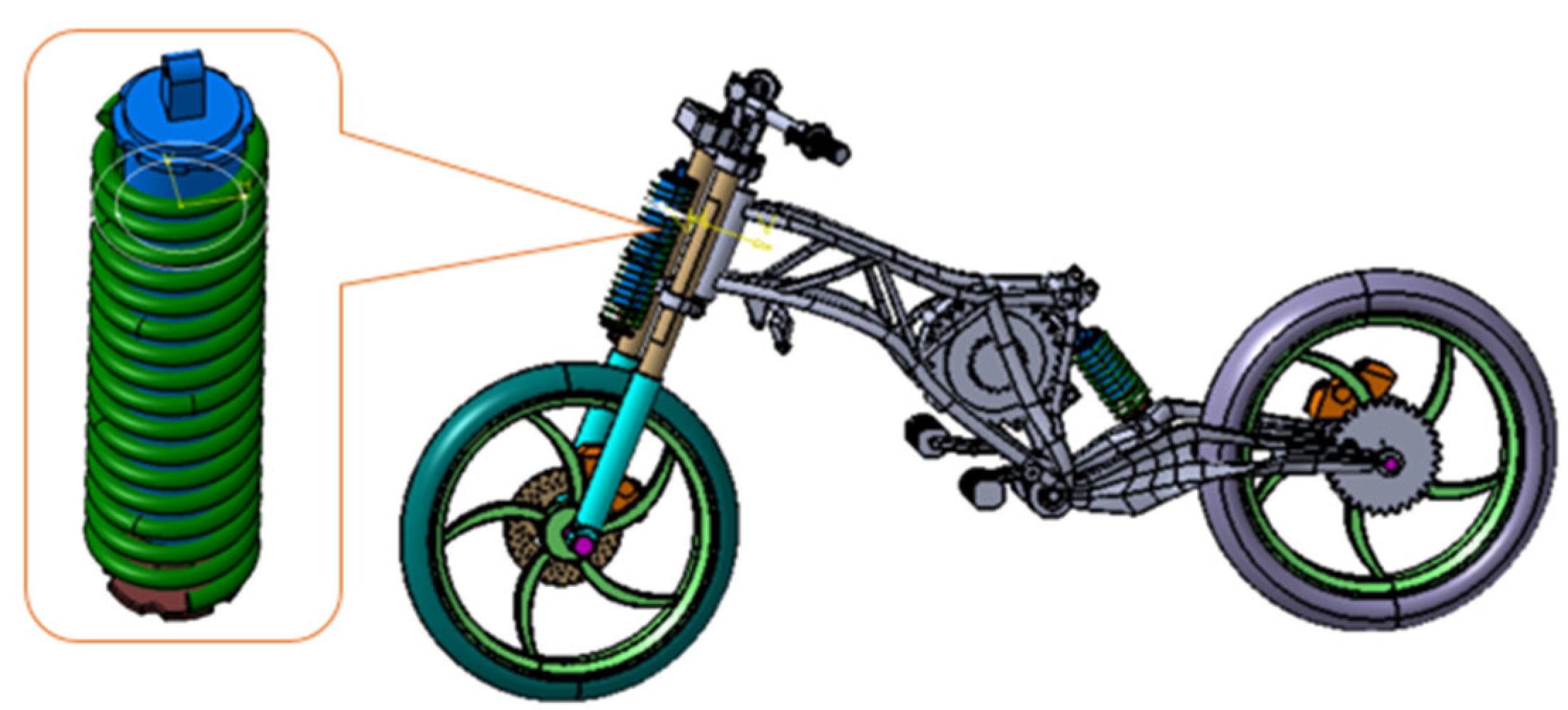

Design of a 120 W Electromagnetic Shock Absorber for Motorcycle Applications

Abstract

:1. Introduction

2. Concept and Analysis

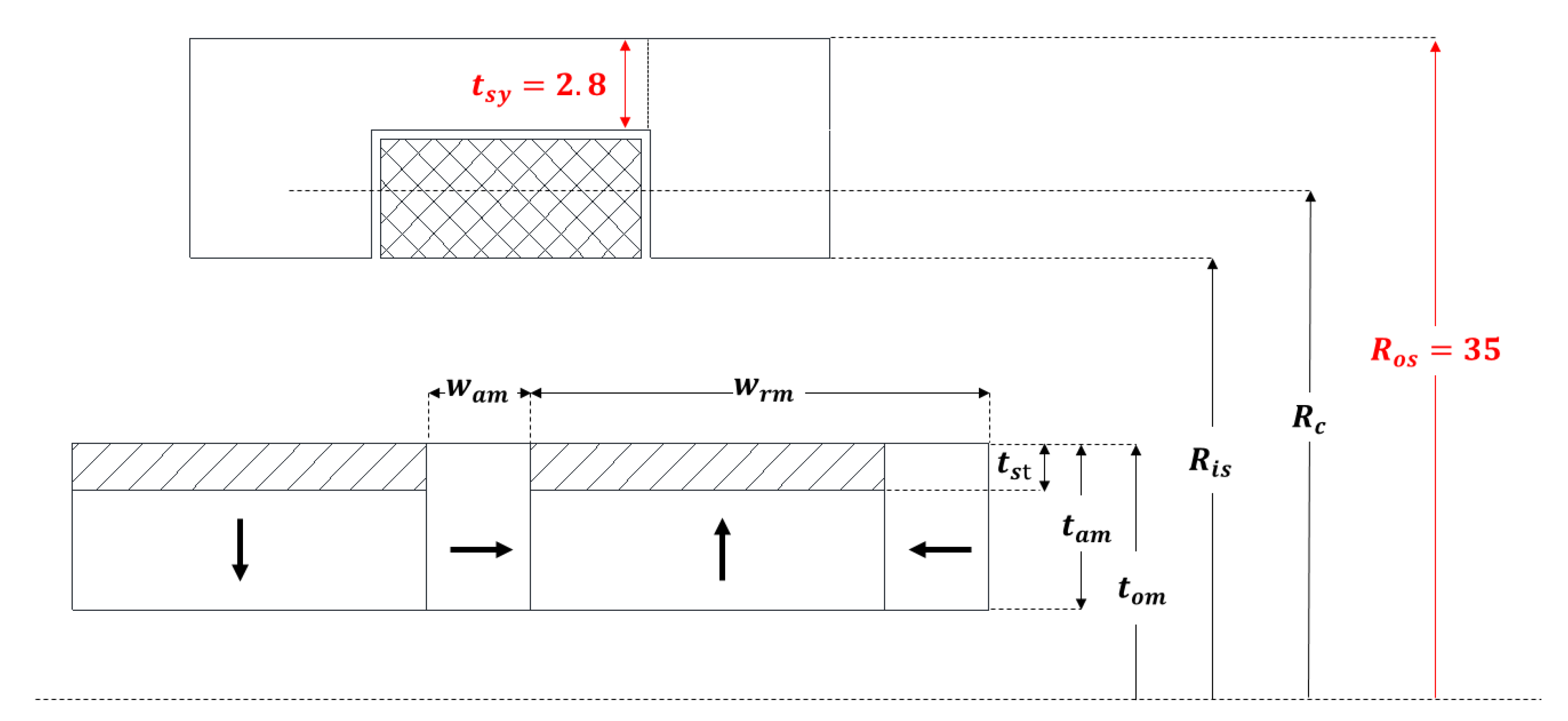

3. Modeling and Parametric Study of EHSA

3.1. Mathematical Modeling of EHSA

3.2. Parametric Geometry Study

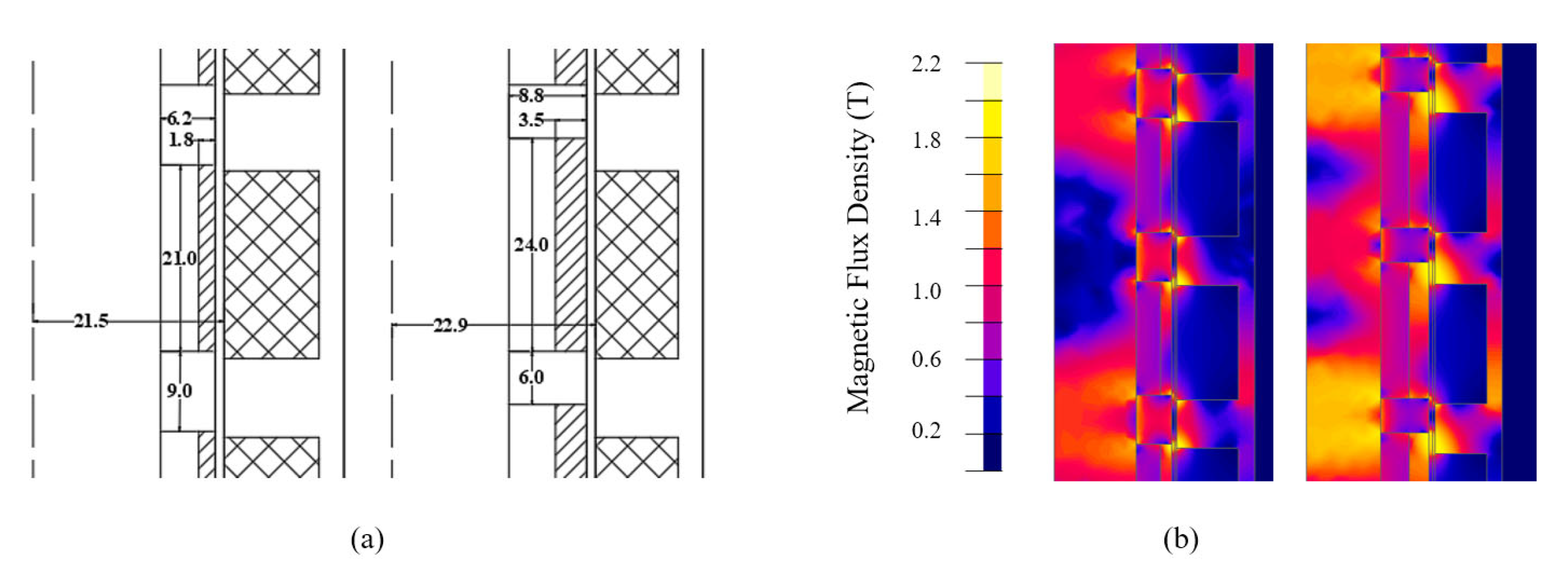

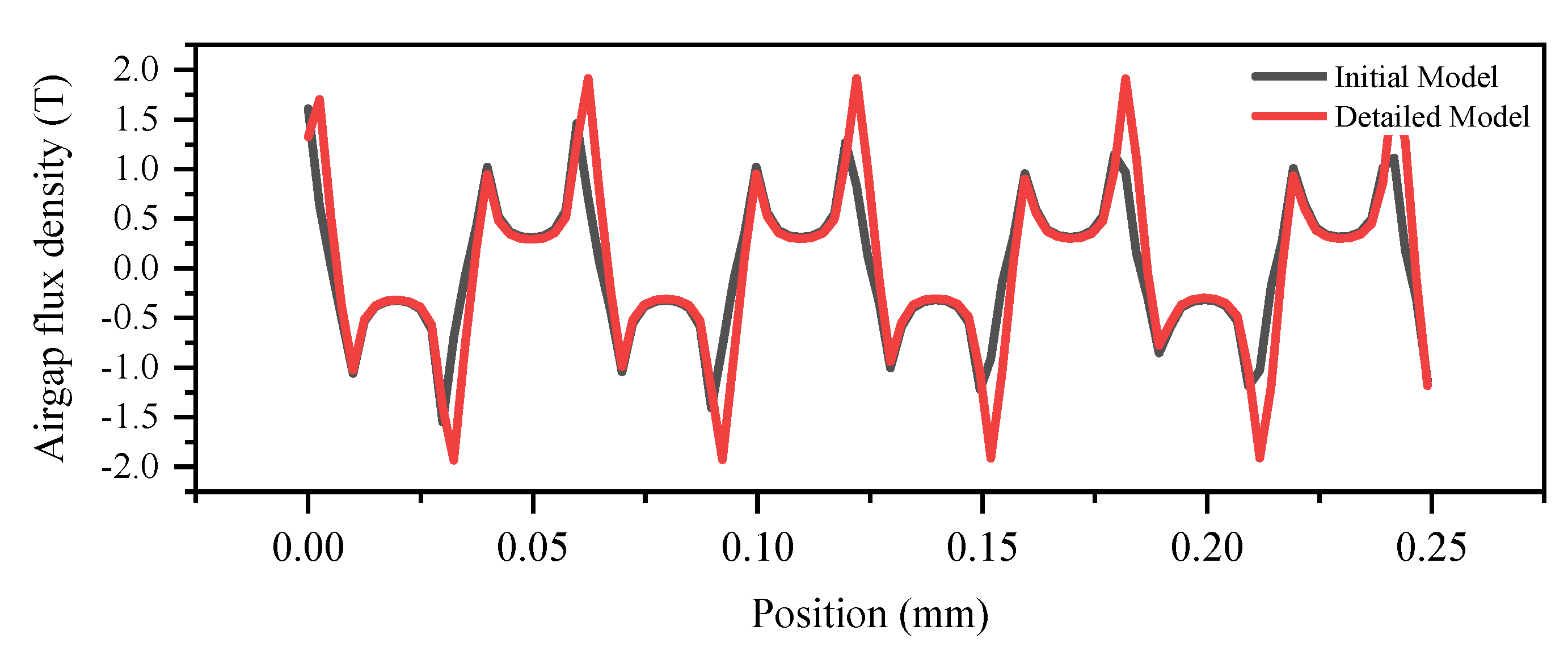

4. Detailed Design

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, R.; Wang, X.; John, S. A Comprehensive Review of the Techniques on Regenerative Shock Absorber Systems. Energies 2018, 11, 1167. [Google Scholar] [CrossRef]

- Abdelkareem, M.A.; Xu, L.; Ali, M.K.A.; Elagouz, A.; Mi, J.; Guo, S.; Liu, Y.; Zuo, L. Vibration energy harvesting in automotive suspension system: A detailed review. Appl. Energy 2018, 229, 672–699. [Google Scholar] [CrossRef]

- Shen, W.; Zhu, S.; Zhu, H.; Xu, Y.-L. Electromagnetic energy harvesting from structural vibrations during earthquakes. Smart Struct. Syst. 2016, 18, 449–470. [Google Scholar] [CrossRef]

- Conroy, G.C.; Sideris, P. Exploring energy harvesting and vibration mitigation in tall buildings accounting for wind and seismic loads. Eng. Struct. 2021, 247, 113126. [Google Scholar] [CrossRef]

- Khan, F.U.; Iqbal, M. Electromagnetic-based bridge energy harvester using traffic-induced bridge’s vibrations and ambient wind. In Proceedings of the 2016 International Conference on Intelligent Systems Engineering (ICISE), Islamabad, Pakistan, 15–17 January 2016; pp. 380–385. [Google Scholar]

- Galchev, T.; McCullagh, J.; Peterson, R.L.; Najafi, K. Harvesting traffic-induced bridge vibrations. In Proceedings of the 2011 16th International Solid-State Sensors, Actuators and Microsystems Conference, Beijing, China, 5–9 June 2011; pp. 1661–1664. [Google Scholar] [CrossRef]

- Rahman, A.; Farrok, O.; Islam, R.; Xu, W. Recent Progress in Electrical Generators for Oceanic Wave Energy Conversion. IEEE Access 2020, 8, 138595–138615. [Google Scholar] [CrossRef]

- Liu, Y.; Li, S.; Liu, C.; Wang, Y.; Zhou, Y.; Yi, H.; Li, Y.; Chang, H.; Tao, K. Spherical electret generator for water wave energy harvesting by folded structure. In Proceedings of the IECON 2019—45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 14–17 October 2019; Volume 1, pp. 812–815. [Google Scholar] [CrossRef]

- Burhanudin, J.; Abu Hasim, A.S.; Ishak, A.M.; Dardin, S.M.F.B.S.M. A Review of Power Electronics for Nearshore Wave Energy Converter Applications. IEEE Access 2022, 10, 16670–16680. [Google Scholar] [CrossRef]

- Kiran, M.R.; Farrok, O.; Mamun, A.A.; Islam, R.; Xu, W. Progress in Piezoelectric Material Based Oceanic Wave Energy Conversion Technology. IEEE Access 2020, 8, 146428–146449. [Google Scholar] [CrossRef]

- ClearMotion—Technology. Available online: http://www.clearmotion.com/technology (accessed on 27 March 2022).

- Tesla. The Magic of Tesla Roadster Regenerative Braking. Available online: https://www.tesla.com/blog/magic-tesla-roadster-regenerative-braking (accessed on 27 March 2022).

- Gonzalez, A.; Olazagoitia, J.L.; Vinolas, J.; Ulacia, I.; Izquierdo, M. An Innovative Energy Harvesting Shock Absorber System for Motorbikes. IEEE ASME Trans. Mechatron. 2021, 1–11. [Google Scholar] [CrossRef]

- Suda, Y.; Shiiba, T. A New Hybrid Suspension System with Active Control and Energy Regeneration. Veh. Syst. Dyn. 1996, 25, 641–654. [Google Scholar] [CrossRef]

- Scully, B.; Zuo, L.; Shestani, J.; Zhou, Y. Design and Characterization of an Electromagnetic Energy Harvester for Vehicle Suspensions. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Lake Buena Vista, FL, USA, 13–19 November 2009; pp. 1007–1016. [Google Scholar] [CrossRef]

- Tang, X.; Lin, T.; Zuo, L. Design and Optimization of a Tubular Linear Electromagnetic Vibration Energy Harvester. IEEE ASME Trans. Mechatron. 2014, 19, 615–622. [Google Scholar] [CrossRef]

- Karnopp, D. Permanent Magnet Linear Motors Used as Variable Mechanical Dampers for Vehicle Suspensions. Veh. Syst. Dyn. 1989, 18, 187–200. [Google Scholar] [CrossRef]

- Singh, S.; Satpute, N.V. Design and analysis of energy-harvesting shock absorber with electromagnetic and fluid damping. J. Mech. Sci. Technol. 2015, 29, 1591–1605. [Google Scholar] [CrossRef]

- Duong, M.-T.; Chun, Y.-D.; Han, P.-W.; Park, B.-G.; Bang, D.-J.; Lee, J.-K. Optimal Design of a Novel Single-Phase 8-Slot 8-Pole Tubular Electromagnetic Shock Absorber to Harvest Energy. IEEE Trans. Ind. Electron. 2020, 67, 1180–1190. [Google Scholar] [CrossRef]

- Duong, M.-T.; Chun, Y.-D. Optimal Design of a Novel Exterior Permanent Magnet Tubular Machine for Energy Harvesting From Vehicle Suspension System. IEEE Trans. Energy Convers. 2020, 35, 1772–1780. [Google Scholar] [CrossRef]

- Liu, C.-T.; Hwang, C.-C.; Lin, W.-P. Design and operational analyses of an electromagnetic hybrid shock absorber system for scooter application. In Proceedings of the 2014 17th International Conference on Electrical Machines and Systems (ICEMS), Hangzhou, China, 22–25 October 2014; pp. 2590–2594. [Google Scholar] [CrossRef]

- Wang, W.; Chen, X.; Wang, J. Unsprung Mass Effects on Electric Vehicle Dynamics based on Coordinated Control Scheme. In Proceedings of the 2019 American Control Conference (ACC), Philadelphia, PA, USA, 10–12 July 2019; Volume 2019, pp. 971–976. [Google Scholar] [CrossRef]

- Li, Z.; Zuo, L.; Luhrs, G.; Lin, L.; Qin, Y.-X. Electromagnetic Energy-Harvesting Shock Absorbers: Design, Modeling, and Road Tests. IEEE Trans. Veh. Technol. 2013, 62, 1065–1074. [Google Scholar] [CrossRef]

- Li, Z.; Brindak, Z.; Zuo, L. Modeling of an Electromagnetic Vibration Energy Harvester with Motion Magnification. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Denver, CO, USA, 11–17 November 2011; pp. 285–293. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, X.; Chen, W.; Rasim, Y.; Salman, W.; Pan, H.; Yuan, Y.; Wang, C. A high-efficiency energy regenerative shock absorber using supercapacitors for renewable energy applications in range extended electric vehicle. Appl. Energy 2016, 178, 177–188. [Google Scholar] [CrossRef]

- Liu, M.; Lin, R.; Zhou, S.; Yu, Y.; Ishida, A.; McGrath, M.; Kennedy, B.; Hajj, M.; Zuo, L. Design, simulation and experiment of a novel high efficiency energy harvesting paver. Appl. Energy 2018, 212, 966–975. [Google Scholar] [CrossRef]

- Li, Z.; Zuo, L.; Kuang, J.; Luhrs, G. Mechanical Motion Rectifier Based Energy-Harvesting Shock Absorber. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Chicago, IL, USA, 12–15 August 2012; Volume 6, pp. 595–604. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, X.; Zhan, M.; Guo, K.; Zhao, F.; Liu, Z. Study on a novel hydraulic pumping regenerative suspension for vehicles. J. Frankl. Inst. 2015, 352, 485–499. [Google Scholar] [CrossRef]

- Peng, M.; Guo, X.; Zou, J.; Zhang, C. Simulation Study on Vehicle Road Performance with Hydraulic Electromagnetic Energy-Regenerative Shock Absorber; SAE Technical Paper 2016-01-1550; SAE International: Warrendale, PA, USA, 2016. [Google Scholar] [CrossRef]

- Li, C.; Tse, P.W.T. Fabrication and testing of an energy-harvesting hydraulic damper. Smart Mater. Struct. 2013, 22, 065024. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, H.; Guo, K.; Zhang, X.; Li, S. Electro-hydraulic damper for energy harvesting suspension: Modeling, prototyping and experimental validation. Appl. Energy 2017, 199, 1–12. [Google Scholar] [CrossRef]

- Li, C.; Zhu, R.; Liang, M.; Yang, S. Integration of shock absorption and energy harvesting using a hydraulic rectifier. J. Sound Vib. 2014, 333, 3904–3916. [Google Scholar] [CrossRef]

- Huang, B.; Hsieh, C.-Y.; Golnaraghi, F.; Moallem, M. Development and optimization of an energy-regenerative suspension system under stochastic road excitation. J. Sound Vib. 2015, 357, 16–34. [Google Scholar] [CrossRef]

- Amati, N.; Festini, A.; Tonoli, A. Design of electromagnetic shock absorbers for automotive suspensions. Veh. Syst. Dyn. 2011, 49, 1913–1928. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, T.; Zhang, Z.; Yuan, Y.; Liu, Y. A high-efficiency regenerative shock absorber considering twin ball screws transmissions for application in range-extended electric vehicles. Energy Built Environ. 2020, 1, 36–49. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, L.; Zuo, L. Design, Modeling, Lab, and Field Tests of a Mechanical-Motion-Rectifier-Based Energy Harvester Using a Ball-Screw Mechanism. IEEE ASME Trans. Mechatron. 2017, 22, 1933–1943. [Google Scholar] [CrossRef]

- Structure Design and Parameter Matching of Ball-Screw Regenerative Damper. Available online: https://www.researchgate.net/publication/289905771_Structure_design_and_parameter_matching_of_ball-screw_regenerative_damper (accessed on 26 July 2022).

- Xie, L.; Cai, S.; Huang, G.; Huang, L.; Li, J.; Li, X. On Energy Harvesting From a Vehicle Damper. IEEE/ASME Trans. Mechatron. 2020, 25, 108–117. [Google Scholar] [CrossRef]

- Bowen, L.; Vinolas, J.; Olazagoitia, J.L. Design and Potential Power Recovery of Two Types of Energy Harvesting Shock Absorbers. Energies 2019, 12, 4710. [Google Scholar] [CrossRef]

- Bowen, L.; Vinolas, J.; Olazagoitia, J.L.; Otero, J.E. An Innovative Energy Harvesting Shock Absorber System Using Cable Transmission. IEEE/ASME Trans. Mechatron. 2019, 24, 689–699. [Google Scholar] [CrossRef]

- Casavola, A.; Di Iorio, F.; Tedesco, F. A multiobjective H∞ control strategy for energy harvesting in regenerative vehicle suspension systems. Int. J. Control 2017, 91, 741–754. [Google Scholar] [CrossRef]

- Di Iorio, F.; Casavola, A. A multiobjective H∞ control strategy for energy harvesting while damping for regenerative vehicle suspension systems. In Proceedings of the 2012 American Control Conference (ACC), Montreal, QC, Canada, 27–29 June 2012; pp. 491–496. [Google Scholar] [CrossRef]

- Scruggs, J. Multi-objective nonlinear control of semiactive and regenerative systems. In Proceedings of the 2010 American Control Conference, Baltimore, MD, USA, 30 June–2 July 2010; pp. 726–731. [Google Scholar] [CrossRef]

- Duong, M.-T.; Chun, Y.-D.; Bang, D.-J. Improvement of Tubular Permanent Magnet Machine Performance Using Dual-Segment Halbach Array. Energies 2018, 11, 3132. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Z.Q.; Shuraiji, A.L.; Lu, Q.F. Comparative Study of Novel Tubular Partitioned Stator Permanent Magnet Machines. IEEE Trans. Magn. 2016, 52, 1–7. [Google Scholar] [CrossRef]

- Zuo, L.; Scully, B.; Shestani, J.; Zhou, Y. Design and characterization of an electromagnetic energy harvester for vehicle suspensions. Smart Mater. Struct. 2010, 19, 045003. [Google Scholar] [CrossRef] [Green Version]

| Item | Value |

|---|---|

| Motorbike mass (kg) | 250 |

| Vibrating speed, v (m/s) | 0.157 |

| Stroke length peak-to-peak Stp (mm) | 10 |

| Vibrating frequency, f (Hz) | 5 |

| Maximum length, L (mm) | 300 |

| Outer diameter (mm) | 70 |

| Pole pitch/Slot pitch (mm) | 30 |

| Mechanical air gap (mm) | 1 |

| Axial PMs material | 50SH: Br = 1.40 T; μr = 1.05 |

| Radial PMs material | 40SH: Br = 1.26 T; μr = 1.05 |

| Electrical steel | S20C |

| Wire diameter, wd (mm) | 0.6 |

| Slot fill factor | 0.5 |

| No. | Parameter | Lower | Upper | Constant |

|---|---|---|---|---|

| 1 | Kr | 0.2 | 0.7 | Kt_pm = 0.7, Kw_pm = 0.3, Ksp = 0.3 |

| 2 | Kt_pm | 0.2 | 0.8 | Kr = 0.6, Kw_pm = 0.3, Ksp = 0.3 |

| 3 | Kw_pm | 0.2 | 0.8 | Kt_pm = 0.7, Kr= 0.6, Ksp = 0.3 |

| 4 | Ksp | 0.2 | 0.8 | Kt_pm = 0.7, Kw_pm = 0.3, Kr= 0.6 |

| Item | Target | Initial | Detailed |

|---|---|---|---|

| Stator radius ratio Kr | 0.6 | 0.64 | |

| Magnet thickness ratio Kt_pm | 0.7 | 0.52 | |

| Magnet width ratio Kw_pm | 0.3 | 0.25 | |

| Iron spacer thickness ratio Ksp | 0.3 | 0.4 | |

| Inner stator radius Ris (mm) | 21.5 | 22.9 | |

| Magnet thickness trm (mm) | 6.15 | 9.92 | |

| Axial PMs thickness tam (mm) | 9.0 | 7.5 | |

| Radial PMs width wrm (mm) | 21.0 | 22.5 | |

| Iron spacer thickness tsp (mm) | 1.845 | 3.968 | |

| Min average output power (W) | 120 | 99.6 | 124 |

| Min average power density (W/cm3) | 104 | 86.3 | 107.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tran, V.-K.; Han, P.-W.; Chun, Y.-D. Design of a 120 W Electromagnetic Shock Absorber for Motorcycle Applications. Appl. Sci. 2022, 12, 8688. https://doi.org/10.3390/app12178688

Tran V-K, Han P-W, Chun Y-D. Design of a 120 W Electromagnetic Shock Absorber for Motorcycle Applications. Applied Sciences. 2022; 12(17):8688. https://doi.org/10.3390/app12178688

Chicago/Turabian StyleTran, Vu-Khanh, Pil-Wan Han, and Yon-Do Chun. 2022. "Design of a 120 W Electromagnetic Shock Absorber for Motorcycle Applications" Applied Sciences 12, no. 17: 8688. https://doi.org/10.3390/app12178688

APA StyleTran, V.-K., Han, P.-W., & Chun, Y.-D. (2022). Design of a 120 W Electromagnetic Shock Absorber for Motorcycle Applications. Applied Sciences, 12(17), 8688. https://doi.org/10.3390/app12178688