Design and Simulation of Manufacturing Organizations Based on a Novel Function-Based Concept

Abstract

:Featured Application

Abstract

1. Introduction

2. Methodology, Fundamentals, and Materials

2.1. Methodology

- Literature research on the manufacturing process, production systems, quality management and control, maintenance management, logistics management, information systems, the human factor, system dynamics, simulation, and the integrated function-based manufacturing organizational model.

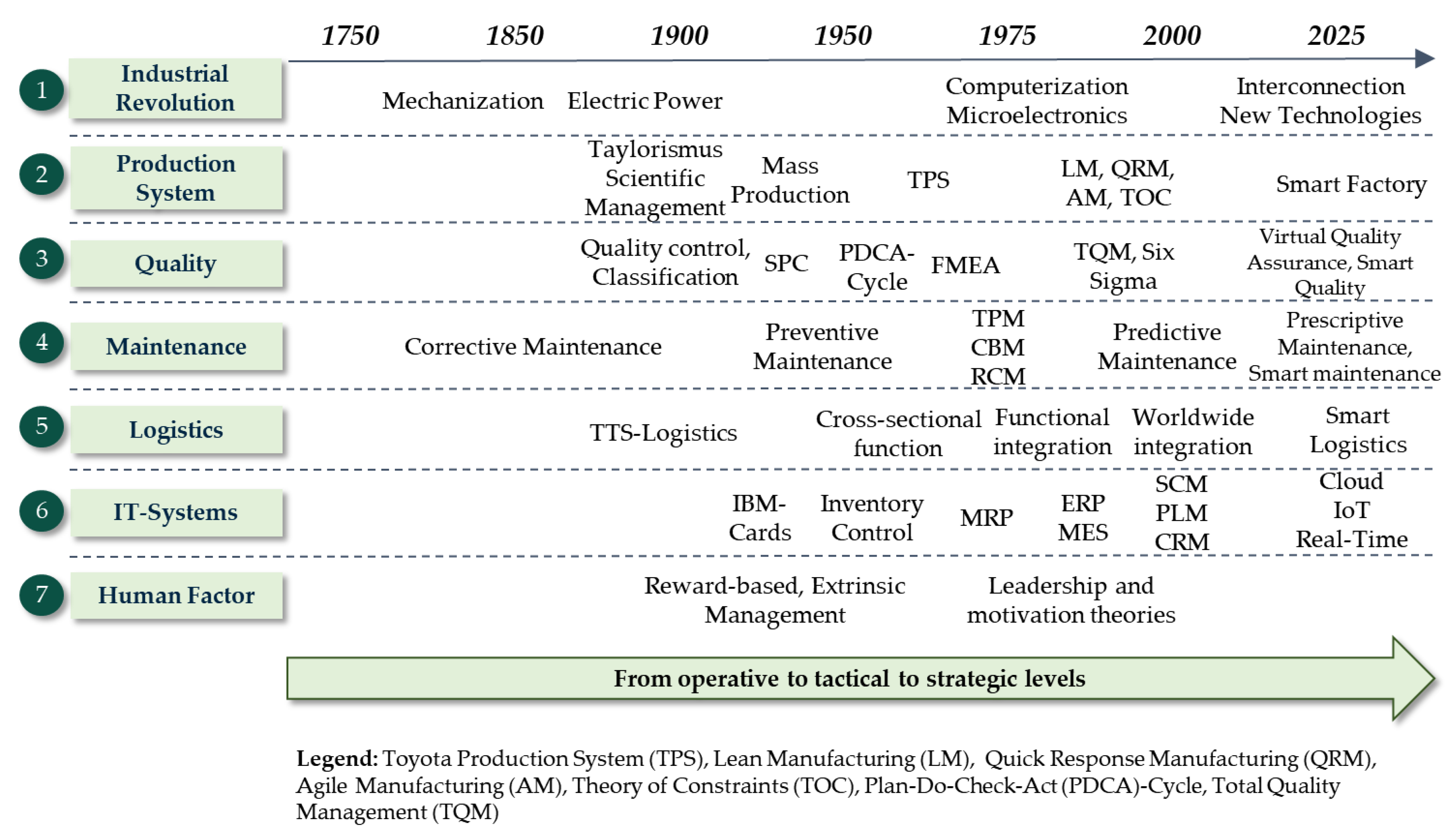

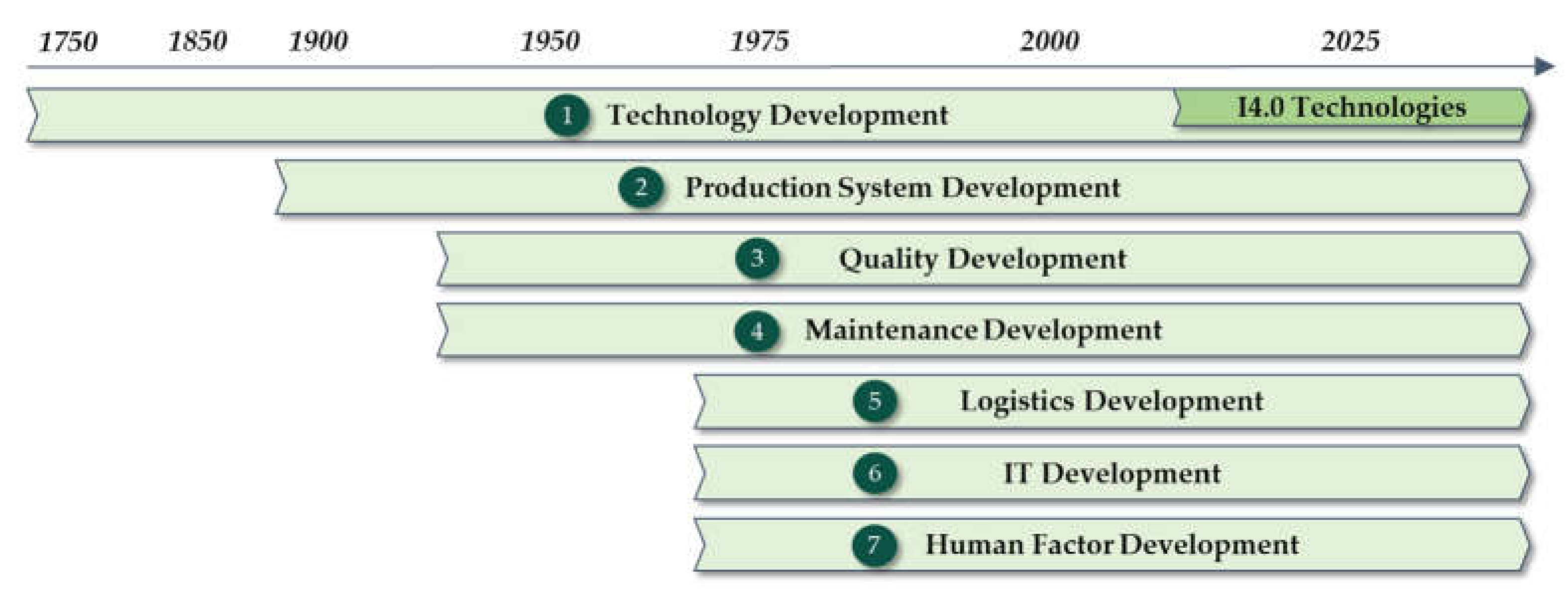

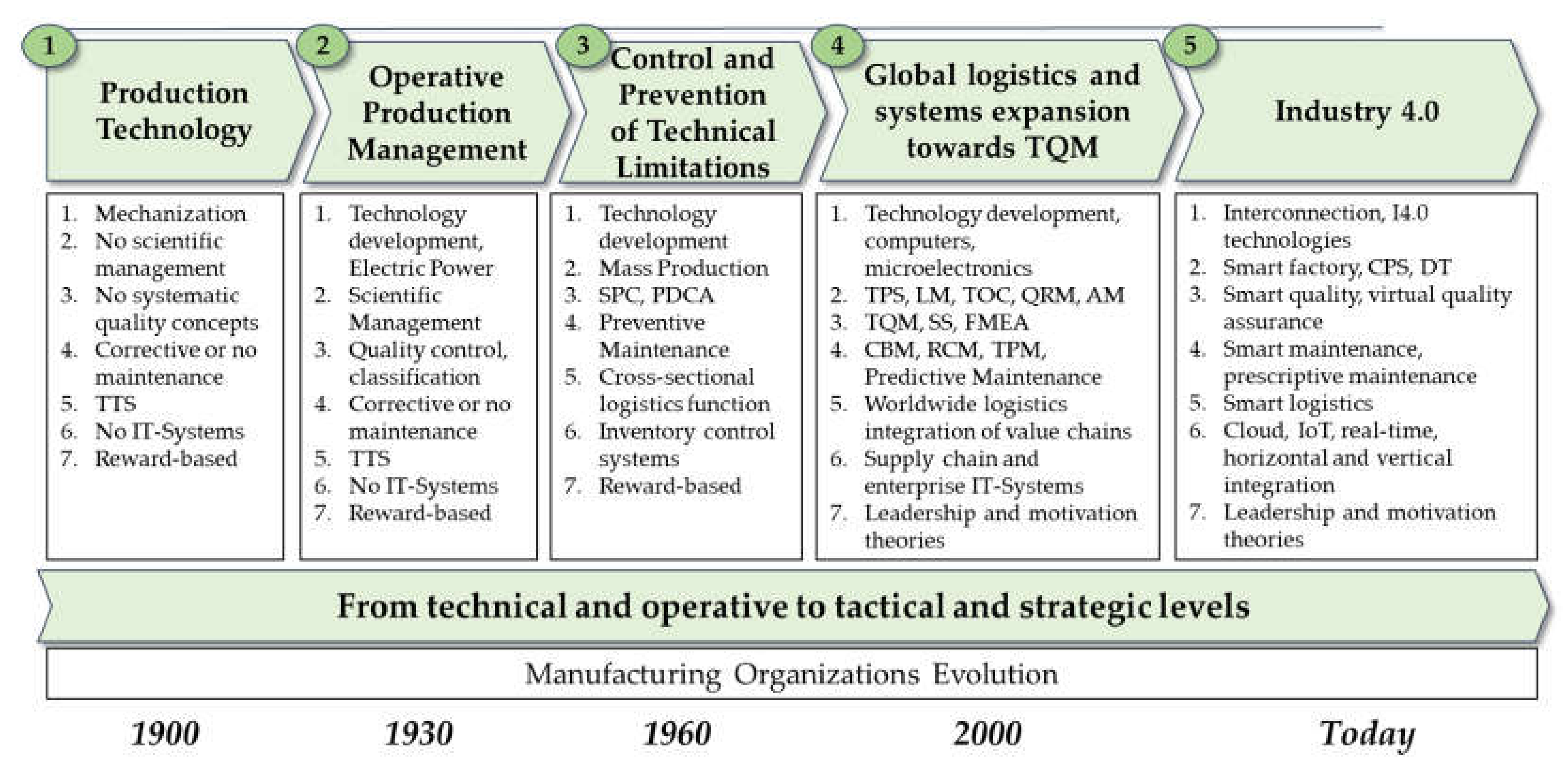

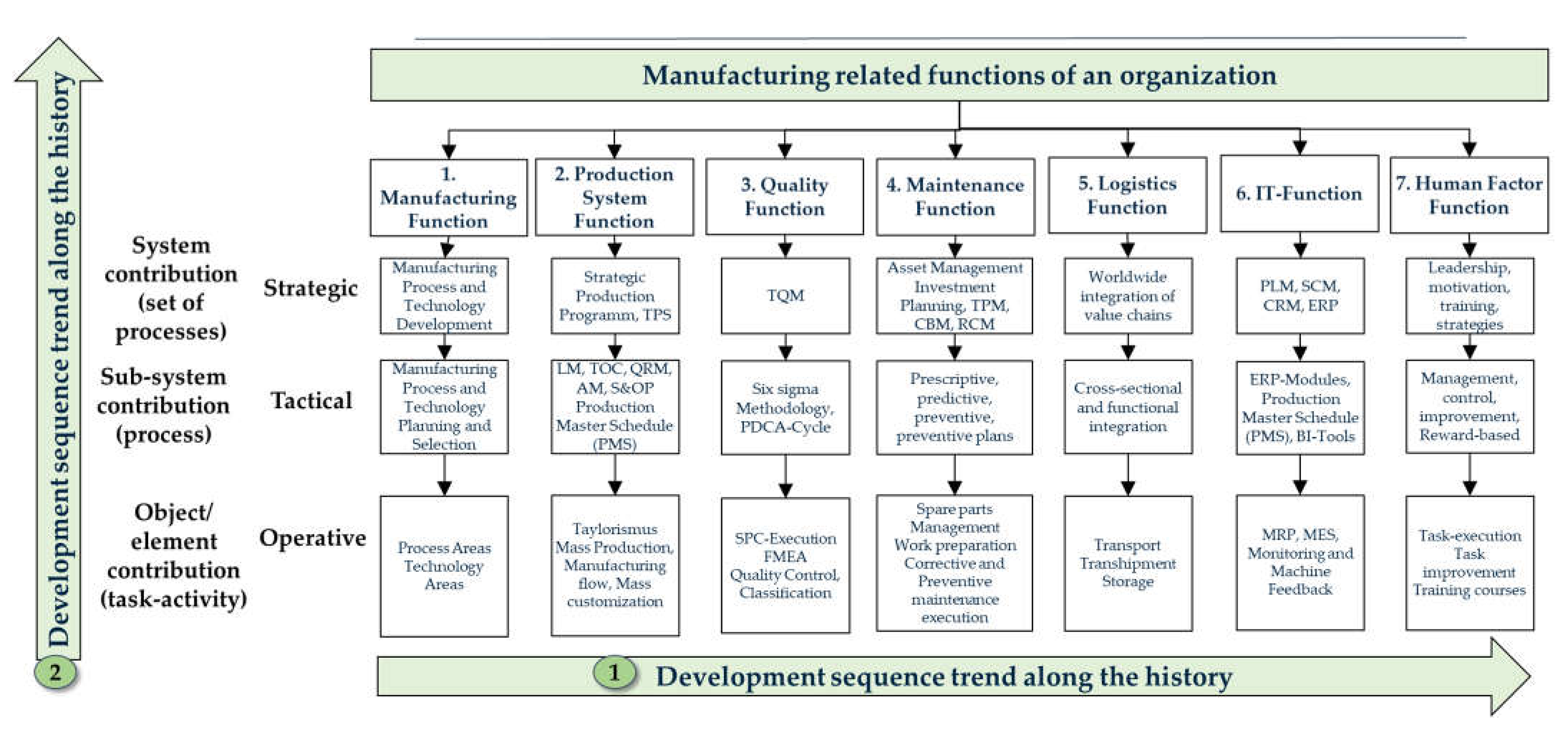

- Function development over history with a focus on seven functional areas: manufacturing processes and technologies, production planning system, quality, maintenance, logistics, information systems, and human resources.

- Development of a conceptual model as an integrated model with the goal of serving as a framework for assessing the functional areas of a manufacturing organization enabling the continuous improvement to support the management, control, and decision making for managerial and technical positions within industrial organizations.

- Interpretation of results and derivation of implications and use cases for managers and technicians.

- Critical reflection of the research performed, and outlook of potential future research based on the findings of the paper.

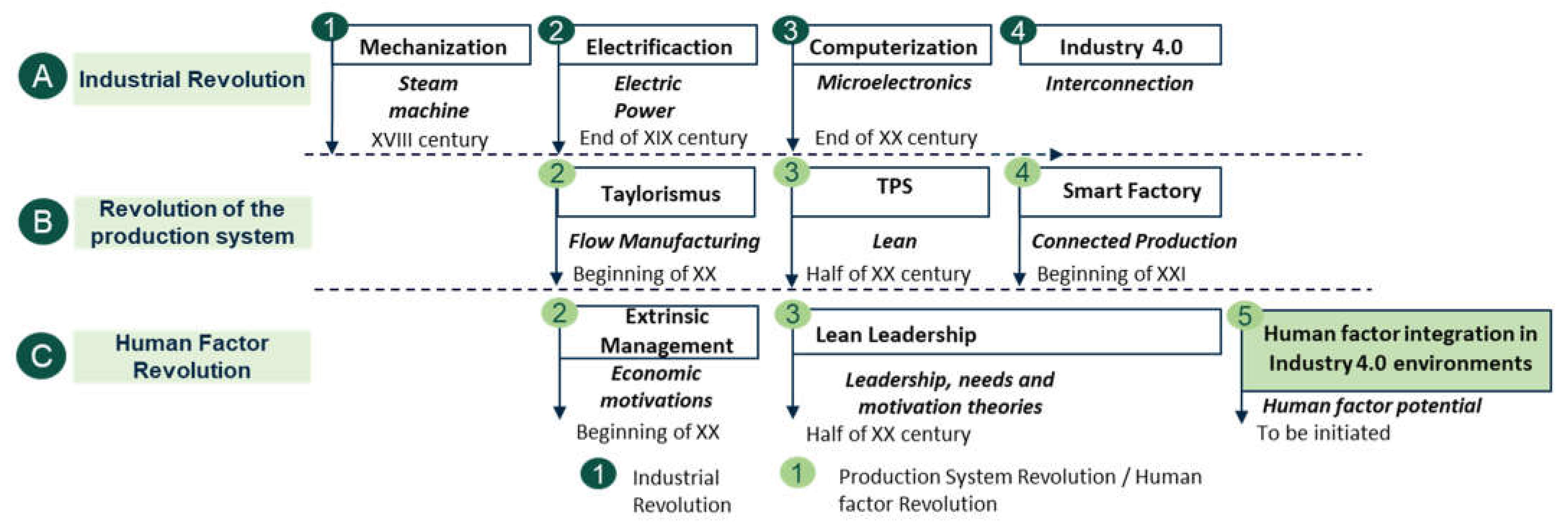

2.2. Functions Development during Industrial Revolutions

- PLM (product lifecycle management): product life management

- CRM (customer relationship management): customer management

- SCM: supply chain management

2.3. Materials and Methods

- Modeling is the representation of a real-world scenario by a mathematical expression and/or a simplification of the real-world system. Simulation uses a model to generate data, and these data can then be analyzed [38]. Simulation allows companies to assess how decisions should be made and the optimal time to make them. Therefore, these analyses can assist in determining whether certain decisions are wise or not, acting as decision-supporting tools [39]. The use of simulation for manufacturing system design and analysis is recognized by scientists and industrial managers [40].

- System dynamics simulation: System dynamics is a method that was created in the mid-1950s by Professor Jay Forrester and is a method of studying dynamic systems. System dynamics suggests a very high abstraction level and is positioned as a strategic modeling methodology [41]. Simulations will be used more extensively in plant operations to leverage real-time data to mirror the physical world in a virtual model, which can include machines, products, and humans. Decision-making quality can be possibly improved by an easy and fast process with the help of simulations [2]. Simulations thus become important and extremely efficient research methods in the current context of manufacturing digitalization. Applied in production systems, simulations can provide answers to how they respond to the various variables and unpredictable situations that arise. Simulation models are usually needed when it is impossible or quite difficult to develop an analytical solution to a studied problem [42]. This type of continuous simulation is chosen over discrete simulations, such as discrete-event or agent-based modeling, due to their high abstraction level that represents global causal dependencies with aggregates and feedback dynamics supporting the integral assessment and selection of strategic alternatives of a manufacturing system, while discrete simulations are focused on events or agents, that is, individual objects with exact sizes, timings, etc.; however, this is not the focus of the current study.

- Simulation software: The use of simulations for manufacturing systems design and analysis is rightfully recognized by scientists and industrial managers and the literature is abundant in this field [40] There are different software packages on the market that enable system dynamics modeling [43]. VENSIM (Ventana Systems) simulation software was selected for this research.

- Databases in Excel files were used as input data for simulations.

3. Design of a Function-Based Model for the Identification of Improvement Potentials

3.1. Design of a Function-Based Conceptual Model for Manufacturing Organizations

3.2. Identification of Functional Improvement Potentials

3.3. Systemic Function-Based Modeling of a Manufacturing Organization

3.4. FMEA Model for Developing Improvement Plans in Manufacturing Organizations

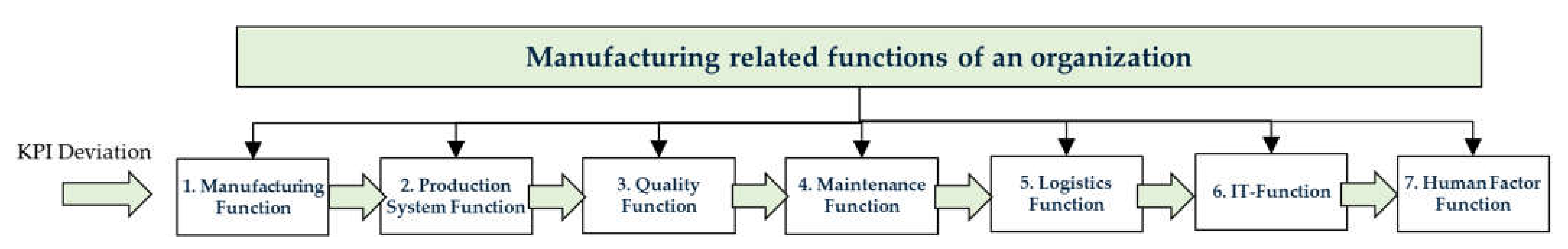

- KPI deviation is identified.

- KPI attracts the attention of top management.

- A process for searching the cause is initiated:

- If the deviation identified refers to a cross-functional manufacturing indicator, normally this process starts from the operative manufacturing function and goes through the organization;

- If the deviation refers to a specific functional area such as the quality rate, the analysis starts from the related functional area, quality function, in relation to the manufacturing function.

- The sequence is normally the same as the historic evolution of the different functions.

- The cause–effect analysis of malfunctions of organizational functions is normally not analyzed with a global holistic perspective considering all the functional areas and interrelationships. However, it is normally assessed in the manufacturing and technical areas such as quality and maintenance, and on occasions, moves up to other logistics and IT functions. In the process of many malfunctions, a real cause is not identified, and occurs as “sporadic cases”; therefore, on many occasions’ managers do not know why certain projects fail to make it impossible to learn from experience.

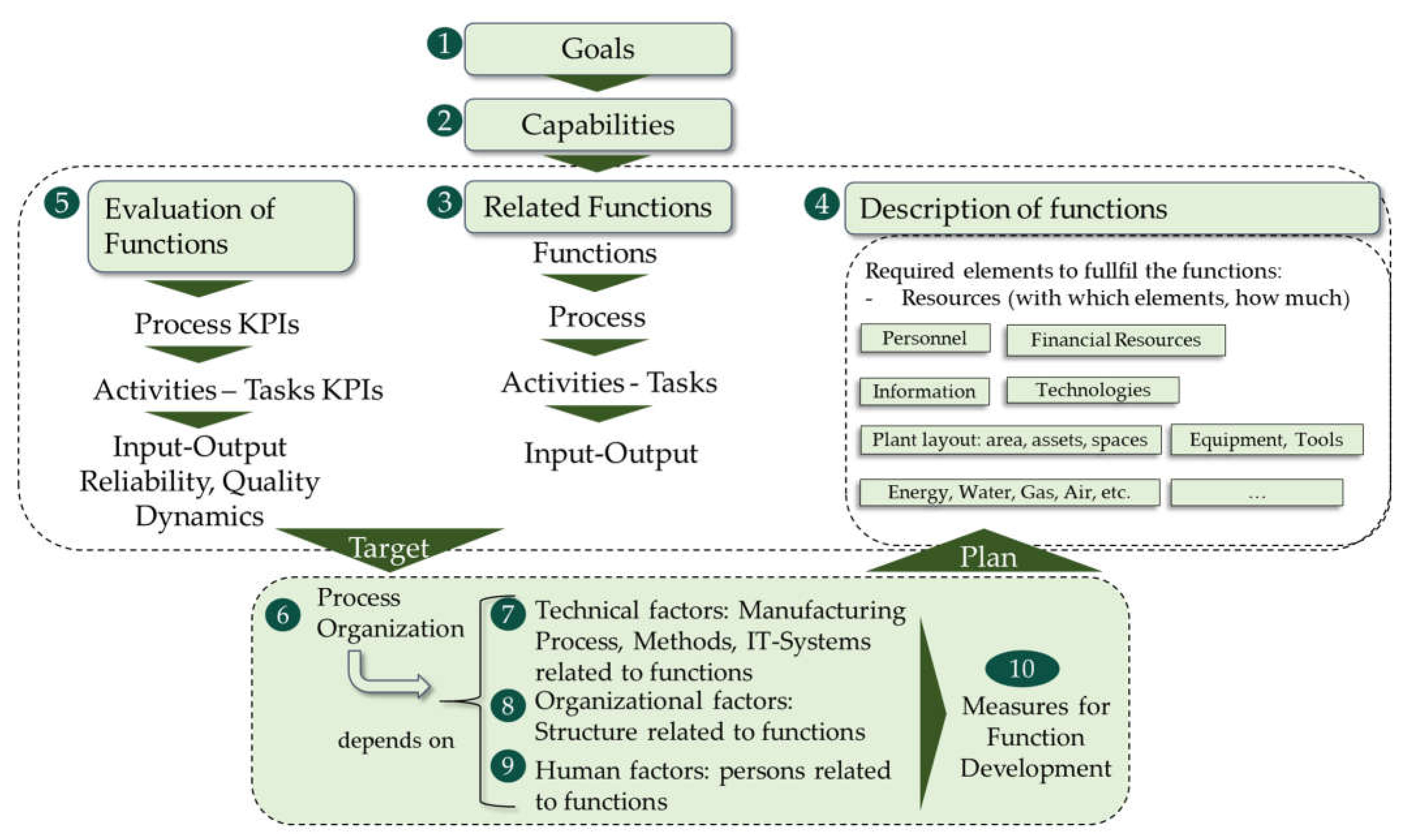

- For doing so, first, it is necessary to analyze the maturity model of the organization by functional area to determine in which evolution state the organization is at. The following steps are considered:

- Current state knowledge: Know the function maturity level of each functional area in the different planning levels according to the historic evolution. A company state will be determined by the moment it was created, the functions implemented at this time, the improvement projects performed until now, and the success, partial success, or failure of this project.

- Identify the problem.

- Perform an holistic malfunction analysis based on an organizational function FMEA process with the help of mapping the interrelationships among functions.

- Optimize the process for executing the function that needs improvement.

- Determine the measures for the technical, organizational, or human factors for executing the new process.

- Implement the plan.

4. Simulation Case Study

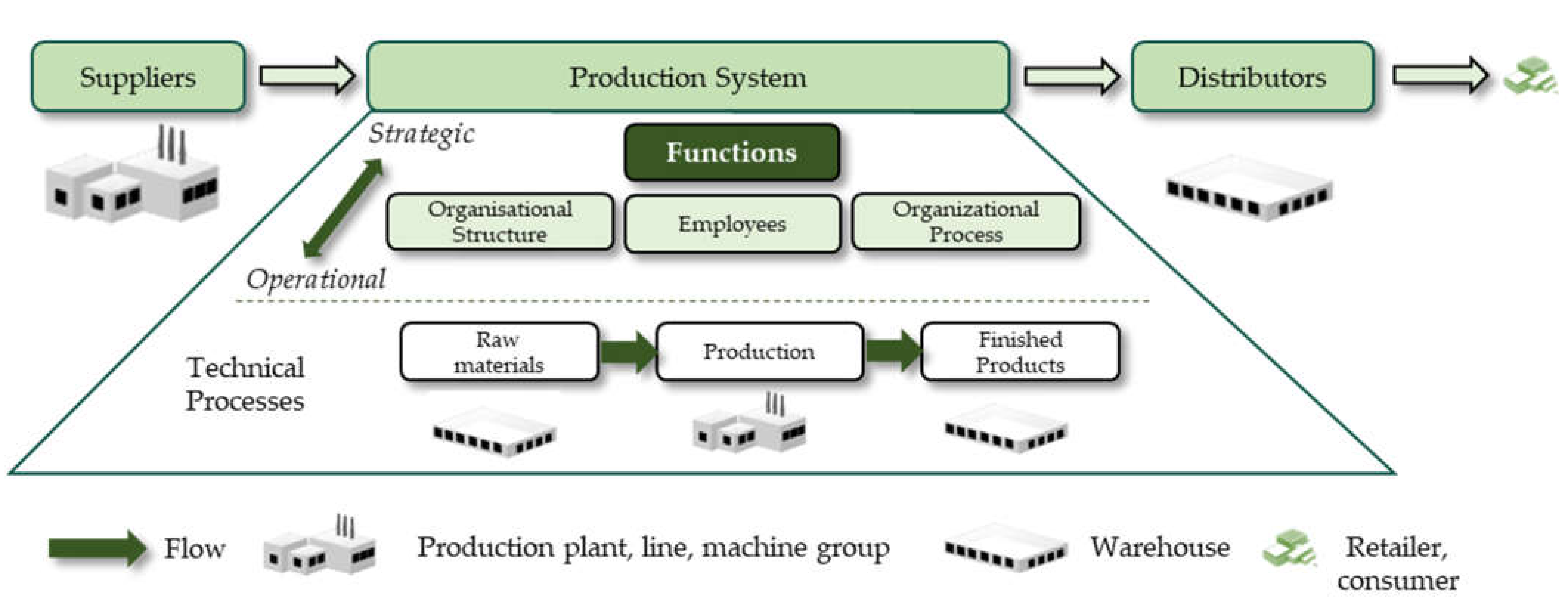

- A generic simulation model consisting of the most relevant manufacturing functions that would serve as a basis for developing specific evaluations for any kind of industrial organization.

- Specific simulation models for each main function in the optimization process that repeats the translation of the evolution of functions. The scope of these models did not include all associated functions, resources, and data.

- A holistic exemplary digital model that could serve as the basis for developing functions within organizations as well as for monitoring their performance and based on this assessment being able to make a diagnosis of malfunctions and their origin within the process and organizational structure of industrial firms.

- The improvement of all relevant indicators along the historical evolution of functions within industrial organizations.

- The importance of each function as each could become a limiting factor acting as a bottleneck.

- The significant implications on key indicators of the qualification factor as well as of the alignment of employees to organizational, department, and position goals.

- Definition of the objective, scope, and hypothesis.

- Manufacturing organizational functions definition.

- Determination of KPIs.

- Development of assumptions and simulation logic.

- Generation of the simulation models and definition of scenarios.

- Validation of simulation models.

- Simulation and extraction of results.

- Interpretation of results.

4.1. Design of the Generic Model of Functions for Industrial Organizations

4.2. Key Performance Indicators

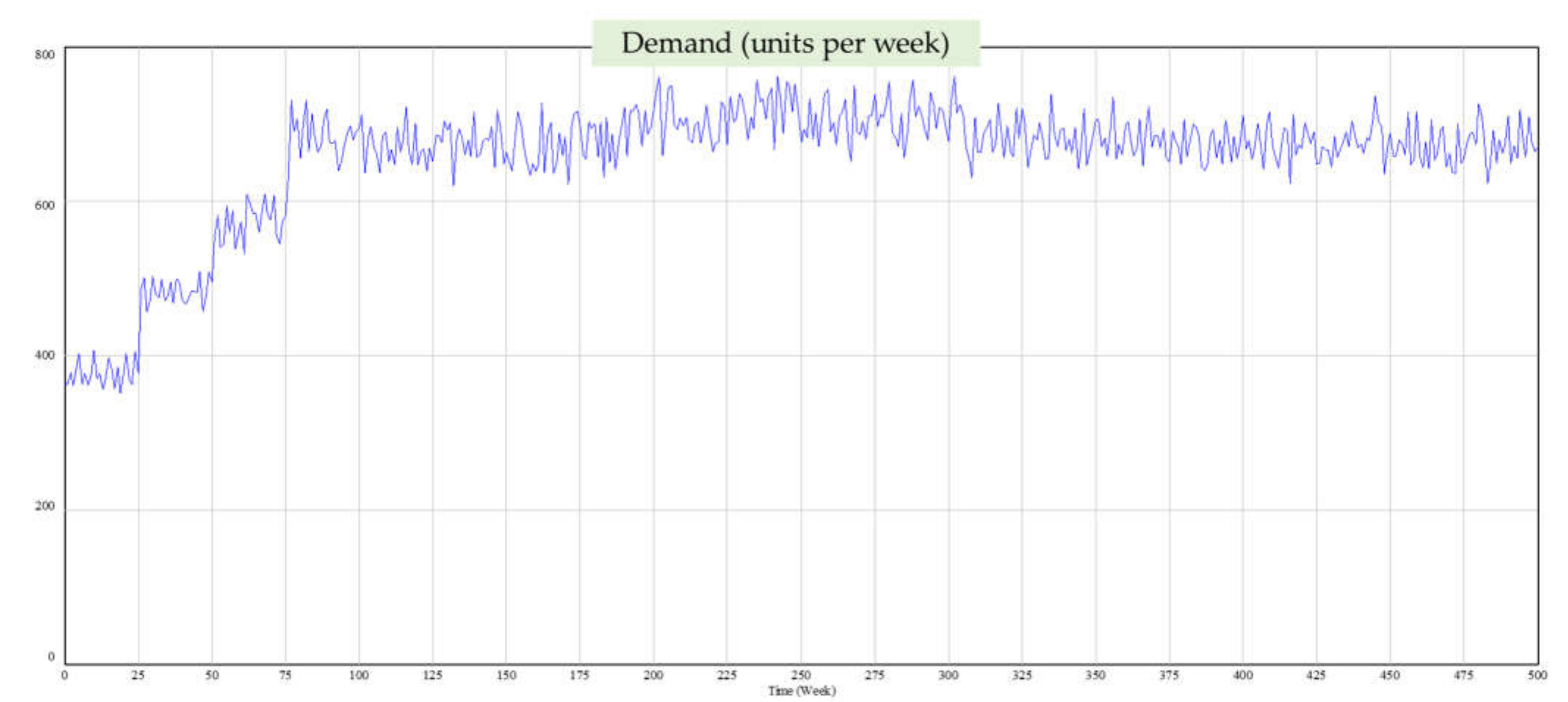

- Cumulated market demand (# thousand products);

- Cumulated real demand (# thousand products);

- Cumulated production (# thousand products): the cumulative sum of all units produced over the 500 simulated-production weeks;

- Ø Utilization rate of the production plant (%);

- Ø Availability of the production plant (%);

- Ø Performance at the final production step (# thousand products/week);

- Ø Quality at the final production step with one-way and no loops (%);

- Ø Labor productivity (products/employee × week);

- Cumulated stocks (# million products);

- Ø Production lead time (# weeks);

- Cumulated service level (%);

- Cumulated sales (USD million);

- Cumulated operational costs (USD million);

4.3. Assumptions

- Time restrictions: 10 working years in periods of weeks assuming 50 working weeks per year, 500 periods in order to evaluate implications in the manufacturing organization in the short, medium, and long terms.

- Fixed lead times for production processes, material transport, and employee movements.

- Real demand that is requested by the manufacturing organization depends on the service level. As a result, the company cannot cover the whole potential market demand if the service level is not appropriate.

- Each order had a production unit.

- Same demand using replication for all the models.

- Same initial situation, with initial inventory in the different warehouses for all the models.

- Same number of employees with the same initial distribution for all the models.

- Same supply chain distribution network (production facility, warehouses, etc.).

- The warehouses had no stock capacity limitations.

- There were no transport limitations between the different production stages.

- One product unit was assumed to be in a mature stage with stable demand and provided a sales value of USD 10,000/unit. The second product was in the process of being launched and provided USD 20,000/unit. These values were used to calculate sales. It was assumed that the new model would have a loss in volume due to unknown future demand.

- The simulation model considered sales loss starting from a customer order lead time greater than 60 days.

- A product was considered a finished product after it left the production facility.

- If no human factor malfunctions, it is assumed that the employees have adequate qualification as well as alignment with organizational, department, and position goals they are in charge of.

4.4. Simulation Models and Scenarios

- 9.

- Base model (BM);

- 10.

- Production technology (PT);

- 11.

- Operative production management (OPM);

- 12.

- Control and prevention of technical limitations (TL);

- 13.

- Global logistics and systems expansion towards TQM (LSQ);

- 14.

- Industry 4.0 (I4.0);

- 15.

- Human factor malfunction in the strategic, tactical, operative levels (HF3);

- 16.

- Human factor malfunction in the tactical, operative levels (HF2);

- 17.

- Human factor malfunction in the operative level (HF1).

5. Simulation Results

6. Discussion

7. Conclusions

- The conceptual framework of the assessment methodology was not developed in the operative level and for specific cases.

- Individual interactions among staff, machines, robots, and other elements were not considered in the simulation model.

- The full complexity of manufacturing processes was not built in detail.

- The organization structure and interfaces were not considered in the simulation model.

- Certain quality requirements of the product were not considered.

- Investment and costs were assumed.

- The concept was not proved in any company.

- Transferring this research method to real manufacturing organization and applying it as a digital twin tool or an assistance tool for strategic, CEOs and vice presidents, for tactical level, sales, production, quality and maintenance leaders, and operative levels, by centralizing all data related to the manufacturing organization, functional area, or function, thereby allowing better planning based on updated information of all interrelated factors as well as providing a tool for the assessment and the simulation of what-if-scenarios in real time.

- Considering organization units, persons, relationships, and their communication within the simulation model.

- Improving the model based on implementation feedbacks as well as applying it to production networks with several production plants.

- Improving the simulation model with better connection to the physical world as well as with expanded data analytics and artificial intelligence to provide suggestions in order to assist human decision-making activities.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing smart factory of industrie 4.0: An outlook. Int. J. Distrib. Sens. Netw. 2016, 12, 3159805. [Google Scholar] [CrossRef] [Green Version]

- Vaidya, S.; Ambad, P.; Bhosle, S. Industry 4.0–A glimpse. Procedia Manuf. 2018, 20, 233–238. [Google Scholar] [CrossRef]

- Permin, E.; Bertelsmeier, F.; Blum, M.; Bützler, J.; Haag, S.; Kuz, S.; Özdemir, D.; Stemmler, S.; Thombansen, U.; Schmitt, R.; et al. Self-optimizing production systems. Procedia Cirp 2016, 41, 417–422. [Google Scholar] [CrossRef]

- Chen, B.; Wan, J.; Shu, L.; Li, P.; Mukherjee, M.; Yin, B. Smart factory of industry 4.0: Key technologies, application case, and challenges. IEEE Access 2017, 6, 6505–6519. [Google Scholar] [CrossRef]

- Qin, J.; Liu, Y.; Grosvenor, R. A categorical framework of manufacturing for industry 4.0 and beyond. Procedia Cirp 2016, 52, 173–178. [Google Scholar] [CrossRef] [Green Version]

- Tao, F.; Qi, Q. New IT driven service-oriented smart manufacturing: Framework and characteristics. IEEE Trans. Syst. Man Cybern. Syst. 2017, 49, 81–91. [Google Scholar] [CrossRef]

- Negri, E.; Fumagalli, L.; Macchi, M. A review of the roles of digital twin in CPS-based production systems. Procedia. Manuf. 2017, 11, 939–948. [Google Scholar] [CrossRef]

- Thombansen, U.; Schuttler, J.; Auerbach, T.; Beckers, M.; Buchholz, G.; Eppelt, U.; Gloy, Y.; Fritz, P.; Kratz, S.; Lose, J.; et al. Model-based self-optimization for manufacturing systems. In Proceedings of the 17th International Conference on Con-current Enterprising (ICE), Aachen, Germany, 20–22 June 2011; pp. 1–9. [Google Scholar]

- Perales, D.P.; Valero, F.A.; García, A.B. Industry 4.0: A classification scheme. In Closing the Gap between Practice and Research in Industrial Engineering; Viles, E., Ormazábal, M., Lleó, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 343–350. [Google Scholar]

- Magnanini, M.C.; Tolio, T.A. A model-based Digital Twin to support responsive manufacturing systems. Cirp Ann. 2021, 70, 353–356. [Google Scholar] [CrossRef]

- Rouhani, A.; Fazelhashemi, S. Forget about TPM, 1st ed.; Rasa Cultural Services Institute: Tehran, Iran, 2009. [Google Scholar]

- Al-Ahmari, A.M.A.; Ridgway, K. An integrated modelling method to support manufacturing systems analysis and design. Comput. Ind. 1999, 38, 225–238. [Google Scholar] [CrossRef]

- Oztemel, E.; Gursev, S. Literature review of Industry 4.0 and related technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar] [CrossRef]

- Scheer, A.W. Industrie 4.0: Wie Sehen Produktionsprozesse im Jahr 2020 Aus; IMC AG: Saarbrücken, Germany, 2013. [Google Scholar]

- Stock, T.; Seliger, G. Opportunities of sustainable manufacturing in industry 4.0. Procedia Cirp 2016, 40, 536–541. [Google Scholar] [CrossRef] [Green Version]

- Dhilon, B.S. Maintainability, Maintenance and Reliability for Engineers; Taylor and Francis: Boca Raton, FL, USA, 2006. [Google Scholar]

- DIN, E. 13306: Instandhaltung–Begriffe der Instandhaltung; Maintenance Terminology: Berlin, Germany, 2010. [Google Scholar]

- Mourtzis, D.; Angelopoulos, J.; Boli, N. Maintenance assistance application of Engineering to Order manufacturing equipment: A Product Service System (PSS) approach. IFAC-PapersOnLine 2018, 51, 217–222. [Google Scholar] [CrossRef]

- Ben-Daya, M.; Duffuaa, S.O.; Raouf, A.; Knezevic, J.; Ait-Kadi, D. Handbook of Maintenance Management and Engineering; Springer: London, UK, 2009; Volume 7. [Google Scholar]

- Mcadam, R.; Duffner, A. Implementation of total productive maintenance in support of an established total quality pro-gramme. Total Qual. Manag. 1996, 7, 613–630. [Google Scholar] [CrossRef]

- Matyas, K. Instandhaltungslogistik: Qualität und Produktivität Steigern, 5th ed.; Carl Hanser Verlag: München, Germany, 2013. [Google Scholar]

- Pawellek, I.G. Planung der Instandhaltung. Integrierte Instandhaltung und Ersatzteillogistik; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Voigt, K.I.; Steinmann, D.I.F.; Bauer, D.I.J.; Dremel, A. Condition Monitoring Als Schlüsseltechnologie–Eine Analyse Der Anforderungen an Neue Geschäftsmodelle Für Den Remote Service; Heinz Nixdorf Institut-Universität Paderborn: Paderborn, Germany, 2013. [Google Scholar]

- Herterich, M.M.; Uebernickel, F.; Brenner, W. The impact of cyber-physical systems on industrial services in manufacturing. Procedia Cirp 2015, 30, 323–328. [Google Scholar] [CrossRef] [Green Version]

- Ivanov, D.; Sokolov, B.V. Adaptive Supply Chain Management; Springer: London, UK, 2010. [Google Scholar]

- Chopra, S.; Meindl, P. Supply Chain Management. Strategy, Planning, and Operation; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Baumgarten, H. Das Beste der Logistik. Innovationen, Strategien, Umsetzungen; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Schuh, G.; Stich, V. Logistikmanagement, 2nd ed.; Springer Vieweg: Berlin, Germany, 2013. [Google Scholar]

- Lummus, R.; Duclos, K.; Vokurka, J. Supply Chain Flexibility: Building a New Model. Glob. J. Flex. Syst. Manag. 2003, 4, 1–13. [Google Scholar]

- Kakouris, A.; Polychronopoulos, G. Enterprise resource planning (ERP) system: An effective tool for production management. Manag. Res. News 2005, 28, 66–78. [Google Scholar] [CrossRef]

- Zäpfel, G. Grundzüge des Produktions-und Logistikmanagement; Walter de Gruyter: München, Germany, 2001. [Google Scholar]

- Hackstein, R. Produktionsplanung und-Steuerung (PPS): Ein Handbuch Für Die Betriebspraxis; VDI-Verlag: Düsseldorf, Germany, 1984. [Google Scholar]

- Schuh, G.; Brosze, T.; Brandenburg, U.; Cuber, S.; Schenk, M.; Quick, J.; Schmidt, C.; Helmig, J.; Schürmeyer, M.; Hering, N. Grundlagen der produktionsplanung und-steuerung. Prod. Steuer. 2012, 1, 9–293. [Google Scholar]

- Stotz, H. 8600 Unternehmen Gaben Auskunft. Comput. Prod. 2001, 2, 32. [Google Scholar]

- Kirby, C.; Brosa, N. La Logística Como Factor De Competitividad De Las Pymes En Las Américas; Banco I nteramericano de Desarrollo: Santo Domingo, Republica Dominicana, 2011. [Google Scholar]

- Muñoz Bosch, M. ERP Para La Pequeña Empresa; Universitat Politècnica de Catalunya: Barcelona, Spain, 2008. [Google Scholar]

- Schilberg, D.; Meisen, T.; Reinhard, R. Virtual Production-The connection of the modules through the Virtual Production Intelligence. In Proceedings of the World Congress on Engineering and Computer Science 2013, San Francisco, CA, USA, 23–25 October 2013; Volume 2, pp. 23–25. [Google Scholar]

- Mittal, S.; Khan, M.A.; Romero, D.; Wuest, T. Smart manufacturing: Characteristics, technologies and enabling factors. J. Eng. Manuf. 2019, 233, 1342–1361. [Google Scholar] [CrossRef]

- Reggelin, T. Schneller Entscheiden. Log.Kompass; DVV Media Group: Hamburg, Germany, 2012; p. 5. [Google Scholar]

- Habchi, G.; Berchet, C. A model for manufacturing systems simulation with a control dimension. Simul. Model. Pract. Theory 2003, 11, 21–44. [Google Scholar] [CrossRef]

- Borshchev, A. Simulation Modeling with AnyLogic: Agent Based, Discrete Event and System Dynamics Methods; DVV Media Group: Hamburg, Germany, 2013; pp. 225–269. [Google Scholar]

- Florescu, A.; Barabas, S.A. Modeling and simulation of a flexible manufacturing system—A basic component of industry 4.0. Appl. Sci. 2020, 10, 8300. [Google Scholar] [CrossRef]

- Campuzano, F.; Bru, J.M. Supply Chain Simulation: A System Dynamics Approach for Improving Performance; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Siestrup, G.; Zeeb, D. Reifegradbestimmung: Der Weg Zur Supply Chain 4.0; Hochschule Furtwangen: Villingen-Schwenningen, Germany, 2017. [Google Scholar]

- McCormick, D.W.; Spee, J.C. IBM and Germany 1922–1941. Organ. Manag. J. 2008, 5, 214–223. [Google Scholar] [CrossRef]

- Gallego-García, S.; Reschke, J.; García-García, M. Design and simulation of a capacity management model using a digital twin approach based on the viable system model: Case study of an automotive plant. Appl. Sci. 2019, 9, 5567. [Google Scholar] [CrossRef] [Green Version]

- Auerbach, T.; Bauhoff, F.; Beckers, M.; Behnen, D.; Brecher, C.; Brosze, T.; Esser, M. Selbstoptimierende produktionssysteme. In Integrative Produktionstechnik Für Hochlohnländer; Springer: Berlin, Germany, 2011; pp. 747–1057. [Google Scholar]

- Mayer, M.P. Entwicklung Eines Kognitionsergonomischen Konzeptes und Eines Simulationssystems Für die Robotergestützte Montage; Shaker: Aachen, Germany, 2012. [Google Scholar]

- Hinckeldeyn, J.; Dekkers, R.; Altfeld, N.; Kreutzfeldt, J. Bottleneck-based synchronisation of engineering and manufacturing. In Proceedings of the International Association for Management of Technology IAMOT 2010 Proceedings of the 19th International Conference on Management of Technology, Cairo, Egypt, 8–11 March 2010. [Google Scholar]

| No. | Simulation Models | Logic Formulation | ||

|---|---|---|---|---|

| Measures | Description of Impacts | Impact on KPIs | ||

| 1 | Base Model | No measures | Initial Situation | Base KPIs |

| 2 | Production Technology | Investment in new equipment for capacity expansion | Increase in painting production capacity | Higher Production Volume |

| 3 | Operative Production Management | Scientific Management, Taylorism | Work organization and management | Higher Performance Rate |

| 4 | Control and Prevention of Technical Limitations | SPC, Preventive Maintenance | Improve condition of equipment, better control of product and process quality by statistical means | Higher Quality Rate, Higher Availability Rate |

| 5 | Global logistics and systems expansion towards TQM | Pull Strategy, IT-Systems, TQM, Predictive Management, TPM | Higher Planning Accuracy, Lower information delays, Improve Quality and Maintenance Strategic Planning | Lower Stocks, Higher Service Levels, Shorter Customer Order Lead Times, Higher quality rate, Higher availability rate |

| 6 | Industry 4.0 | New I4.0 Technologies implementation | Real-time information, Horizontal and vertical integration, Prediction capabilities, Assisted Systems | Higher Performance Rate, Higher Quality Rate, Higher Availability Rate, Shorter Customer Order Lead Times Higher Service Levels |

| 7 | Human factor malfunction in the strategic, tactical, operative levels | Lack of qualification of CEO, no correct alignment of goals of Quality Director and Assembly Manager and Employees | Lower decision-making capabilities. Sub-optimal decisions, without the correct timing | Lower overall performance of company KPIs in all functional areas |

| 8 | Human factor malfunction in the tactical, operative levels | Misalignment of goals of Quality Director and Assembly Manager and Employees | Decision-making capabilities oriented to other goals | Lower performance of company KPIs in quality and manufacturing areas and implications in related functional areas |

| 9 | Human factor malfunction in the operative level | Misalignment of goals of Assembly Manager and Employees | Decision-making capabilities oriented to other goals | Lower performance of the assembly manufacturing functional sub-area and implications in related functional areas |

| No. | Key Indicator | Simulation Models: Cumulative Developments | |||||

|---|---|---|---|---|---|---|---|

| 1-BM | 2-PT | 3-OPM | 4-TL | 5-LSQ | 6-I4.0 | ||

| 1 | Market demand (103 products) | 326.7 | 326.7 | 326.7 | 326.7 | 326.7 | 326.7 |

| 2 | Real demand (103 products) | 59.3 | 72.5 | 142.4 | 176.7 | 267.9 | 317.9 |

| 3 | Production (103 products) | 55.7 | 64.5 | 121.7 | 150.7 | 235.3 | 291.9 |

| 4 | Utilization rate (%) | 13.8 | 16.0 | 30.4 | 37.6 | 58.8 | 73.0 |

| 5 | Availability rate (%) | 51.6 | 51.6 | 51.6 | 63.2 | 88.9 | 95.0 |

| 6 | Performance rate (%) | 44.3 | 44.1 | 79.6 | 78.3 | 83.4 | 99.6 |

| 7 | Quality rate (%) | 87.5 | 87.1 | 84.3 | 87.0 | 92.4 | 93.0 |

| 8 | Stocks (106 products) | 3.5 | 4.7 | 10.6 | 12.0 | 1.5 | 1.9 |

| 9 | Labor productivity (products/empl. × year) | 11.1 | 12.9 | 24.3 | 30.2 | 47.1 | 58.4 |

| 10 | Production lead time (days) | 192 | 182 | 124 | 102 | 67 | 47 |

| 11 | Cumulated service level (%) | 48.6 | 61.0 | 82.4 | 88.4 | 90.2 | 96.6 |

| 12 | Sales (million USD) | 600 | 731 | 1630 | 2171 | 3890 | 4865 |

| 13 | Operational costs (million USD) | 546 | 614 | 931 | 1017 | 517 | 561 |

| No. | Key Indicator | Simulation Models: Human Factor Malfunctions Versus 6-I4.0 | |||

|---|---|---|---|---|---|

| 7-HF3 | 8-HF2 | 9-HF1 | 6-I4.0 | ||

| 1 | Market demand (103 products) | 326,738 | 326,738 | 326,738 | 326,738 |

| 2 | Real demand (103 products) | 82,699 | 243,634 | 276,302 | 317,942 |

| 3 | Production (103 products) | 72,282 | 208,998 | 243,818 | 291,922 |

| 4 | Utilization rate (%) | 18.0 | 52.3 | 61.0 | 73.0 |

| 5 | Availability rate (%) | 93.0 | 95.0 | 95.0 | 95.0 |

| 6 | Performance rate (%) | 101.8 | 100.2 | 100.0 | 99.6 |

| 7 | Quality rate (%) | 84.8 | 88.7 | 92.3 | 93.0 |

| 8 | Stocks (106 products) | 5.2 | 10.8 | 13.4 | 1.9 |

| 9 | Labor productivity (products/empl. × year) | 14.5 | 41.8 | 48.8 | 58.4 |

| 10 | Production lead time (days) | 183 | 78 | 64 | 47 |

| 11 | Cumulated service level (%) | 67.2 | 93.2 | 97.6 | 96.6 |

| 12 | Sales (million USD) | 829 | 3379 | 4043 | 4865 |

| 13 | Operational costs (million USD) | 642 | 975 | 1126 | 561 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Winkler, M.; Gallego-García, S.; García-García, M. Design and Simulation of Manufacturing Organizations Based on a Novel Function-Based Concept. Appl. Sci. 2022, 12, 811. https://doi.org/10.3390/app12020811

Winkler M, Gallego-García S, García-García M. Design and Simulation of Manufacturing Organizations Based on a Novel Function-Based Concept. Applied Sciences. 2022; 12(2):811. https://doi.org/10.3390/app12020811

Chicago/Turabian StyleWinkler, Mareike, Sergio Gallego-García, and Manuel García-García. 2022. "Design and Simulation of Manufacturing Organizations Based on a Novel Function-Based Concept" Applied Sciences 12, no. 2: 811. https://doi.org/10.3390/app12020811

APA StyleWinkler, M., Gallego-García, S., & García-García, M. (2022). Design and Simulation of Manufacturing Organizations Based on a Novel Function-Based Concept. Applied Sciences, 12(2), 811. https://doi.org/10.3390/app12020811