A Smart Handheld Welding Torch Device for Manual Spot Laser Welding

Abstract

:1. Introduction

2. Materials and Methods

3. Results

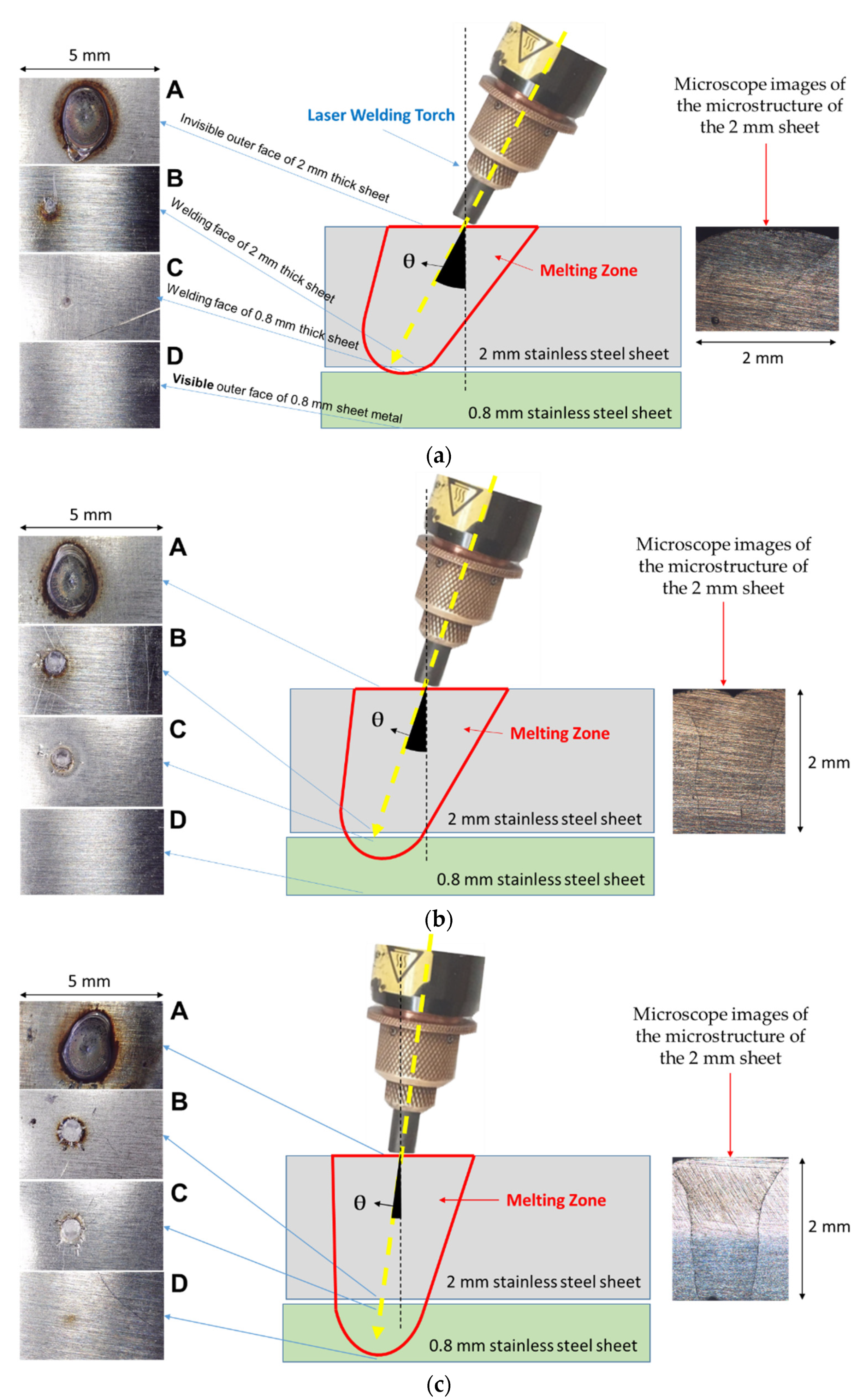

3.1. Determination of the Effect of Torch-Surface Angle on Weld Quality in Manual Laser Spot Welding

3.2. Design, Programming, and Welding with the Angular Positioning Assistant Device (Welding with the Smart Manual Welding Torch)

4. Discussion

5. Conclusions

- It was observed that in cases where laser spot welding must be done manually, standard welding cannot be performed.

- Experiments showed that the quality of the weld changes with the change in angle between the weld surface and the laser beam in laser spot welding, even if all other variables are kept constant.

- It was demonstrated in the study that this problem can be solved with a smart manual torch equipped with a system that measures the surface angle and helps keep the surface laser angle within a certain range.

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Luangpaiboon, P. Constrained response surface optimization for a laser beam welding process. J. Math Stat. 2011, 7, 5–11. [Google Scholar] [CrossRef]

- Tsukamoto, S. Laser welding. Weld. Int. 2003, 17, 767–774. [Google Scholar] [CrossRef]

- Chen, W.; Ackerson, P.; Molian, P. CO2 laser welding of galvanized steel sheets using vent holes. Mater. Design 2009, 30, 245–251. [Google Scholar] [CrossRef]

- Ghosh, P.S.; Sen, A.; Chattopadhyaya, S.; Sharma, S.; Singh, J.; Dwivedi, S.P.; Saxena, A.; Khan, A.M.; Pimenov, D.Y.; Giasin, K. Prediction of Transient Temperature Distributions for Laser Welding of Dissimilar Metals. Appl. Sci. 2021, 11, 5829. [Google Scholar] [CrossRef]

- Ishide, T.; Tsubota, S.; Nayama, M.; Shimokusu, Y.; Nagashima, T.; Okimura, K. 10 kW Class YAG Laser Application for Heavy Components. In High-Power Lasers in Manufacturing, Proceedings of the SPIE, Advanced High-Power Lasers and Applications, Osaka, Japan, 1–5 November 1999; SPIE: Bellingham, WA, USA, 1999; Volume 3888, pp. 543–550. [Google Scholar]

- Katayama, S.; Seto, N.; Kim, J.; Matsunawa, A. Formation Mechanism and Reduction Method of Porosity in Laser Welding of Stainless Steel. In Proceedings of the ICALEO, Section G, San Diego, CA, USA, 17–18 November 1997; pp. 83–92. [Google Scholar]

- Katayama, S.; Matsunawa, A. Formation Mechanism and Prevention of Defects in Laser Welding of Aluminum Alloys. In Proceedings of the 6th International Conference on Welding and Melting by Electron and Laser Beams CISFFEL 6, Toulon, France, 15–19 June 1998; Volume 1, pp. 215–222. [Google Scholar]

- Katayama, S.; Seto, N.; Kim, J.; Matsunawa, A. Formation Mechanism and Suppression Procedure of Porosity in High Power Laser Welding of Aluminum Alloys. In Proceedings of the ICALEO, Section C, Orlando, FL, USA, 16–19 November 1998; pp. 24–33. [Google Scholar]

- Zhou, J.; Tsai, H. Porosity Formation and Prevention in Pulsed Laser Welding. ASME J. Heat Transfer 2006, 129, 1014–1024. [Google Scholar] [CrossRef]

- Sun, J.; Nie, P.; Feng, K.; Li, Z.; Guo, B.; Jiang, E. The elimination of pores in laser welds of AISI 304 plate using different shielding gases. J. Mater Process. Technol. 2017, 248, 56–63. [Google Scholar] [CrossRef]

- Kumar, N.; Mukherjee, M.; Bandyopadhyay, A. Comparative study of pulsed Nd:YAG laser welding of AISI 304 and AISI 316 stainless steels. Opt. Laser Technol. 2017, 88, 24–39. [Google Scholar] [CrossRef]

- Siva Shanmugam, N.; Buvanashekaran, G.; Sankaranarayanasamy, K. Some studies on weld bead geometries for laser spot welding process using finite element analysis. Mater. Des. 2012, 34, 412–426. [Google Scholar] [CrossRef]

- Cedeño-Viveros, L.D.; García-López, E.; Vázquez, E.V.; Siller, H.R.; Rodríguez, C.A. Laser micro-spot welding of AISI 302 stainless steel sheets. In Laser-Based Micro and Nano Processing XII, Proceedings of the SPIE LASE, San Francisco, CA, USA, 27 January–1 February 2018; SPIE: Bellingham, WA, USA, 2018; p. 105. [Google Scholar]

- Kumar, N.; Dhara, S.; Masters, I.; Das, A. Substituting Resistance Spot Welding with Flexible Laser Spot Welding to Join Ultra-Thin Foil of Inconel 718 to Thick 410 Steel. Materials 2022, 15, 3405. [Google Scholar] [CrossRef]

- Ventrella, V.A.; Berretta, J.R.; de Rossi, W. Pulsed Nd:YAG laser seam welding of AISI 316L stainless steel thin foils. J. Mater. Process. Technol. 2010, 210, 1838–1843. [Google Scholar] [CrossRef]

- Kleine, K.F.; Fox, W.J.; Watkins, K.G. Micro Welding with Pulsed Single Mode Fiber Lasers; Laser Institute of America: San Francisco, CA, USA, 2004; p. M501. [Google Scholar]

- Gillner, A.; Holtkamp, J.; Hartmann, C.; Olowinsky, A.; Gedicke, J.; Klages, K.; Bosse, L.; Bayer, A. Laser applications in micro technology. J. Mater. Process. Technol. 2005, 167, 494–498. [Google Scholar] [CrossRef]

- Tolinski, M. Lasers seal the deal in medical. Manuf. Eng. 2008, 140, 14–20. [Google Scholar]

- Quazi, M.; Ishak, M.; Fazal, M.; Arslan, A.; Rubaiee, S.; Aiman, M.; Qaban, A.; Yusof, F.; Sultan, T.; Ali, M. A comprehensive assessment of laser welding of biomedical devices and implant materials: Recent research, development and applications. Crit. Rev. Solid State Mater. Sci. 2021, 46, 109–151. [Google Scholar] [CrossRef]

- Shaikh, U.F.; Das, A.; Barai, A.; Masters, I. Electro-Thermo-Mechanical Behaviours of Laser Joints for Electric Vehicle Battery Interconnects. In Proceedings of the 2019 Electric Vehicles International Conference (EV), Bucharest, Romania, 3–4 October 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–6. [Google Scholar]

- Pakmanesh, M.R.; Shamanian, M. Optimization of pulsed laser welding process parameters in order to attain minimum under fill and undercut defects in thin 316L stainless steel foils. Opt. Laser Technol. 2018, 99, 30–38. [Google Scholar] [CrossRef]

- Kim, J.D.; Kim, C.J.; Chung, C.M. Repair welding of etched tubular components of nuclear power plant by Nd:YAG laser. J. Mater. Process. Tech. 2001, 114, 51–56. [Google Scholar] [CrossRef]

- Ahmad, G.N.; Raza, M.S.; Singh, N.K.; Kumar, H. Experimental investigation on Ytterbium fiber laser butt welding of Inconel 625 and Duplex stainless steel 2205 thin sheets. Opt. Laser Technol. 2020, 126, 106117. [Google Scholar] [CrossRef]

- Ahmad, G.N.; Raza, M.S.; Singh, N.K.; Muvvala, G. Investigating the effect of process parameters on weld pool thermal history and mechanical properties of laser welded Inconel 625 and Duplex stainless steel 2205 dissimilar welds. Optik 2021, 248, 168134. [Google Scholar] [CrossRef]

- Yan, L.; Jam, J.E.; Beni, M.H.; Kholoud, M.J.; Baleanu, D.; Shahraki, M.E.; Ghaemi, F. Effect of laser welding parameters on the temperature distribution, microstructure and mechanical properties of dissimilar weld joint of Inconel 625 and stainless steel 304. Int. Commun. Heat Mass Transf. 2022, 131, 105859. [Google Scholar] [CrossRef]

- Wohlers, T. Making Products by Using Additive Manufacturing. Manuf. Eng. 2011, 146, 70–77. [Google Scholar]

- Sukhov, D.I.; Bogachev, I.A.; Hodyrev, N.A.; Filonova, E.V. Multiple recycling of nickel alloy powder for selective laser melting process: Influence on properties of the powder and printed material. Rapid Prototyp. J. 2022, 28, 1933–1942. [Google Scholar] [CrossRef]

- Sezer, H.; Tang, J.; Ahsan, A.N.; Kaul, S. Modeling residual thermal stresses in layer-by-layer formation of direct metal laser sintering process for different scanning patterns for 316L stainless steel. Rapid Prototyp. J. 2022, 28, 1750–1763. [Google Scholar] [CrossRef]

- Ullah, A.; Ur Rehman, A.; Salamci, M.U.; Pıtır, F.; Liu, T. The influence of laser power and scanning speed on the microstructure and surface morphology of Cu2O parts in SLM. Rapid Prototyp. J. 2022, 28, 1796–1807. [Google Scholar] [CrossRef]

- Khorasani, M.; Ghasemi, A.; Leary, M.; Sharabian, E.; Cordova, L.; Gibson, I.; Downing, D.; Bateman, S.; Brandt, M.; Rolfe, B. The effect of absorption ratio on meltpool features in laser-based powder bed fusion of IN718. Opt. Laser Technol. 2022, 153, 108263. [Google Scholar] [CrossRef]

- Srikanth, S.; Parthiban, A. Microstructural analysis of Nd:YAG laser welding for Inconel alloy. Mater. Today Proc. 2020, 21, 568–571. [Google Scholar] [CrossRef]

- Cheepu, M.; Kumar Reddy, Y.A.; Indumathi, S.; Venkateswarlu, D. Laser welding of dissimilar alloys between high tensile steel and Inconel alloy for high temperature applications. Adv. Mater. Process. Technol. 2020, 1–12. [Google Scholar] [CrossRef]

- Sidharth, D.; KV, P.P.; Rajendran, R.; Narayanan, S. Microstructure and properties of inconel 718 and AISI 416 laser welded joints. J. Mat. Proc. Tech. 2019, 266, 52–62. [Google Scholar]

- Lin, J.; Wang, X.; Lei, Y.; Wei, R.; Guo, F. Study on hot cracking in laser welded joints of inconel 718 alloy foils. J. Manuf. Process. 2021, 64, 1024–1035. [Google Scholar] [CrossRef]

- Lertora, E.; Mandolfino, C.; Gambaro, C. Mechanical Behaviour of Inconel 718 Thin-Walled Laser Welded Components for Aircraft Engines. Int. J. Aer. Eng. 2014, 721680. [Google Scholar] [CrossRef]

- Simonds, B.J.; Sowards, J.; Hadler, J.; Pfeif, E.; Wilthan, B.; Tanner, J.; Harris, C.; Williams, P.; Lehman, J. Time-Resolved Absorptance and Melt Pool Dynamics during Intense Laser Irradiation of a Metal. Phys. Rev. Appl. 2018, 10, 044061. [Google Scholar] [CrossRef]

- Gennari, C.; Lago, M.; Bögre, B.; Meszaros, I.; Calliari, I.; Pezzato, L. Microstructural and Corrosion Properties of Cold Rolled Laser Welded UNS S32750 Duplex Stainless Steel. Metals 2018, 8, 1074. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Yuan, K.; Li, T.; Li, S.; Ren, Y. NDT Method for Line Laser Welding Based on Deep Learning and One-Dimensional Time-Series Data. Appl. Sci. 2022, 12, 7837. [Google Scholar] [CrossRef]

| Grade | Chemical Composition (%) | Shear Stress (N/mm2) | Yield Stress (N/mm2) | Hardness (HV) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Ni | Cr | N | ||||

| 304/304L/1.4301/1.4307 | 0.022 | 0.34 | 1.38 | 0.028 | 0.002 | 8.01 | 18.15 | 0.065 | 632 | 274 | 164 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reis, M.; Şerifağaoğlu, E. A Smart Handheld Welding Torch Device for Manual Spot Laser Welding. Appl. Sci. 2022, 12, 11137. https://doi.org/10.3390/app122111137

Reis M, Şerifağaoğlu E. A Smart Handheld Welding Torch Device for Manual Spot Laser Welding. Applied Sciences. 2022; 12(21):11137. https://doi.org/10.3390/app122111137

Chicago/Turabian StyleReis, Murat, and Emre Şerifağaoğlu. 2022. "A Smart Handheld Welding Torch Device for Manual Spot Laser Welding" Applied Sciences 12, no. 21: 11137. https://doi.org/10.3390/app122111137

APA StyleReis, M., & Şerifağaoğlu, E. (2022). A Smart Handheld Welding Torch Device for Manual Spot Laser Welding. Applied Sciences, 12(21), 11137. https://doi.org/10.3390/app122111137