Development Trend of Electronic Nose Technology in Closed Cabins Gas Detection: A Review

Abstract

:1. Introduction

2. Gases in Enclosed Cabins

2.1. Hazardous Gases

2.2. Warning Gases

3. Concept and Principle of the Electronic Nose

3.1. Basic Mechanism

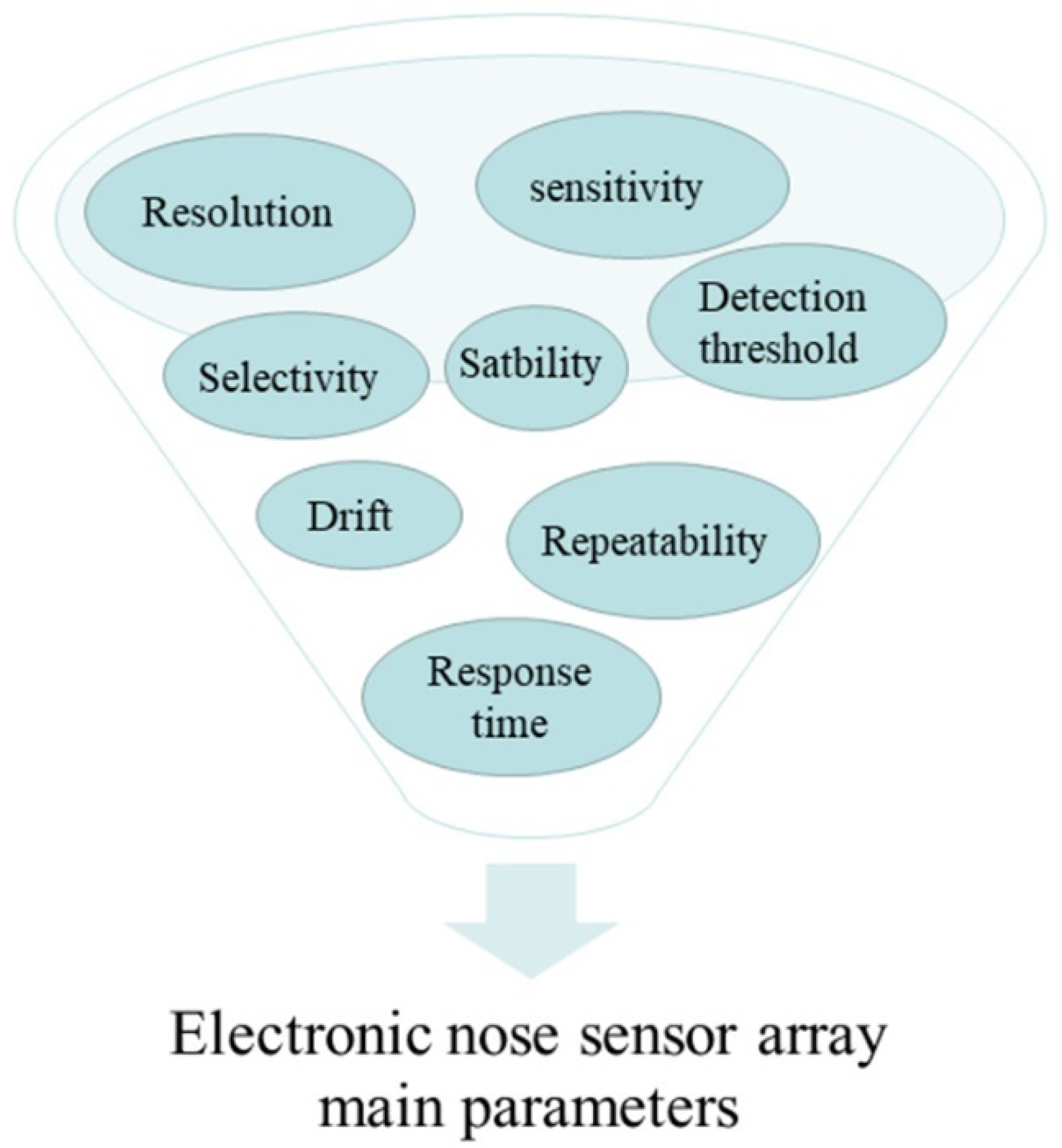

3.2. System Components

3.3. Comparison of Electronic Nose and Other Methods

4. Application of Electronic Nose in Gas Detection of Closed Cabins

4.1. Gas Detection in Vehicle Cabin

4.2. Gas Detection in Aircraft Cabin

4.3. Gas Detection in Space Station Cabin

5. Challenges and Future Trends

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Faber, J.; Brodzik, K.; Gołda-Kopek, A.; Łomankiewicz, D. Air Pollution in New Vehicles as a Result of VOC Emissions from Interior Materials. Pol. J. Environ. Stud. 2013, 22, 1701–1709. [Google Scholar]

- Chien, Y.C. Variations in amounts and potential sources of volatile organic chemicals in new cars. Sci. Total Environ. 2007, 382, 228–239. [Google Scholar] [CrossRef] [PubMed]

- Palmer, P.T.; Limero, T.F. Mass spectrometry in the U.S. space program: Past, present, and future. J. Am. Soc. Mass Spectrom. 2001, 12, 656–675. [Google Scholar] [CrossRef]

- Li, J.; Hodges, R.D.; Gutierrez-Osuna, R.; Luckey, G.; Crowell, J.; Schiffman, S.S.; Nagle, H.T. Odor Assessment of Automobile Cabin Air With Field Asymmetric Ion Mobility Spectrometry and Photoionization Detection. IEEE Sens. J. 2016, 16, 409–417. [Google Scholar] [CrossRef]

- Persaud, K.; Dodd, G. Analysis of discrimination mechanisms in the mammalian olfactory system using a model nose. Nature 1982, 299, 352–355. [Google Scholar] [CrossRef]

- Kalman, E.-L.; Löfvendahl, A.; Winquist, F.; Lundström, I. Classification of complex gas mixtures from automotive leather using an electronic nose. Anal. Chim. Acta 2000, 403, 31–38. [Google Scholar] [CrossRef]

- Ozmen, A.; Dogan, E. Design of a Portable E-Nose Instrument for Gas Classifications. IEEE Trans. Instrum. Meas. 2009, 58, 3609–3618. [Google Scholar] [CrossRef]

- Dragonieri, S.; van der Schee, M.P.; Massaro, T.; Schiavulli, N.; Brinkman, P.; Pinca, A.; Carratu, P.; Spanevello, A.; Resta, O.; Musti, M.; et al. An electronic nose distinguishes exhaled breath of patients with Malignant Pleural Mesothelioma from controls. Lung Cancer 2012, 75, 326–331. [Google Scholar] [CrossRef]

- Arnold, C.; Harms, M.; Goschnick, J. Air quality monitoring and fire detection with the Karlsruhe electronic micronose KAMINA. IEEE Sens. J. 2002, 2, 179–188. [Google Scholar] [CrossRef]

- Jansen, R.; Hofstee, J.W.; Bouwmeester, H.; Henten, E.V. Automated Signal Processing Applied to Volatile-Based Inspection of Greenhouse Crops. Sensors 2010, 10, 7122–7133. [Google Scholar] [CrossRef]

- Cheng, L.; Meng, Q.-H.; Lilienthal, A.J.; Qi, P.-F. Development of compact electronic noses: A review. Meas. Sci. Technol. 2021, 32, 062002. [Google Scholar] [CrossRef]

- Chen, H.; Huo, D.; Zhang, J. Gas Recognition in E-Nose System: A Review. IEEE Trans. Biomed. Circuits Syst. 2022, 16, 169–184. [Google Scholar] [CrossRef] [PubMed]

- Kiani, S.; Minaei, S.; Ghasemi-Varnamkhasti, M. Application of electronic nose systems for assessing quality of medicinal and aromatic plant products: A review. J. Appl. Res. Med. Aromat. Plants 2016, 3, 1–9. [Google Scholar] [CrossRef]

- GÓRska-Horczyczak, E.; Guzek, D.; MolĘDa, Z.; Wojtasik-Kalinowska, I.; Brodowska, M.; Wierzbicka, A. Applications of electronic noses in meat analysis. Food Sci. Technol. 2016, 36, 389–395. [Google Scholar] [CrossRef]

- Yakubu, H.G.; Kovacs, Z.; Toth, T.; Bazar, G. Trends in artificial aroma sensing by means of electronic nose technologies to advance dairy production—A review. Crit. Rev. Food Sci. Nutr. 2021, 1–15. [Google Scholar] [CrossRef]

- Yang, T.; Zhang, P.; Xiong, J. Association between the emissions of volatile organic compounds from vehicular cabin materials and temperature: Correlation and exposure analysis. Indoor Built Environ. 2018, 28, 362–371. [Google Scholar] [CrossRef]

- Yang, T.; Zhang, P.; Xu, B.; Xiong, J. Predicting VOC emissions from materials in vehicle cabins: Determination of the key parameters and the influence of environmental factors. Int. J. Heat Mass Transf. 2017, 110, 671–679. [Google Scholar] [CrossRef]

- Huang, W.; Lv, M.; Yang, X. Long-term volatile organic compound emission rates in a new electric vehicle: Influence of temperature and vehicle age. Build. Environ. 2020, 168, 106465. [Google Scholar] [CrossRef]

- Wang, C.; Yang, X.; Guan, J.; Li, Z.; Gao, K. Source apportionment of volatile organic compounds (VOCs) in aircraft cabins. Build. Environ. 2014, 81, 1–6. [Google Scholar] [CrossRef]

- Kim, K.H.; Szulejko, J.E.; Jo, H.J.; Lee, M.H.; Kim, Y.H.; Kwon, E.; Ma, C.J.; Kumar, P. Measurements of major VOCs released into the closed cabin environment of different automobiles under various engine and ventilation scenarios. Environ. Pollut 2016, 215, 340–346. [Google Scholar] [CrossRef]

- Imahashi, M.; Miyagi, K.; Takamizawa, T.; Hayashi, K.; Gouma, P. Artificial odor map and discrimination of odorants using the odor separating system. AIP Conf. Proc. 2011, 27, 1362. [Google Scholar] [CrossRef]

- Brett, F.; Tormey, W. Alcohol, duty-of-care and common law—Where do the consequences of drunken behaviour lie? Med. -Leg. J. 2014, 82, 119–123. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.; Yang, X.; Licina, D. Emissions of volatile organic compounds from interior materials of vehicles. Build. Environ. 2020, 170, 106599. [Google Scholar] [CrossRef]

- Charumporn, B.; Omatu, S.; Yoshioka, M.; Fujinaka, T.; Kosaka, T. Fire detection systems by compact electronic nose systems using metal oxide gas sensors. In Proceedings of the 2004 IEEE International Joint Conference on Neural Networks (IEEE Cat. No.04CH37541), Budapest, Hungary, 25–29 July 2004; pp. 1317–1320. [Google Scholar] [CrossRef]

- Valente, J.; Munniks, S.; Man, I.d.; Kooistra, L. Validation of a small flying e-nose system for air pollutants control: A plume detection case study from an agricultural machine. In Proceedings of the 2018 IEEE International Conference on Robotics and Biomimetics (ROBIO), Kuala Lumpur, Malaysia, 12–15 December 2018; pp. 1993–1998. [Google Scholar] [CrossRef]

- Liu, H.; Meng, G.; Deng, Z.; Li, M.; Chang, J.; Dai, T.; Fang, X. Progress in Research on VOC Molecule Recognition by Semiconductor Sensors. Acta Phys. Chim. Sin. 2020, 38, 2008018. [Google Scholar] [CrossRef]

- Morvan, M.; Talou, T.; Gaset, A.; Beziau, J.F. Electronic-nose systems for control quality applications in automotive industry. Sens. Actuators B Chem. 2000, 69, 384–388. [Google Scholar] [CrossRef]

- Young, R.C.; Buttner, W.J.; Linnell, B.R.; Ramesham, R. Electronic nose for space program applications. Sens. Actuators B Chem. 2003, 93, 7–16. [Google Scholar] [CrossRef]

- Hsieh, Y.-C.; Yao, D.-J. Intelligent gas-sensing systems and their applications. J. Micromechanics Microengineering 2018, 28, 093001. [Google Scholar] [CrossRef]

- Cheng, L.; Liu, Y.B.; Meng, Q.H. A Novel E-Nose Chamber Design for VOCs Detection in Automobiles. In Proceedings of the 2020 39th Chinese Control Conference (CCC), Shenyang, China, 27–29 July 2020; pp. 6055–6060. [Google Scholar] [CrossRef]

- Wasilewski, T.; Gębicki, J.; Kamysz, W. Advances in olfaction-inspired biomaterials applied to bioelectronic noses. Sens. Actuators B Chem. 2018, 257, 511–537. [Google Scholar] [CrossRef]

- Francioso, L.; Forleo, A.; Taurino, A.M.; Siciliano, P.; Lorenzelli, L.; Guarnieri, V.; Adami, A.; Agnusdei, G. Linear temperature microhotplate gas sensor array for automotive cabin air quality monitoring. Sens. Actuators B Chem. 2008, 134, 660–665. [Google Scholar] [CrossRef]

- Sun, Z.H.; Liu, K.X.; Xu, X.H.; Meng, Q.H. Odor Evaluation of Vehicle Interior Materials Based on Portable E-nose. In Proceedings of the 2020 39th Chinese Control Conference (CCC), Shenyang, China, 27–29 July 2020; pp. 2998–3003. [Google Scholar] [CrossRef]

- Asri, M.I.A.; Hasan, M.N.; Fuaad, M.R.A.; Yunos, Y.M.; Ali, M.S.M. MEMS Gas Sensors: A Review. IEEE Sens. J. 2021, 21, 18381–18397. [Google Scholar] [CrossRef]

- Al-Dayyeni, W.S.; Al-Yousif, S.; Taher, M.M.; Al-Faouri, A.W.; Tahir, N.M.; Jaber, M.M.; Ghabban, F.; Najm, I.A.; Alfadli, I.M.; Ameerbakhsh, O.Z.; et al. A Review on Electronic Nose: Coherent Taxonomy, Classification, Motivations, Challenges, Recommendations and Datasets. IEEE Access 2021, 9, 88535–88551. [Google Scholar] [CrossRef]

- Strike, D.J.; Meijerink, M.G.H.; Koudelka-Hep, M. Electronic noses—A mini-review. Fresenius’ J. Anal. Chem. 1999, 364, 499–505. [Google Scholar] [CrossRef]

- Buchecker, F.; Baum, A.; Loos, H.M.; Buettner, A. Follow your nose—Traveling the world of odorants in new cars. Indoor Air 2022, 32, e13014. [Google Scholar] [CrossRef]

- Librelon, W.; Souza, J.C.; Lins, V.F.C. Chemical compounds emitted by main components used in interior of vehicles. Express Polym. Lett. 2018, 12, 1106–1116. [Google Scholar] [CrossRef]

- Burdack-Freitag, A.; Bullinger, D.; Mayer, F.; Breuer, K. Odor and taste perception at normal and low atmospheric pressure in a simulated aircraft cabin. J. Für Verbrauch. Und Lebensm. 2011, 6, 95–109. [Google Scholar] [CrossRef]

- Loutfi, A.; Coradeschi, S.; Mani, G.K.; Shankar, P.; Rayappan, J.B.B. Electronic noses for food quality: A review. J. Food Eng. 2015, 144, 103–111. [Google Scholar] [CrossRef]

- Chaturvedi, A.K. Aerospace toxicology overview: Aerial application and cabin air quality. Rev. Environ. Contam. Toxicol. 2011, 214, 15–40. [Google Scholar] [CrossRef]

- Hu, W.; Wan, L.; Jian, Y.; Ren, C.; Jin, K.; Su, X.; Bai, X.; Haick, H.; Yao, M.; Wu, W. Electronic Noses: From Advanced Materials to Sensors Aided with Data Processing. Adv. Mater. Technol. 2018, 4, 1800488. [Google Scholar] [CrossRef]

- Morvan, M.; Talou, T.; Beziau, J.-F. MOS–MOSFET gas sensors array measurements versus sensory and chemical characterisation of VOC’s emissions from car seat foams. Sens. Actuators B Chem. 2003, 95, 212–223. [Google Scholar] [CrossRef]

- Guadarrama, A.; Rodríguez-Méndez, M.L.; de Saja, J.A. Conducting polymer-based array for the discrimination of odours from trim plastic materials used in automobiles. Anal. Chim. Acta 2002, 455, 41–47. [Google Scholar] [CrossRef]

- Shi, Y.; Yuan, H.; Zhang, Q.; Sun, A.; Liu, J.; Men, H. Lightweight Interleaved Residual Dense Network for Gas Identification of Industrial Polypropylene Coupled With an Electronic Nose. IEEE Trans. Instrum. Meas. 2021, 70, 1–10. [Google Scholar] [CrossRef]

- Blaschke, M.; Tille, T.; Robertson, P.; Mair, S.; Weimar, U.; Ulmer, H. MEMS Gas-Sensor Array for Monitoring the Perceived Car-Cabin Air Quality. IEEE Sens. J. 2006, 6, 1298–1308. [Google Scholar] [CrossRef]

- Sakairi, M. Water-Cluster-Detecting Breath Sensor and Applications in Cars for Detecting Drunk or Drowsy Driving. IEEE Sens. J. 2012, 12, 1078–1083. [Google Scholar] [CrossRef]

- Rosero-Montalvo, P.D.; Lopez-Batista, V.F.; Peluffo-Ordonez, D.H. Hybrid Embedded-Systems-Based Approach to in-Driver Drunk Status Detection Using Image Processing and Sensor Networks. IEEE Sens. J. 2021, 21, 15729–15740. [Google Scholar] [CrossRef]

- Wu, Z.; Wang, H.; Wang, X.; Zheng, H.; Chen, Z.; Meng, C. Development of Electronic Nose for Qualitative and Quantitative Monitoring of Volatile Flammable Liquids. Sensors 2020, 20, 1817. [Google Scholar] [CrossRef]

- Zhang, T.; Chen, Q.Y.; Lin, C.-H. Optimal Sensor Placement for Airborne Contaminant Detection in an Aircraft Cabin. HVACR Res. 2007, 13, 683–696. [Google Scholar] [CrossRef]

- Mazumdar, S.; Chen, Q. Influence of cabin conditions on placement and response of contaminant detection sensors in a commercial aircraft. J. Environ. Monit. 2008, 10, 71–81. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Li, S.; Ni, W.; Abbott, D.; Johnson, M.; Pei, G.; Hedley, M. Cooperative Localization and Association of Commercial-Off-the-Shelf Sensors in Three-Dimensional Aircraft Cabin. IEEE Trans. Autom. Sci. Eng. 2021, 1–12. [Google Scholar] [CrossRef]

- Yang, X.; Kirsch, J.; Olsen, E.V.; Fergus, J.W.; Simonian, A.L. Anti-fouling PEDOT:PSS modification on glassy carbon electrodes for continuous monitoring of tricresyl phosphate. Sens. Actuators B Chem. 2013, 177, 659–667. [Google Scholar] [CrossRef]

- Ryan, M.A.; Zhou, H.; Buehler, M.G.; Manatt, K.S.; Mowrey, V.S.; Jackson, S.P.; Kisor, A.K.; Shevade, A.V.; Homer, M.L. Monitoring space shuttle air quality using the Jet Propulsion Laboratory electronic nose. IEEE Sens. J. 2004, 4, 337–347. [Google Scholar] [CrossRef]

- Martinelli, E.; Zampetti, E.; Pantalei, S.; Lo Castro, F.; Santonico, M.; Pennazza, G.; Paolesse, R.; Natale, C.D.; D’Amico, A.; Giannini, F.; et al. Design and test of an electronic nose for monitoring the air quality in the international space station. Microgravity Sci. Technol. 2007, 19, 60–64. [Google Scholar] [CrossRef]

- Li, W.; Leung, H.; Kwan, C.; Linnell, B.R. E-Nose Vapor Identification Based on Dempster–Shafer Fusion of Multiple Classifiers. IEEE Trans. Instrum. Meas. 2008, 57, 2273–2282. [Google Scholar] [CrossRef]

- Ni, M.; Stetter, J.R.; Buttner, W.J. Orthogonal gas sensor arrays with intelligent algorithms for early warning of electrical fires. Sens. Actuators B Chem. 2008, 130, 889–899. [Google Scholar] [CrossRef]

- Zhou, H.; Homer, M.; Shevade, A.; Ryan, M. Nonlinear Least-Squares Based Method for Identifying and Quantifying Single and Mixed Contaminants in Air with an Electronic Nose. Sensors 2005, 6, 1–18. [Google Scholar] [CrossRef]

- Ryan, M.A.; Manatt, K.S.; Gluck, S.; Shevade, A.V.; Kisor, A.K.; Zhou, H.; Lara, L.M.; Homer, M.L. The JPL electronic nose: Monitoring air in the U.S. Lab on the International Space Station. In Proceedings of the SENSORS, 2010 IEEE, Waikoloa, HI, USA, 1–4 November 2010; pp. 1242–1247. [Google Scholar] [CrossRef]

- Fonollosa, J.; Rodriguez-Lujan, I.; Shevade, A.V.; Homer, M.L.; Ryan, M.A.; Huerta, R. Human activity monitoring using gas sensor arrays. Sens. Actuators B Chem. 2014, 199, 398–402. [Google Scholar] [CrossRef]

- Gebicki, J. Application of electrochemical sensors and sensor matrixes for measurement of odorous chemical compounds. TrAC Trends Anal. Chem. 2016, 77, 1–13. [Google Scholar] [CrossRef]

- Pelosi, P.; Zhu, J.; Knoll, W. From Gas Sensors to Biomimetic Artificial Noses. Chemosensors 2018, 6, 32. [Google Scholar] [CrossRef]

- Hurot, C.; Scaramozzino, N.; Buhot, A.; Hou, Y. Bio-Inspired Strategies for Improving the Selectivity and Sensitivity of Artificial Noses: A Review. Sensors 2020, 20, 1803. [Google Scholar] [CrossRef]

- Hong, M. Key Technology of Electronic Nose Gas Recognizer Based on Wireless Sensor Networks. Int. J. Online Eng. 2018, 14, 68. [Google Scholar] [CrossRef]

- Park, J.; Jumu, F.; Power, J.; Richard, M.; Elsahli, Y.; Jarkas, M.A.; Ruan, A.; Luican-Mayer, A.; Ménard, J.-M. Drone-Mountable Gas Sensing Platform Using Graphene Chemiresistors for Remote In-Field Monitoring. Sensors 2022, 22, 2383. [Google Scholar] [CrossRef]

- Jian, Y.; Hu, W.; Zhao, Z.; Cheng, P.; Haick, H.; Yao, M.; Wu, W. Gas Sensors Based on Chemi-Resistive Hybrid Functional Nanomaterials. Nanomicro Lett. 2020, 12, 71. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Brady, J.; Al-Badani, F.; Yu, S.; Hart, J.; Jung, S.; Tran, T.T.; Myung, N.V. Nanoengineering Approaches Toward Artificial Nose. Front. Chem. 2021, 9, 629329. [Google Scholar] [CrossRef] [PubMed]

| Gas Classification | Gas Composition | References |

|---|---|---|

Hazardous gases | VOCs | [16,17,18,19] [6,20,21,22] |

| Odors | [23,24,25] | |

| Sensor file://C:\Program Files (x86)\Youdao\Dict\7.5.2.0\resultui\dict\?keyword=location | [26,27,28] | |

Warning gas | Chemical vapors | [29,30,31] [32,33,34,35] |

| Alcohol | [36,37,38] |

| Sample | Sensor | Application | Analysis Method | References |

|---|---|---|---|---|

| Five types of polyurethane materials for automotive interiors | MOS sensor MOSFET sensor CP sensor | Comparing the ability of three sensors to discriminate between materials | PCA, MDA | [16] |

| Three production stages of leather for automobiles | MOS sensor MOSFET sensor | To leather material quality classification | PCA | [6] |

| Seven different vehicle seat materials | MOS sensor MOSFET sensor | Differentiate different materials and connect with sensory analysis | PCA | [20] |

| Preparation of CO, NO2, SO2 gases with different concentrations in the vehicle | MOS sensor | Different evaluations gas heat sensitivity | PCA | [18] |

| Auto interior polyurethane (PU) leather and polyvinyl chloride (PVC) leather | (MEMS) Chip Sensors | Design of electronic nose chamber to improve electronic nose response sensitivity | PCA, SVM | [17] |

| Vehicle manufacturing Eight sample materials | Chemiresistive Polymer Sensors | Analyze part odor characteristics classify and identify | PCA, CA | [21] |

| Two polypropylene materials for automotive interiors | MOS sensor | Differentiate between two materials using a deep learning algorithm | Deep Learning | [22] |

| Cigarette smoke, fast food smells, feces, and biological agents with vehicles | MOS sensor | Assess the air quality level in the vehicle | Custom AQL sensory evaluation algorithm | [23] |

| Automotive interior polyurethane (PU) leather, polyethylene (PVC) leather, rubber strips, foam, seat, and floor mats | MOS type sensor | Design a classifier to distinguish between odor types and classes | KNN, SVM | [19] |

| Volunteer air in the vehicle | WCD alcohol sensor | Detection of drunk and fatigued driving in the vehicle | [36] | |

| Volunteer gas in vehicle | MOS sensor | Identify the alcohol content in the vehicle | Deep learning, KNN | [37] |

| In-vehicle ethanol, tetrahydrofuran, turpentine, paint thinner, and gasoline | MOS sensor | Monitors 5 highly flammable liquids | BP-ANN | [38] |

| Experimental data of a two-aisle aircraft cockpit model | MOS sensor | Optimal monitoring location for a single sensor determined | CDF | [26] |

| Four-row model of a two-aisle passenger cabin | MOS sensor | Study the influence of factors such as the passenger location of the location and number of sensors | CDF | [27] |

| Double-aisle passenger cabin | MOS sensor | Developed a 3D mounting point model for the sensor | CDF | [28] |

| Gaseous tricresyl phosphate (TCP) in aircraft cabin | Electrochemical sensors | The application of electrode antifouling modifiers of continuous detection (TCP) electrochemical sensing systems was investigated | CV curve | [24] |

| Simulated electric steam fire proportioning steam in space station | Chemical sensor | Identify and quantify target gases below the one-hour SMAC | LM-NLS | [30] |

| Simulated electric steam fire proportioning steam in space station | QMB sensor | Develop an electronic nose that continuously monitors air quality inside the spacecraft | PCA | [31] |

| Space station interiors polyvinyl chloride (PVC), Teflon (Teflon), and Kapton insulation-type wires | MOS sensor | Analysis of three application scenarios of electronic nose in space station | Nonlinear classifier | [29] |

| NASA provides data from the space station | MOS sensor | Vapor identification inside the space station | Multi-classifier fusion method | [32] |

| Silicone rubber and PVC insulated wires in the space station | EC sensor MOX sensor | Evaluate specific sensor arrays and multivariate analysis to identify pre-combustion vapor feasibility | Multivariate analysis | [33] |

| Simulated electric steam fire proportioning steam in space station | Chemical sensor | Improving Single and Mixed Gas Identification Accuracy Using LM | LM | [34] |

| Simulated electric steam fire proportioning steam in space station | Chemical sensor | Detecting anomalous events in the space environment | LM | [35] |

| Daily activities of volunteers on space station generate gas | Chemical sensor | To study the relationship between JPL’s third-generation electronic nose and human activities | SVR | [25] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, L.; Feng, Z.; Zheng, H.; Yao, Z.; Weng, X.; Wang, F.; Chang, Z. Development Trend of Electronic Nose Technology in Closed Cabins Gas Detection: A Review. Appl. Sci. 2022, 12, 9326. https://doi.org/10.3390/app12189326

Tan L, Feng Z, Zheng H, Yao Z, Weng X, Wang F, Chang Z. Development Trend of Electronic Nose Technology in Closed Cabins Gas Detection: A Review. Applied Sciences. 2022; 12(18):9326. https://doi.org/10.3390/app12189326

Chicago/Turabian StyleTan, Lidong, Zhaohui Feng, Hongli Zheng, Zongwei Yao, Xiaohui Weng, Fangrong Wang, and Zhiyong Chang. 2022. "Development Trend of Electronic Nose Technology in Closed Cabins Gas Detection: A Review" Applied Sciences 12, no. 18: 9326. https://doi.org/10.3390/app12189326