One-Coil Long-Stroke Permanent Magnetic Actuator Design Applied to Load Breaker Switch for Railway

Abstract

:1. Introduction

2. Permanent Magnet Actuator for Long-Stroke

3. Design of the One-Coil Long Stroke PMA

3.1. Analysis of the Magneto-Static Field and Prototype Design

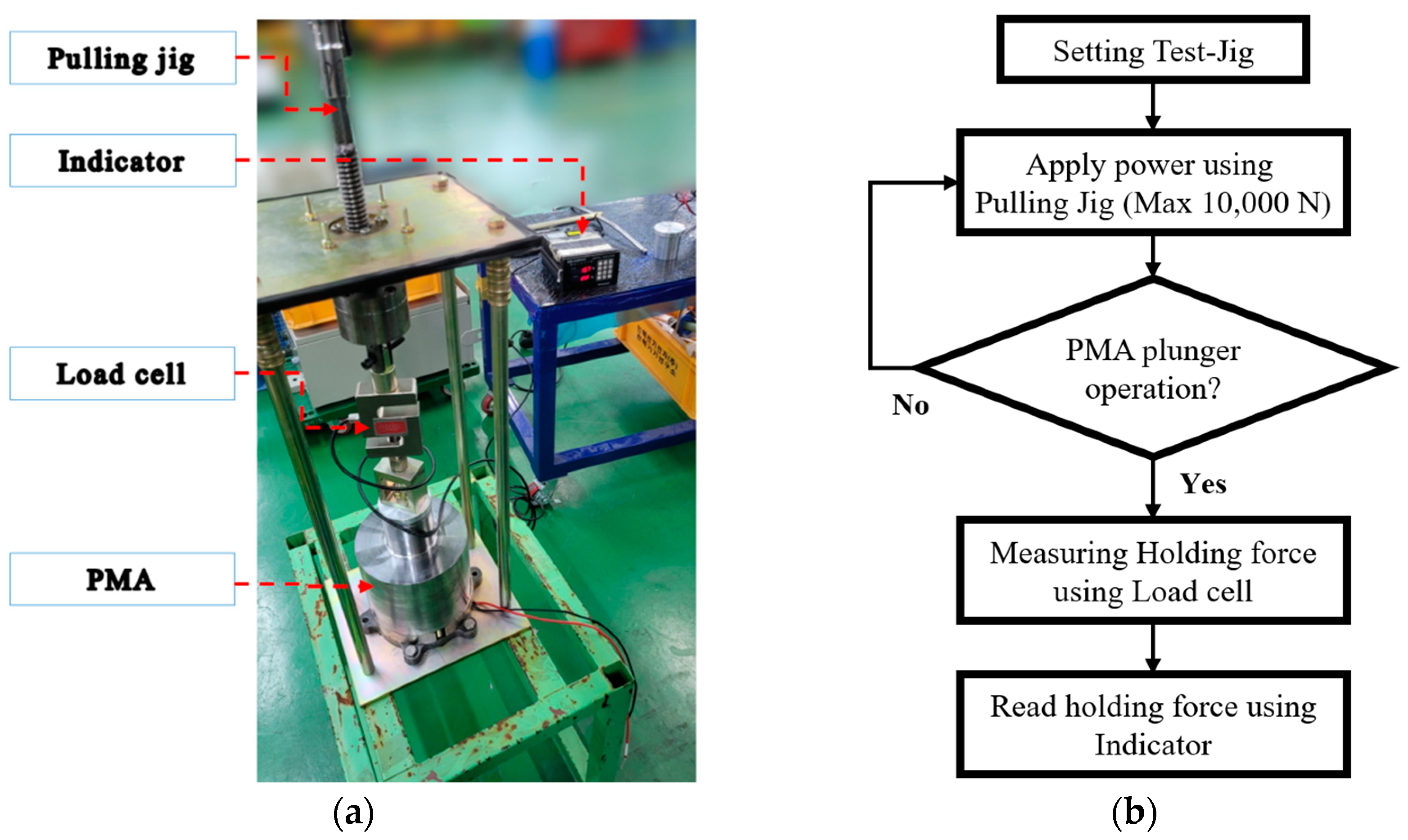

3.2. Holding Force

3.3. Electromagnetic Force

3.4. Plunger Rotation

3.5. Part Weight Ratio

4. Operating Characteristics of the One-Coil Long-Stroke PMA

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Duanlei, Y.; Hongfei, Z.; Junping, C.; Hongyan, W.; Min, L. Investigation of 63kV High Voltage Vacuum Circuit Breaker of Single Phase Bipolar Used on Railway. In Proceedings of the 2011 1st International Conference on Electric Power Equipment—Switching Technology, Xi’an, China, 23–27 October 2011. [Google Scholar]

- Jankowski, P.; Mindykowski, J. Study on the Hazard Limitation of Hybrid Circuit Breaker Actuator Operation. Energies 2018, 11, 416. [Google Scholar] [CrossRef]

- Choi, S.J.; Lim, S.H. Impact on Current-Interrupting Characteristic by Parameter Settings of Superconducting Hybrid DC Circuit Breaker. Energies 2021, 14, 2469. [Google Scholar] [CrossRef]

- Song, X.; Mengyuan, T.; Yang, R.; Yuhang, L.; Zhizong, Y.; Yixiang, S.; Hao, H.; Guoqiang, G.; Guangning, W.; Yaoyao, J.; et al. The characteristic analysis of the operational overvoltage caused by the vacuum circuit breakers on High-speed trains. J. Electr. Eng. Technol. 2022, 17, 221–236. [Google Scholar]

- Choi, M.; Kim, J.; Park, C.; Koh, H.; Kim, Y. A Study of Electrostatic Induced Voltage between the Contacts in Vacuum Interrupter of 25.8kV MV VCB. In Proceedings of the 2022 6th International Conference on Electric Power Equipment—Switching Technology ICEPE-ST, Seoul, Korea, 15–18 March 2022. [Google Scholar]

- Krebs, G.; Tounzi, A.; Pauwels, B.; Willemot, D.; Piriou, F. Modeling of A Linear and Rotary Permanent Magnet Actuator. IEEE Trans. Magn. 2008, 44, 4357–4360. [Google Scholar] [CrossRef]

- Fang, S.; Lin, H.; Ho, S.L. Transient Co-Simulation of Low Voltage Circuit Breaker with Permanent Magnet Actuator. IEEE Trans. Magn. 2009, 45, 1242–1245. [Google Scholar] [CrossRef]

- Ro, J.; Hong, S.; Jung, H. Characteristic analysis and design of a novel permanent magnetic actuator for a vacuum circuit breaker. IET Electr. Power Appl. 2012, 7, 87–97. [Google Scholar] [CrossRef]

- Cai, Z.; Ma, S.; Wang, J. An Approach of Improve Permanent Magnetic Actuator of Vacuum Circuit Breaker. In Proceedings of the 2008 23rd International Symposium on Discharges and Electrical Insulation in Vacuum, Bucharest, Romania, 15–19 September 2008. [Google Scholar]

- Jung, H. Optimal Design and Dynamic Characteristic Analysis of a New Type Electric Actuator for High Voltage Circuit Breaker. In Proceedings of the 2008 International Conference on Electrical Machines and Systems, Wuhan, China, 20 October 2008. [Google Scholar]

- Kim, S.; Hahn, S.; Kim, Y.; Koh, H.; Choi, M. Numerical Investigation for Dynamic Characteristic Analysis of Electromagnetic Actuator for Gas Circuit Breakers. In Proceedings of the 2015 3rd International Conference on Electric Power Equipment–Switching Technology (ICEPE-ST), Busan, Korea, 25–28 October 2015. [Google Scholar]

- Cho, D.; Hong, S.; Woo, D.; Jung, H. Design of Electromagnetic Force driving Actuator for Automatic Transfer Breaker Based on Three-Link Structure. In Proceedings of the 2011 International Conference on Electrical Machines and Systems, Beijing, China, 23 August 2011. [Google Scholar]

- Bae, B.; Kang, J.; Jung, H. Design of Electromagnetic Actuator with 3-bar Linkage Mechanism for Low Voltage Circuit Breaker. In Proceedings of the the 7th International Symposium on Linear Drives for Industry Applications, Incheon, Korea, 20–23 September 2009. [Google Scholar]

| Category | Material | Conductivity (S/m) | Permeability | Density |

|---|---|---|---|---|

| Core | SS41 | 7 × 106 | B-H curve | 7800 |

| Magnet | NdFe35 | 0.625× 106 | 1.0652 | 7400 |

| Plunger | SS41 | 7 × 106 | B-H curve | 7800 |

| Coil | Copper | 58 × 106 | 0.999991 | 8960 |

| Specification | Values |

|---|---|

| Rated voltage (kV) | 29 |

| Short-time withstand current (kA) | 20 |

| Duration of short-circuit (s) | 1 |

| Rated normal current (A) | 2000 |

| Number of poles | 1 |

| VI Stroke (mm) | 21 |

| PMA stroke (mm) | 120 |

| Add contact force (N) | 1800 |

| VI vacuum hold force (N) | 315 |

| DS Contact spring force (N) | 500 |

| Open spring force (N) | Variable |

| VI Average closing speed (m/s) (1/2 of full stroke) | 0.9~1.3 |

| VI Average opening speed (m/s) (1/2 of full stroke) | 1.1~1.5 |

| Analysis Value (N) | Measurement Value (N) | Error (%) |

|---|---|---|

| 3996 | 3800 | 5.2 |

| Specification | Values |

|---|---|

| Induced voltage (V) | 140 |

| Capacitance (uF) | 68,000 |

| Closing time (ms) | 157.1 |

| Closing current (A) | 28.9 |

| VI Average closing speed (m/s) (1/2 of full stroke) | 0.90 |

| Opening time (ms) | 19.94 |

| Opening current (A) | 4.5 |

| VI Average opening speed (m/s) (1/2 of full stroke) | 1.40 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.-J.; Hur, J.-H.; Kim, Y.-I.; Yun, C.-M.; Jung, H. One-Coil Long-Stroke Permanent Magnetic Actuator Design Applied to Load Breaker Switch for Railway. Appl. Sci. 2022, 12, 8214. https://doi.org/10.3390/app12168214

Kim S-J, Hur J-H, Kim Y-I, Yun C-M, Jung H. One-Coil Long-Stroke Permanent Magnetic Actuator Design Applied to Load Breaker Switch for Railway. Applied Sciences. 2022; 12(16):8214. https://doi.org/10.3390/app12168214

Chicago/Turabian StyleKim, Seung-Jin, Jae-Ho Hur, Young-Il Kim, Chi-Myeong Yun, and Hosung Jung. 2022. "One-Coil Long-Stroke Permanent Magnetic Actuator Design Applied to Load Breaker Switch for Railway" Applied Sciences 12, no. 16: 8214. https://doi.org/10.3390/app12168214

APA StyleKim, S.-J., Hur, J.-H., Kim, Y.-I., Yun, C.-M., & Jung, H. (2022). One-Coil Long-Stroke Permanent Magnetic Actuator Design Applied to Load Breaker Switch for Railway. Applied Sciences, 12(16), 8214. https://doi.org/10.3390/app12168214