1. Introduction

This paper proposes an adaptive control strategy for a balancing loading device of a 2-axes gimbal structure for a stair-climbing delivery robot. While the delivery robot climbs stairs, the movement or dislodging of the luggage in the loading box would cause an unstable operation of the delivery robot or damage to the luggage. Therefore, the loading box should maintain balance despite the tilts and impact of the delivery robot.

Figure 1 is a concept figure of a stair-climbing robot and a 2-axes gimbal structure loading device.

The dynamic equation of the loading device changes depending on the properties of the luggage such as mass, moments of inertia, or position of the center of gravity. The luggage cannot be specified, and this makes it difficult to design an appropriate controller. The fixed gains or simple gain scheduler can cause the divergence or long settling time. To optimize the controller for the system in real time, the proposed control strategy includes a system identification and a gain scheduler. The system identification estimates the parameters of the dynamic equations with the only movement of the loading box and torque of the motor. The gain scheduler is composed of surface functions of the estimated parameters, and the surface function is made with optimized PID gains.

In this paper, the 2-axes gimbal structure loading device is interpreted as two independent pendulum systems. There was various preceding research related to the system identification of a pendulum. A study presented an inverted pendulum system identification using an artificial neural network [

1]. Deployed were the Fuzzy T–S identification strategy [

2], genetic algorithms [

3], and modified practical swarm optimization algorithms [

4]. In the other study, the friction coefficient and moment of inertia of the pendulum were identified by the prediction error method [

5]. A study proposed the optimization of the controller of a motor for an inverted pendulum with system identification [

6].

The proposed system identification technique is based on the least-squares method and estimates unknown parameters of the dynamic equation of the loading device in real-time [

7]. At the first, the dynamic equation of the loading device is divided into the known parameters and unknown parameters. The least-squares method-based system identification estimates the unknown parameters by calculating them which minimizes the error function between the motions of a real system and the estimated dynamic equation. The proposed system identification technique can estimate the dynamic equation that produces equal motion with the real loading device in real-time. The technique needs only one IMU and an encoder of the motor without other sensors. However, since the solutions of calculating a dynamic equation are innumerable, the estimated unknown parameters sometimes have large errors. This would be a problem for the gain scheduler that uses the estimated unknown parameters as the variables.

The desired solution can be obtained by adding a null-space solution to the general solution. For example, some studies plan the working path of the robot arm with a null-space solution [

8,

9]. In another study, a null-space solution was used to plan the contact position between a picking object and a robot gripper [

10]. There was a study of behavior-based control techniques for mobile robots [

11]. Like the previous studies, this paper improves the accuracy of the system identification by using a null-space solution. To specify the solution of the null space, a constraint is required. In this study, weights are added to the dynamic equation of the loading device, and a null-space solution is specified with the constraint that the weights should offset. The estimated unknown parameter can be adjusted by the relative size of the weights, and a more accurate estimation is possible. These system identification techniques are verified by a simulation.

After the system identification process, the PID (Proportional–Integral–Differential) controller is determined by gain scheduling. There are previous studies for controller scheduling to respond to a system change. A study handled PID scheduling for sudden braking and acceleration of a vehicle [

12]. In the other studies, the controller for a fixed-wing UAV was adjusted depending on the velocity [

13] and gains for a robot arm were with the degree of the joint [

14]. Also, there were various strategies to schedule PID gains. The Fuzzy logic was used, for example, and there were studies for a UAV [

15] and hybrid stepper motor [

16]. In the other studies, the gain scheduler was based on a genetic Fuzzy model [

17], and neuro-Fuzzy networks [

18]. A quadrotor UAV was controlled with a gain scheduler based on the theory of Lyapunov [

19]. A study developed a gain scheduler for a 2-axes pneumatic artificial muscle robot arm named MIMO neural PID control [

20].

In this paper, there are two independent gain scheduler sets for each frame of each axis of the 2-axes gimbal structure loading device. The gain scheduler is constructed as each surface functions set that uses the estimated unknown parameters in the system identification process as the variables. The gains of each PID controller are determined by assigning each estimated unknown parameter to the gain scheduling surface function. The three-dimensional gain surface functions are constructed in advance by interpolating the optimized PID gains obtained by varying the unknown parameters. In the case of the controller structure, the weights for the null-space solution of the system identification are determined by the torque of each motor. Therefore, the motors can operate with the optimized PID controller to the required torque.

The experiments using a motion platform were conducted with the loading device. This paper shows three experimental results. The weights of the luggage for each experiment change. The tilt motion of the motion platform simultaneously tilts and returns 20 degrees around the pitch axis and 15 degrees around the roll axis. In the results of the experiments, the dynamic equation that moves in equal motion with the real loading device is estimated by the system identification. Also, the PID gain scheduler adjusts the controller depending on the demanded motor torque which changes with the luggage.

The structure of this paper is as follows.

Section 2 presents the system identification technique.

Section 3 handles the structure of the adaptive controller, including the gain scheduler.

Section 4 shows the experiment. Finally,

Section 5 is the conclusion of this paper.

2. System Identification Technique by Parameter Estimator

2.1. Modeling of a 2-Axes Gimbal Structure Loading Device

The inner frame of the 2-axes gimbal structure has much smaller properties like mass and moment of inertia than the outer frame. Also, the tilt of the loading box is mainly caused by the stair climbing of the delivery robot, and the tilt of the inner frame is insignificant. The 2-axes gimbal structure loading device is interpreted as two independent pendulum systems. This simplification is the main assumption of this paper. Each pendulum system maintains the balance by a motor located at the center of its rotation axis. The center of gravity of the loading device can change with loaded luggage.

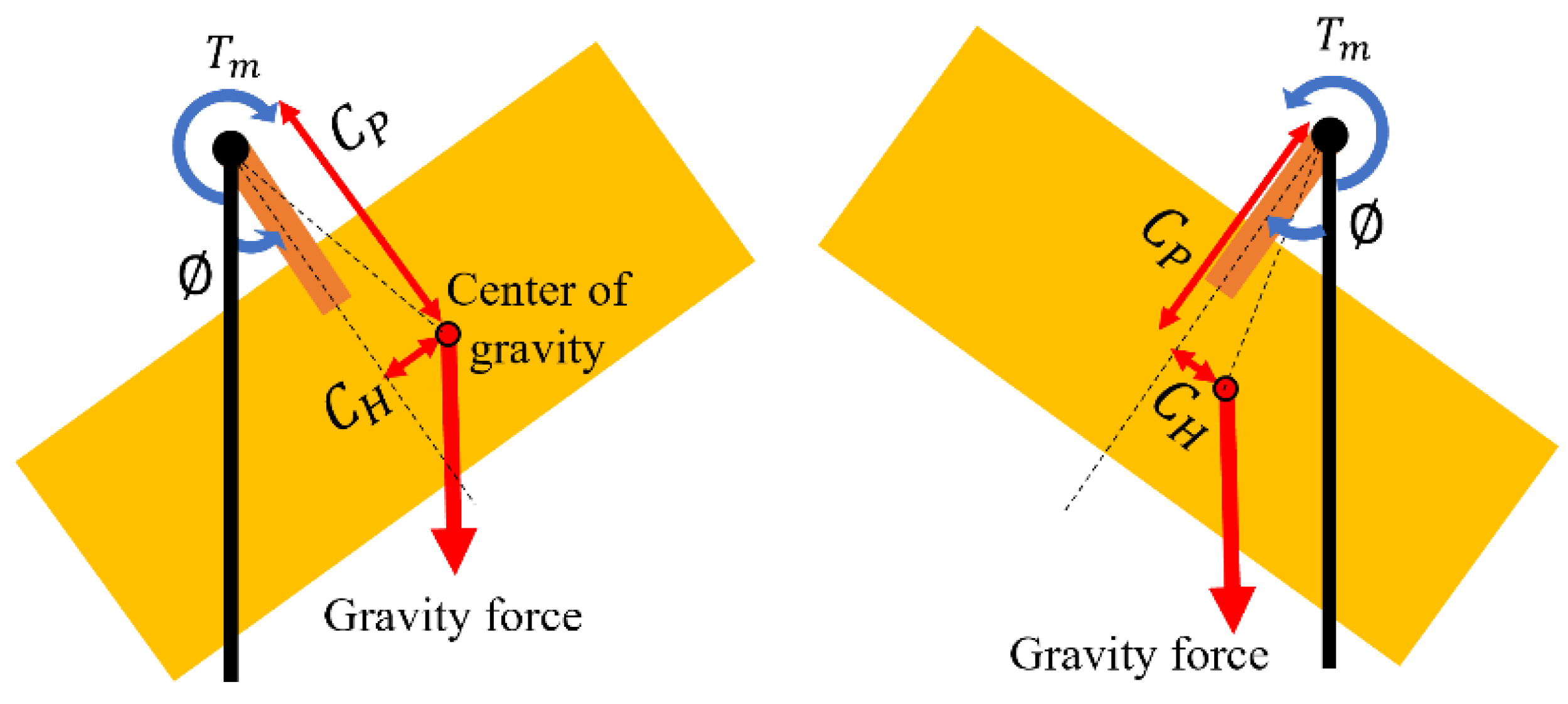

Figure 2 is the free body diagram, and Equation (1) is the dynamic equation of a pendulum structure loading device.

: the tilt of the loading device

: the moment of inertia of the loading device ()

: the mass of the loading device

: the vertical position of the center of gravity from the rotate axis

: the horizontal position of the center of gravity from the rotate axis

: gravitational acceleration

: angular velocity of motor shaft

: damping coefficient of the motor

:

In Equation (1), the

and

are known values that can be measured by an IMU sensor and an encoder of the motor, and the

is determined as a fixed value by experimental data for simplifying. The

, and

are unknown values that change depending on the loaded luggage. For system identification by a parameter estimator, the dynamic equation is expressed by dividing it into the known parameters and unknown parameters in Equations (2)–(4).

In Equation (4), the vector is the known parameters vector with measurable values, and the is the unknown parameters vector. The cannot be determined because the loaded luggage is unspecific, and it makes it difficult to design an appropriate controller. The is divided into the of the empty loading device and the which represents the difference between the empty loading device by luggage. The system identification process aims to estimate the to calculate the in real-time.

2.2. Least-Squares Method-Based System Identification Technique

The proposed system identification technique is based on the least-squares method. The parameter estimator estimates the

that minimizes the error function between the

of the real loading device and the mathematically modeled

in Equation (4). The error function between the

and the

is Equation (5).

To minimize the

, Equation (6) which is the derivative of the

should be 0. The processes of calculating the

when the

is 0 are Equations (7) and (8). The system identification technique estimates the

in real-time by adding the

and the

in Equation (8).

The identification technique can estimate the dynamic equation that moves in equal motion with the real system of the loading device. The system identification technique does not need experimental results and only needs an IMU sensor and encoder of the motor. However, since there are countless solutions in calculating , the accuracy of the parameter estimator is sometimes poor. Although the dynamic equation that produces the equal motion with the real loading device is estimated, the large error of the parameter may cause an inappropriate controller. This is because the gain scheduler uses the unknown parameters as the inputs. As shown in of Equation (8), the system identification technique is dependent on the terms of the known parameter vector . Therefore, the estimation degree of each term of the varies depending on the relative size of each multiplied term of the . This paper proposes an improvement in the accuracy of the parameter estimation by using a null-space solution.

2.3. System Identification Improvement Using Null-Space Solution

In the least-squares method-based system identification technique, the estimation of terms of the

depends on the relative size of each term of the multiplied

. To adjust each term of the

, weights are added to the dynamic equation of the loading device. Equations (9) and (10) are the dynamic equation added by the weights.

The

and

are the weights, the

is the known parameter vector, and the

is the unknown parameter vector. Equation (11) is the desired solution of the

by adding a null-space solution to Equation (8). Equation (8) is the final equation of estimated

in system identification process and it is used to optimize the controller in gain scheduling. Equations (12) and (13) is derived from Equation (8).

in Equation (11) is a null-space solution. Since the weights of Equation (10) should not affect the system of the loading device, they should be offset. The offsetting of the weights is set as a constraint to specify the null-space solution. The constraint is Equation (14). The

of Equation (11) is derived as Equation (15) using this constraint. Then, the null-space solution is calculated by multiplying Equation (15) and the three rows of the

in Equation (11).

The system identification technique using a null-space solution can control the by adjusting the relative size of each term of the with the , and . And the accuracy of the can be improved.

2.4. Simulation of the System Identification Techniques

The proposed system identification techniques are verified by simulation using MATLAB and Simulink (MathWorks, Natick, MA, USA). To verify the system identification, a dynamic equation assumed as a real loading device is defined in advance. The of the predefined dynamic equation is expressed as . The estimated by the least-squares method-based system identification is expressed as . is the estimated by the improved system identification using a null-space solution.

Figure 3 and

Table 1 show the simulation results.

Figure 3a shows that the pendulum motions of the dynamic equation of the

,

, and

are equal. In

Figure 3c, the

and the

are checked how close they are to the

.

Figure 3b is the torque of the motor that is related to the relative size of the terms of the

.

Table 1 is a table that summarizes

,

,

, and

. The

and

are the converged

and

at the stop time of the simulation.

Table 1 also shows the values used in the calculation of

and

.

In the simulation, the movement of the stair-climbing delivery robot is a step function of 15 degrees to simulate the tilting of the frame of the roll axis which is the inner frame of the gimbal structure. A controller of the loading device is a fixed PID controller. The fixed values are as follows:

Gains of the PID controller: , ,

The weights: , ,

In

Figure 3a, the root-mean-square errors of the estimated system and the estimated (NSS) system are

and

. It shows that the proposed system identification techniques estimate the dynamic equation that moves in equal motion with the real system.

In

Figure 3c and

Table 1, the

of the

stays at the

. The cause is that

, the first term of the known parameter vector

, that is multiplied by

, is almost 0 because the

converges to 0. In the calculation of the

by minimizing the error function of the

, the adjustment of the

has a negligible effect, and it causes that the

is almost 0. This problem is also shown for the

and the

depending on the relative size between

, which is the second term of

and motor torque in

Figure 3b affecting the third term of

. In

Table 1, the error rates of each term of the

are 31.960%, 399.427%, and 399.479%. On the other hand, the improved system identification technique using a null-space solution can adjust the

. The error rates of each term of the

are 0.928%, 0.925%, and 0.925%. The accuracy of the parameter estimation can be improved by using a null-space solution.

5. Conclusions

This paper proposes an adaptive control strategy including system identification and gain scheduling. The system identification is conducted by parameter estimation based on least-squares method, and it estimates the unknown parameters of the dynamic equation of the loading device. In the simulation, the root-mean-square error between the motions of a predefined system and the estimated system is almost 0. This means that the least-squares method-based system identification technique estimates the dynamic equation that moves in equal motion with the real loading device. The accuracy of the parameter estimation of the system identification technique is improved using a null-space solution. Compared to the parameter estimation of the normal system identification technique showing error rates of 31.960%, 399.427%, 399.479%, the improved system identification technique shows error rates of 0.928%, 0.925%, 0.925%. In the proposed adaptive control strategy, the weights for the null-space solution are determined by the motor torque. Therefore, the parameter estimator can respond appropriately to the demanded torque in the gain scheduling process.

The PID gain scheduling for the frames of the pitch axis and the roll axis uses independent gain schedulers for each axis. Each gain scheduler consists of surface functions using the estimated unknown parameters in the system identification process as the variables. The surface functions are constructed in advance by interpolating the optimized gains. The gain scheduler can adapt the controller by assigning the unknown parameters to the scheduling surface functions in real-time. In the case of the structure of the controller, it includes not only a system identification and a gain scheduler but also a smoothing filter and anti-wind-up technique.

The experiments using a motion platform are conducted. In the results of the experiments, the root-mean-square error between the angular accelerations of the real loading device and the estimated system is 0. The gain scheduler properly adapts the controller depending on the motor torque in real-time. In the case of the balancing control of the loading box, every overshoot and settling time of 5% error rate of all experiments are 2 degrees and 2.45 s or less. The 2-axes gimbal loading device is well balanced by the proposed adaptive control strategy despite the tilting of the motion platform and system change caused by the luggage.

The next step of this study is to apply the loading device to a stair-climbing delivery robot. The loading device should be lighter, and carefully adjust the position of the center of gravity for the stable operation of the delivery robot.