Efficiency Enhancement of GaAs Single-Junction Solar Cell by Nanotextured Window Layer

Abstract

:1. Introduction

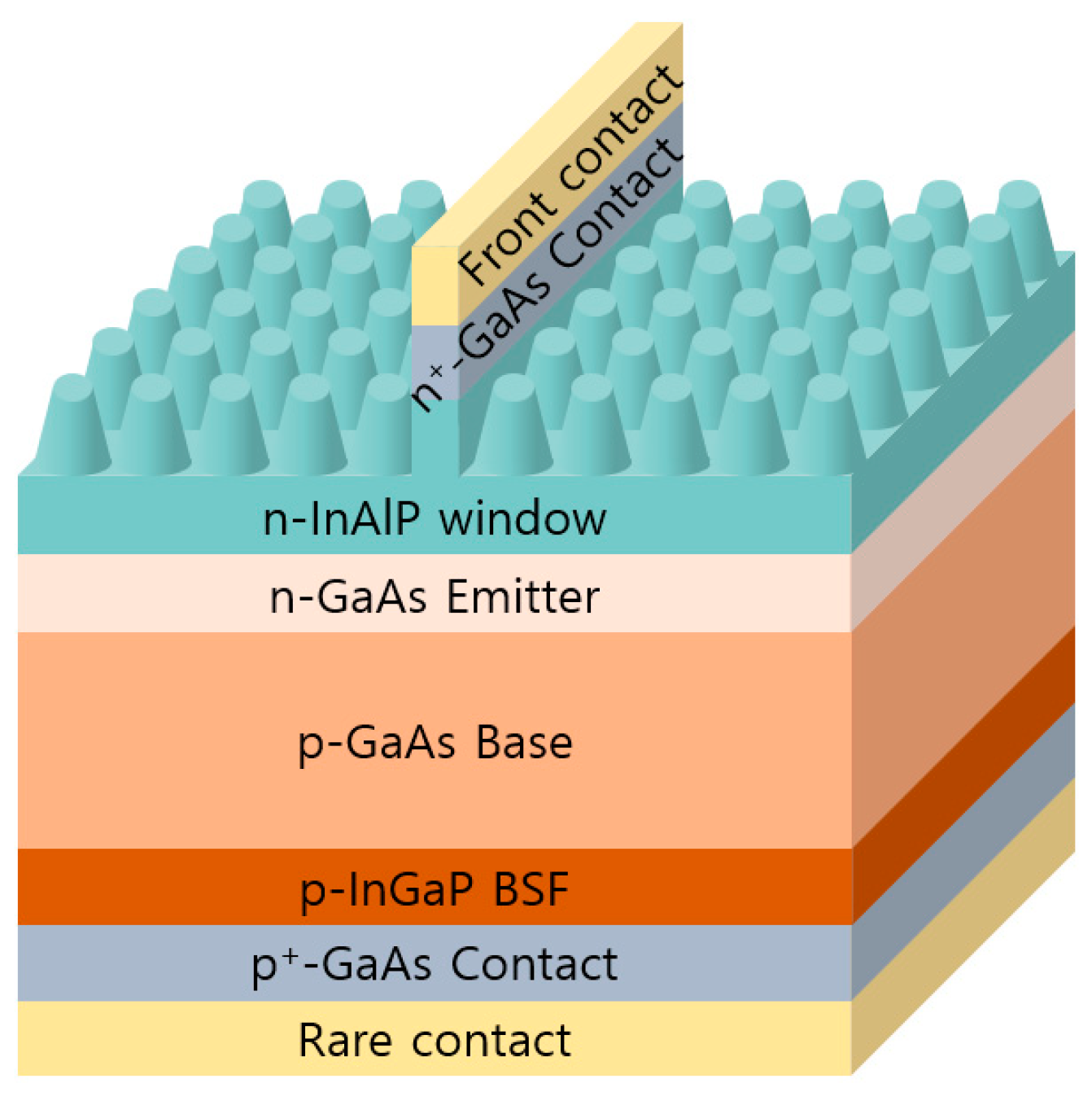

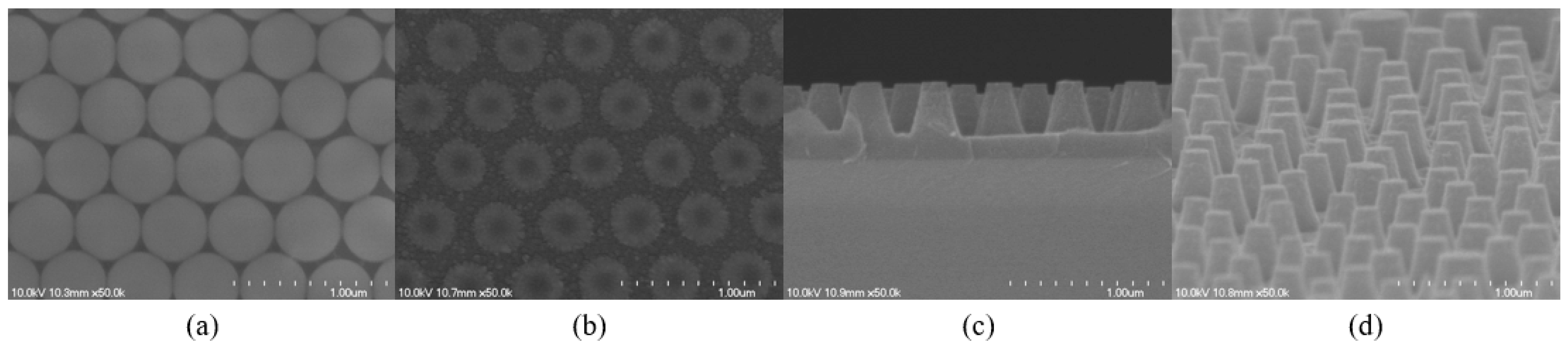

2. Materials and Methods

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Takamoto, T.; Yamaguchi, M.; Taylor, S.J.; Yang, M.-J.; Ikeda, E.; Kurita, H. Radiation resistance of high-efficiency InGaP/GaAs tandem solar cells. Sol. Energy Mater. Sol. Cells 1999, 58, 265–276. [Google Scholar] [CrossRef]

- Danilchenko, B.; Budnyk, A.; Shpinar, L.; Poplavskyy, D.; Zelensky, S.E.; Barnham, K.W.J.; Ekins-Daukes, N.J. 1 MeV electron irradiation influence on GaAs solar cell performance. Sol. Energy Mater. Sol. Cells 2008, 92, 1336–1340. [Google Scholar] [CrossRef]

- Yamaguchi, M. Radiation-resistant solar cells for space use. Sol. Energy Mater. Sol. Cells 2001, 68, 31–53. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Okuda, T.; Taylor, S.J.; Takamoto, T. Superior radiation-resistant properties of InGaP/GaAs tandem solar cells. Appl. Phys. Lett. 1997, 70, 1566. [Google Scholar] [CrossRef]

- Dharmarasu, N.; Yamaguchi, M.; Khan, A. High-radiation-resistant InGaP, InGaAsP, and InGaAs solar cells for multijuction solar cells. Appl. Phys. Lett. 2001, 79, 2399. [Google Scholar] [CrossRef]

- Khan, A.; Marupaduga, S.; Anandakrishnan, S.S.; Alam, M. Radiation response analysis of wide-gap p-AlInGaP for superhigh-efficiency space photovoltaics. Appl. Phys. Lett. 2004, 85, 5218. [Google Scholar] [CrossRef]

- Schubert, M.B.; Werner, J.H. Flexible solar cells for clothing. Materials 2006, 9, 42–50. [Google Scholar] [CrossRef]

- Lee, Y.-H.; Kim, J.-S.; Noh, J.; Lee, I.; Kim, H.J.; Choi, S.; Seo, J.; Jeon, S.; Kim, T.-S.; Lee, J.-Y.; et al. Wearable textile battery rechargeable by solar energy. Nano Lett. 2013, 13, 5753–5761. [Google Scholar] [CrossRef] [PubMed]

- Wen, Z.; Yeh, M.; Guo, H.; Wang, J.; Zi, Y.; Xu, W.; Deng, J.; Zhu, L.; Wang, X.; Hu, C.; et al. Self-powered textile for wearable electronics by hybridizing fiber-shaped nanogenerators, solar cells, and supercapacitors. Sci. Adv. 2016, 2, e1600097. [Google Scholar] [CrossRef] [Green Version]

- Reb, L.K.; Bohmer, M.; Predeschly, B.; Grott, S.; Weindl, C.L.; Ivandekic, G.I.; Guo, R.; Dreibigacker, C.; Gernhauser, R.; Meyier, A.; et al. Perovskite and organic solar cells on a rocket flight. J. Joule 2020, 4, 1880–1892. [Google Scholar] [CrossRef]

- Kishi, Y.; Inoue, H.; Murata, K.; Tanaka, H.; Kouzuma, S.; Morizane, M.; Fukuda, Y.; Nishiwaki, H.; Nakano, K.; Takeoka, A.; et al. Ultralight flexible amorphous silicon solar cell and its application to an airplane. Sol. Energy Mater. 1991, 23, 312–318. [Google Scholar] [CrossRef]

- Dhere, M.G.; Ghongadi, S.R.; Pandit, M.B.; Jahagirdar, A.H.; Scheiman, D. CIGS2 thin-film solar cells on flexible foils for space power. Prog. Photovolt. 2002, 10, 407–416. [Google Scholar] [CrossRef] [Green Version]

- Zhao, J.; Green, M.A. Optimized antireflection coatings for high-efficiency silicon solar cells. IEEE Trans. Electron Devices 1991, 38, 1925–1934. [Google Scholar] [CrossRef]

- Yin, Y.; Li, Z.; Kuo, H.; Lu, T. Efficiency improvement of single-junction InGaP solar cells fabricated by a novel micro-hole array surface texture process. J. Semicond. Sci. Technol. 2009, 24, 085007. [Google Scholar]

- Yeh, L.; Tian, W.; Lai, K.; He, J. Exceptionally omnidirectional broadband light harvesting scheme for multi-junction concentrator solar cells achieved via ZnO nanoneedles. J. Sci. Rep. 2016, 6, 39134. [Google Scholar] [CrossRef] [Green Version]

- Boden, S.A.; Bagnall, D.M. Optimization of moth-eye antirefection schemes for silicon solar cells. Prog. Photovolt. Res. Appl. 2010, 18, 195–203. [Google Scholar] [CrossRef] [Green Version]

- Cai, J.; Qi, L. Recent advances in antirefective surfaces based on nanostructure arrays. Mater. Horiz. 2015, 2, 37–53. [Google Scholar] [CrossRef]

- Allred, D.D.; Larsen, Z.; Muhlestein, J.; Turley, R.S.; Willey, A. Effective medium theory, rough surfaces, and Moth’s eyes. J. Utah Acad. Sci. Arts Lett. 2009, 29, 273–286. [Google Scholar]

- Yeh, L.; Lai, K.; Lin, G.; Fu, P.; Chang, H.; Lin, C.; He, J. Giant efficiency enhancement of GaAs solar cells with graded antirefection layers based on syringelike ZnO nanorod arrays. Adv. Energy Mater. 2011, 1, 506–510. [Google Scholar] [CrossRef]

- Park, H.; Shin, D.; Kang, G.; Baek, S.; Kim, K.; Padilla, W.J. Broadband optical antirefection enhancement by integrating antirefective nanoislands with silicon nanoconical-frustum arrays. Adv. Mater. 2011, 23, 5796–5800. [Google Scholar] [CrossRef]

- Sahoo, K.C.; Lin, M.; Chang, E.; Lu, Y.; Chen, C.; Huang, J.; Chang, C. Fabrication of antirefective sub-wavelength structures on silicon nitride using nano cluster mask for solar cell application. Nanoscale Res. Lett. 2009, 4, 680. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chao, Y.C.; Chen, C.; Lin, C.; Dai, Y.; He, J. Antireflection effect of ZnO nanorods arrays. J. Mater. Chem. 2011, 20, 8134–8138. [Google Scholar] [CrossRef]

- Photovoltaics Education. Available online: https://www.pveducation.org/pvcdrom/solar-cell-operation/quantum-efficiency (accessed on 5 December 2021).

| VOC (V) | JSC (mA/cm2) | FF | η (%) | |

|---|---|---|---|---|

| Bare | 0.91 | 21.50 | 0.71 | 13.81 |

| ARC | 0.92 | 28.94 | 0.72 | 19.07 |

| NT | 0.93 | 28.40 | 0.74 | 19.44 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, C.-W.; Park, G.-Y.; Shin, J.-C.; Kim, H.-J. Efficiency Enhancement of GaAs Single-Junction Solar Cell by Nanotextured Window Layer. Appl. Sci. 2022, 12, 601. https://doi.org/10.3390/app12020601

Kim C-W, Park G-Y, Shin J-C, Kim H-J. Efficiency Enhancement of GaAs Single-Junction Solar Cell by Nanotextured Window Layer. Applied Sciences. 2022; 12(2):601. https://doi.org/10.3390/app12020601

Chicago/Turabian StyleKim, Chae-Won, Gwang-Yeol Park, Jae-Cheol Shin, and Hyo-Jin Kim. 2022. "Efficiency Enhancement of GaAs Single-Junction Solar Cell by Nanotextured Window Layer" Applied Sciences 12, no. 2: 601. https://doi.org/10.3390/app12020601

APA StyleKim, C.-W., Park, G.-Y., Shin, J.-C., & Kim, H.-J. (2022). Efficiency Enhancement of GaAs Single-Junction Solar Cell by Nanotextured Window Layer. Applied Sciences, 12(2), 601. https://doi.org/10.3390/app12020601