1. Introduction

The development of BRDs has attained a significant degree of maturity over the last three decades. Novel advances in mechanical design, electrical instrumentation, and automatic control methods have forced BRDs to exert more complex activities such as autonomous walking, climbing stairs, and jumping, among others [

1]. Nowadays, there is a scientific and technical trend in developing more efficient BRD configuration, which includes using lighter and more resistant materials, faster digital processors, and more advanced electronic sensors and actuators [

2]. This last aspect has attracted attention because actuators’ characteristics define most BRD mobilization abilities. There are diverse actuator options for BRDs, including permanent magnet and brushless motors, steppers, pneumatic muscles [

3], multi-motor drive systems [

4], and more recently, linear actuators [

5].

Linear actuators are devices that are conformed by an electrical motor (usually a DC with a permanent magnet) connected to a ball-screw driving structure (

Figure 1). This device is used increasingly in robotics due to its working characteristics, including the device scalability, setup versatility, stack setting, larger torque, the electrical equivalent operation similar to DC motors actuators, and motion robustness concerning external perturbations, as well as long periods of activity. Using linear actuators for mobilizing BRD has several advantages (compared to other actuation strategies). A heavy actuation device can be placed near the hip joint, limiting the leg inertia, and some others [

6]. Despite the mentioned benefits, some drawbacks must be overcome if the linear actuators are going to be considered a feasible variant for forcing the BRDs motion. Among others, linear actuator dynamics are usually not considered in the device modeling description. The restricted range of motion in the actuator (which implies limited articulation angular displacement) are the main disadvantages that should be corrected.

All the benefits of using linear actuators as driving elements for BRDs have been emphasized by various studies. The Technical University of Munich constructed the humanoid robot LOLA [

7]. They proposed the design of a linear actuator based on a ball screw drive attached to the main structure by Cardan joints. It is used to maintain the moment of inertia of the thigh. Furthermore, the WL family of robots, designed by Waseda University, uses linear motion actuators for its Stewart platform-like mechanism that is oriented as a novel biped walking type wheelchair [

8,

9]. The study introduced in [

10] describes a double linear ball-screw drive structure for the ankle joint. In comparison, ref. [

11] provides a design where both the knee and ankle possess single and double linear actuator structures, respectively.

Most existing studies where the linear actuator has been the active driving element of biped robots have not considered the electromechanical dynamics that characterize it. Such dynamics include the motor’s temporal evolution and connection to the ball-screw configuration. Moreover, the reported studies consider that the linear actuator has an unbounded range of linear displacement. Both characteristics are going to be analyzed in this study and used as limitations for the automatic control design that may enforce the exerting of a gait cycle (even if the BRD is suspended).

The problem of introducing linear actuator dynamics in the BRD augments the complexity not only of its mathematical model but also of the automatic control design that forces the regulated movement of the BRD [

12]. In addition, the linear actuator attached to the BRD also introduces a mechanical reconfiguration in the BRD because of the actuator’s mechanical structure, which is now giving up a new mass distribution [

13], forcing new damping and restricting the angular displacement at each articulation of the BRD (

Figure 1). Including linear actuators in BRD electromechanical configurations introduces novel challenges for the automatic control design. Despite the development of automatic controllers for BRD that has been studied for a long time, the dynamical nature of linear actuators implies some new design paradigms, where the actuator now plays a mechanical role as well as exerting the driving force to the BRD [

14,

15].

The characteristics of linear actuators force an increase in the number of states in the actuated BRD and bound the control action considering the limited velocity of the linear actuator and the restricted screw movement range. These particular settings must be considered in the control design requirements for BRD, which are adjoined to the presence of modeling imprecision and external uncertainties. All these challenging aspects can be overcome if the proposed control design is robust but, at the same time, can satisfy the successful tracking of the designed reference trajectories that define the needed articulation movements for the BRD. Most of the reported control designs for BRD have not considered such restrictions. Furthermore, many studies have not considered BRD designs’ movement restrictions at each joint. Hence, an imprecise gain tuning process for the controllers aimed to mobilize each of the joints, and the robot may manifest unwanted effects in the curse of the transient period. These reasons have motivated the design of automatic controllers that may consider all the referred states or/and control limitations. Penalty state-dependent function, convex set projections, composite state convex sets, and adaptive gain barrier Lyapunov function have been considered the most preferable options to assess the effect of state restrictions on the control design.

Barrier Lyapunov function (BLF) is considered a preferable option that could be related to restricted articulation movement. The number of applications of BLF has grown in recent years due to the benefits of restricted systems’ transient and steady operation. Diverse classes of BLF have been around since the beginning of the previous century, considering the logarithmic, integral, and tangent variants, just to list some of them.

Robotic devices with biped configurations controlled by adaptive gains defined by the application of BLF have shown significant benefits over systems using traditional control formulations such as state feedback, extended state approaches, sliding modes, and many others. However, there is a growing number of applications using adaptive state-dependent gains for the proposed controllers, which are calculated using controlled BLF. However, no reported study proposes the application of adaptive controllers based on BLF for linear actuators for BRDs.

This study introduces a novel design for a state-dependent adaptive controller for a BRD, including the presence of linear actuators in the robot configuration. The control design considers state restrictions in the linear actuator and all the BRD articulations while tracking reference trajectories corresponding to developing a regulated gait cycle for a BRD. The study also includes the dynamics of the DC motor that drives the linear actuator motion.

The central objective of this study is to present the development of an adaptive automatic control method to resolve the trajectory tracking control design related to a BRD that considers that each articulation is driven by a regular electrical linear actuator. As a consequence, the main contributions of this study are the following: (a) the development of an adaptive state-dependent controller, which is estimated with the application of a controlled BLF; (b) the formal stability proof, which yields the calculus of gains depending on the states, which ensure the solution of the reference tracking for the BRD, including the linear actuator dynamics and (c) the numerical evaluations, considering the application of a virtual BRD yield to confirm the effectiveness of the proposed controller.

This manuscript is organized according to the following strategy. The modeling strategy presented in

Section 2 details the method to include the linear actuator presence for each articulation in the BRD. This section also shows the mathematical model of the BRD, including the dynamics of the linear actuators driving the movement of each articulation in the robot.

Section 3 describes the proposed adaptive controller based on the application of logarithmic BLF functions and its corresponding proof and a variant of the proposed controller implementing the estimation of the tracking error via a set of super-twisting robust differentiators.

Section 4 details the virtual BpR designed to test the proposed controller implemented in Sim-Mechanics/Matlab. The numerical evaluations of the controller are presented in

Section 5, where the proposed controller is compared with a classical PID controller. Finally, in

Section 6, the conclusions of this paper are presented.

2. Mathematical Modeling Strategy

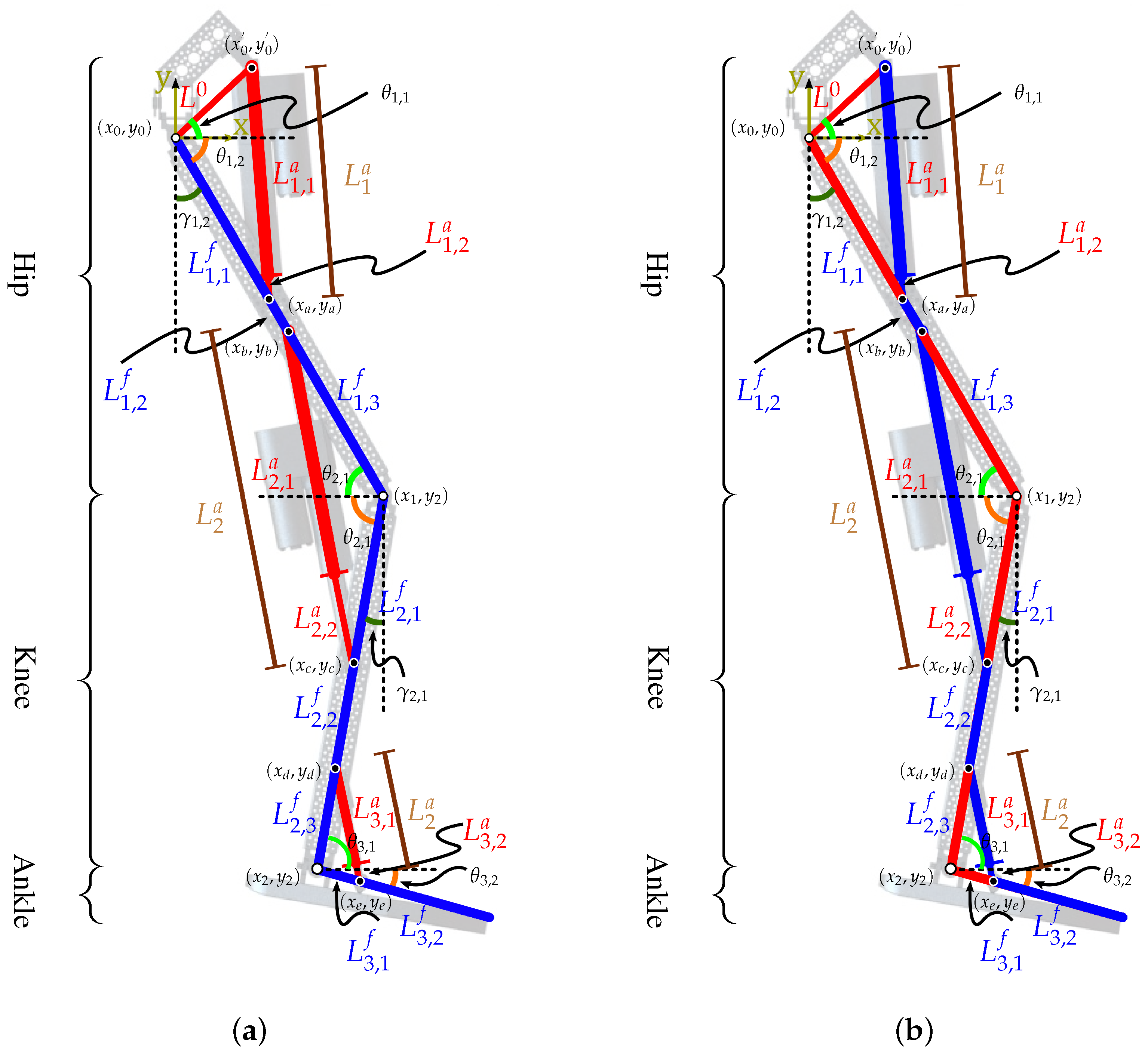

Including linear actuators on the biped robot structure introduces two possible modeling strategies. The first one considers the passive mechanical structure as the core part to be modeled and the linear actuators as the active section that provides the mobilization of the mechanical parts. The second strategy includes using the linear actuator as part of the mechanical structure. The difference between these strategies can be visualized considering the mechanical and active sections shown in

Figure 1.

This section presents the general characteristics of the modeling strategies. For both models, this study considers the following characteristics:

The biped robot can mobilize the legs on the sagittal plane,

The contact points between the actuator tip and the structural section of the biped are not dynamic. Then, there is no dynamic contact (stiffness-damping).

The linear actuator for each articulation is a lead screw and nut structure, which is developing the linear action related to the linear actuator.

The actuator is activated by a DC motor, which is also considered part of the control design.

All articulations in the biped robot are static based on a rotational joint which is justified using the argument related to the motion in the sagittal plane.

The biped robot is suspended, and it does not have any impact contact with the supporting surface. These kinds of robots are aimed to serve as a basis for exoskeleton devices, which can contribute to the rehabilitation processes.

Considering that

is the vector of generalized coordinates and

, then the kinetic energy

,

and the potential energy

,

for the complete system may be obtained from the aggregated analysis of subsystems forming the biped robot. The energetic components of the individual subsystems can be calculated independently. Hence, the equations of motion are obtained with the calculation of the Euler–Lagrange equations:

Here, we present the generalized forcing–dissipation terms

,

, and the Lagrangian:

. The principles justifying this formalism can be consulted in classical mechanics textbooks. Except for the differentiation that may become cumbersome for systems with many articulations, the Euler–Lagrange equations formalism can be applied straightforwardly because it is based on energetic-based functions. Based on the calculus for the Lagrangian and the application of the Euler–Lagrange schemes, the complete model for a single leg of the BRD satisfies the following differential equation:

where

is the vector of angular positions that includes all joints of a single leg in the exoskeleton. The inertia matrix is represented by

,

is the matrix of Coriolis and centrifugal forces,

includes the terms related to the gravitational forces. The time-dependent term

is the vector that represents the effect of viscous and dried frictions, external perturbations and modeling imprecision.

2.1. Development of Mathematical Model 1

The mechanical section of the biped robot depicted in

Figure 1a is made up of fixed links that are interconnected by the linear actuator structures. This figure demonstrates the configuration of the articulations in the BRD, which are restricted by the linear movement of the actuator.

The expression of the kinetic energy of this first model corresponds to

where the individual kinetic energies for the masses in the biped robot are presented below. The first section of individual kinetic energies corresponds to the masses of the fixed mechanical sections of the BRD (solid links), i.e.,

,

and

, respectively, for the three sections of the device:

The second section of individual kinetic energies corresponds to the fixed mechanical sections of each linear actuator in the BRD, i.e.,

, respectively, for the three actuators of the device:

where

is

The third section of individual kinetic energies corresponds to the mobile mechanical sections of each linear actuator in the BRD, i.e.,

, respectively, for the three actuators of the device:

where

corresponds to

Correspondingly, the formal expression of the potential energy is defined as follows

The first section of individual potential energies corresponds to the masses of the fixed mechanical sections of the BRD (solid links), i.e.,

, respectively, for the three sections of the device:

The second section of individual potential energies corresponds to the fixed mechanical sections of each linear actuator in the BRD, that is,

, respectively, for the three actuators of the device:

The third section of individual potential energies corresponds to the mobile mechanical sections of each linear actuator in the BRD, that is,

, respectively, for the three actuators of the device:

The calculus of both the potential and kinetic energies in the BRD uses the estimation of the centers of masses of the fixed sections in the robot

and

that correspond to

The configuration of the linear actuators in the form shown in

Figure 1 implies the necessity of connecting the active length of the actuators with respect to the angular motion obtained at each articulation in the legs of the BRD. These relationships are the following:

Complementarily, the angles with .

The corresponding coordinates for the fixed sections of the linear actuators are

while the coordinates for the mobile section are defined by

, which can be expressed as follows

where

,

;

,

and

,

. The relationships for the coordinates of the fixed and mobile sections require the analysis of the connections between the lengths of the actuators and the angular motions, which are

The corresponding velocities for the fixed sections of the links in the BRD are the following:

The corresponding velocities of fixed and mobile masses for the linear actuators are given by

Considering the basis of the linear actuators, the following restrictions hold for the relationships between the time-varying lengths of the linear actuators:

The mathematical expressions of the linear positions and their corresponding velocities are obtained using the configurations in the BRD and considering the relative motions of all the linear actuator devices with respect to the fixed sections of the BRD.

2.1.1. Tendon-Driven Actuation Principle

The expected behavior of the linear screw-lead and nut device as a linear actuator on the biped robot can be described in the following form: first, an electrical DC motor transfers the rotational motion to a ball screw where the nut is locked in rotation. This configuration allows free space for displacement along the screw axis, using an anti-rotation mechanism. This configuration has been used in diverse linear actuators. This study considered a similar structure. The generated linear displacement of the nut is transmitted over a specific link, which is eventually driving the rotational joint by the associated rotational torque. This configuration permits a single actuation architecture that reproduces tendon routing, therefore reducing friction. Notice that the friction effect associated with the force transmission tendons is the major source of friction in complex mechanical biped robot configurations. In the case of the BRD considered in this study, the activity of the linear actuator operates at the level of rotational torque that mobilizes each articulation. Noticing that each articulation is driven by two main forces (the linear actuator and gravitational), the following relation is considered:

where

is the vector from the articulated joint and the point of actuator insertion on the robot link,

is the mass of the mobile section in the linear actuator,

is the displacement of the same mobile section,

is the number of links placed below the analyzed joint, which induces torque action,

is the vector connecting the coordinates of the joint and those of the center of mass of each link

J,

is the mass of the link and

is the gravity vector.

2.1.2. Actuator Dynamics

An electromechanical actuator (EMA) is made of an electric DC motor (that corresponds to the electrical section) and an associated mechanical gearbox (that defines the mechanical section). EMAs are categorized in both rotative and linear stages. A linear actuator is as follows: geared and direct-driven linearly operated EMA. The geared linear electromechanical actuator generally consists of a DC motor with a lead-screw (or ball-screw or roller-screw) and a nut assembly. The motor shaft connects to the lead screw using a shaft coupling or a transformation gearbox. The DC motor transforms the electrical energy to the respective rotational motion of the shaft. Hence, the lead screw converts the rotary motion into proportional linear motion. The motor shaft rotates either anti-clockwise or clockwise, depending on the voltage input polarity. Once the rotational motion is transferred to the lead screw, the nut assembles the needed motion (XN), either forward or backward, depending on the forced rotational direction of the shaft.

In the direct-driven linear actuator (considering both electrical and mechanical sections), the nut is the rotational element, and the lead screw represents the translational element. The lead screw structure is accommodated inside the actuator itself, considering the technical composition of the DC motor. The interiorly threaded nut is placed inside the rotor. The rotor and the nut rotate when the engine receives electrical energy. This rotational motion of the nut forces the linear lead-screw motion. The shaft attached to the ending section of the lead screw has slotted grooves. This configuration restricts the rotational motion of the associated lead screw simultaneously with the nut. In terms of their functionalities, the two mentioned actuators are not significantly different. Nonetheless, the direct-driven EMA has a compact size compared to the geared EMA. This configuration makes the direct-driven EMA a suitable and appropriate technical option for aerospace, robotics, and other industries.

Modeling a single EMA is crucial for developing a multi-element set of actuators operating as HRA. This section presents the mathematical model of a direct-driven linear EMA. The electric circuit implies that the supplied electrical power using a given voltage

forces the current

flow whose conduction is opposed by the conducting path resistance

, inductance

and a back electromechanical force or e.m.f. for short

, which is equivalent to

. The voltage balance is expressed as:

Here

represents the back e.m.f parameter. The parameter

characterizes the angular variation of the DC motor. In the mechanical part, inertia, damping, and frictional settings are concentrated parameters. When the electromagnetic torque performed by the electrical section is supplied to the mechanical section of the actuator (lead-screw and nut) rotational element, it moves at a given rate of

, which corresponds to the given moment of inertia

. The angular speed of both sections, the rotor and the nut are the same because they are attached to each other [

13].

The variables labeled as

and

represent linear variations of the lead screw and the load correspondingly. The matrix

defines the relative stiffness existing between the lead screw with respect to the nut. The damping between the bearing and rotor is defined by the variable

. The produced torque

is operating in opposition by damping torque

, load torque

and the inertial torque

. Therefore, the electromagnetic-related torque is balanced by the other three developed torques [

16], that is:

where

D is viscous damping at the armature. The torque

produced as a function of the current

that passes through the armature appears in (

28). The matrix

defines the torque constant. Equivalently, the inertial, damping, and load torques are described in the subsequent expressions in (

28), respectively. In that equation, the term

is used for converting the angular displacement of the nut to linear displacement of the lead screw, where

l is the screw lead. The substitution of

,

,

and

in (

28) and bringing the electrical relationship in (

27) yields:

with

the relationship between the angular displacement and the displacement of the linear actuator (considering the lead screw configuration). In terms of the movement efficiency, the following relationship is also valid

, where

is the resistive torque, and

is the ball-screw efficiency.

The application of the assumption describing the class of interaction between the tip of the actuator and the link in the biped robot results in

. Using the state variable theory for each actuator

with the definitions

,

and

and the corresponding parameters (labeled with a superscript

i) yields the following model for the actuator:

The pushing force of the linear actuator can be estimated as , therefore the torque produced by this force over the joint i corresponds to .

2.2. Development of Mathematical Model 2

Considering that the actuators are considered part of the mechanical section of the biped robot, let us consider the model presented in

Figure 1. This section develops the geometrical analysis that integrates the mechanical section and the actuator’s dynamic movement. Considering the model in

Figure 1 and studying the section corresponding to the hip section, the following relations are valid:

The fixed relation between

and

yields

Now consider that the length of the selected linear actuator for the hip section

is given by

. In view of the mechanical relation between

,

and

, the following equation is produced:

In view of (

33),

, the following relations are valid:

Using a similar geometrical study for the knee study, the following angular equation is valid:

The static relation given for

and

yields

Taking into account the length of the selected linear actuator for the knee section,

is given by

. In view of the mechanical relation between

,

and

, the following equation is produced:

In view of (

37),

, the following relations are valid:

For the ankle analysis, the corresponding angular equation is valid:

The static relation given for

and

yields

In view of the length of the selected linear actuator for the ankle section,

corresponds to

. Considering the mechanical relation between

,

and

yields:

According to (

41),

, the following relations are valid:

According to the mechanical relations described in this section, the kinetic and potential energies can be obtained in the form presented in the Mathematical Model 1. The calculus is omitted just to avoid unnecessary repetition of similar information.

Notice that integrating the actuator as an active element of the mechanical section simplifies the analysis of the actuator effect. Indeed, one may notice that mathematical modeling of the actuator dynamics for this case corresponds to

in (

28), with

. Therefore, the model for the actuation system inside the actuator (which is operating here as a prismatic joint) satisfies the dynamics presented in (

30) with

.

Despite that this second model appears as a more simple version of the mathematical description of the BRD, it could be more complicated to use in the control design formulation.

5. Numerical Evaluations

Figure 2 depicts the numerical results related to the tracking result for the reference trajectory for the left-hip articulation of the BRD using the selected PID and the adaptive controllers. These results confirm that both controllers show similar tracking outcomes. A high-quality tracking of the reference trajectories is attained after 0.2 s for both controllers. The equivalence in the tracking is no longer valid, considering that the proposed adaptive controller tracks the reference without exhibiting fast oscillations as the regular PID enforces. PID cannot provide an efficient, robust tracking of the references, highlighting the suggested controller’s benefits. The three articulations validate this fact on the left side of the biped robot. Consequently, the tracking error converges to a characterized invariant set, which characterizes this study’s main result.

Figure 2a–c detail the evolution of angular displacements for the hip, knee and ankle, respectively, including the comparison of PID and the proposed adaptive controller. These individual comparisons confirm that the adaptive controller tracks each reference with smaller oscillations around the reference trajectories.

Figure 3 depicts the evolution of the tracking deviations generated with the adaptive and the regular PID controllers. The comparison validates that the selected PID controller produces oscillations with larger amplitudes around the zero value when the time increases. These oscillations confirm that despite the fact that the PID controller may work robustly concerning external perturbations and uncertain modeling sections, there is no efficient tracking of the reference (measured in terms of the tracking errors). At the same time, implementing the adaptive gains improves the tracking quality. Even when the differences between the tracking errors produced by the PID and the adaptive controller are insignificant, their values are relevant in the BDR performing the gait cycle process.

Figure 4 shows the temporal evolution of the Euclidean norm for the tracking deviation produced with the implementation of both controllers, the PID, and the proposed adaptive form. These norms are presented simultaneously here to evaluate the adaptive control quality. The comparison highlights that the suggested controller drives the tracking error toward the origin, implementing both adaptive and PID forms. The more significant norm produced by the PID controller also proves that the adaptive form induces better tracking of the reference trajectory, which yields a better gait cycle developed by the suggested biped robotic device. This figure also shows that the adaptive control form produces a minor mean square error, significantly improving traditional control forms such as the PID.

Figure 5 and

Figure 6 compare the torque evolution measured at all three joints in a particular leg of the biped robot. This comparison exhibits similar temporal evolutions for both controllers (for both PID and adaptive structures) for the three articulations. The individual torque obtained for each articulation is larger if the PID controller is compared with the adaptive form. Notice that such comparison confirms that the adaptive form enhances the tracking in both senses, the better tracking quality and the corresponding smaller energy (

Figure 6).

Figure 6 also highlights the high energy consumed by the PID controller, while the adaptive controller is significantly smaller in comparison. The temporal evolution of the control norm motivates the inclusion of the adaptive controller for mobile robots, such as the biped structure considered in this study, with the linear actuators as driving elements.

Figure 7 and

Figure 8 show the comparison of the torque enforced by both controllers, adaptive and PID forms. Notice that these reference torques are different due to the back-stepping formulation using either the PID or the adaptive control forms, which limits the ability to obtain a unified comparison of all three trajectories. The numerical outcomes correspond to the tracking of the reference PID and adaptive torques for hip, knee, and ankle articulations of the biped robot. In all these comparisons, the adaptive controller performs better in the tracking of the reference trajectories.

The reference tracking for the requested torques attains a similar time (0.12 s), which is smaller than the needed time for the position tracking. The equivalent quality tracking for torques in the PID case is not as good as in the case of the adaptive control form. Considering that the adaptive control structure forces a better tracking of the reference torque, the better tracking of the reference angular motion is even more justified. PID cannot provide an efficient tracking of the reference torques, highlighting the benefits of the suggested controller. This fact is confirmed for all three articulations in the biped robot structure corresponding to the calculated torques. The tracking errors for both torques produced by adaptive and PID converge to a particular invariant set that is part of this study’s main result for such variables. The individual comparisons of torques confirm that the adaptive controller tracks each reference torque with smaller oscillations around the reference torques. Notice also that tracking both torques at each articulation seems to correspond to the tracking of the reference position for each joint. This fact confirms the interplay between the linear actuator performance and the articulation motion in the biped robot joint.

Figure 9 depicts the comparison of the torque’s deviation from their corresponding reference torques. This comparison shows a similar control tracking performance for both controllers (PID and adaptive forms) with similar quality. Nevertheless, the comparison seems to offer a similar quality to the torque tracking, but the improved position tracking exhibited by the adaptive form justifies its application for enforcing a more efficient gait cycle for biped robots.

Figure 10 illustrates the temporal evolution of the Euclidean norm for the torque tracking error enforced with the pair of studied controllers (PID and adaptive structures). These norms are shown simultaneously in the same figure. Such comparison may highlight that the proposed controller drives the torque tracking error toward the origin by implementing both adaptive and PID forms. Nonetheless, both norms shown in this figure also prove that the adaptive form induces a good tracking of torque as the adaptive form does, but the adaptive formulation yields a better gait cycle developed by the suggested biped robotic device.

Figure 11 renders the square of voltage needed to drive the tracking of torque as well as the position. The temporal evolution of the voltage proves that the adaptive form requires half of the energy associated with the electrical source compared to the PID structure. This main characteristic is one of the most motivating aspects of the adaptive controller included in this study, considering the mobile nature of the biped robotic device.

With the aim of numerically evaluating the performance of both controllers, the

norm of the control and error signals at each articulation (

Table 1) were calculated.

The evaluation of the performance index was obtained as , where is the vector of errors at the hip, the knee and the ankle. In the same way, was obtained as , where is the vector of the control signals for the articulations. These comparisons also confirm the benefits of using the proposed controller with state-dependent gains.