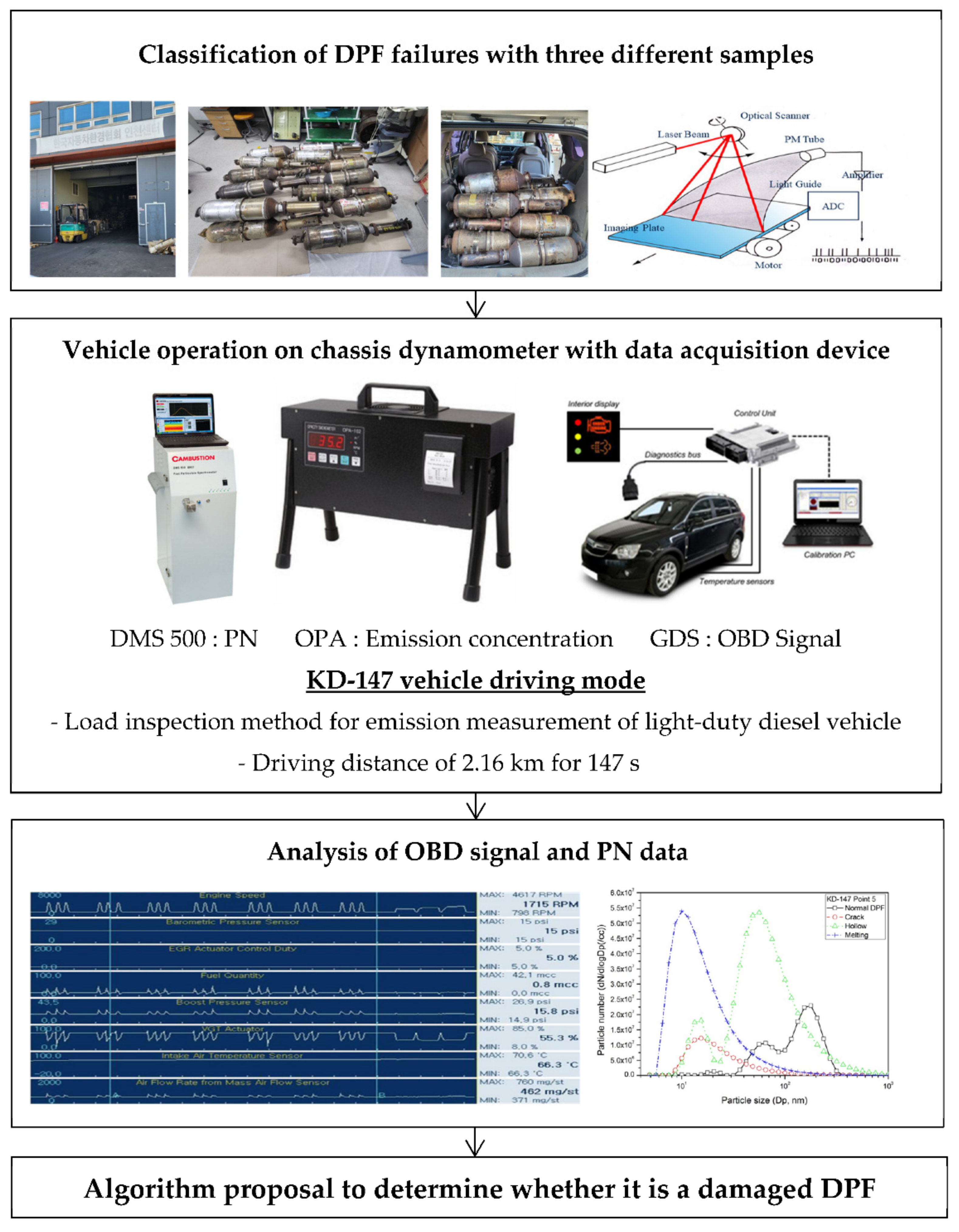

- Classification of DPF failures with three samples

- 2.

- Vehicle operation on chassis dynamometer

- 3.

- Analysis of OBD signal and PN data

- 4.

- Recommendation of algorithm to detect the type of damaged DPF

2. Experimental Apparatus and Procedure

2.1. Experimental Setup

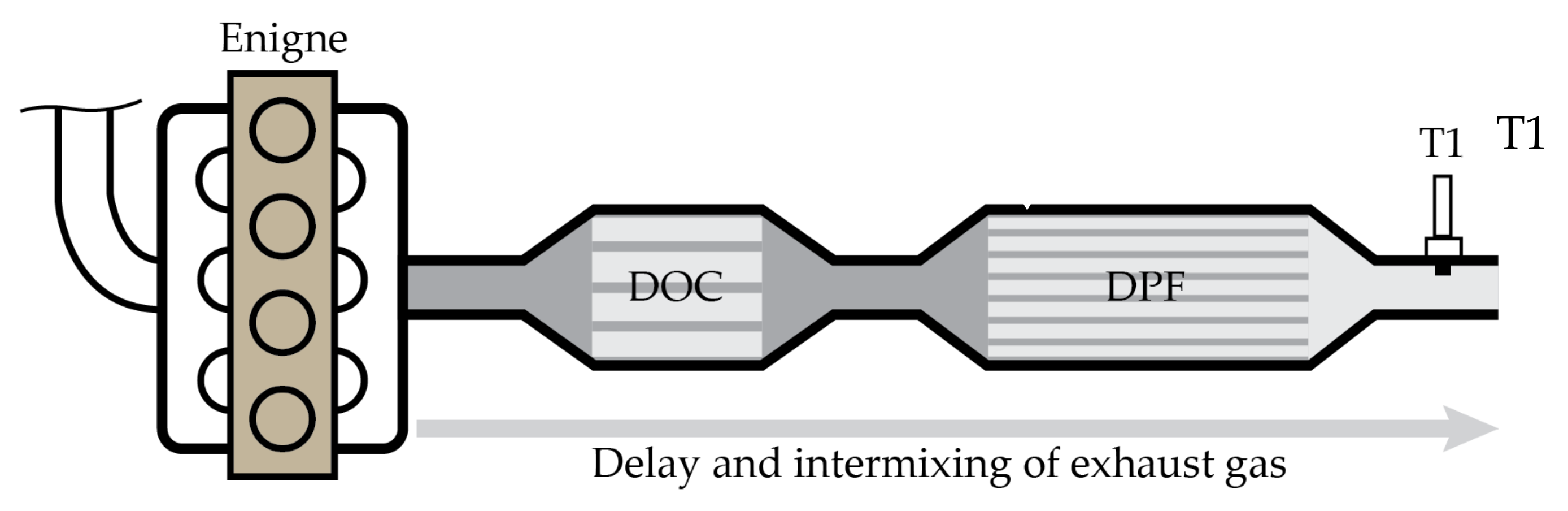

2.1.1. After-Treatment System

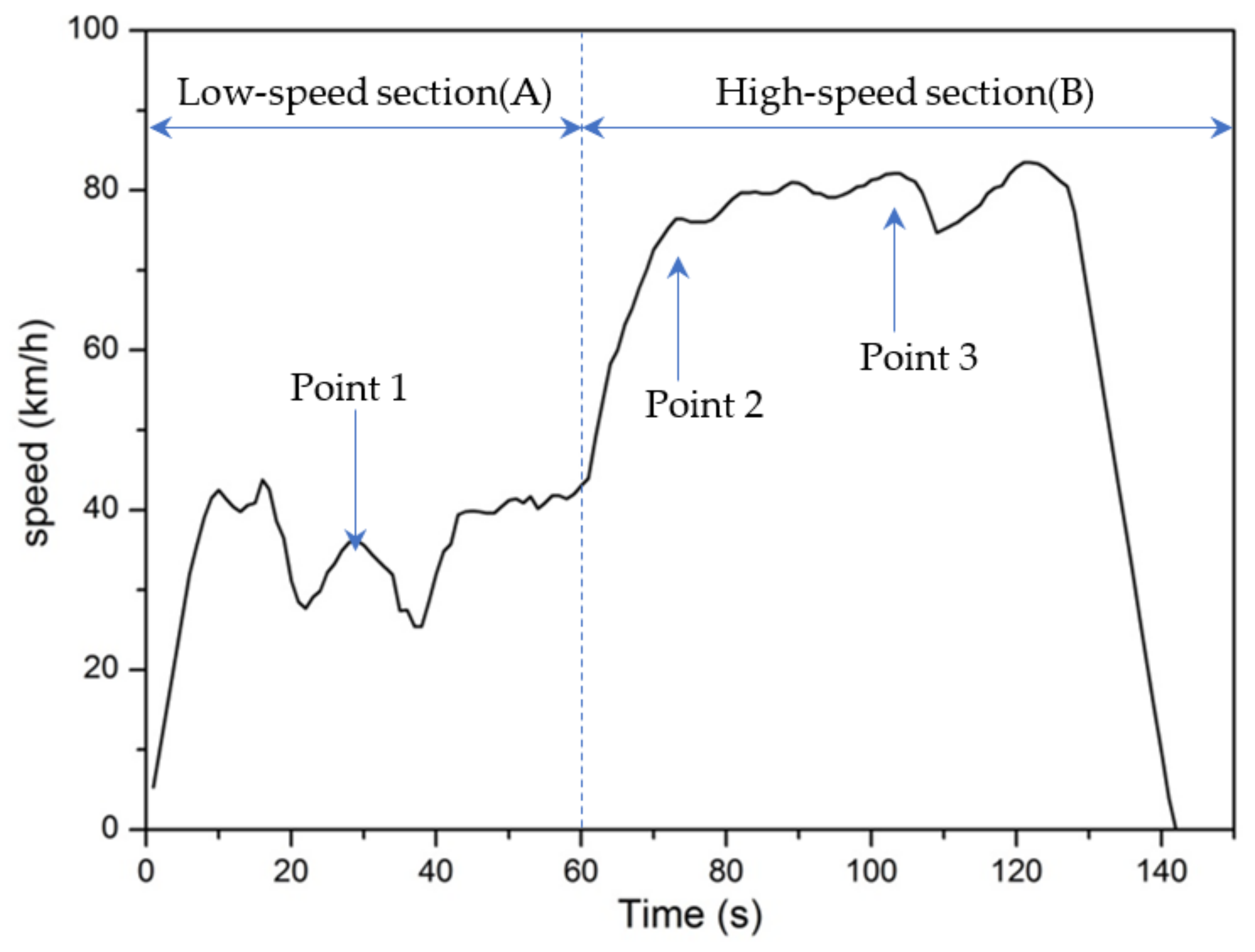

2.1.2. Vehicle Driving Cycle (KD-147 Mode)

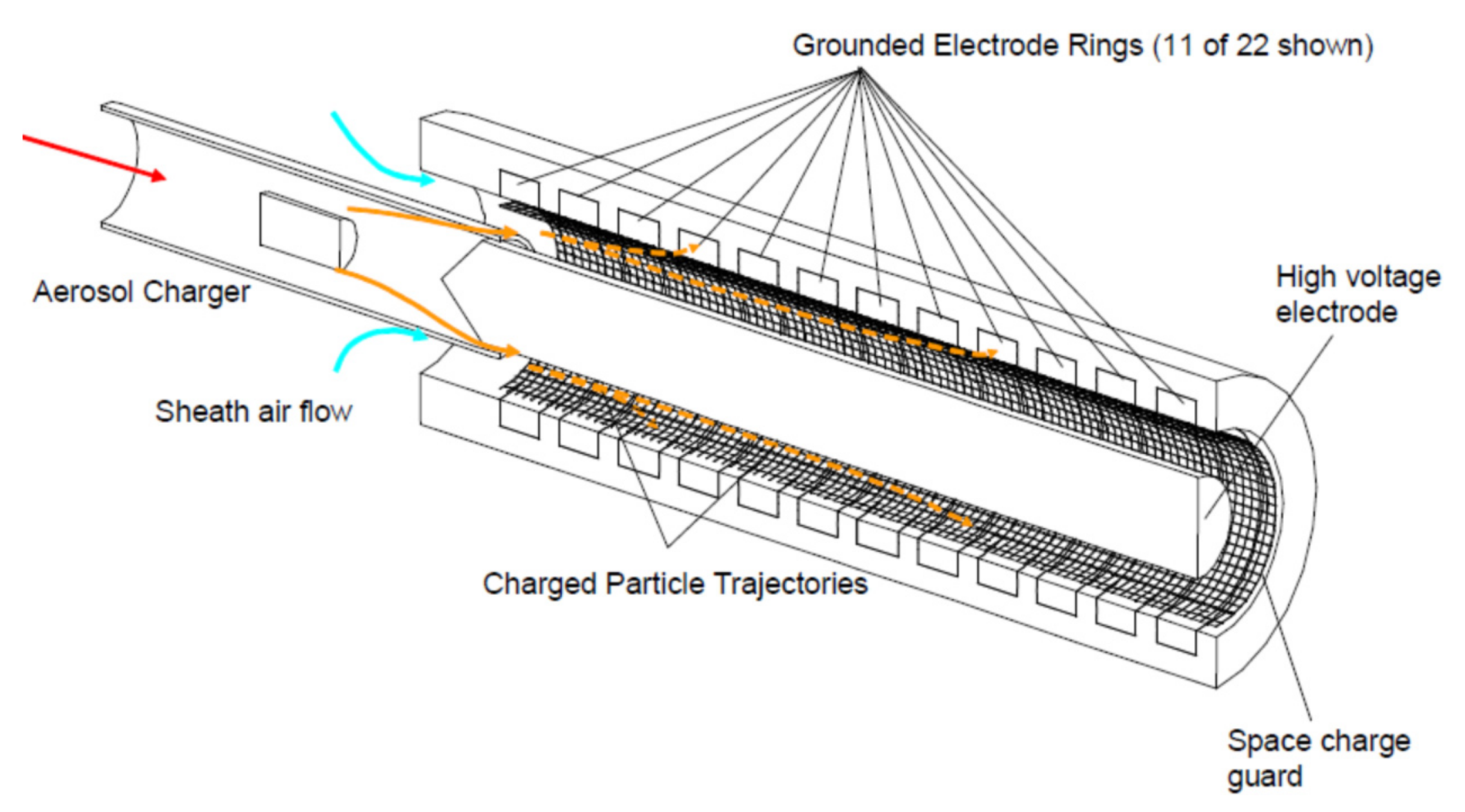

2.1.3. Vehicle Emission and OBD Data Acquisition Devices on Chassis Dynamometer

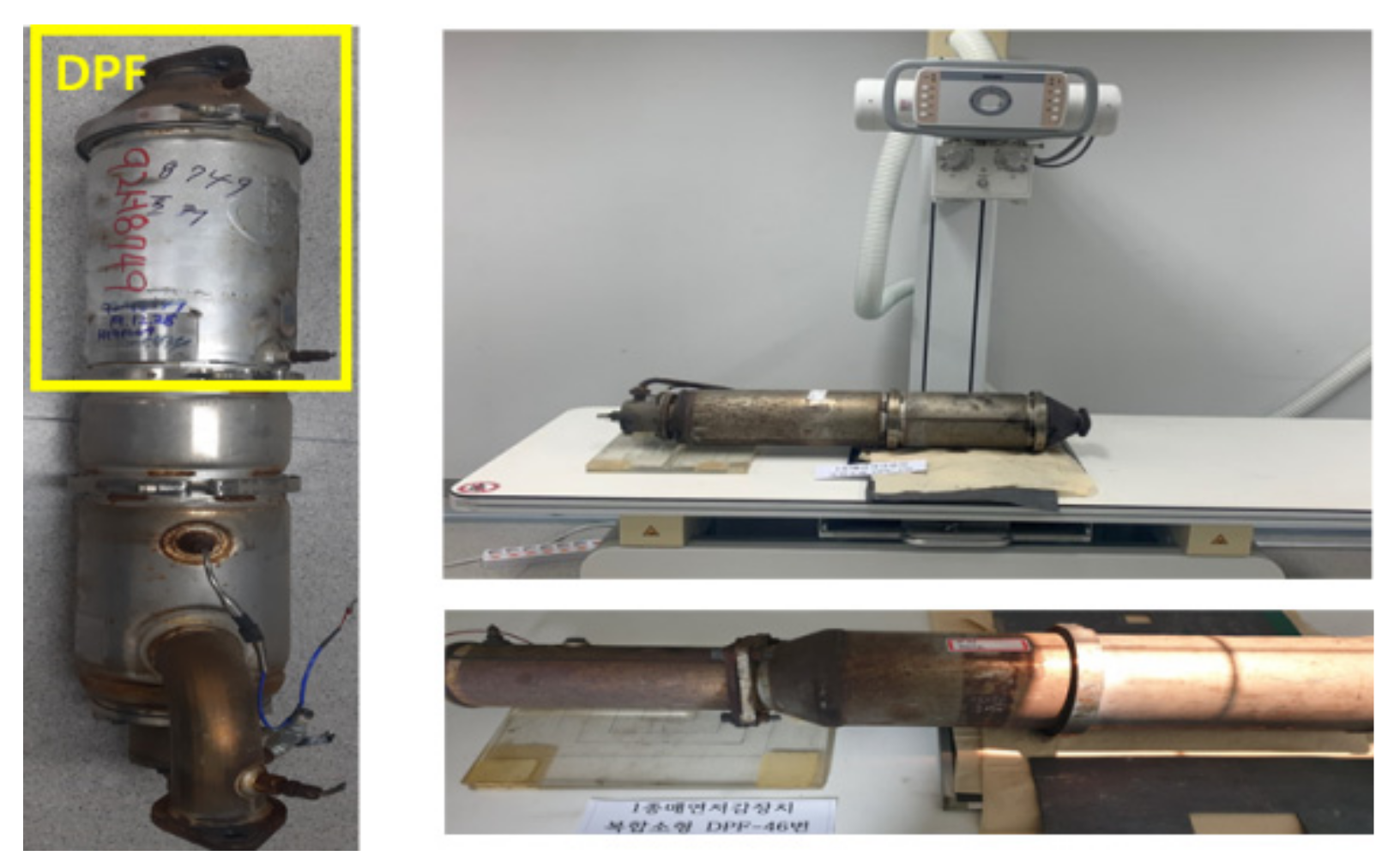

2.2. Three DPF Samples with Different Types of Damage (Crack, Melting and Hollow)

2.3. Experimental Condition

3. Experimental Results and Discussions

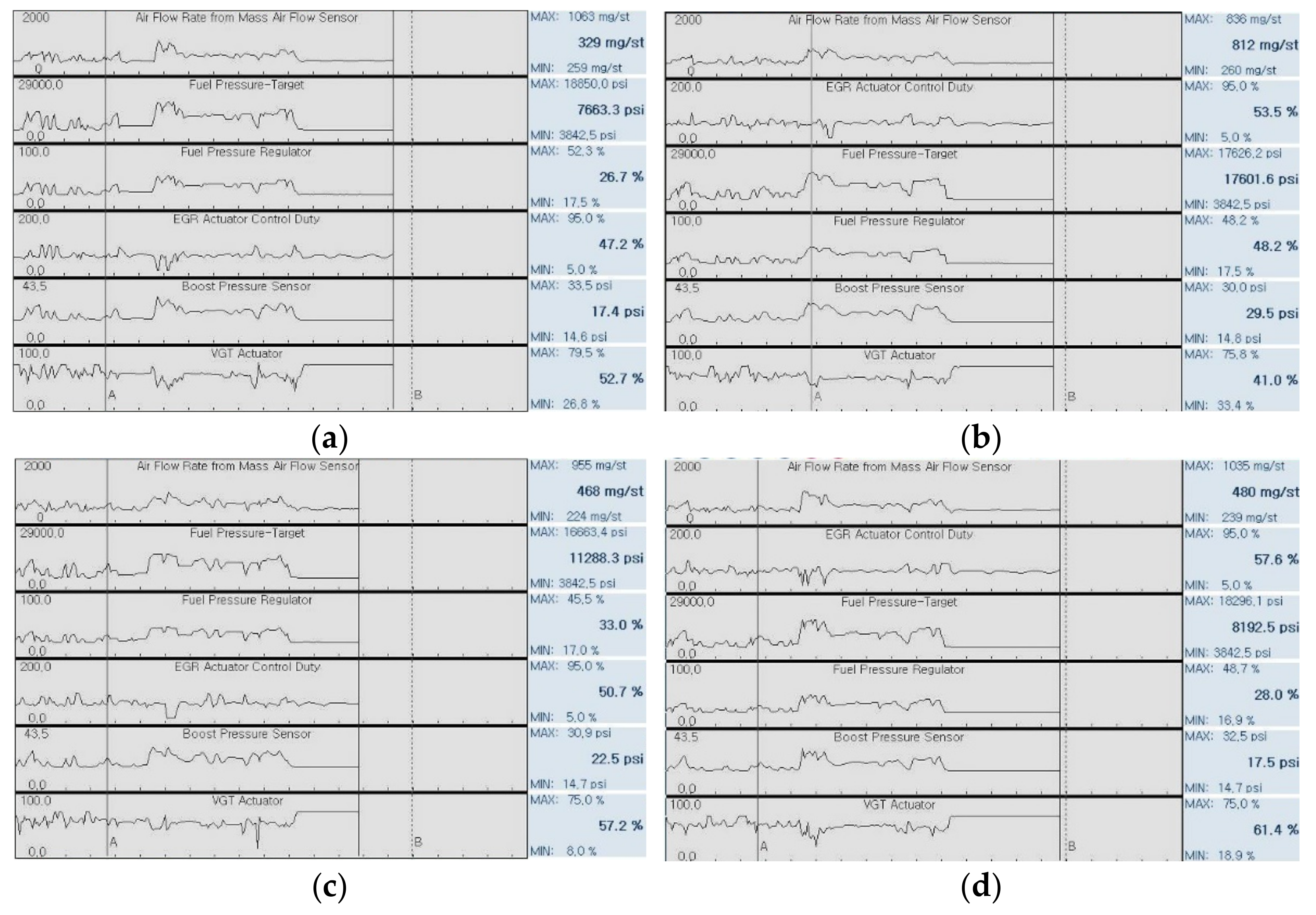

3.1. OBD Signal Comparison

3.2. Particulate Emission Comparison

3.2.1. Soot Emission Concentration

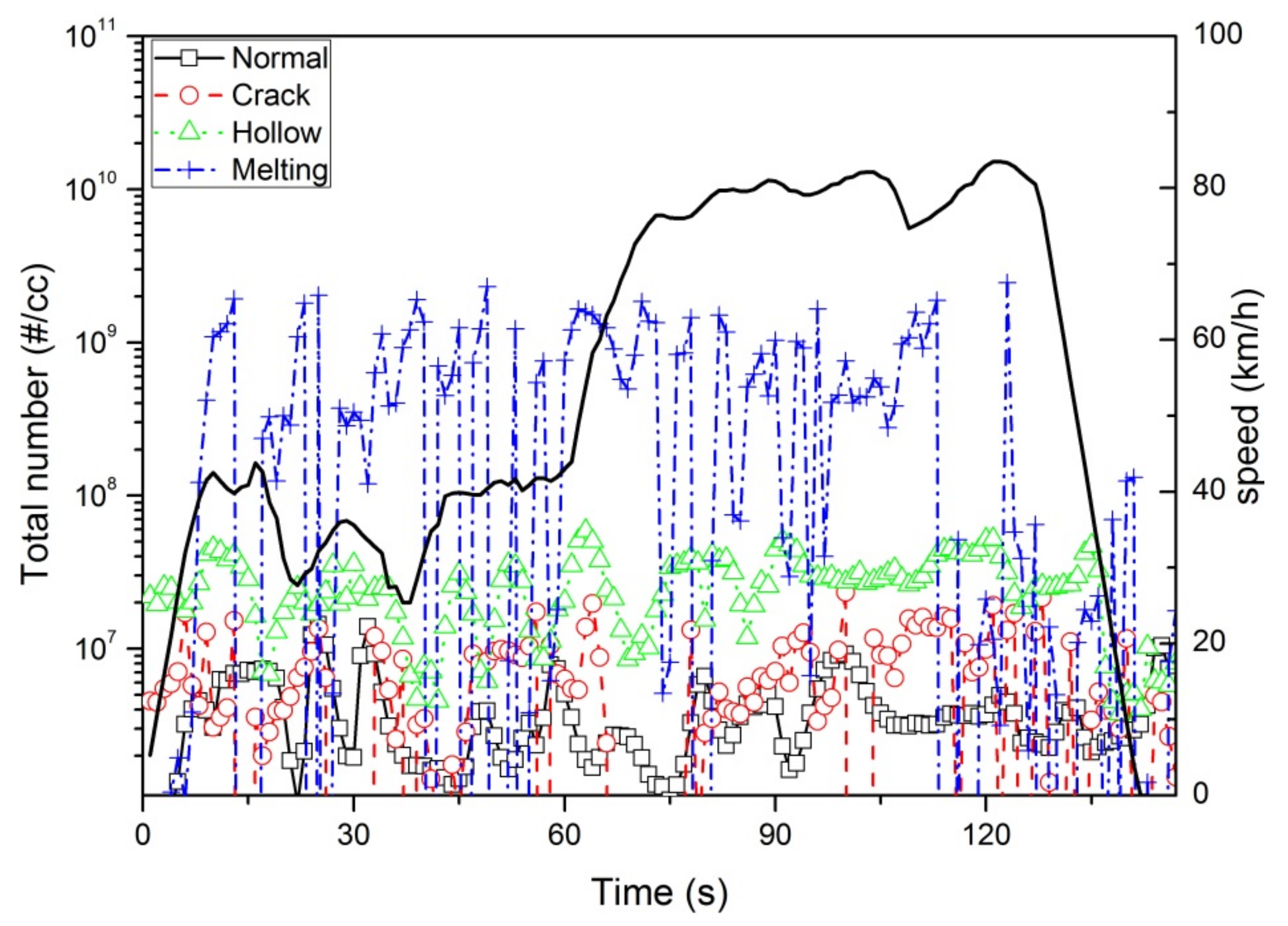

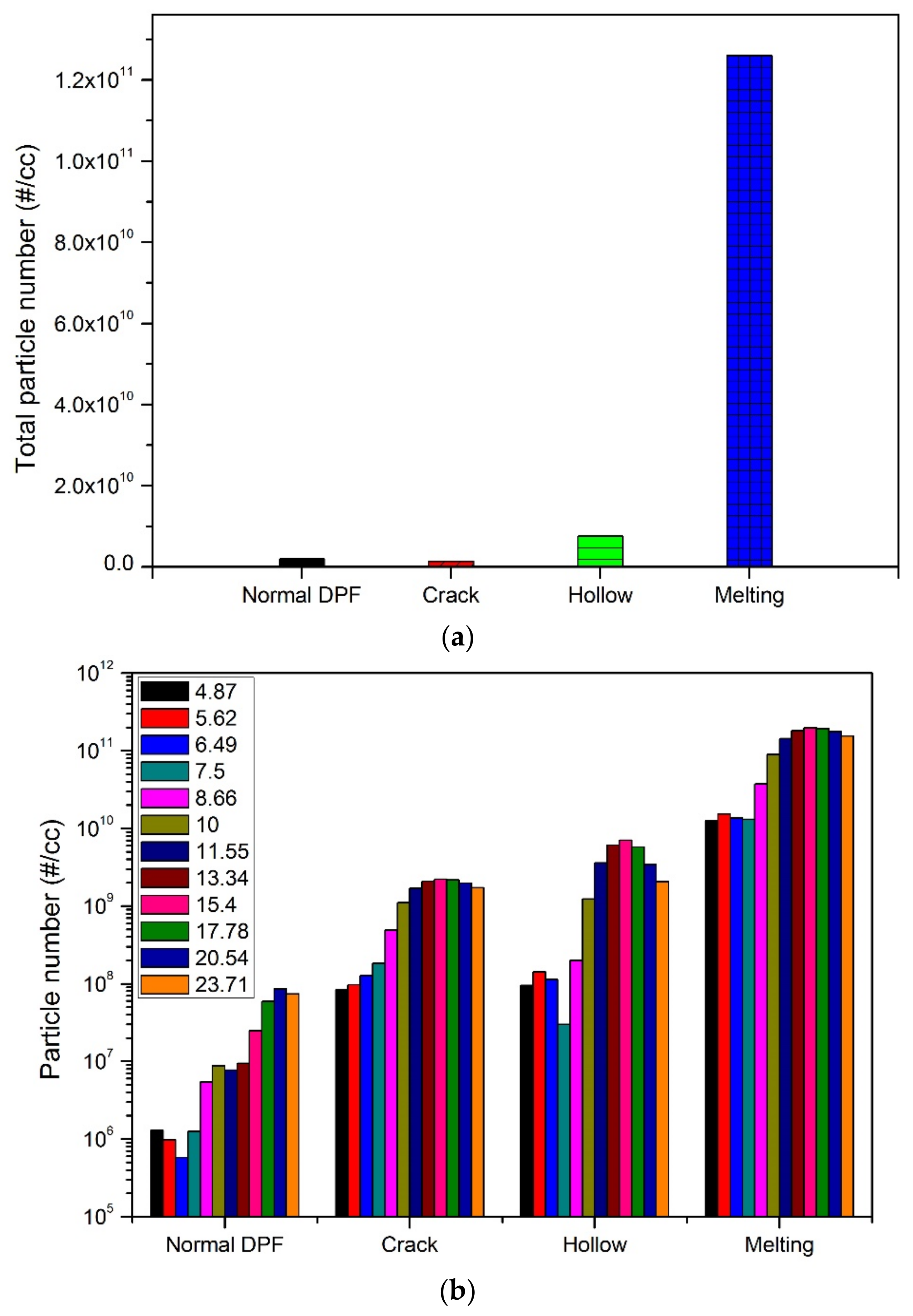

3.2.2. Particle Number and Size Concentration

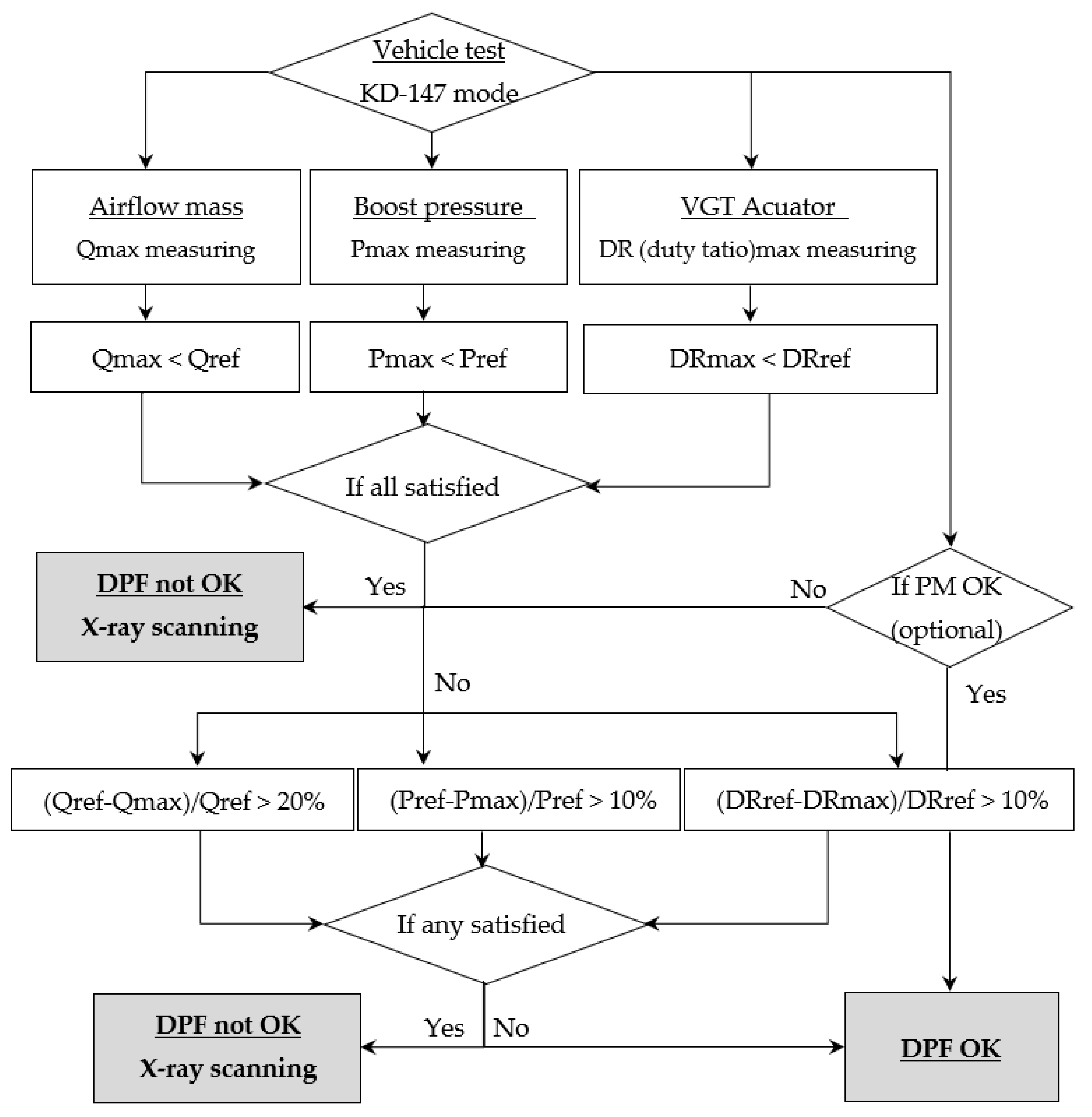

3.3. Algorithm for Determining Damaged DPF

4. Conclusions

- The three types of DPF damage were identified using X-ray images with a tube voltage of 125 kV. The failures in the cordierite DPF substrates were classified into the following types: cracks in the material inside the DPF, its melting, and hollow fractures.

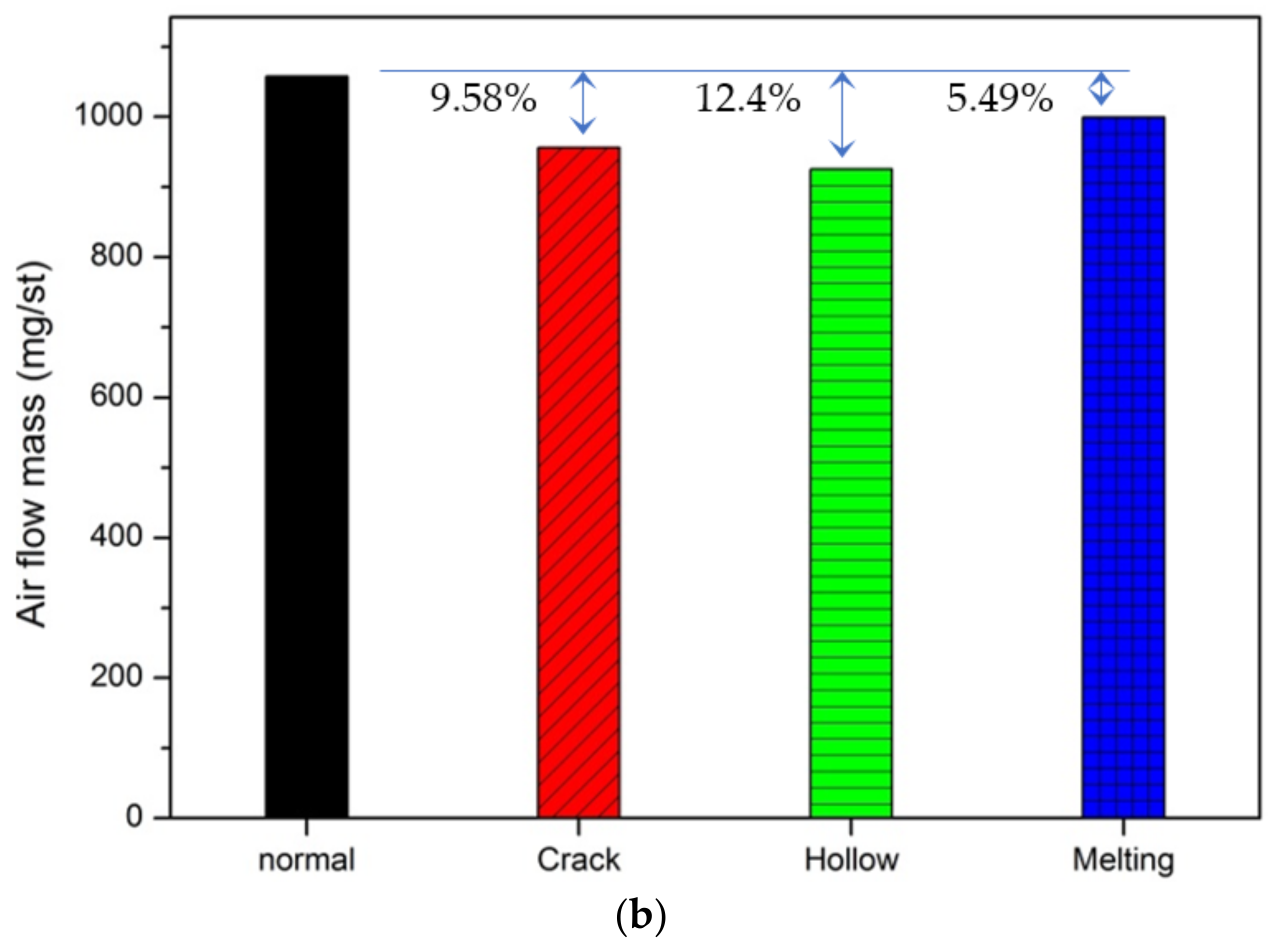

- A comparison of the characteristics of the OBD data obtained by the GDS under the KD-147 driving mode with each of the DPF samples revealed that the difference in maximum value of the OBD data was larger than the difference in minimum value. In particular, the maximum values of the three parameters (airflow mass, boost pressure, and VGT actuator) were distinctly different for each of the DPF samples.

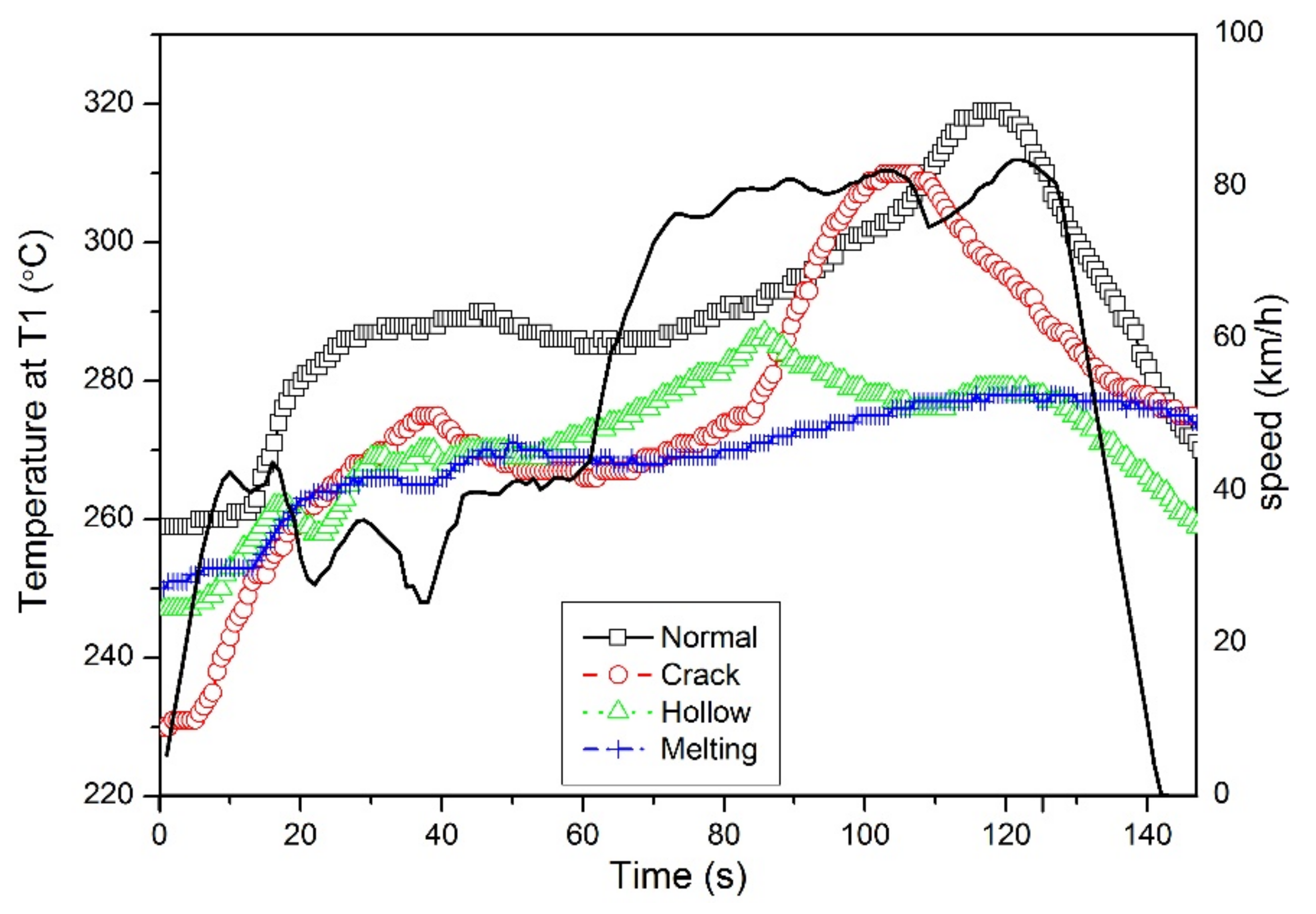

- A comparison of the exhaust temperature at the rear end of the DPF revealed that the exhaust temperature gradient in the case of the normal DPF and crack-damaged DPF followed the KD-147 driving pattern. This was because volume damage had not occurred inside the cordierite DPF substrates. However, in the case of the hollow- and melting-damaged DPFs, the volume inside the cordierite DPF substrates reduced, or the time for the exhaust gas to stay in the DPF substrates decreased. Thereby, these present relatively smooth shape patterns.

- In the case of the normal DPF device, the emissions were less than 10% of the permissible exhaust emissions for diesel vehicles in Korea. Meanwhile, the emissions with each of the three damaged DPFs exceeded this value.

- At particle number and size concentration, the normal DPF sample showed the lowest maximum number of total particle emission levels (within 107). Meanwhile, the crack- and hollow-damaged DPF samples showed total PN emission levels within 108. The melting-damaged DPF continuously emitted the largest number of nanoparticles (of the order of 109 #/cc) regardless of the vehicle driving speed in the KD-147 driving mode. The normal DPF also emitted a significant number of nanoparticles with sizes of at most 23 nm.

- Finally, the OBD-based algorithm to determine whether a DPF is damaged was developed from the airflow mass, boost pressure, and VGT actuator control duty data measured by the GDS diagnostic as comparable signals. It is anticipated that prior to obtaining an X-ray image to determine whether the DPF is damaged, it can be primarily selected using the algorithm developed in this study.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zoldy, M.; Szalmane Csete, M.; Kolozsi, P.P.; Bordas, P.; Torok, A. Cognitive Sustainability. Cogn. Sustain. 2022, 1, 1. [Google Scholar] [CrossRef]

- Cloudt, R. Diagnostics development for cost-effective temperature sensor based particulate matter OBD method. SAE Int. J. Passeng. Cars-Electron. Electr. Syst. 2014, 7, 573–582. [Google Scholar] [CrossRef]

- Gill, S.; Turner, D.; Tsolakis, A.; York, A. Understanding the Role of Filtered EGR on PM Emissions. In SAE Technical Paper 2011-01-2080; SAE: Warrendale, PA, USA, 2011. [Google Scholar] [CrossRef]

- Automobile Magazine. Available online: https://www.autmag.co.kr/660 (accessed on 7 November 2021).

- York, A.P.; Watling, T.C.; Ramskill, N.P.; Gladden, L.F.; Sederman, A.J.; Tsolakis, A.; Herreros, J.M.; Lefort, I. Visualization of the Gas Flow Field within a Diesel Particulate Filter Using Magnetic Resonance Imaging. In SAE Technical Paper 2015-01-2009; SAE: Warrendale, PA, USA, 2015. [Google Scholar] [CrossRef]

- Di Sarli, V.; Landi, G.; Lisi, L.; Di Benedetto, A. Catalytic diesel particulate filters with highly dispersed ceria: Effect of the soot-catalyst contact on the regeneration performance. Appl. Catal. B Environ. 2016, 197, 116–124. [Google Scholar] [CrossRef]

- Di Sarli, V.; Landi, G.; Lisi, L.; Di Benedetto, A. Ceria-coated diesel particulate filters for continuous regeneration. AIChE J. 2017, 63, 3442–3449. [Google Scholar] [CrossRef]

- Di Sarli, V.; Landi, G.; Lisi, L.; Di Benedetto, A. Synergy Between Ceria and Metals (Ag or Cu) in Catalytic Diesel Particulate Filters: Effect of the Metal Content and of the Preparation Method on the Regeneration Performance. Top Catal. 2021, 64, 256–269. [Google Scholar] [CrossRef]

- Technical Bulletin: Diesel Particulate Filter Operation and Maintenance. Available online: https://www.epa.gov/sites/production/files/2016-03/documents/420f10027.pdf (accessed on 7 November 2021).

- Liu, S.; Lü, M. Fault diagnosis of the blocking diesel particulate filter based on spectral analysis. Processes 2019, 7, 943. [Google Scholar] [CrossRef] [Green Version]

- Yang, K.; Fox, J.T.; Hunsicker, R. Characterizing diesel particulate filter failure During commercial fleet use due to pinholes, melting, cracking, and fouling. Emiss. Control Sci. Technol. 2016, 2, 145–155. [Google Scholar] [CrossRef] [Green Version]

- Health Effects of Particulate Matter. Policy Implications for Countries in Eastern Europe, Caucasus and Central Asia. WHO. 2013. Available online: https://www.euro.who.int/__data/assets/pdf_file/0006/189051/Health-effects-of-particulate-matter-final-Eng.pdf (accessed on 3 July 2022).

- Moos, R. Microwave-based catalyst state diagnosis—State of the art and future perspectives. SAE Int. J. Engines 2015, 8, 1240–1245. [Google Scholar] [CrossRef]

- C.A.R.B. Evaluation of Particulate Matter Filters in on Road Heavy Duty Diesel Vehicle Application. 2015. Available online: http://www.arb.ca.gov/sites/default/files/2020-08/dpfeval_0.pdf (accessed on 28 July 2022).

- Hoepfner, A.; Roduner, C. PM Sensor Based on-board diagnosis of particulate filter efficiency. In SAE Technical Paper 2013-01-1515; SAE: Warrendale, PA, USA, 2013. [Google Scholar] [CrossRef]

- Ochs, T.; Schittenhelm, H.; Genssle, A.; Kamp, B. Particulate matter sensor for on Board Diagnostics (OBD) of diesel particulate filters (DPF). SAE Int. J. Fuels Lubr. 2010, 3, 61–69. [Google Scholar] [CrossRef]

- Premchand, K.; Raghavan, K.; Johnson, J. A modeling study of the exhaust flow rate and temperature effects on the particulate matter thermal oxidation occurring during the active regeneration of a diesel particulate filter. In SAE Technical Paper 2015-01-1044; SAE: Warrendale, PA, USA, 2015. [Google Scholar] [CrossRef]

- Meloni, E.; Palma, V. Most recent advances in diesel engine catalytic soot abatement: Structured catalysts and alternative approaches. Catalysts 2020, 10, 745. [Google Scholar] [CrossRef]

- Zandhuis, J.; Finney, C.; Toops, T.; Partridge, W.; Daw, C.; Fox, T. Nondestructive X-ray inspection of thermal damage, soot and ash distributions in diesel particulate filters. In SAE Technical Paper 2009-01-0289; SAE: Warrendale, PA, USA, 2009. [Google Scholar] [CrossRef]

- Nishina, S.; Takeuchi, K.; Shinohara, M.; Imamura, M.; Shibata, M.; Hashimoto, Y.; Watanabe, F. Novel nondestructive imaging analysis for catalyst Washcoat loading and DPF soot distribution using terahertz wave computed tomography. SAE Int. J. Fuels Lubr. 2012, 5, 343–351. [Google Scholar] [CrossRef]

| Engine Type | Unit | D4EA (CRDi VGT) |

|---|---|---|

| Type of fuel | - | Diesel |

| Rated power | PS/RPM | 126/4000 |

| Displacement | cc | 1991 |

| DOC + DPF | cpsi | 400 (ceramic type DOC) 200 (cordierite type DPF) |

| Curb vehicle weight | kg | 1745 |

| Gross vehicle weight | kg | 2185 |

| Item | Unit | Particulate (Soot) Analyzer |

|---|---|---|

| Target Subject | % m−1 °C | Smoke Opacity Light extinction coefficient Temperature (option) |

| Principle | - | Light extinction method (Partial-flow sampling type) |

| LED Type | nm | Green LED (565) |

| Detector | - | Photo Diode |

| Range | % | 0.0~100.0 (0.00~21.42 m−1) |

| Accuracy | % | Less than 1 |

| Item | Particle Analyzer |

|---|---|

| Particle size range | 5 nm~1 μm |

| Spectral Elements | 38 (1 μm) (at 16/decade, 32/decade available) |

| Size Classification | Electrical Mobility |

| Dilution Factor Range | 1~6 (1st Dilution), 1~3000 (1st and 2nd) |

| Maximum 1st dilution/ Heated Line temperatures | 150 °C |

| Sample Flow rate | 8 slpm (1 μm range), All at 0 °C + 100 kPa |

| Time Response | T10–90% 200 ms (1 μm range) |

| Maximum Concentration | ≈1011 dN/dlogDp/cc (diluter on) |

| Damaged Type | Crack | Hollow | Melting |

|---|---|---|---|

| Phenomenon | Cracked inside cordierite DPF substrates | Hollow failure from front to rear of DPF | Melting inside DPF substrates |

| X-ray image captured in this study |  |  |  |

| Driving Mode | Measurement Device | DPF Sample | Number of Experiment |

|---|---|---|---|

| KD-147 cycle | GDS OPA-120 DMS-500 | Normal DPF Crack Melting Hollow | 4 times in each DPF sample |

| Parameter | Unit | Normal | Crack | Hollow | Melting | |

|---|---|---|---|---|---|---|

| Air-flow mass | mg/st | Max. | 1057.3 | 956.0 | 925.7 | 919.3 |

| min. | 246.7 | 254.0 | 234.3 | 228.3 | ||

| EGR ACD * | % | Max. | 95.0 | 94.0 | 94.6 | 95.0 |

| min. | 5.0 | 5.0 | 5.0 | 5.0 | ||

| Fuel Pressure | psi | Max. | 18,725.8 | 18,337.2 | 18,499.6 | 18,572.6 |

| min. | 3842.5 | 3842.5 | 3842.5 | 3842.5 | ||

| Boost Pressure | psi | Max. | 32.5 | 31.5 | 31.8 | 32.3 |

| min. | 14.6 | 14.8 | 14.8 | 14.6 | ||

| VGT Actuator | % | Max. | 77.8 | 76.6 | 75.4 | 75.0 |

| min. | 28.5 | 25.7 | 23.6 | 23.0 |

| Air-Flow Mass | Boost Pressure | VGT Actuator | ||

|---|---|---|---|---|

| Normal DPF | 1057.3 | 32.5 | 77.8 | |

| Damaged DPF | Crack | 956.0 | 31.5 | 76.6 |

| Hollow | 925.7 | 31.8 | 75.4 | |

| Melting | 919.3 | 32.3 | 75.0 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cho, I.; Moon, I.; Kim, D.; Park, T.; Lee, D.; Lee, J. Experimental Investigation on OBD Signal and PN Emission Characteristics by Damaged-DPF Types of 2.0 L Diesel Vehicle. Appl. Sci. 2022, 12, 7853. https://doi.org/10.3390/app12157853

Cho I, Moon I, Kim D, Park T, Lee D, Lee J. Experimental Investigation on OBD Signal and PN Emission Characteristics by Damaged-DPF Types of 2.0 L Diesel Vehicle. Applied Sciences. 2022; 12(15):7853. https://doi.org/10.3390/app12157853

Chicago/Turabian StyleCho, Insu, Iljoo Moon, Daekuk Kim, Taeyoung Park, Dokyeong Lee, and Jinwook Lee. 2022. "Experimental Investigation on OBD Signal and PN Emission Characteristics by Damaged-DPF Types of 2.0 L Diesel Vehicle" Applied Sciences 12, no. 15: 7853. https://doi.org/10.3390/app12157853

APA StyleCho, I., Moon, I., Kim, D., Park, T., Lee, D., & Lee, J. (2022). Experimental Investigation on OBD Signal and PN Emission Characteristics by Damaged-DPF Types of 2.0 L Diesel Vehicle. Applied Sciences, 12(15), 7853. https://doi.org/10.3390/app12157853