End-Effectors Developed for Citrus and Other Spherical Crops

Abstract

:1. Introduction

2. Materials and Methods

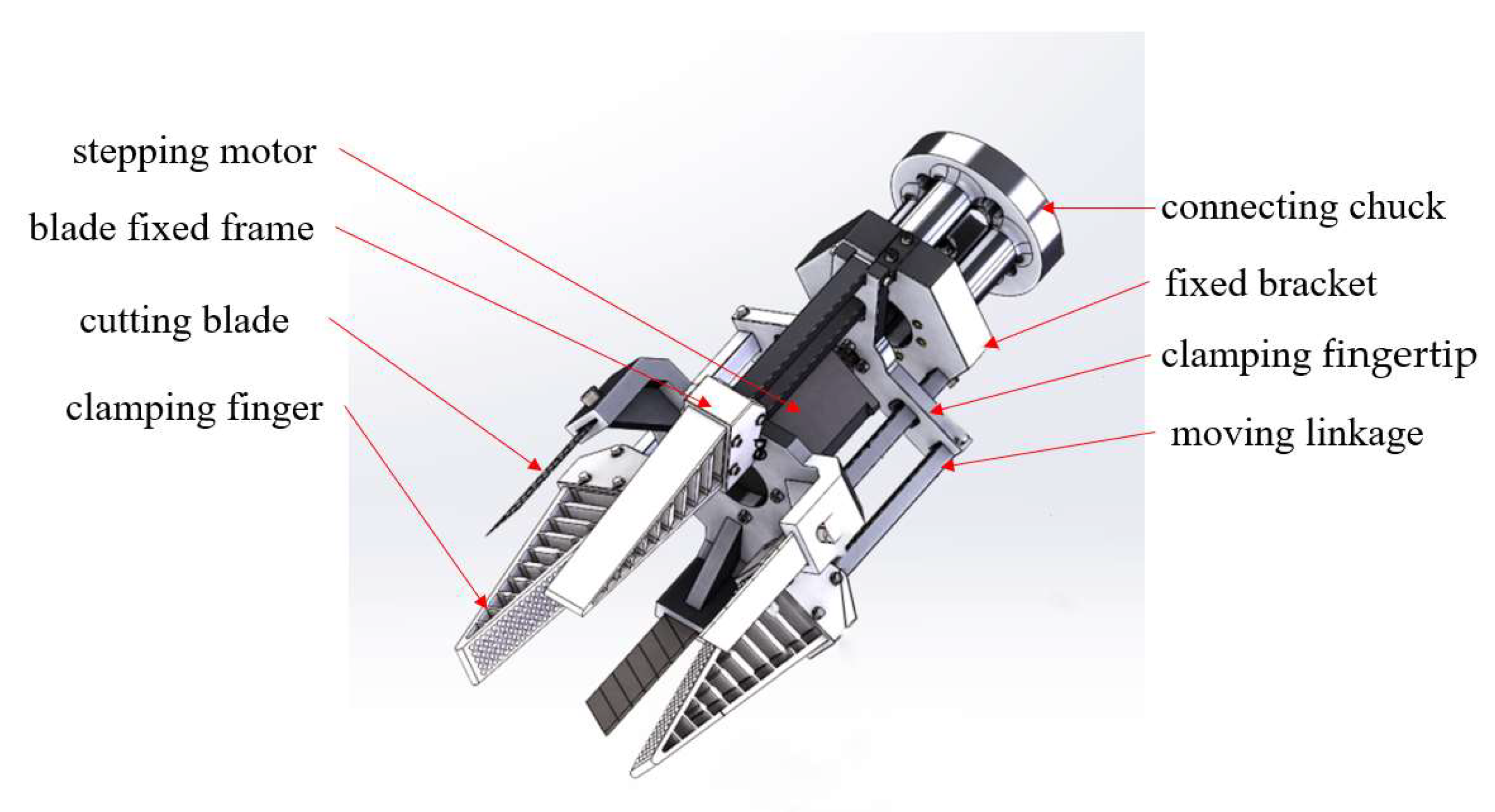

2.1. Overall Design of the End-Effector

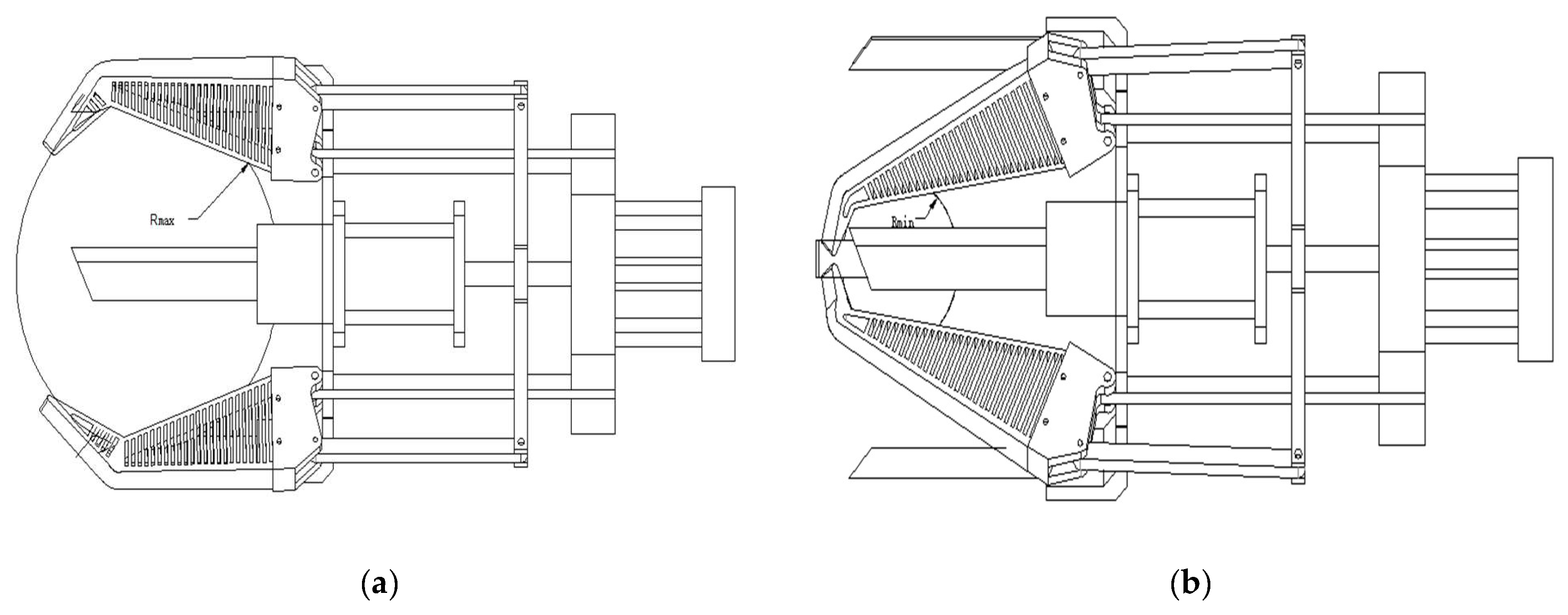

2.2. Clamping Mechanism Design

2.2.1. Clamping Finger Form

2.2.2. Number of Fingers

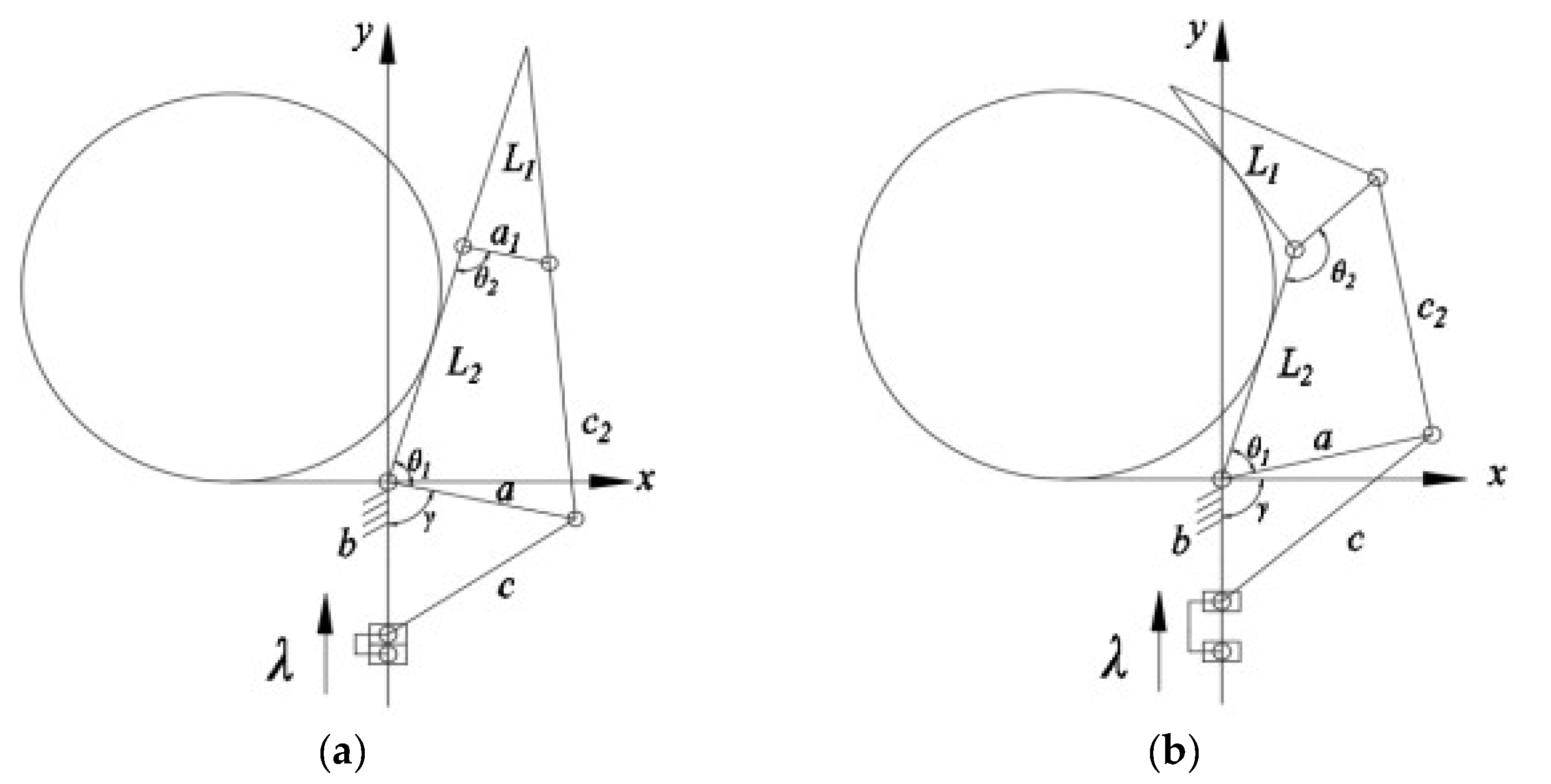

2.2.3. Mathematical Model of Citrus Picking Finger Length

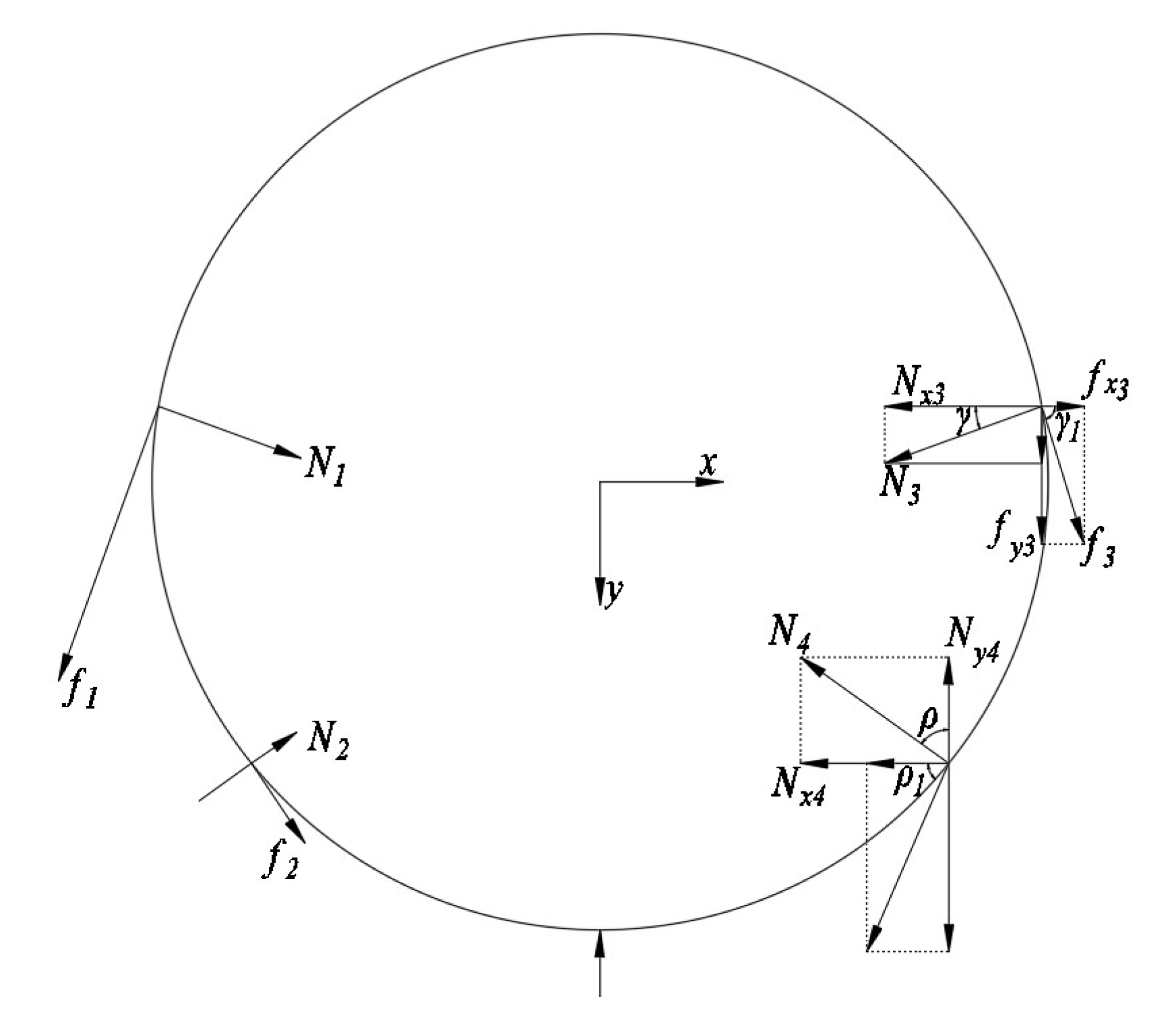

2.2.4. Analysis of Stresses on Citrus Fruits

2.2.5. Clamping Mechanism Parameter Setting

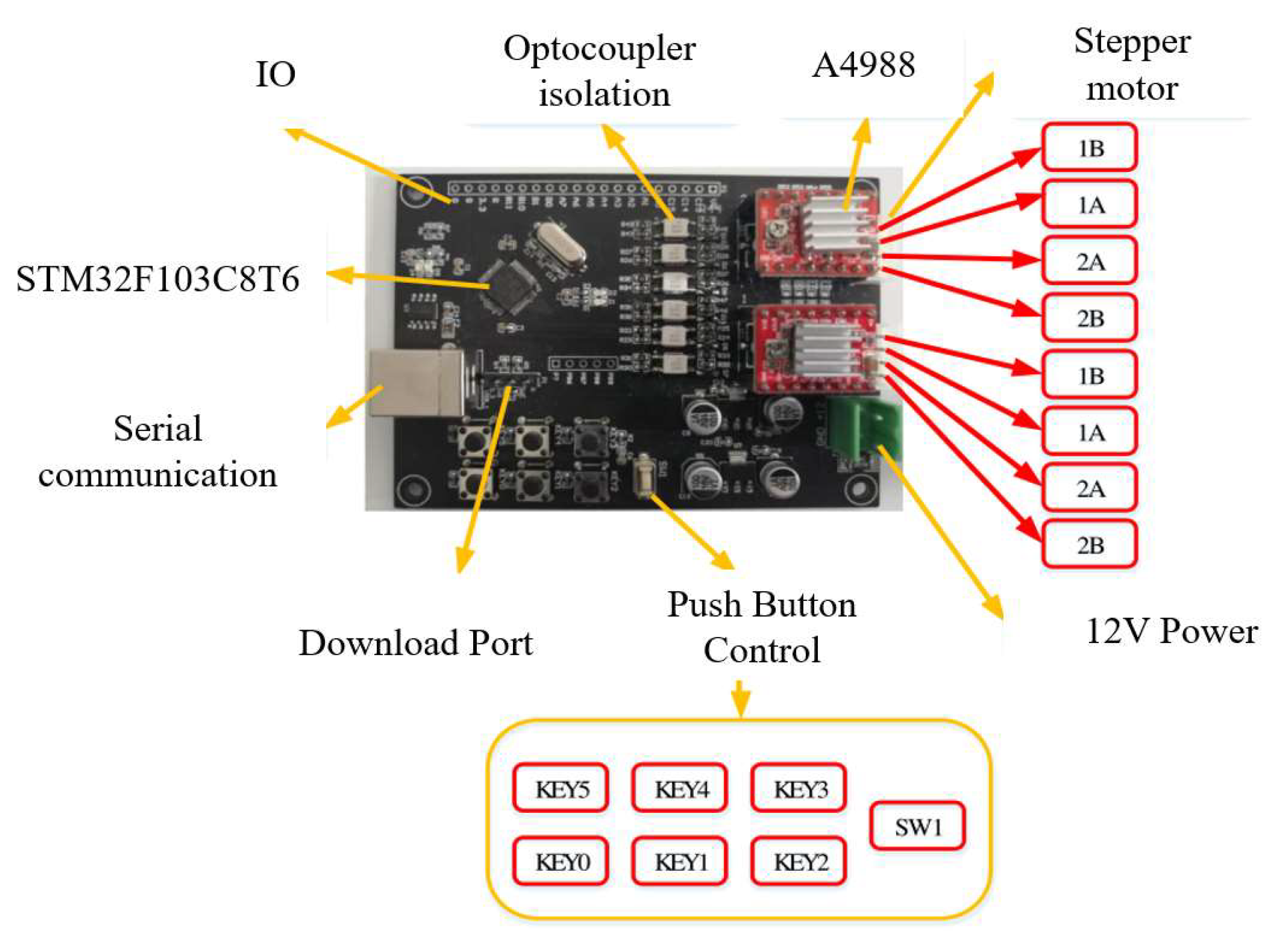

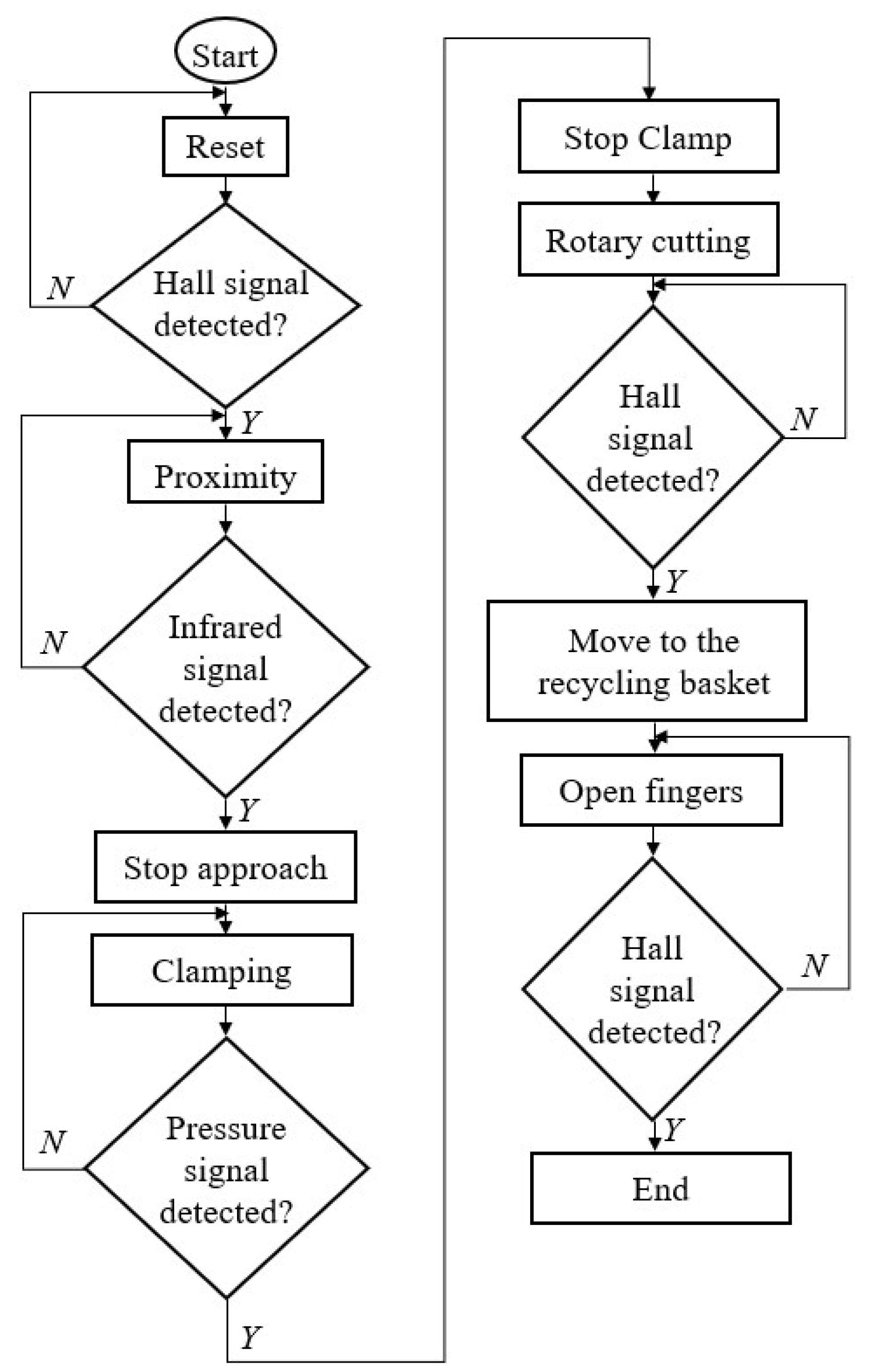

2.2.6. Control System Design

2.3. Picking Simulation Analysis

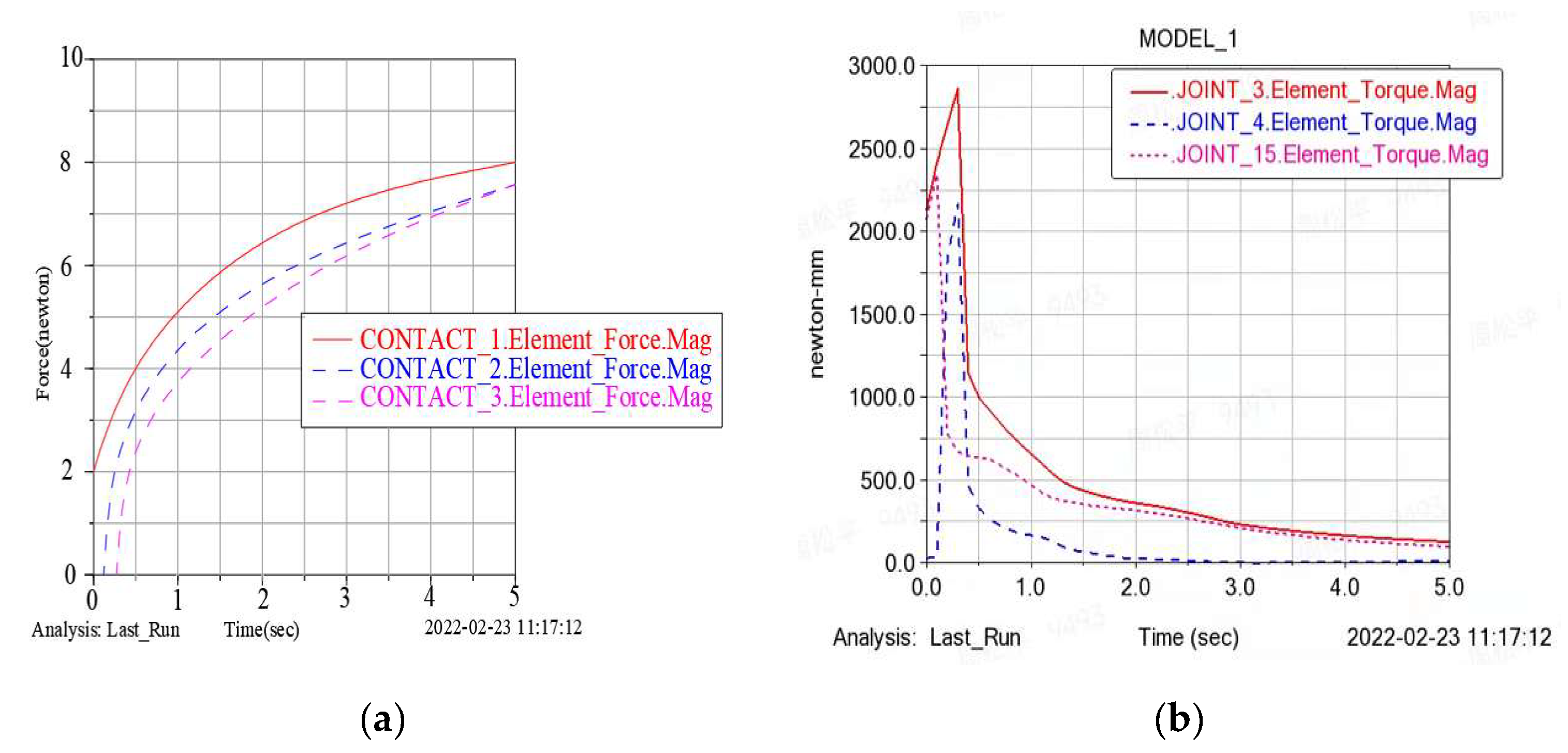

2.3.1. ADAMS-Based End-of-Pick Actuator Model

2.3.2. Picking Simulation Analysis

2.4. Fruit Stalks Cutting Simulation Analysis

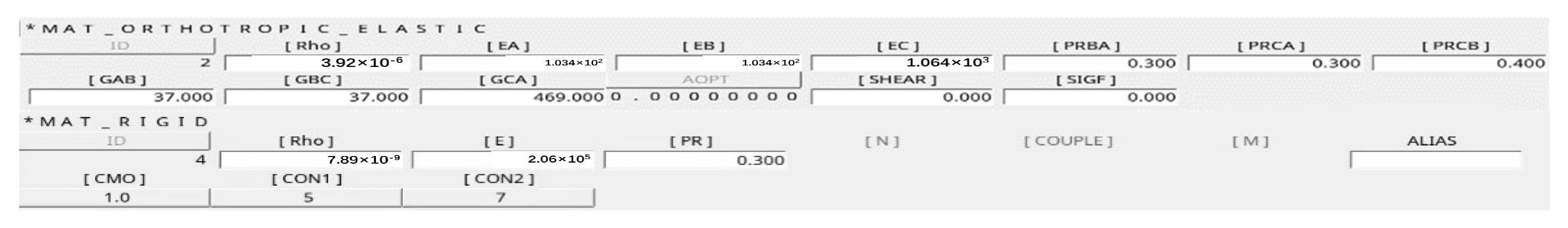

2.4.1. Build Simulation Environment

2.4.2. Parameter Settings

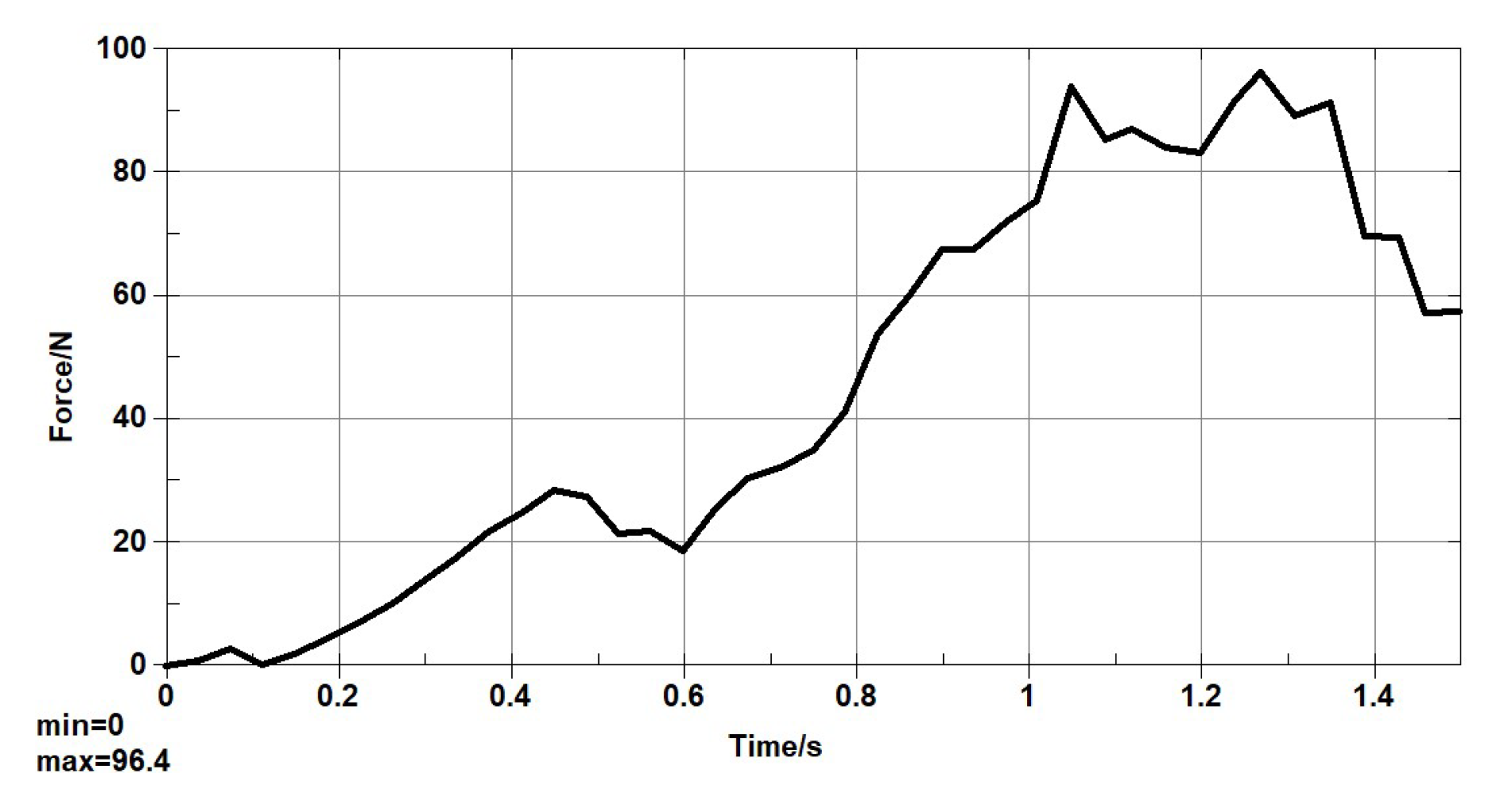

2.4.3. Fruit Stalk Cutting Simulation Test

2.4.4. Picking Simulation Analysis

3. Picking Performance Tests

3.1. Test Materials

3.2. Test Methods and Evaluation

3.3. Single-Factor Tests

3.3.1. Influence of Stepper Motor Speed on Picking Performance

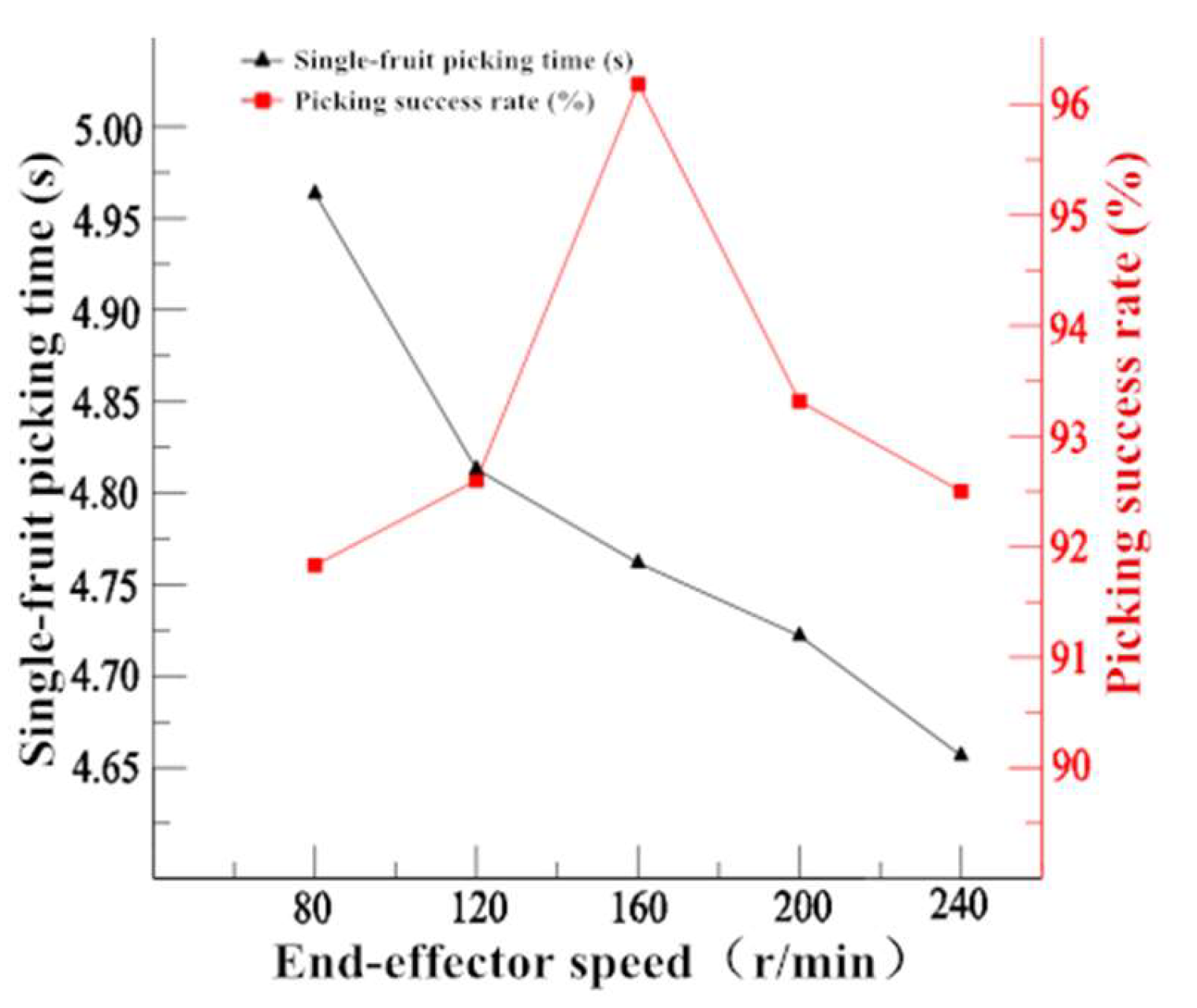

3.3.2. Effect of End-Effector Speed on Picking Performance

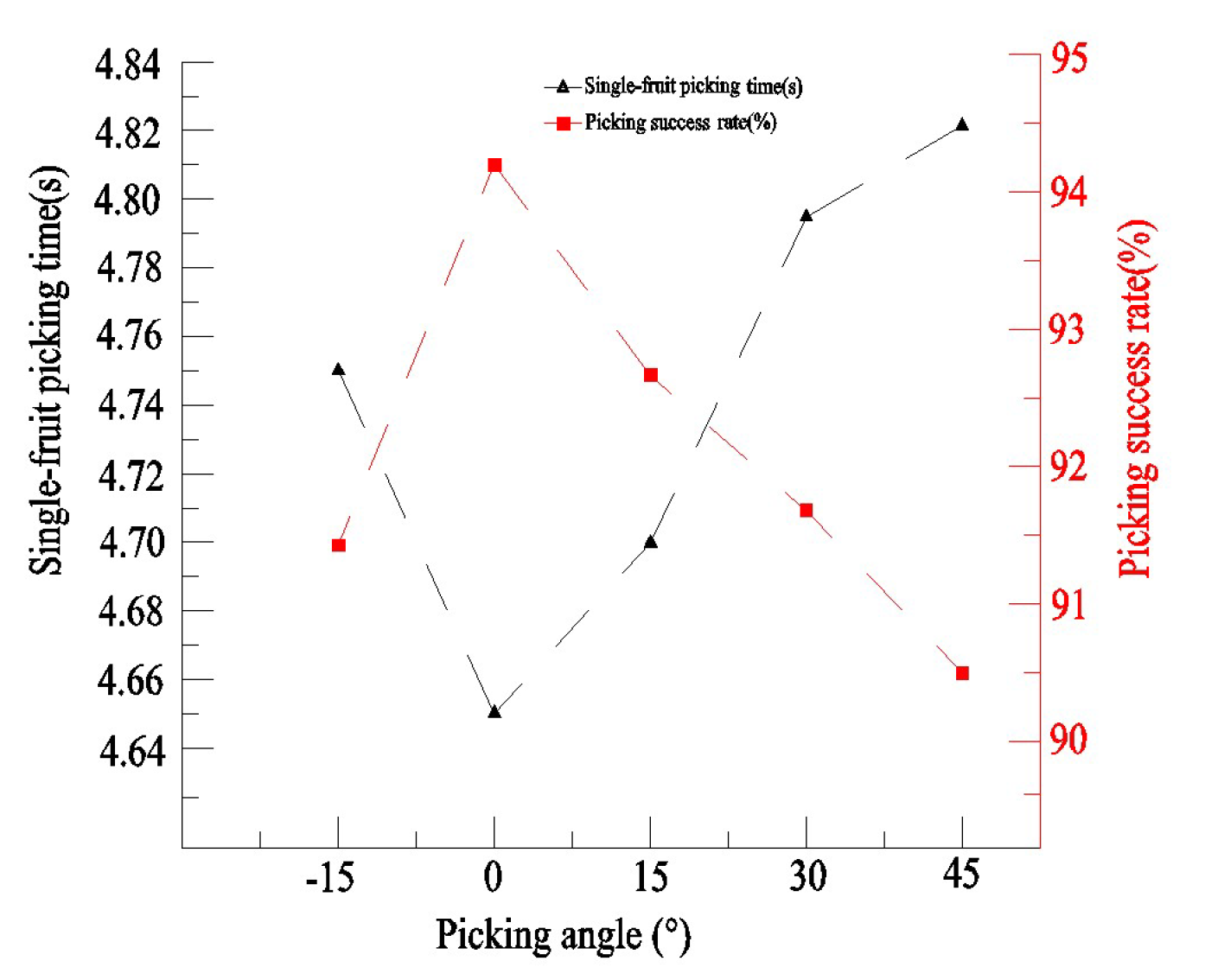

3.3.3. Effect of Picking Angle on Picking Performance

3.4. Multi-Factor Tests

4. Conclusions

- (1)

- The end-effector is mainly composed of a clamping mechanism, cutting mechanism, and stepper motor. The clamping mechanism adopts the principle of three-finger clamping, which can carry out stable clamping according to the different sizes of the fruits. The cutting mechanism is fixedly installed on both sides of the clamping fingers, which can cut the stem of the fruit quickly and effectively.

- (2)

- Through the simulation analysis of the picking process of the citrus picking end-effector, it is concluded that the clamping fingers can complete the stable picking of citrus fruits within the safe clamping force for citrus fruits, and the cutting blades can complete the cutting of citrus fruit stems stably, and the overall picking performance of the end-effector is stable.

- (3)

- The single-factor test of the end-effector’s picking performance shows that the picking performance is best when the stepper motor speed is 250 r/min, the end-effector speed is 160 mm/min, and the picking angle is 0°. Multi-factor or orthogonal tests showed that the factors affecting the end-effector picking performance were end-effector speed, stepper motor speed, and picking angle, in that order.

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gao, Y.; Kang, F.; Kan, J.; Wang, Y.; Tong, S. Analysis and experiment of cutting mechanical parameters for Caragana korshinskii (CK) branches. Forests 2021, 12, 1359. [Google Scholar] [CrossRef]

- Ferreira, M.D.; Sanchez, A.C.; Braunbeck, O.A.; Santos, E.A. Harvesting fruits using a mobile platform: A case study applied to citrus. Eng. Agrícola 2018, 38, 293–299. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Liu, D.; Zhang, Y.; He, Y.; Zhao, H.; Wang, K.; Li, Y. A Mechanical Model of Cutting Citrus Fruit Stems Based on Partial Least Squares Method. Trans. ASABE 2021, 64, 577–586. [Google Scholar] [CrossRef]

- Narimoto, L.R.; Costa Belussi, S.E.; Camarotto, J.A. Design-in-use applied to Brazilian agriculture: The case of citrus and sugarcane harvesting. Work 2020, 65, 689–698. [Google Scholar] [CrossRef] [PubMed]

- Torregrosa, A.; Molina, J.M.; Pérez, M.; Ortí, E.; Xamani, P.; Ortiz, C. Mechanical harvesting of ornamental citrus trees in Valencia, Spain. Agronomy 2019, 9, 827. [Google Scholar] [CrossRef] [Green Version]

- Chen, S.; Xiong, J.; Jiao, J.; Xie, Z.; Huo, Z.; Hu, W. Citrus fruits maturity detection in natural environments based on convolutional neural networks and visual saliency map. Precis. Agric. 2022, 107, 2411–2502. [Google Scholar] [CrossRef]

- Oliveira, L.F.; Moreira, A.P.; Silva, M.F. Advances in agriculture robotics: A state-of-the-art review and challenges ahead. Robotics 2021, 10, 52. [Google Scholar] [CrossRef]

- Jia, W.; Zhang, Y.; Lian, J.; Zheng, Y.; Zhao, D.; Li, C. Apple harvesting robot under information technology: A review. Int. J. Adv. Robot. Syst. 2020, 17, 1729881420925310. [Google Scholar] [CrossRef]

- Rose, D.C.; Lyon, J.; de Boon, A.; Hanheide, M.; Pearson, S. Responsible development of autonomous robotics in agriculture. Nat. Food 2021, 2, 306–309. [Google Scholar] [CrossRef]

- Wang, S.; Zhou, H.; Zhang, C.; Ge, L.; Li, W.; Yuan, T.; Zhang, J. Design, development and evaluation of latex harvesting robot based on flexible Toggle. Robot. Auton. Syst. 2022, 147, 103906. [Google Scholar] [CrossRef]

- Zhang, B.; Xie, Y.; Zhou, J.; Wang, K.; Zhang, Z. State-of-the-art robotic grippers, grasping and control strategies, as well as their applications in agricultural robots: A review. Comput. Electron. Agric. 2020, 177, 105694. [Google Scholar] [CrossRef]

- Fan, P.; Yan, B.; Wang, M.; Lei, X.; Liu, Z.; Yang, F. Three-finger grasp planning and experimental analysis of picking patterns for robotic apple harvesting. Comput. Electron. Agric. 2021, 188, 106353. [Google Scholar] [CrossRef]

- Tian, S.; Ashraf, M.A.; Kondo, N.; Shiigi, T.; Momin, M.A. Optimization of machine vision for tomato grafting robot. Sens. Lett. 2013, 11, 1190–1194. [Google Scholar] [CrossRef]

- Chiu, Y.C.; Chen, S.; Lin, J.F. Study of an autonomous fruit picking robot system in greenhouses. Eng. Agric. Environ. Food 2013, 6, 92–98. [Google Scholar] [CrossRef]

- Changhui, Y.A.; Yanping, L.I.; Yi, W.A.; Longye, X.I.; Hongbin, X.U.; Wanhua, Z.H. Research and experiment on recognition and location system for citrus picking robot in natural environment. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2019, 50, 626–634. [Google Scholar]

- Huang, M.; Jiang, X.; He, L.; Choi, D.; Pecchia, J.; Li, Y. Development of a robotic harvesting mechanism for button mushrooms. Trans. ASABE 2021, 64, 565–575. [Google Scholar] [CrossRef]

- Li, Z.; Yuan, X.; Wang, C. A review on structural development and recognition–localization methods for end-effector of fruit–vegetable picking robots. Int. J. Adv. Robot. Syst. 2022, 19, 17298806221104906. [Google Scholar] [CrossRef]

- Kurpaska, S.; Sobol, Z.; Pedryc, N.; Nawara, P. Analysis of the pneumatic system parameters of the suction cup integrated with the head for harvesting strawberry fruit. Sensors 2020, 20, 4389. [Google Scholar] [CrossRef]

- Mehta, S.S.; MacKunis, W.; Burks, T.F. Robust visual servo control in the presence of fruit motion for robotic citrus harvesting. Comput. Electron. Agric. 2016, 123, 362–375. [Google Scholar] [CrossRef]

- Bac, C.W.; Hemming, J.; Van Tuijl, B.A.J.; Barth, R.; Wais, E.; van Henten, E.J. Performance evaluation of a harvesting robot for sweet pepper. J. Field Robot. 2017, 34, 1123–1139. [Google Scholar] [CrossRef]

- Bac, C.W.; Roorda, T.; Reshef, R.; Berman, S.; Hemming, J.; van Henten, E.J. Analysis of a motion planning problem for sweet-pepper harvesting in a dense obstacle environment. Biosyst. Eng. 2016, 146, 85–97. [Google Scholar] [CrossRef]

- Inkulu, A.K.; Bahubalendruni, M.R.; Dara, A.; Sankaranarayanasamy, K. Challenges and opportunities in human robot collaboration context of Industry 4.0-a state of the art review. Ind. Robot. Int. J. Robot. Res. Appl. 2021, 49, 226–239. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, Y.; Yang, C.; Zhao, H.; Chen, G.; Zhang, Z.; Xu, H. End-effector with a bite mode for harvesting citrus fruit in random stalk orientation environment. Comput. Electron. Agric. 2019, 157, 454–470. [Google Scholar] [CrossRef]

- Yu, Y.; Wu, F.; Zhu, R.; Zhang, F. Principle Analysis and Parameter Optimization for Underactuated End-Effector Manipulator for Apple Picking. Open Mater. Sci. J. 2015, 9, 50–55. [Google Scholar]

- Zhao, D.H.; Zhang, H.; Hou, J.X. Design of Fruit Picking Device Based on the Automatic Control Technology. In Key Engineering Materials; Trans Tech Publications Ltd.: Bäch, Switzerland, 2014; Volume 620, pp. 471–477. [Google Scholar]

- Hohimer, C.J.; Wang, H.; Bhusal, S.; Miller, J.; Mo, C.; Karkee, M. Design and field evaluation of a robotic apple harvesting system with a 3D-printed soft-robotic end-effector. Trans. ASABE 2019, 62, 405–414. [Google Scholar] [CrossRef]

- Jiang, A.; Yao, X.; Cheng, M.; Zhou, J. Kinematics analysis and experiment of a lily picking mechanical arm. J. Eng. 2018, 2018, 1674–1681. [Google Scholar] [CrossRef]

- Yang, C.H.; Xiong, L.; Wang, Z.; Wang, Y.; Shi, G.; Kuremot, T.; Yang, Y. Integrated detection of citrus fruits and branches using a convolutional neural network. Comput. Electron. Agric. 2020, 174, 105469. [Google Scholar] [CrossRef]

- Xiao, X.; Huang, J.; Li, M.; Xu, Y.; Zhang, H. Parameter analysis and experiment of citrus stalk cutting for robot picking. Eng. Agrícola 2021, 41, 551–558. [Google Scholar] [CrossRef]

- Davidson, J.; Silwal, A.; Karkee, M.; Mo, C.; Zhang, Q. Hand-picking dynamic analysis for undersensed robotic apple harvesting. Trans. ASABE 2016, 59, 745–758. [Google Scholar]

- Bu, L.X.; Chen, C.K.; Hu, G.R.; Sugirbay, A.; Chen, J. Technological development of robotic apple harvesters: A review. INMATEH-Agric. Eng. 2020, 61, 151–164. [Google Scholar]

- Malekzadeh, M.S.; Queißer, J.F.; Steil, J.J. Multi-level control architecture for Bionic Handling Assistant robot augmented by learning from demonstration for apple-picking. Adv. Robot. 2019, 33, 469–485. [Google Scholar] [CrossRef]

- Mu, L.; Cui, G.; Liu, Y.; Cui, Y.; Fu, L.; Gejima, Y. Design and simulation of an integrated end-effector for picking kiwifruit by robot. Inf. Processing Agric. 2020, 7, 58–71. [Google Scholar] [CrossRef]

- Huangfei, C. Design and research on the End Actuator of Tomato Picking Robot. J. Phys. Conf. Ser. 2019, 1314, 012112. [Google Scholar] [CrossRef]

- Xiao, X.; Huang, J.; Li, M.; Xu, Y.; Zhang, H.; Wen, C.; Dai, S. Fast recognition method for citrus under complex environments based on improved YOLOv3. J. Eng. 2022, 2022, 148–159. [Google Scholar] [CrossRef]

- Chiu, Y.C.; Yang, P.Y.; Chen, S. Development of the end-effector of a picking robot for greenhouse-grown tomatoes. Appl. Eng. Agric. 2013, 29, 1001–1009. [Google Scholar]

- Qingchun, F.; Wei, C.; Jianjun, Z.; Xiu, W. Design of structured-light vision system for tomato harvesting robot. Int. J. Agric. Biol. Eng. 2014, 7, 19–26. [Google Scholar]

- Feng, Q.; Zou, W.; Fan, P.; Zhang, C.; Wang, X. Design and test of robotic harvesting system for cherry tomato. Int. J. Agric. Biol. Eng. 2018, 11, 96–100. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, Y.; Wang, J.; Yuan, Y.; Zhang, Z. An ontology-based approach to integration of hilly citrus production knowledge. Comput. Electron. Agric. 2015, 113, 24–43. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.; Yang, Y.; Zhao, H.; Yang, C.; He, Y.; Xu, H. Discrete element modelling of citrus fruit stalks and its verification. Biosyst. Eng. 2020, 200, 400–414. [Google Scholar] [CrossRef]

- Wei, J.; Zhijie, Q.; Bo, X.; Dean, Z. A nighttime image enhancement method based on Retinex and guided filter for object recognition of apple harvesting robot. Int. J. Adv. Robot. Syst. 2018, 15, 1729881417753871. [Google Scholar] [CrossRef] [Green Version]

- Ji, W.; Zhao, D.; Cheng, F.; Xu, B.; Zhang, Y.; Wang, J. Automatic recognition vision system guided for apple harvesting robot. Comput. Electr. Eng. 2012, 38, 1186–1195. [Google Scholar] [CrossRef]

- Longsheng, F.; Bin, W.; Yongjie, C.; Shuai, S.; Gejima, Y.; Kobayashi, T. Kiwifruit recognition at nighttime using artificial lighting based on machine vision. Int. J. Agric. Biol. Eng. 2015, 8, 52–59. [Google Scholar]

- Zhou, L.; Ren, L.; Chen, Y.; Niu, S.; Han, Z.; Ren, L. Bio-Inspired Soft Grippers Based on Impactive Gripping. Adv. Sci. 2021, 8, 2002017. [Google Scholar] [CrossRef] [PubMed]

- Zahid, A.; Mahmud, M.S.; He, L.; Heinemann, P.; Choi, D.; Schupp, J. Technological advancements towards developing a robotic pruner for apple trees: A review. Comput. Electron. Agric. 2021, 189, 106383. [Google Scholar] [CrossRef]

- Ning, Z.; Luo, L.; Ding, X.M.; Dong, Z.; Yang, B.; Cai, J.; Lu, Q. Recognition of sweet peppers and planning the robotic picking sequence in high-density orchards. Comput. Electron. Agric. 2022, 196, 106878. [Google Scholar] [CrossRef]

- Arad, B.; Balendonck, J.; Barth, R.; Ben-Shahar, O.; Edan, Y.; Hellström, T.; van Tuijl, B. Development of a sweet pepper harvesting robot. J. Field Robot. 2020, 37, 1027–1039. [Google Scholar] [CrossRef]

- Polic, M.; Tabak, J.; Orsag, M. Pepper to fall: A perception method for sweet pepper robotic harvesting. Intell. Serv. Robot. 2021, 15, 193–201. [Google Scholar] [CrossRef]

- Mehta, S.S.; Burks, T.F. Vision-based control of robotic manipulator for citrus harvesting. Comput. Electron. Agric. 2014, 102, 146–158. [Google Scholar] [CrossRef]

- Wang, Z.; Xun, Y.; Wang, Y.; Yang, Q. Review of smart robots for fruit and vegetable picking in agriculture. Int. J. Agric. Biol. Eng. 2022, 15, 33–54. [Google Scholar]

- Gao, J.; Zhang, F.; Zhang, J.; Yuan, T.; Yin, J.; Guo, H.; Yang, C. Development and evaluation of a pneumatic finger-like end-effector for cherry tomato harvesting robot in greenhouse. Comput. Electron. Agric. 2022, 197, 106879. [Google Scholar] [CrossRef]

- Wang, M.; Li, J.; Zhu, P.; Yu, Q.; Xu, Z.; Ji, M. Photoelectric automatic rotation direction-finding detection method and mechanism design of cherry tomato petiole. Trans. Chin. Soc. Agric. Eng. 2017, 33, 42–48. [Google Scholar]

- Kondo, N.; Monta, M.; Fujiura, T. Basic constitution of a robot for agricultural use. Adv. Robot. 2012, 10, 339–353. [Google Scholar] [CrossRef]

| Measured Values | Average Value/mm | Standard Deviation/mm | Coefficient of Variation |

|---|---|---|---|

| Longitudinal diameter of citrus | 50.24 | 5.630 | 0.121 |

| Cross diameter of citrus | 52.38 | 6.125 | 0.103 |

| Level | Factor | ||

|---|---|---|---|

| X1/(r/min) | X2/(mm/min) | X3/(°) | |

| 1.682 | 200 | 80 | −15 |

| 1 | 225 | 120 | 0 |

| 0 | 250 | 160 | 15 |

| −1 | 275 | 200 | 30 |

| −1.682 | 300 | 240 | 45 |

| Serial Number | Level of Factor | Picking Success Rate Q/% | Single-Fruit Picking Time T/s | ||

|---|---|---|---|---|---|

| X1/(r/min) | X2/(mm/min) | X3/(°) | |||

| 1 | −1 | −1 | −1 | 92.38 | 4.95 |

| 2 | 1 | −1 | −1 | 90.05 | 4.88 |

| 3 | −1 | 1 | −1 | 93.61 | 4.65 |

| 4 | 1 | 1 | −1 | 92.64 | 4.84 |

| 5 | −1 | −1 | 1 | 91.88 | 4.54 |

| 6 | 1 | 1 | 1 | 90.38 | 4.68 |

| 7 | 1 | 1 | 1 | 91.35 | 4.62 |

| 8 | 1.682 | 0 | 0 | 93.21 | 4.85 |

| 9 | 1.682 | 0 | 0 | 94.22 | 4.74 |

| 10 | 0 | 1.682 | 0 | 92.56 | 4.68 |

| 11 | 0 | −1.682 | 0 | 91.62 | 4.69 |

| 12 | 0 | 0 | 1.682 | 91.46 | 4.66 |

| 13 | 0 | 0 | 1.682 | 91.20 | 4.82 |

| 14 | 0 | 0 | 0 | 93.25 | 4.86 |

| 15 | 0 | 0 | 0 | 92.88 | 4.69 |

| 16 | 0 | 0 | 0 | 91.95 | 4.73 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, X.; Wang, Y.; Jiang, Y. End-Effectors Developed for Citrus and Other Spherical Crops. Appl. Sci. 2022, 12, 7945. https://doi.org/10.3390/app12157945

Xiao X, Wang Y, Jiang Y. End-Effectors Developed for Citrus and Other Spherical Crops. Applied Sciences. 2022; 12(15):7945. https://doi.org/10.3390/app12157945

Chicago/Turabian StyleXiao, Xu, Yaonan Wang, and Yiming Jiang. 2022. "End-Effectors Developed for Citrus and Other Spherical Crops" Applied Sciences 12, no. 15: 7945. https://doi.org/10.3390/app12157945

APA StyleXiao, X., Wang, Y., & Jiang, Y. (2022). End-Effectors Developed for Citrus and Other Spherical Crops. Applied Sciences, 12(15), 7945. https://doi.org/10.3390/app12157945