Separation of Albumin from Bovine Serum Applying Ionic-Liquid-Based Aqueous Biphasic Systems

Abstract

:1. Introduction

2. Materials and Methods

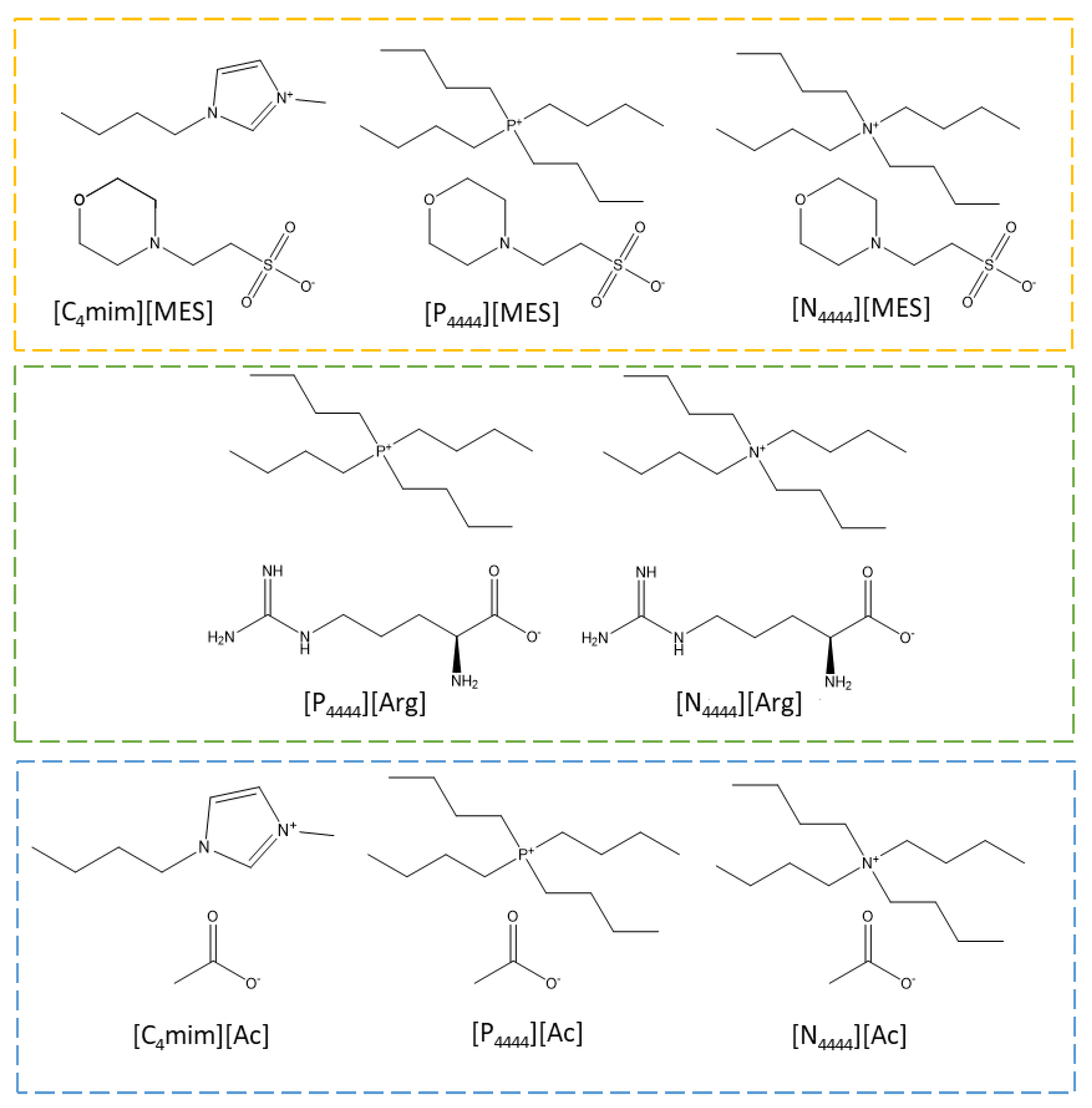

2.1. Chemicals and Reagents

2.2. Determination of ABS Phase Diagrams

2.3. Extraction and Purification of BSA

2.4. SDS-PAGE and Circular Dichroism

3. Results and Discussion

3.1. ABS Phase Diagrams

3.2. Extraction and Purification of BSA

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wong, F.W.F.; Ariff, A.B.; Stuckey, D.C. Downstream protein separation by surfactant precipitation: A review. Crit. Rev. Biotechnol. 2018, 38, 31–46. [Google Scholar] [CrossRef] [PubMed]

- Ayyar, B.V.; Arora, S.; Murphy, C.; O’Kennedy, R. Affinity chromatography as a tool for antibody purification. Methods 2012, 56, 116–129. [Google Scholar] [CrossRef] [PubMed]

- Berg, J.M.; Tymoczko, J.L.; Stryer, L. Biochemistry, 5th ed.; W.H. Freeman and Company: New York, NY, USA, 2002. [Google Scholar]

- Ribeiro, S.C.; Monteiro, G.A.; Cabral, J.M.S.; Prazeres, D.M.F. Isolation of plasmid DNA from cell lysates by aqueous two-phase systems. Biotechnol. Bioeng. 2002, 78, 376–384. [Google Scholar] [CrossRef] [PubMed]

- Almeida, M.R.; Passos, H.; Pereira, M.M.; Lima, Á.S.; Coutinho, J.A.P.; Freire, M.G. Ionic liquids as additives to enhance the extraction of antioxidants in aqueous two-phase systems. Sep. Purif. Technol. 2014, 128, 1–10. [Google Scholar] [CrossRef]

- Cabral, J.M.S. Cell Partitioning in Aqueous Two-Phase Polymer Systems. In Cell Separation; Springer: Berlin/Heidelberg, Germany, 2007; pp. 151–171. [Google Scholar]

- Frerix, A.; Müller, M.; Kula, M.; Hubbuch, J. Scalable recovery of plasmid DNA based on aqueous two-phase separation. Biotechnol. Appl. Biochem. 2005, 42, 57–66. [Google Scholar] [PubMed]

- Wysoczanska, K.; Do, H.T.; Held, C.; Sadowski, G.; Macedo, E.A. Effect of different organic salts on amino acids partition behaviour in PEG-salt ATPS. Fluid Phase Equilib. 2018, 456, 84–91. [Google Scholar] [CrossRef]

- Rosa, P.A.J.; Azevedo, A.M.; Ferreira, I.F.; De Vries, J.; Korporaal, R.; Verhoef, H.J.; Visser, T.J.; Aires-Barros, M.R. Affinity partitioning of human antibodies in aqueous two-phase systems. J. Chromatogr. A 2007, 1162, 103–113. [Google Scholar] [CrossRef]

- Iqbal, M.; Tao, Y.; Xie, S.; Zhu, Y.; Chen, D.; Wang, X.; Huang, L.; Peng, D.; Sattar, A.; Shabbir, M.A.B. Aqueous two-phase system (ATPS): An overview and advances in its applications. Biol. Proced. Online 2016, 18, 1–8. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Torres-Acosta, M.A.; Pereira, J.F.B.; Freire, M.G.; Aguilar-Yáñez, J.M.; Coutinho, J.A.P.; Titchener-Hooker, N.J.; Rito-Palomares, M. Economic evaluation of the primary recovery of tetracycline with traditional and novel aqueous two-phase systems. Sep. Purif. Technol. 2018, 203, 178–184. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Silvério, S.C.; Rodríguez, O.; Tavares, A.P.M.; Teixeira, J.A.; Macedo, E.A. Laccase recovery with aqueous two-phase systems: Enzyme partitioning and stability. J. Mol. Catal. B Enzym. 2013, 87, 37–43. [Google Scholar] [CrossRef] [Green Version]

- Freire, M.G.; Claudio, A.F.M.; Araujo, J.M.M.; Coutinho, J.A.P.; Marrucho, I.M.; Lopes, J.N.C.; Rebelo, L.P.N. Aqueous biphasic systems: A boost brought about by using ionic liquids. Chem. Soc. Rev. 2012, 41, 4966–4995. [Google Scholar] [CrossRef]

- Gutowski, K.E.; Broker, G.A.; Willauer, H.D.; Huddleston, J.G.; Swatloski, R.P.; Holbrey, J.D.; Rogers, R.D. Controlling the aqueous miscibility of ionic liquids: Aqueous biphasic systems of water-miscible ionic liquids and water-structuring salts for recycle, metathesis, and separations. J. Am. Chem. Soc. 2003, 125, 6632–6633. [Google Scholar] [CrossRef] [PubMed]

- Pereira, J.F.B.; Lima, Á.S.; Freire, M.G.; Coutinho, J.A.P. Ionic liquids as adjuvants for the tailored extraction of biomolecules in aqueous biphasic systems. Green Chem. 2010, 12, 1661–1669. [Google Scholar] [CrossRef]

- Pereira, J.F.B.; Rebelo, L.P.N.; Rogers, R.D.; Coutinho, J.A.P.; Freire, M.G. Combining ionic liquids and polyethylene glycols to boost the hydrophobic–hydrophilic range of aqueous biphasic systems. Phys. Chem. Chem. Phys. 2013, 15, 19580–19583. [Google Scholar] [CrossRef] [PubMed]

- Taha, M.; e Silva, F.A.; Quental, M.V.; Ventura, S.P.M.; Freire, M.G.; Coutinho, J.A.P. Good’s buffers as a basis for developing self-buffering and biocompatible ionic liquids for biological research. Green Chem. 2014, 16, 3149–3159. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Taha, M.; Quental, M.V.; Correia, I.; Freire, M.G.; Coutinho, J.A.P. Extraction and stability of bovine serum albumin (BSA) using cholinium-based Good’s buffers ionic liquids. Process Biochem. 2015, 50, 1158–1166. [Google Scholar] [CrossRef] [Green Version]

- Taha, M.; Quental, M.V.; e Silva, F.A.; Capela, E.V.; Freire, M.G.; Ventura, S.P.M.; Coutinho, J.A.P. Good’s buffer ionic liquids as relevant phase-forming components of self-buffered aqueous biphasic systems. J. Chem. Technol. Biotechnol. 2017, 92, 2287–2299. [Google Scholar] [CrossRef]

- Tang, F.; Zhang, Q.; Ren, D.; Nie, Z.; Liu, Q.; Yao, S. Functional amino acid ionic liquids as solvent and selector in chiral extraction. J. Chromatogr. A 2010, 1217, 4669–4674. [Google Scholar] [CrossRef]

- Li, Z.; Liu, X.; Pei, Y.; Wang, J.; He, M. Design of environmentally friendly ionic liquid aqueous two-phase systems for the efficient and high activity extraction of proteins. Green Chem. 2012, 14, 2941–2950. [Google Scholar] [CrossRef]

- Deive, F.J.; Rodríguez, A.; Rebelo, L.P.N.; Marrucho, I.M. Extraction of Candida antarctica lipase A from aqueous solutions using imidazolium-based ionic liquids. Sep. Purif. Technol. 2012, 97, 205–210. [Google Scholar] [CrossRef]

- Du, Z.; Yu, Y.; Wang, J. Extraction of proteins from biological fluids by use of an ionic liquid/aqueous two-phase system. Chem. Eur. J. 2007, 13, 2130–2137. [Google Scholar] [CrossRef] [PubMed]

- Belchior, D.C.V.; Quental, M.V.; Pereira, M.M.; Mendonça, C.M.N.; Duarte, I.F.; Freire, M.G. Performance of tetraalkylammonium-based ionic liquids as constituents of aqueous biphasic systems in the extraction of ovalbumin and lysozyme. Sep. Purif. Technol. 2020, 233, 116019. [Google Scholar] [CrossRef]

- Akdogan, Y.; Emrullahoglu, M.; Tatlidil, D.; Ucuncu, M.; Cakan-Akdogan, G. EPR studies of intermolecular interactions and competitive binding of drugs in a drug–BSA binding model. Phys. Chem. Chem. Phys. 2016, 18, 22531–22539. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lang, X.-D.; Zhang, S.; Song, Q.-W.; He, L.-N. Tetra-butylphosphonium arginine-based ionic liquid-promoted cyclization of 2-aminobenzonitrile with carbon dioxide. RSC Adv. 2015, 5, 15668–15673. [Google Scholar] [CrossRef]

- Carreira, A.R.F.; Rocha, S.N.; e Silva, F.A.; Sintra, T.E.; Passos, H.; Ventura, S.P.M.; Coutinho, J.A.P. Amino-acid-based chiral ionic liquids characterization and application in aqueous biphasic systems. Fluid Phase Equilib. 2021, 542, 113091. [Google Scholar] [CrossRef]

- Ventura, S.P.M.; Sousa, S.G.; Serafim, L.S.; Lima, Á.S.; Freire, M.G.; Coutinho, J.A.P. Ionic liquid based aqueous biphasic systems with controlled pH: The ionic liquid cation effect. J. Chem. Eng. Data 2011, 56, 4253–4260. [Google Scholar] [CrossRef]

- Mourão, T.; Cláudio, A.F.M.; Boal-Palheiros, I.; Freire, M.G.; Coutinho, J.A.P. Evaluation of the impact of phosphate salts on the formation of ionic-liquid-based aqueous biphasic systems. J. Chem. Thermodyn. 2012, 54, 398–405. [Google Scholar] [CrossRef]

- Merchuk, J.C.; Andrews, B.A.; Asenjo, J.A. Aqueous two-phase systems for protein separation: Studies on phase inversion. J. Chromatogr. B Biomed. Sci. Appl. 1998, 711, 285–293. [Google Scholar] [CrossRef]

- Miles, A.J.; Ramalli, S.G.; Wallace, B.A. DichroWeb, a website for calculating protein secondary structure from circular dichroism spectroscopic data. Protein Sci. 2021, 31, 37–46. [Google Scholar] [CrossRef]

- Louros, C.L.S.; Cláudio, A.F.M.; Neves, C.M.S.S.; Freire, M.G.; Marrucho, I.M.; Pauly, J.; Coutinho, J.A.P. Extraction of biomolecules using phosphonium-based ionic liquids + K3PO4 aqueous biphasic systems. Int. J. Mol. Sci. 2010, 11, 1777–1791. [Google Scholar] [CrossRef]

- Bridges, N.J.; Gutowski, K.E.; Rogers, R.D. Investigation of aqueous biphasic systems formed from solutions of chaotropic salts with kosmotropic salts (salt–salt ABS). Green Chem. 2007, 9, 177–183. [Google Scholar] [CrossRef]

- Dreyer, S.; Kragl, U. Ionic liquids for aqueous two-phase extraction and stabilization of enzymes. Biotechnol. Bioeng. 2008, 99, 1416–1424. [Google Scholar] [CrossRef] [PubMed]

- Oppermann, S.; Stein, F.; Kragl, U. Ionic liquids for two-phase systems and their application for purification, extraction and biocatalysis. Appl. Microbiol. Biotechnol. 2011, 89, 493–499. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.Y.; Khoiroh, I.; Ooi, C.W.; Ling, T.C.; Show, P.L. Recent advances in protein extraction using ionic liquid-based aqueous two-phase systems. Sep. Purif. Rev. 2017, 46, 291–304. [Google Scholar] [CrossRef]

- Nunes, J.C.F.; Almeida, M.R.; Faria, J.L.; Silva, C.G.; Neves, M.C.; Freire, M.G.; Tavares, A.P.M. Overview on Protein Extraction and Purification Using Ionic-Liquid-Based Processes. J. Solut. Chem. 2021, 50, 1–36. [Google Scholar] [CrossRef]

- Dreyer, S.; Salim, P.; Kragl, U. Driving forces of protein partitioning in an ionic liquid-based aqueous two-phase system. Biochem. Eng. J. 2009, 46, 176–185. [Google Scholar] [CrossRef]

- Pei, Y.; Wang, J.; Wu, K.; Xuan, X.; Lu, X. Ionic liquid-based aqueous two-phase extraction of selected proteins. Sep. Purif. Technol. 2009, 64, 288–295. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Y.; Zeng, Q.; Ding, X.; Huang, Y. Partition of proteins with extraction in aqueous two-phase system by hydroxyl ammonium-based ionic liquid. Anal. Methods 2014, 6, 4067–4076. [Google Scholar] [CrossRef]

- Raja, S.; Murty, V.R. Development and evaluation of environmentally benign aqueous two phase systems for the recovery of proteins from tannery waste water. ISRN Chem. Eng. 2012, 2012, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Chaiyasut, C.; Tsuda, T. Isoelectric points estimation of proteins by electroosmotic flow: pH relationship using physically adsorbed proteins on silica gel. Chromatography 2001, 22, 91–96. [Google Scholar]

- Shu, Y.; Liu, M.; Chen, S.; Chen, X.; Wang, J. New insight into molecular interactions of imidazolium ionic liquids with bovine serum albumin. J. Phys. Chem. B 2011, 115, 12306–12314. [Google Scholar] [CrossRef]

- Attri, P.; Venkatesu, P. Ammonium ionic liquids as convenient co-solvents for the structure and stability of succinylated Con A. J. Chem. Thermodyn. 2012, 52, 78–88. [Google Scholar] [CrossRef]

- Zafarani-Moattar, M.T.; Shekaari, H.; Jafari, P. Thermodynamic study of aqueous two-phase systems containing biocompatible cholinium aminoate ionic-liquids and polyethylene glycol di-methyl ether 250 and their performances for bovine serum albumin separation. J. Chem. Thermodyn. 2019, 130, 17–32. [Google Scholar] [CrossRef]

- Pereira, M.M.; Pedro, S.N.; Quental, M.V.; Lima, Á.S.; Coutinho, J.A.P.; Freire, M.G. Enhanced extraction of bovine serum albumin with aqueous biphasic systems of phosphonium-and ammonium-based ionic liquids. J. Biotechnol. 2015, 206, 17–25. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zafarani-Moattar, M.T.; Shekaari, H.; Jafari, P. Structural effects of choline amino acid ionic liquids on the extraction of bovine serum albumin by green and biocompatible aqueous biphasic systems composed of polypropylene glycol400 and choline amino acid ionic liquids. J. Mol. Liq. 2020, 301, 112397. [Google Scholar] [CrossRef]

- Zafarani-Moattar, M.T.; Shekaari, H.; Jafari, P. Design of Novel Biocompatible and Green Aqueous two-Phase Systems containing Cholinium L-alaninate ionic liquid and polyethylene glycol di-methyl ether 250 or polypropylene glycol 400 for separation of bovine serum albumin (BSA). J. Mol. Liq. 2018, 254, 322–332. [Google Scholar] [CrossRef]

- Pei, Y.; Li, Z.; Liu, L.; Wang, J.; Wang, H. Selective separation of protein and saccharides by ionic liquids aqueous two-phase systems. Sci. China Chem. 2010, 53, 1554–1560. [Google Scholar] [CrossRef]

- Schröder, C. Proteins in Ionic Liquids: Current Status of Experiments and Simulations. In Ionic Liquids II; Springer: Berlin/Heidelberg, Germany, 2017; pp. 127–152. [Google Scholar]

- Fujita, K.; MacFarlane, D.R.; Forsyth, M. Protein solubilising and stabilising ionic liquids. Chem. Commun. 2005, 38, 4804–4806. [Google Scholar] [CrossRef]

- Haberler, M.; Schröder, C.; Steinhauser, O. Hydrated ionic liquids with and without solute: The influence of water content and protein solutes. J. Chem. Theory Comput. 2012, 8, 3911–3928. [Google Scholar] [CrossRef]

- Klähn, M.; Lim, G.S.; Seduraman, A.; Wu, P. On the different roles of anions and cations in the solvation of enzymes in ionic liquids. Phys. Chem. Chem. Phys. 2011, 13, 1649–1662. [Google Scholar] [CrossRef]

- Egorov, V.M.; Smirnova, S.V.; Pletnev, I.V. Highly efficient extraction of phenols and aromatic amines into novel ionic liquids incorporating quaternary ammonium cation. Sep. Purif. Technol. 2008, 63, 710–715. [Google Scholar] [CrossRef]

- Stepnowski, P.; Skladanowski, A.C.; Ludwiczak, A.; Laczyńska, E. Evaluating the cytotoxicity of ionic liquids using human cell line HeLa. Hum. Exp. Toxicol. 2004, 23, 513–517. [Google Scholar] [CrossRef] [PubMed]

- Stolte, S.; Abdulkarim, S.; Arning, J.; Blomeyer-Nienstedt, A.-K.; Bottin-Weber, U.; Matzke, M.; Ranke, J.; Jastorff, B.; Thöming, J. Primary biodegradation of ionic liquid cations, identification of degradation products of 1-methyl-3-octylimidazolium chloride and electrochemical wastewater treatment of poorly biodegradable compounds. Green Chem. 2008, 10, 214–224. [Google Scholar] [CrossRef]

- Cohn, E.J.; Strong, L.E.; Hughes, W.; Mulford, D.J.; Ashworth, J.N.; Melin, M.E.; Taylor, H.L. Preparation and Properties of Serum and Plasma Proteins. IV. A System for the Separation into Fractions of the Protein and Lipoprotein Components of Biological Tissues and Fluids 1a,b,c,d. J. Am. Chem. Soc. 1946, 68, 459–475. [Google Scholar] [CrossRef]

- Cohn, E.J.; Gurd, F.R.N.; Surgenor, D.M.; Barnes, B.A.; Brown, R.K.; Derouaux, G.; Gillespie, J.M.; Kahnt, F.W.; Lever, W.F.; Liu, C.H. A system for the separation of the components of human blood: Quantitative procedures for the separation of the protein components of human plasma1a, b, c. J. Am. Chem. Soc. 1950, 72, 465–474. [Google Scholar] [CrossRef]

- Johnston, A.; Adcock, W. The use of chromatography to manufacture purer and safer plasma products. Biotechnol. Genet. Eng. Rev. 2000, 17, 37–70. [Google Scholar] [CrossRef] [Green Version]

- Tanaka, K.; Shigueoka, E.M.; Sawatani, E.; Dias, G.A.; Arashiro, F.; Campos, T.; Nakao, H.C. Purification of human albumin by the combination of the method of Cohn with liquid chromatography. Braz. J. Med. Biol. Res. 1998, 31, 1383–1388. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Raoufinia, R.; Mota, A.; Keyhanvar, N.; Safari, F.; Shamekhi, S.; Abdolalizadeh, J. Overview of albumin and its purification methods. Adv. Pharm. Bull. 2016, 6, 495. [Google Scholar] [CrossRef] [Green Version]

- Odunuga, O.O.; Shazhko, A. Ammonium sulfate precipitation combined with liquid chromatography is sufficient for purification of bovine serum albumin that is suitable for most routine laboratory applications. Biochemical Compounds Comp. 2013, 1, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Vasileva, R.; Jakab, M.; Hasko, F. Application of ion-exchange chromatography for the production of human albumin. J. Chromatogr. A 1981, 216, 279–284. [Google Scholar] [CrossRef]

- Denizli, A.; Pişkin, E. Dye-ligand affinity systems. J. Biochem. Biophys. Methods 2001, 49, 391–416. [Google Scholar] [CrossRef]

- Balkani, S.; Shamekhi, S.; Raoufinia, R.; Parvan, R.; Abdolalizadeh, J. Purification and characterization of bovine serum albumin using chromatographic method. Adv. Pharm. Bull. 2016, 6, 651. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Imamoglu, S. Simulated Moving Bed Chromatography (SMB) for Application in Bioseparation. In Modern Advances in Chromatography; Springer: Berlin/Heidelberg, Germany, 2002; pp. 211–231. [Google Scholar]

- Wang, C.; Bai, S.; Tao, S.-P.; Sun, Y. Evaluation of steric exclusion chromatography on cryogel column for the separation of serum proteins. J. Chromatogr. A 2014, 1333, 54–59. [Google Scholar] [CrossRef] [PubMed]

- Soares, B.P.; Santos, J.H.P.M.; Martins, M.; Almeida, M.R.; Santos, N.V.; Freire, M.G.; Santos-Ebinuma, V.C.; Coutinho, J.A.P.; Pereira, J.F.B.; Ventura, S.P.M. Purification of green fluorescent protein using fast centrifugal partition chromatography. Sep. Purif. Technol. 2021, 257, 117648. [Google Scholar] [CrossRef]

- Capela, E.V.; Santiago, A.E.; Rufino, A.F.C.S.; Tavares, A.P.M.; Pereira, M.M.; Mohamadou, A.; Aires-Barros, M.R.; Coutinho, J.A.P.; Azevedo, A.M.; Freire, M.G. Sustainable strategies based on glycine–betaine analogue ionic liquids for the recovery of monoclonal antibodies from cell culture supernatants. Green Chem. 2019, 21, 5671–5682. [Google Scholar] [CrossRef]

- Kelly, S.M.; Jess, T.J.; Price, N.C. How to study proteins by circular dichroism. Biochim. Biophys. Acta (BBA)-Proteins Proteom. 2005, 1751, 119–139. [Google Scholar] [CrossRef]

- Güler, G.; Vorob’ev, M.M.; Vogel, V.; Mäntele, W. Proteolytically-induced changes of secondary structural protein conformation of bovine serum albumin monitored by Fourier transform infrared (FT-IR) and UV-circular dichroism spectroscopy. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2016, 161, 8–18. [Google Scholar] [CrossRef]

- Charbonneau, D.M.; Tajmir-Riahi, H.-A. Study on the interaction of cationic lipids with bovine serum albumin. J. Phys. Chem. B 2010, 114, 1148–1155. [Google Scholar] [CrossRef]

- Tian, J.; Liu, J.; Hu, Z.; Chen, X. Binding of the scutellarin to albumin using tryptophan fluorescence quenching, CD and FT-IR spectra. Am. J. Immunol. 2005, 1, 21–23. [Google Scholar] [CrossRef] [Green Version]

- Boyle, A.L. Applications of de novo designed peptides. In Peptide Applications in Biomedicine, Biotechnology and Bioengineering; Elsevier: Amsterdam, The Netherlands, 2018; pp. 51–86. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rufino, A.F.C.S.; Almeida, M.R.; Sharma, M.; Coutinho, J.A.P.; Freire, M.G. Separation of Albumin from Bovine Serum Applying Ionic-Liquid-Based Aqueous Biphasic Systems. Appl. Sci. 2022, 12, 707. https://doi.org/10.3390/app12020707

Rufino AFCS, Almeida MR, Sharma M, Coutinho JAP, Freire MG. Separation of Albumin from Bovine Serum Applying Ionic-Liquid-Based Aqueous Biphasic Systems. Applied Sciences. 2022; 12(2):707. https://doi.org/10.3390/app12020707

Chicago/Turabian StyleRufino, Ana F. C. S., Mafalda R. Almeida, Mukesh Sharma, João A. P. Coutinho, and Mara G. Freire. 2022. "Separation of Albumin from Bovine Serum Applying Ionic-Liquid-Based Aqueous Biphasic Systems" Applied Sciences 12, no. 2: 707. https://doi.org/10.3390/app12020707