Abstract

This paper examines the degradation trends of polymeric materials during heat conversion and solvolysis processes. The presence of different fractions of polymeric materials, such as PET, PP, SBR, ABS, resin, and tier waste, necessitates the use of different procedures for degradation, transformation, and further elimination from the natural environment. A significant part of the work was devoted to discussing the issue of thermal pyrolysis, taking into account the chemical composition and the possible impact of the process reaction mechanism, the type of raw material used, and the influence of the process temperature on the yields of low, medium, and high boiling products. The issue was extended to the possibility of decomposition of polymers based on the use of catalytic additives for the improvement and efficiency of the process and the structural modification of reactors. The major goal of this investigation of these various options was to generate a spectrum of accessible strategies for polymeric material degradation. The optimal technique depends on the polymer type and predicted final product qualities. Different catalysts, such as ZSM-5 (Zeolite Socony Mobil-5 one of the most efficient catalysts), ZSM-5 with ammonium groups, and ZSM-5 with 10% Ni, improved the efficiency of several heating processes. The final products after polymeric material degradation were determined by the type and conditions of the degradation processes, results of the materials characterisation, and the scale of the reactors utilised.

1. Introduction

The production of various waste fractions is one of the most important variables influencing the advancement of social and economic development. For many years, increases in a country’s gross domestic output were linked to increased garbage generation. As a result, the most developed countries generate the greatest amount of waste. Polymers are a large class of multi-particulate materials whose global output has climbed from 1.5 million tons in the early 1950s to 322 million tons in 2019. During this time, nearly 7.8 billion tons of polymers were manufactured. Global production continued to rise from 2016 to 2019, and the global plastics output totalled 368 million metric tons in 2019. The amounts of thermoplastics, polyurethanes, thermosets, elastomers, adhesives, coatings, sealants, and polypropylene fibres are included in that group of materials. The COVID-19 pandemic in 2020, together with its influence on the industry and the local economy, has exacerbated this situation. Plastics manufacturing has been declining annually for many years. COVID-19’s effects are expected to diminish output by around 0.3 percent in 2020 [1]. The automotive, electrical, and electronics industries generate the most demand for polymeric materials [2]. The main materials used in these industries include polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), styrene–butadiene rubber (SBR), polyethylene terephthalate (PET), and acrylonitrile–butadiene–styrene (ABS) [2,3,4]. Polymeric materials wide use in industry and services is governed by their resistance to degradation by biological and chemical processes, as well as their low manufacturing costs [5]. They are frequently utilised to manufacture household goods, buildings, and packaging [6]. Polymers make up a significant share of plastic materials. However, because each good is defined by its time of use, after which it is transformed into waste that must be removed from the environment, the massive demand for polymeric materials is responsible for the massive amounts of waste that pose a hazardous risk to the environment [7]. This impacts the polymers’ resilience to external conditions, causing problems with their disposal. Soil and groundwater are the parts of the environment most vulnerable to the impact of polymers. As a result, reducing the emission of polymeric waste into the environment through removal and neutralisation is critical [8]. Polymeric materials can be treated by thermal processing in the event of hazardous biomass and biomaterial waste [9,10,11,12,13]. However, the most desirable direction for waste management should be prevention. The design of products, technological processes, and activities that produce the least amounts of byproducts, or if such an opportunity exists, is reuse and recycle. However, there is no way to completely avoid byproduct creation in all processes. As a result, preparation for reuse, recycling, recovery, and disposal are alternate pathways [14].

The processing of polymeric waste by pyrolysis, which, similar to combustion and gasification, is a thermal process, is the principal direction of this alternate route for polymeric waste transformation. The contrasts between the three thermal conversion techniques of organic matter, including plastic waste, are depicted schematically [15]. This was later revised by [16]. Waste management with the smallest environmental impact is a widespread problem and a serious challenge. As a result, it can be carried out in a variety of ways. The primary goals are the disposal and prevention of its formation. Waste prevention is the most desirable, but it is impossible to completely exclude byproduct creation from activities. The two most important methods are landfilling and recycling via various procedures. Landfilling is the most hazardous waste disposal method owing to its high environmental impact due to dust and leachate. As a result, different strategies have been investigated [17]. Some procedures, such as mechanical processing, allow for the preparation of raw materials for the further processing of primary and secondary products. Selected secondary goods are crushed into lower fractions and recycled using chemical processes. Blended fractions can be used to make RDF/SRF (solid-recovered fuels), which can be used as alternative fuels in thermal processes such as gasification, pyrolysis, and combustion. Co-processing allows for the blending of fractions with diverse origins and their applications in thermal processes. Biological recycling is a significant category of approaches whose primary application is in the treatment of wastewater and leachate byproducts. Hazardous sludges can be stabilised to neutral post-materials while producing combustible biogas that can be used for energy in such procedures.

The most desirable advantage of energy processes from an energy standpoint is the possibility of energy recovery [18]. As shown by the data in Table 1, the primary goal of all conceivable technical solutions aimed at the thermochemical conversion of fuel is, in most cases, the recovery of heat and power via co-generation. This yield is possible because of the right way liquids, heat, char, gas, and syngas are changed. Aside from the raw materials used, energy efficiency is heavily reliant on technological solutions for specific operations. As demonstrated by the Institute of Energy and Fuel Processing Technology tests, one of the primary technological problems is, aside from the proper design of a technological process, its transition from laboratory-size to pilot-scale. Then, while executing the solution at full industrial scale, solutions must be adjusted as much as is feasible so that the achieved pilot-scale effects operate and fulfil technological functions with full industrial scale implementation.

Table 1.

Thermal and chemical processing and products in the plastic waste utilisation (ITPE (Institute of Energy and Fuel Processing Technology) and SUT (Silesian University of Technology), elaboration).

As a result, in addition to technical knowledge, the use of numerical tools and methodologies is critical for the precise mapping of chemical phenomena, as well as the appropriate dynamic processes. Post-consumer plastic garbage is now disposed of by either recycling (31.1%) or preparation with energy recovery technologies (41.6%) [4]. A wide range of approaches and methodologies for the transformation of polymeric materials may be applied. Thermal processes, in addition to providing useable energy in the form of heat and calorific combustible gases, can also provide important compounds such as BTEX (benzene, toluene, ethylbenzene, and xylene) through pyrolysis [19]. The article discusses a number of issues related to the disposal and challenges related to the degradation of polymeric materials. The problem of thermal conversion has been developed, taking into account the importance of the application of specific materials to the charge, the reaction mechanism, together with the chemistry and dynamics of the process, among others, with the use of closed-loop and polymer chain degradation reactions. Among the basic processes used to transform plastics, the main types of processes were indicated along with their limitations resulting from the scale and design of the reactors used. The influence of the process temperature on the type of produced fractions depending on their molecular weight was discussed. The importance of the use of catalytic additives as tools to increase the efficiency of the process was indicated. It is not without significance that all the indicated processes should have the lowest possible impact on the environment, thus constituting a tool for its protection with the use of the so-called best available techniques and opportunities for the disposal of plastics. The conducted scientific review consists of an analysis of scientific and research works spanning the years 1994 to 2022, and a selection of books published between the years 1960 and 1980 that serve as the source of essential and fundamental knowledge [20,21].

2. Thermal Pyrolysis

Liquefaction is another method for degrading waste polymers or waste composites. The first method relies on transesterification reactions between the hydroxyl groups of the reaction mixture’s components, which include ethylene glycol, an organic solvent, and a catalyst, and the ester bonds found in the epoxy network of epoxy and polyester resins used in the production of composite materials [22]. This type of process can be carried out under a wide range of conditions, including different temperatures, pressures, and solvent-to-catalyst ratios. The design of experiments approach can be used to determine the optimal process conditions that result in the maximum degree of productivity (DOE) [23]. Statistical and chemometric analysis of experimental data can be utilised to identify the most relevant elements influencing the degradation of waste composite materials. The second method, known as the hydrothermal wet oxidation of rubbish, is relatively new, and its primary purpose is to reduce solid waste composed mostly of plastic. The waste degrades in water via wet oxidation at subcritical pressures (20–150 bar) and temperatures (150–320 °C). The oxygen-pressurized hydrothermal vessel maintains the liquid-state contents. Reducing waste volume [24,25], recovering phosphate from sewage sludge [26], reducing heavy metals in sewage sludge [27], recovering valuable substrates from waste [28], and producing organic acids—but only from sewage sludge [29,30]—are currently the focus of research using the aforementioned method. Hydrothermal processing is widely used in laboratories to treat and degrade organic compounds. As a result, there are few studies on the hydrothermal treatment of municipal solid waste, for example, plastics and products manufactured from them, such as fibres and fabrics used to make disposable masks. Because of the significance of this relationship, it is critical to understand how municipal solid wastes are handled using hydrothermal techniques. Municipal solid wastes are tough and sluggishly broken down in landfills, and they harm the environment when thermally processed. The gradual deterioration of the ecosystem promotes microplastic contamination, which has already been discovered in glacier snow. Investigations on the oxidative melting of plastics have only examined the impact of basic process variables such as temperature or pressure [31], and they have only examined one type of plastic, polyethylene (PE) [32].

2.1. Feedstock Types and Possible Degradation Reactions

Polymeric materials are a common raw material in a wide range of industries, sectors, and services. One of their most significant advantages is their ease of processing and high applicability to diverse technological solutions. Polymers have numerous industrial applications that have been well documented for many years and are composed of several assemblies of simple monomers. However, some fractions are more important than others in applications. Their significance can be seen in the share of their global consumption shown in Table 2.

Table 2.

Main plastic types, their parameters, and global consumption [33], with permission from Elsevier.

Polymeric materials are applied in a wide range of industries, including automotive, construction, furniture, electronics, and telecommunications. Furthermore, polymers are used in healthcare, but unlike the previously mentioned uses, this sector does not allow for material recovery because medical materials must be disposed of neutrally. The most common materials are PE (polyethylene), PP (polypropylene), and PVC (polyvinyl chloride) (Table 2), which account for nearly 70% of total plastic applications and demand globally. Their application potential is determined by their quality and physiochemical properties. Polystyrene and thermosetting plastic blends have also played important roles, accounting for roughly 20% of total global use. The remainder of the worldwide market includes various specialised fractions such as PA (polyamide), PBT (polybutylene terepththalate), and ABS (acrylonitrile budatiene styrene). All these materials have unique physicochemical features that influence their applications and processing. The existence of these constituents, particularly volatiles and carbon content, has a considerable impact on its subsequent application, particularly during thermal pyrolysis. All plastics have a volatile content of more than 90%. On the other hand, the amount of fixed carbon content varies from 0.04% for PE to 6.3% for PVC and 7.77% for PET.

Based on the monomers, the process of polymerization, and the creation of co-polymers with different parts in different amounts, a wide range of physical and chemical properties can be made [34]:

- Polyolefins, such as PE/PP, are extremely inert and hydrophobic, with a low density.

- Poly(tetrafluoroethylene) PTFE (Teflon) has an ethylene backbone and four fluorine molecules that are covalently bonded.

- Poly (vinyl chloride) PVC has an ethylene backbone with one covalently bonded chlorine

- Silicone -Si-O- has a backbone with a variable chain length and crosslinks that govern its mechanical properties and ranges from liquid oil to gel to rubber elastomer. Polyolefin silicones are notable for being hydrophobic and biostable elastomers.

- Methacrylate’s (PMMA) properties include substantial stiffness, and its primary application is in medical applications (orthopaedics and dentistry).

- Polyesters are biodegradable and biostable polymers that are also used in biomedicine (drug-eluting coatings, orthopaedic applications, etc.).

- Polyurethane can be synthesised in a variety of chemistries and characteristics. This large group’s structure is flexible due to the combination of hard and soft segments.

Some fractions are flame-retardant, steam-resistant, or operate at high/low temperatures. Medicine uses many polymers. General surgical implants, orthopaedic implants, temporary in vivo applications (wound dressings, vascular catheters), ophthalmology, and dentistry are key medical areas. Plastics are used in many economic sectors, but each product is profitable. Life cycle ends = trash. This means the owner or manufacturer discards, plans to discard, or must discard it. Different methods are used. Preventing waste is the most environmentally friendly option, but manufacturing byproducts cannot be eliminated. In addition to removing byproducts, solutions should neutralise them. Plastic pyrolysis produces good results. A method without air access decomposes raw material by degrading polymer chains into monomers. According to [35], pyrolysis of plastics can generate hydrocarbon-rich gas with a calorific value of 24–25 MJ/kg, making it attractive for energy recovery. Pyrolysis uses thermal cracking at 350–900 °C. Depending on the heat, pyrolysis can be done at different rates. Slow (non-isothermal), rapid (isothermal), and ultra-fast/flash pyrolysis are described. This process can be managed based on the desired outcome (gas, char, or oil). Slow pyrolysis, 10 °C/s heating rate, allows for the partial evaporation of organic materials, and the residual product (char) is over 80% carbon. Fast pyrolysis at 100 °C/s targets liquid pyrolusite. It is one of the most popular pyrolytic plastic processing methods. Flash pyrolysis involves rapid heating. Compound decomposition is fast and produces gas [36]. In terms of end products, the type of material used and the construction of the reactor, the technique used, and the meaning of regulating heating rate and temperature in the chamber are important for pyrolysis of plastics. This allows for variations in pyrolysis end-product oil, gas, and liquid levels. The authors of [37] did extensive research. HDPE (high-density polyethylene) pyrolyzed at 350 °C in a horizontal steel reactor yielded 80% oil and 16% gas. Fixed-bed reactors for low LDPE (low density polyethylene) pyrolysis at 500 °C produced 95% particle-free pyrolysis oil. Batch, semi-batch, vacuum, and pressurised batch reactors operate under different conditions and use different plastic fractions. In most cases, pyrolysis of plastics is used to create pyrolytic oil, whose calorific value ranges from 21.1 to 43 MJ/kg for PVC (polyvinyl chloride) and PS (polystyrene), respectively. Changing the parameters allows for flexible product selection [37]. In some cases, the pyrolysis oil obtained had physical properties similar to gasoline and diesel. The current international situation may affect the development of the following transportation solutions.

2.2. Feedstock Closed-Loop Disposal

Plastic waste materials are a type of polymer that comes in a wide range, of which poly(ethylene terephthalate) makes up a significant share. According to [38], a huge portion of total PET (polyethylene terephthalate) output, which includes materials such as films, plastics, and fibres, is recycled using diverse technologies and for a wide range of applications, making PET one of the most recycled polymers. It is generally triggered by the PET application option for the direct reuse of uncontaminated old plastic, sometimes known as "closed-loop recycling." From an ecological standpoint, recycling in a closed loop is the best option. However, because of the combination of multiple types of materials, the method in which the material is developed and used in consumer goods is restricted in many ways. This is because, at the end of a product’s life cycle, fractions of different origins are subjected to different separation and recycling processes. To make closed-loop recycling better, waste management needs to be more proactive and friendly to the environment, and political efforts need to focus on obtaining funds for developing and making new recycling technologies [39].

Other difficulties arise when attempting to recycle complex composite materials. The fundamental difficulty in processing composite waste is the variety of physicochemical properties, and composites are difficult to recycle due to the use of crosslinked thermoset polymers in their matrix, which cannot be remelted or remoulded [40,41]. Composite waste that is difficult to recycle includes wind turbine waste blades. Wind energy is a renewable, limitless, and energy-efficient energy source. In 2020, the worldwide wind power industry installed more than 93 GW, bringing the total to 742.7 GW (707.4 GW onshore and 35.5 GW offshore) [42]. The global wind energy industry uses 2.5 million tons of composite materials. Recycling and reusing waste blades is the most effective way to safeguard the environment and encourage long-term growth. Pyrolysis and gasification are two thermal recycling processes for such waste, with TRL levels of 9 and 5/6 [43,44]. Pyrolysis can degrade the fibre quality by leaving oxidation residue or char on the fibres or by damaging their chemical structure. Gasification may be facilitated by energy recovery processes, the stream of chemical precursors it produces, and a higher heat-transfer efficiency. A chemical recycling approach based on solvolysis is another viable option for this type of composite waste. Most resin samples are epoxy resins, which, as previous research has demonstrated, require organic solvents and long reaction times to break them down and separate them from glass fibres. According to a previous study’s findings and analysis, solvolysis removed complex, frequently multi-component wind turbine blade waste matrices. An organic catalyst–alcohol solution can be used to chemically recycle (solvolyze) cured epoxy resins by fast transesterifying ester bonds with an alcohol to dissolve samples of wind turbine blades. The solvolysis of wind turbine blades allowed for the chemical recycling of both glass fibres and epoxy resin oligomers. Depending on the solvents utilised and the processing conditions, this procedure can take place in an inert N2 environment at temperatures ranging from 100 to 190 °C. The resin breakdown rate of this method reached 90%. Different solutions with the option of adding different supplements and opportunities for polymeric materials pyrolysis were reported.

2.3. Degradation Reactions

The chemical reaction mechanisms that may occur under diverse situations have a significant impact on polymer material transformation. Polymer degradation is defined as a change in polymer properties such as tensile strength and molecular weight that is caused by factors such as heat, chemicals, or temperature. For example, when heated over 450 °C, polyethylene degrades into a blend of hydrocarbon derivatives [45]. Under some conditions, polymers may undesirably lose their chemical structure and physical properties in polymer-based products [46]. As a result, polymer processing, such as injection and moulding, must take place under conditions that allow the material to liquefy (by rising its temperature in the case of thermoplastics) while also limiting the degree of degradation. If the injection temperature or time is too high or too long, the plastic can break down partially. This changes the product’s mechanical and aesthetic properties and lowers its quality.

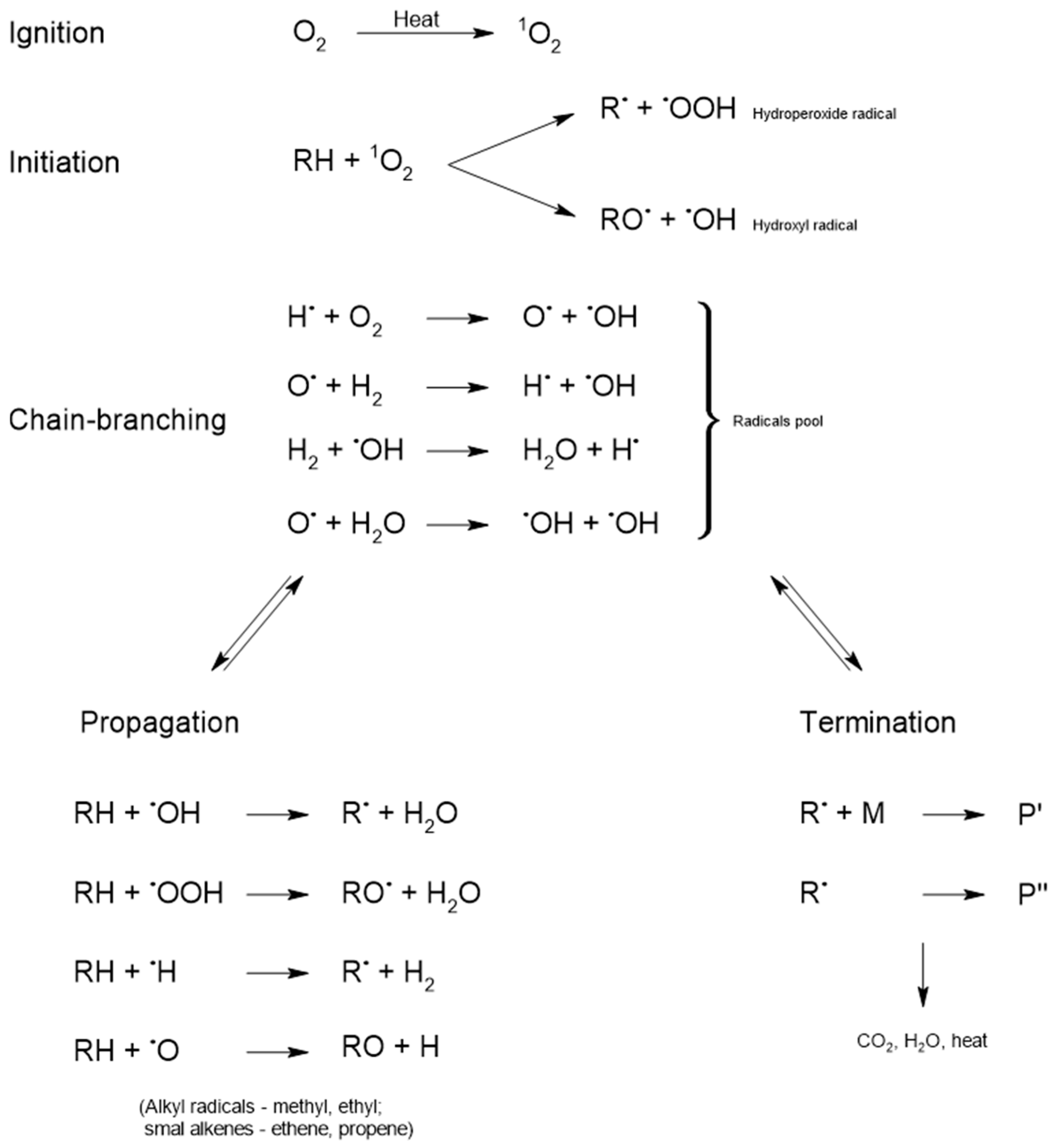

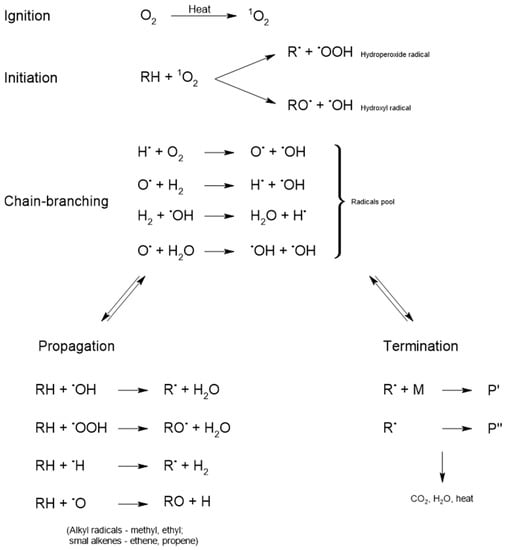

Depending on the type of conversion process and its conditions, the polymer degradation mechanism is significant. One of the significant parameters that has a significant impact on the process is λ (lambda), which is known as the ratio of the excess air in the process, the actual amount of air (converting agent), to the minimum amount (calculated on the basis of the fuel stoichiometry allowing the thermal process to occur). To date, the most widely utilised procedure, combustion, employs extra oxygen (λ > 1) to completely oxidise the organic matter. In this situation, the products of combustion of the organic matter contained in the plastic material, e.g., PE (which solely contains carbon and hydrogen atoms), are CO2, H2O, N2 (from the air), and possibly gaseous pollutants resulting from material contamination. The combustion mechanism is complex and includes several chemical reactions between the fuel components (e.g., hydrocarbons) and the oxidant (e.g., oxygen in the air), which produces heat and (sometimes) light in the form of a flame. Even though many chemical reactions produce active radicals during combustion, it is generally agreed that the whole process can be summarised in a few basic steps, as shown in Figure 1.

Figure 1.

Schematic overview of the combustion process [47], with permission from Elsevier.

First-stage combustion heat creates singlet oxygen (ignition). Singlet oxygen reacts more strongly with organic compounds, resulting in hydrogen extraction from combusted material (fuel). Hydroperoxide and hydroxyl radicals are produced during initiation. Oxy-hydrogenation forms hydrogen, hydroxyl, and oxygen radicals. First, dissociation over 400 °C creates radicals. In the presence of hydrocarbons, produced radicals may react further, forming new reaction products and other radicals. Propagation termination is the final stage of a radical reaction, which produces the simplest, most stable molecules. A decrease in process temperature may stop the radical reaction, causing no new radicals to form and existing radicals to form a stable molecule. In this stage, radicals (R) combine with other molecules (M) to create new unreactive species (P′) and (P″). These processes produce CO2, water, and heat.

Gasification is another popular thermal waste plastics process. Partial thermal degradation of organic matter in the presence of oxygen λ = 0.3–0.45. At 850–900 °C, gasification occurs. Gasification produces combustible methane, hydrogen, carbon dioxide, and carbon monoxide. Gasification produces a gas that can be used for energy generation and chemical synthesis. Gasification can filter gas in a smaller stream volume than burning. Waste incineration requires 2.5 m3/kg of air and produces 14 m3/kg of cleaned flue gases. Using 1.2 m3/kg of air, gasification produces 2.5 m3/kg of pure gas, which is this method’s benefit. Unlike combustion, gasification is complex. Oxidation and radical reactions are not unique to oxygen-depleted conditions. Disproportionation and methanization also occur. The main gasification reactions are given in [47,48]. Gasification is a cycle of primary and secondary reactions between the gasifying agent and fuel (its combustible component). Process conditions, such as reactor temperature distribution and variability during operation (startup and shutdown), affect reaction kinetics. The efficiency of this process and the calorific value of the resulting process gas depend on the type of fuel, the converting agent, its quantity, and the dosing method. It depends on the reactor’s technology. The processes for generating the above gas components are fundamental to the production of combustible gas, whose calorific value is determined by CO, H2, CH4, and CnHm (higher hydrocarbons). The fuel gasification process aims to produce high-calorific synthesis gas without complex technology. This gas is used to power gas turbines and make chemicals.

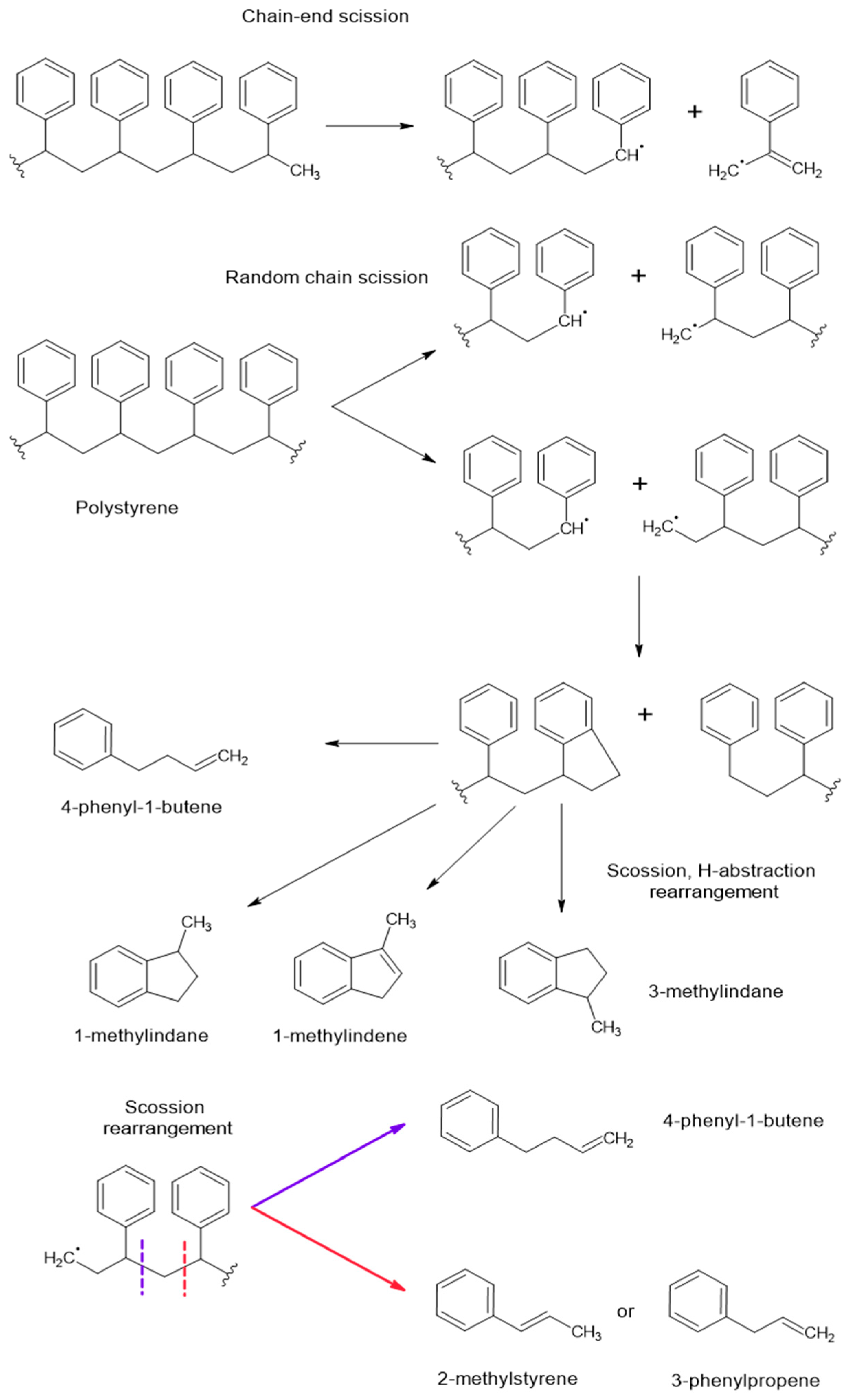

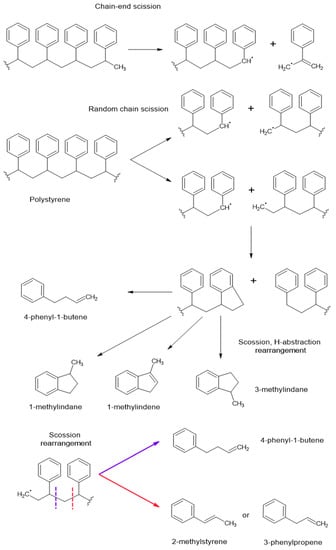

This review examines pyrolysis, a thermal waste conversion method. Organic materials are decomposed at 400 to 800 °C under an inert gas, often nitrogen. The pyrolysis temperature of waste plastics depends on the polymer breakdown temperatures. Waste polymer pyrolysis primarily produces free radicals [48,49,50,51]. The process is similar to burning. Some waste polymers, such as PET [20,21], and catalytic polymerization use ionic reactions [52]. Figure 2 shows free-radical first steps. Initiation, propagation, and termination are the stages of polymer degradation [53,54]. Polystyrene shows this technique. There are two ways to begin. First, random chain scission occurs; second, terminal group scission takes place. Both scenarios form a primary and secondary transition state radical. In the next stage, free radicals propagate through hydrogen transfer and unzipping reactions. Recombination or disproportionation of active radical fragments stops degradation. A graphical representation is shown in Figure 2 [54].

Figure 2.

Schematic overview of the free-radical reactions (based on [53,54]).

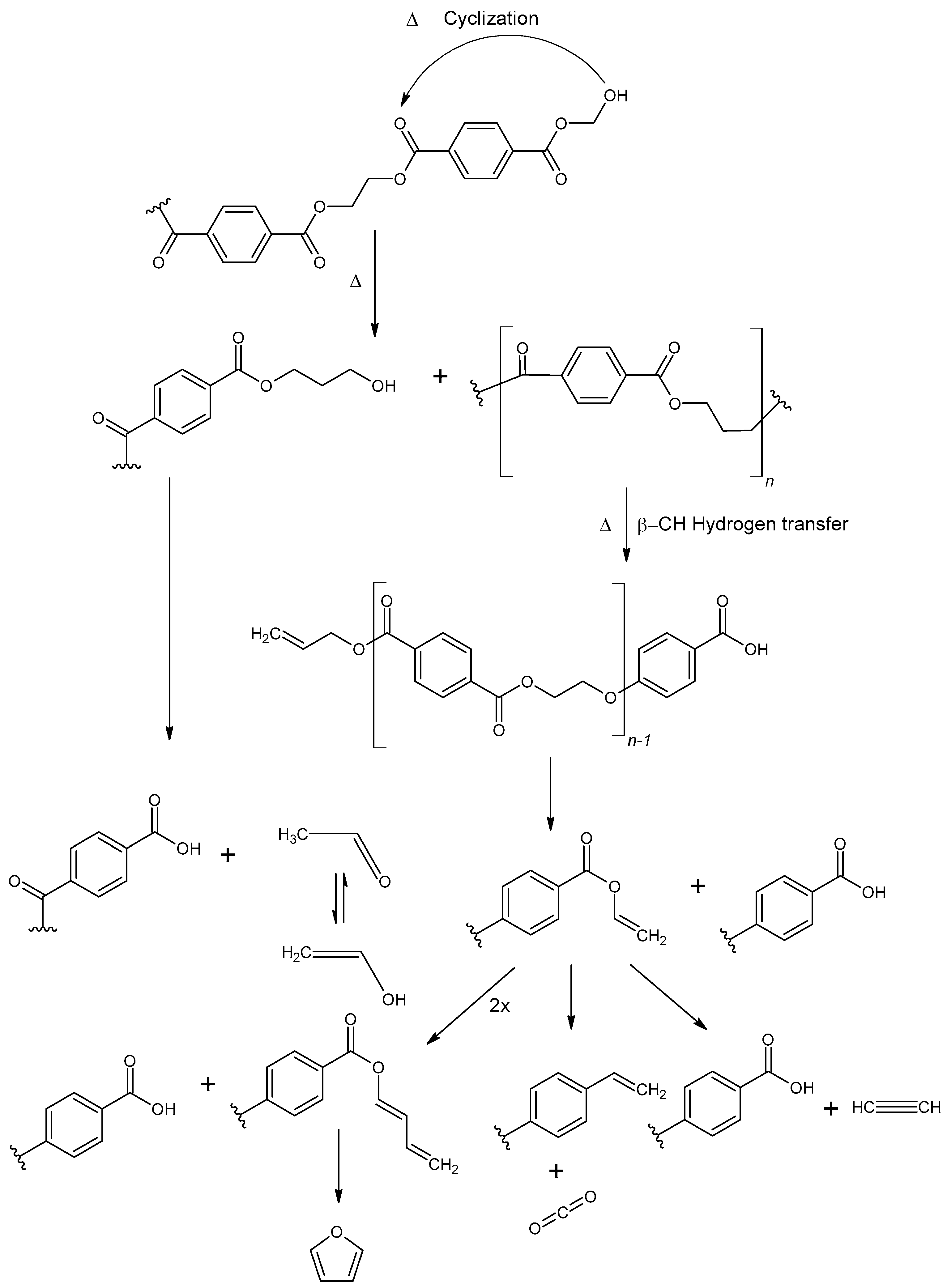

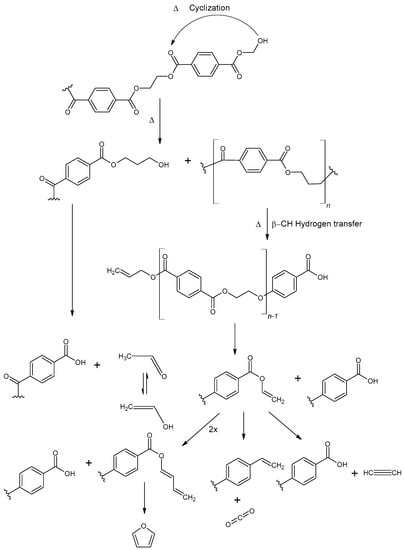

Table 3 [54,55,56] shows that, depending on the PS pyrolysis temperature, a mixture of products with varying quantitative and qualitative contents is formed. The findings of significant research on this topic [57,58,59,60,61,62,63] confirm the mechanisms of PS breakdown by free radical reactions that have been proposed for many years. The polymer degradation mechanism is primarily temperature dependent, and different volatile products are produced at different temperatures. At 300, 350, and 420 °C, styrene, toluene, and alpha-meta-styrene benzene are produced. Aside from volatiles, the highest diversity of final products is formed at 350 °C [54]. In the case of the second previously indicated method of polymeric material degradation observed during pyrolysis, degradation proceeds via an ionic mechanism. Degradation is most noticeable in the case of catalytic pyrolysis, although it is also seen in the case of PET pyrolysis. Buxbaum’s research [20,21] showed evidence for the thermal ionic breakdown of PET via beta-CH hydrogen transfer, culminating in the production of an oligomer with a carboxyl group. Subsequent experiments and computational analysis [64] showed that the thermal degradation of PET occurs by cyclization, specifically via an intramolecular (ionic) alcoholizing reaction between 250 and 300 °C. This reaction (intramolecular exchange) is an ionic process that produces cyclic oligomers and is the primary thermal mechanism occurring in PET below 300 °C. In contrast, the previously described beta-CH hydrogen transfer reaction happens only as a secondary process (Figure 3).

Table 3.

Thermal degradation reactions of polystyrene during pyrolysis [54], with permission from Elsevier.

Figure 3.

Thermal degradation reactions of PET (based on [65]).

2.4. Process Limitation and Restrictions Related to the Reactor Type

Despite the importance of pyrolysis in polymer transformation, engineers face constraints and technological challenges related to process conduct and end product quality and efficiency. The diversity of these materials shows that alternative process conditions can achieve desired results. Inappropriate use of plastics and lax control over chemical additives cause the most problems, as further processing may result in the use of dangerous substances and their emission into the environment. Economic, regulatory, political, technical, and technological constraints limit such applications [30]. Technologically, pyrolysis feedstock and reactor type constraints are easier to identify. Process restrictions include feedstock type. As with all thermal processes, pyrolysis feedstock must contain enough combustible components for process efficiency. Extra materials such as catalysts may help overcome limits without additional materials [66]. Using catalysts may reduce pyrolysis temperature and increase biomass conversion, improving process efficiency. Additional effects include polymer type selection and pre-processing to achieve fractions. Water limits make segregation costly and difficult, according to proper granulation [67]. Before processing, glues and self-adhesive labels must be removed to avoid chemical contamination. Purifying, cutting, shedding, and compacting can improve feedstock quality. Catalytic pyrolysis with various catalysts extracts valuable hydrocarbons from polymeric materials. Economic and engineering constraints prevent its use in reactors [68]. The limited polymer–catalyst contact inside the reactor and the feedstock’s stickiness cause these problems. Unsatisfactory polymer–catalyst interactions cause deactivation and efficiency loss. Non-effective catalyst efficiency causes higher demand and additional costs due to increased catalyst consumption. In order to develop a catalytic pyrolysis process effectively, the feedstock must be properly treated and purified. Properly handled raw materials reduce catalyst consumption, making the process more economical. Increasing catalyst–raw material contact is a key to improving process efficiency.

2.5. Co-Pyrolysis and Catalytic Pyrolysis

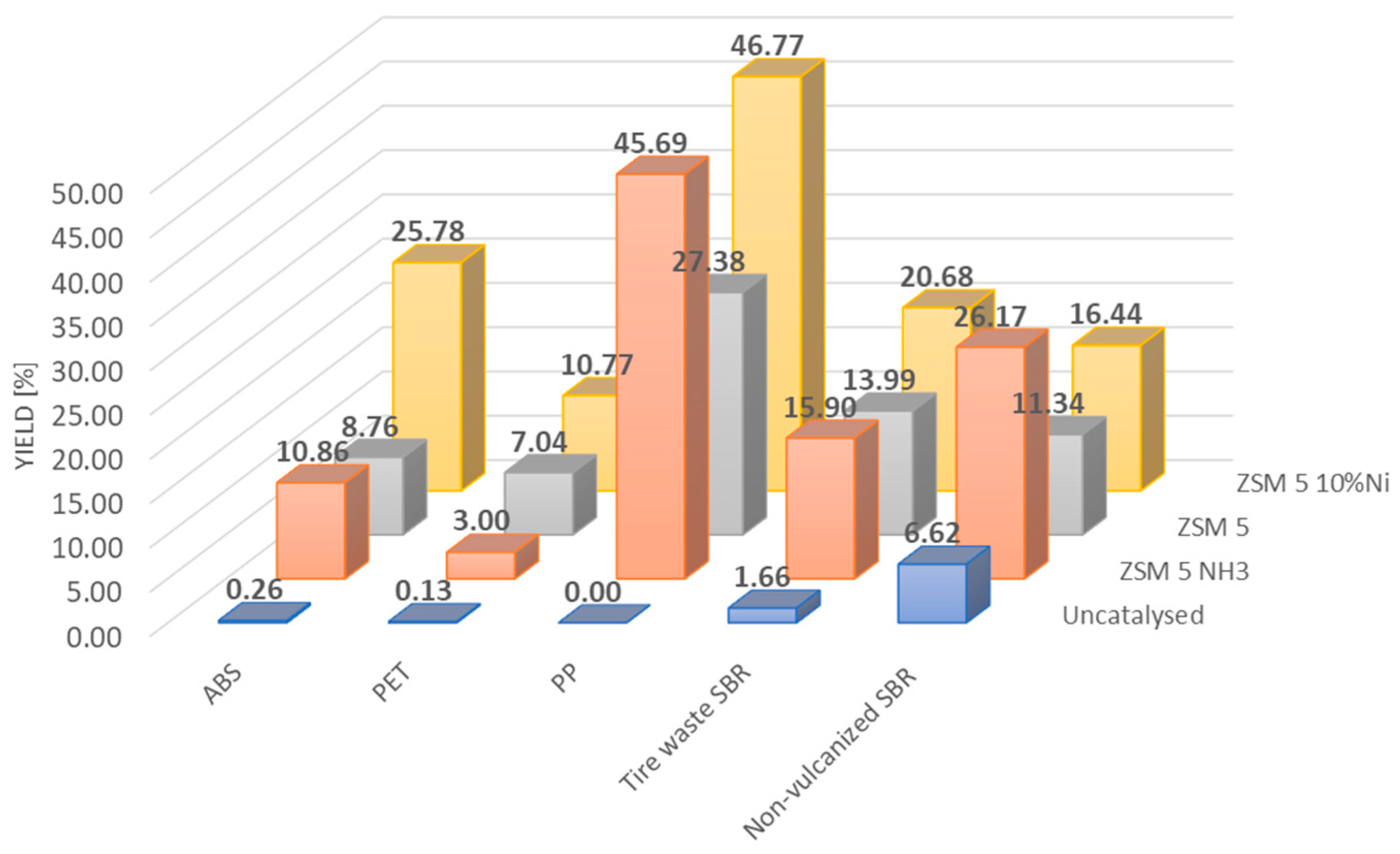

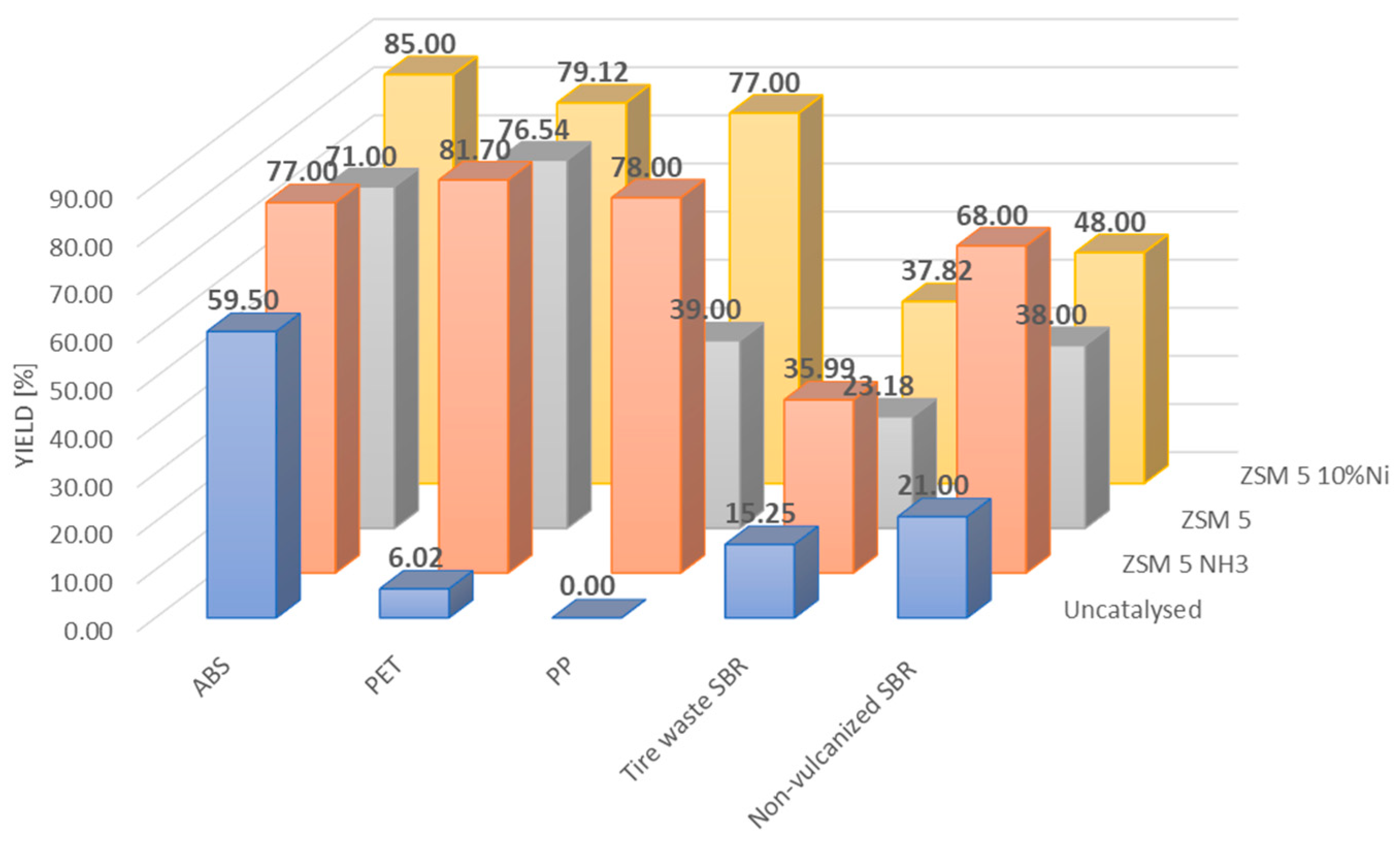

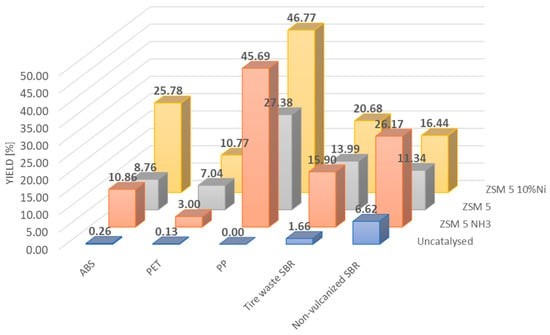

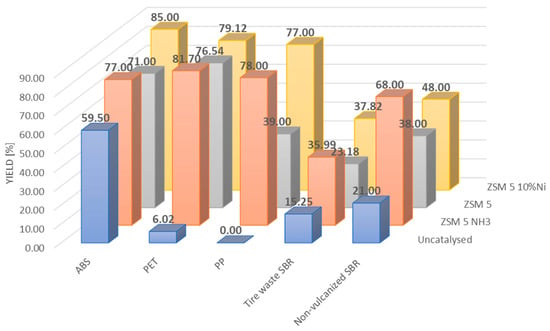

In addition to co-combustion and co-gasification, co-pyrolysis has recently received ample attention. One of the primary benefits of co-pyrolysis is the reduced release of harmful compounds into the environment. This approach, in contrast to single pyrolysis, decomposes two separate starting materials in a single operation. Others have demonstrated that, in some settings, the chosen fractions of polymers such as polypropylene and polystyrene co-pyrolyzed with biomass may have a better effect than the single pyrolysis of plastic/biomass [68,69]. Furthermore, the action may be enhanced using certain catalysts. Co-pyrolysis allows for the modification of the composition of solid, liquid, and gaseous products and their adaptation as liquid fuels (Figure 4 and Figure 5). The conclusion is that the process’s future efficiency is contingent on the development of a co-pyrolysis process that integrates catalytic materials into the reactors. This level of efficiency could be attained by optimising catalyst synthesis procedures from industrial and agricultural waste fractions [70]. Catalytic pyrolysis of polymer waste processing is an alternate method to individual pyrolysis and polymeric co-pyrolysis. One of the main goals of catalytic pyrolysis and co-pyrolysis is to increase the value of the biomass pyrolysis process. One of the most important aspects for many scientists is to produce aromatic hydrocarbons from catalytic pyrolysis, particularly with the use of Zeolite Socony Mobil-5 (ZSM-5), which is regarded as one of the most efficient pyrolysis catalysts [70].

Figure 4.

BTEX yield as a function of material and catalyst ratio (based on [19]).

Figure 5.

All aromatics yield as a function of material and catalyst ratio (based on [19]).

2.6. Influence of Polymer Type on Technological Aspects of Pyrolysis and Catalytic Pyrolysis Requirements

The operational parameters of the pyrolysis process are determined by the type of polymer used. Various polymer applications have different requirements, such as reactor type and ideal temperature ranges. For example, PP may be changed at temperatures ranging from 300 to 740 °C, and the best type of reactor for this application is a semi-batch reactor. In contrast, for PET thermal transformation, the best efficiency can be obtained in a fixed-bed reactor at 500 °C. The pyrolysis conditions directly affect the output of gas and liquid products [12]. During typical pyrolysis at 690 °C, around 40% of the entire amount of final product is pyrolytic oil, of which more than half is benzene, toluene, and xylene. At higher temperatures and using a fluidized bed reactor on a technological scale at 730 °C, the amount of compounds in the total mass of organic products such as toluene, xylene, styrene, and benzene was 31.4%. This demonstrates a link between rising process temperatures and organic matter degradation [71]. At 700 °C, a high concentration of olefins was detected. The principal products included 20–31 wt.% ethane, 14–18 wt.% propane, 3–6 wt.% butane, and 19–23 wt.% pyrolysis gasoline.

3. Evaluation of Polymeric Materials in Thermal Processes

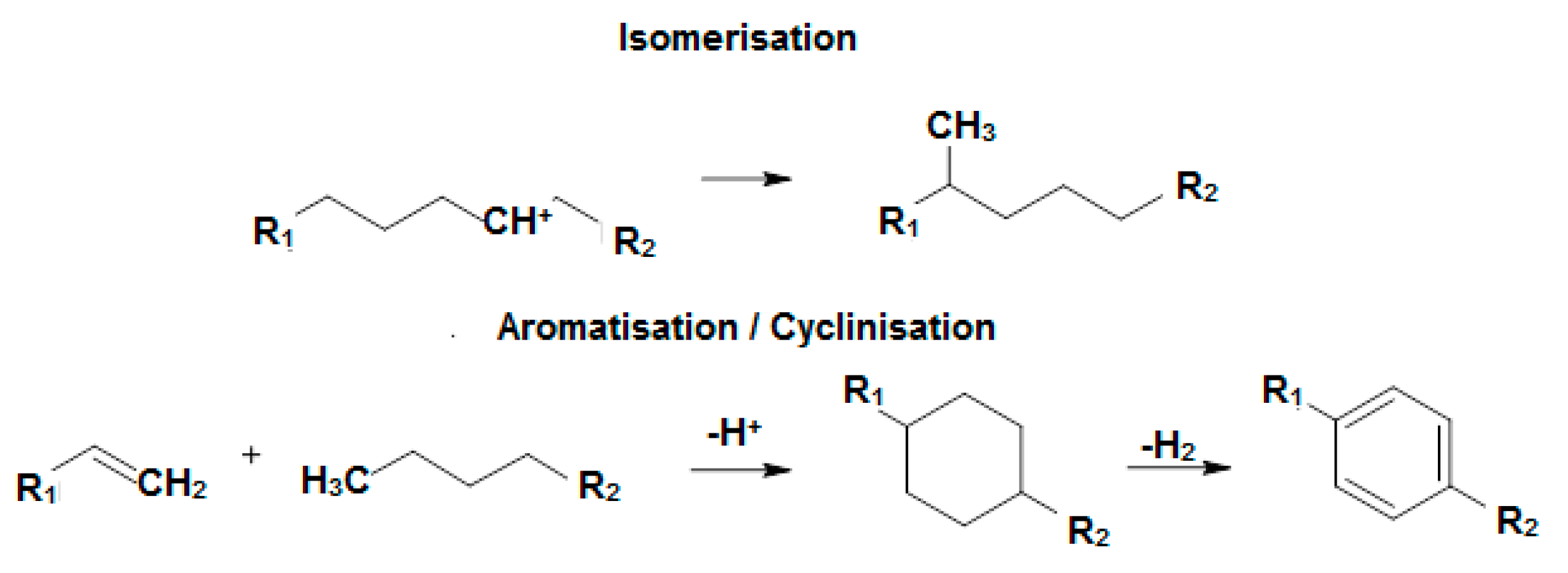

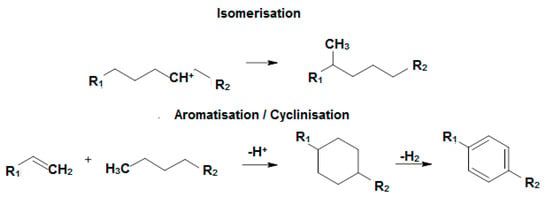

The evaluation of pyrolysis and other thermal preparation methods of polymeric materials is critical to ensuring the profitability of a process. Action should be focused on three primary areas in this context: raw material evaluation, process parameters and associated conditions, and product evaluation. A physicochemical property evaluation is important for all thermal processes, including combustion and gasification. Ultimate analysis, proximal analysis, differential thermal analysis, and thermogravimetric analysis all play key roles in this regard [12,13,72]. The ash content, volatile matter, and moisture content are all included in the proximate analysis. The concentrations of elements such as carbon, hydrogen, sulphur, and oxygen are included in the final analysis and combined to generate a combustible and incombustible material, the same as traditional fuels. The concentration of these parameters influences energy usability by determining the lower and higher heating values [12,13,72]. Thermogravimetric analysis (TGA) is used to evaluate the temperature ranges at which polymeric materials disintegrate. Gas chromatography, on the other hand, is used to investigate volatile products of catalytic and non-catalytic pyrolysis. All of these approaches are carried out automatically, owing to the availability of specialised analysers with great sensitivity and accuracy [12]. BTEX generated from polymeric material pyrolysis yields important compounds such as phenol, chlorobenzene, styrene, maleic anhydride, and phthalic anhydride. Aside from the process parameters, one of the most essential components is the variety of polymeric materials and catalysts available. The use of PP during catalytic pyrolysis facilitates the synthesis of long-chain alkenes and alkanes at many stages through isomerization and aromatization, as illustrated in Figure 6.

Figure 6.

Isomerization, cyclization and aromatization pathway (data published in accordance, with permission from Elsevier [19]).

As a result of Walden inversion, one isomer is changed into a second at the first stage (isomerization; in a chiral carbon atom with an R or S configuration). Second, cyclization converts the a-cyclic component of the chain into a cyclic component. A new chemical bond was generated [73]. As an example, the authors demonstrated that the product obtained from ABS pyrolysis without a catalyst contained less than 50% of 2-phenylpropene [73], which was utilised instead of styrene to polymerize heat-resistant ABS. This was used as a raw material for organic compounds used as pigments, paints, adhesive agents, and latex. Despite the lack of catalyst applications, ABS with a lower concentration of 2-phenylpropene can be processed as pigments, paint, adhesive agents, and latex, and an additive to plastics.

Thermal and Chemical Utilisation of Polymeric Materials and Their Waste and Environmental Impact

Each technological solution involving the chemical usage of polymer materials and their byproducts results in environmental problems. Chemical substances generated during the thermal degradation of polyolefins have significant carcinogenic and mutagenic potential. As a result, one of the primary challenges is the use of systems that enable the minimisation of negative phenomena such as exhaust gases, dust, and process effluents, and, preferably, their reuse. High-temperature pyrolysis enables satisfactory degradation or recovery of valuable components. High temperatures are advantageous because temperature regimes above 700–800 °C allow for the thermal cracking of molecules into compounds with lower oxidation states, which is advantageous, for example, from an energetic standpoint. The high temperature, causes high energy costs, making the process more expensive and, as a result, less lucrative. As a result, several types of strategies aimed at lowering energy consumption, such as heat recovery and recirculation, are required to boost the process’s cost-effectiveness. The chemical disposal of polymers is determined by the type of reagents utilised and their applicability depending on temperature regimes. As a result, the ideal operation is to achieve a balance between the process’s heat conditions and the employment of favourable reagents, which allows for the most desirable outcome.

4. Opportunities for Polymeric Materials Thermal Decomposition and Degradation

This paper summarises pyrolysis methods, solutions, and procedures for processing polymeric materials. In recent years, technological development and the usefulness of more complex techniques and technologies have broadened this trend, indicating that thermal techniques such as pyrolysis can treat a wide range of wastes. Byproducts and chlorinated compounds hinder these approaches [33]. A strict treatment system can limit hazardous substance emissions, but it is expensive and high-tech. Compared to fuel incineration, pyrolysis emits far fewer pollutants. Process characteristics determine the final product volume and quality. Key parameters include pressure, temperature, catalyst application, process agent (heat quantity or gasification agent), and fuel ratio. As with other thermal processes, these conditions are determined by the kinetic reaction rate [9,11,74]. The radical process is key to polymer heat breakdown [75]. These mechanisms favour less-complex matrix forms. In the presence of catalysts, these matrices generate more diverse but less complex materials. Polymer transformation into valuable chemical goods has a large environmental impact due to the high quality of the end products [76]. Catalytic thermal pyrolysis of polymeric materials has been studied extensively [63,77,78,79,80]. Fixed-bed reactors are one of the simplest solutions due to their basic design and lack of particle size constraints, resulting in low capital investments and building needs. This type of reactor is common in semi-scale, semi-laboratory, and laboratory solutions [81,82]. The solution’s continuous operation cycle affects the difficulty of controlling operating conditions (such as temperature and residence time) and the heat-transfer coefficient. Thermal inertia and limited feedstock–catalyst interactions characterise these reactors. The pyrolysis technique affects polymer quality, final product composition, and catalyst availability.

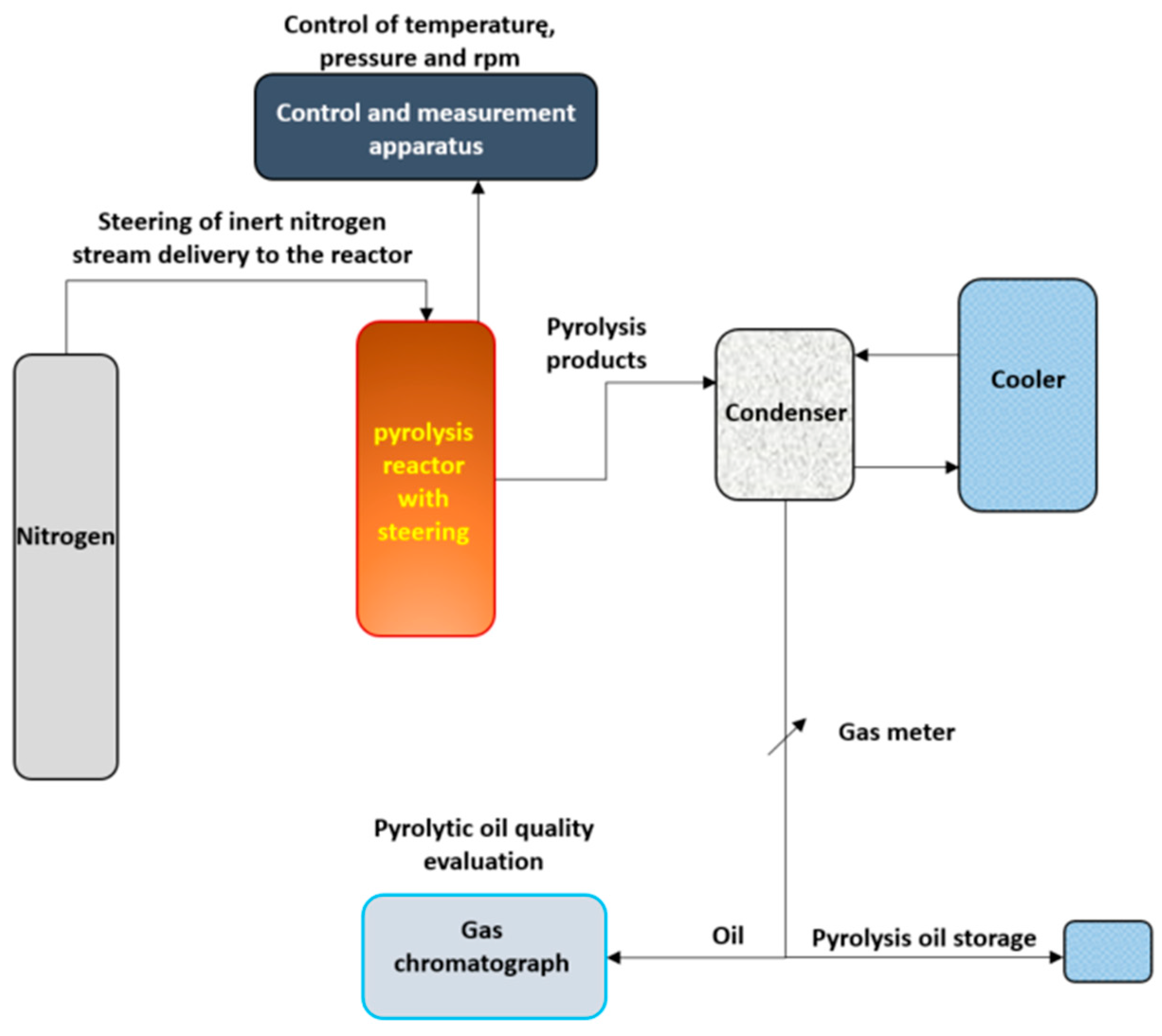

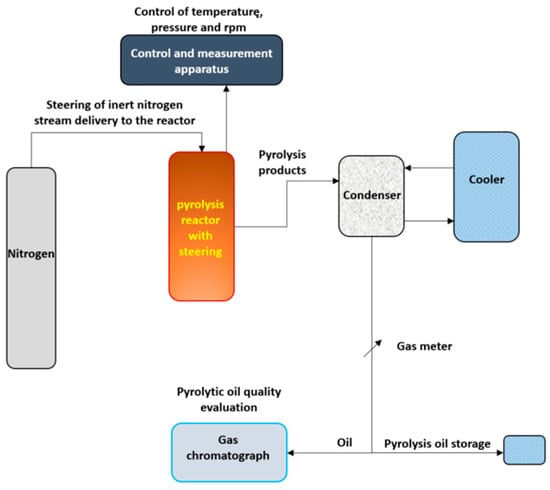

Such indications determine the types of reactors used for this purpose and the process’ mass, heat, and energy balance. Polyolefin waste can be converted in a fluidized bed reactor with a char removal device. In this case, pyrolytic gas with an LHV (lower heat value) of 50 MJ/m3 had the highest calorific value. Hydrocarbons’ high molecular weight and suitability influenced these values. Adding a catalyst changes the polymer transformation method. A catalyst accelerates and improves polymer chain isomerization, aromatization, and cracking [83]. Figure 7 depicts a stirred batch reactor scheme for PS and PP pyrolysis [84].

Figure 7.

Schematic diagram of an exemplary pyrolysis reactor according to the concept of [84], with permission from Elsevier.

In this design, the controller measures pyrolysis parameters. After passing through the control-measuring device, GC (gas chromatrograph) can assess the composition of the pyrolytic gas. The investigation found a correlation between the apparent increase in activation energy and the degree of material conversion during kinetics evaluation of pyrolysis at 0.5 to 2.0 °C/min. Retention increases the energy needed to break down organic substances. PS (polystyrene) pyrolysis was very selective for monomers and dimers, in contrast to PP (polypropylene). Fluidized-bed reactors replace fixed-bed reactors. They are structurally and technologically superior to the previous solution. They have a better heat transfer coefficient and can adjust temperature and resistance time. Fluidized bed reactors have better catalyst recovery and recirculation than fixed-bed reactors [85,86,87]. This solution reduces heat transfer better. Fluidized bed reactor materials interact effectively with the catalyst, but adequate material fragmentation is a critical technological need. The size distribution in a fuel is critical to the fluidization process [63,71,72,79], which limits the processing options. Expanding the technological line for the part responsible for material fragmentation increases costs and reduces return on initial investments. These are some options for pyrolyzing plastic [88]. A simple crew cline reactor is another alternative that can be easily scaled. This approach combines fixed and fluidized bed reactors. It has superior process control, high mixing efficiency, satisfactory material–catalyst interactions, and no particle size impact on processing conditions (unlike fluidized bed). Additionally, semi-technical installations use this method. Furthermore, this method is applied in semi-technical scale installations, but one of the main disadvantages of this system is its lower thermal efficiency compared with fluidal methods, together with challenges with moving elements and their integration with the reactor [79,89].

5. A Different Method to Increase the Process Efficiency

According to several research findings, adding waste polymers with a significant quantity of polyolefin as an additive improved the amount of liquid generated in addition to the gaseous fraction from biomass pyrolysis [12,13,71,72,73,74,75,76,77,78,79,80,81,82,83,84,85,86,87,88,89]. Some polymeric pyrolysis solutions can be made more efficient by including catalysts. Their applications can potentially improve the thermochemical processing efficiency of plastic waste pyrolysis. Catalysts can increase the process efficiency, allowing for a lower reaction temperature [90] and boosting process selectivity by minimising the production of undesired byproducts [91]. They can also impact the rate of polymeric chain breakdown. Using a catalyst can accelerate polymer breakdown [92]. The heat degradation of polymeric materials makes them a valuable source of polycyclic aromatic hydrocarbons. Aside from being detrimental to one’s health and the environment, they also play a significant role in a variety of industry sectors. Benzene is commonly found in unleaded gasoline as a lead alternative, allowing for smoother operation. Furthermore, materials containing 50% benzene are used in the production of ethylbenzene, which is widely used to create styrene, together with a solvent for dyes and inks [19]. Approximately 20% of benzene is utilised as a raw material in the synthesis of phenol, 15% in the synthesis of hydrogenated cyclohexane, 5% in the synthesis of aniline and alkyl benzenes, and 10% in the synthesis of maleic anhydride, chlorobenzene, and other compounds. p-Xylene is utilised in the production of PET, which is used to create plastic bottles [19]. Toluene is a low-cost and simple solvent that is widely utilised in industrial processes. To boost the octane value of gasoline, it is typically combined with toluene [93,94,95]. Furthermore, toluene is a significant source of polyurethane synthesis. Toluene is used to make toluene diisocyanate (TDI) monomers, which are used in the manufacturing of polyurethane [96]. Ethylbenzene is commonly used in industrial operations to produce styrene, which is then used to produce polystyrene. Ethylbenzene can also be found as a solvent in inks, dyes, and gasoline. Xylene is widely employed in the production of plastic bottles and polyester clothes, and a solvent with a wide range of uses, including circuit board cleaning and paint and varnish thinning [97,98]. Xylene mixtures are employed in solvents, and o-xylene is used as a feedstock for phthalic anhydrite synthesis. The principal applications are the manufacture of toluene and phenol, which are raw ingredients for the synthesis of caprolactams [99]. As a result, aromatic hydrocarbons including benzene, toluene, ethylbenzene, and xylene (BTEX) are desirable commodity chemicals in the fine chemical and petrochemical industries [98]. Aromatic nitriles, such as terephthalonitrile and benzonitrile, have a wide range of applications in the pharmaceutical industry, insecticides, dyes, and polymers [100,101]. On the other hand, 1,4-benzenedicarbonitrile [102,103,104] is a highly valuable chemical that can be used to produce the raw materials for producing epoxy and polyurethane resins (p-phenylenediamine), terephthalic acid (for PET production), or polyamide polymers (as a light-sensitive material) [105,106,107,108,109,110,111,112,113]. Another chemical, methylstyrene, has numerous applications in diverse industries. Plastics used to create ABS resins, for example, are utilised as a raw material in paintings and as an adhesive in the manufacture of lubricants and plasticizers [114,115,116,117,118,119,120,121].

6. Conclusions

Waste management of polymeric materials require their removal from the natural environment. The forecasted wide applications of polymeric materials in industry and services in the next years indicate that the stream of produced materials and, eventually, polymeric trash will continue to expand, posing a significant problem for the natural environment. The examination of numerous solutions for polymeric component processing has revealed that thermal pyrolysis can be used to process a variety of polymeric materials. The high costs of polymeric material disposal necessitate the quest for innovative and economically effective solutions that will be usable on a large scale. Other useful sources for chemical manufacturing can be obtained by modifying the catalyst type and process parameters, such as the temperature and processing time. BTEX compounds are not the only commercially valuable products derived from the catalytic and non-catalytic pyrolysis of polymeric materials. Intensive research by experts worldwide has demonstrated the value and importance of this topic. When pyrolysis processes are integrated into a cascade waste management system, precautions must be taken to avoid pollutants such as PVC. Obtaining a viable product from post-processed polymeric materials is included in one of the most important directions at the same time in terms of waste prevention and recycling. However, because it is impossible to completely eliminate waste generation, it is expected that the trend related to the development of processes and technologies allowing for the utilisation of plastic waste at a low cost without negatively impacting the environment will significantly increase in the future. All of these measures are intimately related to the principles of sustainable development, the main goal of which is to preserve natural resources for future generations.

Author Contributions

Conceptualisation, G.G. and M.S.; resources, G.G. and M.S.; data curation, G.G. and M.S.; writing—original draft preparation, G.G. and M.S.; writing—review and editing, G.G. and M.S.; visualisation, G.G. and M.S.; supervision, M.S.; project administration, G.G. and M.S.; funding acquisition, M.S. All authors have read and agreed to the published version of the manuscript.

Funding

This publication was supported by the Excellence Initiative Research University program, the Silesian University of Technology, 2021 “Disposal and recovery of raw materials from end-of-life WTBs by chemical processes” 08/020/SDU/10-21-01. This work was also supported by the Faculty of Energy and Environmental Engineering at the Silesian University of Technology (statutory research).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Statista (2021)-Annual Production of Plastics Worldwide from 1950 to 2020. Available online: https://www.statista.com/statistics/282732/global-production-of-plastics-since-1950/ (accessed on 7 October 2021).

- Migdał, A.R.; Kijeński, J.; Kawalec, A.; Kędziora, A.; Rejewski, P.; Śmigiera, E. Odzysk Energetyczny Materiałów Odpadowych Z Tworzyw Sztucznych. Chemik 2014, 68, 1056–1073. [Google Scholar]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, Use, and Fate of All Plastics Ever Made. Sci. Adv. 2017, 3, e1700872. [Google Scholar] [CrossRef] [PubMed]

- Plastic the Facts 2012–2019. Available online: https://www.plasticseurope.org/en/resources/market-data (accessed on 28 March 2022).

- Shahnawaz, M.; Sangale, M.K.; Ade, A.B. Bioremediation Technology for Plastic Waste; Springer: Singapore, 2019; ISBN 978-981-13-7491-3. [Google Scholar]

- Varda, D.N.A. Mehta Production and Evaluation of Microbial Plastics for Its Degradation Capabilities Project: PRACRITI-PRogrAmme on Climate Change Research. In Terrestrial Environment View Project Perils of Plastic: Are We Leaving behind? View Project; Indian Research Programme: Bangalore, India, 2014. [Google Scholar]

- Payne, J.; McKeown, P.; Jones, M.D. A Circular Economy Approach to Plastic Waste. Polym. Degrad. Stab. 2019, 165, 170–181. [Google Scholar] [CrossRef]

- Gertsakis, J.; Lewis, H. Sustainability and the Waste Management Hierarchy—A Discussion Paper; Victoria: Singapore, 2003. [Google Scholar]

- Gałko, G.; Król, D. Evaluation of Selected Sewage Sludge Gasification Technological Parameters. In Proceedings of the E3S Web of Conferences, IWA YWP 2017 Conference, Cracow, Poland, 12–13 September 2018; Volume 30. [Google Scholar]

- Król, D.; GaŁko, G. Studies on Sewage Sludge Gasification. Przem. Chem. 2017, 1, 96. [Google Scholar] [CrossRef]

- Król, D.; Gałko, G. Stoichometric Equilibrium Model of Sewage Sludge Gasification with Athmospheric Air. Przem. Chem. 2018, 97, 1698–1702. [Google Scholar] [CrossRef]

- Sajdak, M.; Muzyka, R. Use of Plastic Waste as a Fuel in the Co-Pyrolysis of Biomass. Part I: The Effect of the Addition of Plastic Waste on the Process and Products. J. Anal. Appl. Pyrolysis 2014, 107, 267–275. [Google Scholar] [CrossRef]

- Sajdak, M.; Słowik, K. Use of Plastic Waste as a Fuel in the Co-Pyrolysis of Biomass: Part II. Variance Analysis of the Co-Pyrolysis Process. J. Anal. Appl. Pyrolysis 2014, 109, 152–158. [Google Scholar] [CrossRef]

- Partial Report Preventing Plastic Waste EEA Report; Euroepan Environment Agency: Kopehnagen, Denmark, 2019.

- Bridgwater, A.V. Catalysis in Thermal Biomass Conversion. Appl. Catal. A Gen. 1994, 116, 5–47. [Google Scholar] [CrossRef]

- Molino, A.; Chianese, S.; Musmarra, D. Biomass Gasification Technology: The State of the Art Overview. J. Energy Chem. 2016, 25, 10–25. [Google Scholar] [CrossRef]

- Gałko, G. The Influence of Infiltration of Leachate from Landfills on the Changes of Chemical Parameters of the Soil. J. Ecol. Eng. 2015, 198–205. [Google Scholar] [CrossRef]

- Lombardi, L.; Carnevale, E.; Corti, A. A Review of Technologies and Performances of Thermal Treatment Systems for Energy Recovery from Waste. Waste Manag. 2015, 37, 26–44. [Google Scholar] [CrossRef] [PubMed]

- Gałko, G.; Rejdak, M.; Tercki, D.; Bogacka, M.; Sajdak, M. Evaluation of the Applicability of Polymeric Materials to BTEX and Fine Product Transformation by Catalytic and Non-Catalytic Pyrolysis as a Part of the Closed Loop Material Economy. J. Anal. Appl. Pyrolysis 2021, 154, 105017. [Google Scholar] [CrossRef]

- Buxbaum, L.H. The Degradation of Poly(Ethylene Terephthalate). Angew. Chem. Int. Ed. 1968, 7, 182–190. (In English) [Google Scholar] [CrossRef]

- Zimmermann, H. Degradation and Stabilisation of Polyesters in Developments in Polymer Degradation. Appl. Sci. 1984, 5, 79–119. [Google Scholar]

- Zhang, Z.; Baroutian, S.; Munir, M.T.; Young, B.R. Variation in Metals during Wet Oxidation of Sewage Sludge. Bioresour. Technol. 2017, 245, 234–241. [Google Scholar] [CrossRef] [PubMed]

- Munir, M.T.; Kheirkhah, H.; Baroutian, S.; Quek, S.Y.; Young, B.R. Subcritical Water Extraction of Bioactive Compounds from Waste Onion Skin. J. Clean. Prod. 2018, 183, 487–494. [Google Scholar] [CrossRef]

- Bertanza, G.; Galessi, R.; Menoni, L.; Salvetti, R.; Slavik, E.; Zanaboni, S. Wet Oxidation of Sewage Sludge: Full-Scale Experience and Process Modeling. Environ. Sci. Pollut. Res. 2015, 22, 7306–7316. [Google Scholar] [CrossRef] [PubMed]

- Menoni, L.; Bertanza, G. Wet Oxidation of Sewage Sludge: A Mathematical Model for Estimating the Performance Based on the VSS/TSS Ratio. Chem. Eng. J. 2016, 306, 685–692. [Google Scholar] [CrossRef]

- Zhou, W.; Zhong, H.; Jin, F. Hydrothermal Oxidation of Polyethylene (PE) Plastic to Short-Chain Fatty Acids (C1-C5). In IOP Conference Series: Earth and Environmental Science; Institute of Physics Publishing: Bristol, UK, 2020; Volume 450, p. 12049. [Google Scholar]

- Anthraper, D.; McLaren, J.; Baroutian, S.; Munir, M.T.; Young, B.R. Hydrothermal Deconstruction of Municipal Solid Waste for Solid Reduction and Value Production. J. Clean. Prod. 2018, 201, 812–819. [Google Scholar] [CrossRef]

- Maitz, M.F. Applications of Synthetic Polymers in Clinical Medicine. Biosurface Biotribology 2015, 1, 161–176. [Google Scholar] [CrossRef]

- Qureshi, M.S.; Oasmaa, A.; Pihkola, H.; Deviatkin, I.; Tenhunen, A.; Mannila, J.; Minkkinen, H.; Pohjakallio, M.; Laine-Ylijoki, J. Pyrolysis of Plastic Waste: Opportunities and Challenges. J. Anal. Appl. Pyrolysis 2020, 152, 104804. [Google Scholar] [CrossRef]

- Eze, W.U.; Umunakwe, R.; Obasi, H.C.; Ugbaja, M.I.; Uche, C.C.; Madufor, I.C.; Eze, W.U.; Umunakwe, R.; Obasi, H.C.; Ugbaja, M.I.; et al. Plastics Waste Management: A Review of Pyrolysis Technology. Clean Technol. Recycl. 2021, 1, 50–69. [Google Scholar] [CrossRef]

- Sharuddin, S.D.A.; Abnisa, F.; Daud, W.M.A.W.; Aroua, M.K. Pyrolysis of Plastic Waste for Liquid Fuel Production as Prospective Energy Resource. In IOP Conference Series: Material Science and Engineering, 3rd ed.; ICChESA 2017; Institute of Physics Publishing: Bristol, UK, 2018; Volume 334. [Google Scholar] [CrossRef]

- Chanda, M. Chemical Aspects of Polymer Recycling. Adv. Ind. Eng. Polym. Res. 2021, 4, 133–150. [Google Scholar] [CrossRef]

- Dwivedi, P.; Mishra, P.K.; Mondal, M.K.; Srivastava, N. Non-Biodegradable Polymeric Waste Pyrolysis for Energy Recovery. Heliyon 2019, 5, e02198. [Google Scholar] [CrossRef]

- Sherwood, J. Closed-Loop Recycling of Polymers Using Solvents. Johns. Matthey Technol. Rev. 2020, 64, 4–15. [Google Scholar] [CrossRef]

- Yang, Y.; Boom, R.; Irion, B.; van Heerden, D.J.; Kuiper, P.; de Wit, H. Recycling of Composite Materials. Chem. Eng. Process. Process Intensif. 2012, 51, 53–68. [Google Scholar] [CrossRef]

- Ye, S.Y.; Bounaceur, A.; Soudais, Y.; Barna, R. Parameter Optimization of the Steam Thermolysis: A Process to Recover Carbon Fibres from Polymer-Matrix Composites. Waste Biomass Valorization 2013, 4, 73–86. [Google Scholar] [CrossRef]

- Wind, G.; Council, E. Gwec|Global Wind Report 2021; Global Wind Energy Council: Brussels, Belgium, 2021. [Google Scholar]

- Devic, A.-C.; Ierides, M.; Fernandez, V.; Verbenkov, M.; Bax, L. Polymer Composites Circularity. SusChem 2018, 21. [Google Scholar]

- Vollmer, I.; Jenks, M.J.F.; Roelands, M.C.P.; White, R.J.; van Harmelen, T.; de Wild, P.; van der Laan, G.P.; Meirer, F.; Keurentjes, J.T.F.; Weckhuysen, B.M. Beyond Mechanical Recycling: Giving New Life to Plastic Waste. Angew. Chem. Int. Ed. 2020, 59, 15402–15423. [Google Scholar] [CrossRef]

- Li, S.; Li, J.; Xu, J. Investigating the Release Behavior of Biomass and Coal during the Co-Pyrolysis Process. Int. J. Hydrogen Energy 2021, 46, 34652–34662. [Google Scholar] [CrossRef]

- Farzad, S.; Mandegari, M.; Görgens, J.F. A Novel Approach for Valorization of Waste Tires into Chemical and Fuel (Limonene and Diesel) through Pyrolysis: Process Development and Techno Economic Analysis. Fuel Process. Technol. 2021, 224, 107006. [Google Scholar] [CrossRef]

- Su, G.; Ong, H.C.; Mofijur, M.; Mahlia, T.M.I.; Ok, Y.S. Pyrolysis of Waste Oils for the Production of Biofuels: A Critical Review. J. Hazard. Mater. 2022, 424, 127396. [Google Scholar] [CrossRef] [PubMed]

- Su, G.; Ong, H.C.; Fattah, I.M.R.; Ok, Y.S.; Jang, J.H.; Wang, C.T. State-of-the-Art of the Pyrolysis and Co-Pyrolysis of Food Waste: Progress and Challenges. Sci. Total Environ. 2022, 809, 151170. [Google Scholar] [CrossRef] [PubMed]

- Joo, J.; Kwon, E.E.; Lee, J. Achievements in Pyrolysis Process in E-Waste Management Sector. Environ. Pollut. 2021, 287, 117621. [Google Scholar] [CrossRef] [PubMed]

- Speight, J.G. Handbook of Industrial Hydrocarbon Processes; Elsevier: Amsterdam, The Netherlands, 2019; ISBN 9780128099230. [Google Scholar]

- Jasso-Gestinel, C.F.K.J.M. Modification of Polymer Properties; Elsevier: Amsterdam, The Netherlands, 2017; ISBN 9780323443531. [Google Scholar]

- Farris, S.; Pozzoli, S.; Biagioni, P.; Duó, L.; Mancinelli, S.; Piergiovanni, L. The Fundamentals of Flame Treatment for the Surface Activation of Polyolefin Polymers—A Review. Polymer 2010, 51, 3591–3605. [Google Scholar] [CrossRef]

- Kumar, A.; Jones, D.; Hanna, M. Thermochemical Biomass Gasification: A Review of the Current Status of the Technology. Energies 2009, 2, 556–581. [Google Scholar] [CrossRef]

- Serrano, D.P.; Aguado, J.; Escola, J.M. Catalytic Conversion of Polystyrene over HMCM-41, HZSM-5 and Amorphous SiO2–Al2O3: Comparison with Thermal Cracking. Appl. Catal. B Environ. 2000, 25, 181–189. [Google Scholar] [CrossRef]

- de La Puente, G.; Klocker, C.; Sedran, U. Conversion of Waste Plastics into Fuels Recycling Polyethylene in FCC. Appl. Catal. B Environ. 2002, 36, 279–285. [Google Scholar] [CrossRef]

- Karagöz, S.; Yanik, J.; Uçar, S.; Saglam, M.; Song, C. Catalytic and Thermal Degradation of High-Density Polyethylene in Vacuum Gas Oil over Non-Acidic and Acidic Catalysts. Appl. Catal. A Gen. 2003, 242, 51–62. [Google Scholar] [CrossRef]

- Miskolczi, N.; Nagy, R. Hydrocarbons Obtained by Waste Plastic Pyrolysis: Comparative Analysis of Decomposition Described by Different Kinetic Models. Fuel Process. Technol. 2012, 104, 96–104. [Google Scholar] [CrossRef]

- Faravelli, T.; Pinciroli, M.; Pisano, F.; Bozzano, G.; Dente, M.; Ranzi, E. Thermal Degradation of Polystyrene. J. Anal. Appl. Pyrolysis 2001, 60, 103–121. [Google Scholar] [CrossRef]

- McNeill, I.C.; Zulfiqar, M.; Kousar, T. A Detailed Investigation of the Products of the Thermal Degradation of Polystyrene. Polym. Degrad. Stab. 1990, 28, 131–151. [Google Scholar] [CrossRef]

- Liu, Y.; Qian, J.; Wang, J. Pyrolysis of Polystyrene Waste in a Fluidized-Bed Reactor to Obtain Styrene Monomer and Gasoline Fraction. Fuel Process. Technol. 2000, 63, 45–55. [Google Scholar] [CrossRef]

- Salamah, S.; Aktawan, A. Product Distribution of Pyrolysis of Polystyrene Foam Waste Using Catalyst of Natural Zeolite and Nickel/Silica. In IOP Conference Series: Earth and Environmental Science; Institute of Physics Publishing: Bristol, UK, 2018; Volume 175, p. 012012. [Google Scholar] [CrossRef]

- Folger, H.S. Elements of Chemical Reaction Engineering, 3rd ed.; The University of Michigan: Ann Arbor, MI, USA, 1987; Volume 42. [Google Scholar]

- Saad, J.M.; Nahil, M.A.; Williams, P.T. Influence of Process Conditions on Syngas Production from the Thermal Processing of Waste High Density Polyethylene. J. Anal. Appl. Pyrolysis 2015, 113, 35–40. [Google Scholar] [CrossRef]

- Elordi, G.; Olazar, M.; Castaño, P.; Artetxe, M.; Bilbao, J. Polyethylene Cracking on a Spent FCC Catalyst in a Conical Spouted Bed. Ind. Eng. Chem. Res. 2012, 51, 14008–14017. [Google Scholar] [CrossRef]

- Araduman, A.; Simsek, E.H.; Cicek, B.; Bilgesu, A.Y. Flash Pyrolysis of Polystyrene Wastes in a Free-Fall Reactor under Vacuum. J. Anal. Appl. Pyrolysis 2001, 60, 179–186. [Google Scholar] [CrossRef]

- Undri, A.; Frediani, M.; Rosi, L.; Frediani, P. Reverse Polymerization of Waste Polystyrene through Microwave Assisted Pyrolysis. J. Anal. Appl. Pyrolysis 2014, 105, 35–42. [Google Scholar] [CrossRef]

- Miandad, R.; Rehan, M.; Barakat, M.A.; Aburiazaiza, A.S.; Khan, H.; Ismail, I.M.I.; Dhavamani, J.; Gardy, J.; Hassanpour, A.; Nizami, A.S. Catalytic Pyrolysis of Plastic Waste: Moving toward Pyrolysis Based Biorefineries. Front. Energy Res. 2019, 7, 27. [Google Scholar] [CrossRef]

- Elordi, G.; Olazar, M.; Lopez, G.; Amutio, M.; Artetxe, M.; Aguado, R.; Bilbao, J. Catalytic Pyrolysis of HDPE in Continuous Mode over Zeolite Catalysts in a Conical Spouted Bed Reactor. J. Anal. Appl. Pyrolysis 2009, 1–2, 345–351. [Google Scholar] [CrossRef]

- Odian, G. Principles of Polymerization, 4th ed.; John Wiley & Sons: New York, NY, USA, 2004. [Google Scholar]

- Montaudo, G.; Puglisi, C.; Samperi, F. Primary Thermal Degradation Mechanisms of PET and PBT. Polym. Degrad. Stab. 1993, 42, 13–28. [Google Scholar] [CrossRef]

- Zhang, L.; Bao, Z.; Xia, S.; Lu, Q.; Walters, K.B. Catalytic Pyrolysis of Biomass and Polymer Wastes. Catalysts 2018, 8, 659. [Google Scholar] [CrossRef]

- Vijayakumar, A.; Sebastian, J. Pyrolysis Process to Produce Fuel from Different Types of Plastic–a Review. In IOP Conference Series: Materials Science and Engineering; Institute of Physics Publishing: Bristol, UK, 2018; Volume 396, p. 012062. [Google Scholar] [CrossRef]

- Munir, M.T.; Li, B.; Boiarkina, I.; Baroutian, S.; Yu, W.; Young, B.R. Phosphate Recovery from Hydrothermally Treated Sewage Sludge Using Struvite Precipitation. Bioresour. Technol. 2017, 239, 171–179. [Google Scholar] [CrossRef] [PubMed]

- Gin, A.W.; Hassan, H.; Ahmad, M.A.; Hameed, B.H.; Mohd Din, A.T. Recent Progress on Catalytic Co-Pyrolysis of Plastic Waste and Lignocellulosic Biomass to Liquid Fuel: The Influence of Technical and Reaction Kinetic Parameters. Arab. J. Chem. 2021, 14, 103035. [Google Scholar] [CrossRef]

- Sajdak, M.M. Optimization Frameworks in Resource Management and Process Engineering. In Plastics to Energy: Fuel, Chemicals, and Sustainability Implications; William Andrew: Norwich, NY, USA, 2019; pp. 425–442. [Google Scholar] [CrossRef]

- Sieradzka, M.; Rajca, P.; Zajemska, M.; Mlonka-Mędrala, A.; Magdziarz, A. Prediction of Gaseous Products from Refuse Derived Fuel Pyrolysis Using Chemical Modelling Software-Ansys Chemkin-Pro. J. Clean. Prod. 2020, 248, 119277. [Google Scholar] [CrossRef]

- Sieradzka, M.; Gao, N.; Quan, C.; Mlonka-Mędrala, A.; Magdziarz, A. Biomass Thermochemical Conversion via Pyrolysis with Integrated CO2 Capture. Energies 2020, 13, 1050. [Google Scholar] [CrossRef]

- Ash, M.; Ash, I. Handbook of Paint and Coating Raw Materials, 2nd ed.; Ashgate Brookfield Vermont: Gower, UK, 2013; Volume 1. [Google Scholar]

- Chen, D.; Yin, L.; Wang, H.; He, P. Pyrolysis Technologies for Municipal Solid Waste: A Review. Waste Manag. 2014, 34, 2466–2486. [Google Scholar] [CrossRef] [PubMed]

- Al-Salem, S. Plastics to Energy; Elsevier: Amsterdam, The Netherlands, 2019; ISBN 9780128131404. [Google Scholar]

- Lin, Y.-H.; Yang, M.-H. Catalytic Pyrolysis of Polyolefin Waste into Valuable Hydrocarbons over Reused Catalyst from Refinery FCC Units. Appl. Catal. A Gen. 2007, 328, 132–139. [Google Scholar] [CrossRef]

- Serrano, D.P.; Aguado, J.; Escola, J.M.; Garagorri, E. Conversion of Low Density Polyethylene into Petrochemical Feedstocks Using a Continuous Screw Kiln Reactor. J. Anal. Appl. Pyrolysis 2001, 58–59, 789–801. [Google Scholar] [CrossRef]

- Al-Salem, S.M.; Lettieri, P.; Baeyens, J. Recycling and Recovery Routes of Plastic Solid Waste (PSW): A Review. Waste Manag. 2009, 29, 2625–2643. [Google Scholar] [CrossRef]

- Gałko, G.; Król, D. Experimental Research of Oily Sawdust Air Gasification. Environ. Sci. Pollut. Res. 2021, 28, 14293–14298. [Google Scholar] [CrossRef]

- Zhang, X.; Lei, H.; Yadavalli, G.; Zhu, L.; Wei, Y.; Liu, Y. Gasoline-Range Hydrocarbons Produced from Microwave-Induced Pyrolysis of Low-Density Polyethylene over ZSM-5. Fuel 2015, 144, 33–42. [Google Scholar] [CrossRef]

- Lopez, G.; Artetxe, M.; Amutio, M.; Bilbao, J.; Olazar, M. Thermochemical Routes for the Valorization of Waste Polyolefinic Plastics to Produce Fuels and Chemicals. A Review. Renew. Sustain. Energy Rev. 2017, 73, 346–368. [Google Scholar] [CrossRef]

- Wu, M.S.; Jin, B.C.; Li, X.; Nutt, S. A Recyclable Epoxy for Composite Wind Turbine Blades. Adv. Manuf. Polym. Compos. Sci. 2019, 5, 114–127. [Google Scholar] [CrossRef]

- del Remedio Hernández, M.; García, Á.N.; Marcilla, A. Study of the Gases Obtained in Thermal and Catalytic Flash Pyrolysis of HDPE in a Fluidized Bed Reactor. J. Anal. Appl. Pyrolysis 2005, 73, 314–322. [Google Scholar] [CrossRef]

- Mastral, F.J.; Esperanza, E.; Berrueco, C.; Juste, M.; Ceamanos, J. Fluidized Bed Thermal Degradation Products of HDPE in an Inert Atmosphere and in Air–Nitrogen Mixtures. J. Anal. Appl. Pyrolysis 2003, 70, 1–17. [Google Scholar] [CrossRef]

- Artetxe, M.; Lopez, G.; Amutio, M.; Elordi, G.; Bilbao, J.; Olazar, M. Cracking of High Density Polyethylene Pyrolysis Waxes on HZSM-5 Catalysts of Different Acidity. Ind. Eng. Chem. Res. 2013, 52, 10637–10645. [Google Scholar] [CrossRef]

- Chmielniak, T.; Słowik, K.; Sajdak, M. Mercury Removal by Mild Thermal Treatment of Coal. Fuel 2017, 195, 290–298. [Google Scholar] [CrossRef]

- Sajdak, M.; Muzyka, R.; Hrabak, J.; Słowik, K. Use of Plastic Waste as a Fuel in the Co-Pyrolysis of Biomass: Part III: Optimisation of the Co-Pyrolysis Process. J. Anal. Appl. Pyrolysis 2015, 112, 298–305. [Google Scholar] [CrossRef]

- Kim, S.-S.; Kim, S. Pyrolysis Characteristics of Polystyrene and Polypropylene in a Stirred Batch Reactor. Chem. Eng. J. 2004, 98, 53–60. [Google Scholar] [CrossRef]

- Jung, S.-H.; Cho, M.-H.; Kang, B.-S.; Kim, J.-S. Pyrolysis of a Fraction of Waste Polypropylene and Polyethylene for the Recovery of BTX Aromatics Using a Fluidized Bed Reactor. Fuel Process. Technol. 2010, 91, 277–284. [Google Scholar] [CrossRef]

- Ratnasari, D.K.; Nahil, M.A.; Williams, P.T. Catalytic Pyrolysis of Waste Plastics Using Staged Catalysis for Production of Gasoline Range Hydrocarbon Oils. J. Anal. Appl. Pyrolysis 2017, 124, 631–637. [Google Scholar] [CrossRef]

- Xu, X.; Jiang, E.; Li, Z.; Sun, Y. BTX from Anisole by Hydrodeoxygenation and Transalkylation at Ambient Pressure with Zeolite Catalysts. Fuel 2018, 221, 440–446. [Google Scholar] [CrossRef]

- Gaurh, P.; Pramanik, H. Production of Benzene/Toluene/Ethyl Benzene/Xylene (BTEX) via Multiphase Catalytic Pyrolysis of Hazardous Waste Polyethylene Using Low Cost Fly Ash Synthesized Natural Catalyst. Waste Manag. 2018, 77, 114–130. [Google Scholar] [CrossRef]

- Huang, W.C.; Huang, M.S.; Huang, C.F.; Chen, C.C.; Ou, K.L. Thermochemical Conversion of Polymer Wastes into Hydrocarbon Fuels over Various Fluidizing Cracking Catalysts. Fuel 2010, 89, 2305–2316. [Google Scholar] [CrossRef]

- Falcke, H.; Holbrook, S.; Clenahan, I.; Carretero, A.L.; Sanalan, T.; Brinkmann, T.; Joze, R.; Benoît, Z.; Serge, R.; Sancho, L.D. Best Available Techniques (BAT) Reference Document for the Production of Large Volume Organic Chemicals; Publications Office: Luxembourg, 2018; Available online: https://data.europa.eu/doi/10.2760/773042018 (accessed on 10 August 2021).

- What Is BTEX. Available online: https://www.aeroqual.com/what-is-btex (accessed on 10 August 2021).

- Almeida, D.; de Fátima Marques, M. Thermal and Catalytic Pyrolysis of Plastic Waste. Polímeros 2016, 26, 44–51. [Google Scholar] [CrossRef]

- Wang, J.; Jiang, J.; Sun, Y.; Zhong, Z.; Wang, X.; Xia, H.; Liu, G.; Pang, S.; Wang, K.; Li, M.; et al. Recycling Benzene and Ethylbenzene from In-Situ Catalytic Fast Pyrolysis of Plastic Wastes. Energy Convers. Manag. 2019, 200, 112088. [Google Scholar] [CrossRef]

- Bornschein, C.; Werkmeister, S.; Wendt, B.; Jiao, H.; Alberico, E.; Baumann, W.; Junge, H.; Junge, K.; Beller, M. Mild and Selective Hydrogenation of Aromatic and Aliphatic (Di)Nitriles with a Well-Defined Iron Pincer Complex. Nat. Commun. 2014, 5, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Hao, L.; Luo, B.; Li, X.; Jin, M.; Fang, Y.; Tang, Z.; Jia, Y.; Liang, M.; Thomas, A.; Yang, J.; et al. Terephthalonitrile-Derived Nitrogen-Rich Networks for High Performance Supercapacitors. Energy Environ. Sci. 2012, 5, 9747–9751. [Google Scholar] [CrossRef]

- Kim, J.; Kim, H.J.; Chang, S. Synthesis of Aromatic Nitriles Using Nonmetallic Cyano-Group Sources. Angew. Chem. Int. Ed. 2012, 51, 11948–11959. [Google Scholar] [CrossRef]

- Kholkhoev, B.C.; Burdukovskii, V.F.; Mognonov, D.M. Synthesis of Polyamidines Based on 1,4-Dicyanobenzene and 4,4´-Diaminodiphenyl Oxide in Ionic Liquids. Russ. Chem. Bull. 2010, 11, 2159–2160. [Google Scholar] [CrossRef]

- Springer-Verlag, C.; Kobayashi, M.; Nagasawa, T.; Yamada, H. Applied Microbiology Biotechnology Regiospecific Hydrolysis of Dinitrile Compounds by Nitrilase from Rhodococcus Rhodochrous J1. Appl. Microbiol. Biotechnol. 1988, 29, 231–233. [Google Scholar]

- Shen, Y.; Yuan, R. Pyrolysis of Agroforestry Bio-Wastes with Calcium/Magnesium Oxides or Carbonates–Focusing on Biochar as Soil Conditioner. Biomass Bioenergy 2021, 155, 106277. [Google Scholar] [CrossRef]

- Dionisio, K.L.; Phillips, K.; Price, P.S.; Grulke, C.M.; Williams, A.; Biryol, D.; Hong, T.; Isaacs, K.K. The Chemical and Products Database, a Resource for Exposure-Relevant Data on Chemicals in Consumer Products. Sci. Data 2018, 5, 1–9. [Google Scholar] [CrossRef]

- Rajca, P.; Poskart, A.; Chrubasik, M.; Sajdak, M.; Zajemska, M.; Skibiński, A.; Korombel, A. Technological and Economic Aspect of Refuse Derived Fuel Pyrolysis. Renew. Energy 2020, 161, 482–494. [Google Scholar] [CrossRef]

- dos Santos, I.F.S.; Mensah, J.H.R.; Gonçalves, A.T.T.; Barros, R.M. Incineration of Municipal Solid Waste in Brazil: An Analysis of the Economically Viable Energy Potential. Renew. Energy 2020, 149, 1386–1394. [Google Scholar] [CrossRef]

- Singh, R.K.; Ruj, B.; Sadhukhan, A.K.; Gupta, P. Impact of Fast and Slow Pyrolysis on the Degradation of Mixed Plastic Waste: Product Yield Analysis and Their Characterization. J. Energy Inst. 2019, 92, 1647–1657. [Google Scholar] [CrossRef]

- Williams, P.T.; Williams, E.A. Fluidised Bed Pyrolysis of Low Density Polyethylene to Produce Petrochemical Feedstock. J. Anal. Appl. Pyrolysis 1999, 51, 107–126. [Google Scholar] [CrossRef]

- Schirmer, J.; Kim, J.S.; Klemm, E. Catalytic Degradation of Polyethylene Using Thermal Gravimetric Analysis and a Cycled-Spheres-Reactor. J. Anal. Appl. Pyrolysis 2001, 60, 205–217. [Google Scholar] [CrossRef]

- Miandad, R.; Barakat, M.A.; Aburiazaiza, A.S.; Rehan, M.; Nizami, A.S. Catalytic Pyrolysis of Plastic Waste: A Review. Process Saf. Environ. Prot. 2016, 102, 822–838. [Google Scholar] [CrossRef]

- Arabiourrutia, M.; Elordi, G.; Lopez, G.; Borsella, E.; Bilbao, J.; Olazar, M. Characterization of the Waxes Obtained by the Pyrolysis of Polyolefin Plastics in a Conical Spouted Bed Reactor. J. Anal. Appl. Pyrolysis 2012, 94, 230–237. [Google Scholar] [CrossRef]

- Xu, L.; Na, X.W.; Zhang, L.Y.; Dong, Q.; Dong, G.H.; Wang, Y.T.; Fang, Z. Selective Production of Terephthalonitrile and Benzonitrile via Pyrolysis of Polyethylene Terephthalate (PET) with Ammonia over Ca(OH)2/Al2O3 Catalysts. Catalysts 2019, 9, 436. [Google Scholar] [CrossRef]

- Stoye, D.; Freitag, W. Paints, Coatings, and Solvents, 2nd ed.; Completely Edition; Willey-Vch: Weinheim, Germany, 2007. [Google Scholar]

- Hasanova, A.M.; Aliyev, F.Y.; Mammadli, S.B.; Mammadov, B.A. Synthesis of Binary Cooligomers of α-Methylstyrene with Decylmethacrylate and Their Investigation as Additives for Oils. PPOR 2017, 18, 351–360. [Google Scholar]

- McNaught, A.D.; Wilkinson, A. Compendium of Chemical Terminology—The “Gold Book”, 2nd ed.; Nic, M., Jirat, J., Kosata, B., Eds.; IUPAC: Zurich, Switzerland, 1997. [Google Scholar]

- Bertanza, G.; Galessi, R.; Menoni, L.; Zanaboni, S. Wet Oxidation of Sewage Sludge from Municipal and Industrial WWTPs. Desalination Water Treat. 2016, 57, 2422–2427. [Google Scholar] [CrossRef]

- Kim, Y.M.; Jeong, J.; Ryu, S.; Lee, H.W.; Jung, J.S.; Siddiqui, M.Z.; Jung, S.C.; Jeon, J.K.; Jae, J.; Park, Y.K. Catalytic Pyrolysis of Wood Polymer Composites over Hierarchical Mesoporous Zeolites. Energy Convers. Manag. 2019, 195, 727–737. [Google Scholar] [CrossRef]

- Baroutian, S.; Smit, A.M.; Andrews, J.; Young, B.; Gapes, D. Hydrothermal Degradation of Organic Matter in Municipal Sludge Using Non-Catalytic Wet Oxidation. Chem. Eng. J. 2015, 260, 846–854. [Google Scholar] [CrossRef]

- Abnisa, F.; Alaba, P.A. Recovery of Liquid Fuel from Fossil-Based Solid Wastes via Pyrolysis Technique: A Review. J. Environ. Chem. Eng. 2021, 9, 106593. [Google Scholar] [CrossRef]

- Sun, X.; Zhu, Z.; Zaman, F.; Huang, Y.; Guan, Y. Detection and Kinetic Simulation of Animal Hair/Wool Wastes Pyrolysis toward High-Efficiency and Sustainable Management. Waste Manag. 2021, 131, 305–312. [Google Scholar] [CrossRef]

- Kharasch, M.S.; Beck, T.M. The Chemistry of Organic Gold Compounds. V. Auration of Aromatic Nitriles. J. Am. Chem. Soc. 2002, 56, 2057–2060. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).