Three-Dimensional Printed, Dual-Band, Dual-Circularly Polarized Antenna Array Using Gap Waveguide Technology

Abstract

1. Introduction

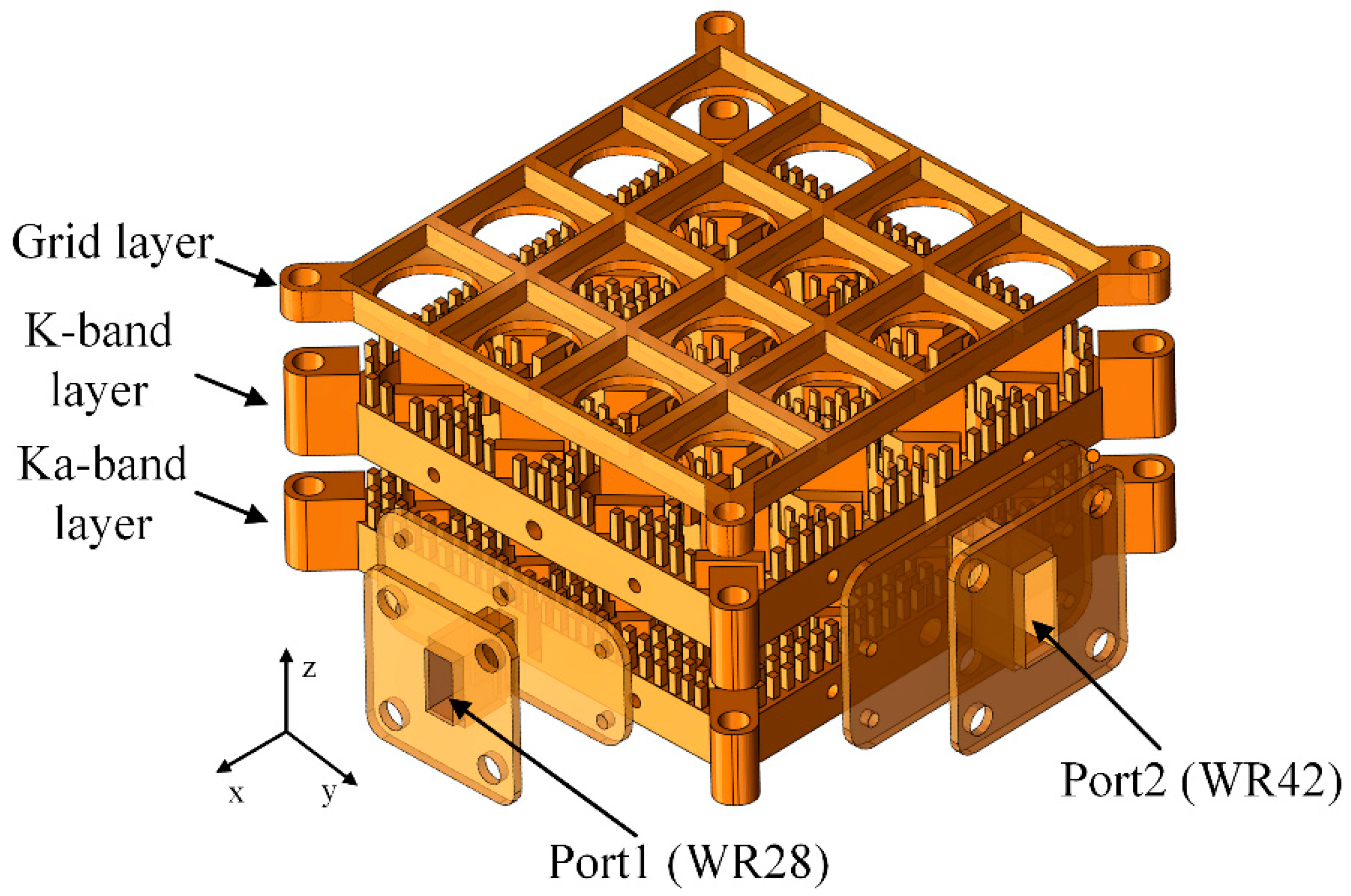

2. Antenna Design Procedure and Methods

2.1. Operating Principle and Simulation of the GWs

2.2. Design of the Dual-Band, Dual-CP Antenna Unit

2.3. Design of the 1 to 16 Feeding Networks

2.4. Design of the Waffle Grid and Waveguide Transitions

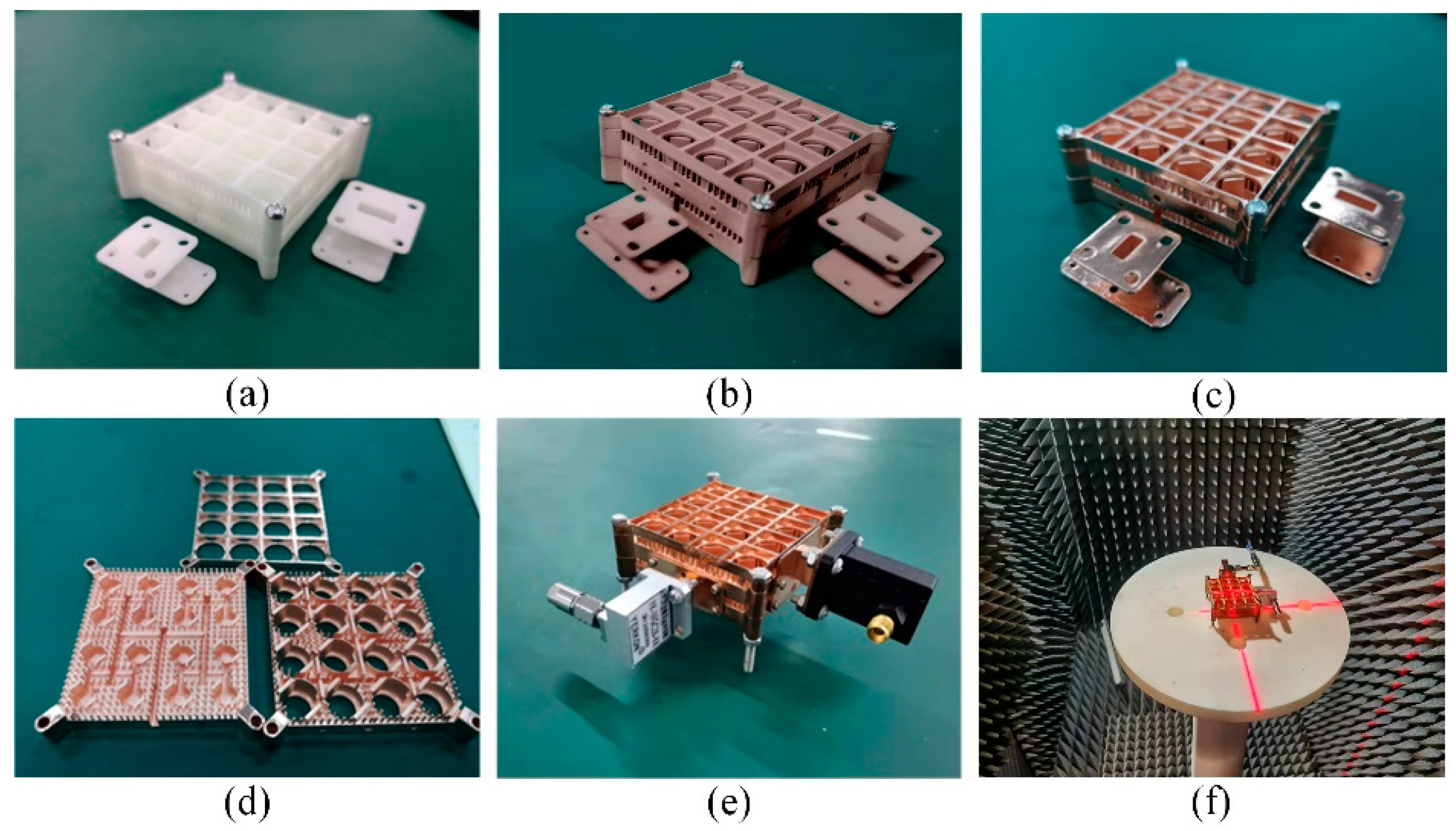

3. Experimental Results and Discussions

3.1. Design of the Waffle Grid and Waveguide Transitions

3.2. Experimental Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Majeed, A.; Zhang, J.; Awan, Z.A.; Memon, S.; Ishfaq, M.; Wang, C. A high-efficiency dual-band linear-to-circular polarization converter based on rectangular-slot reflective metasurface. Appl. Sci. 2022, 12, 9172. [Google Scholar] [CrossRef]

- Cao, Y.; Yan, S.; Li, J.; Chen, J. A pillbox based dual circularly-polarized millimeter-wave multi-beam antenna for future vehicular radar applications. IEEE Trans. Veh. Technol. 2022, 71, 7095–7103. [Google Scholar] [CrossRef]

- Li, J.; Shi, H.; Li, H.; Zhang, A. Quad-band probe-fed stacked annular patch antenna for GNSS applications. IEEE Antennas Wirel. Propag. Lett. 2014, 13, 372–375. [Google Scholar] [CrossRef]

- Iqbal, J.; Illahi, U.; Khan, M.A.; Rauf, A.; Ali, E.M.; Bari, I.; Ali, H.; Khan, M.A.; Alibakhshikenari, M.; Dalarsson, M. A Novel single-fed dual-band dual-circularly polarized dielectric resonator antenna for 5G Sub-6GHz applications. Appl. Sci. 2022, 12, 5222. [Google Scholar] [CrossRef]

- Huang, J.; Lin, W.; Qiu, F.; Jiang, C.; Lei, D.; Guo, Y. A low profile, ultra-lightweight, high efficient circularly-polarized antenna array for Ku band satellite applications. IEEE Access 2017, 5, 18356–18365. [Google Scholar] [CrossRef]

- Li, J.; Hu, P.; Chen, J.; Xu, K.; Mao, C.; Zhang, X. Dual-polarized duplex base-station antenna with a duplexer-integrated balun. IEEE Antennas Wirel. Propag. Lett. 2022, 21, 317–321. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, W.; Fang, D. Dual-band and dual-circularly polarized shared-aperture array antennas with single-layer substrate. IEEE Trans. Antennas Propag. 2016, 64, 109–116. [Google Scholar] [CrossRef]

- Liu, Y.; Yue, Z.; Jia, Y.; Xu, Y.; Xue, Q. Dual-band dual-circularly polarized antenna array with printed ridge gap waveguide. IEEE Trans. Antennas Propag. 2021, 69, 5118–5123. [Google Scholar] [CrossRef]

- Zhu, J.; Yang, Y.; Li, S.; Liao, S.; Xue, Q. Dual-band dual circularly polarized antenna array using FSS-integrated polarization rotation AMC ground for vehicle satellite communications. IEEE Trans. Veh. Technol. 2019, 68, 10742–10751. [Google Scholar] [CrossRef]

- Li, T.; Meng, H.; Dou, W. Design and implementation of dual-frequency dual-polarization slotted waveguide antenna array for Ka-band application. IEEE Antennas Wirel. Propag. Lett. 2014, 13, 1317–1320. [Google Scholar]

- Mizutani, A.; Sakakibara, K.; Kikuma, N.; Hirayama, H. Grating lobe suppression of narrow-wall slotted hollow waveguide millimeter-wave planar antenna for arbitrarily linear polarization. IEEE Trans. Antennas Propag. 2007, 55, 313–320. [Google Scholar] [CrossRef]

- Hirokawa, J.; Zhang, M.; Ando, M. 94Ghz fabrication of a slotted waveguide array antenna by diffusion bonding of laminated thin plates. In Proceedings of the Sensors, 2009 IEEE, Christchurch, New Zealand, 25–28 October 2009; pp. 907–911. [Google Scholar]

- Hamedani, M.; Oraizi, H.; Zarifi, D.; Amini, A. High gain and wide band leaky wave holograms using gap waveguide surface wave launchers. In Proceedings of the 2019 13th European Conference on Antennas and Propagation (EuCAP), Krakow, Poland, 31 March–5 April 2019; pp. 1–4. [Google Scholar]

- Vukomanovic, M.; Vazquez-Roy, J.; Quevedo-Teruel, O.; Rajo-Iglesias, E.; Sipus, Z. Gap waveguide leaky wave antenna. IEEE Trans. Antennas Propag. 2016, 64, 2055–2060. [Google Scholar] [CrossRef]

- Zaman, A.; Emanuelsson, T. Millimeter wave high gain antenna based on gap waveguide technology. In Proceedings of the 2017 Sixth Asia-Pacific Conference on Antennas and Propagation (APCAP), Xi’an, China, 16–19 October 2017; pp. 1–3. [Google Scholar]

- Nasri, M.; Zarifi, D.; Zaman, A. A wideband 3-dB directional coupler in GGW for use in V-band communication systems. IEEE Access 2020, 8, 17819–17823. [Google Scholar] [CrossRef]

- Sun, D.; Xu, J. A novel iris waveguide bandpass filter using air gapped waveguide technology. IEEE Antennas Wirel. Propag. Lett. 2016, 26, 475–477. [Google Scholar] [CrossRef]

- Cao, D.; Li, Y.; Wang, J.; Sun, F.; Ge, L. Millimeter-wave three-dimensional substrate-integrated omt-fed horn antenna using vertical and planar groove gap waveguides. IEEE Trans. Microw. Theory Tech. 2021, 69, 4448–4459. [Google Scholar] [CrossRef]

- Ferrando-Rocher, M.; Herranz-Herruzo, J.; Valero-Nogueira, A.; Vila-Jiménez, A. Single-layer circularly-polarized Ka-band antenna using gap waveguide technology. IEEE Trans. Antennas Propag. 2018, 66, 3837–3845. [Google Scholar] [CrossRef]

- Ferrando-Rocher, M.; Herranz-Herruzo, J.; Valero-Nogueira, A.; Bernardo-Clemente, B.; Zaman, A.; Yang, J. 8×8 Ka-band dual-polarized array antenna based on gap waveguide technology. IEEE Trans. Antennas Propag. 2019, 67, 4579–4588. [Google Scholar] [CrossRef]

- Ferrando-Rocher, M.; Herranz-Herruzo, J.; Valero-Nogueira, A.; Bernardo-Clemente, B. Dual circularly polarized aperture array antenna in gap waveguide for high-efficiency Ka-band satellite communications. IEEE Open J. Antennas Propag. 2020, 1, 283–289. [Google Scholar] [CrossRef]

- Ferrando-Rocher, M.; Herranz-Herruzo, J.; Valero-Nogueira, A.; Bernardo-Clemente, B. Full-metal K-Ka dual-band shared-aperture array antenna fed by combined ridge-groove gap waveguide. IEEE Antennas Wirel. Propag. Lett. 2019, 18, 1463–1467. [Google Scholar] [CrossRef]

- He, W.; Wu, S.; Li, J.; Yan, S.; Chen, J. Dual-band dual-circularly polarized antenna array using gap waveguide technology. In Proceedings of the 2021 IEEE 4th International Conference on Electronic Information and Communication Technology (ICEICT), Xi’an, China, 18–20 August 2021; pp. 906–908. [Google Scholar]

- Cao, Y.; Yan, S. A low-profile high-gain multi-beam antenna based on 3D-printed cylindrical Luneburg lens. Microw. Opt. Technol. Lett. 2021, 63, 1965–1971. [Google Scholar] [CrossRef]

- Cao, Y.; Yan, S. A dual-mode SIW compact monopulse comparator for sum and difference multibeam radar applications. IEEE Microw. Wirel. Compon. Lett. 2022, 32, 41–44. [Google Scholar] [CrossRef]

- Rajo-Iglesias, E.; Ferrando-Rocher, M.; Zaman, A. Gap waveguide technology for millimeter-wave antenna systems. IEEE Commun. Mag. 2018, 56, 14–20. [Google Scholar] [CrossRef]

- Sáez, A.; Valero-Nogueira, A.; Herranz, J.; Bernardo, B. Single layer cavity-backed slot array fed by groove gap waveguide. IEEE Antennas Wirel. Propag. Lett. 2016, 15, 1402–1405. [Google Scholar] [CrossRef]

- Kildal, P.; Kehn, M. The ridge gap waveguide as a wideband rectangular hard waveguide. In Proceedings of the Fourth European Conference on Antennas and Propagation, Barcelona, Spain, 12–16 April 2010; pp. 1–4. [Google Scholar]

- Ferrando-Rocher, M.; Valero-Nogueira, A.; Herranz-Herruzo, J. New feeding network topologies for high-gain single-layer slot array antennas using gap waveguide concept. In Proceedings of the 2017 11th European Conference on Antennas and Propagation (EUCAP), Paris, France, 19–24 March 2017; pp. 1654–1657. [Google Scholar]

- Li, J.; Guo, C.; Mao, L.; Xiang, J.; Huang, G.; Yuan, T. Monolithically 3-D printed hemispherical resonator waveguide filters with improved out-of-band rejections. IEEE Access 2018, 6, 57030–57048. [Google Scholar] [CrossRef]

- Uchimura, H.; Takenoshita, T.; Fujii, M. Development of a ‘laminated waveguide’. IEEE Trans. Microw. Theory Tech. 1998, 46, 2438–2443. [Google Scholar] [CrossRef]

| GGW1 | GGW2 | GGW3 | GGW4 | GGW5 | GGW6 | |

|---|---|---|---|---|---|---|

| width | 1.78 | 1.9 | 1.9 | 1.2 | 0.8 | 2.25 |

| height | 4.62 | 4.62 | 4.62 | 4.8 | 4.8 | 4.9 |

| length | 3.5 | 3 | NA. | 1.6 | 1.6 | NA. |

| RGW1 | RGW2 | RGW3 | RGW4 | |

|---|---|---|---|---|

| width | 0.8 | 0.8 | 1.2 | 1.17 |

| height | 1.6 | 1.53 | 2.9 | 2.82 |

| length | 0.45 | 0.45 | 0.45 | 0.45 |

| Frequency (GHz) | 20.25 | 20.5 | 20.75 | 28 | 28.5 | 29 |

|---|---|---|---|---|---|---|

| Polarization | RHCP | RHCP | RHCP | LHCP | LHCP | LHCP |

| Sim. gain (dB) | 21.1 | 21.1 | 20.8 | 20.5 | 20.8 | 21.2 |

| Mea. gain (dB) | 20.0 | 20.1 | 19.8 | 19.9 | 20.3 | 20.2 |

| Efficiency (%) | 92.1 | 91.5 | 88.9 | 91.3 | 91.5 | 89.1 |

| Reference | Band | Polarization | Gain (dB) | Efficiency (%) | Technology | Aperture Size (λL × λL) |

|---|---|---|---|---|---|---|

| [7] | X/Ku | Dual-CP | 17.5/18.3 | -- | PCB | 28.4 × 25.6 |

| [8] | K/Ka | Dual-CP | 13.2/11.5 | 78/87 | PCB and GW | 1.53 × 1.53 |

| [9] | X/Ku | Dual-CP | 16.1/15.2 | -- | PCB | 2.9 × 1.7 |

| [19] | Ka | Single-CP | 22.0 | 98 | CNC and GW | 5.12 × 5.12 |

| [20] | Ka | Dual-LP | 27.5 | 75 | CNC and GW | 10 × 10 |

| [21] | Ka | Dual-CP | 27.0 | 75 | CNC and GW | 9.7 × 9.7 |

| [22] | K/Ka | Dual-LP | 25.8/29.5 | 84/88 | CNC and GW | 6.3 × 6.3 |

| This work | K/Ka | Dual-CP | 20.1/20.3 | 92.1/91.5 | SLA and GW | 2.6 × 2.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, S.; Li, J.; Cao, Y.; Yan, S.; Xu, K.; Luyen, H. Three-Dimensional Printed, Dual-Band, Dual-Circularly Polarized Antenna Array Using Gap Waveguide Technology. Appl. Sci. 2022, 12, 10704. https://doi.org/10.3390/app122110704

Wu S, Li J, Cao Y, Yan S, Xu K, Luyen H. Three-Dimensional Printed, Dual-Band, Dual-Circularly Polarized Antenna Array Using Gap Waveguide Technology. Applied Sciences. 2022; 12(21):10704. https://doi.org/10.3390/app122110704

Chicago/Turabian StyleWu, Sifan, Jianxing Li, Yuanxi Cao, Sen Yan, Kaida Xu, and Hung Luyen. 2022. "Three-Dimensional Printed, Dual-Band, Dual-Circularly Polarized Antenna Array Using Gap Waveguide Technology" Applied Sciences 12, no. 21: 10704. https://doi.org/10.3390/app122110704

APA StyleWu, S., Li, J., Cao, Y., Yan, S., Xu, K., & Luyen, H. (2022). Three-Dimensional Printed, Dual-Band, Dual-Circularly Polarized Antenna Array Using Gap Waveguide Technology. Applied Sciences, 12(21), 10704. https://doi.org/10.3390/app122110704