4.1. Parameter Determination Method of the HJC Model for Sandstone

The HJC constitutive model proposed by Holmquist et al. contains 21 parameters. The value of the parameter has a great influence on the calculation accuracy. After the HJC model was proposed, scholars introduced the numerical calculation of rock dynamics but did not propose a set of test methods for the determination of the parameters for specific rocks.

The HJC model includes three parts: the equation of the yield surface, the equation of damage evolution and the equation of the state, as shown in

Figure 12. The equation of the yield surface is given as:

where

/

and

are the normalized equivalent stress and normalized pressure, respectively;

and

denote the actual equivalent stress and actual pressure, respectively;

is the dimensionless strain rate, where

and

are the actual and reference strain rates, respectively;

is the normalized cohesive strength;

is the damage parameter;

is the normalized pressure-hardening coefficient;

is the strain rate coefficient; and

is the pressure-hardening exponent.

The model incrementally accumulates damage,

D, from both the equivalent plastic strain and plastic volumetric strain, which is expressed as:

where

and

are the equivalent plastic strain and plastic volumetric strain, respectively, during a cycle of integration;

is the normalized maximum tensile hydrostatic pressure, where

is the maximum tensile hydrostatic pressure the material can withstand and

and

are material constants.

The equation of the state is as follows:

where

is the volumetric strain;

and

are the current density and initial density, respectively;

is the elastic bulk modulus;

and

are the pressure and volumetric strain, respectively, when the material begins to undergo plastic deformation;

and

are the volumetric strain and pressure, respectively, when the air voids are completely removed from the material;

is the modified volumetric strain;

is the volumetric strain when the density

reaches the grain density

;

,

and

are material constants.

As can be seen from the above introduction, the HJC model parameters can be divided into five categories, namely the basic mechanical parameters, limit surface parameters, pressure parameters, damage parameters and strain-rate-dependent parameters, as shown in

Table 1. The test methods for the value of each parameter include the uniaxial compression test, triaxial compression test, single impact test and repeated impact test.

The basic mechanical parameters are RO, FC, G and T, which can be measured using uniaxial compression tests. The static stress–strain curves of sandstone specimens are shown in

Figure 5b. According to the basic theory of rock mechanics, the mechanical parameters can be obtained as shown in

Table 2.

The limit surface parameters include A, B, N and SFMAX. The influence of the damage and strain rate is not considered in the determination of the limit surface parameters; thus,

The limit surface of the HJC model and the envelope of the Mohr–Coulomb (M-C) criterion start from the same point and have an intersection, as shown in

Figure 13. In the M-C criterion, the intercept C of the envelope is the cohesion, which is obtained via a series of triaxial compression tests. Therefore, the triaxial compression tests of sandstone under different confining pressures are carried out, as shown in

Figure 14 and

Table 3, and the established series of Mohr’s circles is shown in

Figure 15. Here,

and

denote the confining pressure and axial pressure at failure, respectively. The common tangent of the series of Mohr’s circles was assessed, and the C value was 22.61 MPa.

The limit surface of the HJC model and the envelope of the M-C criterion pass through the same point (0,

C):

Thus, the value of

A is 0.297. In the triaxial compression test, the failure strength increases with increasing confining pressure. After a series of triaxial tests under different confining pressures, a set of

and

values can be obtained using Equations (22)–(25).

where

is the axial pressure corresponding to sandstone failure in the triaxial test;

is the confining pressure; and

and

are the normalized hydrostatic pressure and normalized stress difference, respectively, as shown in

Table 4.

Figure 16 shows the relationship between

and

by using Equation (26):

Figure 15 shows that the values of

B and

N are 1.947 and 0.537, respectively.

is the ratio of the stress difference when the axial compressive strength of the specimen does not increase with increasing confining pressure from the triaxial test to the static compressive strength:

According to the triaxial compression test results, the axial pressure remains stable when the confining pressure is approximately 90 MPa. The limit surface parameters of sandstone are shown in

Table 5.

The strain-rate-dependent parameters include C and EPSO. The parameter C is obtained by using a single impact test under different strain rates. In addition, the influence of the hydrostatic pressure on

and

should be eliminated in the calculation of the parameter C. The specific method is as follows:

and the corresponding

are taken when

is approximately

; then, the relationship between the obtained series of

and

is fit with a linear equation, the slope of which is the value of C. Here, the normalized dynamic compressive strength is introduced:

where

is the normalized dynamic compressive strength. The corresponding points of

and

for sandstone are shown in

Table 6, and the fitting relationship is shown in

Figure 17. The strain rate coefficient C is 0.0127. The reference strain rate EPSO is a fixed value, i.e., 1.0.

where

and

UC are the hydrostatic pressure and volume strain corresponding to the elastic limit, respectively, and

is the volumetric strain at plastic deformation.

PC,

UC and

UL are calculated to be 25.38, 0.0016, and 0.08, respectively. The value of

is determined by

in

Figure 11c, and

K1,

K2 and

K3 are determined by the stress amplitude and corresponding equivalent volumetric strain under impact loading. Therefore, it is necessary to carry out impact tests to obtain the fitting relationship by using Equation (32):

The relationship between the stress amplitude and equivalent volumetric strain under impact loading is shown in

Figure 18. The parameters related to the state equation are calculated as shown in

Table 7.

The damage parameters include D1, D2 and EFMIN. The damage in the HJC model is determined by the equivalent plastic strain and volumetric strain. When determining the parameter values of D1 and D2, it is assumed that the material is only damaged under repeated impacts, and that the corresponding damage value is 1, so the following equation is obtained:

where

is the fracture plastic strain under repeated impacts. EFMIN is the failure strain under repeated impacts. The specific method is to draw a common tangent of the peak strength of the constitutive curve cluster obtained under repeated impacts, and the strain value corresponding to the intersection of the common tangent and the abscissa axis is the failure strain under repeated impacts, as shown in

Figure 19. The failure strain of sandstone is 0.00465. The relationship between the strain and damage is determined by Equation (32). Since the repeated impact stress amplitude does not exceed the elastic limit of the sandstone, only recoverable elastic strain occurs in the sandstone at this time, and no plastic strain occurs. Therefore, the left part of Equation (32) is equal to the value of the failure strain. Additionally, it is assumed that the value of D2 is 1.0.32 The value of

p* is 0.82, which is determined by the stress wave amplitude, and

T* is 0.1002. The calculated value of D1 is 0.005.

In summary, a total of 19 parameters of the HJC model for sandstone were measured, which are shown in

Table 8.

4.2. Application of the Parameter Determination Method in LS-DYNA

The model of the SHPB system with a diameter of 50 mm was established in LS-DYNA, as shown in

Figure 20. The lengths of the impact bar, incident bar and transmitted bar are 400 mm, 2000 mm and 2000 mm, respectively. The diameter of the specimen is 50 mm, and the length is 40 mm. The material of the bar is defined as an elastic material, and the properties of the aluminum–magnesium alloy are a density of 2800 kg/m

3, elastic modulus of 77 GPa and Poisson’s ratio of 0.27. The dynamic stress–strain curves of the sandstone under different impact velocities are extracted to calculate the elastic limit, peak strength, maximum strain and other mechanical indicators.

The impact velocities are taken as 7.5 m/s, 9.5 m/s, 11.5 m/s and 13.5 m/s, and the incident wave at each impact velocity is shown in

Figure 21. The stress waves generated by the collision of elastic bars conform to the one-dimensional wave theory, and their amplitudes conform to the calculation results of

; the durations are all 158.4 μs, consistent with the theoretical calculations.

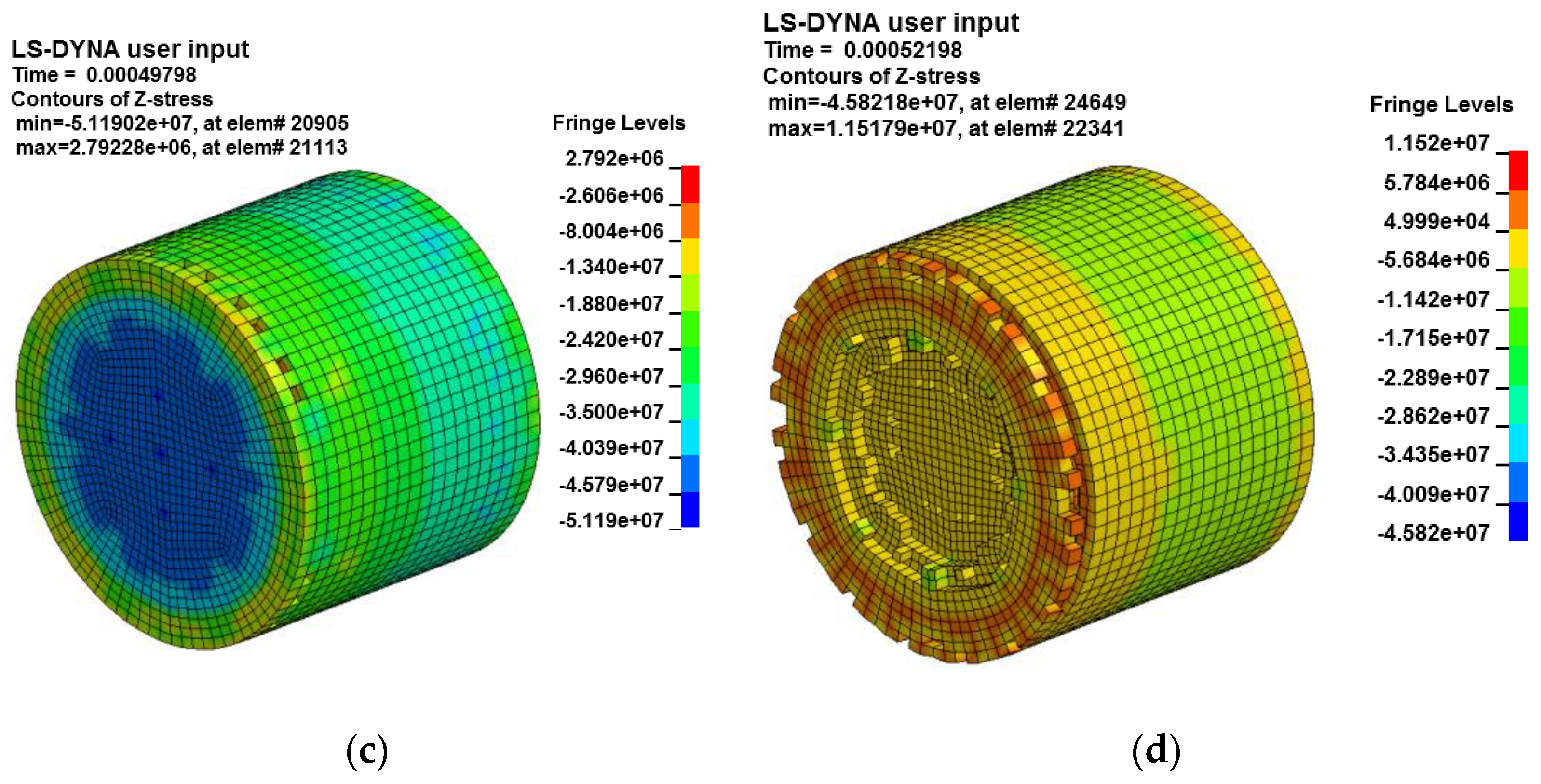

The stress and failure state of the specimen after the stress wave loading are intercepted, as shown in

Figure 22.

Figure 22a shows that the stress wave acts on the contact surface of the specimen and the input bar relatively uniformly at this time, and the maximum compressive stress is consistent with the amplitude of the incident wave; with the passage of time, the stress wave gradually moves towards the specimen. Internal propagation and action of the force occur, and stress reflection occurs on the end face of the specimen, with the stress cloud diagram shown in

Figure 22b. Then, the internal compressive stress of the specimen gradually increases, individual elements meet the failure criteria and the element is deleted, indicating that the specimen begins to crack at the macroscopic scale. Finally, more elements are damaged and deleted, which shows the fracture of the specimen at the macroscopic level.

In LS-DYNA, the stress–time history curve and strain–time history curve of the object element can be directly extracted from the calculation results, and the stress–strain curve can be obtained after corresponding the two data points. A summary of the stress–strain curves is shown in

Figure 23, which shows that with increasing impact velocity, the dynamic peak strength also increases, which conforms to the characteristic that the strength increases with the strain rate; at the same time, with increasing impact velocity, the dynamic elastic modulus of the curve also increases, which is also in line with the relevant situation for the previous SHPB trial. The dynamic mechanical properties of sandstone at each impact speed and a comparison with the test conditions are shown in

Table 9.

Table 9 shows that the simulated strain rate, dynamic compressive strength and maximum strain of the sandstone specimen are highly similar to the experimental results under the same impact velocity, and the error does not exceed 10%. The method used for determining the parameters of the HJC model for rock materials provided in this paper is effective.