Propagation Characteristics of Fractures Induced by Supercritical Carbon Dioxide Jet in Hard and Soft Layered Rocks

Abstract

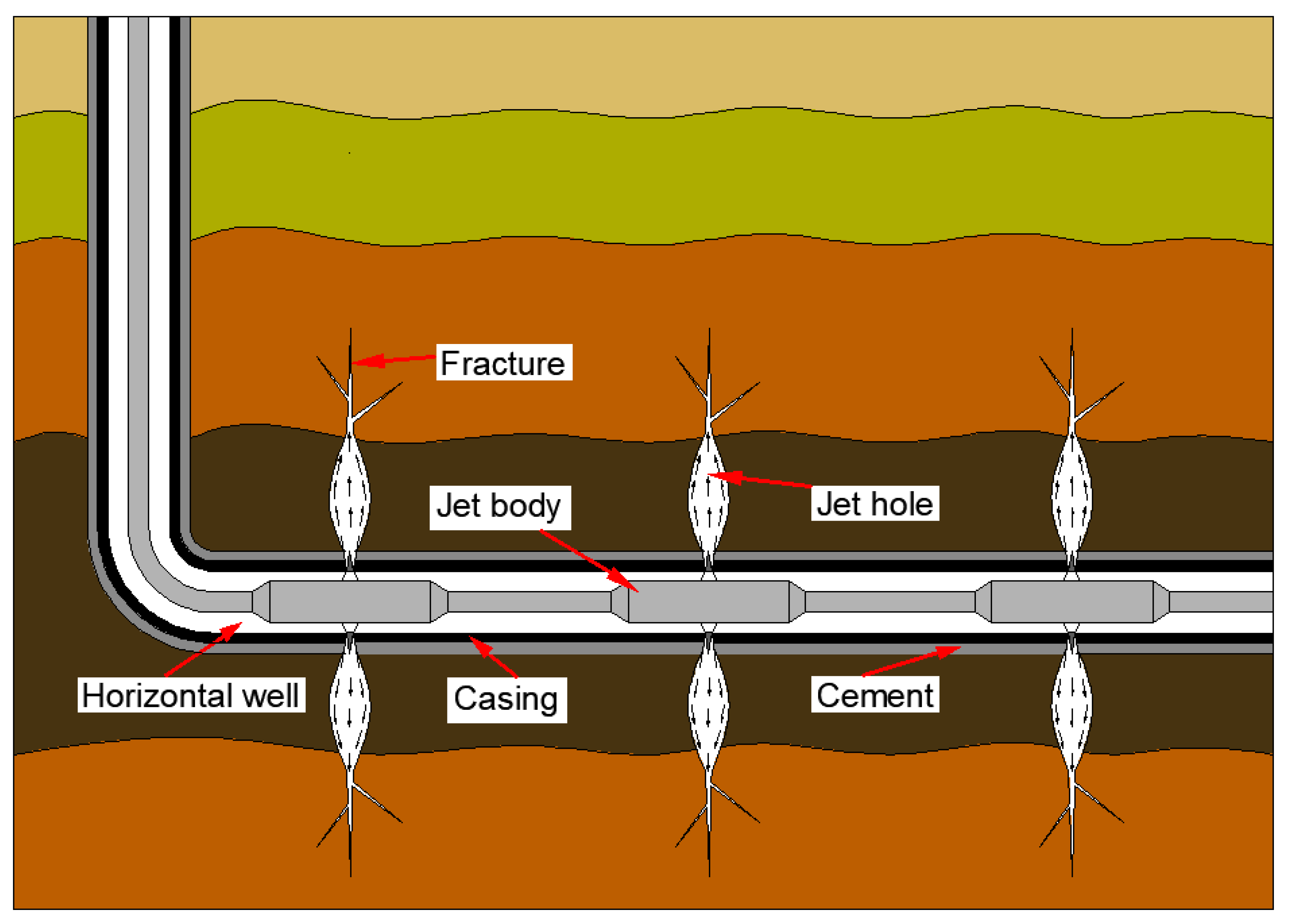

:1. Introduction

2. Experimental Materials and Methods

2.1. Specimen Preparation

2.2. Experimental Apparatuses

2.3. Experimental Procedure

3. Experimental Results

3.1. Characteristics of Fracture Propagation

3.1.1. Characteristics of Main Fractures

3.1.2. Analysis of Fracture Branches

3.1.3. Tortuosity of the Longitudinal Fractures

3.1.4. Morphologies of the Main Fracture Surfaces

3.2. Analysis of Strain Response

3.2.1. The Strain Differences between Two Layers

3.2.2. Characteristics of Strain Curve

4. Discussion

4.1. Formation Mechanism of the Main Fractures

4.2. Effect of Rock Mechanical Properties on Fracture Propagation

4.3. Fracture Propagation Behavior in Hard and Soft Layered Rocks

5. Conclusions

- (1)

- Three types of main fractures are observed, and their formation mechanism has been discussed. The longitudinal fractures and oblique fractures were caused by the pressurization of SC-CO2 in perforation. The transverse fractures were caused by the combined effect of the strong heterogeneity at the transition areas of hard-soft and soft-hard rocks, the stress concentration on the tip of perforation due to discontinuity of structure, and the stagnation pressure pressing on the tip of perforation.

- (2)

- The SC-CO2 jet fracturing can be divided into two stages, the pressurization of the perforation pressure stage and fracture propagation stage, and the fractures initiation and propagation is intermittent. Through the strain curve, the fracturing time can be obtained, which can evaluate the rate of jet fracturing, and the rate of jet fracturing can be enhanced by increasing injection rate.

- (3)

- The rock mechanical properties have great impact on fracture propagation. The rock strength can affect the number and complexity of fractures created and the fracturing rate. When the rock strength is low, more fractures can be created, and the fracturing rate is high. The Young’s modulus of rock has an effect on fracture propagation length.

- (4)

- The fractures mainly develop near the perforation and are difficult to propagate to another layer with different mechanical properties, and the fractures are prone to develop in the transition areas of hard-soft rocks and soft-hard rocks due to the stress concentration caused by the strong heterogeneity of transition areas. When the perforation position is at the soft layer, complicated fracture networks can be created, which is conductive to the selection of perforation location in the actual field.

6. Limitations and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Deng, B.Z.; Yin, G.Z.; Zhang, D.M.; Li, M.H.; Liu, Y.B.; Lu, J. Experimental investigation of fracture propagation induced by carbon dioxide and water in coal seam reservoirs. Powder Technol. 2018, 338, 847–856. [Google Scholar] [CrossRef]

- Liu, H.; Wang, F.; Zhang, J.; Meng, S.W.; Duan, Y.W. Fracturing with carbon dioxide: Application status and development trend. Pet. Explor. Dev. 2014, 41, 513–519. [Google Scholar] [CrossRef]

- McGlade, C.; Speirs, J.; Sorrell, S. Unconventional gas—A review of regional and global resource estimates. Energy 2013, 55, 571–584. [Google Scholar] [CrossRef]

- Guo, J.C.; Luo, B.; Lu, C.; Lai, J.; Ren, J.C. Numerical investigation of hydraulic fracture propagation in a layered reservoir using the cohesive zone method. Eng. Fract. Mech. 2017, 186, 195–207. [Google Scholar] [CrossRef]

- Fu, W.; Ames, B.C.; Bunger, A.P.; Savitski, A.A. Impact of Partially Cemented and Non-persistent Natural Fractures on Hydraulic Fracture Propagation. Rock Mech. Rock Eng. 2016, 49, 4519–4526. [Google Scholar] [CrossRef]

- Surjaatmadja, J.B.; Grundmann, S.R.; McDaniel, B.; Deeg, W.F.J.; Brumley, J.L.; Swor, L.C. Hydrajet Fracturing: An Effective Method for Placing Many Fractures in Openhole Horizontal Wells. In Proceedings of the SPE International Oil and Gas Conference and Exhibition in China, Beijing, China, 2–6 November 1998; p. 6. [Google Scholar]

- Li, G.S.; Huang, Z.W.; Tian, S.C.; Shen, Z.H. Research and application of water jet technology in well completion and stimulation in China. Pet. Sci. 2010, 7, 239–244. [Google Scholar] [CrossRef]

- Sheng, M.; Li, G.; Huang, Z.; Tian, S.; Qu, H. Experimental study on hydraulic isolation mechanism during hydra-jet fracturing. Exp. Therm. Fluid Sci. 2013, 44, 722–726. [Google Scholar] [CrossRef]

- Qu, H.; Li, G.; Huang, Z.; Tian, S. The Boosting Mechanism and Effects in Cavity During Hydrajet Fracturing Process. Pet. Sci. Technol. 2010, 28, 1345–1350. [Google Scholar] [CrossRef]

- Middleton, R.S.; Carey, J.W.; Currier, R.P.; Hyman, J.D.; Kang, Q.J.; Karra, S.; Jimenez-Martinez, J.; Porter, M.L.; Viswanathan, H.S. Shale gas and non-aqueous fracturing fluids: Opportunities and challenges for supercritical CO2. Appl. Energy 2015, 147, 500–509. [Google Scholar] [CrossRef]

- Middleton, R.; Viswanathan, H.; Currier, R.; Gupta, R. CO2 as a fracturing fluid: Potential for commercial-scale shale gas production and CO2 sequestration. Energy Procedia 2014, 63, 7780–7784. [Google Scholar] [CrossRef] [Green Version]

- Cai, C.; Kang, Y.; Wang, X.C.; Hu, Y.; Chen, H.; Yuan, X.H.; Cai, Y. Mechanism of supercritical carbon dioxide (SC-CO2) hydro-jet fracturing. J. CO2 Util. 2018, 26, 575–587. [Google Scholar] [CrossRef]

- Zhou, J.; Liu, G.; Jiang, Y.; Xian, X.; Liu, Q.; Zhang, D.; Tan, J. Supercritical carbon dioxide fracturing in shale and the coupled effects on the permeability of fractured shale: An experimental study. J. Nat. Gas Sci. Eng. 2016, 36, 369–377. [Google Scholar] [CrossRef]

- Jiang, Y.D.; Qin, C.; Kang, Z.P.; Zhou, J.P.; Li, Y.; Liu, H.; Song, X. Experimental study of supercritical CO2 fracturing on initiation pressure and fracture propagation in shale under different triaxial stress conditions. J. Nat. Gas Sci. Eng. 2018, 55, 382–394. [Google Scholar] [CrossRef]

- Zou, Y.S.; Li, N.; Ma, X.F.; Zhang, S.C.; Li, S. Experimental study on the growth behavior of supercritical CO2-induced fractures in a layered tight sandstone formation. J. Nat. Gas Sci. Eng. 2018, 49, 145–156. [Google Scholar] [CrossRef]

- Gupta, A.P.; Gupta, A.; Langlinais, J. Feasibility of Supercritical Carbon Dioxide as a Drilling Fluid for Deep Underbalanced Drilling Operation. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 9–12 October 2005; p. 10. [Google Scholar]

- Zhang, H.; Liu, Y.; Tang, J.; Liu, W.; Chen, C. Investigation on the fluctuation characteristics and its influence on impact force of supercritical carbon dioxide jet. Energy 2022, 253, 124125. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, X.; Wei, J.; Zhang, H. Application of supercritical carbon dioxide jet: A parametric study using numerical simulation model. J. Pet. Sci. Eng. 2021, 201, 108422. [Google Scholar] [CrossRef]

- Wang, H.Z.; Li, G.S.; He, Z.G.; Tian, S.C.; Wang, M.; Yang, B.; Lu, Q.; Weng, L.Z. Experimental investigation on abrasive supercritical CO2 jet perforation. J. CO2 Util. 2018, 28, 59–65. [Google Scholar] [CrossRef]

- Abedini, A.; Torabi, F. On the CO2 storage potential of cyclic CO2 injection process for enhanced oil recovery. Fuel 2014, 124, 14–27. [Google Scholar] [CrossRef]

- He, Z.G.; Tian, S.C.; Li, G.S.; Wang, H.Z.; Shen, Z.H.; Xu, Z.M. The pressurization effect of jet fracturing using supercritical carbon dioxide. J. Nat. Gas Sci. Eng. 2015, 27, 842–851. [Google Scholar] [CrossRef]

- Tian, S.; He, Z.; Li, G.; Wang, H.; Shen, Z.; Liu, Q. Influences of ambient pressure and nozzle-to-target distance on SC-CO2 jet impingement and perforation. J. Nat. Gas Sci. Eng. 2016, 29, 232–242. [Google Scholar] [CrossRef]

- Hu, Y.; Liu, Y.W.; Cai, C.; Kang, Y.; Wang, X.C.; Huang, M.; Chen, F. Fracture Initiation of an Inhomogeneous Shale Rock under a Pressurized Supercritical CO2 Jet. Appl. Sci. 2017, 7, 1093. [Google Scholar] [CrossRef]

- Liu, J.; Hu, Y.; Kang, Y.; Chen, H.; Liu, Y.; Liu, F.; Liu, Z. Experimental study on fracture propagation induced by supercritical CO2 jet fracturing in artificial samples with prefabricated bedding planes. J. Nat. Gas Sci. Eng. 2019, 72, 103037. [Google Scholar] [CrossRef]

- Bennour, Z.; Watanabe, S.; Chen, Y.; Ishida, T.; Akai, T. Evaluation of stimulated reservoir volume in laboratory hydraulic fracturing with oil, water and liquid carbon dioxide under microscopy using the fluorescence method. Geomech. Geophys. Geo-Energy Geo-Resour. 2017, 4, 39–50. [Google Scholar] [CrossRef]

- Chen, Y.Q.; Nagaya, Y.; Ishida, T. Observations of Fractures Induced by Hydraulic Fracturing in Anisotropic Granite. Rock Mech. Rock Eng. 2015, 48, 1455–1461. [Google Scholar] [CrossRef]

- Zhang, X.W.; Lu, Y.Y.; Tang, J.R.; Zhou, Z.; Liao, Y. Experimental study on fracture initiation and propagation in shale using supercritical carbon dioxide fracturing. Fuel 2017, 190, 370–378. [Google Scholar] [CrossRef]

- Tan, P.; Jin, Y.; Han, K.; Hou, B.; Chen, M.; Guo, X.F.; Gao, J. Analysis of hydraulic fracture initiation and vertical propagation behavior in laminated shale formation. Fuel 2017, 206, 482–493. [Google Scholar] [CrossRef]

- Wang, L.; Yao, B.W.; Xie, H.J.; Winterfeld, P.H.; Kneafsey, T.J.; Yin, X.L.; Wu, Y.S. CO2 injection-induced fracturing in naturally fractured shale rocks. Energy 2017, 139, 1094–1110. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, Y.; Kang, Y. The Propagation of Hydraulic Fractures in a Natural Fracture Network: A Numerical Study and Its Implications. Appl. Sci. 2022, 12, 4738. [Google Scholar] [CrossRef]

- Zhang, Y.S.; Zhang, J.C.; Yuan, B.; Yin, S.X. In-situ stresses controlling hydraulic fracture propagation and fracture breakdown pressure. J. Pet. Sci. Eng. 2018, 164, 164–173. [Google Scholar] [CrossRef]

- Zhou, J.; Chen, M.; Jin, Y.; Zhang, G.Q. Analysis of fracture propagation behavior and fracture geometry using a tri-axial fracturing system in naturally fractured reservoirs. Int. J. Rock Mech. Min. Sci. 2008, 45, 1143–1152. [Google Scholar] [CrossRef]

- Hou, B.; Chen, M.; Li, Z.M.; Wang, Y.H.; Diao, C. Propagation area evaluation of hydraulic fracture networks in shale gas reservoirs. Pet. Explor. Dev. 2014, 41, 833–838. [Google Scholar] [CrossRef]

- Heng, S.; Liu, X.; Li, X.Z.; Zhang, X.D.; Yang, C.H. Experimental and numerical study on the non-planar propagation of hydraulic fractures in shale. J. Pet. Sci. Eng. 2019, 179, 410–426. [Google Scholar] [CrossRef]

- Warpinski, N.R.; Teufel, L.W. Influence of Geologic Discontinuities on Hydraulic Fracture Propagation (includes associated papers 17011 and 17074). J. Pet. Technol. 2013, 39, 209–220. [Google Scholar] [CrossRef]

- Cheng, W.; Jin, Y.; Chen, M.A.; Xu, T.; Zhang, Y.K.; Diao, C. A criterion for identifying hydraulic fractures crossing natural fractures in 3D space. Pet. Explor. Dev. 2014, 41, 371–376. [Google Scholar] [CrossRef]

- He, J.M.; Afolagboye, L.O.; Lin, C.; Wan, X.L. An Experimental Investigation of Hydraulic Fracturing in Shale Considering Anisotropy and Using Freshwater and Supercritical CO2. Energies 2018, 11, 557. [Google Scholar] [CrossRef]

- Wang, Z.; Pan, C.; Hu, Y.; Zeng, D.; Huang, M.; Jiang, Y. High-quality ground tire rubber production from scrap tires by using supercritical carbon dioxide jet pulverization assisted with diphenyl disulfide. Powder Technol. 2022, 398, 117061. [Google Scholar] [CrossRef]

- Cai, C.; Wang, X.C.; Yuan, X.H.; Kang, Y.; Wang, Z.F.; Huang, M.; Chen, H. Experimental investigation on perforation of shale with ultra-high pressure abrasive water jet: Shape, mechanism and sensitivity. J. Nat. Gas Sci. Eng. 2019, 67, 196–213. [Google Scholar] [CrossRef]

- Cai, C.; Kang, Y.; Wang, X.C.; Hu, Y.; Huang, M.; Liu, Y.W.; Liu, J.W.; Chen, H.; Li, X.H. Experimental study on shale fracturing enhancement by using multi-times pulse supercritical carbon dioxide (SC-CO2) jet. J. Pet. Sci. Eng. 2019, 178, 948–963. [Google Scholar] [CrossRef]

- Zhou, D.W.; Zhang, G.Q.; Wang, Y.Y.; Xing, Y.K. Experimental investigation on fracture propagation modes in supercritical carbon dioxide fracturing using acoustic emission monitoring. Int. J. Rock Mech. Min. Sci. 2018, 110, 111–119. [Google Scholar] [CrossRef]

- Jia, Y.Z.; Lu, Y.Y.; Elsworth, D.; Fang, Y.; Tang, J.R. Surface characteristics and permeability enhancement of shale fractures due to water and supercritical carbon dioxide fracturing. J. Pet. Sci. Eng. 2018, 165, 284–297. [Google Scholar] [CrossRef]

- Zhao, Z.H.; Li, X.; He, J.M.; Mao, T.Q.; Zheng, B.; Li, G.F. A laboratory investigation of fracture propagation induced by supercritical carbon dioxide fracturing in continental shale with interbeds. J. Pet. Sci. Eng. 2018, 166, 739–746. [Google Scholar] [CrossRef]

- Liang, Y.P.; Cheng, Y.H.; Zou, Q.L.; Wang, W.D.; Ma, Y.K.; Li, Q.G. Response characteristics of coal subjected to hydraulic fracturing: An evaluation based on real-time monitoring of borehole strain and acoustic emission. J. Nat. Gas Sci. Eng. 2017, 38, 402–411. [Google Scholar] [CrossRef]

- Blair, S.C.; Cook, N.G.W. Analysis of compressive fracture in rock using statistical techniques: Part I. A non-linear rule-based model. Int. J. Rock Mech. Min. Sci. 1998, 35, 837–848. [Google Scholar] [CrossRef]

- Nasehi, M.J.; Mortazavi, A. Effects of in-situ stress regime and intact rock strength parameters on the hydraulic fracturing. J. Pet. Sci. Eng. 2013, 108, 211–221. [Google Scholar] [CrossRef]

- Tang, C.A.; Liu, H.; Lee, P.K.K.; Tsui, Y.; Tham, L.G. Numerical studies of the influence of microstructure on rock failure in uniaxial compression—Part I: Effect of heterogeneity. Int. J. Rock Mech. Min. Sci. 2000, 37, 555–569. [Google Scholar] [CrossRef]

| Layer | Natural Siliceous | Cement | Clay Minerals |

|---|---|---|---|

| Hard | 56.7% | 28.3% | 15% |

| Soft | 68% | 17% | 15% |

| Layer | Uniaxial Compressive Strength/MPa | Shear Strength/MPa | Elastic Modulus/GPa | Poisson’s Ratio |

|---|---|---|---|---|

| Hard | 25.52 | 5.873 | 5.16 | 0.17 |

| Soft | 11.54 | 2.18 | 3.58 | 0.14 |

| Group | Upper Layer | Lower Layer | Specimen NO. | Injection Pressure/MPa |

|---|---|---|---|---|

| A | Hard | Hard | A1 | 35 |

| A2 | 30 | |||

| A3 | 25 | |||

| B | Soft | Soft | B1 | 25 |

| B2 | 30 | |||

| B3 | 35 | |||

| C | Hard | Soft | C1-1 | 25 |

| C1-2 | 25 | |||

| C2-1 | 30 | |||

| C2-2 | 30 | |||

| C3-1 | 35 | |||

| C3-2 | 35 | |||

| D | Soft | Hard | D1-1 | 25 |

| D1-2 | 25 | |||

| D2-1 | 30 | |||

| D2-2 | 30 | |||

| D3-1 | 35 | |||

| D3-2 | 35 |

| Group | Specimen NO. | Main Fracture Type | Fracture Branch Type | Typical Result |

|---|---|---|---|---|

| A | A1 | Two type-A fractures cutting through the specimen completely | None |  |

| A2 | None | None | ||

| A3 | Two type-A fractures cutting through the specimen completely | None | ||

| B | B1 | Four type-A fractures and three type-C fractures | None |  |

| B2 | Four type-A fractures and two type-C fractures | Type-Ⅰ and type-Ⅱ | ||

| B3 | Three type-A fractures and one type-C fracture | Type-Ⅰ and type-Ⅱ | ||

| C | C1-1 | None | None |  |

| C1-2 | None | None | ||

| C2-1 | Type-B fracture | None | ||

| C2-2 | None | None | ||

| C3-1 | Type-B fracture | None | ||

| C3-2 | Type-B fracture | Type-Ⅰ | ||

| D | D1-1 | Three type-A fractures, one type-B fracture and one type-C fracture | Type-Ⅱ |  |

| D1-2 | Three type-A fractures, and one type-B fracture | Type-Ⅱ and type-Ⅲ | ||

| D2-1 | Two type-A fractures, and one type-B fracture | None | ||

| D2-2 | Two type-A fractures, and one type-B fracture | None | ||

| D3-1 | Four type-A fractures, one type-B fracture and one type-C fracture | Type-Ⅱ and type-Ⅲ | ||

| D3-2 | Three type-A fractures extended to the middle, and one type-B fracture | Type-Ⅱ |

| Group | Specimen NO. | Main Fracture Type | AR (/) | Overall AR (/) |

|---|---|---|---|---|

| A | A1 | longitudinal fracture | 1.067 | 1.067 |

| A3 | longitudinal fracture | 1.070 | 1.070 | |

| B | B1 | longitudinal fracture | 1.151 | 1.162 |

| oblique fracture | 1.170 | |||

| B2 | longitudinal fracture | 1.192 | 1.239 | |

| oblique fracture | 1.332 | |||

| B3 | longitudinal fracture | 1.181 | 1.188 | |

| oblique fracture | 1.203 | |||

| C | C2-1 | transverse fracture | 1.073 | 1.073 |

| C3-1 | transverse fracture | 1.082 | 1.082 | |

| C3-2 | transverse fracture | 1.092 | 1.092 | |

| D | D1-2 | longitudinal fracture | 1.098 | 1.087 |

| transverse fracture | 1.071 | |||

| D2-2 | longitudinal fracture | 1.132 | 1.089 | |

| transverse fracture | 1.054 | |||

| D3-2 | longitudinal fracture | 1.142 | 1.096 | |

| transverse fracture | 1.066 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, F.; Hu, Y.; Liu, J. Propagation Characteristics of Fractures Induced by Supercritical Carbon Dioxide Jet in Hard and Soft Layered Rocks. Appl. Sci. 2022, 12, 9013. https://doi.org/10.3390/app12189013

Liu F, Hu Y, Liu J. Propagation Characteristics of Fractures Induced by Supercritical Carbon Dioxide Jet in Hard and Soft Layered Rocks. Applied Sciences. 2022; 12(18):9013. https://doi.org/10.3390/app12189013

Chicago/Turabian StyleLiu, Feng, Yi Hu, and Jiawei Liu. 2022. "Propagation Characteristics of Fractures Induced by Supercritical Carbon Dioxide Jet in Hard and Soft Layered Rocks" Applied Sciences 12, no. 18: 9013. https://doi.org/10.3390/app12189013

APA StyleLiu, F., Hu, Y., & Liu, J. (2022). Propagation Characteristics of Fractures Induced by Supercritical Carbon Dioxide Jet in Hard and Soft Layered Rocks. Applied Sciences, 12(18), 9013. https://doi.org/10.3390/app12189013