Fine Characterization Method of Concrete Internal Cracks Based on Borehole Optical Imaging

Abstract

:1. Introduction

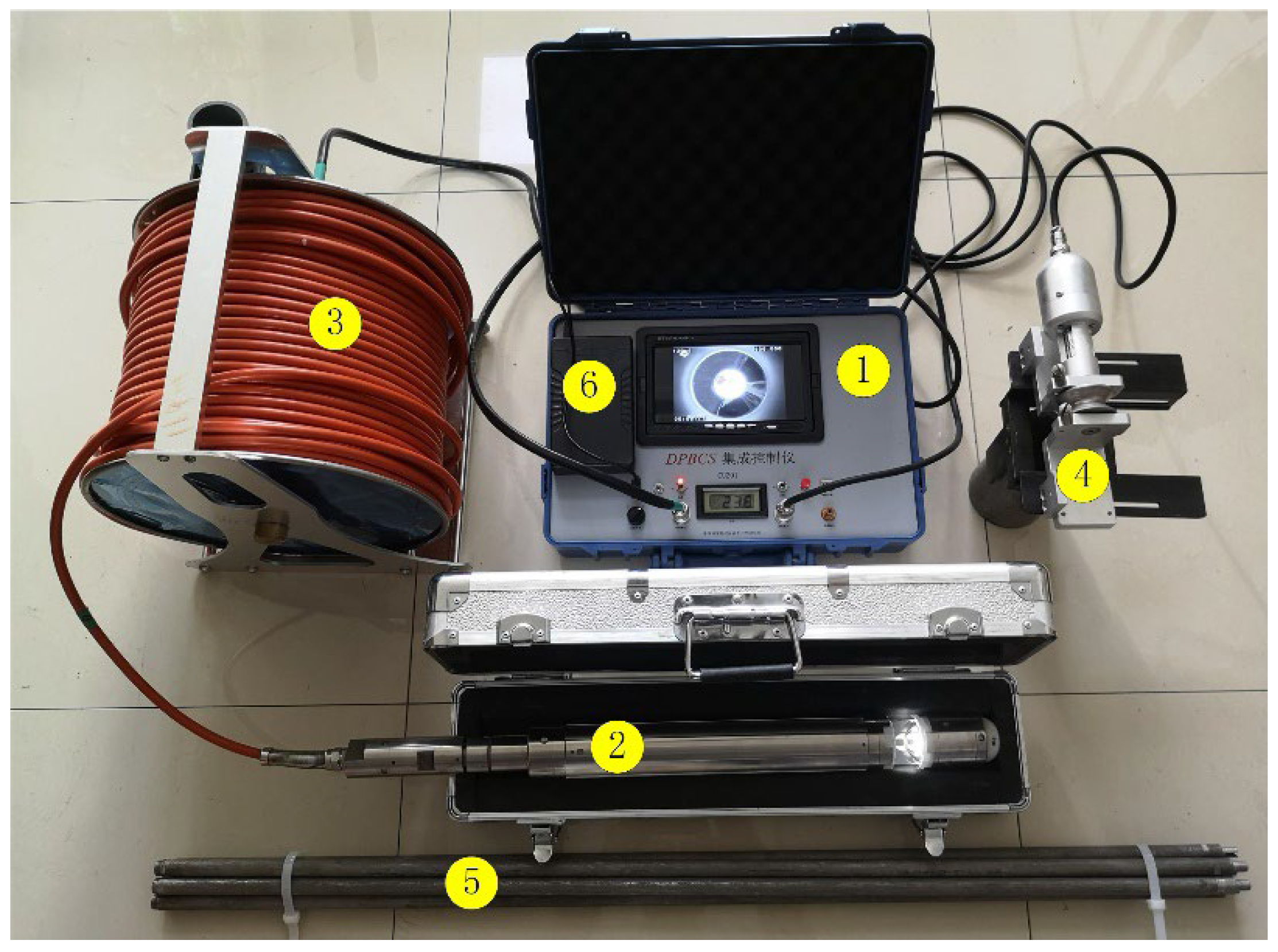

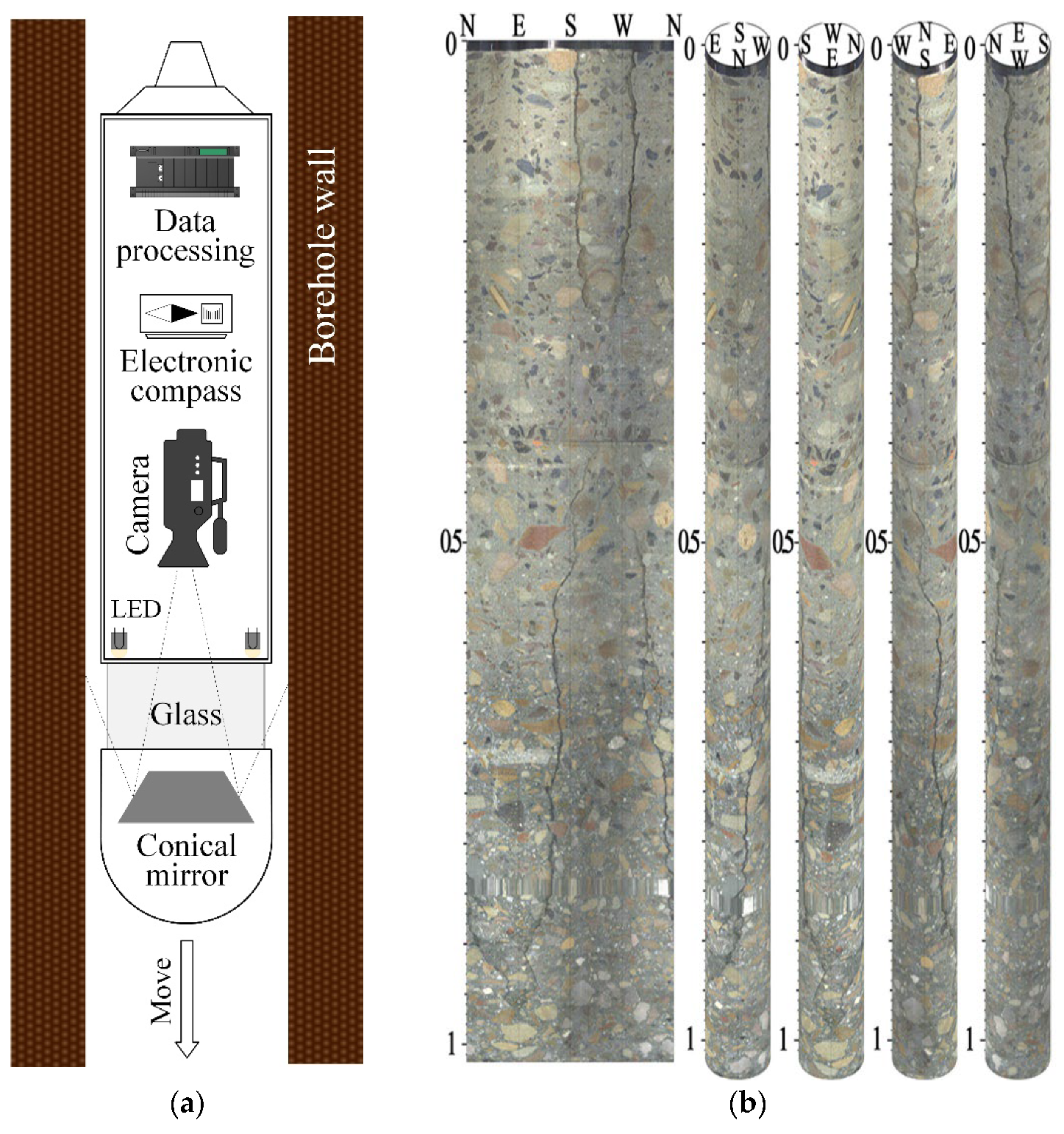

2. Crack Image Acquisition

2.1. Borehole Camera Technology

2.2. Measurement Accuracy Analysis

2.3. Measuring Project

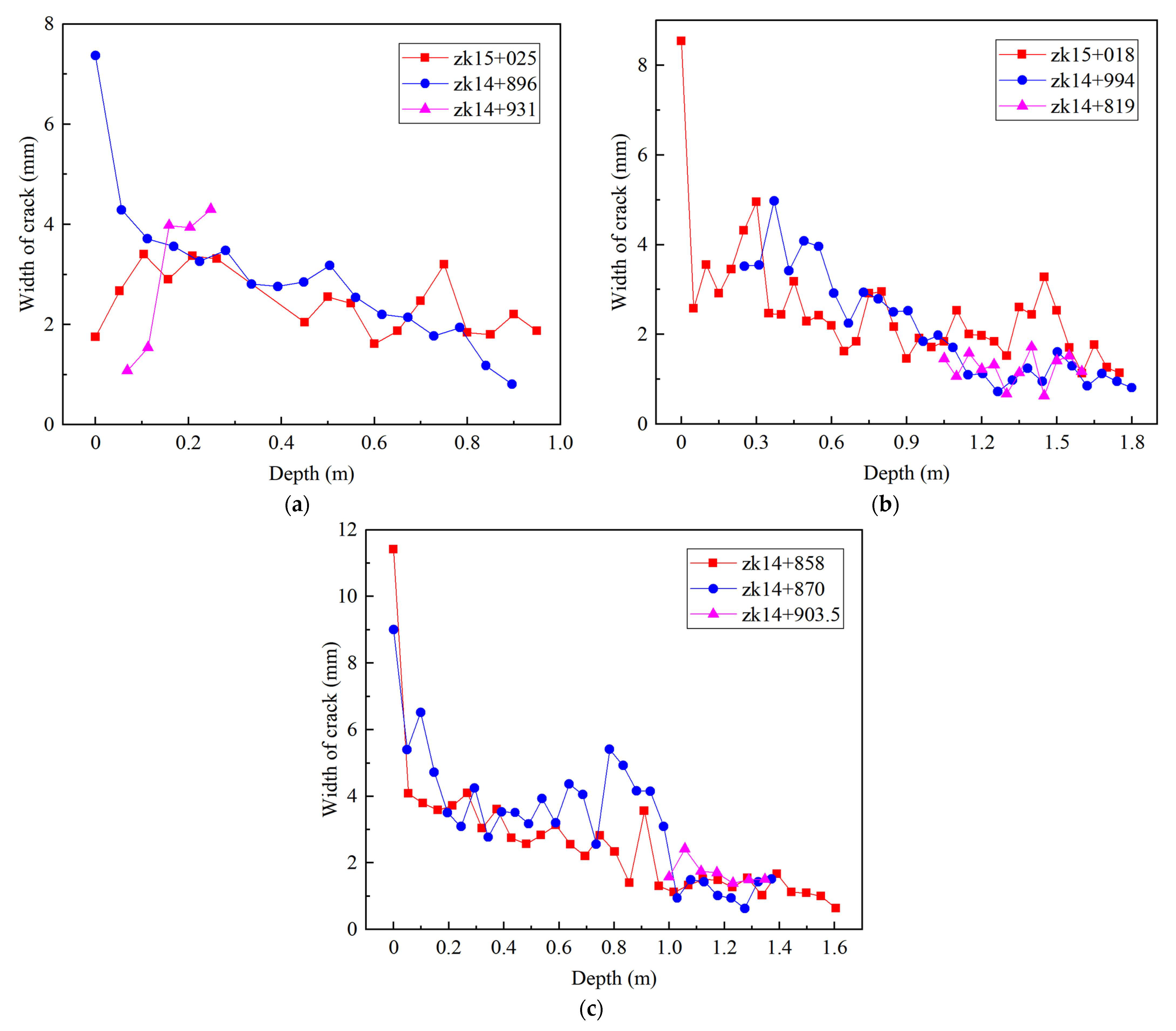

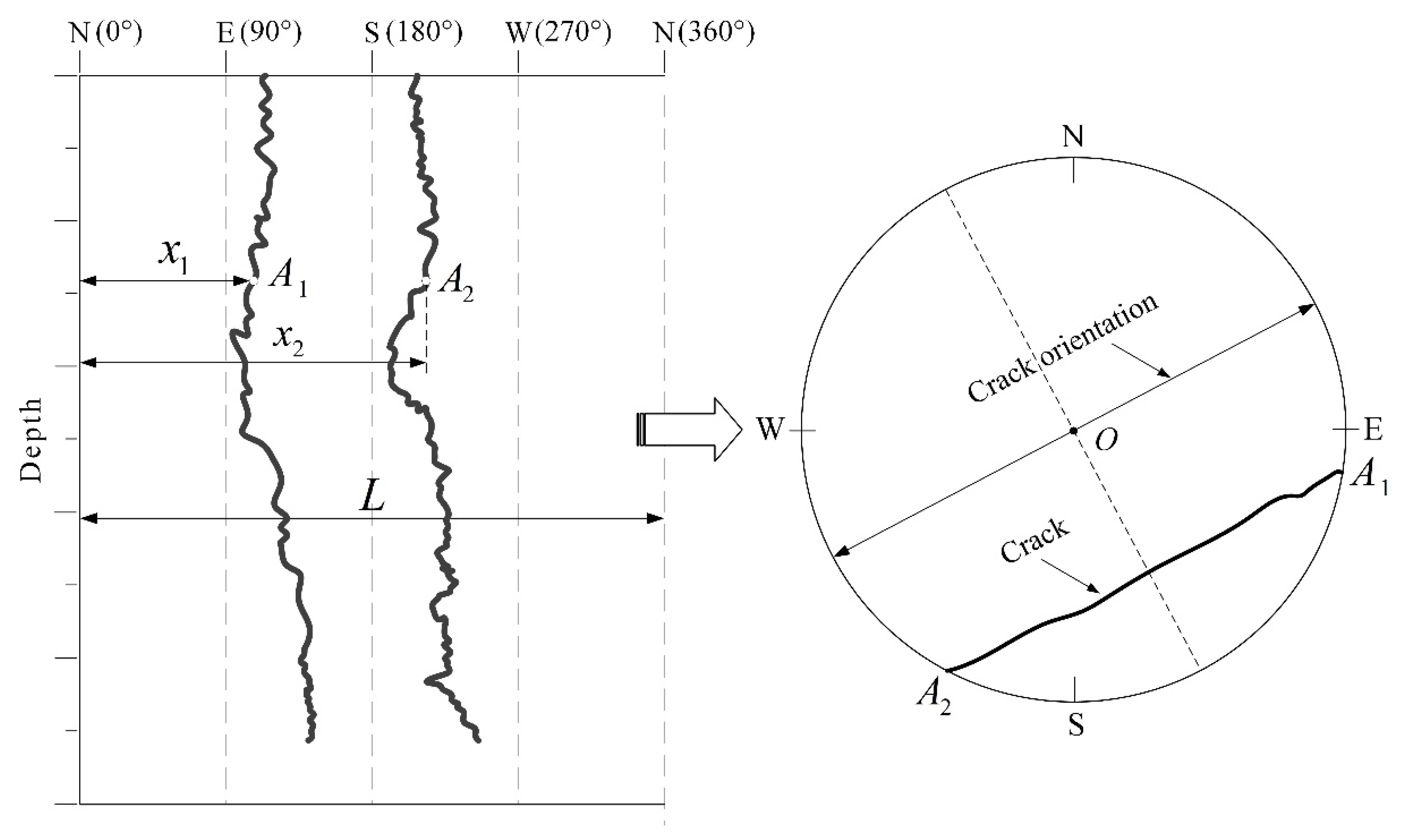

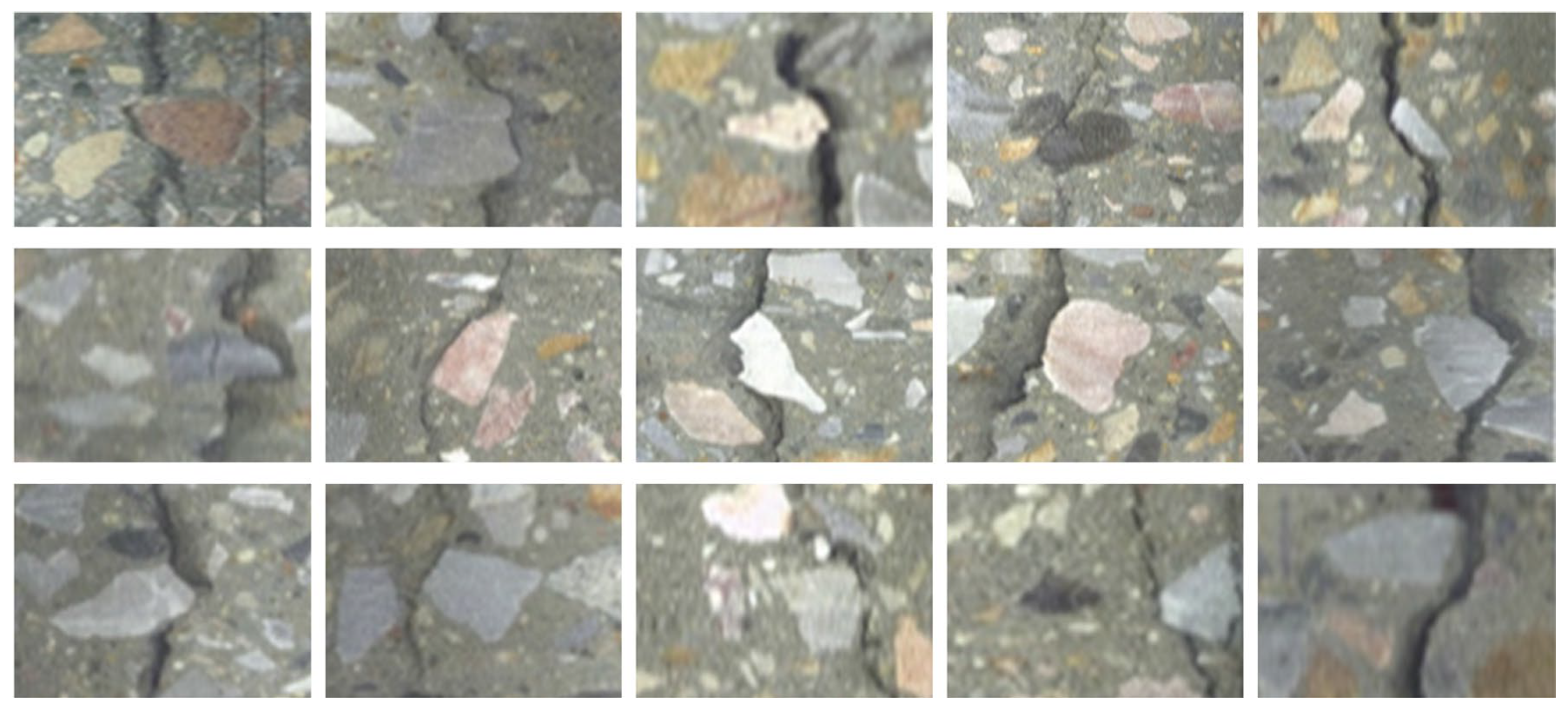

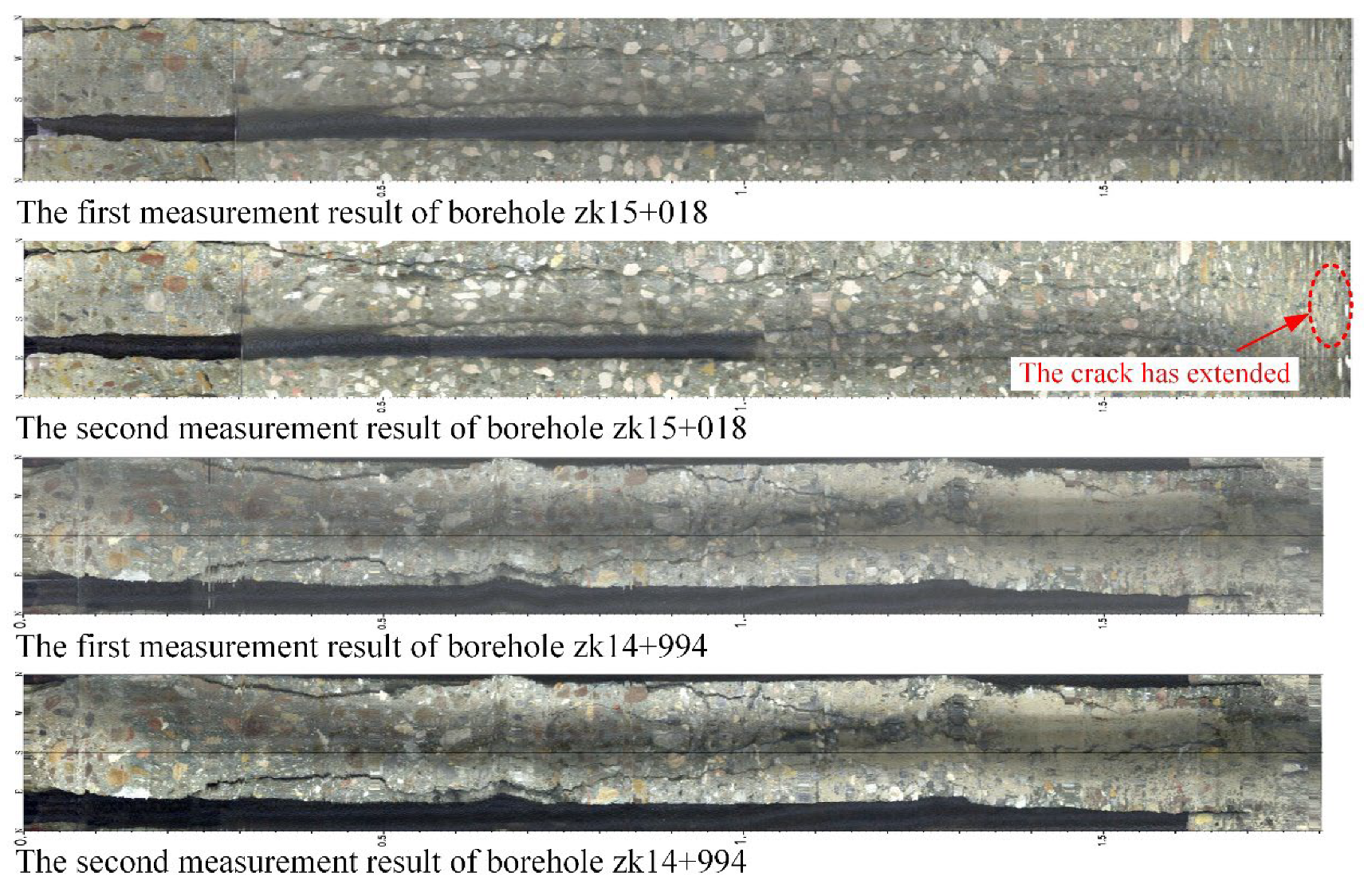

3. Morphological Characteristics Analysis of Cracks

3.1. Analysis of Width and Depth

3.2. Analysis of Crack Orientation

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Damasceno, I.I.R.; Ferreira, M.D.P.; De Oliveira, D.R.C. RC beams with steel fibers under impact loads. Acta Sci. Technol. 2013, 36, 23. [Google Scholar] [CrossRef]

- Tarefder, R.A.; Ahmad, M. Evaluating the Relationship between Permeability and Moisture Damage of Asphalt Concrete Pavements. J. Mater. Civ. Eng. 2015, 27, 04014172. [Google Scholar] [CrossRef]

- Soumya; Pandey, A.D.; Das, R.; Mahesh, M.J.; Anvesh, S.; Saini, P. Structural analysis of a historical dam. Procedia Eng. 2016, 144, 140–147. [Google Scholar] [CrossRef]

- Cui, X.; Wang, Q.; Dai, J.; Zhang, R.; Li, S. Intelligent recognition of erosion damage to concrete based on improved YOLO-v3. Mater. Lett. 2021, 302, 130363. [Google Scholar] [CrossRef]

- Galouei, M.; Fakhimi, A. Size effect, material ductility and shape of fracture process zone in quasi-brittle materials. Comput. Geotech. 2015, 65, 126–135. [Google Scholar] [CrossRef]

- Wang, H.L.; Dai, J.G.; Sun, X.Y.; Xiao, Y.; Zhang, X.L. Characteristics of concrete cracks and their influence on chloride penetration. Constr. Build. Mater. 2016, 107, 216–225. [Google Scholar] [CrossRef]

- Jiang, W.; Zhou, G.; Wang, C.; Xue, Y.; Niu, C. Synthesis and self-healing properties of composite microcapsule based on sodium alginate/melamine-phenol–formaldehyde resin. Constr. Build. Mater. 2020, 271, 121541. [Google Scholar] [CrossRef]

- Zhou, C.; Li, K.; Pang, X. Geometry of crack network and its impact on transport properties of concrete. Cem. Concr. Res. 2012, 42, 1261–1272. [Google Scholar] [CrossRef]

- Li, M.; Chen, H.; Liu, L.; Lin, J.; Ullah, K. Permeability of concrete considering the synergetic effect of crack’s shape- and size-polydispersities on the percolation. Constr. Build. Mater. 2021, 315, 125684. [Google Scholar] [CrossRef]

- Li, K.; Li, L. Crack-altered durability properties and performance of structural concretes. Cem. Concr. Res. 2019, 124, 105811. [Google Scholar] [CrossRef]

- Fernandes, F.M.; Pais, J.C. Laboratory observation of cracks in road pavements with GPR. Constr. Build. Mater. 2017, 154, 1130–1138. [Google Scholar] [CrossRef]

- Tong, Z.; Yuan, D.; Gao, J.; Wei, Y.; Dou, H. Pavement-distress detection using ground-penetrating radar and network in networks. Constr. Build. Mater. 2019, 233, 117352. [Google Scholar] [CrossRef]

- Hong, S.; Chen, D.; Dong, B. Numerical simulation and mechanism analysis of GPR-based reinforcement corrosion detection. Constr. Build. Mater. 2021, 317, 125913. [Google Scholar] [CrossRef]

- Choi, P.; Kim, D.-H.; Lee, B.-H.; Won, M.C. Application of ultrasonic shear-wave tomography to identify horizontal crack or delamination in concrete pavement and bridge. Constr. Build. Mater. 2016, 121, 81–91. [Google Scholar] [CrossRef]

- Cook, K.; Garg, N.; Singh, A.; Flynn, M. Detection of Delamination in the HMA Layer of Runway Pavement Structure Using Asphalt Strain Gauges. J. Transp. Eng. 2016, 142, 04016047. [Google Scholar] [CrossRef]

- Grabke, S.; Clauß, F.; Bletzinger, K.-U.; Ahrens, M.A.; Mark, P.; Wüchner, R. Damage Detection at a Reinforced Concrete Specimen with Coda Wave Interferometry. Materials 2021, 14, 5013. [Google Scholar] [CrossRef]

- Xu, X.; Zeng, Q.; Li, D.; Wu, J.; Wu, X.; Shen, J. GPR detection of several common subsurface voids inside dikes and dams. Eng. Geol. 2010, 111, 31–42. [Google Scholar] [CrossRef]

- Song, X.; Xiang, D.; Zhou, K.; Su, Y. Fast Prescreening for GPR Antipersonnel Mine Detection via Go Decomposition. IEEE Geosci. Remote Sens. Lett. 2018, 16, 15–19. [Google Scholar] [CrossRef]

- Tsai, Y.-C.; Kaul, V.; Mersereau, R.M. Critical Assessment of Pavement Distress Segmentation Methods. J. Transp. Eng. 2010, 136, 11–19. [Google Scholar] [CrossRef]

- Asadollahi, A.; Khazanovich, L. Numerical investigation of the effect of heterogeneity on the attenuation of shear waves in concrete. Ultrasonics 2018, 91, 34–44. [Google Scholar] [CrossRef]

- Chekroun, M.; Le Marrec, L.; Abraham, O.; Durand, O.; Villain, G. Analysis of coherent surface wave dispersion and attenu-ation for non-destructive testing of concrete. Ultrasonics 2009, 49, 743–751. [Google Scholar] [CrossRef] [PubMed]

- Chapeleau, X.; Blanc, J.; Hornych, P.; Gautier, J.L.; Carroget, J. Assessment of cracks detection in pavement by a distributed fber optic sensing technology. J. Civil. Struct. Health Monit. 2017, 7, 459–470. [Google Scholar] [CrossRef]

- De Maeijer, P.K.; Luyckx, G.; Vuye, C.; Voet, E.; Bergh, W.V.D.; Vanlanduit, S.; Braspenninckx, J.; Stevens, N.; De Wolf, J. Fiber Optics Sensors in Asphalt Pavement: State-of-the-Art Review. Infrastructures 2019, 4, 36. [Google Scholar] [CrossRef]

- Zheng, D.; Tan, S.; Li, X.; Cai, H. Research on the Infrared Thermographic Detection of Concrete under Solar Heating. Adv. Civ. Eng. 2021, 2021, 6692729. [Google Scholar] [CrossRef]

- Sirca, G.F.; Adeli, H. Infrared Thermography for Detecting Defects in Concrete Structures. J. Civ. Eng. Manag. 2018, 24, 508–515. [Google Scholar] [CrossRef]

- Payab, M.; Abbasina, R.; Khanzadi, M. A Brief Review and a New Graph-Based Image Analysis for Concrete Crack Quanti-fication. Arch. Comput. Methods Eng. 2019, 26, 347–365. [Google Scholar] [CrossRef]

- Shan, B.; Zheng, S.; Ou, J. A stereovision-based crack width detection approach for concrete surface assessment. KSCE J. Civ. Eng. 2015, 20, 803–812. [Google Scholar] [CrossRef]

- Zhao, P.; Zsaki, A.M.; Nokken, M.R. Using digital image correlation to evaluate plastic shrinkage cracking in cement-based materials. Constr. Build. Mater. 2018, 182, 108–117. [Google Scholar] [CrossRef]

- Ahmed, M.; Haas, C.T.; Haas, R. Toward low-cost 3D automatic pavement distress surveying: The close range photogrammetry approach. Can. J. Civ. Eng. 2011, 38, 1301–1313. [Google Scholar]

- Ouyang, W.; Xu, B. Pavement cracking measurements using 3D laser-scan images. Meas. Sci. Technol. 2013, 24, 105204. [Google Scholar] [CrossRef]

- Zhang, C.; Elaksher, A. An Unmanned Aerial Vehicle-Based Imaging System for 3D Measurement of Unpaved Road Surface Distresses1. Comput. Civ. Infrastruct. Eng. 2011, 27, 118–129. [Google Scholar] [CrossRef]

- Fu, R.; Xu, H.; Wang, Z.; Shen, L.; Cao, M.; Liu, T.; Novák, D. Enhanced Intelligent Identification of Concrete Cracks Using Multi-Layered Image Preprocessing-Aided Convolutional Neural Networks. Sensors 2020, 20, 2021. [Google Scholar] [CrossRef] [PubMed]

- Zakeri, H.; Nejad, F.M.; Fahimifar, A. Image Based Techniques for Crack Detection, Classification and Quantification in Asphalt Pavement: A Review. Arch. Comput. Methods Eng. 2016, 24, 935–977. [Google Scholar] [CrossRef]

- Kim, H.; Ahn, E.; Shin, M.; Sim, S.-H. Crack and Noncrack Classification from Concrete Surface Images Using Machine Learning. Struct. Health Monit. 2018, 18, 725–738. [Google Scholar] [CrossRef]

- Calderón, L.S.; Bairán, J. Semi-automatic detection and measurement of cracks in concrete elements in digital photos using image processing. Hormig. Acero. 2020, 71, 21–27. [Google Scholar]

- Li, S.; Zhao, X. Automatic crack detection and measurement of concrete structure using convolutional encoder-decoder network. IEEE Access 2020, 8, 134602–134618. [Google Scholar] [CrossRef]

- Bayar, G.; Bilir, T. A novel study for the estimation of crack propagation in concrete using machine learning algorithms. Constr. Build. Mater. 2019, 215, 670–685. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Z. Concrete Surface Crack Recognition Based on Coordinate Attention Neural Networks. Comput. Intell. Neurosci. 2022, 2022, 7454746. [Google Scholar] [CrossRef]

- Li, S.J.; Feng, X.-T.; Wang, C.Y.; Hudson, J.A. ISRM Suggested Method for Rock Fractures Observations Using a Borehole Digital Optical Televiewer. Rock Mech. Rock Eng. 2012, 46, 635–644. [Google Scholar] [CrossRef]

- Zou, X.; Song, H.; Wang, C. A High-Precision Digital Panoramic Borehole Camera System for the Precise Analysis of In Situ Rock Structures. Rock Mech. Rock Eng. 2021, 54, 5945–5952. [Google Scholar] [CrossRef]

- Han, Z.; Wang, C.; Liu, S.; Zhu, H. Research on Connectivity of Deep Ore-Lodes of Borehole based on Digital Borehole Camera. Disaster Adv. 2013, 6, 41–46. [Google Scholar]

- Han, Z.; Wang, C.; Hu, S.; Wang, Y. Application of Borehole Camera Technology in Fractured Rock Mass Investigation of a Submarine Tunnel. J. Coast. Res. 2018, 83, 609–614. [Google Scholar] [CrossRef]

- Zou, X.; Wang, C.; Wang, Y.; Song, H. Morphological Feature Description Method of Structural Surface in Borehole Image during In-Situ Instrumentation. Rock Mech. Rock Eng. 2020, 53, 2947–2956. [Google Scholar] [CrossRef]

- Wang, J.-C.; Wang, C.-Y. Analysis and Evaluation of Coral Reef Integrity Based on Borehole Camera Technology. Mar. Georesources Geotechnol. 2015, 35, 26–33. [Google Scholar] [CrossRef]

- GB/T 50344-2019; Technical Standard for Inspection of Building Structure. National Standard of the People’s Republic of China: Taiwan, China, 2019. Available online: https://www.chinesestandard.net/PDF/English.aspx/GBT50344-2019 (accessed on 27 August 2022).

| Borehole | zk15 + 025 | zk14 + 896 | zk14 + 931 | zk15 + 018 | zk14 + 994 | zk14 + 819 | zk14 + 858 | zk14 + 870 | zk14 + 903.5 |

|---|---|---|---|---|---|---|---|---|---|

| Depth/m | 1.02 | 1.70 | 1.06 | 1.85 | 1.80 | 1.78 | 1.84 | 1.50 | 1.69 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Han, Z.; Wang, Y.; Wang, C.; Wang, J.; Chen, S.; Hu, S. Fine Characterization Method of Concrete Internal Cracks Based on Borehole Optical Imaging. Appl. Sci. 2022, 12, 9080. https://doi.org/10.3390/app12189080

Wang C, Han Z, Wang Y, Wang C, Wang J, Chen S, Hu S. Fine Characterization Method of Concrete Internal Cracks Based on Borehole Optical Imaging. Applied Sciences. 2022; 12(18):9080. https://doi.org/10.3390/app12189080

Chicago/Turabian StyleWang, Chao, Zengqiang Han, Yiteng Wang, Chuanying Wang, Jinchao Wang, Shuangyuan Chen, and Sheng Hu. 2022. "Fine Characterization Method of Concrete Internal Cracks Based on Borehole Optical Imaging" Applied Sciences 12, no. 18: 9080. https://doi.org/10.3390/app12189080