Anaerobic Co-Digestion of Wastes: Reviewing Current Status and Approaches for Enhancing Biogas Production

Abstract

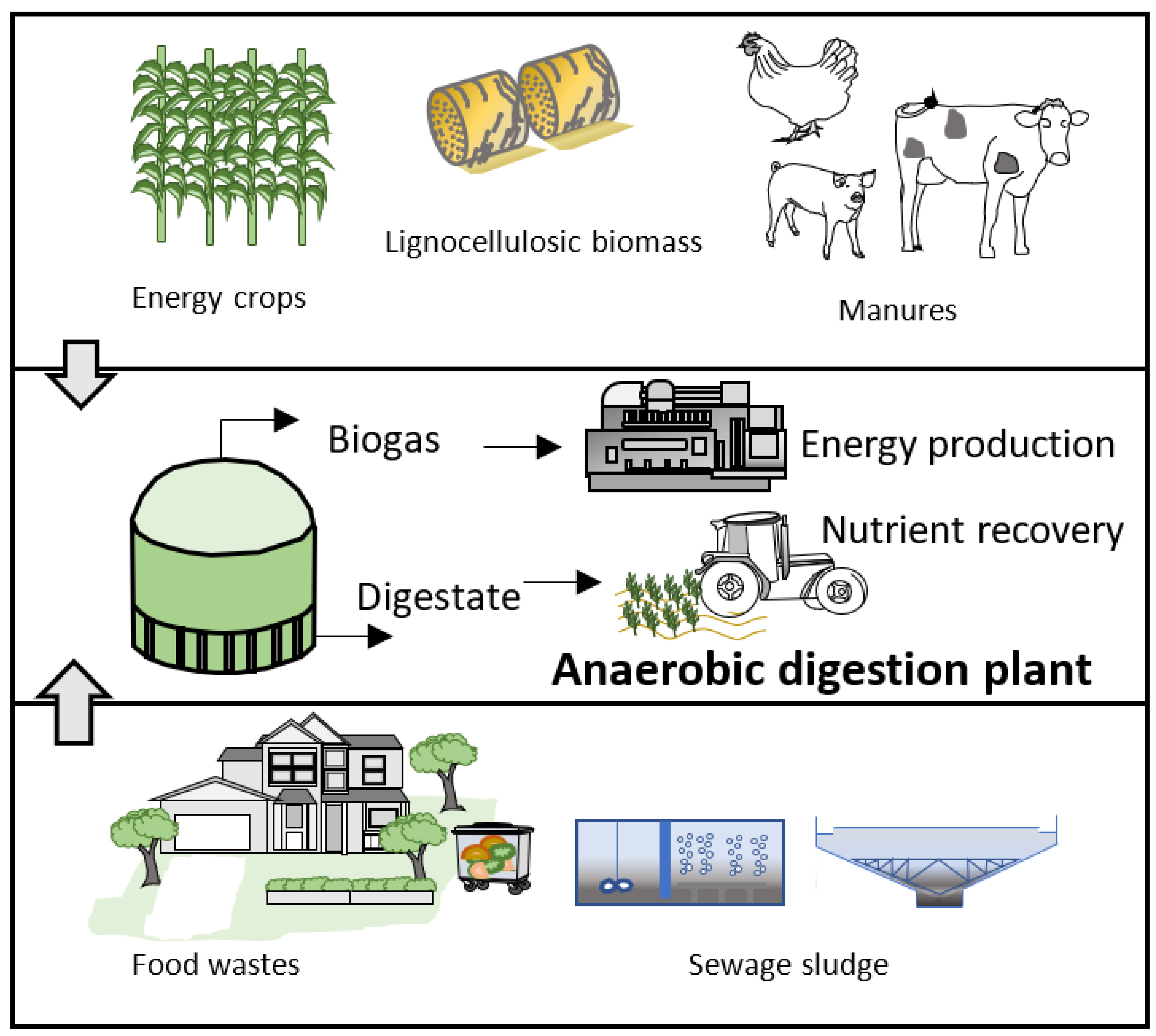

:1. Introduction

2. Common Substrates Used in Anaerobic Digestion

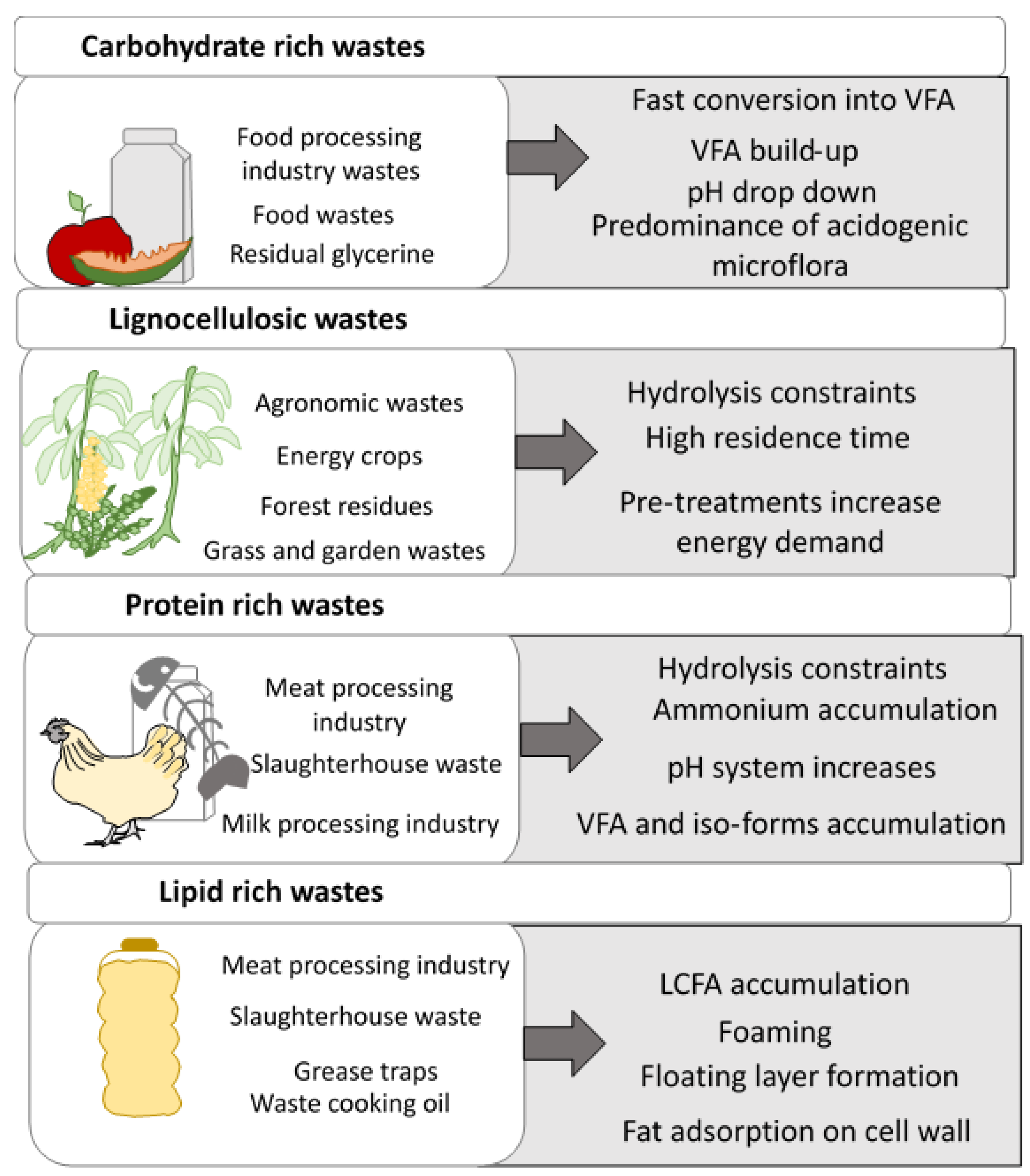

2.1. Carbohydrate-Rich Substrates

2.2. Lignocellulosic Biomass

2.3. Protein-Rich Substrates

2.4. Lipid-Containing Materials

3. Modelling Cumulative Methane Production

4. Taking Advantage of Process Synergies

Co-Digestion at Large Scale

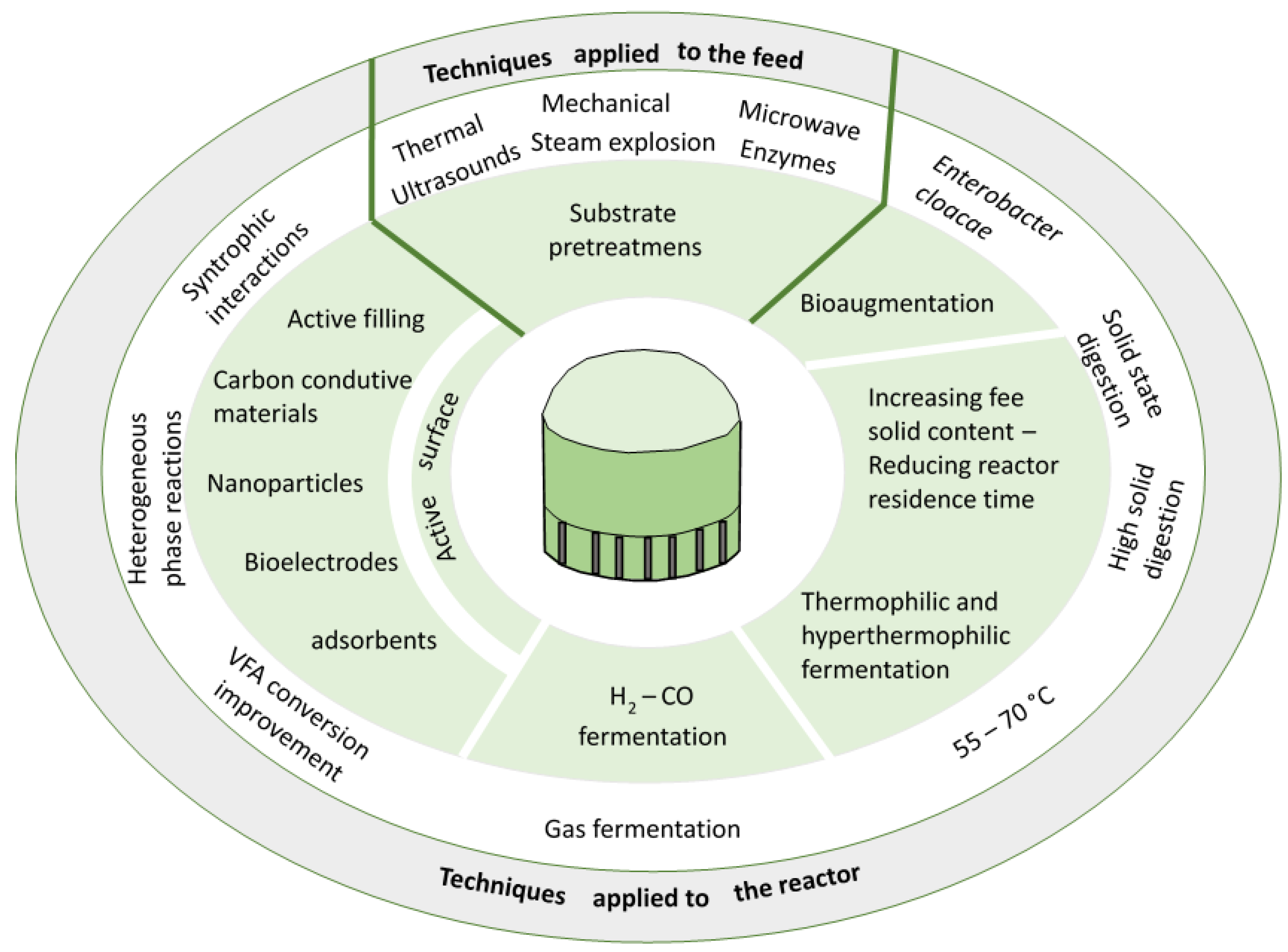

5. Improving Reactor Performance

5.1. Bioaugmentation

5.2. Operating at a Higher Solid Content

5.3. Thermophilic Regimen to Increase Reactor Treatment Capacity

5.4. Addition of Adsorbents, Conductive Materials and Nanoparticles

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Akturk, A.S.; Demirer, G.N. Improved Food Waste Stabilization and Valorization by Anaerobic Digestion Through Supplementation of Conductive Materials and Trace Elements. Sustainability 2020, 12, 5222. [Google Scholar] [CrossRef]

- Pecorini, I.; Peruzzi, E.; Albini, E.; Doni, S.; Macci, C.; Masciandaro, G.; Lanelli, R. Evaluation of MSW Compost and Digestate Mixtures for a Circular Economy Application. Sustainability 2020, 12, 3042. [Google Scholar] [CrossRef]

- Stürmer, B.; Pfundtner, E.; Kirchmeyr, F.; Uschnig, S. Legal requirements for digestate as fertilizer in Austria and the European Union compared to actual technical parameters. J. Environ. Manag. 2020, 253, 109756. [Google Scholar] [CrossRef] [PubMed]

- Rekleitis, G.; Haralambous, K.-J.; Loizidou, M.; Aravossis, K. Utilization of Agricultural and Livestock Waste in Anaerobic Digestion (A.D): Applying the Biorefinery Concept in a Circular Economy. Energies 2020, 13, 4428. [Google Scholar] [CrossRef]

- Chow, W.L.; Chong, S.; Lim, J.W.; Chan, Y.J.; Chong, M.F.; Tiong, T.J.; Chin, J.K.; Pan, G.-T. Anaerobic Co-Digestion of Wastewater Sludge: A Review of Potential Co-Substrates and Operating Factors for Improved Methane Yield. Processes 2020, 8, 39. [Google Scholar] [CrossRef]

- Esposito, G.; Frunzo, L.; Giordano, A.; Liotta, F.; Panico, A.; Pirozzi, F. Anaerobic co-digestion of organic wastes. Rev. Environ. Sci. Biotechnol. 2012, 11, 325–341. [Google Scholar] [CrossRef]

- Banks, C.J.; Salter, A.M.; Heaven, S.; Riley, K. Energetic and environmental benefits of co-digestion of food waste and cattle slurry: A preliminary assessment. Resour. Conserv. Recycl. 2011, 56, 71–79. [Google Scholar] [CrossRef]

- García-Cascallana, J.; Borge-Díez, D.; Gómez, X. Enhancing the efficiency of thermal hydrolysis process in wastewater treatment plants by the use of steam accumulation. Int. J. Environ. Sci. Technol. 2019, 16, 3403–3418. [Google Scholar] [CrossRef]

- Hu, P.; Liu, J.; Bao, H.; Wu, L.; Jiang, L.; Zou, L.; Wu, Y.; Qian, G.; Li, Y.Y. Enhancing phosphorus release from waste activated sludge by combining high-voltage pulsed discharge pretreatment with anaerobic fermentation. J. Clean. Prod. 2018, 196, 1044–1051. [Google Scholar] [CrossRef]

- Arenas-Sevillano, C.B.; Chiappero, M.; Gomez, X.; Fiore, S.; Martínez, E.J. Improving the anaerobic digestion of wine-industry liquid wastes: Treatment by electro-oxidation and use of biochar as an additive. Energies 2020, 13, 5971. [Google Scholar] [CrossRef]

- Kuşçu, Ö.S.; Çömlekçi, S.; Çört, N. Disintegration of sewage sludge using pulsed electrical field technique: PEF optimization, simulation, and anaerobic digestion. Environ. Technol. 2022, 43, 2809–2824. [Google Scholar] [CrossRef] [PubMed]

- Cuetos, M.J.; Martinez, E.J.; Moreno, R.; Gonzalez, R.; Otero, M.; Gomez, X. Enhancing anaerobic digestion of poultry blood using activated carbon. J. Adv. Res. 2017, 8, 297–307. Available online: http://linkinghub.elsevier.com/retrieve/pii/S2090123216301096 (accessed on 1 September 2022). [CrossRef] [PubMed]

- Wang, J.; Westerholm, M.; Qiao, W.; Mahdy, A.; Wandera, S.M.; Yin, D.; Bi, S.; Fan, R.; Dong, R. Enhancing anaerobic digestion of dairy and swine wastewater by adding trace elements: Evaluation in batch and continuous experiments. Water Sci. Technol. 2019, 80, 1662–1672. [Google Scholar] [CrossRef] [PubMed]

- Tang, H.; Xu, X.; Wang, B.; Lv, C.; Shi, D. Removal of ammonium from swine wastewater using synthesized zeolite from fly ash. Sustainability 2020, 12, 3423. [Google Scholar] [CrossRef]

- El Nemr, A.; Hassaan, M.A.; Elkatory, M.R.; Ragab, S.; Pantaleo, A. Efficiency of Fe3O4 Nanoparticles with Different Pretreatments for Enhancing Biogas Yield of Macroalgae Ulva intestinalis Linnaeus. Molecules 2021, 26, 5105. [Google Scholar] [CrossRef]

- Singh, D.; Malik, K.; Sindhu, M.; Kumari, N.; Rani, V.; Mehta, S.; Malik, K.; Ranga, P.; Sharma, K.; Dhull, N.; et al. Biostimulation of Anaerobic Digestion Using Iron Oxide Nanoparticles (IONPs) for Increasing Biogas Production from Cattle Manure. Nanomaterials 2022, 12, 497. [Google Scholar] [CrossRef]

- Bundschuh, M.; Filser, J.; Lüderwald, S.; McKee, M.S.; Metreveli, G.; Schaumann, G.E.; Schulz, R.; Wagner, S. Nanoparticles in the environment: Where do we come from, where do we go to? Environ. Sci. Eur. 2018, 30, 6. [Google Scholar] [CrossRef]

- Gadaleta, G.; De Gisi, S.; Notarnicola, M. Feasibility analysis on the adoption of decentralized anaerobic co-digestion for the treatment of municipal organic waste with energy recovery in urban districts of metropolitan areas. Int. J. Environ. Res. Public Health 2021, 18, 1820. [Google Scholar] [CrossRef]

- Wang, F.; Pei, M.; Qiu, L.; Yao, Y.; Zhang, C.; Qiang, H. Performance of Anaerobic Digestion of Chicken Manure Under Gradually Elevated Organic Loading Rates. Int. J. Environ. Res. Public Health 2019, 16, 2239. [Google Scholar] [CrossRef]

- Cudjoe, D.; Han, M.S.; Nandiwardhana, A.P. Electricity generation using biogas from organic fraction of municipal solid waste generated in provinces of China: Techno-economic and environmental impact analysis. Fuel Process. Technol. 2020, 203, 106381. [Google Scholar] [CrossRef]

- Zhao, Q.; Kugel, G. Thermophilic/mesophilic digestion of sewage sludge and organic wastes. J. Environ. Sci. Health A 1996, 31, 2211–2231. [Google Scholar] [CrossRef]

- Gómez, X.; Cuetos, M.J.; Cara, J.; Morán, A.; García, A.I. Anaerobic co-digestion of primary sludge and the fruit and vegetable fraction of the municipal solid wastes. Renew. Energy 2006, 31, 2017–2024. [Google Scholar] [CrossRef]

- Fierro, J.; Martinez, E.J.; Rosas, J.G.; Fernández, R.A.; López, R.; Gómez, X. Co-Digestion of Swine Manure and Crude Glycerine: Increasing Glycerine Ratio Results in Preferential Degradation of Labile Compounds. Water Air Soil Pollut. 2016, 227, 78. [Google Scholar] [CrossRef]

- Arenas, C.B.; Meredith, W.; Snape, C.E.; Gómez, X.; González, J.F.; Martínez, E.J. Effect of char addition on anaerobic digestion of animal by-products: Evaluating biogas production and process performance. Environ. Sci. Pollut. Res. 2020, 27, 24387–24399. [Google Scholar] [CrossRef]

- Lü, C.; Shen, Y.; Li, C.; Zhu, N.; Yuan, H. Redox-Active Biochar and Conductive Graphite Stimulate Methanogenic Metabolism in Anaerobic Digestion of Waste-Activated Sludge: Beyond Direct Interspecies Electron Transfer. ACS Sustain. Chem. Eng. 2020, 8, 12626–12636. [Google Scholar] [CrossRef]

- Rajagopal, R.; Massé, D.I.; Singh, G. A critical review on inhibition of anaerobic digestion process by excess ammonia. Bioresour. Technol. 2013, 143, 632–641. [Google Scholar] [CrossRef]

- Meng, X.; Yu, D.; Wei, Y.; Zhang, Y.; Zhang, Q.; Wang, Z.; Liu, J.; Wang, Y. Endogenous ternary pH buffer system with ammonia-carbonates-VFAs in high solid anaerobic digestion of swine manure: An alternative for alleviating ammonia inhibition? Process Biochem. 2018, 69, 144–152. [Google Scholar] [CrossRef]

- Kübler, H.; Hoppenheidt, K.; Hirsch, P.; Kottmair, A.; Nimmrichter, R.; Nordsieck, H.; Mücke, W.; Swerev, M. Full scale co-digestion of organic waste. Water Sci. Technol. 2000, 41, 195–202. [Google Scholar] [CrossRef]

- Mata-Alvarez, J.; Dosta, J.; Romero-Güiza, M.S.; Fonoll, X.; Peces, M.; Astals, S. A critical review on anaerobic co-digestion achievements between 2010 and 2013. Renew. Sustain. Energy Rev. 2014, 36, 412–427. [Google Scholar] [CrossRef]

- Cheong, W.L.; Chan, Y.J.; Tiong, T.J.; Chong, W.C.; Kiatkittipong, W.; Kiatkittipong, K.; Mohamad, M.; Daud, H.; Suryawan, I.W.K.; Sari, M.M.; et al. Anaerobic Co-Digestion of Food Waste with Sewage Sludge: Simulation and Optimization for Maximum Biogas Production. Water 2022, 14, 1075. [Google Scholar] [CrossRef]

- Lytras, G.; Lytras, C.; Mathioudakis, D.; Papadopoulou, K.; Lyberatos, G. Food Waste Valorization Based on Anaerobic Digestion. Waste Biomass Valori. 2021, 12, 1677–1697. [Google Scholar] [CrossRef]

- Aromolaran, A.; Sartaj, M.; Alqaralleh, R.M.Z. Biogas production from sewage scum through anaerobic co-digestion: The effect of organic fraction of municipal solid waste and landfill leachate blend addition. Biomass Convers. Biorefin. 2022, 1–17. [Google Scholar] [CrossRef]

- Sevillano, C.A.; Pesantes, A.A.; Peña Carpio, E.; Martínez, E.J.; Gómez, X. Anaerobic Digestion for Producing Renewable Energy—The Evolution of This Technology in a New Uncertain Scenario. Entropy 2021, 23, 145. [Google Scholar] [CrossRef]

- Rico, C.; Muñoz, N.; Fernández, J.; Rico, J.L. High-load anaerobic co-digestion of cheese whey and liquid fraction of dairy manure in a one-stage UASB process: Limits in co-substrates ratio and organic loading rate. Chem. Eng. J. 2015, 262, 794–802. [Google Scholar] [CrossRef]

- Calero, R.; Iglesias-Iglesias, R.; Kennes, C.; Veiga, M.C. Organic loading rate effect on the acidogenesis of cheese whey: A comparison between UASB and SBR reactors. Environ. Technol. 2018, 39, 3046–3054. [Google Scholar] [CrossRef]

- Treu, L.; Tsapekos, P.; Peprah, M.; Campanaro, S.; Giacomini, A.; Corich, V.; Kougias, P.G.; Angelidaki, I. Microbial profiling during anaerobic digestion of cheese whey in reactors operated at different conditions. Bioresour. Technol. 2019, 275, 375–385. [Google Scholar] [CrossRef]

- Fernández, C.; Cuetos, M.J.; Martínez, E.J.; Gómez, X. Thermophilic anaerobic digestion of cheese whey: Coupling H2 and CH4 production. Biomass Bioenergy 2015, 81, 55–62. [Google Scholar] [CrossRef]

- Shilton, A.; Powell, N.; Broughton, A.; Pratt, C.; Pratt, S.; Pepper, C. Enhanced biogas production using cow manure to stabilize co-digestion of whey and primary sludge. Environ. Technol. 2013, 34, 2491–2496. [Google Scholar] [CrossRef] [PubMed]

- Hallaji, S.M.; Kuroshkarim, M.; Moussavi, S.P. Enhancing methane production using anaerobic co-digestion of waste activated sludge with combined fruit waste and cheese whey. BMC Biotechnol. 2019, 19, 19. [Google Scholar] [CrossRef]

- Park, M.J.; Jo, J.H.; Park, D.; Lee, D.S.; Park, J.M. Comprehensive study on a two-stage anaerobic digestion process for the sequential production of hydrogen and methane from cost-effective molasses. Int. J. Hydrogen Energy 2010, 35, 6194–6202. [Google Scholar] [CrossRef]

- Chojnacka, A.; Szczęsny, P.; Błaszczyk, M.K.; Zielenkiewicz, U.; Detman, A.; Salamon, A.; Sikora, A. Noteworthy Facts about a Methane-Producing Microbial Community Processing Acidic Effluent from Sugar Beet Molasses Fermentation. PLoS ONE 2015, 10, e0128008. [Google Scholar] [CrossRef] [PubMed]

- Ali, M.M.; Mustafa, A.M.; Zhang, X.; Zhang, X.; Danhassan, U.A.; Lin, H.; Choe, U.; Sheng, K.; Wang, K. Biohythane production from tofu processing residue via two-stage anaerobic digestion: Operational conditions and microbial community dynamics. Biomass Convers. Biorefin. 2022, 1–20. [Google Scholar] [CrossRef]

- Monties, B. Plant cell walls as fibrous lignocellulosic composites: Relations with lignin structure and function. Anim. Feed Sci. Technol. 1991, 32, 159–175. [Google Scholar] [CrossRef]

- Park, S.; Baker, J.O.; Himmel, M.E.; Parilla, P.A.; Johnson, D.K. Cellulose crystallinity index: Measurement techniques and their impact on interpreting cellulase performance. Biotechnol. Biofuels 2010, 3, 10. [Google Scholar] [CrossRef] [PubMed]

- Leschine, S.B. Cellulose Degradation in Anaerobic Environments. Annu. Rev. Microbiol. 1995, 49, 399–426. [Google Scholar] [CrossRef] [PubMed]

- Schwarz, W.H. The cellulosome and cellulose degradation by anaerobic bacteria. Appl. Microbiol. Biotechnol. 2001, 56, 634–649. [Google Scholar] [CrossRef] [PubMed]

- Pérez, J.; Muñoz-Dorado, J.; de la Rubia, T.; Martínez, J. Biodegradation and biological treatments of cellulose, hemicellulose and lignin: An overview. Int. Microbiol. 2002, 5, 53–63. [Google Scholar] [CrossRef]

- Chapleur, O.; Madigou, C.; Civade, R.; Rodolphe, Y.; Mazéas, L.; Bouchez, T. Increasing concentrations of phenol progressively affect anaerobic digestion of cellulose and associated microbial communities. Biodegrad 2016, 27, 15–27. [Google Scholar] [CrossRef]

- Tambone, F.; Adani, F.; Gigliotti, G.; Volpe, D.; Fabbri, C.; Provenzano, M.R. Organic matter characterization during the anaerobic digestion of different biomasses by means of CPMAS 13C NMR spectroscopy. Biomass Bioenergy 2013, 48, 111–120. [Google Scholar] [CrossRef]

- Yamazawa, A.; Iikura, T.; Morioka, Y.; Shino, A.; Ogata, Y.; Date, Y.; Kikuchi, J. Cellulose Digestion and Metabolism Induced Biocatalytic Transitions in Anaerobic Microbial Ecosystems. Metabolites 2013, 4, 36–52. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Khalid, H.; Zhu, Z.; Zhang, R.; Liu, G.; Chen, C.; Thorin, E. Methane production through anaerobic digestion: Participation and digestion characteristics of cellulose, hemicellulose and lignin. Appl. Energy 2018, 226, 1219–1228. [Google Scholar] [CrossRef]

- Dutta, N.; Usman, M.; Luo, G.; Zhang, S. An insight into valorization of lignocellulosic biomass by optimization with the combination of hydrothermal (HT) and biological techniques: A review. Sustain. Chem. 2022, 3, 3. [Google Scholar] [CrossRef]

- Gómez, X.; Diaz, M.C.; Cooper, M.; Blanco, D.; Morán, A.; Snape, C.E. Study of biological stabilization processes of cattle and poultry manure by thermogravimetric analysis and 13C NMR. Chemosphere 2007, 68, 1889–1897. [Google Scholar] [CrossRef]

- Fernández-Domínguez, D.; Guilayn, F.; Patureau, D.; Jimenez, J. Characterising the stability of the organic matter during anaerobic digestion: A selective review on the major spectroscopic techniques. Rev. Environ. Sci. Biotechnol. 2022, 21, 691–726. [Google Scholar] [CrossRef]

- Iocoli, G.A.; Zabaloy, M.C.; Pasdevicelli, G.; Gómez, M.A. Use of biogas digestates obtained by anaerobic digestion and co-digestion as fertilizers: Characterization, soil biological activity and growth dynamic of Lactuca sativa L. Sci. Total Environ. 2019, 647, 11–19. [Google Scholar] [CrossRef]

- Tambone, F.; Genevini, P.; D’Imporzano, G.; Adani, F. Assessing amendment properties of digestate by studying the organic matter composition and the degree of biological stability during the anaerobic digestion of the organic fraction of MSW. Bioresour. Technol. 2009, 100, 3140–3142. [Google Scholar] [CrossRef]

- Tambone, F.; Scaglia, B.; D’Imporzano, G.; Schievano, A.; Orzi, V.; Salati, S.; Adani, F. Assessing amendment and fertilizing properties of digestates from anaerobic digestion through a comparative study with digested sludge and compost. Chemosphere 2010, 81, 577–583. [Google Scholar] [CrossRef]

- Ghosh, S.; Henry, M.P.; Christopher, R.W. Hemicellulose conversion by anaerobic digestion. Biomass 1985, 6, 257–269. [Google Scholar] [CrossRef]

- Li, P.; Li, W.; Sun, M.; Xu, X.; Zhang, B.; Sun, Y. Evaluation of Biochemical Methane Potential and Kinetics on the Anaerobic Digestion of Vegetable Crop Residues. Energies 2018, 12, 26. [Google Scholar] [CrossRef]

- Waliszewska, H.; Zborowska, M.; Stachowiak-Wencek, A.; Waliszewska, B.; Czekała, W. Lignin Transformation of One-Year-Old Plants During Anaerobic Digestion (AD). Polymers 2019, 11, 835. [Google Scholar] [CrossRef] [Green Version]

- Wagner, A.; Lackner, N.; Mutschlechner, M.; Prem, E.; Markt, R.; Illmer, P. Biological Pretreatment Strategies for Second-Generation Lignocellulosic Resources to Enhance Biogas Production. Energies 2018, 11, 1797. [Google Scholar] [CrossRef] [PubMed]

- Xiao, L.P.; Song, G.Y.; Sun, R.C. Effect of Hydrothermal Processing on Hemicellulose Structure. In Hydrothermal Processing in Biorefineries; Ruiz, H., Hedegaard Thomsen, M., Trajano, H., Eds.; Springer: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

- Paul, S.; Dutta, A. Challenges and opportunities of lignocellulosic biomass for anaerobic digestion. Resour. Conserv. Recycl. 2018, 130, 164–174. [Google Scholar] [CrossRef]

- Rasmussen, H.; Sørensen, H.R.; Meyer, A.S. Formation of degradation compounds from lignocellulosic biomass in the biorefinery: Sugar reaction mechanisms. Carbohydr. Res. 2014, 385, 45–57. [Google Scholar] [CrossRef]

- Ahmed, B.; Aboudi, K.; Tyagi, V.K.; Álvarez-Gallego, C.J.; Fernández-Güelfo, L.A.; Romero-García, L.I.; Kazmi, A.A. Improvement of Anaerobic Digestion of Lignocellulosic Biomass by Hydrothermal Pretreatment. Appl. Sci. 2019, 9, 3853. [Google Scholar] [CrossRef]

- Davidsson, Å.; Lövstedt, C.; la Cour Jansen, J.; Gruvberger, C.; Aspegren, H. Co-digestion of grease trap sludge and sewage sludge. Waste Manag. 2008, 28, 986–992. [Google Scholar] [CrossRef] [PubMed]

- Martínez, E.; Rosas, J.; Morán, A.; Gómez, X. Effect of Ultrasound Pretreatment on Sludge Digestion and Dewatering Characteristics: Application of Particle Size Analysis. Water 2015, 7, 6483–6495. [Google Scholar] [CrossRef]

- Martínez, E.; Sotres, A.; Arenas, C.; Blanco, D.; Martínez, O.; Gómez, X. Improving Anaerobic Digestion of Sewage Sludge by Hydrogen Addition: Analysis of Microbial Populations and Process Performance. Energies 2019, 12, 1228. [Google Scholar] [CrossRef]

- Keucken, A.; Habagil, M.; Batstone, D.; Jeppsson, U.; Arnell, M. Anaerobic Co-Digestion of Sludge and Organic Food Waste—Performance, Inhibition, and Impact on the Microbial Community. Energies 2018, 11, 2325. [Google Scholar] [CrossRef]

- Li, P.; Cheng, C.; He, C.; Yu, R.; Shen, D.; Jiao, Y. Experimental study on anaerobic co-digestion of the individual component of biomass with sewage sludge: Methane production and microbial community. Biomass Convers. Biorefin. 2020, 1–14. [Google Scholar] [CrossRef]

- Wei, L.; Qin, K.; Ding, J.; Xue, M.; Yang, C.; Jiang, J.; Zhao, Q. Optimization of the co-digestion of sewage sludge, maize straw and cow manure: Microbial responses and effect of fractional organic characteristics. Sci. Rep. 2019, 9, 2374. [Google Scholar] [CrossRef]

- Cabbai, V.; Ballico, M.; Aneggi, E.; Goi, D. BMP tests of source selected OFMSW to evaluate anaerobic codigestion with sewage sludge. Waste Manag. 2013, 33, 1626–1632. [Google Scholar] [CrossRef] [PubMed]

- Xue, S.; Zhao, N.; Song, J.; Wang, X. Interactive Effects of Chemical Composition of Food Waste during Anaerobic Co-Digestion under Thermophilic Temperature. Sustainability 2019, 11, 2933. [Google Scholar] [CrossRef]

- Ahn, H.K.; Smith, M.C.; Kondrad, S.L.; White, J.W. Evaluation of Biogas Production Potential by Dry Anaerobic Digestion of Switchgrass–Animal Manure Mixtures. Appl. Biochem. Biotechnol. 2010, 160, 965–975. [Google Scholar] [CrossRef] [PubMed]

- Cuetos, M.J.; Fernández, C.; Gómez, X.; Morán, A. Anaerobic co-digestion of swine manure with energy crop residues. Biotechnol. Bioprocess Eng. 2011, 16, 1044–1052. [Google Scholar] [CrossRef]

- Jurado, E.; Skiadas, I.V.; Gavala, H.N. Enhanced methane productivity from manure fibers by aqueous ammonia soaking pretreatment. Appl. Energy 2013, 109, 104–111. [Google Scholar] [CrossRef]

- Wang, M.; Lee, E.; Zhang, Q.; Ergas, S.J. Anaerobic Co-digestion of Swine Manure and Microalgae Chlorella sp.: Experimental Studies and Energy Analysis. BioEnergy Res. 2016, 9, 1204–1215. [Google Scholar] [CrossRef]

- Rubežius, M.; Venslauskas, K.; Navickas, K.; Bleizgys, R. Influence of Aerobic Pretreatment of Poultry Manure on the Biogas Production Process. Processes 2020, 8, 1109. [Google Scholar] [CrossRef]

- Fierro, J.; Martínez, J.E.; Rosas, J.G.; Blanco, D.; Gómez, X. Anaerobic codigestion of poultry manure and sewage sludge under solid-phase configuration. Environ. Prog. Sustain. Energy. 2014, 33, 866–8872. [Google Scholar] [CrossRef]

- Mahato, P.; Goyette, B.; Rahaman, M.; Rajagopal, R. Processing High-Solid and High-Ammonia Rich Manures in a Two-Stage (Liquid-Solid) Low-Temperature Anaerobic Digestion Process: Start-Up and Operating Strategies. Bioengineering 2020, 7, 80. Available online: https://www.mdpi.com/2306-5354/7/3/80 (accessed on 22 May 2022). [CrossRef]

- Ning, Z.; Ji, J.; He, Y.; Huang, Y.; Liu, G.; Chen, C. Effect of Lipase Hydrolysis on Biomethane Production from Swine Slaughterhouse Waste in China. Energy Fuels 2016, 30, 7326–7330. [Google Scholar] [CrossRef]

- Amon, T.; Amon, B.; Kryvoruchko, V.; Zollitsch, W.; Mayer, K.; Gruber, L. Biogas production from maize and dairy cattle manure—Influence of biomass composition on the methane yield. Agric. Ecosyst. Environ. 2007, 118, 173–182. [Google Scholar] [CrossRef]

- Baek, G.; Kim, D.; Kim, J.; Kim, H.; Lee, C. Treatment of Cattle Manure by Anaerobic Co-Digestion with Food Waste and Pig Manure: Methane Yield and Synergistic Effect. Int. J. Environ. Res. Public Health 2020, 17, 4737. [Google Scholar] [CrossRef] [PubMed]

- Kafle, G.K.; Kim, S.H.; Sung, K.I. Ensiling of fish industry waste for biogas production: A lab scale evaluation of biochemical methane potential (BMP) and kinetics. Bioresour. Technol. 2013, 127, 326–336. [Google Scholar] [CrossRef] [PubMed]

- Gunes, B.; Carrié, M.; Benyounis, K.; Stokes, J.; Davis, P.; Connolly, C.; Lawler, J. Optimisation and Modelling of Anaerobic Digestion of Whiskey Distillery/Brewery Wastes after Combined Chemical and Mechanical Pre-Treatment. Processes 2020, 8, 492. [Google Scholar] [CrossRef]

- González, R.; Smith, R.; Blanco, D.; Fierro, J.; Gómez, X. Application of thermal analysis for evaluating the effect of glycerine addition on the digestion of swine manure. J. Therm. Anal. Calorim. 2019, 135, 2277–2286. [Google Scholar] [CrossRef]

- Joseph, G.; Zhang, B.; Mahzabin-Rahman, Q.; Wang, L.; Shahbazi, A. Two-stage thermophilic anaerobic co-digestion of corn stover and cattle manure to enhance biomethane production. J. Environ. Sci. Health A 2019, 54, 452–460. [Google Scholar] [CrossRef]

- Raposo, F.; Borja, R.; Martín, M.A.; Martín, A.; de la Rubia, M.A.; Rincón, B. Influence of inoculum–substrate ratio on the anaerobic digestion of sunflower oil cake in batch mode: Process stability and kinetic evaluation. Chem. Eng. J. 2009, 149, 70–77. [Google Scholar] [CrossRef]

- Zhurka, M.; Spyridonidis, A.; Vasiliadou, I.A.; Stamatelatou, K. Biogas Production from Sunflower Head and Stalk Residues: Effect of Alkaline Pretreatment. Molecules 2019, 25, 164. [Google Scholar] [CrossRef]

- Kaldis, F.; Cysneiros, D.; Day, J.G.; Karatzas, K.-A.; Chatzifragkou, A. Anaerobic Digestion of Steam-Exploded Wheat Straw and Co-Digestion Strategies for Enhanced Biogas Production. Appl. Sci. 2020, 10, 8284. [Google Scholar] [CrossRef]

- Demirbas, A. Biogas Potential of Manure and Straw Mixtures. Energy Sources A Recovery Util. Environ. Eff. 2006, 28, 71–78. [Google Scholar] [CrossRef]

- Mancini, G.; Papirio, S.; Lens, P.; Esposito, G. A Preliminary Study of the Effect of Bioavailable Fe and Co on the Anaerobic Digestion of Rice Straw. Energies 2019, 12, 577. [Google Scholar] [CrossRef]

- Pizarro-Loaiza, C.A.; Torres-Lozada, P.; Illa, J.; Palatsi, J.; Bonmatí, A. Effect of Harvesting Age and Size Reduction in the Performance of Anaerobic Digestion of Pennisetum Grass. Processes 2020, 8, 1414. [Google Scholar] [CrossRef]

- Kacprzak, A.; Krzystek, L.; Paździor, K.; Ledakowicz, S. Investigation of kinetics of anaerobic digestion of Canary grass. Chem. Pap. 2012, 66, 550–555. [Google Scholar] [CrossRef]

- Thaemngoen, A.; Saritpongteeraka, K.; Leu, S.-Y.; Phuttaro, C.; Sawatdeenarunat, C.; Chaiprapat, S. Anaerobic Digestion of Napier Grass (Pennisetum purpureum) in Two-Phase Dry Digestion System Versus Wet Digestion System. BioEnergy Res. 2020, 13, 853–865. [Google Scholar] [CrossRef]

- Søndergaard, M.M.; Fotidis, I.A.; Kovalovszki, A.; Angelidaki, I. Anaerobic Co-digestion of Agricultural Byproducts with Manure for Enhanced Biogas Production. Energy Fuels 2015, 29, 8088–8094. [Google Scholar] [CrossRef]

- Hidaka, T.; Takabe, Y.; Tsumori, J.; Minamiyama, M. Characterization of microalgae cultivated in continuous operation combined with anaerobic co-digestion of sewage sludge and microalgae. Biomass Bioenergy 2017, 99, 139–146. [Google Scholar] [CrossRef]

- Saleem, M.; Hanif, M.U.; Bahadar, A.; Iqbal, H.; Capareda, S.C.; Waqas, A. The Effects of Hot Water and Ultrasonication Pretreatment of Microalgae (Nannochloropsis oculata) on Biogas Production in Anaerobic Co-Digestion with Cow Manure. Processes 2020, 8, 1558. [Google Scholar] [CrossRef]

- Tápparo, D.C.; do Amaral, A.C.; Steinmetz, R.L.R.; Kunz, A. Co-digestion of Animal Manure and Carcasses to Increase Biogas Generation. In Improving Biogas Production. Biofuel and Biorefinery Technologies, Vol 9; Treichel, H., Fongaro, G., Eds.; Springer: Cham, Switzerland, 2019; pp. 99–116. Available online: http://link.springer.com/10.1007/978-3-030-10516-7_5 (accessed on 13 June 2022).

- Tápparo, D.C.; Viancelli, A.; do Amaral, A.C.; Fongaro, G.; Steinmetz, R.L.R.; Magri, M.E.; Monte-Barardi, C.R.; Kunz, A. Sanitary effectiveness and biogas yield by anaerobic co-digestion of swine carcasses and manure. Environ. Technol. 2020, 41, 682–690. [Google Scholar] [CrossRef]

- Xu, J.; Lin, H.; Sheng, K. Effects of Hydrothermal Pretreatment and Hydrochar Addition on the Performance of Pig Carcass Anaerobic Digestion. Front. Microbiol. 2021, 12, 62235. [Google Scholar] [CrossRef]

- Procházka, J.; Dolejš, P.; Máca, J.; Dohányos, M. Stability and inhibition of anaerobic processes caused by insufficiency or excess of ammonia nitrogen. Appl. Microbiol. Biotechnol. 2012, 93, 439–447. [Google Scholar] [CrossRef]

- Hernández-Regalado, R.E.; Häner, J.; Baumkötter, D.; Wettwer, L.; Brügging, E.; Tränckner, J. Continuous Co-Digestion of Agro-Industrial Mixtures in Laboratory Scale Expanded Granular Sludge Bed Reactors. Appl. Sci. 2022, 12, 2295. [Google Scholar] [CrossRef]

- Rasapoor, M.; Young, B.; Brar, R.; Sarmah, A.; Zhuang, W.-Q.; Baroutian, S. Recognizing the challenges of anaerobic digestion: Critical steps toward improving biogas generation. Fuel 2020, 261, 116497. [Google Scholar] [CrossRef]

- Kabouris, J.C.; Tezel, U.; Pavlostathis, S.G.; Engelmann, M.; Dulaney, J.A.; Todd, A.C.; Gillette, R.A. Mesophilic and Thermophilic Anaerobic Digestion of Municipal Sludge and Fat, Oil, and Grease. Water Environ. Res. 2009, 81, 476–485. [Google Scholar] [CrossRef] [PubMed]

- Martínez, E.J.; Fierro, J.; Sánchez, M.E.; Gómez, X. Anaerobic co-digestion of FOG and sewage sludge: Study of the process by Fourier transform infrared spectroscopy. Int. Biodeterior. Biodegrad. 2012, 75, 1–6. [Google Scholar] [CrossRef]

- Marchetti, R.; Vasmara, C.; Bertin, L.; Fiume, F. Conversion of waste cooking oil into biogas: Perspectives and limits. Appl. Microbiol. Biotechnol. 2020, 104, 2833–2856. [Google Scholar] [CrossRef] [PubMed]

- Long, J.H.; Aziz, T.N.; de los Reyes, F.L.; Ducoste, J.J. Anaerobic co-digestion of fat, oil, and grease (FOG): A review of gas production and process limitations. Process Saf. Environ. Prot. 2012, 90, 231–245. [Google Scholar] [CrossRef]

- Alqaralleh, R.M.; Kennedy, K.; Delatolla, R. Improving biogas production from anaerobic co-digestion of Thickened Waste Activated Sludge (TWAS) and fat, oil and grease (FOG) using a dual-stage hyper-thermophilic/thermophilic semi-continuous reactor. J. Environ. Manag. 2018, 217, 416–428. [Google Scholar] [CrossRef]

- Nuchdang, S.; Phalakornkule, C. Anaerobic digestion of glycerol and co-digestion of glycerol and pig manure. J. Environ. Manag. 2012, 101, 164–172. [Google Scholar] [CrossRef]

- Ahmad, A.; Ghufran, R.; Wahid, Z.A. Bioenergy from anaerobic degradation of lipids in palm oil mill effluent. Rev. Environ. Sci. Biotechnol. 2011, 10, 353–376. [Google Scholar] [CrossRef] [Green Version]

- Diamantis, V.; Eftaxias, A.; Stamatelatou, K.; Noutsopoulos, C.; Vlachokostas, C.; Aivasidis, A. Bioenergy in the era of circular economy: Anaerobic digestion technological solutions to produce biogas from lipid-rich wastes. Renew. Energy 2021, 168, 438–447. [Google Scholar] [CrossRef]

- Buivydas, E.; Navickas, K.; Venslauskas, K.; Žalys, B.; Župerka, V.; Rubežius, M. Biogas Production Enhancement through Chicken Manure Co-Digestion with Pig Fat. Appl. Sci. 2022, 12, 4652. [Google Scholar] [CrossRef]

- Martínez, E.J.; Gil, M.V.; Fernandez, C.; Rosas, J.G.; Gómez, X. Anaerobic Codigestion of Sludge: Addition of Butcher’s Fat Waste as a Cosubstrate for Increasing Biogas Production. PLoS ONE 2016, 11, e0153139. [Google Scholar] [CrossRef]

- Porselvam, S.; Mahendra, B.; Srinivasan, S.V.; Ravindranath, E.; Suthanthararajan, R. Enhanced Biogas Production from Co-digestion of Intestine Waste from Slaughterhouse and Food Waste. Energy Fuels 2017, 31, 12133–12140. [Google Scholar] [CrossRef]

- Ning, Z.; Zhang, H.; Li, W.; Zhang, R.; Liu, G.; Chen, C. Anaerobic digestion of lipid-rich swine slaughterhouse waste: Methane production performance, long-chain fatty acids profile and predominant microorganisms. Bioresour. Technol. 2018, 269, 426–433. [Google Scholar] [CrossRef] [PubMed]

- Usman, M.; Zha, L.; Abomohra, A.E.-F.; Li, X.; Zhang, C.; Salama, E.-S. Evaluation of animal- and plant-based lipidic waste in anaerobic digestion: Kinetics of long-chain fatty acids degradation. Crit. Rev. Biotechnol. 2020, 40, 733–749. [Google Scholar] [CrossRef]

- Labatut, R.A.; Angenent, L.T.; Scott, N.R. Biochemical methane potential and biodegradability of complex organic substrates. Bioresour. Technol. 2011, 102, 2255–2264. [Google Scholar] [CrossRef]

- Edwiges, T.; Frare, L.; Mayer, B.; Lins, L.; Mi Triolo, J.; Flotats, X.; Costa, M. Influence of chemical composition on biochemical methane potential of fruit and vegetable waste. Waste Manag. 2018, 71, 618–625. [Google Scholar] [CrossRef]

- Dębowski, M.; Zieliński, M.; Kazimierowicz, J. Anaerobic Reactor Filling for Phosphorus Removal by Metal Dissolution Method. Materials 2022, 15, 2263. [Google Scholar] [CrossRef]

- Dębowski, M.; Zieliński, M. Technological Effectiveness of Sugar-Industry Effluent Methane Fermentation in a Fluidized Active Filling Reactor (FAF-R). Energies 2020, 13, 6626. [Google Scholar] [CrossRef]

- Maleki, E.; Bokhary, A.; Liao, B.Q. A review of anaerobic digestion bio-kinetics. Rev. Environ. Sci. Biotechnol. 2018, 17, 691–705. [Google Scholar] [CrossRef]

- Liotta, F.; d’Antonio, G.; Esposito, G.; Fabbricino, M.; Frunzo, L.; van Hullebusch, E.D.; Lens, P.N.L.; Pirozzi, F. Effect of moisture on disintegration kinetics during anaerobic digestion of complex organic substrates. Waste Manag. Res. 2014, 32, 40–48. [Google Scholar] [CrossRef]

- Aldin, S.; Nakhla, G.; Ray, M.B. Modeling the Influence of Particulate Protein Size on Hydrolysis in Anaerobic Digestion. Ind. Eng. Chem. Res. 2011, 50, 10843–10849. [Google Scholar] [CrossRef]

- Pham, C.H.; Triolo, J.M.; Cu, T.T.T.; Pedersen, L.; Sommer, S.G. Validation and Recommendation of Methods to Measure Biogas Production Potential of Animal Manure. Asian-Australas. J. Anim. Sci. 2013, 26, 864–873. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Lee, C.; Kim, J.Y. Thermal hydrolysis pre-treatment combined with anaerobic digestion for energy recovery from organic wastes. J. Mater. Cycles Waste Manag. 2020, 22, 1370–1381. [Google Scholar] [CrossRef]

- Sánchez, E.; Borja, R.; Weiland, P.; Travieso, L.; Martín, A. Effect of temperature and pH on the kinetics of methane production, organic nitrogen and phosphorus removal in the batch anaerobic digestion process of cattle manure. Bioprocess Eng. 2000, 22, 247–252. [Google Scholar] [CrossRef]

- López, I.; Benzo, M.; Passeggi, M.; Borzacconi, L. A simple kinetic model applied to anaerobic digestion of cow manure. Environ. Technol. 2021, 42, 3451–3462. [Google Scholar] [CrossRef]

- Wall, D.M.; O’Kiely, P.; Murphy, J.D. The potential for biomethane from grass and slurry to satisfy renewable energy targets. Bioresour. Technol. 2013, 149, 425–431. [Google Scholar] [CrossRef] [PubMed]

- Ebner, J.H.; Labatut, R.A.; Lodge, J.S.; Williamson, A.A.; Trabold, T.A. Anaerobic co-digestion of commercial food waste and dairy manure: Characterizing biochemical parameters and synergistic effects. Waste Manag. 2016, 52, 286–294. [Google Scholar] [CrossRef]

- Li, Y.; Feng, L.; Zhang, R.; He, Y.; Liu, X.; Xiao, X.; Ma, X.; Chen, C.; Liu, G. Influence of Inoculum Source and Pre-incubation on Bio-Methane Potential of Chicken Manure and Corn Stover. Appl. Biochem. Biotech. 2013, 171, 117–127. [Google Scholar] [CrossRef]

- Borja, R.; Martín, A.; Sánchez, E.; Rincón, B.; Raposo, F. Kinetic modelling of the hydrolysis, acidogenic and methanogenic steps in the anaerobic digestion of two-phase olive pomace (TPOP). Process Biochem. 2005, 40, 1841–1847. [Google Scholar] [CrossRef]

- Vavilin, V. Modeling solid waste decomposition. Bioresour. Technol. 2004, 94, 69–81. [Google Scholar] [CrossRef] [PubMed]

- Ali, A.; Mahar, R.B.; Abdelsalam, E.M.; Sherazi, S.T.H. Kinetic Modeling for Bioaugmented Anaerobic Digestion of the Organic Fraction of Municipal Solid Waste by Using Fe3O4 Nanoparticles. Waste Biomass Valori. 2019, 10, 3213–3224. [Google Scholar] [CrossRef]

- Yoon, Y.; Lee, S.; Kim, K.; Jeon, T.; Shin, S. Study of anaerobic co-digestion on wastewater treatment sludge and food waste leachate using BMP test. J. Mater. Cycles Waste Manag. 2018, 20, 283–292. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, R.; Chen, C.; Liu, G.; He, Y.; Liu, X. Biogas production from co-digestion of corn stover and chicken manure under anaerobic wet, hemi-solid, and solid state conditions. Bioresour. Technol. 2013, 149, 406–412. [Google Scholar] [CrossRef]

- Li, D.; Huang, X.; Wang, Q.; Yuan, Y.; Yan, Z.; Li, Z.; Huang, Y.; Xiaofeng, L. Kinetics of methane production and hydrolysis in anaerobic digestion of corn stover. Energy 2016, 102, 1–9. [Google Scholar] [CrossRef]

- González, R.; Blanco, D.; Cascallana, J.G.; Carrillo-Peña, D.; Gómez, X. Anaerobic co-digestion of sheep manure and waste from a potato processing factory: Techno-economic analysis. Fermentation 2021, 7, 235. [Google Scholar] [CrossRef]

- de Castro, T.M.; Torres, D.G.B.; Arantes, E.J.; de Carvalho, K.Q.; Passig, F.H.; Christ, D.; Gotardo, J.T.; Gomes, S.D. Anaerobic co-digestion of industrial landfill leachate and glycerin: Methanogenic potential, organic matter removal and process optimization. Environ. Technol. 2020, 41, 2583–2593. [Google Scholar] [CrossRef]

- Ali, M.M.; Ndongo, M.; Yetilmezsoy, K.; Bahramian, M.; Bilal, B.; Youm, I.; Goncaloğlu, B.İ. Appraisal of methane production and anaerobic fermentation kinetics of livestock manures using artificial neural networks and sinusoidal growth functions. J. Mater. Cycles Waste Manag. 2021, 23, 301–314. [Google Scholar] [CrossRef]

- Meneses-Quelal, W.O.; Velázquez-Martí, B.; Gaibor-Chávez, J.; Niño-Ruiz, Z. Biochemical potential of methane (BMP) of camelid waste and the Andean region agricultural crops. Renew. Energy 2021, 168, 406–415. [Google Scholar] [CrossRef]

- Zhang, Q.; Yao, Y.; Xi, X. Effects of freezing–thawing pretreatment on anaerobic digestion of wheat straw and its kinetics analysis. Clean Technol. Environ. Policy 2022, 24, 125–1241. [Google Scholar] [CrossRef]

- Gomes, C.S.; Strangfeld, M.; Meyer, M. Diauxie Studies in Biogas Production from Gelatin and Adaptation of the Modified Gompertz Model: Two-Phase Gompertz Model. Appl. Sci. 2021, 11, 1067. [Google Scholar] [CrossRef]

- Opurum, C.C.; Nweke, C.O.; Nwanyanwu, C.E.; Nwogu, N.A. Modelling of Biphasic Biogas Production Process from Mixtures of Livestock Manure Using Bi-logistic Function and Modified Gompertz Equation. Ann. Res. Rev. Biol. 2021, 36, 116–129. Available online: https://www.journalarrb.com/index.php/ARRB/article/view/30358 (accessed on 15 July 2022). [CrossRef]

- Zhao, C.; Yan, H.; Liu, Y.; Huang, Y.; Zhang, R.; Chen, C.; Liu, G. Bio-energy conversion performance, biodegradability, and kinetic analysis of different fruit residues during discontinuous anaerobic digestion. Waste Manag. 2016, 52, 295–301. [Google Scholar] [CrossRef] [PubMed]

- dos Santos, L.A.; Valença, R.B.; da Silva, L.C.S.; Holanda, S.H. de B.; da Silva, A.F.V.; Jucá, J.F.T.; Santos, A.F.M.S. Methane generation potential through anaerobic digestion of fruit waste. J. Clean. Prod. 2020, 256, 120389. [Google Scholar] [CrossRef]

- Sánchez, Z.; Poggio, D.; Castro, L.; Escalante, H. Simultaneous Synergy in CH4 Yield and Kinetics: Criteria for Selecting the Best Mixtures during Co-Digestion of Wastewater and Manure from a Bovine Slaughterhouse. Energies 2021, 14, 384. [Google Scholar] [CrossRef]

- Andriamanohiarisoamanana, F.J.; Saikawa, A.; Tarukawa, K.; Qi, G.; Pan, Z.; Yamashiro, T.; Iwasaki, M.; Ihara, I.; Nishida, T.; Umetsu, K. Anaerobic co-digestion of dairy manure, meat and bone meal, and crude glycerol under mesophilic conditions: Synergistic effect and kinetic studies. Energy Sustain. Dev. 2017, 40, 11–18. [Google Scholar] [CrossRef]

- Kafle, G.K.; Chen, L. Comparison on batch anaerobic digestion of five different livestock manures and prediction of biochemical methane potential (BMP) using different statistical models. Waste Manag. 2016, 48, 492–502. [Google Scholar] [CrossRef]

- Arenas, C.B.; González, R.; González, J.; Cara, J.; Papaharalabos, G.; Gómez, X.; Martínez, E.J. Assessment of electrooxidation as pre- and post-treatments for improving anaerobic digestion and stabilisation of waste activated sludge. J. Environ. Manag. 2021, 288, 112365. [Google Scholar] [CrossRef]

- Martinez, E.J.; Micolucci, F.; Gomez, X.; Molinuevo-Salces, B.; Uellendahl, H. Anaerobic digestion of residual liquid effluent (brown juice) from a green biorefinery. Int. J. Environ. Sci. Technol. 2018, 15, 2615–2624. [Google Scholar] [CrossRef]

- al bkoor Alrawashdeh, K.; Pugliese, A.; Slopiecka, K.; Pistolesi, V.; Massoli, S.; Bartocci, P.; Bidini, G.; Fantozzi, F. Codigestion of Untreated and Treated Sewage Sludge with the Organic Fraction of Municipal Solid Wastes. Fermentation 2017, 3, 35. [Google Scholar] [CrossRef]

- Gómez-Quiroga, X.; Aboudi, K.; Álvarez-Gallego, C.J.; Romero-García, L.I. Enhancement of Methane Production in Thermophilic Anaerobic Co-Digestion of Exhausted Sugar Beet Pulp and Pig Manure. Appl. Sci. 2019, 9, 1791. [Google Scholar] [CrossRef]

- Li, J.X.; Wang, L.A.; Wang, L.; Zhan, X.Y.; Huang, C. Exploring the biogas production and microbial community from co-digestion of sewage sludge with municipal solid waste incineration fresh leachate. Int. J. Environ. Sci. Technol. 2021, 18, 901–912. [Google Scholar] [CrossRef]

- Anjum, M.; Khalid, A.; Mahmood, T.; Arshad, M. Anaerobic co-digestion of municipal solid organic waste with melon residues to enhance biodegradability and biogas production. J. Mater. Cycles Waste Manag. 2012, 14, 388–395. [Google Scholar] [CrossRef]

- Ghaleb, A.A.S.; Kutty, S.R.M.; Ho, Y.-C.; Jagaba, A.H.; Noor, A.; Al-Sabaeei, A.M.; Almahbashi, N.M.Y. Response Surface Methodology to Optimize Methane Production from Mesophilic Anaerobic Co-Digestion of Oily-Biological Sludge and Sugarcane Bagasse. Sustainability 2020, 12, 2116. [Google Scholar] [CrossRef]

- Insam, H.; Markt, R. Comment on Aichinger et al. Synergistic co-digestion of solid-organic-waste and municipal-sewage-sludge: 1 plus 1 equals more than 2 in terms of biogas production and solids reduction. Water Res. 2015, 87, 416–423. [Google Scholar] [CrossRef]

- Seekao, N.; Sangsri, S.; Rakmak, N.; Dechapanya, W.; Siripatana, C. Co-digestion of palm oil mill effluent with chicken manure and crude glycerol: Biochemical methane potential by monod kinetics. Heliyon 2021, 7, e06204. [Google Scholar] [CrossRef]

- Zahedi, S.; Martín, C.; Solera, R.; Pérez, M. Evaluating the Effectiveness of Adding Chicken Manure in the Anaerobic Mesophilic Codigestion of Sewage Sludge and Wine Distillery Wastewater: Kinetic Modeling and Economic Approach. Energy Fuels 2020, 34, 12626–12633. [Google Scholar] [CrossRef]

- Cuetos, M.J.; Gómez, X.; Otero, M.; Morán, A. Anaerobic digestion of solid slaughterhouse waste (SHW) at laboratory scale: Influence of co-digestion with the organic fraction of municipal solid waste (OFMSW). Biochem. Eng. J. 2008, 40, 99–106. [Google Scholar] [CrossRef]

- Cuetos, M.J.; Gómez, X.; Martínez, E.J.; Fierro, J.; Otero, M. Feasibility of anaerobic co-digestion of poultry blood with maize residues. Bioresour. Technol. 2013, 144, 513–520. [Google Scholar] [CrossRef]

- Alatriste-Mondragón, F.; Samar, P.; Cox, H.H.J.; Ahring, B.K.; Iranpour, R. Anaerobic Codigestion of Municipal, Farm, and Industrial Organic Wastes: A Survey of Recent Literature. Water Environ. Res. 2006, 78, 607–636. [Google Scholar] [CrossRef]

- Mata-Alvarez, J.; Dosta, J.; Macé, S.; Astals, S. Codigestion of solid wastes: A review of its uses and perspectives including modeling. Crit. Rev. Biotechnol. 2011, 31, 99–111. [Google Scholar] [CrossRef] [PubMed]

- Babaee, A.; Shayegan, J.; Roshani, A. Anaerobic slurry co-digestion of poultry manure and straw: Effect of organic loading and temperature. J. Environ. Health Sci. Eng. 2013, 11, 15. [Google Scholar] [CrossRef] [PubMed]

- Bolzonella, D.; Battistoni, P.; Susini, C.; Cecchi, F. Anaerobic codigestion of waste activated sludge and OFMSW: The experiences of Viareggio and Treviso plants (Italy). Water Sci. Technol. 2006, 53, 203–211. [Google Scholar] [CrossRef]

- Sembera, C.; Macintosh, C.; Astals, S.; Koch, K. Benefits and drawbacks of food and dairy waste co-digestion at a high organic loading rate: A Moosburg WWTP case study. Waste Manag. 2019, 95, 217–226. [Google Scholar] [CrossRef]

- Koch, K.; Plabst, M.; Schmidt, A.; Helmreich, B.; Drewes, J.E. Co-digestion of food waste in a municipal wastewater treatment plant: Comparison of batch tests and full-scale experiences. Waste Manag. 2016, 47, 28–33. [Google Scholar] [CrossRef] [PubMed]

- Dereli, R.K.; Ersahin, M.E.; Gomec, C.Y.; Ozturk, I.; Ozdemir, O. Co-digestion of the organic fraction of municipal solid waste with primary sludge at a municipal wastewater treatment plant in Turkey. Waste Manag. Res. 2010, 28, 404–410. [Google Scholar] [CrossRef]

- García-Cascallana, J.; Carrillo-Peña, D.; Morán, A.; Smith, R.; Gómez, X. Energy Balance of Turbocharged Engines Operating in a WWTP with Thermal Hydrolysis. Co-Digestion Provides the Full Plant Energy Demand. Appl. Sci. 2021, 11, 11103. [Google Scholar] [CrossRef]

- Jellali, S.; Charabi, Y.; Usman, M.; Al-Badi, A.; Jeguirim, M. Investigations on Biogas Recovery from Anaerobic Digestion of Raw Sludge and Its Mixture with Agri-Food Wastes: Application to the Largest Industrial Estate in Oman. Sustainability 2021, 13, 3698. [Google Scholar] [CrossRef]

- Nghiem, L.D.; Koch, K.; Bolzonella, D.; Drewes, J.E. Full scale co-digestion of wastewater sludge and food waste: Bottlenecks and possibilities. Renew. Sust. Energy Rev. 2017, 72, 354–362. [Google Scholar] [CrossRef] [Green Version]

- Park, N.D.; Thring, R.W.; Garton, R.P.; Rutherford, M.P.; Helle, S.S. Increased biogas production in a wastewater treatment plant by anaerobic co-digestion of fruit and vegetable waste and sewer sludge—A full scale study. Water Sci. Technol. 2011, 64, 1851–1856. [Google Scholar] [CrossRef]

- Mattioli, A.; Gatti, G.B.; Mattuzzi, G.P.; Cecchi, F.; Bolzonella, D. Co-digestion of the organic fraction of municipal solid waste and sludge improves the energy balance of wastewater treatment plants: Rovereto case study. Renew. Energy 2017, 113, 980–988. [Google Scholar] [CrossRef]

- Macintosh, C.; Astals, S.; Sembera, C.; Ertl, A.; Drewes, J.E.; Jensen, P.D.; Koch, K. Successful strategies for increasing energy self-sufficiency at Grüneck wastewater treatment plant in Germany by food waste co-digestion and improved aeration. Appl. Energy 2019, 242, 797–808. [Google Scholar] [CrossRef]

- Aichinger, P.; Wadhawan, T.; Kuprian, M.; Higgins, M.; Ebner, C.; Fimml, C.; Murthy, S.; Wett, B. Synergistic co-digestion of solid-organic-waste and municipal-sewage-sludge: 1 plus 1 equals more than 2 in terms of biogas production and solids reduction. Water Res. 2015, 87, 416–423. [Google Scholar] [CrossRef] [PubMed]

- Zupančič, G.D.; Uranjek-Ževart, N.; Roš, M. Full-scale anaerobic co-digestion of organic waste and municipal sludge. Biomass Bioenergy 2008, 32, 162–167. [Google Scholar] [CrossRef]

- Masłoń, A.; Czarnota, J.; Szaja, A.; Szulżyk-Cieplak, J.; Łagód, G. The Enhancement of Energy Efficiency in a Wastewater Treatment Plant through Sustainable Biogas Use: Case Study from Poland. Energies 2020, 13, 6056. [Google Scholar] [CrossRef]

- Ek, A.E.W.; Hallin, S.; Vallin, L.; Schnurer, A.; Karlsson, M. Slaughterhouse Waste Co-Digestion-Experiences from 15 Years of Full-Scale Operation. In Proceedings of the World Renewable Energy Congress—Sweden, Linkoping, Sweden, 8–13 May 2011; pp. 64–71. Available online: https://ep.liu.se/en/conference-article.aspx?series=ecp&issue=57&Article_No=9 (accessed on 10 May 2022).

- Wehner, M.; Lichtmannegger, T.; Robra, S.; do Carmo Precci Lopes, A.; Ebner, C.; Bockreis, A. The economic efficiency of the co-digestion at WWTPs: A full-scale study. Waste Manag. 2021, 133, 110–118. [Google Scholar] [CrossRef]

- Schaubroeck, T.; de Clippeleir, H.; Weissenbacher, N.; Dewulf, J.; Boeckx, P.; Vlaeminck, S.E.; Wett, B. Environmental sustainability of an energy self-sufficient sewage treatment plant: Improvements through DEMON and co-digestion. Water Res. 2015, 74, 166–179. [Google Scholar] [CrossRef]

- Neshat, S.A.; Mohammadi, M.; Najafpour, G.D.; Lahijani, P. Anaerobic co-digestion of animal manures and lignocellulosic residues as a potent approach for sustainable biogas production. Renew. Sust. Energy Rev. 2017, 79, 308–322. [Google Scholar] [CrossRef]

- Ellacuriaga, M.; García-Cascallana, J.; Gómez, X. Biogas Production from Organic Wastes: Integrating Concepts of Circular Economy. Fuels 2021, 2, 9. [Google Scholar] [CrossRef]

- Yuan, H.; Zhu, N. Progress in inhibition mechanisms and process control of intermediates and by-products in sewage sludge anaerobic digestion. Renew. Sust. Energy Rev. 2016, 58, 429–438. [Google Scholar] [CrossRef]

- Siegert, I.; Banks, C. The effect of volatile fatty acid additions on the anaerobic digestion of cellulose and glucose in batch reactors. Process Biochem. 2005, 40, 3412–3418. [Google Scholar] [CrossRef]

- Jiang, Y.; Dennehy, C.; Lawlor, P.G.; Hu, Z.; McCabe, M.; Cormican, P.; Zhan, X.; Gardiner, G.E. Inhibition of volatile fatty acids on methane production kinetics during dry co-digestion of food waste and pig manure. Waste Manag. 2018, 79, 302–311. [Google Scholar] [CrossRef]

- Moestedt, J.; Müller, B.; Westerholm, M.; Schnürer, A. Ammonia threshold for inhibition of anaerobic digestion of thin stillage and the importance of organic loading rate. Microb. Biotechnol. 2016, 9, 180–194. [Google Scholar] [CrossRef] [PubMed]

- Bi, S.; Westerholm, M.; Hu, W.; Mahdy, A.; Dong, T.; Sun, Y.; Qiao, W.; Dong, R. The metabolic performance and microbial communities of anaerobic digestion of chicken manure under stressed ammonia condition: A case study of a 10-year successful biogas plant. Renew. Energy 2021, 167, 644–651. [Google Scholar] [CrossRef]

- Yan, M.; Fotidis, I.A.; Tian, H.; Khoshnevisan, B.; Treu, L.; Tsapekos, P.; Angelidaki, I. Acclimatization contributes to stable anaerobic digestion of organic fraction of municipal solid waste under extreme ammonia levels: Focusing on microbial community dynamics. Bioresour. Technol. 2019, 286, 121376. [Google Scholar] [CrossRef]

- Bagi, Z.; Ács, N.; Bálint, B.; Horváth, L.; Dobó, K.; Perei, K.R.; Rákhely, G.; Kovács, K. Biotechnological intensification of biogas production. Appl. Microbiol. Biotechnol. 2007, 76, 473–482. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.; Chen, L.; Chen, Y.; Cao, Q.; Liu, X.; Li, D. Effect of H2 addition on the microbial community structure of a mesophilic anaerobic digestion system. Energy 2020, 198, 117368. [Google Scholar] [CrossRef]

- Ács, N.; Bagi, Z.; Rákhely, G.; Minárovics, J.; Nagy, K.; Kovács, K.L. Bioaugmentation of biogas production by a hydrogen-producing bacterium. Bioresour. Technol. 2015, 186, 286–293. [Google Scholar] [CrossRef]

- Kovács, K.L.; Ács, N.; Kovács, E.; Wirth, R.; Rákhely, G.; Strang, O.; Herbel, Z.; Bagi, Z. Improvement of Biogas Production by Bioaugmentation. Biomed Res. Int. 2013, 2013, 482653. Available online: http://www.hindawi.com/journals/bmri/2013/482653/ (accessed on 8 April 2022). [CrossRef] [Green Version]

- André, L.; Pauss, A.; Ribeiro, T. Solid anaerobic digestion: State-of-art, scientific and technological hurdles. Bioresour. Technol. 2018, 247, 1027–1037. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, H.; Liu, C.; Cheng, Y. Influencing mechanism of high solid concentration on anaerobic mono-digestion of sewage sludge without agitation. Front. Environ. Sci. Eng. 2015, 9, 1108–1116. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, H.; Cheng, Y.; Liu, C. Influence of solids concentration on diffusion behavior in sewage sludge and its digestate. Chem. Eng. Sci. 2016, 152, 674–677. [Google Scholar] [CrossRef]

- Xu, Y.; Gong, H.; Dai, X. High-solid anaerobic digestion of sewage sludge: Achievements and perspectives. Front. Environ. Sci. Eng. 2021, 15, 71. [Google Scholar] [CrossRef]

- Liao, X.; Li, H.; Cheng, Y.; Chen, N.; Li, C.; Yang, Y. Process performance of high-solids batch anaerobic digestion of sewage sludge. Environ. Technol. 2014, 35, 2652–2659. [Google Scholar] [CrossRef]

- Pastor-Poquet, V.; Papirio, S.; Trably, E.; Rintala, J.; Escudié, R.; Esposito, G. High-solids anaerobic digestion requires a trade-off between total solids, inoculum-to-substrate ratio and ammonia inhibition. Int. J. Environ. Sci. Technol. 2019, 16, 7011–7024. [Google Scholar] [CrossRef]

- Donoso-Bravo, A.; Retamal, C.; Carballa, M.; Ruiz-Filippi, G.; Chamy, R. Influence of temperature on the hydrolysis, acidogenesis and methanogenesis in mesophilic anaerobic digestion: Parameter identification and modeling application. Water Sci. Technol. 2009, 60, 9–17. [Google Scholar] [CrossRef]

- Gómez, X.; Cuetos, M.J.; Tartakovsky, B.; Martínez-Núñez, M.F.; Morán, A. A comparison of analytical techniques for evaluating food waste degradation by anaerobic digestion. Bioprocess Biosyst. Eng. 2010, 33, 427–438. [Google Scholar] [CrossRef]

- Nges, I.A.; Liu, J. Effects of solid retention time on anaerobic digestion of dewatered-sewage sludge in mesophilic and thermophilic conditions. Renew. Energy 2010, 35, 2200–2206. [Google Scholar] [CrossRef]

- Banks, C.J.; Chesshire, M.; Stringfellow, A. A pilot-scale comparison of mesophilic and thermophilic digestion of source segregated domestic food waste. Water Sci. Technol. 2008, 58, 1475–1481. [Google Scholar] [CrossRef] [Green Version]

- Silvestre, G.; Fernández, B.; Bonmatí, A. Addition of crude glycerine as strategy to balance the C/N ratio on sewage sludge thermophilic and mesophilic anaerobic co-digestion. Bioresour. Technol. 2015, 193, 377–385. [Google Scholar] [CrossRef]

- Chen, Z.; Li, W.; Qin, W.; Sun, C.; Wang, J.; Wen, X. Long-term performance and microbial community characteristics of pilot-scale anaerobic reactors for thermal hydrolyzed sludge digestion under mesophilic and thermophilic conditions. Sci. Total Environ. 2020, 720, 137566. [Google Scholar] [CrossRef] [PubMed]

- Gómez, X.; Blanco, D.; Lobato, A.; Calleja, A.; Martínez-Núñez, F.; Martin-Villacorta, J. Digestion of cattle manure under mesophilic and thermophilic conditions: Characterization of organic matter applying thermal analysis and 1H NMR. Biodegradation 2011, 22, 623–635. [Google Scholar] [CrossRef] [PubMed]

- Provenzano, M.R.; Daniela Malerba, A.; Buscaroli, A.; Zannoni, D.; Senesi, N. Anaerobic digestion of municipal solid waste and sewage sludge under mesophilic and thermophilic conditions. J. Therm. Anal. Calorim. 2013, 111, 1861–1870. [Google Scholar] [CrossRef]

- Yenigün, O.; Demirel, B. Ammonia inhibition in anaerobic digestion: A review. Process Biochem. 2013, 48, 901–911. [Google Scholar] [CrossRef]

- Takashima, M.; Yaguchi, J. High-solids thermophilic anaerobic digestion of sewage sludge: Effect of ammonia concentration. J. Mater. Cycles Waste Manag. 2021, 23, 205–213. [Google Scholar] [CrossRef]

- Wang, G.; Li, Q.; Gao, X.; Wang, X.C. Sawdust-Derived Biochar Much Mitigates VFAs Accumulation and Improves Microbial Activities To Enhance Methane Production in Thermophilic Anaerobic Digestion. ACS Sustain. Chem. Eng. 2019, 7, 2141–2150. [Google Scholar] [CrossRef]

- Petracchini, F.; Liotta, F.; Paolini, V.; Perilli, M.; Cerioni, D.; Gallucci, F.; Carnevale, M.; Bencini, A. A novel pilot scale multistage semidry anaerobic digestion reactor to treat food waste and cow manure. Int. J. Environ. Sci. Technol. 2018, 15, 1999–2008. [Google Scholar] [CrossRef]

- Bardi, M.J.; Rad, H.A. Simultaneous synergistic effects of addition of agro-based adsorbent on anaerobic co-digestion of food waste and sewage sludge. J. Mater. Cycles Waste Manag. 2020, 22, 65–79. [Google Scholar] [CrossRef]

- Achi, C.G.; Hassanein, A.; Lansing, S. Enhanced Biogas Production of Cassava Wastewater Using Zeolite and Biochar Additives and Manure Co-Digestion. Energies 2020, 13, 491. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Li, X.; Wu, S.; Tan, Z.; Yang, C. Enhancing anaerobic digestion process with addition of conductive materials. Chemosphere 2021, 278, 130449. [Google Scholar] [CrossRef]

- Kumar, V.; Nabaterega, R.; Khoei, S.; Eskicioglu, C. Insight into interactions between syntrophic bacteria and archaea in anaerobic digestion amended with conductive materials. Renew. Sust. Energy Rev. 2021, 144, 110965. [Google Scholar] [CrossRef]

- Nozhevnikova, A.N.; Russkova, Y.I.; Litti, Y.V.; Parshina, S.N.; Zhuravleva, E.A.; Nikitina, A.A. Syntrophy and Interspecies Electron Transfer in Methanogenic Microbial Communities. Microbiology 2020, 89, 129–147. [Google Scholar] [CrossRef]

- Gahlot, P.; Ahmed, B.; Tiwari, S.B.; Aryal, N.; Khursheed, A.; Kazmi, A.A.; Tyagi, V.K. Conductive material engineered direct interspecies electron transfer (DIET) in anaerobic digestion: Mechanism and application. Environ. Technol. Innov. 2020, 20, 101056. [Google Scholar] [CrossRef]

- Cerrillo, M.; Viñas, M.; Bonmatí, A. Anaerobic digestion and electromethanogenic microbial electrolysis cell integrated system: Increased stability and recovery of ammonia and methane. Renew. Energy 2018, 120, 178–189. [Google Scholar] [CrossRef]

- Martínez, E.J.; Rosas, J.G.; Sotres, A.; Moran, A.; Cara, J.; Sánchez, M.E.; Gómez, X. Codigestion of sludge and citrus peel wastes: Evaluating the effect of biochar addition on microbial communities. Biochem. Eng. J. 2018, 137, 314–325. [Google Scholar] [CrossRef]

- Cui, Y.; Mao, F.; Zhang, J.; He, Y.; Tong, Y.W.; Peng, Y. Biochar enhanced high-solid mesophilic anaerobic digestion of food waste: Cell viability and methanogenic pathways. Chemosphere 2021, 272, 129863. [Google Scholar] [CrossRef]

- Moreno, R.; Martínez, E.; Escapa, A.; Martínez, O.; Díez-Antolínez, R.; Gómez, X. Mitigation of Volatile Fatty Acid Build-Up by the Use of Soft Carbon Felt Electrodes: Evaluation of Anaerobic Digestion in Acidic Conditions. Fermentation 2018, 4, 2. [Google Scholar] [CrossRef]

- Ali, A.; Keerio, H.A.; Panhwar, S.; Ahad, M.Z. Experimental Investigation of Methane Generation in the Presence of Surface and Un-Surface Nanoparticles of Iron Oxide. AgriEngineering 2022, 4, 9. [Google Scholar] [CrossRef]

- Zaidi, A.A.; Feng, R.; Malik, A.; Khan, S.Z.; Shi, Y.; Bhutta, A.J.; Shah, A.H. Combining microwave pretreatment with iron oxide nanoparticles enhanced biogas and hydrogen yield from green algae. Processes 2019, 7, 24. [Google Scholar] [CrossRef] [Green Version]

- Madondo, N.I.; Tetteh, E.K.; Rathilal, S.; Bakare, B.F. Synergistic Effect of Magnetite and Bioelectrochemical Systems on Anaerobic Digestion. Bioengineering 2021, 8, 198. [Google Scholar] [CrossRef]

- Samer, M.; Abdelsalam, E.M.; Mohamed, S.; Elsayed, H.; Attia, Y. Impact of photoactivated cobalt oxide nanoparticles addition on manure and whey for biogas production through dry anaerobic co-digestion. Environ. Dev. Sustain. 2022, 24, 7776–7793. [Google Scholar] [CrossRef]

- Ajayi-Banji, A.A.; Rahman, S. Efficacy of magnetite (Fe3O4) nanoparticles for enhancing solid-state anaerobic co-digestion: Focus on reactor performance and retention time. Bioresour. Technol. 2021, 324, 124670. [Google Scholar] [CrossRef] [PubMed]

- Donia, D.T.; Carbone, M. Fate of the nanoparticles in environmental cycles. Int. J. Environ. Sci. Technol. 2019, 16, 583–600. [Google Scholar] [CrossRef]

| Organic Substrates | Methane Yield | References |

|---|---|---|

| Sewage sludge | 0.13–0.45 | [66,67,68,69,70,71,72] |

| Food wastes | 0.33–0.5 | [69,72,73] |

| Pig, swine manure | 0.3–0.5 | [19,74,75,76,77,78] |

| Poultry manure | 0.03–0.11 | [19,74,78,79] |

| Chicken manure | 0.52 0.053–0.75 | [80] [19] |

| Cattle manure | 0.11–0.54 | [12,81] |

| Slaughterhouse waste | 0.2–0.8 | [82,83] |

| Brewery waste | 0.3–0.51 | [84,85] |

| Residual glycerine | 0.56 | [86] |

| Corn stover | 0.3–0.4 | [75,87] |

| Sunflower crop wastes | 0.2–0.4 | [88,89] |

| Rapeseed crop wastes | 0.25 | [75] |

| Wheat straw (steam explosion pretreatment) | 0.25–0.35 | [90,91] |

| Rice straw | 0.26 | [92] |

| Grass: Napier grass, Canary grass, King grass | 0.15–0.60 | [93,94,95] |

| Meadow grass | 0.39 | [96] |

| Microalgae Chlorella sp. | 0.23–0.26 | [77,97] |

| Microalgae Nannochloropsis oculata | 0.3–0.35 | [98] |

| Substrate | k (1/d) | Methane Yield (L/g VS) | Reference |

|---|---|---|---|

| Cattle, pig manure | 0.106–0.149 | 0.217–0.287 | [125] |

| Pig manure, swine manure | 0.213 | 0.202 | [86] |

| 0.11 | 0.161 | [126] | |

| Cattle manure | 0.037–0.086 | 0.254–0.290 1 | [127] |

| 0.069–0.278 | - | [128] | |

| 0.082 | 0.239 | [129] | |

| 0.19 | 0.238 | [130] | |

| Chicken manure | 0.07–0.12 | 0.298–0.351 | [131] |

| Grass | 0.107 | 0.400 | [129] |

| Two-phase olive pomace | 0.054 | - | [132] |

| Food wastes | 0.55 | - | [133] |

| 0.2 | 0.524 | [126] | |

| Organic fraction municipal solid wastes | 0.0061 | - | [134] |

| Fruit and vegetable wastes | 0.34 | 0.350 2 | [130] |

| Vegetable crop residues | 0.094–0.167 | 0.094–0.147 | [59] |

| Food waste leachate–sewage sludge | 0.08 | 0.343 | [135] |

| Corn stover | 0.197 | 0.0008–0.0023 | [136] |

| 0.06–0.11 | 0.218–0.300 | [131] | |

| Green corn stover | 0.159 | 0.347 | [137] |

| Air-dried corn stover | 0.0624 | 0.319 | [137] |

| Cellulose | 0.123 | 0.348 | [129] |

| 0.32 | 0.353 | [130] |

| Substrate | λ (Days) | Rmax (mL CH4/g vs. d) | Methane Yield (L/g VS) | Reference |

|---|---|---|---|---|

| Swine manure | 0 | 25.2 | 0.322 | [149] |

| 0.5 | 12.8 | 0.161 | [126] | |

| Cattle manure | 2.45 | 15.7 | 0.239 | [129] |

| 0 | 11.9 | 0.202 | [149] | |

| Chicken manure | 0.3–2.8 | 19.4–48.9 | 0.180 1 | [136] |

| 0 | 19.2 | 0.258 | [149] | |

| Food wastes | 0.5 | 72.3 | 0.524 | [126] |

| Food waste leachate–sewage sludge | 1.98 | 28.4 | 0.343 | [135] |

| Waste activated sludge | 5.4 | 19.2 | 0.253 | [150] |

| Grass | 1.94 | 34.5 | 0.400 | [129] |

| Corn stover | 0.9–1.9 | 16–32.1 | 0.218–0.300 | [131] |

| Liquid effluent from Biorefinery (treating grass material) | 3.9–10.2 | 44.7–66.3 | 0.459–0.505 | [151] |

| Cellulose | 2.93 | 42.0 | 0.348 | [129] |

| Digestion Mixture | Methane Yield (L CH4/g VS) | Reference |

|---|---|---|

| Sewage sludge + food wastes | 0.293–0.365 | [72] |

| Waste activated sludge + organic fraction of municipal solid wastes | 0.162–0.243 | [152] |

| Sewage sludge + sludge from brewery | 0.176–0.263 | [135] |

| Sewage sludge + food waste leachate | 0.233–0.344 | [135] |

| Sewage sludge + maize straw | 0.336–0.472 | [71] |

| Sewage sludge + cattle manure | 0.352–0.470 | [71] |

| Swine Manure + glycerine | 0.349–0.467 | [86] |

| Pig manure + ESBP 1 | 0.212 | [153] |

| Co-Digestion | Amount Added | Benefits | Disadvantage | Reference |

|---|---|---|---|---|

| SS * + food waste Grüneck WWTP (Munich, Germany) | 5.5 t/d | 16% increase in energy production | Poor dewaterability | [174] |

| SS + organic solid waste Zirl WWTP (Tyrol, Austria) | Increase in OLR from 1.17 to 2.18 kg VS/m3 d | 174% increase in biogas production. Energy obtained was 115% of the plant energy demand | 33% increase in digestate production and nitrogen back load was doubled | [175] |

| SS + food waste WWTP Garching/Alz (Germany) | 10% (w/w) | Enhanced methane yield reporting synergism (12% increase). Biogas production doubled | High nitrogen load in reject water. Reduced dewaterability | [167] |

| SS + organic waste from domestic refuse Velenje WWTP (Slovenia) | Increase in OLR by 25% | 80% biogas increase. Increase in vs. degradation | No reported | [176] |

| SS + fat-waste Iława WWTP (Poland) | Variable amount-Added to set the OLR at a value of 4.8 g/L d as maximum | 82% biogas increase 29% vs. removal enhancement Attain close to total energy consumption | No reported | [177] |

| Slaughterhouse waste + mixture of substrates Co-digestion plant operated by the company Svensk Biogas AB (SvB). Linköping (Sweden) | 35–75% (w/w) | Energy savings, better odor control, higher gas quality and production | High ammonia load. Need addition of ferrous chloride and hydrochloric acid to increase process stability | [178] |

| SS + mixture (milk processing industry wastes and fat from grease traps) WWTP Moosburg (Germany) | 186% OLR increase | 300% CH4 increase | Solid accumulation inside the digester. Nitrogen backload. Decrease in retention time and lower sludge dewaterability. | [166] |

| SS and mixture of food waste-garden waste (95:5% based on fresh mass) and grease trap sludge Grossache-Nord WWTP, Tyrol (Austria) | Amount of SS: 850 t/year Amount of co-substrate: 397 t/year | Increase in methane yield: PS: 302 m3/t TS added WS: 133 m3/t TS added Co-digestion: 627 m3/t TS added (plant data) Benefit to cost ratio greater than one | Lower TS removal, higher amount of dewatered sludge and increase demand of flocculants. Sludge disposal represented 64% of overall costs (plant data) | [179] |

| SS + mixture of wastes (kitchen wastes and fats) WWTP Strass (Austria) | Kitchen waste added 329 g DM/m3 treated SS Fat added 9 g DM/m3 treated SS | Additional amount of electricity produced: 0.035–0.041 kWh/m3 Energy self-sufficiency achieved for the WWTP | Higher nitrogen input, requiring a more efficient denitrification stage. | [180] |

| Process Parameter | Effect |

|---|---|

| Temperature | The increase in temperature accelerates degradation rates, fluid dynamics and settling characteristics of particles [181]. The improvement in microbial activity increases the reactor treatment capacity of organics reducing the digester volume needed [182]. |

| pH and alkalinity | pH values should be close to neutral conditions. The stability of the digestion is closely related to the capacity of buffering acid intermediaries, the release of CO2 and the presence of ammonia. The interaction between the ionic species and free forms attenuates pH deviations making the process more robust to organic loading fluctuations [27]. |

| Organic loading rate (OLR) | Represents the amount of organic material entering into the digester with the influent. Increasing the volumetric flow or increasing the solid content of the feeding material leads to an increase in organic loading. Biogas production is directly associated with the amount of organics fed into the reactor, and any increment in OLR is usually associated with an improvement in the biogas production rate. The increase in solid content attained by adding a co-substrate in anaerobic digestion is one of the main reasons for obtaining a better volumetric efficiency of the reactor. However, an excess in OLR may also cause process imbalances due to the accumulation of acid intermediaries associated with disturbances in the acidogenic and methanogenic phases. |

| Hydraulic retention time (HRT) | Refers to the time the fluid spends in the reactor. This time is calculated as the ratio between the volume of the reactor and the volumetric flow applied. HRT and OLR are linked by the volumetric flow, thus increasing the incoming flow also leads to an increase in OLR and a decrease in HRT. The time needed for the substrate to be fully degraded depends on the characteristics of the material, complexity in the structure of organic compounds and the activity of the microflora. Co-substrates characterized by a limited hydrolysis phase will need a higher retention time in the anaerobic reactor. Inhibitory conditions lead to poor performance of the microbial activity, with the digestion system not being able to degrade organics in the time given by the HRT. |

| Volatile fatty acids (VFAs) | Short-chain fatty acids are produced as intermediary compounds during the anaerobic conversion of organics. Process imbalances lead to the accumulation of these acids, inhibition of methanogens, and therefore a decline in biogas evolution along with pH variations when the buffer capacity of the system is surpassed [183]. Process inhibition has been reported to occur at VFA concentrations in the range of 2000–4000 mg/L [184] depending on the type of substrate evaluated. However, co-digestion with high N-containing organics allows the maintenance of process stability even though high levels of VFA may be present. Stable performance was reported by Jiang et al. [185] when studying co-digestion of pig manure, reporting as inhibitory the VFA range of 16.5–18.0 g/L |

| Ammonium | This compound is derived from the conversion of protein-rich material. The toxicity of ammonia in the digester is linked to the level of free ammonia, which is dependent on the system pH. Nitrogen is an essential nutrient for the process, but excessive levels lead to methanogenic inhibitory conditions. The ammonium concentration found in the reactor liquor depends on substrate C/N ratio, HRT and OLR applied to the reactor, and the degradability of the substrates (hydrolysis performance). Ammonia also plays a relevant role in the buffer capacity of the system by attenuating pH drops through the equilibrium ammonia–ammonium reaction. However, a high concentration of ammonium ions may be detrimental to the anaerobic microorganisms. Moestedt et al. [186] reported that a threshold for stability is found at 1 g NH3-N/L (free ammonia), irrespective of the OLR studied. Acclimation of the microflora to high ammonia levels may attain stable performance when treating high-nitrogen-containing wastes. Bi et al. [187] reported stable performance of a full-scale chicken manure digestion plant under ammonium-N levels of 6.2 g/L and Yan et al. [188] indicated that 8.5 g NH4+-N/L was the threshold for experiencing inhibitory conditions, with this value being associated with free ammonia nitrogen (FAN) values greater than 800 mg NH3-N/L. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

González, R.; Peña, D.C.; Gómez, X. Anaerobic Co-Digestion of Wastes: Reviewing Current Status and Approaches for Enhancing Biogas Production. Appl. Sci. 2022, 12, 8884. https://doi.org/10.3390/app12178884

González R, Peña DC, Gómez X. Anaerobic Co-Digestion of Wastes: Reviewing Current Status and Approaches for Enhancing Biogas Production. Applied Sciences. 2022; 12(17):8884. https://doi.org/10.3390/app12178884

Chicago/Turabian StyleGonzález, Rubén, Daniela Carrillo Peña, and Xiomar Gómez. 2022. "Anaerobic Co-Digestion of Wastes: Reviewing Current Status and Approaches for Enhancing Biogas Production" Applied Sciences 12, no. 17: 8884. https://doi.org/10.3390/app12178884

APA StyleGonzález, R., Peña, D. C., & Gómez, X. (2022). Anaerobic Co-Digestion of Wastes: Reviewing Current Status and Approaches for Enhancing Biogas Production. Applied Sciences, 12(17), 8884. https://doi.org/10.3390/app12178884