Axial Compression Behavior of Steel Angle-Corrugated Steel Plate-Confined Concrete Columns

Abstract

1. Introduction

2. Experimental Programs

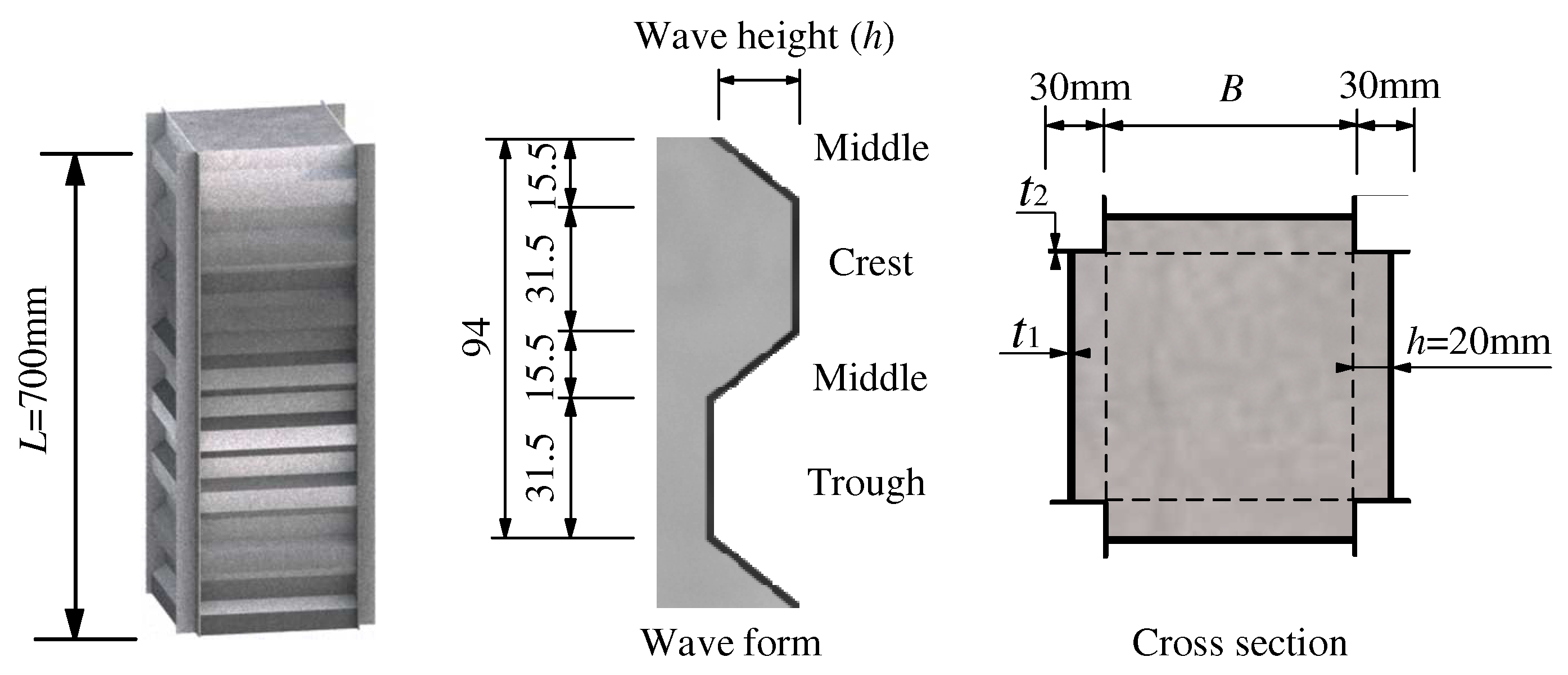

2.1. Specimen Design and Material Properties

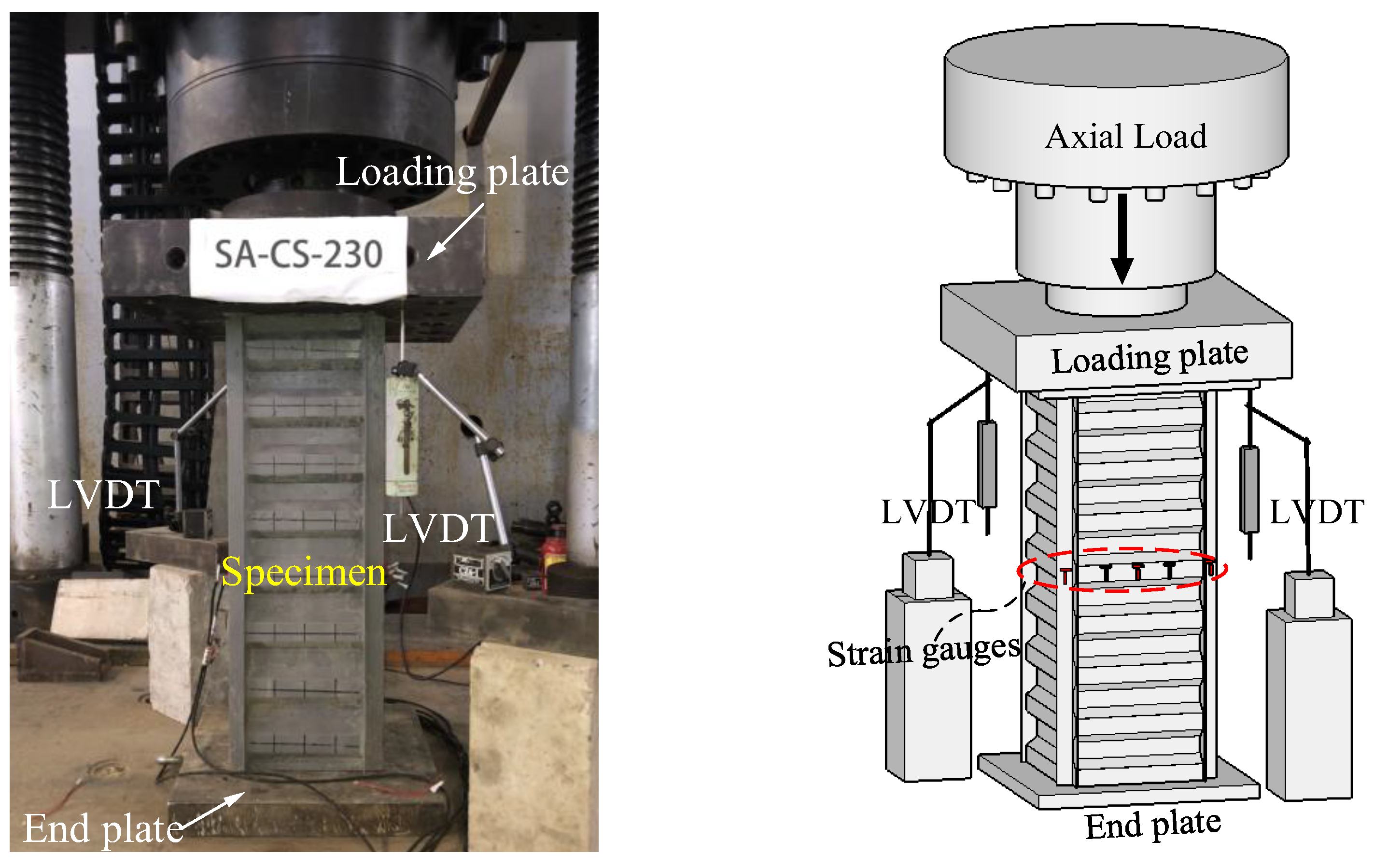

2.2. Test Method

3. Experimental Results and Discussion

3.1. Failure Modes

3.2. Load–Axial Displacement Curves

3.3. Load–Strain Curves of Steel Angle and Steel Tube

3.4. Strength Index of Core Concrete

3.5. Ductility Index of Specimens

4. Finite Element Analysis

4.1. Model Set-Up

4.2. Material Models

- (1)

- Core concrete

- (2)

- Steel

4.3. Model Validation

4.4. Parametric Analysis

5. Ultimate Bearing Capacity

5.1. Comparison with the Existing Codes

5.1.1. GB50936-2014

5.1.2. Eurocode 4-2004

5.1.3. ACI 318-14

5.1.4. DBJ/T13-51-2010

5.1.5. AIJ-2001

5.2. Proposed Design Model

6. Conclusions

- (1)

- All the SA-CS columns failed with the severe local buckling of the steel angle and the spalling of the crest of the core concrete. The CFST column failed with the steel tube’s buckling and the internal concrete’s shear failure. The strength index (Is) and ductility index (μ) of the SA-CS column were better than those of the CFST column with a similar steel ratio, indicating that the SA-CS column provided more excellent confinement effects on the core concrete than the CFST column.

- (2)

- The increase in the section width (decrease of the steel ratio) of the SA-CS column improved the ultimate bearing capacity but reduced Is and μ. However, the degree of decline of Is and μ was slight, indicating that the SA-CS column’s mechanical properties were only slightly affected by the steel ratio in a particular range. In practical engineering, reducing the steel ratio of the SA-CS column can be considered to improve economic benefits.

- (3)

- The FE models were in good agreement with the experimental results. The parametric analysis results have shown that the corrugated steel plate primarily confined the core concrete, and the steel angle bore a part of the axial load.

- (4)

- Increasing the compression strength of concrete can effectively improve the ultimate bearing capacity of the specimens but Is and μ will decrease. Increasing the yield strength and thickness of the corrugated steel plate will improve the confinement effect on the core concrete to enhance the axial compression behavior of the specimen. The yield strength and the thickness of the steel angle had little influence on the mechanical properties of the specimens. The variation trend of Is was not monotonous with the increase in the wave height of the corrugated steel plate (h), and the confinement of the corrugated steel plate to the core concrete was the strongest when h was taken as 24 mm.

- (5)

- A comparison of the ultimate bearing capacities between the FE results and calculated results by some current codes was conducted, and it was found that the existing codes always underrated or overrated the ultimate bearing capacity of the SA-CS column. The fundamental reason is that the current codes cannot accurately calculate the effective confining stress on the core concrete provided by the corrugated steel plate. Thus, a new design model for the SA-CS column was proposed, which provided reasonably good predictions with FE-simulated results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- EN 1994-1-1; Eurocode 4. Design of Composite Steel and Concrete Structures. European Committee for Standardization: Brussels, Belgium, 2004.

- DBJ/T13-2010; Technical Specification for Concrete-Filled Steel Tubular Structures. The Department of Housing and Urban-Rural Development of Fujian Province: Fuzhou, China, 2010.

- GB 50936-2014; Technical Code for Concrete Filled Steel Tubular Structures. Chinese National Standards: Beijing, China, 2014.

- ISO 6892-1:2019; Metallic Materials-Tensile Testing, Part 1: Method of Test at Room Temperature. Standards Press of China: Beijing, China, 2010.

- GB 50010-2002; Code for Design of Concrete Structures. Ministry of Housing and UrbanRural Development of the People’s Republic of China: Beijing, China, 2010.

- Afaghi-Darabi, A.; Abdollahzadeh, G. Effect of cooling rate on the post-fire behavior of CFST column. Comput. Concr. 2019, 23, 281–294. [Google Scholar]

- AIJ Standards for Structural Calculation of Steel Reinforced Concrete Structures; Architectural Institute of Japan: Tokyo, Japan, 2001.

- Candappa, D.C.; Sanjayan, J.G.; Setunge, S. Complete triaxial stress-strain curves of high-strength concrete. J. Mater. Civ. Eng. 2001, 13, 209–215. [Google Scholar] [CrossRef]

- Che, Y.; Wang, Q.L.; Shao, Y.B. Compressive performances of the concrete filled circular cfrp-steel tube (C-CFRP-CFST). Adv. Steel Constr. 2012, 8, 331–358. [Google Scholar]

- Chen, J.; Chan, T.-M.; Chung, K.-F. Design of square and rectangular CFST cross-sectional capacities in compression. J. Constr. Steel Res. 2021, 176, 106419. [Google Scholar] [CrossRef]

- Chen, Z.; Xu, R.; Ning, F.; Liang, Y. Compression behaviour and bearing capacity calculation of concrete filled double skin square steel columns. J. Build. Eng. 2021, 42, 103022. [Google Scholar] [CrossRef]

- Chen, Z.; Zhou, J.; Jing, C.; Tan, Q. Mechanical behavior of spiral stirrup reinforced concrete filled square steel tubular columns under compression. Eng. Struct. 2021, 226, 111377. [Google Scholar] [CrossRef]

- ACI 318-14; Building Code Requirements for Structural Concrete and Commentary. American Concrete Institute: Farmington Hills, MI, USA, 2011.

- Ding, F.; Ying, X.; Zhou, L.; Yu, Z. Unified calculation method and its application in determining the uniaxial mechanical properties of concrete. Front. Archit. Civ. Eng. China 2011, 5, 381. [Google Scholar] [CrossRef]

- Fang, Y.; Wang, Y.; Hou, C.; Lu, B. CFDST stub columns with galvanized corrugated steel tubes: Concept and axial behaviour. Thin Wall Struct 2020, 157, 107116. [Google Scholar] [CrossRef]

- Gan, D.; Zhou, Z.; Zhou, X.H. Axially Loaded Thin-Walled Square Concrete-Filled Steel Tubes Stiffened with Diagonal Binding Ribs. ACI Struct. J. 2019, 116, 265–280. [Google Scholar] [CrossRef]

- Han, L.-H.; Li, W.; Bjorhovde, R. Developments and advanced applications of concrete-filled steel tubular (CFST) structures: Members. J. Constr. Steel Res. 2014, 100, 211–228. [Google Scholar] [CrossRef]

- Han, L.-H.; Yao, G.-H.; Tao, Z. Performance of concrete-filled thin-walled steel tubes under pure torsion. Thin Wall. Struct. 2007, 45, 24–36. [Google Scholar] [CrossRef]

- İpek, S.; Erdoğan, A.; Güneyisi, E.M. Compressive behavior of concrete-filled double skin steel tubular short columns with the elliptical hollow section. J. Build. Eng. 2021, 38, 102200. [Google Scholar] [CrossRef]

- Liu, J.; Zhou, X.; Dan, G. Effect of friction on axially loaded stub circular tubed columns. Adv. Struct. Eng. 2016, 19, 546–559. [Google Scholar] [CrossRef]

- Kharoob, O.F.; Ghazy, M.F.; Yosser, N.M. Behavior of beam-high performance fiber reinforced CFST column joints. Thin Wall. Struct. 2017, 113, 217–227. [Google Scholar] [CrossRef]

- Li, G.-C.; Chen, B.-W.; Yang, Z.-J.; Liu, Y.-P.; Feng, Y.-H. Experimental and numerical behavior of eccentrically loaded square concrete-filled steel tubular long columns made of high-strength steel and concrete. Thin Wall. Struct. 2021, 159, 107289. [Google Scholar] [CrossRef]

- Pagoulatou, M.; Sheehan, T.; Dai, X.H.; Lam, D. Finite element analysis on the capacity of circular concrete-filled double-skin steel tubular (CFDST) stub columns. Eng. Struct. 2014, 72, 102–112. [Google Scholar] [CrossRef]

- Ren, Z.; Wang, D.; Li, P. Axial compressive behaviour and confinement effect of round-ended rectangular CFST with different central angles. Compos. Struct. 2022, 285, 115193. [Google Scholar] [CrossRef]

- Su, R.; Li, X.; Zhong, T.; Zhou, T. Axial behavior of novel CFDST columns with outer welded corrugated steel tubes. Structures 2021, 34, 2708–2720. [Google Scholar] [CrossRef]

- Sun, Z.-X.; Zou, Y.; Wang, C.-Q.; Pan, J.; Wang, L.; Chen, M. Axial compressive behavior and load-bearing capacity of steel tubular-corrugated steel plate confined concrete composite columns. Structures 2022, 44, 135–151. [Google Scholar] [CrossRef]

- Sun, Z.; Zou, Y.; Wang, C.; Pan, J.; Wang, L.; Chen, M. Study on confinement mechanism of core concrete in steel tubular-corrugated steel plate confined concrete columns. J. Build. Eng. 2022, 52, 104497. [Google Scholar] [CrossRef]

- Tang, X.L.; Cai, J.; Chen, Q.J.; Liu, X.P.; He, A. Seismic behaviour of through-beam connection between square CFST columns and RC beams. J. Constr. Steel Res. 2016, 122, 151–166. [Google Scholar] [CrossRef]

- Tao, Z.; Han, L.H.; Wang, D.Y. Experimental. behaviour of concrete-filled stiffened thin-walled steel tubular columns. Thin Wall. Struct. 2007, 45, 517–527. [Google Scholar] [CrossRef]

- Tao, Z.; Uy, B.; Han, L.-H.; Wang, Z.-B. Analysis and design of concrete-filled stiffened thin-walled steel tubular columns under axial compression. Thin Wall. Struct. 2009, 47, 1544–1556. [Google Scholar] [CrossRef]

- Wang, C.; Zou, Y.; Li, T.; Ding, J.; Feng, X.; Lei, T. Ductility and Ultimate Capacity of Concrete-Filled Lattice Rectangular Steel Tube Columns. Struct. Durab. Health Monit. 2018, 12, 99–110. [Google Scholar]

- Wang, F.-C.; Han, L.-H. Analytical behavior of special-shaped CFST stub columns under axial compression. Thin Wall. Struct. 2018, 129, 404–417. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, L.; Su, S.; Gao, J.; Li, Y.; Li, Y. Experimental research on seismic behavior of corrugated steel plate shear wall. J. Build. Struct. 2018, 39, 36–44. [Google Scholar]

- Wang, Y.; Yang, L.; Yang, H.; Liu, C. Behaviour of concrete-filled corrugated steel tubes under axial compression. Eng. Struct. 2019, 183, 475–495. [Google Scholar] [CrossRef]

- Wang, Y.T.; Cai, J.; Long, Y.L. Hysteretic behavior of square CFT columns with binding bars. J. Constr. Steel Res. 2017, 131, 162–175. [Google Scholar] [CrossRef]

- Xu, Y.; Tang, H.Y.; Chen, J.L.; Jia, Y.G.; Liu, R.Z. Numerical analysis of CFRP-confined concrete-filled stainless steel tubular stub columns under axial compression. J. Build. Eng. 2021, 37, 102130. [Google Scholar] [CrossRef]

- Yang, L.; Wang, Y.; Elchalakani, M.; Fang, Y. Experimental behavior of concrete-filled corrugated steel tubular short columns under eccentric compression and non-uniform confinement. Eng. Struct. 2020, 220, 111009. [Google Scholar] [CrossRef]

- Yang, M.G.; Cai, C.S.; Chen, Y. Creep performance of concrete-filled steel tubular (CFST) columns and applications to a CFST arch bridge. Steel Compos. Struct. 2015, 19, 111–129. [Google Scholar] [CrossRef]

- Yang, Y.L.; Wang, Y.Y.; Fu, F. Effect of reinforcement stiffeners on square concrete-filled steel tubular columns subjected to axial compressive load. Thin Wall Struct 2014, 82, 132–144. [Google Scholar] [CrossRef]

- Ye, Y.; Yun, Z.; Wang, C.; Wu, Y.; Ming, C. Behaviour of concrete-filled horizontal corrugated steel tubular short columns under axial compression. J. Exp. Mech. 2021, 36, 230–240. [Google Scholar]

- Zhou, X.; Lin, X.; Tan, D.; Lu, W.; Yang, L. Fatigue Test of Composite Box Beams with Corrugated Steel Webs. China J. Highw. Transp. 2010, 23, 33. [Google Scholar]

| Specimen Designation | B (mm) | t1 (mm) | t2 (mm) | h (mm) | fcu (MPa) | fy (Mpa) | fu (Mpa) | Es (Gpa) |

|---|---|---|---|---|---|---|---|---|

| SA-CS-230 | 230 | 2 | 2 | 20 | 35.4 | 324 | 363 | 202 |

| SA-CS-280 | 280 | 2 | 2 | 20 | ||||

| SA-CS-330 | 330 | 2 | 2 | 20 | ||||

| B0 (mm) | t0 (mm) | |||||||

| CFST-1 | 230 | 2 | 35.4 | 324 | 363 | 202 | ||

| CFST-2 | 230 | 2 | 44.4 | 347 | 425 | 206 | ||

| Parameters | Symbols and Units | Values |

|---|---|---|

| Compressive strength of concrete | fcu (MPa) | 30, 40, 50, 60 |

| Yield strength of corrugated steel plate | fy1 (MPa) | 235, 345, 420, 490 |

| Thickness of corrugated steel plate | t1 (mm) | 1, 2, 3, 4 |

| Yield strength of steel angle | fy2 (MPa) | 235, 345, 420, 490 |

| Thickness of steel angle | t2 (mm) | 1, 2, 3, 4 |

| Wave height of corrugated steel plate | h (mm) | 15, 20, 25, 30 |

| Specimen Designation | B/mm | t1/mm | t2/mm | fcu/MPa | fy1/MPa | fy2/MPa | h/mm | Is | Nu-FEM/kN |

|---|---|---|---|---|---|---|---|---|---|

| SA-CS-1 | 280 | 2 | 2 | 30 | 325 | 325 | 20 | 1.195 | 2606.1 |

| SA-CS-2 | 280 | 2 | 2 | 40 | 325 | 325 | 20 | 1.103 | 3253.7 |

| SA-CS-3 | 280 | 2 | 2 | 50 | 325 | 325 | 20 | 1.058 | 3740.8 |

| SA-CS-4 | 280 | 2 | 2 | 60 | 325 | 325 | 20 | 1.008 | 4215.7 |

| SA-CS-5 | 280 | 2 | 2 | 30 | 235 | 325 | 20 | 1.133 | 2476.3 |

| SA-CS-6 | 280 | 2 | 2 | 30 | 420 | 325 | 20 | 1.218 | 2654.7 |

| SA-CS-7 | 280 | 2 | 2 | 30 | 490 | 325 | 20 | 1.230 | 2681.8 |

| SA-CS-8 | 280 | 2 | 2 | 30 | 325 | 235 | 20 | 1.190 | 2545.0 |

| SA-CS-9 | 280 | 2 | 2 | 30 | 325 | 420 | 20 | 1.197 | 2646.4 |

| SA-CS-10 | 280 | 2 | 2 | 30 | 325 | 490 | 20 | 1.201 | 2683.4 |

| SA-CS-11 | 280 | 1 | 2 | 30 | 325 | 325 | 20 | 1.060 | 2252.6 |

| SA-CS-12 | 280 | 3 | 2 | 30 | 325 | 325 | 20 | 1.256 | 2743.9 |

| SA-CS-13 | 280 | 4 | 2 | 30 | 325 | 325 | 20 | 1.319 | 2875.2 |

| SA-CS-14 | 280 | 2 | 1 | 30 | 325 | 325 | 20 | 1.161 | 2454.4 |

| SA-CS-15 | 280 | 2 | 3 | 30 | 325 | 325 | 20 | 1.202 | 2699.5 |

| SA-CS-16 | 280 | 2 | 4 | 30 | 325 | 325 | 20 | 1.204 | 2761.3 |

| SA-CS-17 | 280 | 2 | 2 | 30 | 325 | 325 | 15 | 1.189 | 2448.6 |

| SA-CS-18 | 280 | 2 | 2 | 30 | 325 | 325 | 21 | 1.195 | 2605.1 |

| SA-CS-19 | 280 | 2 | 2 | 30 | 325 | 325 | 22 | 1.198 | 2623.9 |

| SA-CS-20 | 280 | 2 | 2 | 30 | 325 | 325 | 23 | 1.202 | 2641.6 |

| SA-CS-21 | 280 | 2 | 2 | 30 | 325 | 325 | 24 | 1.203 | 2657.0 |

| SA-CS-22 | 280 | 2 | 2 | 30 | 325 | 325 | 25 | 1.198 | 2672.8 |

| SA-CS-23 | 280 | 2 | 2 | 30 | 325 | 325 | 30 | 1.180 | 2688.4 |

| SA-CS-230 | 230 | 2 | 2 | 35.4 | 324 | 324 | 20 | 1.261 | 2288.3 |

| SA-CS-280 | 280 | 2 | 2 | 35.4 | 324 | 324 | 20 | 1.232 | 3127.6 |

| SA-CS-330 | 330 | 2 | 2 | 35.4 | 324 | 324 | 20 | 1.221 | 4261.5 |

| Specimen Designation | GB50936-2014 | Eurocode 4-2004 | ACI 318-14 | DBJ/T13-51-2010 | AIJ-2001 | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Nu-Cal | Nu-FEM/Nu-Cal | Nu-Cal | Nu-FEM/Nu-Cal | Nu-Cal | Nu-FEM/Nu-Cal | Nu-Cal | Nu-FEM/Nu-Cal | Nu-Cal | Nu-FEM/Nu-Cal | |

| SA-CS-1 | 3201.6 | 0.814 | 2191.7 | 1.189 | 1885.5 | 1.382 | 3197.2 | 0.815 | 1926.2 | 1.353 |

| SA-CS-2 | 4026.9 | 0.808 | 2871.9 | 1.133 | 2463.8 | 1.321 | 4005.5 | 0.812 | 2504.5 | 1.299 |

| SA-CS-3 | 4858.2 | 0.770 | 3164.7 | 1.182 | 2712.6 | 1.379 | 4813.9 | 0.777 | 2753.3 | 1.359 |

| SA-CS-4 | 5681.5 | 0.742 | 4232.5 | 0.996 | 3620.3 | 1.164 | 5622.3 | 0.750 | 3661.0 | 1.152 |

| SA-CS-5 | 2987.1 | 0.829 | 2191.7 | 1.130 | 1885.5 | 1.313 | 3020.5 | 0.820 | 1926.2 | 1.286 |

| SA-CS-6 | 3447.7 | 0.770 | 2191.7 | 1.211 | 1885.5 | 1.408 | 3383.6 | 0.785 | 1926.2 | 1.378 |

| SA-CS-7 | 3638.8 | 0.737 | 2191.7 | 1.224 | 1885.5 | 1.422 | 3521.0 | 0.762 | 1926.2 | 1.392 |

| SA-CS-8 | 3189.2 | 0.798 | 2149.9 | 1.184 | 1843.8 | 1.380 | 3160.0 | 0.805 | 1873.2 | 1.359 |

| SA-CS-9 | 3211.7 | 0.824 | 2235.7 | 1.184 | 1929.6 | 1.371 | 3236.3 | 0.818 | 1982.2 | 1.335 |

| SA-CS-10 | 3221.4 | 0.833 | 2268.2 | 1.183 | 1962.1 | 1.368 | 3265.2 | 0.822 | 2023.5 | 1.326 |

| SA-CS-11 | 2869.6 | 0.785 | 2219.6 | 1.015 | 1909.3 | 1.180 | 2809.3 | 0.802 | 1855.9 | 1.214 |

| SA-CS-12 | 3522.3 | 0.779 | 2163.9 | 1.268 | 1861.9 | 1.474 | 3588.6 | 0.765 | 1993.4 | 1.376 |

| SA-CS-13 | 3838.7 | 0.749 | 2136.3 | 1.346 | 1838.5 | 1.564 | 3983.7 | 0.722 | 2057.5 | 1.397 |

| SA-CS-14 | 3191.7 | 0.769 | 2130.6 | 1.152 | 1822.5 | 1.347 | 3184.2 | 0.771 | 1937.4 | 1.267 |

| SA-CS-15 | 3206.1 | 0.842 | 2250.1 | 1.200 | 1945.9 | 1.387 | 3210.0 | 0.841 | 1915.1 | 1.410 |

| SA-CS-16 | 3210.8 | 0.860 | 2305.9 | 1.197 | 2003.7 | 1.378 | 3222.6 | 0.857 | 1904.0 | 1.450 |

| SA-CS-17 | 3111.3 | 0.787 | 2126.2 | 1.152 | 1829.9 | 1.338 | 3122.5 | 0.784 | 1870.6 | 1.309 |

| SA-CS-18 | 3216.2 | 0.810 | 2204.7 | 1.182 | 1896.6 | 1.374 | 3212.1 | 0.811 | 1937.4 | 1.345 |

| SA-CS-19 | 3235.4 | 0.811 | 2217.8 | 1.183 | 1907.8 | 1.375 | 3227.0 | 0.813 | 1948.5 | 1.347 |

| SA-CS-20 | 3253.2 | 0.812 | 2230.9 | 1.184 | 1918.9 | 1.377 | 3242.0 | 0.815 | 1959.6 | 1.348 |

| SA-CS-21 | 3272.2 | 0.812 | 2244.0 | 1.184 | 1930.0 | 1.377 | 3256.9 | 0.816 | 1970.7 | 1.348 |

| SA-CS-22 | 3287.6 | 0.813 | 2257.1 | 1.184 | 1941.1 | 1.377 | 3271.8 | 0.817 | 1981.8 | 1.349 |

| SA-CS-23 | 3377.4 | 0.796 | 2322.5 | 1.158 | 1996.7 | 1.346 | 3346.5 | 0.803 | 2037.4 | 1.319 |

| SA-CS-230 | 2627.2 | 0.871 | 1806.3 | 1.267 | 1557.9 | 1.469 | 2649.0 | 0.864 | 1598.5 | 1.432 |

| SA-CS-280 | 3645.2 | 0.858 | 2558.5 | 1.222 | 2197.3 | 1.423 | 3631.3 | 0.861 | 2237.9 | 1.398 |

| SA-CS-330 | 4820.7 | 0.884 | 3450.7 | 1.235 | 2955.6 | 1.442 | 4773.0 | 0.893 | 2996.2 | 1.422 |

| Mean value | 0.806 | 1.183 | 1.374 | 0.808 | 1.345 | |||||

| Standard deviation | 0.038 | 0.068 | 0.078 | 0.037 | 0.064 | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Z.; Zou, Y.; Wang, C.; Pan, J.; Wang, L. Axial Compression Behavior of Steel Angle-Corrugated Steel Plate-Confined Concrete Columns. Appl. Sci. 2022, 12, 10819. https://doi.org/10.3390/app122110819

Sun Z, Zou Y, Wang C, Pan J, Wang L. Axial Compression Behavior of Steel Angle-Corrugated Steel Plate-Confined Concrete Columns. Applied Sciences. 2022; 12(21):10819. https://doi.org/10.3390/app122110819

Chicago/Turabian StyleSun, Zexuan, Yun Zou, Chengquan Wang, Jie Pan, and Li Wang. 2022. "Axial Compression Behavior of Steel Angle-Corrugated Steel Plate-Confined Concrete Columns" Applied Sciences 12, no. 21: 10819. https://doi.org/10.3390/app122110819

APA StyleSun, Z., Zou, Y., Wang, C., Pan, J., & Wang, L. (2022). Axial Compression Behavior of Steel Angle-Corrugated Steel Plate-Confined Concrete Columns. Applied Sciences, 12(21), 10819. https://doi.org/10.3390/app122110819