A Research on Image Semantic Refinement Recognition of Product Surface Defects Based on Causal Knowledge

Abstract

:1. Introduction

- (1)

- The DCNN only obtains the data output of the category and location information of product surface defects but cannot express the implicit causal knowledge behind the image defects, which ignores the rich semantic information of the surface defect image itself and the huge potential connection among information.

- (2)

- The knowledge graph can visualize knowledge, making finding the relationship between knowledge easier. Therefore, to enrich the semantic information of surface defect images through knowledge graph technology, it is necessary to fuse the content of image classification technology and knowledge graph technology. Still, they have a vast semantic gap, and the joint task is challenging to solve.

2. Related Works

2.1. Computer Vision Technology

2.2. Knowledge Graph Technology

2.3. Research on Image Semantic Refinement Recognition of Product Surface Defects Based on Causal Knowledge

3. The Framework of the Proposed Method and the Data Required for the Experiment

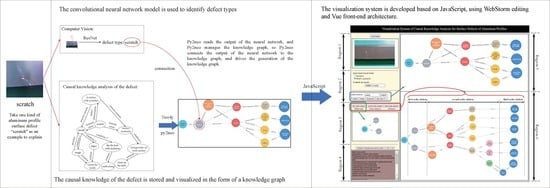

3.1. Overall Framework

3.1.1. Image Classification in Computer Vision

- (1)

- Selection of convolutional neural network model

- (2)

- Introduction of deformable convolution modules

- (3)

- Improved ResNet network model

3.1.2. Construction Process of Knowledge Graph

3.2. Data Collection and Preprocessing

3.2.1. Selection and Preprocessing of Surface Defect Dataset for Industrial Products

3.2.2. Text Data Acquisition and Preprocessing

4. Experiments on Convolutional Neural Network and Construction of Surface Defect Ontology

4.1. Convolutional Neural Network Experiment

4.2. Ontology Construction of Aluminum Profile Surface Defect

4.2.1. Methods of Constructing Ontology

- (1)

- Entity extraction: Four types of surface defects of aluminum profiles are selected and the entity types of defects are shown in Table 7.

- (2)

- Relational extraction: The extraction of the surface defect relationship needs to integrate relevant manufacturing tools, manufacturing processes, and other information so that complex defect causes can be expressed as the relationship between various processes and redundant information can be effectively removed, as shown in Table 8.

- (3)

- Attribute extraction: Information is extracted from the formation mechanism and solution of each defect type as the relevant explanations of entity or relationship. The results of the partial attribute extraction are shown in Table 9.

4.2.2. Storage of Knowledge

5. Development of Web Visualization System

5.1. Image Classification Layer

5.2. Data Layer

5.3. User Layer

6. Conclusions

- (1)

- Given the irregular defects on the surface of industrial products, an improved ResNet deep convolutional neural network model is proposed and verified on the dataset of surface defects. The results show that the improved network model’s average accuracy, recall, and precision are increased by 11%, 8.15%, and 8.3%, respectively, effectively improving its classification effect.

- (2)

- Based on the four elements of “defect type, characteristic, cause, and solution”, we constructed the knowledge graph of aluminum profile surface defects, which realizes the storage and visual representation of causal knowledge about aluminum profile surface defects.

- (3)

- By establishing a web visualization platform, the deep convolutional neural network model was integrated with the causal knowledge graph to realize the causal visualization of the defects in the causal knowledge graph driven by the output data of the network model.

- (1)

- We will increase the types of defects in future work and conduct a more detailed analysis of the causes of surface defects.

- (2)

- We will design the corresponding application according to the framework structure. For example, KBQA (knowledge graph question answering) has a broad application prospect in solving the causes of product surface defects. Fast response to the causes of defects can be achieved through KBQA.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, Y.; Ding, Y.; Zhao, F.; Zhang, E.; Wu, Z.; Shao, L. Surface Defect Detection Methods for Industrial Products: A Review. Appl. Sci. 2021, 11, 7657. [Google Scholar] [CrossRef]

- Vuković, M.; Thalmann, S. Causal Discovery in Manufacturing: A Structured Literature Review. J. Manuf. Mater. Process. 2022, 6, 10. [Google Scholar] [CrossRef]

- Gao, H.; Zhang, Y.; Lv, W.; Yin, J.; Qasim, T.; Wang, D. A Deep Convolutional Generative Adversarial Networks-Based Method for Defect Detection in Small Sample Industrial Parts Images. Appl. Sci. 2022, 12, 6569. [Google Scholar] [CrossRef]

- Akram, M.W.; Li, G.; Jin, Y.; Chen, X.; Zhu, C.; Zhao, X.; Khaliq, A.; Faheem, M.; Ahmad, A. CNN based automatic detection of photovoltaic cell defects in electroluminescence images. Energy 2019, 189, 116319. [Google Scholar] [CrossRef]

- Alipour, M.; Harris, D.K.; Miller, G.R. Robust Pixel-Level Crack Detection Using Deep Fully Convolutional Neural Networks. J. Comput. Civ. Eng. 2019, 33, 854. [Google Scholar] [CrossRef]

- Hedberg, T.D.; Bajaj, M.; Camelio, J.A. Using Graphs to Link Data Across the Product Lifecycle for Enabling Smart Manufacturing Digital Threads. J. Comput. Inf. Sci. Eng. 2019, 20, 011011. [Google Scholar] [CrossRef]

- Dombrowski, U.; Reiswich, A.; Imdahl, C. Knowledge Graphs for an Automated Information Provision in the Factory Planning. In Proceedings of the 2019 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 15–19 December 2019; pp. 1074–1078. [Google Scholar] [CrossRef]

- Zhou, Y.; Sun, Y.; Honavar, V. Improving Image Captioning by Leveraging Knowledge Graphs. In Proceedings of the IEEE Winter Conference on Applications of Computer Vision (WACV), Waikoloa, HI, USA, 4–8 January 2019; pp. 283–293. [Google Scholar] [CrossRef]

- Zhang, D.; Cui, M.; Yang, Y.; Yang, P.; Xie, C.; Liu, D.; Yu, B.; Chen, Z. Knowledge Graph-Based Image Classification Refinement. IEEE Access 2019, 7, 57678–57690. [Google Scholar] [CrossRef]

- Menglong, C.; Detao, J.; Ting, Z.; Dehai, Z.; Cheng, X.; Zhibo, C.; Xiaoqiang, X. Image Classification Based on Image Knowledge Graph and Semantics. In Proceedings of the IEEE 23rd International Conference on Computer Supported Cooperative Work in Design (CSCWD), Porto, Portugal, 6–8 May 2019. [Google Scholar] [CrossRef]

- Huang, B.; He, B.; Wu, L.; Lin, Y. A Deep Learning Approach to Detecting Ships from High-Resolution Aerial Remote Sensing Images. J. Coast. Res. 2020, 111, 16–20. [Google Scholar] [CrossRef]

- Li, X.; Liu, B.; Zheng, G.; Ren, Y.; Zhang, S.; Liu, Y.; Gao, L.; Liu, Y.; Zhang, B.; Wang, F. Deep-learning-based information mining from ocean remote-sensing imagery. Natl. Sci. Rev. 2020, 7, 1584–1605. [Google Scholar] [CrossRef]

- Zhao, F.; Li, J.; Zhang, L.; Li, Z.; Na, S.-G. Multi-view face recognition using deep neural networks. Futur. Gener. Comput. Syst. 2020, 111, 375–380. [Google Scholar] [CrossRef]

- Li, X.; Li, Y.; Cao, Y.; Duan, S.; Wang, X.; Zhao, Z. Fault Diagnosis Method for Aircraft EHA Based on FCNN and MSPSO Hyperparameter Optimization. Appl. Sci. 2022, 12, 8562. [Google Scholar] [CrossRef]

- Islam, M.; Hossain, B.; Akhtar, N.; Moni, M.A.; Hasan, K.F. CNN Based on Transfer Learning Models Using Data Augmentation and Transformation for Detection of Concrete Crack. Algorithms 2022, 15, 287. [Google Scholar] [CrossRef]

- Ryselis, K.; Blažauskas, T.; Damaševičius, R.; Maskeliūnas, R. Agrast-6: Abridged VGG-Based Reflected Lightweight Architecture for Binary Segmentation of Depth Images Captured by Kinect. Sensors 2022, 22, 6354. [Google Scholar] [CrossRef]

- Bang, J.; Di Marco, P.; Shin, H.; Park, P. Deep Transfer Learning-Based Fault Diagnosis Using Wavelet Transform for Limited Data. Appl. Sci. 2022, 12, 7450. [Google Scholar] [CrossRef]

- He, K.; Zhang, X.; Ren, S.; Sun, Q. Deep residual learning for image recognition. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 27–30 June 2016; pp. 770–778. [Google Scholar]

- Wang, J.; Deng, F.; Wei, B. Defect Detection Scheme for Key Equipment of Transmission Line for Complex Environment. Electronics 2022, 11, 2332. [Google Scholar] [CrossRef]

- Zhou, Y.; Chang, H.; Lu, Y.; Lu, X. CDTNet: Improved Image Classification Method Using Standard, Dilated and Transposed Convolutions. Appl. Sci. 2022, 12, 5984. [Google Scholar] [CrossRef]

- Zhao, D.; Tian, X. A Multiscale Fusion Lightweight Image-Splicing Tamper-Detection Model. Electronics 2022, 11, 2621. [Google Scholar] [CrossRef]

- Wang, T.; Xu, X.; Pan, H.; Chang, X.; Yuan, T.; Zhang, X.; Xu, H. Rolling Bearing Fault Diagnosis Based on Depth-Wise Separable Convolutions with Multi-Sensor Data Weighted Fusion. Appl. Sci. 2022, 12, 7640. [Google Scholar] [CrossRef]

- Dai, J.; Qi, H.; Xiong, Y. Deformable convolutional networks. In Proceedings of the IEEE International Conference on Computer Vision, Venice, Italy, 22–29 October 2017; pp. 764–773. [Google Scholar]

- Nanni, L.; Brahnam, S.; Paci, M.; Ghidoni, S. Comparison of Different Convolutional Neural Network Activation Functions and Methods for Building Ensembles for Small to Midsize Medical Data Sets. Sensors 2022, 22, 6129. [Google Scholar] [CrossRef]

- Shong, Y.; Gao, X.; Zhang, D. The piecewise non-linear approximation of the sigmoid function and its implementation in FPGA. Appl. Electron. Tech. 2017, 43, 49–51. [Google Scholar]

- Yan, Z.; Liu, H. SMoCo: A Powerful and Efficient Method Based on Self-Supervised Learning for Fault Diagnosis of Aero-Engine Bearing under Limited Data. Mathematics 2022, 10, 2796. [Google Scholar] [CrossRef]

- Zhai, S.; Wu, H.; Kumar, A. S3pool: Pooling with stochastic spatial sampling. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Honolulu, HI, USA, 21–26 July 2017; pp. 4970–4978. [Google Scholar]

- Zhang, Y.; Liu, X.; Guo, J.; Zhou, P. Surface Defect Detection of Strip-Steel Based on an Improved PP-YOLOE-m Detection Network. Electronics 2022, 11, 2603. [Google Scholar] [CrossRef]

- Lu, Y.; Qiu, Z.; Liao, C.; Zhou, Z.; Li, T.; Wu, Z. A GIS Partial Discharge Defect Identification Method Based on YOLOv5. Appl. Sci. 2022, 12, 8360. [Google Scholar] [CrossRef]

- Shi, L.; Long, Y.; Wang, Y.; Chen, X.; Zhao, Q. Evaluation of Internal Cracks in Turbine Blade Thermal Barrier Coating Using Enhanced Multi-Scale Faster R-CNN Model. Appl. Sci. 2022, 12, 6446. [Google Scholar] [CrossRef]

- Fu, R.; He, J.; Liu, G.; Li, W.; Mao, J.; He, M.; Lin, Y. Fast Seismic Landslide Detection Based on Improved Mask R-CNN. Remote Sens. 2022, 14, 3928. [Google Scholar] [CrossRef]

- Hu, J.; Shen, L.; Sun, G. Squeeze-and-excitation networks. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Salt Lake City, UT, USA, 18–23 June 2018; pp. 7132–7141. [Google Scholar]

- Wang, K.; Liew, J.H.; Zou, Y. Panet: Few-shot image semantic segmentation with prototype alignment. In Proceedings of the IEEE/CVF International Conference on Computer Vision, Seoul, Korea, 27–28 October 2019; pp. 9197–9206. [Google Scholar]

- Han, K.; Wang, Y.; Tian, Q. Ghostnet: More features from cheap operations. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition, Seattle, WA, USA, 14–19 June 2020; pp. 1580–1589. [Google Scholar]

- Yang, K.; Fang, C.; Duan, L. Automatic detection of casting defects based on deep learning model fusion. Chin. J. Sci. Inst. 2021, 12, 100. [Google Scholar]

- Xie, Q.; Wang, N.; Yang, Y.J. Detection and Evaluation of Welded Joints of Steel Structures with Defects. J. Mech. Eng. 2021, 134, 28–37. [Google Scholar]

- Zhang, S.J.; Jin, Z.L. Casting Defect Detection Method Based on Multi Model Cascade and Binocular Vision. J. Mech. Eng. 2021, 58, 34–43. [Google Scholar]

- Li, B.; Wang, C.; Ding, X.Y. Surface defect detection algorithm based on improved YOLOv4. J. Beijing Univ. Aeron. Astron. 2021, 1631, 012081. [Google Scholar]

- Yan, J.; Lv, T.; Yu, Y. Construction and Recommendation of a Water Affair Knowledge Graph. Sustainability 2018, 10, 3429. [Google Scholar] [CrossRef]

- Deng, J.; Wang, T.; Wang, Z.; Zhou, J.; Cheng, L. Research on event logic knowledge graph construction method of robot transmission system fault diagnosis. IEEE Access 2022, 10, 17656–17673. [Google Scholar] [CrossRef]

- Gong, F.; Wang, M.; Wang, H.; Wang, S.; Liu, M. SMR: Medical Knowledge Graph Embedding for Safe Medicine Recommendation. Big Data Res. 2020, 23, 100174. [Google Scholar] [CrossRef]

- Shi, D.; Wang, T.; Xing, H.; Xu, H. A learning path recommendation model based on a multidimensional knowledge graph framework for e-learning. Knowl.-Based Syst. 2020, 195, 105618. [Google Scholar] [CrossRef]

- Zhang, Q.; Wen, Y.; Zhou, C.; Long, H.; Han, D.; Zhang, F.; Xiao, C. Construction of Knowledge Graphs for Maritime Dangerous Goods. Sustainability 2019, 11, 2849. [Google Scholar] [CrossRef]

- Wei, Z.; Wan, G.; Mu, Y.; Liu, L.; Hu, X. Design and Construction of Geographic Knowledge Graph. In Proceedings of the IEEE, 9th Joint International Information Technology and Artificial Intelligence Conference (ITAIC), Chongqing, China, 11–13 December 2020; pp. 2252–2256. [Google Scholar] [CrossRef]

- Domingo-Fernández, D.; Baksi, S.; Schultz, B. COVID-19 Knowledge Graph: A computable, multi-modal, cause-and-effect knowledge model of COVID-19 pathophysiology. Bioinformatics 2021, 37, 1332–1334. [Google Scholar] [CrossRef]

- Nguyen, H.L.; Jung, J.J. Social event decomposition for constructing knowledge graph. Futur. Gener. Comput. Syst. 2019, 100, 10–18. [Google Scholar] [CrossRef]

- Hellweg, F.; Brückmann, H.; Beul, T.; Mandel, C.; Albers, A. Knowledge graph for manufacturing cost estimation of gear shafts-a case study on the availability of product and manufacturing information in practice. Procedia CIRP 2022, 109, 245–250. [Google Scholar] [CrossRef]

- Zeng, Y.; Qin, Y.; Liu, D.; Fu, Y.; Gong, M.; Zhang, X. Railway Train Device Fault Causality Model Based on Knowledge Graph. In Proceedings of the International Conference on Sensing, Diagnostics, Prognostics, and Control (SDPC), Beijing, China, 5–7 August 2020; pp. 385–390. [Google Scholar] [CrossRef]

- Mavropoulos, T.; Symeonidis, S.; Tsanousa, A.; Giannakeris, P.; Rousi, M.; Kamateri, E.; Meditskos, G.; Ioannidis, K.; Vrochidis, S.; Kompatsiaris, I. Smart integration of sensors, computer vision and knowledge representation for intelligent monitoring and verbal human-computer interaction. J. Intell. Inf. Syst. 2021, 57, 321–345. [Google Scholar] [CrossRef]

- Toor, A.S.; Wechsler, H.; Nappi, M. Biometric surveillance using visual question answering. Pattern Recognit. Lett. 2019, 126, 111–118. [Google Scholar] [CrossRef]

- Hong, J.; Fu, J.; Uh, Y.; Mei, T.; Byun, H. Exploiting hierarchical visual features for visual question answering. Neurocomputing 2019, 351, 187–195. [Google Scholar] [CrossRef]

- Pan, Z.; Su, C.; Deng, Y.; Cheng, J. Video2Entities: A computer vision-based entity extraction framework for updating the architecture, engineering and construction industry knowledge graphs. Autom. Constr. 2021, 125, 103617. [Google Scholar] [CrossRef]

- Qiang, W.; He, Y.; Guo, Y.; Li, B.; He, L. Exploring Underwater Target Detection Algorithm Based on Improved SSD. Xibei Gongye Daxue Xuebao/J. Northwest. Polytech. Univ. 2020, 38, 747–754. [Google Scholar] [CrossRef]

- Guan, S.Y.; Zhang, W.Y.; Jiang, Y.F. A surface defect detection method of the magnesium alloy sheet based on deformable convolution neural network. Metalurgija 2020, 59, 325–328. [Google Scholar]

- Jia, M.; Zhang, Y.; Pan, T.; Wu, W.; Su, F. Ontology Modeling of Marine Environmental Disaster Chain for Internet Information Extraction: A Case Study on Typhoon Disaster. J. Geo-Inform. Sci. 2020, 22, 2289–2303. [Google Scholar] [CrossRef]

| Category | Training Set | Validation Set | Label |

|---|---|---|---|

| scratch | 1015 | 145 | 1 |

| bump | 905 | 129 | 2 |

| ai-powder | 888 | 127 | 3 |

| dirty spot | 987 | 140 | 4 |

| Model | The Change Curve of Accuracy and CrossEntropy Loss on the Training Set and the Validation Set | Comparison of Four Models in Accuracy and Cross Entropy Loss | |

|---|---|---|---|

| 1 |  |  |  |

| 2 |  |  |  |

| 3 |  |  |  |

| 4 |  |  |  |

| Confusion Matrix | Prediction | ||||

|---|---|---|---|---|---|

| Scratch | Bump | Al-Powder | Dirty Spot | ||

| true | scratch | 120 | 3 | 3 | 8 |

| bump | 3 | 138 | 4 | 5 | |

| al-powder | 6 | 6 | 128 | 3 | |

| dirty spot | 10 | 5 | 8 | 110 | |

| Confusion Matrix | Prediction | ||||

|---|---|---|---|---|---|

| Scratch | Bump | Al-Powder | Dirty Spot | ||

| true | scratch | 128 | 5 | 1 | 0 |

| bump | 0 | 148 | 0 | 2 | |

| al-powder | 2 | 1 | 140 | 1 | |

| dirty spot | 1 | 6 | 0 | 125 | |

| Model | Scratch | Bump | Al-Powder | Dirty Spot |

|---|---|---|---|---|

| ResNet101 | 86.3 | 90.8 | 95.8 | 87.3 |

| Deform_ResNet101 | 97.7 | 92.5 | 99.3 | 97.7 |

| Model | Scratch | Bump | Al-Powder | Dirty Spot |

|---|---|---|---|---|

| ResNet101 | 89.6 | 92 | 89.5 | 82.7 |

| Deform_ResNet101 | 95.6 | 98.7 | 97.2 | 94.7 |

| Entity Name | Description |

|---|---|

| scratch | Slight rubbing of other objects after surface treatment (painting), resulting in marks. |

| bump | When the aluminum is lifted by the crane, it is accidentally touched, or the forklift is not careful to lift the material, resulting in the concave surface of the aluminum. |

| al-powder | Surface treatment powder spraying failed to evenly spray powder, resulting in a pile of a pile of protrusion. |

| dirty spot | Surface treatment, dust or some dirty things failed to erase, resulting in coating particles more prominent. |

| Head of the Entity | Relationship | Tail Entity |

|---|---|---|

| scratch | defect phenomenon | scratches on the surface |

| scratches on the surface | process | surface treatment |

| surface treatment | condition | slide wiped |

| slide wiped | measure | move carefully after surface treatment to avoid collision |

| scratch | internal cause | mould |

| scratch | external cause | surface treatment |

| rough | position | mould |

| Object | Property |

|---|---|

| mould | rough, ribbed, die hole blocked with foreign body |

| surface treatment | foreign body on work surface |

| Neo4j Diagram Database Elements | Function | Expression Object |

|---|---|---|

| label | description of ontology concepts | ontology concepts such as defect type, formation mechanism and solution |

| node | description of entity | scratch, surface treatment, grinding wall and other specific objects |

| relationship | description of relationships between entities | process flow, cause position, condition, internal cause, external cause and so on |

| property | description of attributes of entities and relationships | defect type description, process number and other entity attributes and relationship attributes |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhuang, W.; Zhang, T.; Yao, L.; Lu, Y.; Yuan, P. A Research on Image Semantic Refinement Recognition of Product Surface Defects Based on Causal Knowledge. Appl. Sci. 2022, 12, 8828. https://doi.org/10.3390/app12178828

Zhuang W, Zhang T, Yao L, Lu Y, Yuan P. A Research on Image Semantic Refinement Recognition of Product Surface Defects Based on Causal Knowledge. Applied Sciences. 2022; 12(17):8828. https://doi.org/10.3390/app12178828

Chicago/Turabian StyleZhuang, Weibin, Taihua Zhang, Liguo Yao, Yao Lu, and Panliang Yuan. 2022. "A Research on Image Semantic Refinement Recognition of Product Surface Defects Based on Causal Knowledge" Applied Sciences 12, no. 17: 8828. https://doi.org/10.3390/app12178828

APA StyleZhuang, W., Zhang, T., Yao, L., Lu, Y., & Yuan, P. (2022). A Research on Image Semantic Refinement Recognition of Product Surface Defects Based on Causal Knowledge. Applied Sciences, 12(17), 8828. https://doi.org/10.3390/app12178828