Stability Analysis of Surrounding Rock in the Diversion Tunnel at the Xulong Hydropower Station based on RFPA3D and Microseismic Monitoring

Abstract

:1. Introduction

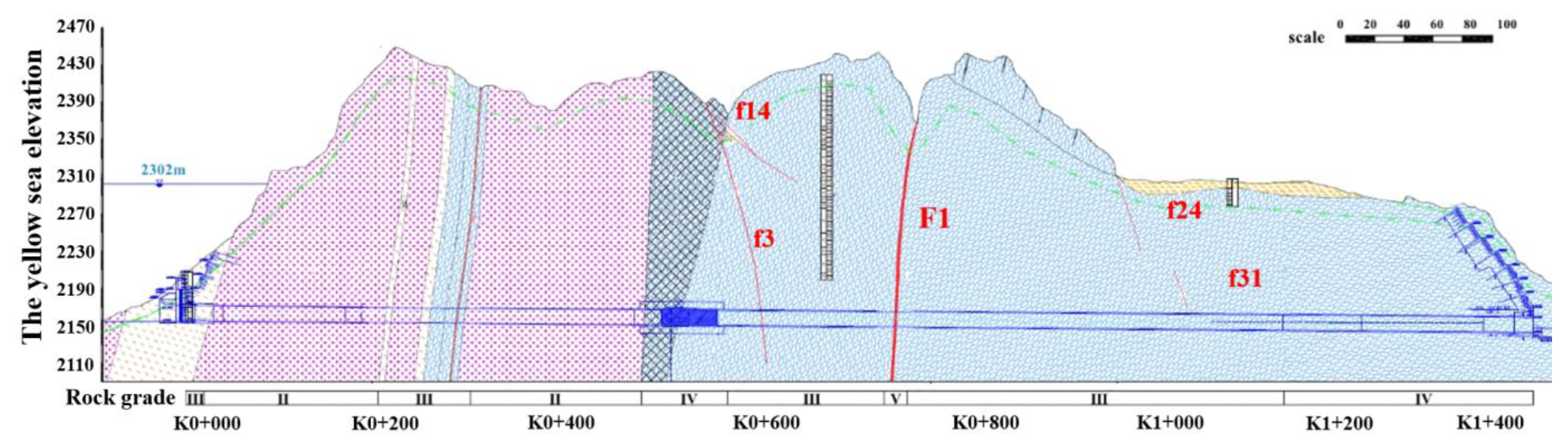

2. Engineering Background

3. Numerical Modeling

3.1. Basic Principles of RFPA

3.2. Twin-Shear Unified Strength Criterion

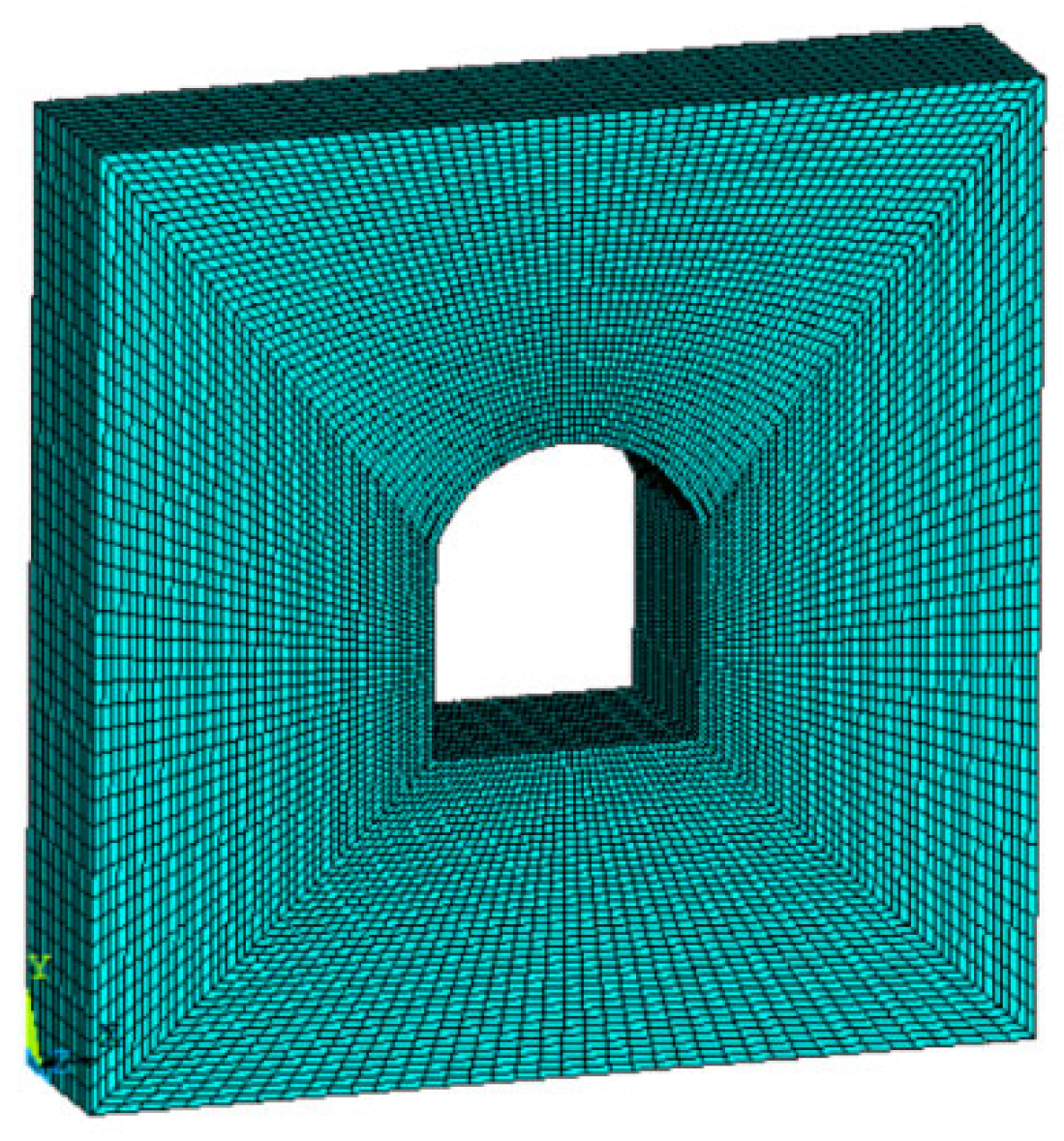

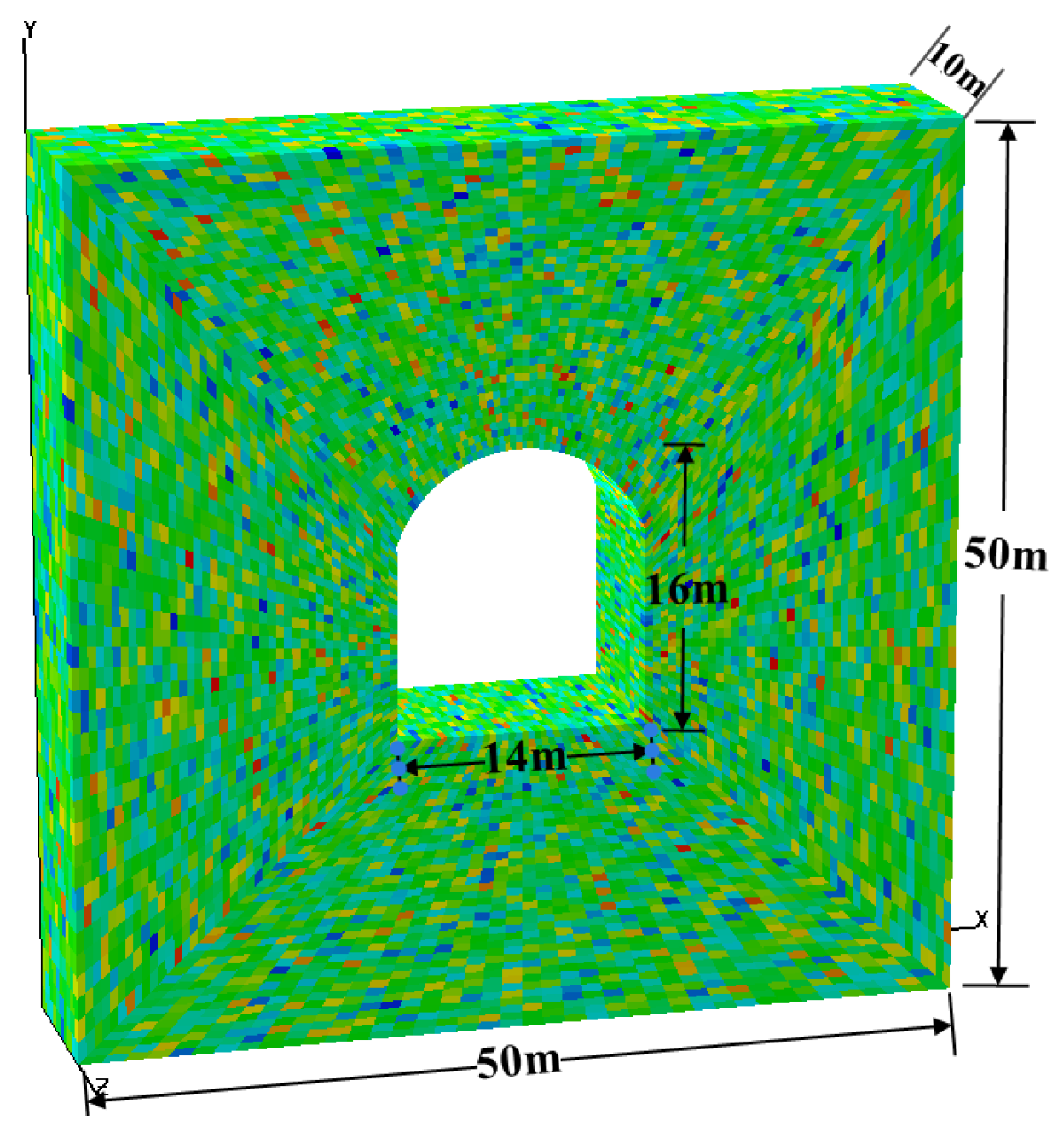

3.3. Modeling

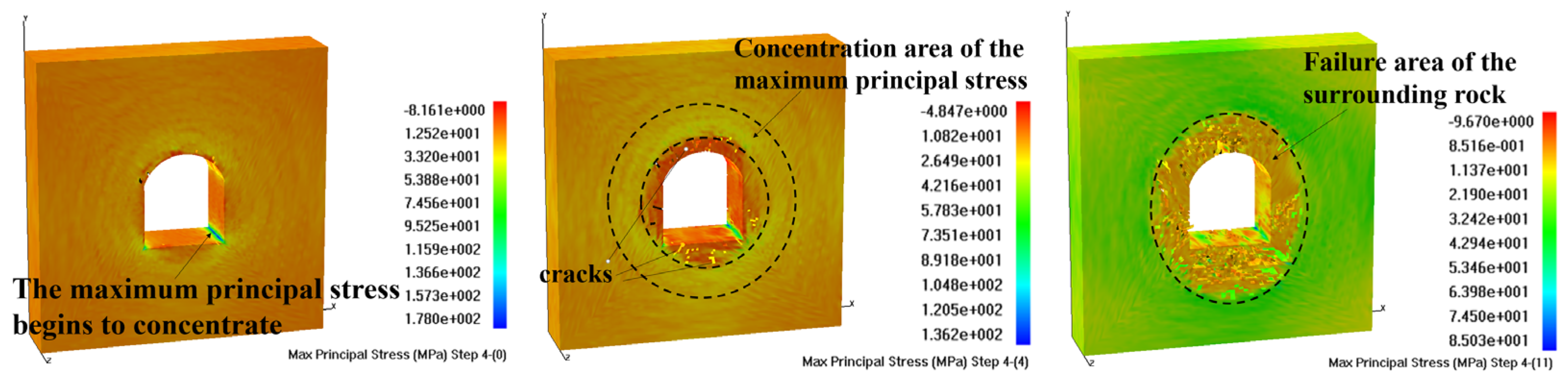

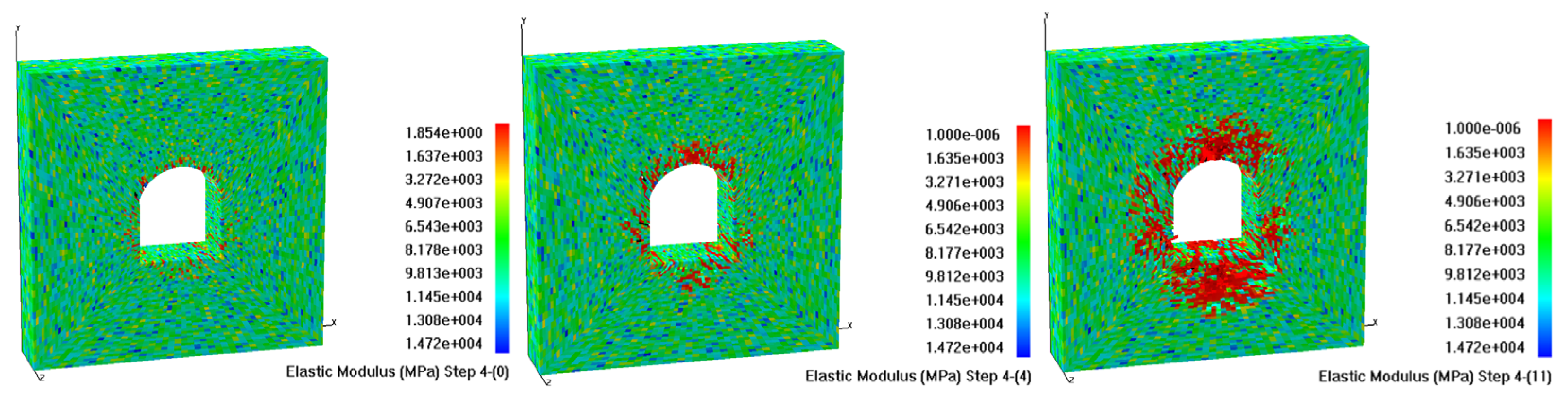

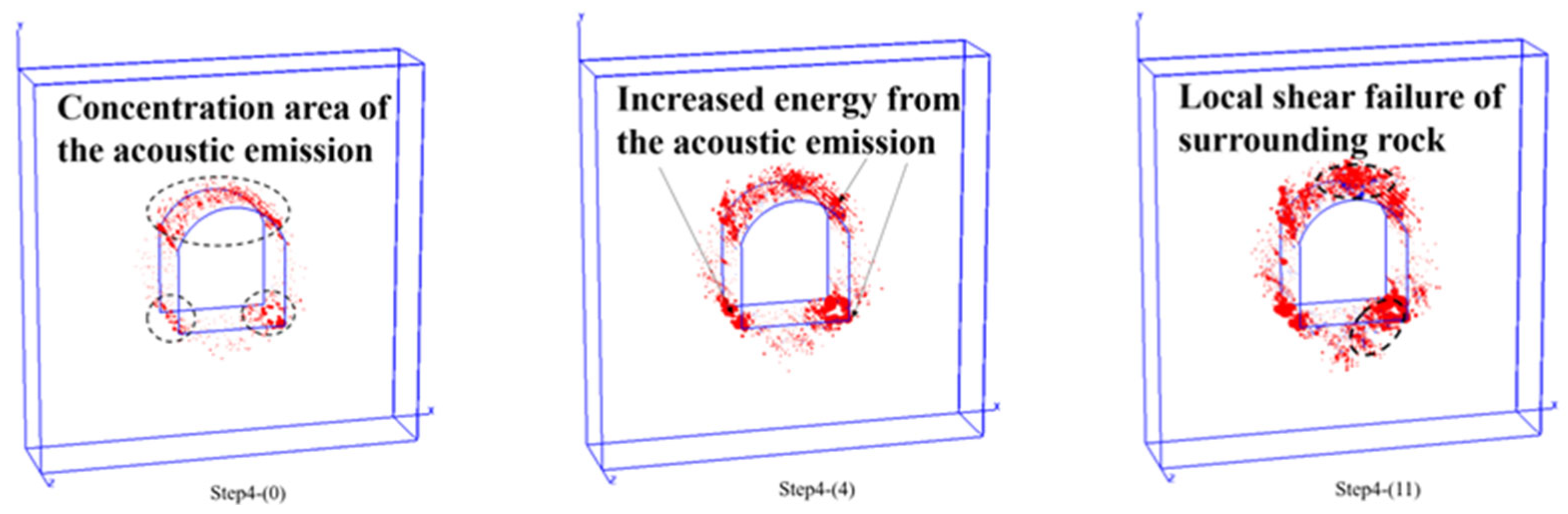

3.4. Modeling Results and Analysis

4. Characteristics of Microseismic Events in the Tunnel

4.1. Microseismic Monitoring System of the #2 Diversion Tunnel

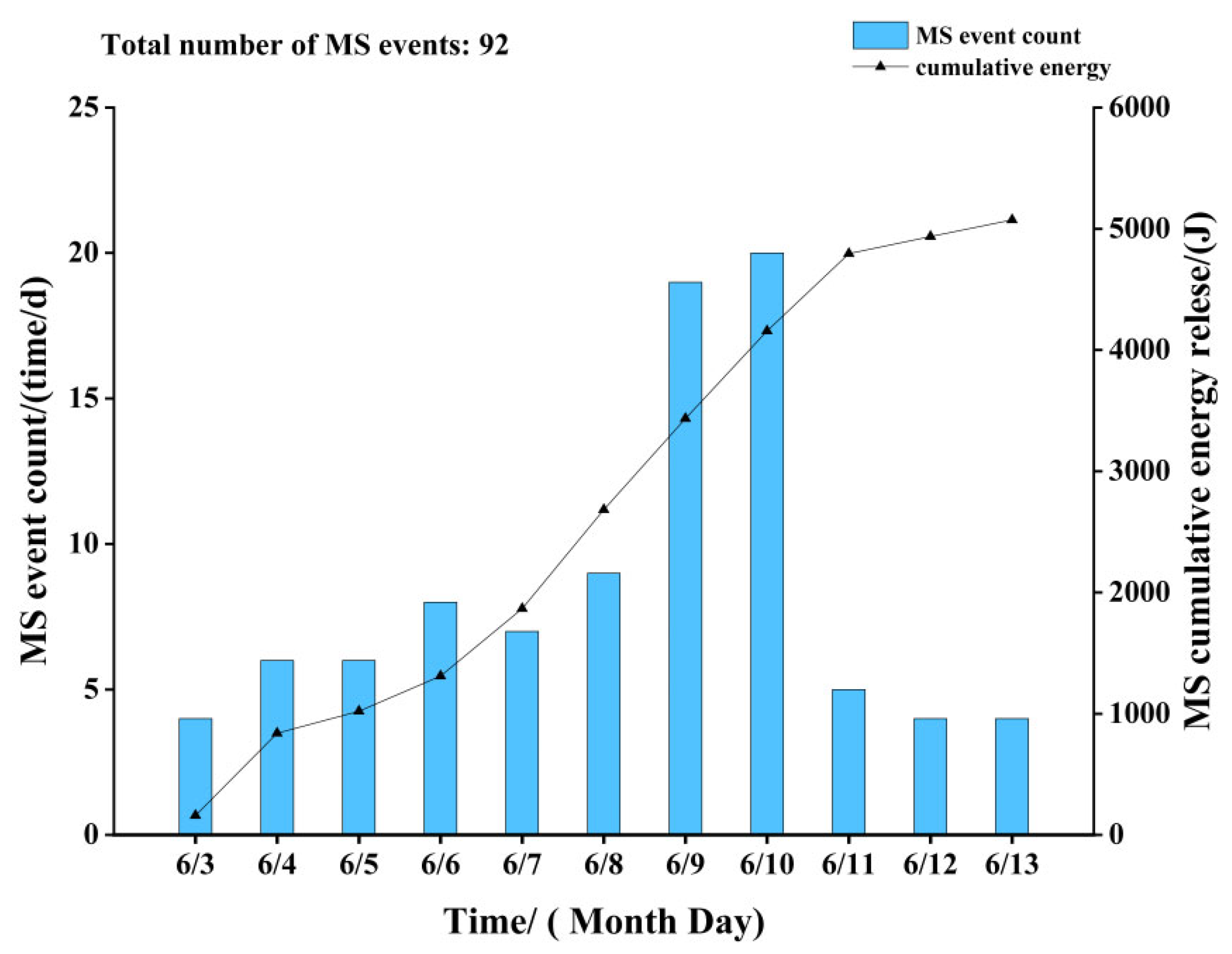

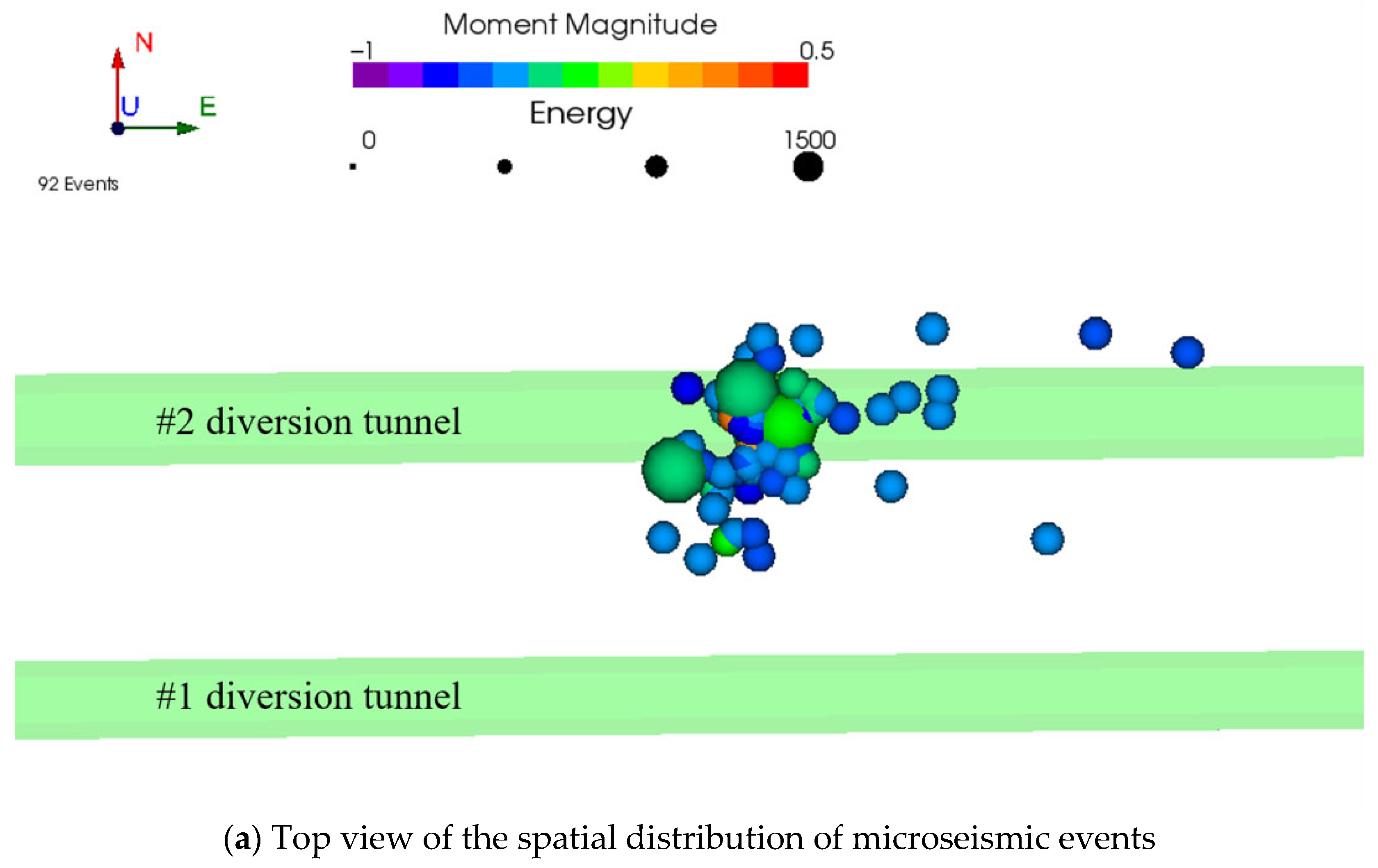

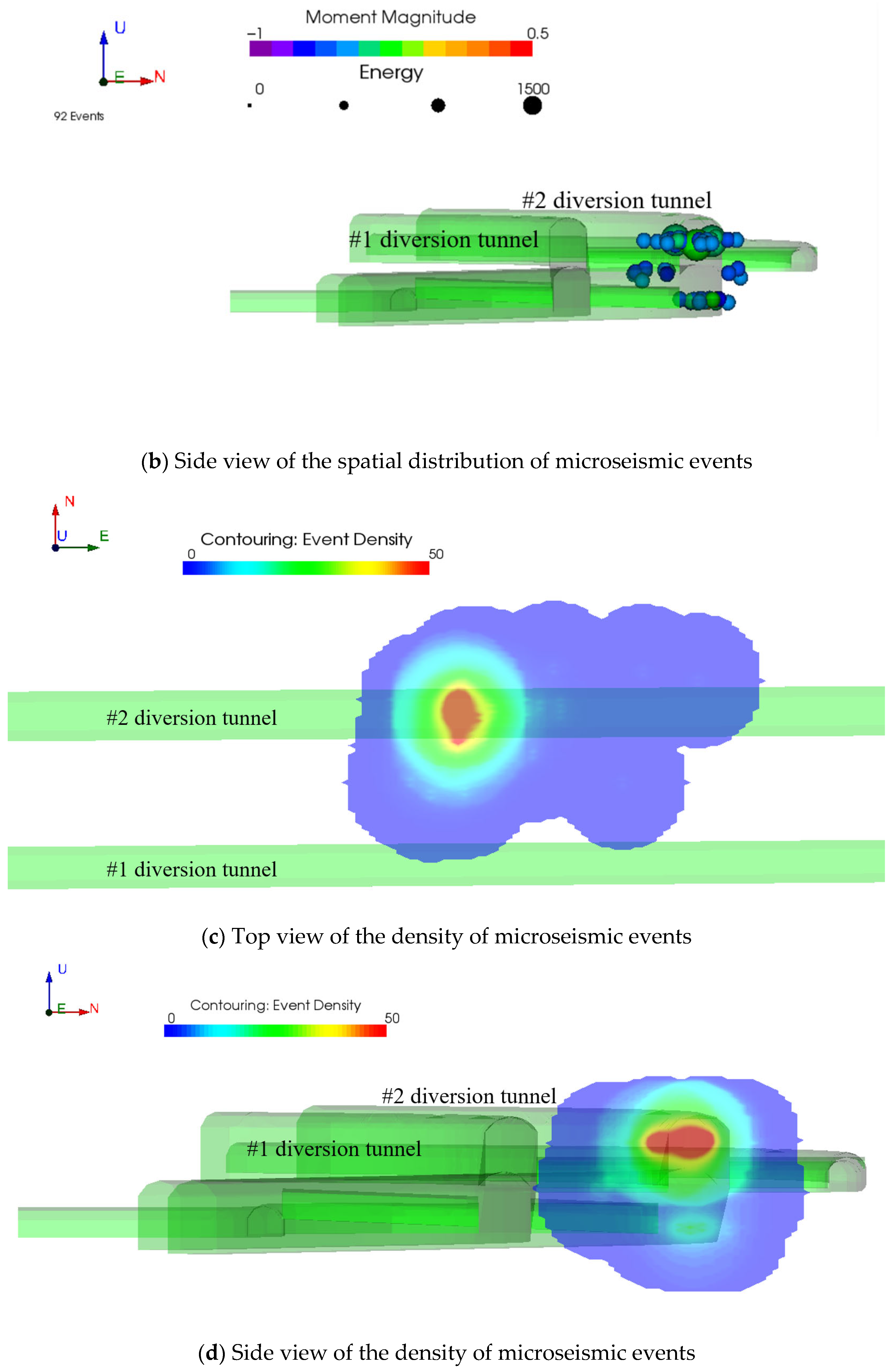

4.2. Spatial and Temporal Distribution of Microseismic Events

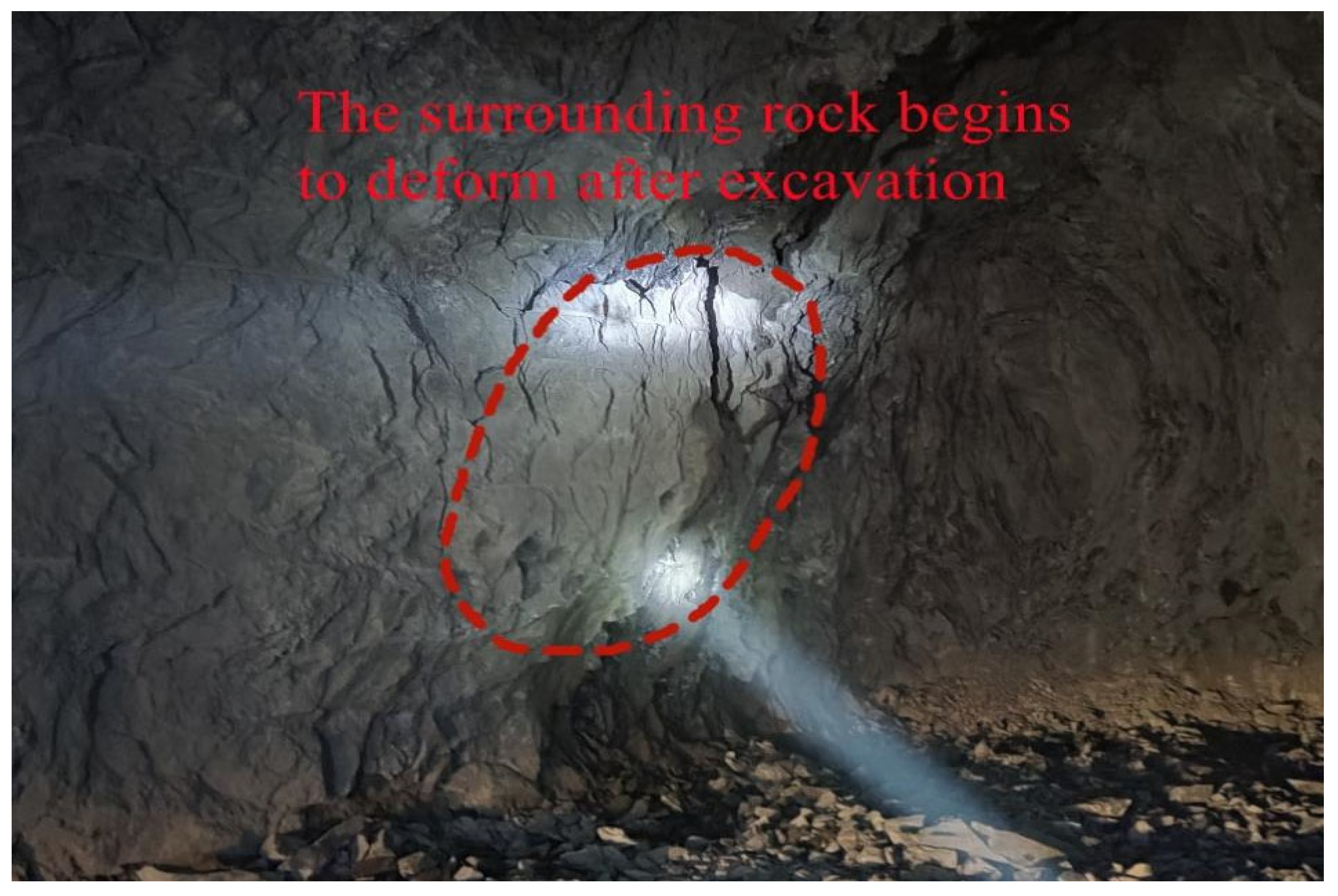

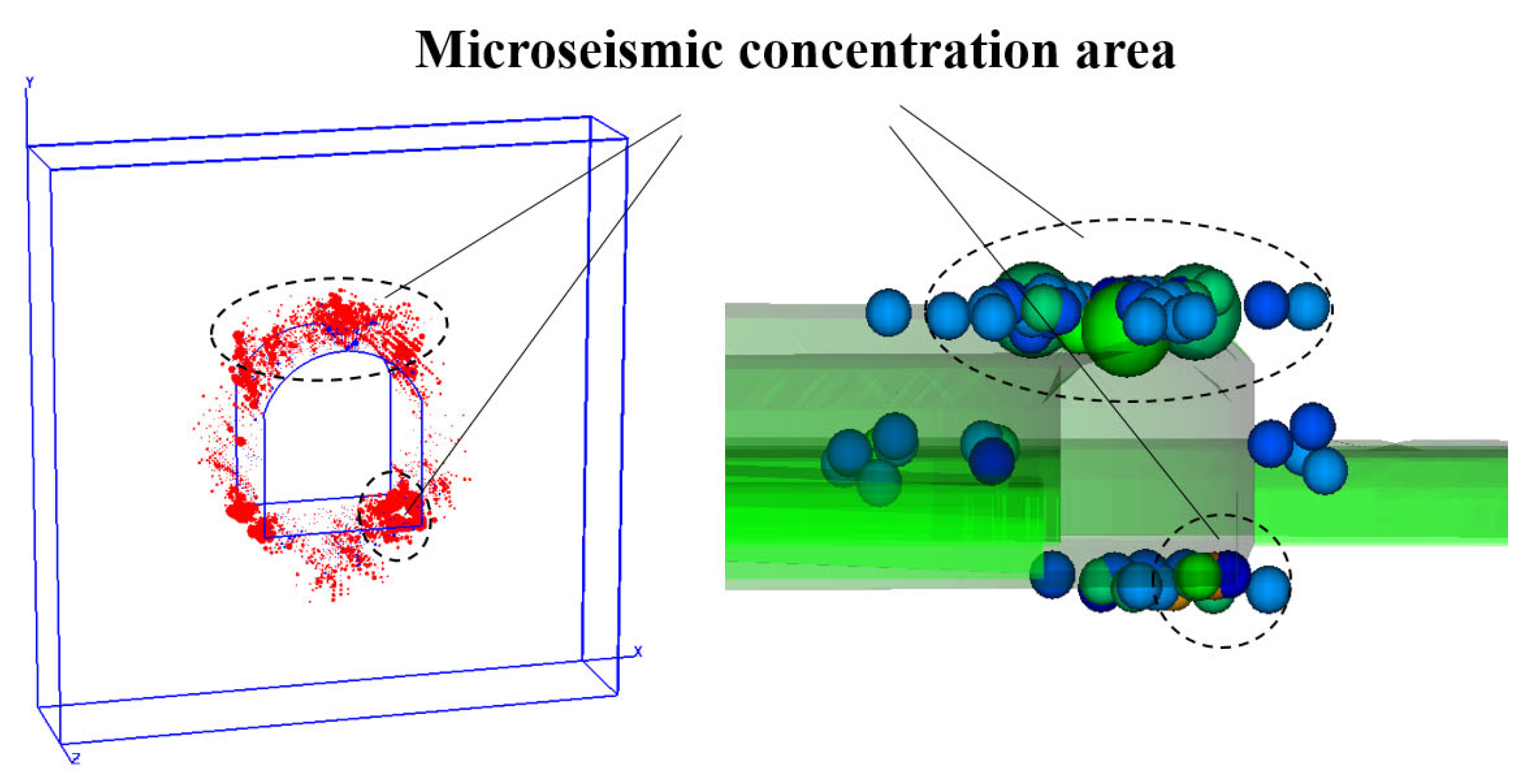

4.3. Comparison between Modeling Results and Microseismic Monitoring Results

5. Conclusions

- (1)

- Surrounding rock damage after excavation of the geologically weak section of the #2 diversion tunnel was modeled by using RFPA3D. The maximum principal stress concentrated around the tunnel profile and at the corners of the side wall in the study area, and cracks were initiated and grew from the tunnel vault and bottom corner of the side wall until they penetrated the entire profile. Acoustic emissions also started to accumulate at the vault and corners of the side wall and then propagated along the floor and side wall. The acoustic emissions at the vault and corners of the side wall gradually increased in energy, making it a key monitoring target in the study area.

- (2)

- Microseismic events were mainly concentrated near the vault and footwall during the excavation of stakes K0+765 to K0+775. It was dominated by tensile failure accompanied by shear failure. The frequency of microseismic events could better reflect the frequency of excavation activities in underground plants, and microseismic monitoring helped infer the damage evolution of the rock during the instability failure process of the surrounding rock and delineate the potential risk area.

- (3)

- The RFPA3D numerical modeling results and the data collected by the actual microseismic monitoring system were consistent, which verified the damage area of the surrounding rock in the excavated geologically weak section. The vault and corners of the side wall, in particular, sustained the most serious damage, so it is necessary to pay close attention to this area and provide timely support. Microseismic monitoring played a key role in controlling the stability of the tunnel surrounding rock, and it is required to continue to strengthen microseismic monitoring and take effective measures to ensure the safety and stability of the slope during the construction and operation periods in the subsequent construction process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xiao, Y.-X.; Feng, X.-T.; Feng, G.-L.; Liu, H.-J.; Jiang, Q.; Qiu, S.-L. Mechanism of evolution of stress–structure controlled collapse of surrounding rock in caverns: A case study from the Baihetan hydropower station in China. Tunn. Undergr. Space Technol. 2016, 51, 56–67. [Google Scholar] [CrossRef]

- Zhang, C.Q.; Feng, X.-T.; Zhou, H.; Qiu, S.L.; Wu, W.P. Case Histories of Four Extremely Intense Rockbursts in Deep Tunnels. Rock Mech. Rock Eng. 2012, 45, 275–288. [Google Scholar] [CrossRef]

- Hafeezur, R.; Abdul, M.N.; Kyoungmin, N.; Saeed, A.; Khan, M.; Han, K.Y. Impact of construction method and ground composition on headrace tunnel stability in the Neelum–Jhelum Hydroelectric Project: A case study review from Pakistan. Appl. Sci. 2021, 11, 1655. [Google Scholar]

- Dhawan, K.R.; Singh, D.N.; Gupta, I.D. Three-Dimensional Finite Element Analysis of Underground Caverns. Int. J. Géoméch. 2004, 4, 224–228. [Google Scholar] [CrossRef]

- Hao, Y.; Azzam, R. The plastic zones and displacements around underground openings in rock masses containing a fault. Tunn. Undergr. Space Technol. 2005, 20, 49–61. [Google Scholar] [CrossRef]

- Yazdani, M.; Sharifzadeh, M.; Kamrani, K.; Ghorbani, M. Displacement-based numerical back analysis for estimation of rock mass parameters in Siah Bisheh powerhouse cavern using continuum and discontinuum approach. Tunn. Undergr. Space Technol. 2012, 28, 41–48. [Google Scholar] [CrossRef]

- Ma, K.; Liu, G.Y. Three-dimensional Discontinuous Deformation Analysis of Failure Mechanisms and Movement Characteristics of Slope Rockfalls. Rock Mech. Rock Eng. 2022, 55, 275–296. [Google Scholar] [CrossRef]

- Song, R.; Liu, J.; Yang, C.; Sun, S. Study on the multiphase heat and mass transfer mechanism in the dissociation of methane hydrate in reconstructed real-shape porous sediments. Energy 2022, 254, 124421. [Google Scholar] [CrossRef]

- Cai, M.; Kaiser, P.; Morioka, H.; Minami, M.; Maejima, T.; Tasaka, Y.; Kurose, H. FLAC/PFC coupled numerical simulation of AE in large-scale underground excavations. Int. J. Rock Mech. Min. Sci. 2006, 44, 550–564. [Google Scholar] [CrossRef]

- Jing, L. Formulation of discontinuous deformation analysis (DDA)—An implicit discrete element model for block systems. Eng. Geol. 1998, 49, 371–381. [Google Scholar] [CrossRef]

- Andersson, J.C.; Martin, C.D. The Äspö pillar stability experiment: Part I—Experiment design. Int. J. Rock Mech. Min. Sci. 2009, 46, 865–878. [Google Scholar] [CrossRef]

- Yan, C.-B. Blasting cumulative damage effects of underground engineering rock mass based on sonic wave measurement. J. Central South Univ. Technol. 2007, 14, 230–235. [Google Scholar] [CrossRef]

- Li, S.; Yu, H.; Liu, Y.; Wu, F. Results from in-situ monitoring of displacement, bolt load, and disturbed zone of a powerhouse cavern during excavation process. Int. J. Rock Mech. Min. Sci. 2008, 45, 1519–1525. [Google Scholar] [CrossRef]

- Yan, P.; Lu, W.; Chen, M.; Hu, Y.-G.; Zhou, C.-B.; Wu, X.-X. Contributions of In-Situ Stress Transient Redistribution to Blasting Excavation Damage Zone of Deep Tunnels. Rock Mech. Rock Eng. 2014, 48, 715–726. [Google Scholar] [CrossRef]

- Li, B.; Ding, Q.F.; Xu, N.W.; Dai, F.; Xu, Y.; Qu, H.L. Characteristics of microseismic bvalue associated with rock mass large deformation in underground powerhouse caverns at different stresslevels. J. Cent. South Univ. 2022, 29, 693–711. [Google Scholar] [CrossRef]

- Li, B.; Xu, N.; Dai, F.; Zhang, G.; Xiao, P. Dynamic analysis of rock mass deformation in large underground caverns considering microseismic data. Int. J. Rock Mech. Min. Sci. 2019, 122, 104078. [Google Scholar] [CrossRef]

- Leśniak, A.; Isakow, Z. Space–time clustering of seismic events and hazard assessment in the Zabrze-Bielszowice coal mine, Poland. Int. J. Rock Mech. Min. Sci. 2009, 46, 918–928. [Google Scholar] [CrossRef]

- Hudyma, M.; Potvin, Y.H. An Engineering Approach to Seismic Risk Management in Hardrock Mines. Rock Mech. Rock Eng. 2009, 43, 891–906. [Google Scholar] [CrossRef]

- Ma, J.; Dong, L.; Zhao, G.; Li, X. Focal Mechanism of Mining-Induced Seismicity in Fault Zones: A Case Study of Yongshaba Mine in China. Rock Mech. Rock Eng. 2019, 52, 3341–3352. [Google Scholar] [CrossRef]

- Cai, M.; Kaiser, P.; Martin, C. Quantification of rock mass damage in underground excavations from microseismic event monitoring. Int. J. Rock Mech. Min. Sci. 2001, 38, 1135–1145. [Google Scholar] [CrossRef]

- Ma, K.; Tang, C.-A.; Xu, N.-W.; Liu, F.; Xu, J.-W. Failure precursor of surrounding rock mass around cross tunnel in high-steep rock slope. J. Central South Univ. 2013, 20, 207–217. [Google Scholar] [CrossRef]

- Dai, F.; Li, B.; Xu, N.; Fan, Y.; Zhang, C. Deformation forecasting and stability analysis of large-scale underground powerhouse caverns from microseismic monitoring. Int. J. Rock Mech. Min. Sci. 2016, 86, 269–281. [Google Scholar] [CrossRef]

- Liang, B.; Jiang, H.L.; Sun, W.J.; Jin, J.X. Numerical simulation study on seepage characteristics of multi-fractured rock mass. J. Water Resour. Water Eng. 2013, 6, 79–81. [Google Scholar]

- Tang, C.A.; Hudson, J.A. Rock Failure Mechanisms: Explained and Illustrated; CRC Press: Baca Raton, FL, USA, 2010. [Google Scholar]

- Liang, Z.Z. Three-Dimensional Failure Process Analysis of Rock and Associated Numerical Tests; Northeastern University: Shenyang, China, 2005. [Google Scholar]

- Yu, M.H. Unified strength theory for geomaterials and its applications. Chin. J. Geotech. Eng. 1994, 16, 1–9. [Google Scholar]

- Liang, C.; Zhang, G.; Li, L.; Li, B.; Luo, Y.; Li, Y.; Duan, J.; Wu, X. Efficient Fault Surface Grouping in 3-D Seismic Fault Data. IEEE Trans. Geosci. Remote Sens. 2022, 60, 5916213. [Google Scholar] [CrossRef]

- Wu, N.; Liang, Z.; Zhang, Z.; Li, S.; Lang, Y. Development and verification of three-dimensional equivalent discrete fracture network modelling based on the finite element method. Eng. Geol. 2022, 306, 106759. [Google Scholar] [CrossRef]

- Wu, N.; Liang, Z.; Li, Y.; Qian, X.; Gong, B. Effect of confining stress on representative elementary volume of jointed rock masses. Geomech. Eng. 2019, 18, 627–638. [Google Scholar]

- Xue, R.X.; Liang, Z.Z.; Xu, N.W. Rockburst prediction and analysis of activity characteristics within surrounding rock based on microseismic monitoring and numerical simulation. Int. J. Rock Mech. Min. Sci. 2021, 142, 104750. [Google Scholar] [CrossRef]

- Tang, C.A.; Li, L.C.; Li, C.W.; Ma, T.H. RFPA strength reduction method for stability analysis of geotechnical engineering. Chin. J. Rock Mech. Eng. 2006, 25, 1522–1530. [Google Scholar]

- Li, S.Y.; He, X.S.; Zhang, S.Q.; Lu, Q.H.; Jiang, X.Q.; Tong, X.H.; Li, T.; Guan, E.F.; Zuo, Y.; Sun, X.H.; et al. Progress and latest achievements of mine seismic monitoring technology. Prog. Geophys. 2004, 4, 853–859. [Google Scholar]

- Boatwright, J.; Fletcher, J.B. The partition of radiated energy between P and S waves. Bull. Seismol. Soc. Am. 1984, 74, 361–376. [Google Scholar] [CrossRef]

| Elastic Modulus (GPa) | Uniaxial Compressive Strength (MPa) | Poisson’s Ratio | Internal Friction Angle (°) | Residual Strength | Coefficient of Confining Pressure | Coefficient of Homogeneity |

|---|---|---|---|---|---|---|

| 10 | 35 | 0.25 | 30 | 0.1 | 2 | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qian, H.; Tan, Z.; Li, B. Stability Analysis of Surrounding Rock in the Diversion Tunnel at the Xulong Hydropower Station based on RFPA3D and Microseismic Monitoring. Appl. Sci. 2022, 12, 9939. https://doi.org/10.3390/app12199939

Qian H, Tan Z, Li B. Stability Analysis of Surrounding Rock in the Diversion Tunnel at the Xulong Hydropower Station based on RFPA3D and Microseismic Monitoring. Applied Sciences. 2022; 12(19):9939. https://doi.org/10.3390/app12199939

Chicago/Turabian StyleQian, Hongjian, Zhou Tan, and Biao Li. 2022. "Stability Analysis of Surrounding Rock in the Diversion Tunnel at the Xulong Hydropower Station based on RFPA3D and Microseismic Monitoring" Applied Sciences 12, no. 19: 9939. https://doi.org/10.3390/app12199939

APA StyleQian, H., Tan, Z., & Li, B. (2022). Stability Analysis of Surrounding Rock in the Diversion Tunnel at the Xulong Hydropower Station based on RFPA3D and Microseismic Monitoring. Applied Sciences, 12(19), 9939. https://doi.org/10.3390/app12199939