Real-Time Prediction Model of Carbon Content in RH Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Method Overview

- A new method to measure CO and CO2 concentrations in the off-gas

- (a)

- Application of a new off-gas analyzer close to the vacuum chamber

- (b)

- Comparison and verification of measurement results

- Offline decarburization model

- (a)

- Construction and verification of decarburization curves of molten steel

- Online prediction model

- (a)

- Training the ANN model using the decarburization curve as the target value

- (b)

- Verification using endpoint carbon contents

- Determination of the decarburization endpoint using online predictive model

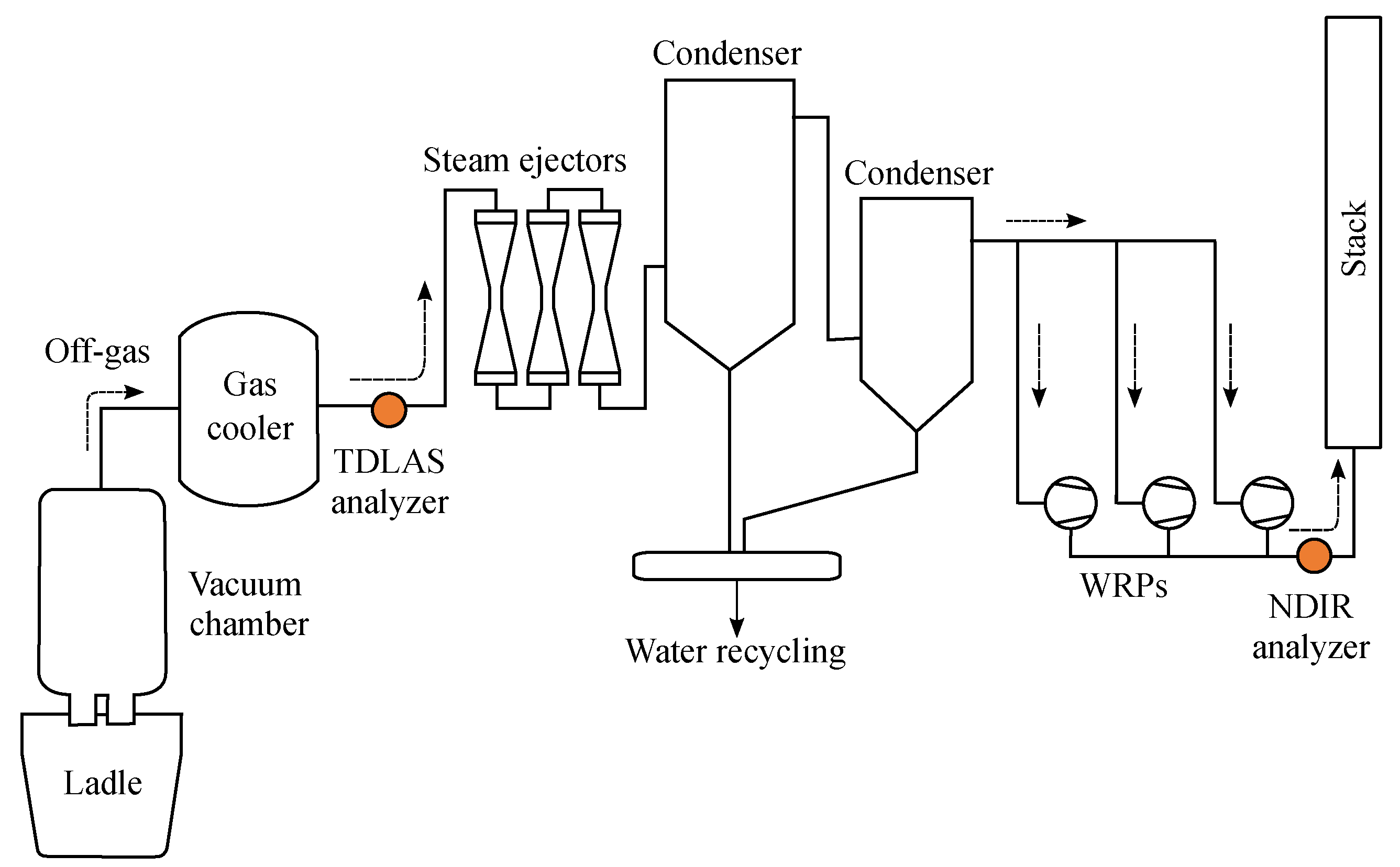

2.2. RH Vacuum Degassing Process

2.3. Measurement of the Carbon Oxide Concentration

2.4. Estimation of the Carbon Content in the Molten Steel

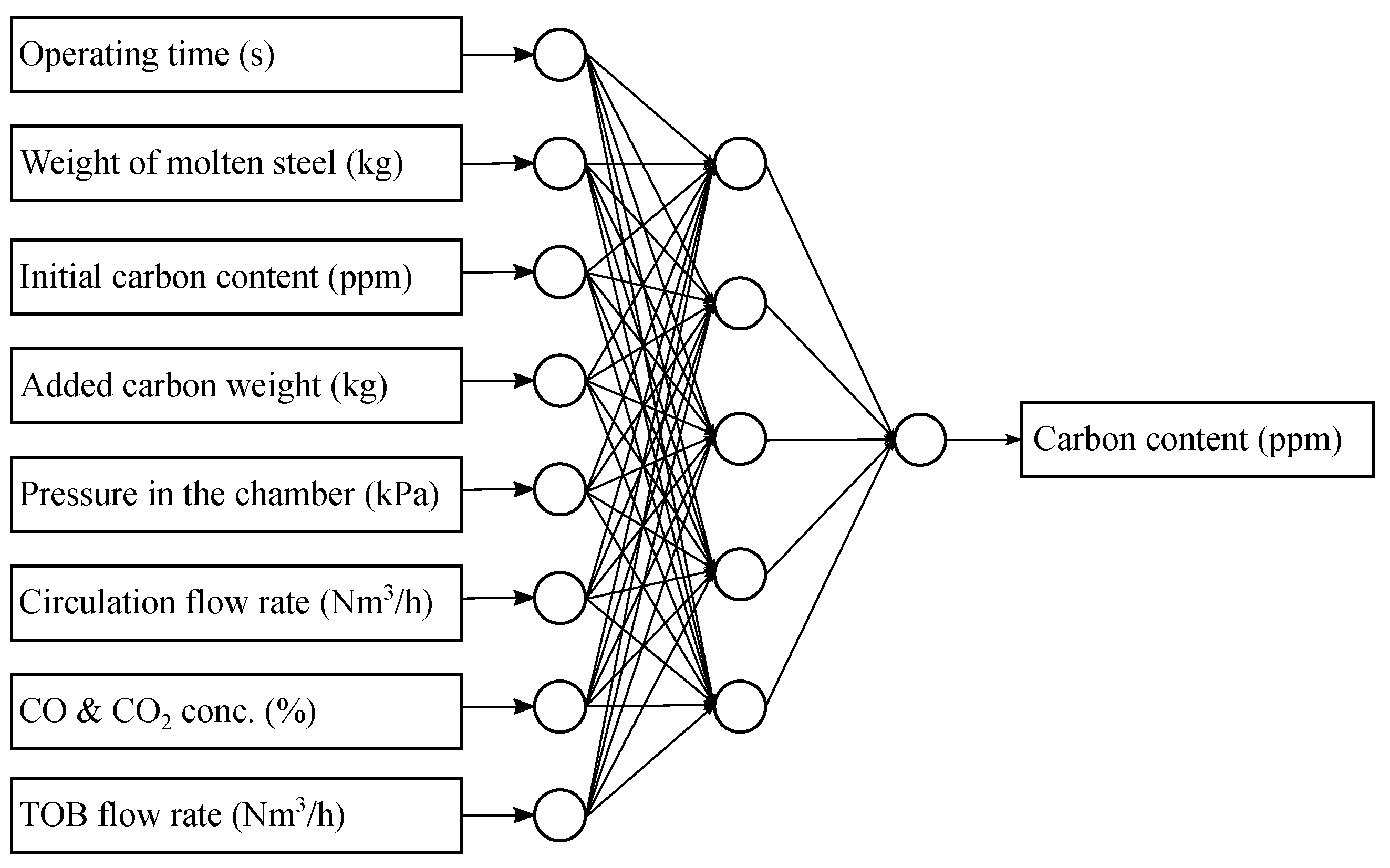

2.5. Artificial Neural Network Model

3. Results and Discussion

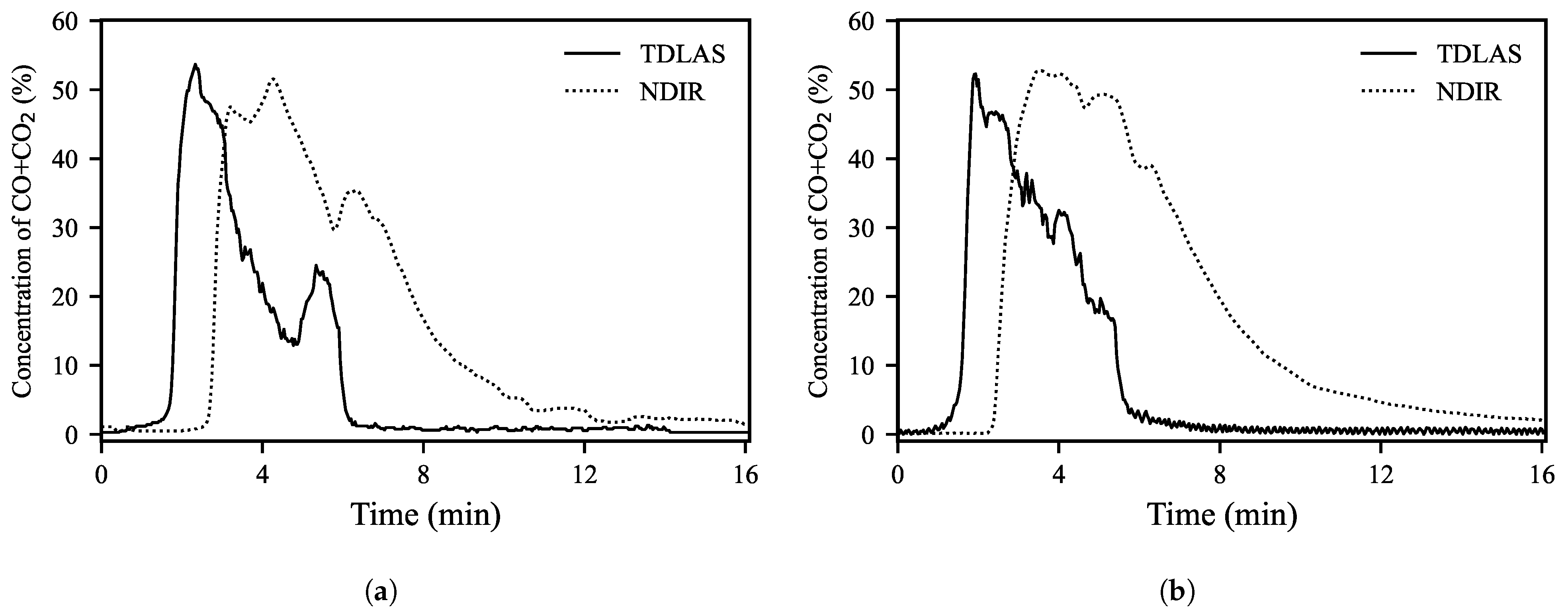

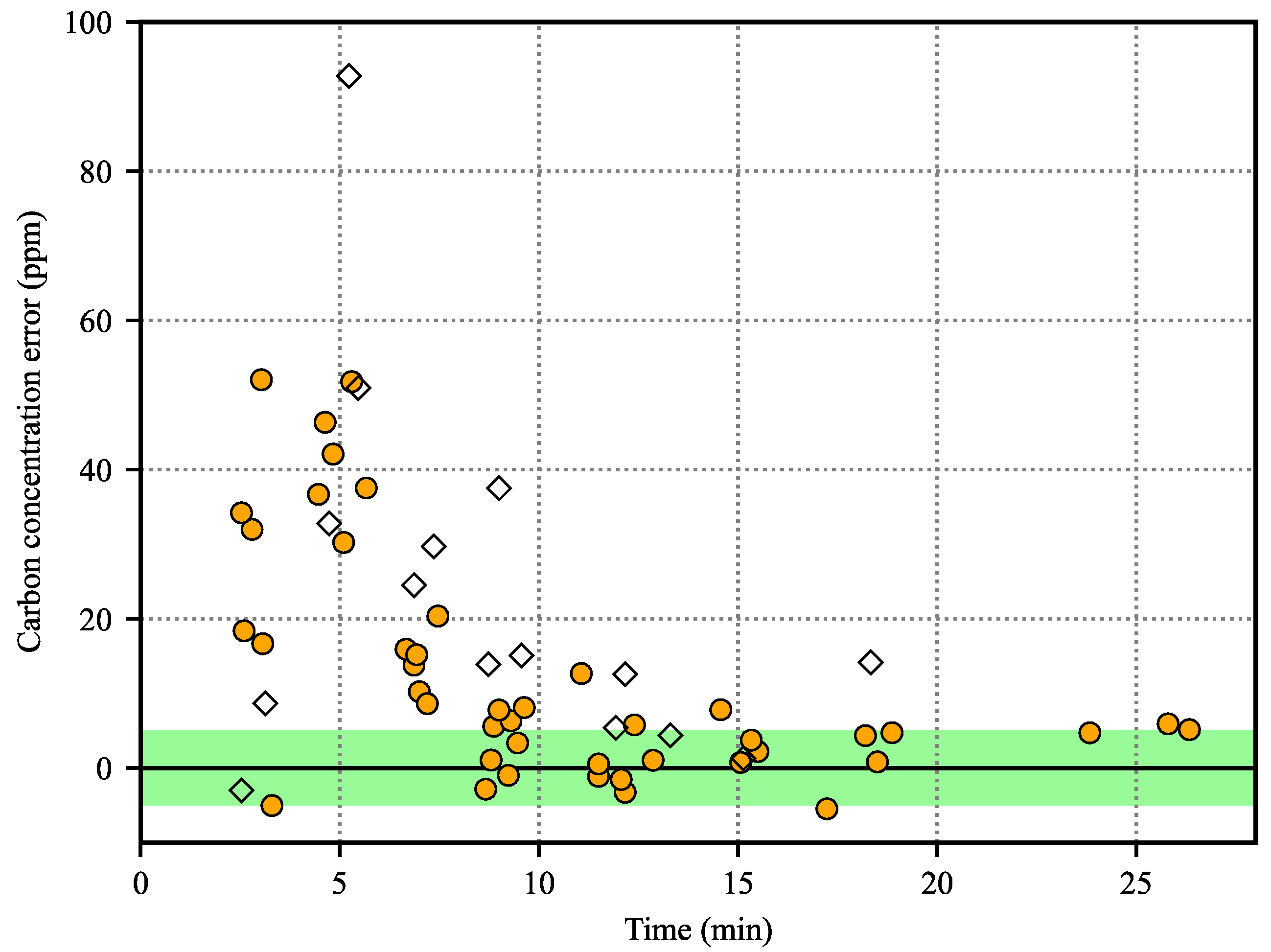

3.1. Comparison of Off-Gas Measurements Using TDLAS and NDIR Analyzers

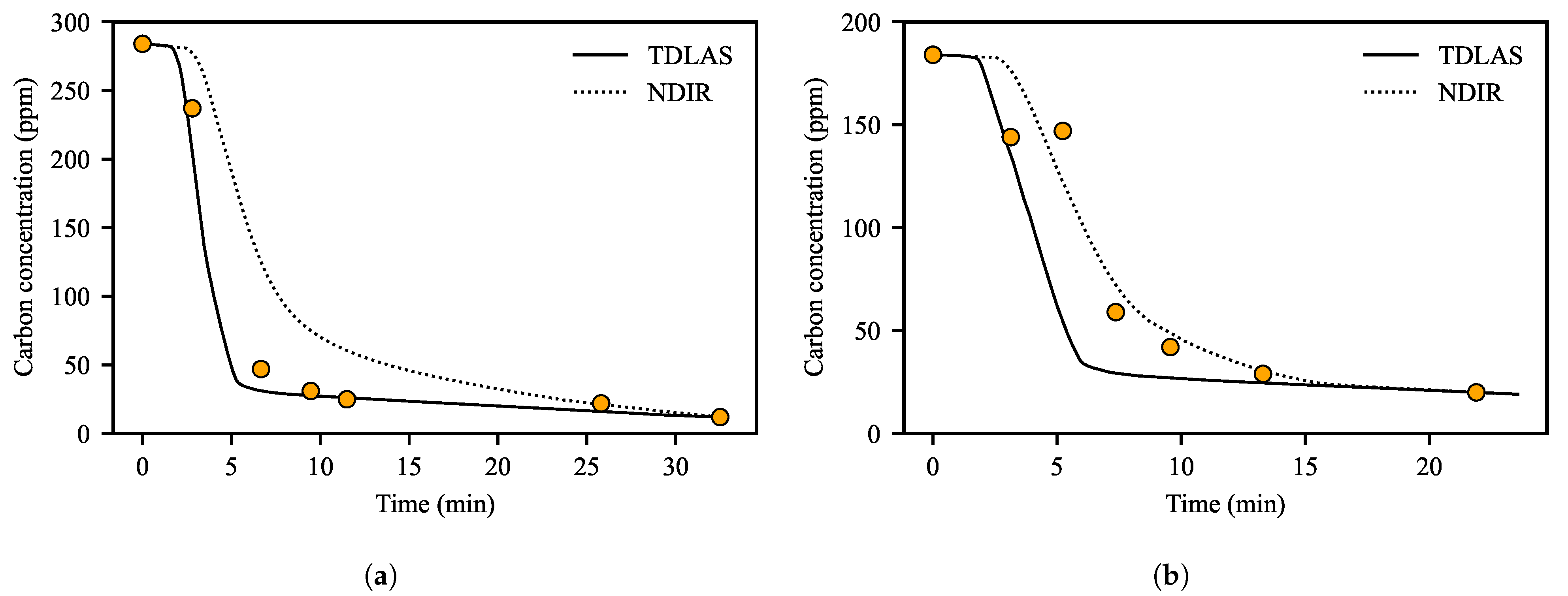

3.2. Verification of the Consistency of the Decarburization Curve

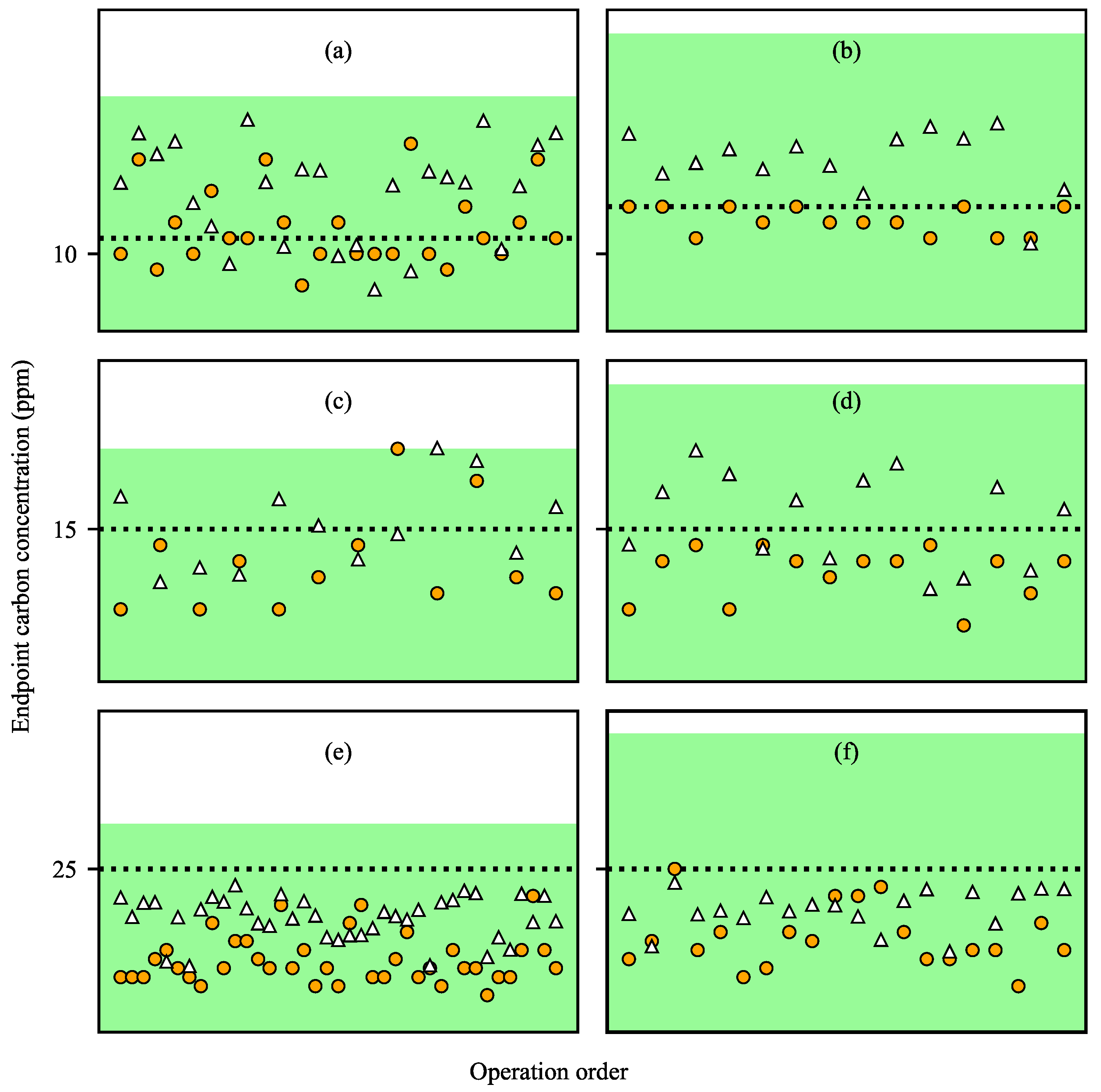

3.3. Predictive Performance of ANN Model

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ghosh, A. Secondary Steelmaking: Principles and Applications; CRC Press: Boca Raton, FL, USA, 2000; pp. 147–185. [Google Scholar]

- Stolte, G. Secondary Metallurgy: Fundamentals, Processes, Applications; Stahleisen: Dusseldorf, Germany, 2002; pp. 24–97. [Google Scholar]

- Kor, G.J.W.; Glaws, P.C. Ladle refining and vacuum degassing. In The Making, Shaping and Treating of Steel; AISE Steel Foundation: Pittsburgh, PA, USA, 1998; pp. 661–713. [Google Scholar]

- Zulhan, Z.; Schrade, C. Vacuum treatment of molten steel: RH (Rurhstahl Heraeus) versus VTD (vacuum tank degasser). In Proceedings of the 2014 SEAISI Conference and Exhibition, Kuala Lumpur, Malaysia, 26–29 May 2014. [Google Scholar]

- Zhan, D.P.; Zhang, Y.P.; Jiang, Z.H.; Zhang, H.S. Model for Ruhrstahl–Heraeus (RH) decarburization process. J. Iron Steel Res. Int. 2018, 25, 409–416. [Google Scholar] [CrossRef]

- Kuwabara, T.; Umezawa, K.; Mori, K.; Watanabe, H. Investigation of decarburization behavior in RH-reactor and its operation improvement. ISIJ Int. 1988, 28, 305–314. [Google Scholar] [CrossRef]

- Schrade, C.; Huellen, M.; Zulhan, Z. New concepts for high-productivity RH plants. Metall. Res. Technol. 2006, 103, 445–451. [Google Scholar] [CrossRef]

- Fukuda, Y.; Onoyama, S.; Imai, T.; Mukawa, S.; Sado, T.; Fukiage, K.; Kunitake, O.; Takagi, N.; Matsumoto, H. Development of high-grade steel manufacturing technology for mass production at Nagoya works. Nippon Steel Tech. Rep. 2013, 104, 90–96. [Google Scholar]

- Baker, L.J.; Daniel, S.R.; Parker, J.D. Metallurgy and processing of ultralow carbon bake hardening steels. Mater. Sci. Technol. 2013, 18, 355–368. [Google Scholar] [CrossRef]

- Hoshida, T.; Endou, G.; Ebisawa, T.; Taguchi, K.; Takahashi, K.; Kikuchi, Y. Melting of ultra-low carbon steel with RH. Tetsu-to-Hagane 1983, 69, S179. [Google Scholar]

- Sumida, N.; Fujii, T.; Oguchi, Y.; Morishita, H.; Yoshimura, K.; Sudo, F. Production of ultra-low carbon steel by combined process of bottom-blown converter and RH degasser. Kawasaki Steel Tech. Rep. 1983, 8, 69–76. [Google Scholar]

- Harashima, K.; Mizoguchi, S.; Kajioka, H. Kinetics of decaburization of low carbon liquid iron under reduced pressures. Tetsu-to-Hagane 1988, 74, 449–456. [Google Scholar] [CrossRef] [Green Version]

- Kishimoto, Y.; Yamaguchi, K.; Sakuraya, T.; Fujii, T. Decarburization reaction in ultra-low carbon iron melt under reduced pressure. ISIJ Int. 1993, 33, 391–399. [Google Scholar] [CrossRef] [Green Version]

- Higuchi, Y.; Ikenaga, H.; Shirota, Y. Effects of [C], [O] and pressure on RH vacuum decarburization. Tetsu-to-Hagane 1998, 84, 709–714. [Google Scholar] [CrossRef] [Green Version]

- Han, C.; Ai, L.; Liu, B.; Zhang, J.; Bao, Y.; Cai, K. Decarburization mechanism of RH-MFB refining process. Int. J. Miner. Metall. Mater. 2006, 13, 218–221. [Google Scholar] [CrossRef]

- Tavares, R.P.; Nascimento, A.A.; Pujatti, H.L.V. Mass transfer coefficients during steel decarburization in a RH degasser. Defect Diffus. Forum 2008, 273, 679–684. [Google Scholar]

- Liu, B.S.; Zhu, G.S.; Li, H.X.; Li, B.H.; Cui, A.M. Decarburization rate of RH refining for ultra low carbon steel. Int. J. Miner. Metall. Mater. 2010, 17, 22–27. [Google Scholar] [CrossRef]

- Tavares, R.P. Mass Transfer in Steelmaking Operations. In Mass Transfer in Multiphase Systems and its Applications; IntechOpen: London, UK, 2011; pp. 255–273. [Google Scholar]

- Saint-Raymond, H.; Huin, D.; Stouvenot, F. Mechanisms and modeling of liquid steel decarburization below 10 ppm carbon. Mater. Trans. JIM 2000, 41, 17–21. [Google Scholar] [CrossRef]

- Tembergen, D.; Teworte, R.; Robey, R. RH metallurgy. Millennium Steel 2008, 104–108. [Google Scholar]

- Li, P.H.; Wu, Q.J.; Hu, W.H.; Ye, J.S. Mathematical simulation of behavior of carbon and oxygen in RH decarburization. J. Iron Steel Res. Int. 2015, 22, 63–67. [Google Scholar] [CrossRef]

- Van Ende, M.A.; Kim, Y.M.; Cho, M.K.; Choi, J.; Jung, I.H. A kinetic model for the Ruhrstahl Heraeus (RH) degassing process. Metall. Mater. Trans. B 2011, 42, 477–489. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, L.; Zhao, X.; Lei, S.; Dong, Q. Mathematical model for decarburization process in RH refining process. ISIJ Int. 2014, 54, 1560–1569. [Google Scholar] [CrossRef] [Green Version]

- Ling, H.; Zhang, L. A Mathematical model for prediction of carbon concentration during RH refining process. Metall. Mater. Trans. B 2018, 49, 2963–2968. [Google Scholar] [CrossRef]

- Inoue, S.; Furuno, Y.; Usui, T.; Miyahara, S. Acceleration of decarburization in RH vacuum degassing process. ISIJ Int. 1992, 32, 120–125. [Google Scholar] [CrossRef] [Green Version]

- Kim, B.I.; Choi, Y.J.; Park, S.Y.; Lee, J.S. The development of decarburization prediction model in RH process by Fuzzy logic technology. In Proceedings of the 2nd Asian Control Conference, Seoul, Korea, 22–25 July 1997; pp. 635–638. [Google Scholar]

- Kim, B.I. The Development of Decarburization Ending Point Prediction Model Using Fuzzy Logic Technology in Secondary Refining Process. Master’s Thesis, Pohang University of Science and Technology (POSTECH), Pohang, Korea, 1997. [Google Scholar]

- Kleimt, B.; Köhle, S.; Paura, G.; De Santis, M.; Granati, P.; Liberati, L.; Jungreithmeier, A.; Zuba, G. Improvement of Vacuum Circulation Plant Operation on the Basis of the BFI Simulation Model; EUR: Luxembourg, 2000.

- Kleimt, B.; Köhle, S.; Jungreithmeier, A. Dynamic model for on-line observation of the current process state during RH degassing. Steel Res. Int. 2001, 72, 337–345. [Google Scholar] [CrossRef]

- Zhang, G.F.; Chen, Y. Decarburization automatic prediction system in RH degasser. In Proceedings of the 2010 5th International Conference on Computer Science & Education (ICCSE), Hefei, China, 24–27 August 2010; pp. 986–989. [Google Scholar]

- Jianwen, L.; Chengzhuang, L. Endpoint carbon content prediction of VOD using RBF neural network. In Proceedings of the 2013 2nd International Symposium on Instrumentation and Measurement, Sensor Network and Automation (IMSNA), Toronto, ON, Canada, 23–24 December 2013; pp. 588–590. [Google Scholar]

- Rezaee, B. Desulfurization process using Takagi–Sugeno–Kang Fuzzy modeling. Int. J. Adv. Manuf. Technol. 2010, 46, 191–197. [Google Scholar] [CrossRef]

- Chauhan, S.; Singh, M.; Meena, V.K. Comparative study of BOF steelmaking process based on ANFIS and GRNN model. Int. J. Eng. Innov. Technol. IJEIT 2013, 2, 198–202. [Google Scholar]

- Wang, Z.; Liu, Q.; Liu, H.; Wei, S. A review of end-point carbon prediction for BOF steelmaking process. High Temp. Mater. Process. 2020, 39, 653–662. [Google Scholar] [CrossRef]

- Meradi, H.; Bouhouche, S.; Lahreche, M. Prediction of bath temperature using neural networks. World Acad. Eng. Technol. 2008, 2, 946–950. [Google Scholar]

- Yamaguchi, K.; Kishimoto, Y.; Sakuraya, T.; Fujii, T.; Aratani, M.; Nishikawa, H. Effect of refining conditions for ultra low carbon steel on decarburization reaction in RH degasser. ISIJ Int. 1992, 32, 126–135. [Google Scholar] [CrossRef]

- Crawley, L.H. Application of Non-Dispersive Infrared (NDIR) Spectroscopy to the Measurement of Atmospheric Trace Gases. Master’s Thesis, University of Canterbury, Christchurch, New Zealand, 2008. [Google Scholar]

- Hodgkinson, J.; Smith, R.; Ho, W.O.; Saffell, J.R.; Tatam, R.P. Non-dispersive infra-red (NDIR) measurement of carbon dioxide at 4.2 μm in a compact and optically efficient sensor. Sens. Actuators B Chem. 2013, 186, 580–588. [Google Scholar] [CrossRef]

- Thomas, S.; Haider, N.S. A study on basics of a gas analyzer. Int. J. Adv. Res. Electr. Instrum. Eng. 2013, 2, 6016–6025. [Google Scholar]

- Kazuto, T.; Tomoaki, N.; Yukihiko, T.; Junichi, M. TDLS200 tunable diode laser gas analyzer and its application to industrial process. Yokogawa Tech. Rep. English 2010, 53, 113–116. [Google Scholar]

- Madabushi, J.; Fahle, D.; Heinlein, C. Calibration and validation philosophy and procedures for tunable diode laser analyzer in process applications. In Proceedings of the ISA 55th Analysis Division Symposium 2010, New Orleans, LA, USA, 25–29 April 2010. [Google Scholar]

- Avetisov, V.; Bjoroey, O.; Wang, J.; Geiser, P.; Paulsen, K.G. Hydrogen sensor based on tunable diode laser absorption spectroscopy. Sensors 2019, 19, 5313. [Google Scholar] [CrossRef] [Green Version]

- Kikkari, J.J. An Optical Process Sensor for Steel Furnace Pollution Control and Energy Efficiency. Master’s Thesis, University of Toronto, Toronto, ON, Canada, 2000. [Google Scholar]

- Schlosser, E.; Ebert, V.; Williams, B.A.; Fleming, J.W.; Sheinson, R.S. NIR-diode laser based in situ measurement of molecular oxygen in full-scale fire suppression tests. In Proceedings of the 2000 Halon Options Technical Working Conference, Albuquerque, NM, USA, 2–4 May 2000; pp. 492–503. [Google Scholar]

- Allemand, B.; Bockel-Macal, S.; Bruchet, P.; Januard, F.; Laurent, J. Continuous fumes monitoring for dynamic control of oxygen injections in EAF. In Proceedings of the 2nd International Conference On Process Development in Iron and Steelmaking, Scanmet II, Lulea, Sweden, 6–9 June 2004. [Google Scholar]

- Januard, F.; Bockel-Macal, S.; Vuillermoz, J.C.; Laurent, J.; Lebrun, C. Dynamic control of fossil fuel injections in EAF through continuous fumes monitoring. Metall. Res. Technol. 2006, 103, 275–280. [Google Scholar] [CrossRef]

- Lackner, M. Tunable diode laser absorption spectroscopy (TDLAS) in the process industries—A review. Rev. Chem. Eng. 2007, 23, 65–147. [Google Scholar] [CrossRef]

- Krassnig, H.J.; Kleimt, B.; Voj, L.; Antrekowitsch, H. EAF post-combustion control by on-line laser-based off-gas measurement. Arch. Metall. Mater. 2008, 53, 455–462. [Google Scholar]

- Tolazzi, D.; Marcuzzi, S.; Beorchia, S. LINDARC EAF off-gas analysis system-installation at Gerdau Ameristeel Jacksonville (Florida-USA). In Proceedings of the AisTech 2011, Indianapolis, IN, USA, 2–5 May 2011. [Google Scholar]

- Arimoto, H.; Takeuchi, N.; Mukaihara, S.; Kimura, T.; Kano, R.; Ohira, T.; Kawashima, S.; Iwakura, K. Applicability of TDLAS gas detection technique to combustion control and emission monitoring under harsh environment. Int. J. Technol. 2011, 1, 1–9. [Google Scholar]

- Brisson, D.; Grieshaber, K.W.; Sappey, A.D.; Chigwedu, C. Robust EAF laser gas analysis system-ZoloSCAN. In Proceedings of the AisTech 2014, Indianapolis, IN, USA, 5–8 May 2014. [Google Scholar]

- Frish, M.B.; Laderer, M.C.; Smith, C.J.; Ehid, R.; Dallas, J. Cost-effective manufacturing of compact TDLAS sensors for hazardous area applications. Components Packag. Laser Syst. II 2016, 9730, 135–143. [Google Scholar]

- Drozdz, P.; Falkus, J. The modeling of vacuum steel refining in the RH degassing unit based on thermodynamic analysis of the system. Arch. Metall. Mater. 2007, 52, 585–591. [Google Scholar]

| Processing Time | Error in Operations without Carbon Addition | Error in Operations with Carbon Addition | ||

|---|---|---|---|---|

| Mean | Std. Dev. | Mean | Std. Dev. | |

| <10 min | 19.44 ppm | 17.29 ppm | 22.45 ppm | 20.58 ppm |

| ≥10 min | 2.72 ppm | 3.08 ppm | 3.77 ppm | 4.90 ppm |

| Prediction Error | Target Carbon Content | ||

|---|---|---|---|

| 10 ppm | 15 ppm | 25 ppm | |

| Mean | −2.09 ppm | −2.22 ppm | −2.80 ppm |

| Std. dev. | 3.56 ppm | 3.96 ppm | 4.47 ppm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heo, J.; Kim, T.-W.; Jung, S.-J.; Han, S. Real-Time Prediction Model of Carbon Content in RH Process. Appl. Sci. 2022, 12, 10753. https://doi.org/10.3390/app122110753

Heo J, Kim T-W, Jung S-J, Han S. Real-Time Prediction Model of Carbon Content in RH Process. Applied Sciences. 2022; 12(21):10753. https://doi.org/10.3390/app122110753

Chicago/Turabian StyleHeo, Jeongheon, Tae-Won Kim, Soon-Jong Jung, and Soohee Han. 2022. "Real-Time Prediction Model of Carbon Content in RH Process" Applied Sciences 12, no. 21: 10753. https://doi.org/10.3390/app122110753

APA StyleHeo, J., Kim, T.-W., Jung, S.-J., & Han, S. (2022). Real-Time Prediction Model of Carbon Content in RH Process. Applied Sciences, 12(21), 10753. https://doi.org/10.3390/app122110753