Numerical Simulation and Experimental Research on Multi-Channel Laser Directional Energy Deposition of IN718

Abstract

:1. Introduction

2. Numerical Modeling

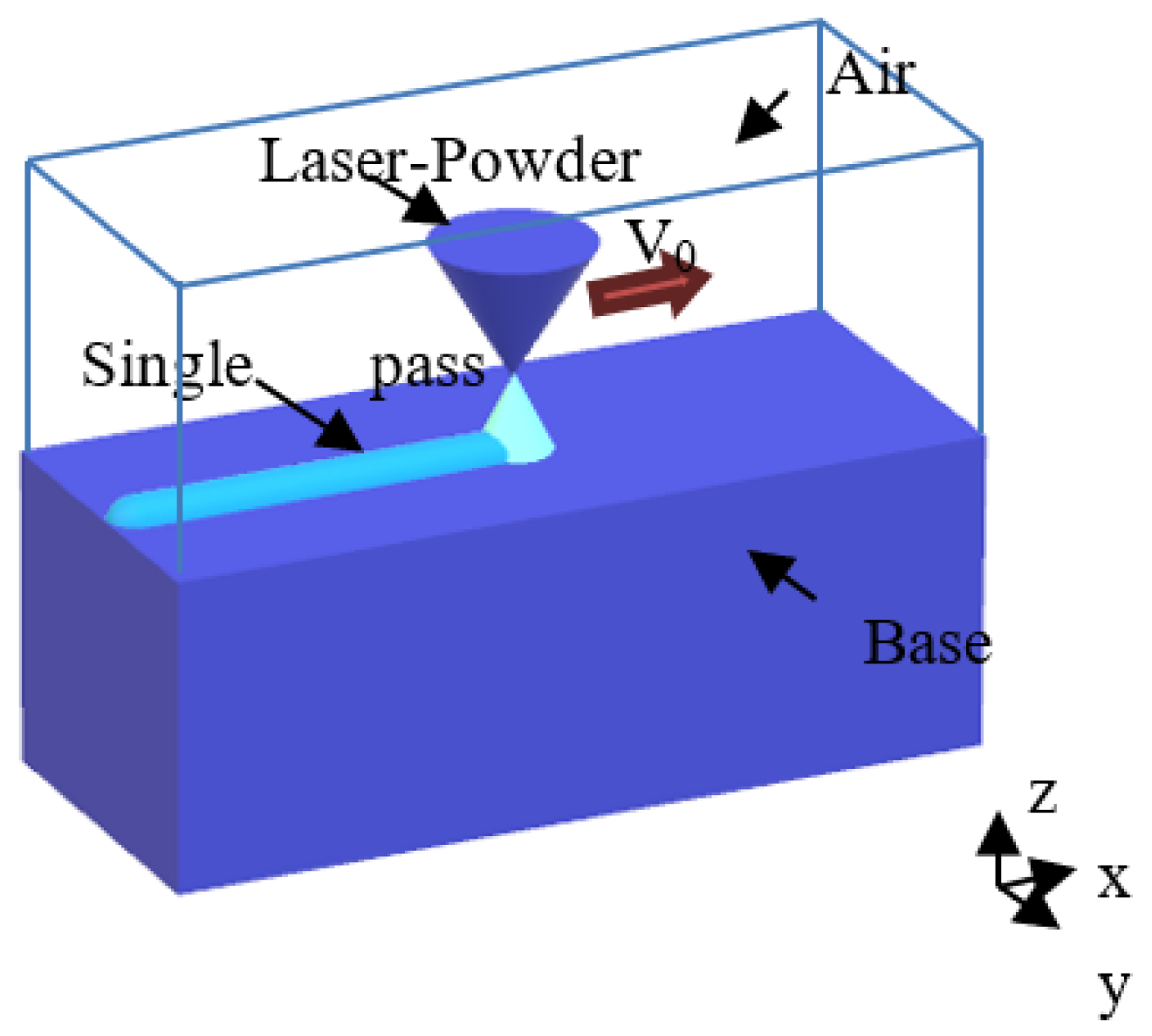

2.1. Geometric and Physical Models

2.2. Mathematical Model

2.2.1. Control Equations

2.2.2. Deposition Shape Calculation Model

2.2.3. Moving Gaussian Heat Sources and Other Boundary Conditions

3. Experimental Method

4. Results Analysis and Discussion

4.1. Single-Channel Deposition

4.1.1. Influence of Powder Feeding Rate on the Shape of Single-Channel Deposition

4.1.2. Effect of Laser Power on the Shape of the Single-Channel Deposition

4.2. Temperature Field Characteristics of Single-Channel Deposition

4.3. Double-Channel Overlapping Deposition

4.3.1. Calculation and Comparison of Double-Channel Overlapping Deposition Shapes

4.3.2. Analysis of the Temperature Field and Melt Pool Characteristics of Double-Channel Overlapping Deposition

4.4. Analysis of Simulation Results for Single-Layer Multi-Channel Deposition

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Disclosures

References

- Zhang, J.P.; Shi, S.H.; Jiang, W.W.; Shi, T.; Ji, S.S. Simulation Analysis of Temperature Field and Process Optimization of Laser Cladding Based on Internal Wire Feeding of Three Beams. Chin. J. Lasers 2019, 46, 1002004. [Google Scholar]

- Guo, W.; Zhang, Y.P.; Chai, R.X. Numerical Simulation and Experimental Study of Single Track Laser Cladding of 304 Stainless Steels. Laser Optoelectron. Prog. 2019, 56, 091401. [Google Scholar] [CrossRef]

- Shi, T.; Wang, Y.Q.; Lu, B.H.; Shi, S.; Lu, B.; Fu, G. Laser Cladding Forming of Cantilevered Thin Walled PartBased on Hollow-Laser Beam Inside Powder Feeding Technology. Chin. J. Lasers 2015, 42, 1003003. [Google Scholar]

- An, X.L.; Lu, Y.Z.; Tan, Z.X.; Lu, X. Progerss in Numerical Simulation of Laser 3D Printing of Metal by Coaxial Powder Feeding: Flow in Welding Pool, Composition Distribution and Tissue Growth. Mater. Rev. 2018, 32, 69–79. [Google Scholar]

- Xu, L.; Hong, J.; Wang, W. Simulation Analysis and Experimental Study on Nanosecond Laser Cladding Silicon Nano Film. Chin. J. Lasers 2019, 46, 0402008. [Google Scholar]

- Acharya, R.; Bansal, R.; Gambone, J.J.; Da, S. A Coupled Thermal, Fluid Flow, and Solidification Model for the Processing of Single-Crystal Alloy CMSX-4 Through Scanning Laser Epitaxy for Turbine Engine Hot-Section Component Repair (Part I). Metall. Mater. Trans. B 2014, 45, 2247. [Google Scholar] [CrossRef]

- Zhang, D.Y.; Wu, R.; Zhang, H.F.; Liu, Z. Numerical Simulation of Temperature Field Evolution in the Process of Laser Metal Deposition. Chin. J. Lasers 2015, 42, 503006. [Google Scholar] [CrossRef]

- Ren, Z.H.; Wu, M.P.; Tang, Y.H.; Han, J.; Gong, Y. Numerical Simulation and Experimental Research of Laser Cladding Based on Thermo-Mechanical Coupling. Laser Optoelectron. Prog. 2019, 56, 051404. [Google Scholar]

- Caiazzo, F.; Alfieri, V. Simulation of Laser-assisted Directed Energy Deposition of Aluminum Powder: Prediction of Geometry and Temperature Evolution. Materials 2019, 12, 2100. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, W.Z.; Zhou, H.; Xu, L.J. Effect of pause time on temperature field of multi-channel cladding nickel-based alloy. Opt. Tech. 2020, 46, 96–101. [Google Scholar]

- Wang, W.; Liu, Q.; Yang, G.; Qin, L.Y.; Xue, X. Numerical simulation of flow field and temperature field in laser melting pool of titanium alloy. Appl. Laser 2014, 34, 389–394. [Google Scholar] [CrossRef]

- Guan, X.Y.; Zhao, Y.Y. Numerical modeling of coaxial powder stream in laser-powder-based Directed Energy Deposition process. Addit. Manuf. 2020, 34, 101226. [Google Scholar] [CrossRef]

- Xiong, A.H.; Ding, J.Q.; Liu, Y.H.; Zhang, X.M.; Shao, S.J. Numerical simulation of laser cladding pool on titanium alloy surface. Appl. Laser 2019, 39, 381–386. [Google Scholar]

- He, L.J.; Zhang, T.L.; Xu, G.; Gu, G.S.; Ma, C.W. Effect of surface tension on small hole of laser deep fusion welding pool. Light Ind. Mach. 2021, 39, 51–55. [Google Scholar]

- Romano, J.; Ladani, L.; Sadowski, M. Laser Additive Melting and Solidification of Inconel 718: Finite Element Simulation and Experiment. JOM 2016, 68, 967–977. [Google Scholar] [CrossRef]

- Wu, C.W.; Dong, J.X.; Zhang, M.C.; Wang, G.; Xie, X. Thermodynamic Calculation And Precipitation Behavior of α-Cr Phase In IN718 Alloy. Acta Metall. Sin. 2001, 37, 1174–1178. [Google Scholar]

| Parameter | Value |

|---|---|

| Powder feeding radius rp (m) | |

| Laser absorptivity η | 70% |

| (W/m2/K) | 350 |

| Ambient temperature Tr (K) | 300 |

| Surface emissivity of substrate ε | 0.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, A.; Huang, Y.; Wang, Y.; Yang, Y.; Li, W.; Wang, T. Numerical Simulation and Experimental Research on Multi-Channel Laser Directional Energy Deposition of IN718. Appl. Sci. 2022, 12, 11014. https://doi.org/10.3390/app122111014

Hu A, Huang Y, Wang Y, Yang Y, Li W, Wang T. Numerical Simulation and Experimental Research on Multi-Channel Laser Directional Energy Deposition of IN718. Applied Sciences. 2022; 12(21):11014. https://doi.org/10.3390/app122111014

Chicago/Turabian StyleHu, Ankai, Yanlu Huang, Yu Wang, Yongqiang Yang, Wei Li, and Tianyu Wang. 2022. "Numerical Simulation and Experimental Research on Multi-Channel Laser Directional Energy Deposition of IN718" Applied Sciences 12, no. 21: 11014. https://doi.org/10.3390/app122111014

APA StyleHu, A., Huang, Y., Wang, Y., Yang, Y., Li, W., & Wang, T. (2022). Numerical Simulation and Experimental Research on Multi-Channel Laser Directional Energy Deposition of IN718. Applied Sciences, 12(21), 11014. https://doi.org/10.3390/app122111014