Femtosecond Laser-Induced Evolution of Surface Micro-Structure in Depth Direction of Nickel-Based Alloy

Abstract

:1. Introduction

2. Experimental Methods and Results

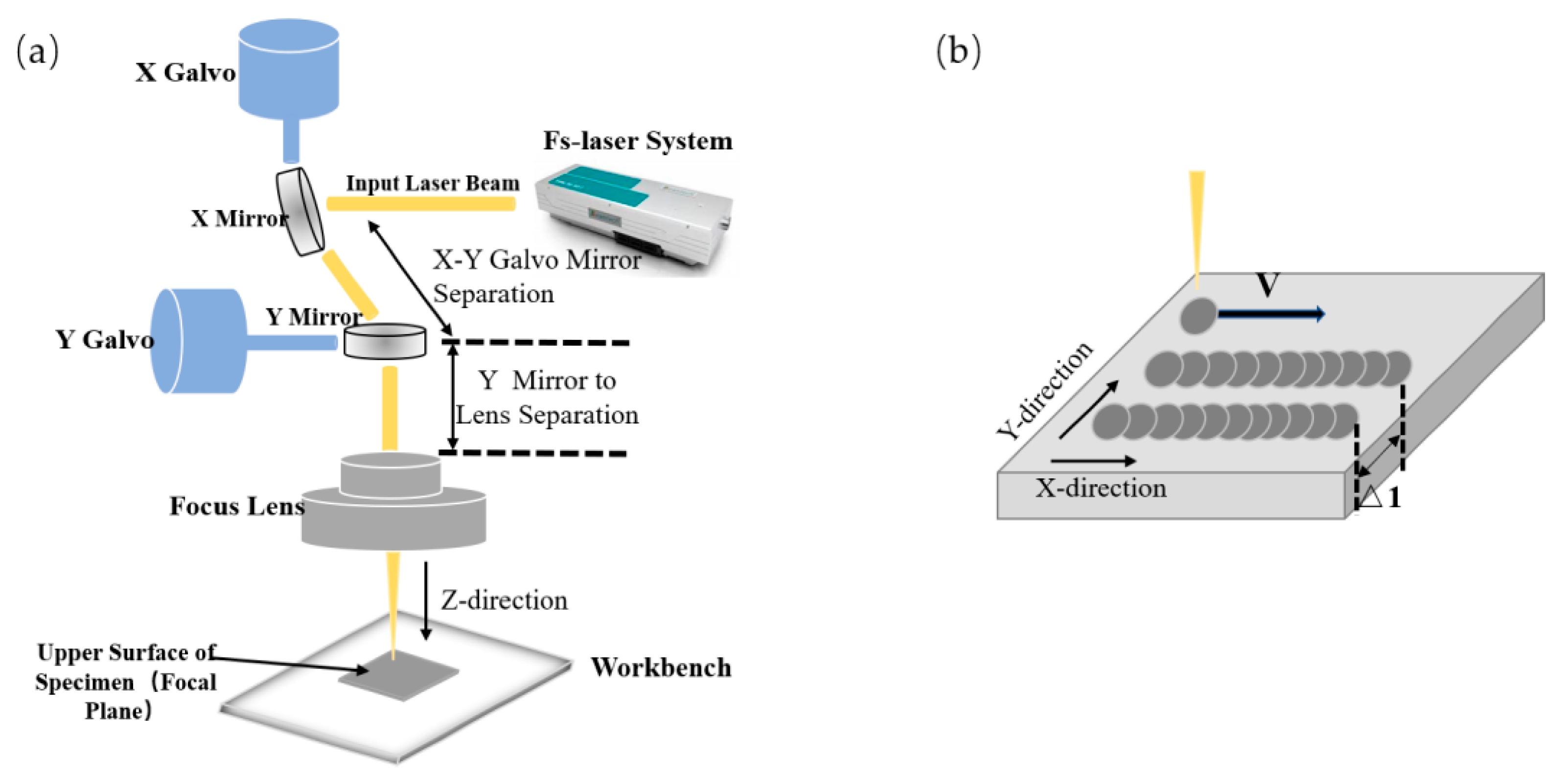

2.1. Experimental Method

2.2. Experimental Results

3. Simulation Results and Discussion

3.1. Simulation Method

3.2. Simulation Process

3.3. Simulation Results

3.3.1. Effect of Single Pulse Energy on the Ablation Depth of Different Micro-Structures

3.3.2. Effect of Focal Plane Location on the Ablation Depth of Different Micro-Structure

3.3.3. Effect of Scanning Speed on the Ablation Depth of Different Micro-Structure

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Perepezko, J.H. The Hotter the Engine, the Better. Science 2009, 326, 1068–1069. [Google Scholar] [CrossRef] [PubMed]

- McNally, C.A.; Folkes, J.; Pashby, I.R. Laser drilling of cooling holes in aeroengines: State of the art and future challenges. Mater. Sci. Technol. 2004, 20, 805–813. [Google Scholar] [CrossRef]

- Pollock, T.M.; Tin, S. Nickel-Based Superalloys for Advanced Turbine Engines: Chemistry, Microstructure and Properties. J. Propuls. Power 2006, 22, 361–374. [Google Scholar] [CrossRef]

- Clarke, D.R.; Phillpot, S.R. Thermal barrier coating materials. Mater. Today 2005, 8, 22–29. [Google Scholar] [CrossRef]

- Zhang, D.; Gong, S.; Xu, H.; Wu, Z. Effect of bond coat surface roughness on the thermal cyclic behavior of thermal barrier coatings. Surf. Coat. Technol. 2006, 201, 649–653. [Google Scholar] [CrossRef]

- VanEvery, K.; Krane, M.J.M.; Trice, R.W.; Wang, H.; Porter, W.; Besser, M.; Sordelet, D.; Ilavsky, J.; Almer, J. Column Formation in Suspension Plasma-Sprayed Coatings and Resultant Thermal Properties. J. Therm. Spray Technol. 2011, 20, 817–828. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Li, C.J.; Ohmori, A. Influence of substrate roughness on the bonding mechanisms of high velocity oxy-fuel sprayed coatings. Thin Solid Film. 2005, 485, 141–147. [Google Scholar] [CrossRef]

- Staia, M.H.; Ramos, E.; Carrasquero, A.; Roman, A.; Lesage, J.; Chicot, D.; Mesmacque, G. Effect of substrate roughness induced by grit blasting upon adhesion of WC-17% Co thermal sprayed coatings. Thin Solid Film. 2000, 377–378, 657–664. [Google Scholar] [CrossRef]

- Amada, S.; Hirose, T. Influence of grit blasting pre-treatment on the adhesion strength of plasma sprayed coatings: Fractal analysis of roughness. Surf. Coat. Technol. 1998, 102, 132–137. [Google Scholar] [CrossRef]

- Curry, N.; Tang, Z.; Markocsan, N.; Nylén, P. Influence of bond coat surface roughness on the structure of axial suspension plasma spray thermal barrier coatings—Thermal and lifetime performance. Surf. Coat. Technol. 2015, 268, 15–23. [Google Scholar] [CrossRef]

- Xiao, F.; Yuan, S.; Liang, B.; Li, G.; Pehkonen, S.O.; Zhang, T. Superhydrophobic CuO nanoneedle-covered copper surfaces for anticorrosion. J. Mater. Chem. A 2015, 3, 4374–4388. [Google Scholar] [CrossRef]

- Su, F.; Yao, K.; Liu, C.; Huang, P. Rapid Fabrication of Corrosion Resistant and Superhydrophobic Cobalt Coating by a One-Step Electrodeposition. J. Electrochem. Soc. 2013, 160, D593–D599. [Google Scholar] [CrossRef]

- Qian, B.; Shen, Z. Fabrication of Superhydrophobic Surfaces by Dislocation-Selective Chemical Etching on Aluminum, Copper, and Zinc Substrates. Langmuir 2005, 21, 9007–9009. [Google Scholar] [CrossRef]

- Bharati, M.S.S.; Kalam, S.A.; Chandu, B.; Hamad, S.; Venugopal Rao, S. Instantaneous trace detection of nitro-explosives and mixtures with nanotextured silicon decorated with Ag–Au alloy nanoparticles using the SERS technique. Anal. Chim. Acta 2020, 1101, 157–168. [Google Scholar] [CrossRef]

- Zhang, H.; Colombier, J.P.; Li, C.; Faure, N.; Cheng, G.; Stoian, R. Coherence in ultrafast laser-induced periodic surface structures. Phys. Rev. B 2015, 92, 174109. [Google Scholar] [CrossRef]

- Vorobyev, A.Y.; Guo, C. Colorizing metals with femtosecond laser pulses. Appl. Phys. Lett. 2008, 92, 041914. [Google Scholar] [CrossRef]

- Florian, C.; Skoulas, E.; Puerto, D.; Mimidis, A.; Stratakis, E.; Solis, J.; Siegel, J. Controlling the Wettability of Steel Surfaces Processed with Femtosecond Laser Pulses. ACS Appl. Mater. Interfaces 2018, 10, 36564–36571. [Google Scholar] [CrossRef]

- Bonse, J.; Kirner, S.V.; Griepentrog, M.; Spaltmann, D.; Krüger, J. Femtosecond Laser Texturing of Surfaces for Tribological Applications. Materials 2018, 11, 801. [Google Scholar] [CrossRef]

- Valette, S.; Steyer, P.; Richard, L.; Forest, B.; Donnet, C.; Audouard, E. Influence of femtosecond laser marking on the corrosion resistance of stainless steels. Appl. Surf. Sci. 2006, 252, 4696–4701. [Google Scholar] [CrossRef]

- Long, J.; Fan, P.; Gong, D.; Jiang, D.; Zhang, H.; Li, L.; Zhong, M. Superhydrophobic Surfaces Fabricated by Femtosecond Laser with Tunable Water Adhesion: From Lotus Leaf to Rose Petal. ACS Appl. Mater. Interfaces 2015, 7, 9858–9865. [Google Scholar] [CrossRef]

- Liu, H.; Lin, W.; Lin, Z.; Ji, L.; Hong, M. Self-Organized Periodic Microholes Array Formation on Aluminum Surface via Femtosecond Laser Ablation Induced Incubation Effect. Adv. Funct. Mater. 2019, 29, 1903576. [Google Scholar] [CrossRef]

- Bizi-Bandoki, P.; Benayoun, S.; Valette, S.; Beaugiraud, B.; Audouard, E. Modifications of roughness and wettability properties of metals induced by femtosecond laser treatment. Appl. Surf. Sci. 2011, 257, 5213–5218. [Google Scholar] [CrossRef]

- Nayak, B.K.; Gupta, M.C.; Kolasinski, K.W. Ultrafast-laser-assisted chemical restructuring of silicon and germanium surfaces. Appl. Surf. Sci. 2007, 253, 6580–6583. [Google Scholar] [CrossRef]

- Zuhlke, C.A.; Anderson, T.P.; Alexander, D.R. Fundamentals of layered nanoparticle covered pyramidal structures formed on nickel during femtosecond laser surface interactions. Appl. Surf. Sci. 2013, 283, 648–653. [Google Scholar] [CrossRef]

- Yang, Z.; Ji, P.; Zhang, Z.; Ju, Y.; Wang, Z.; Zhang, Q.; Wang, C.; Xu, W. Fundamental 3D simulation of the femtosecond laser ablation for cooling hole drilling on Ni and Fe based aero-engine components. Opt. Commun. 2020, 475, 126237. [Google Scholar] [CrossRef]

- Anisimov, S.I.; Kapeliovich, B.L.; Perelman, T.L.; Physics, T. Electron emission from metal surfaces exposed to ultrashort laser pulses. J. Exp. Theor. Phys. 1974, 66, 375–377. [Google Scholar]

- Wellershoff, S.S.; Hohlfeld, J.; Güdde, J.; Matthias, E. The role of electron–phonon coupling in femtosecond laser damage of metals. Appl. Phys. A 1999, 69, S99–S107. [Google Scholar] [CrossRef]

- Wang, R.; Duan, W.; Wang, K.; Dong, X.; Fan, Z.; Mei, X.; Wang, W.; Zhang, S. Computational and experimental study on hole evolution and delamination in laser drilling of thermal barrier coated nickel superalloy. Opt. Lasers Eng. 2018, 107, 161–175. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, Z.; Wang, C.; Zhang, Q.; Zheng, S.; Xu, W. Mechanisms of femtosecond laser ablation of Ni3Al: Molecular dynamics study. Opt. Laser Technol. 2021, 133, 106505. [Google Scholar] [CrossRef]

- Zhigilei, D. Combined atomistic-continuum modeling of short-pulse laser melting and disintegration of metal films. Phys. Rev. B 2003, 68, 064114. [Google Scholar] [CrossRef]

- Zhigilei, L.V.; Lin, Z.; Ivanov, D.S. Atomistic Modeling of Short Pulse Laser Ablation of Metals: Connections between Melting, Spallation, and Phase Explosion. J. Phys. Chem. C 2009, 113, 11892–11906. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Chen, Y.; Hu, M.; Chen, X. An improved three-dimensional two-temperature model for multi-pulse femtosecond laser ablation of aluminum. J. Appl. Phys. 2015, 117, 063104. [Google Scholar] [CrossRef]

- Mannion, P.T.; Magee, J.; Coyne, E.; O’Connor, G.M.; Glynn, T.J. The effect of damage accumulation behaviour on ablation thresholds and damage morphology in ultrafast laser micro-machining of common metals in air. Appl. Surf. Sci. 2004, 233, 275–287. [Google Scholar] [CrossRef]

- Desai, P.D. Thermodynamic properties of nickel. Int. J. Thermophys. 1987, 8, 763–780. [Google Scholar] [CrossRef]

- Ho, C.-C.; Chang, Y.-J.; Hsu, J.-C.; Chiu, C.-M.; Kuo, C.-L. Optical emission monitoring for defocusing laser percussion drilling. Measurement 2016, 80, 251–258. [Google Scholar] [CrossRef]

- Harilal, S.S.; Freeman, J.R.; Diwakar, P.K.; Hassanein, A. Femtosecond Laser Ablation: Fundamentals and Applications. In Laser-Induced Breakdown Spectroscopy: Theory and Applications; Springer: Berlin/Heidelberg, Germany, 2014; pp. 143–166. [Google Scholar] [CrossRef]

| Physical Parameters | Symbol | Value | Reference |

|---|---|---|---|

| Reflectance of the target material | R | 0.65 | [30] |

| Depth of ballistic transportation | LP | 13.5 nm | [31] |

| Coefficient of the thermal conductivity of electron | k0 | 91 J/(m·K·s) | [27] |

| Heat capacity of lattice | Cl | 4.1 × 106 J (m3·K) | [21] |

| Thermal conductivity of lattice | kl | 3.496 + 0.026733 × Tl − 1.11803 × 10−5 Tl2 + 3.60684 × 10−9 Tl3 + 8.23555 × 10−14 Tl4 J/(m·K·s) | [28] |

| Electron-specific heat coefficient | γ | 188.86 J/(m3·K2) | [29] |

| Electron-phonon coupling strength | g | 3.6 × 1017 W/(m3·K) | [27] |

| Physical Parameters | Symbol | Value |

|---|---|---|

| Pulse energy | E | 80/100/120 μJ |

| Laser fluence | F | 203.8/254.8/305.7 J/cm2 |

| Repetition rate | f | 100 kHz |

| Scanning speed | v | 100/200/300/400/500/600/700 mm/s |

| Number of pulses at Z = 0 | n | 10/5/3.3/2.5/2/1.7/1.4 |

| Wavelength | λ | 1030 nm |

| Beam radius at Z = 0 | 0 | 5 μm |

| Single Pulse Energy (μJ) | Value (μm) | |

|---|---|---|

| Initial depth | 80 | 29.4 |

| 100 | 40.5 | |

| 120 | 46.4 | |

| Absolute distance | 80 | 16.1 |

| 100 | 20.5 | |

| 120 | 26 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Zhang, Z.; Yang, Z.; Wang, C. Femtosecond Laser-Induced Evolution of Surface Micro-Structure in Depth Direction of Nickel-Based Alloy. Appl. Sci. 2022, 12, 8464. https://doi.org/10.3390/app12178464

Liu S, Zhang Z, Yang Z, Wang C. Femtosecond Laser-Induced Evolution of Surface Micro-Structure in Depth Direction of Nickel-Based Alloy. Applied Sciences. 2022; 12(17):8464. https://doi.org/10.3390/app12178464

Chicago/Turabian StyleLiu, Shangyu, Zhen Zhang, Zenan Yang, and Chenchong Wang. 2022. "Femtosecond Laser-Induced Evolution of Surface Micro-Structure in Depth Direction of Nickel-Based Alloy" Applied Sciences 12, no. 17: 8464. https://doi.org/10.3390/app12178464