Performance and Optimization of a Dual-Stage Vibration Isolation System Using Bio-Inspired Vibration Isolators

Abstract

1. Introduction

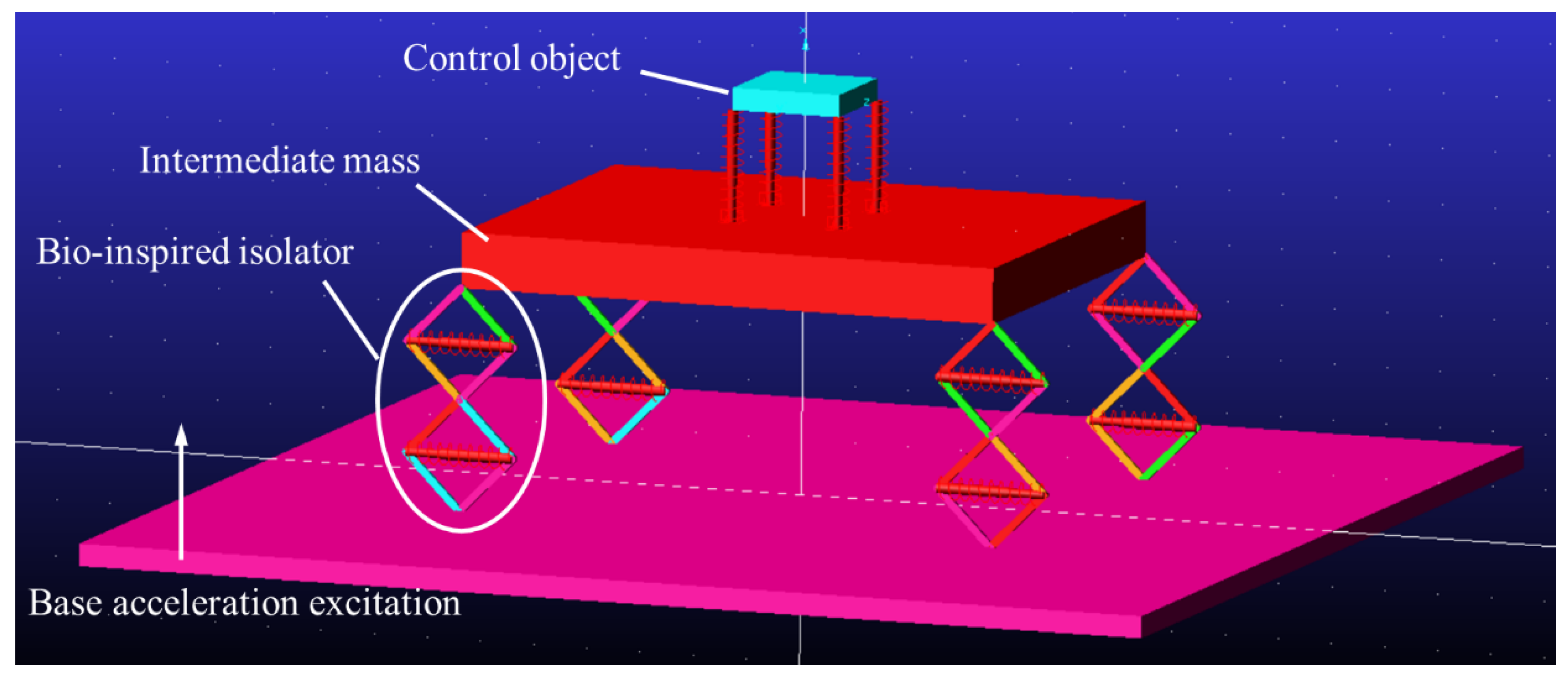

2. Dynamic Model

2.1. Model Description

2.2. Governing Equations

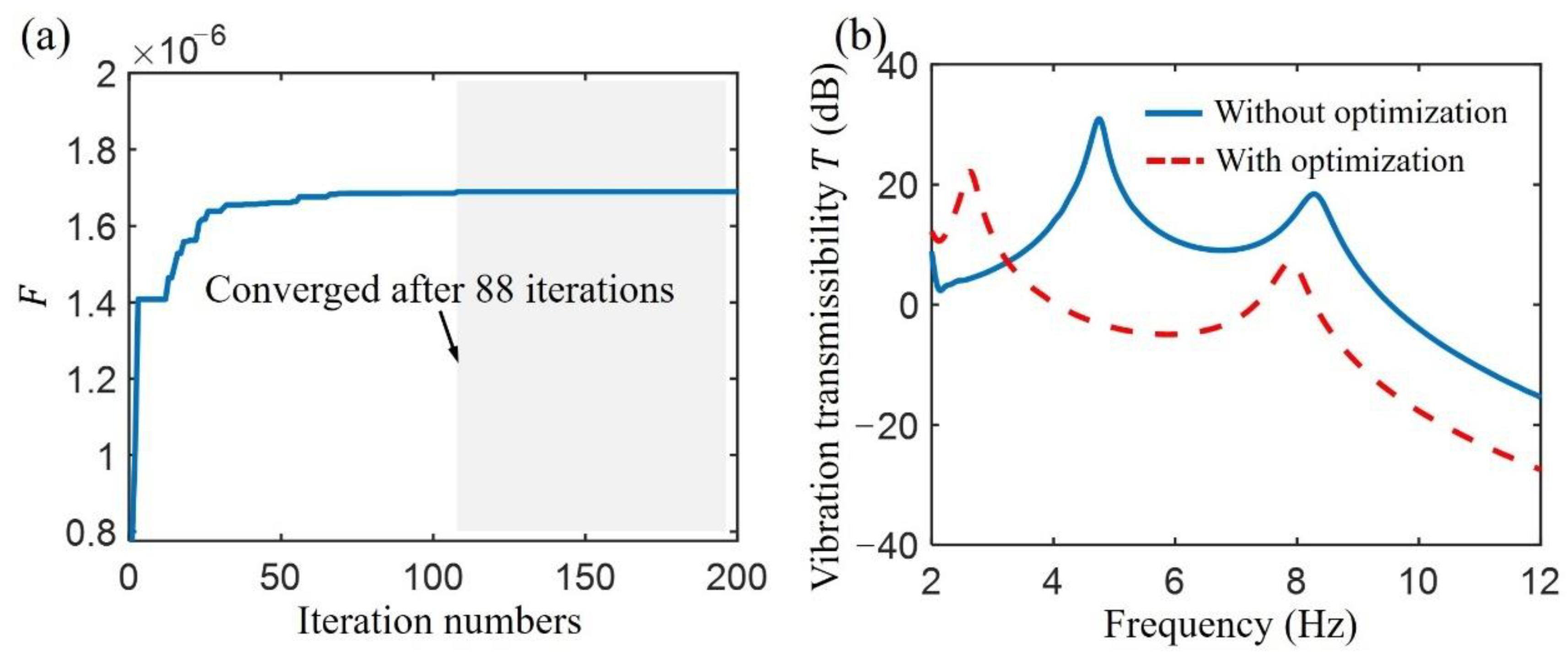

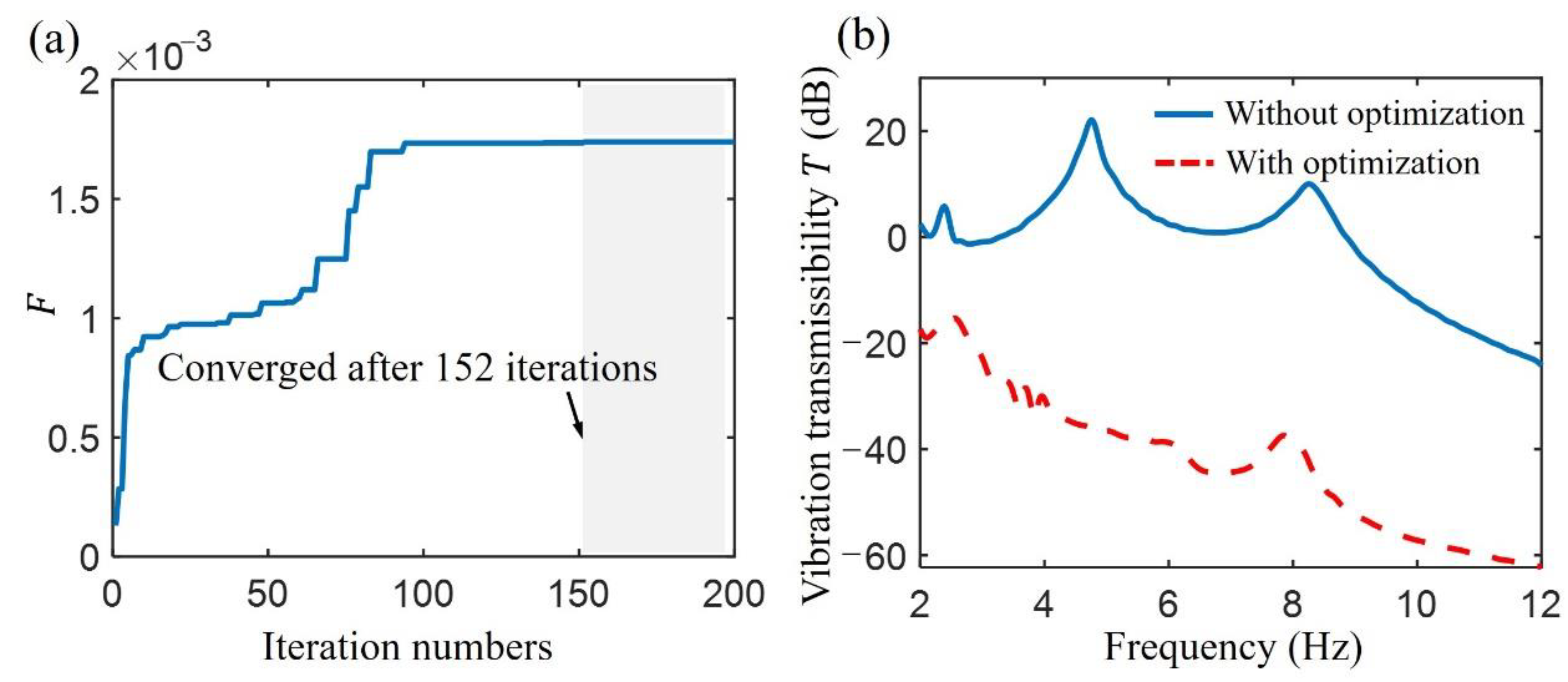

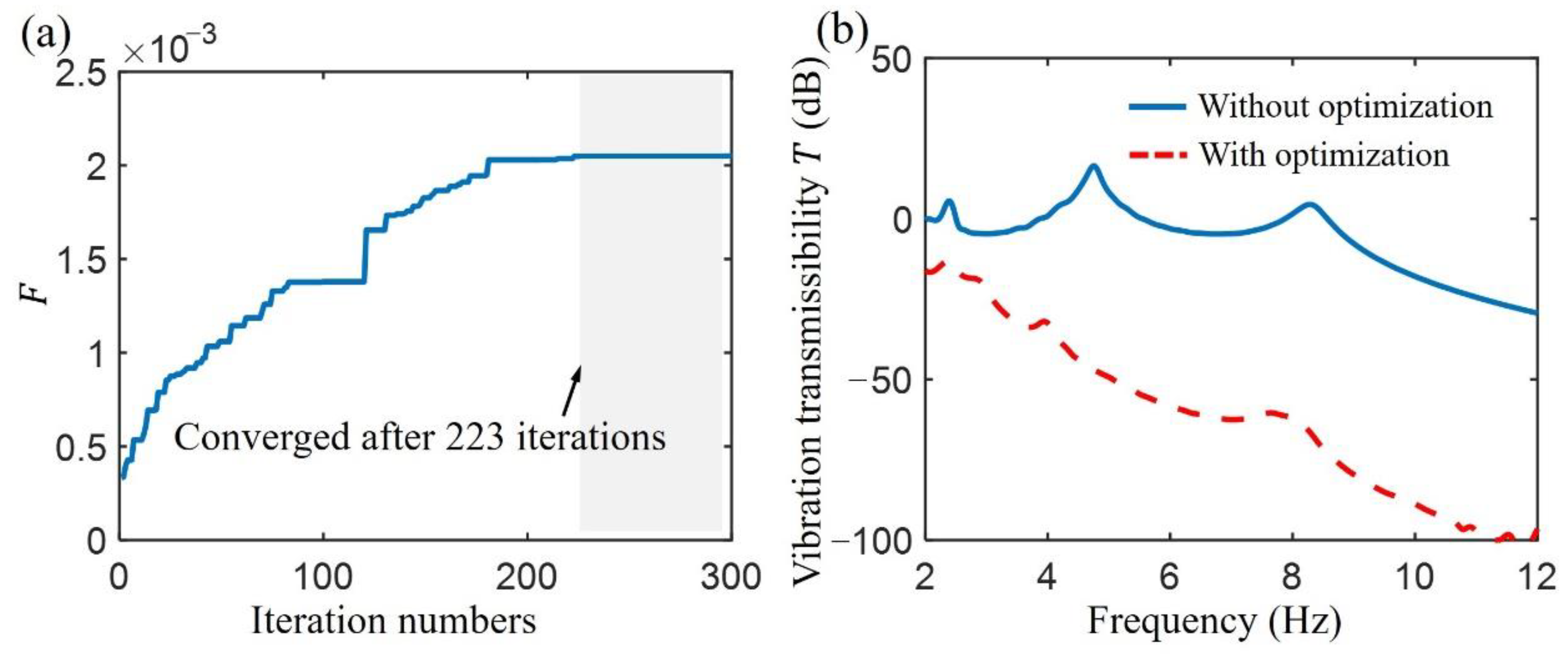

3. Performance Optimization Using Genetic Algorithm

3.1. Definition of the Optimization Problem

3.2. Optimization Procedure

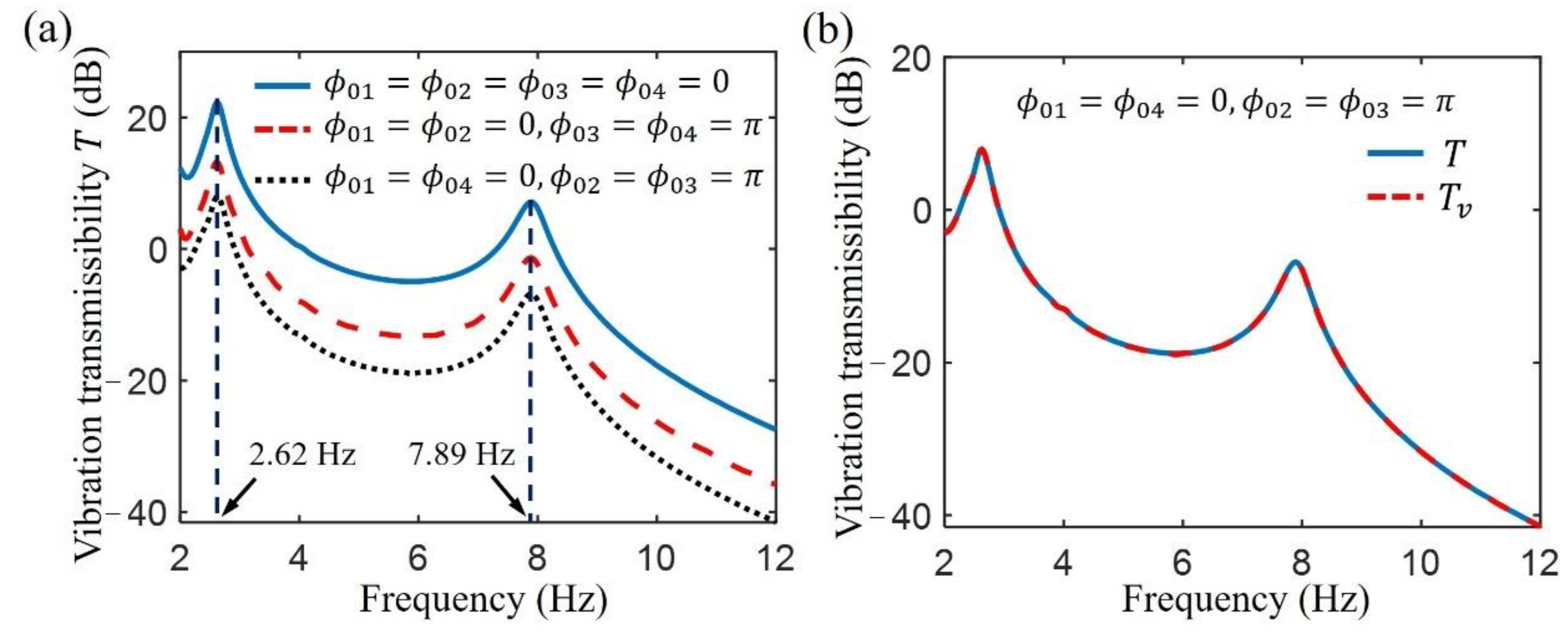

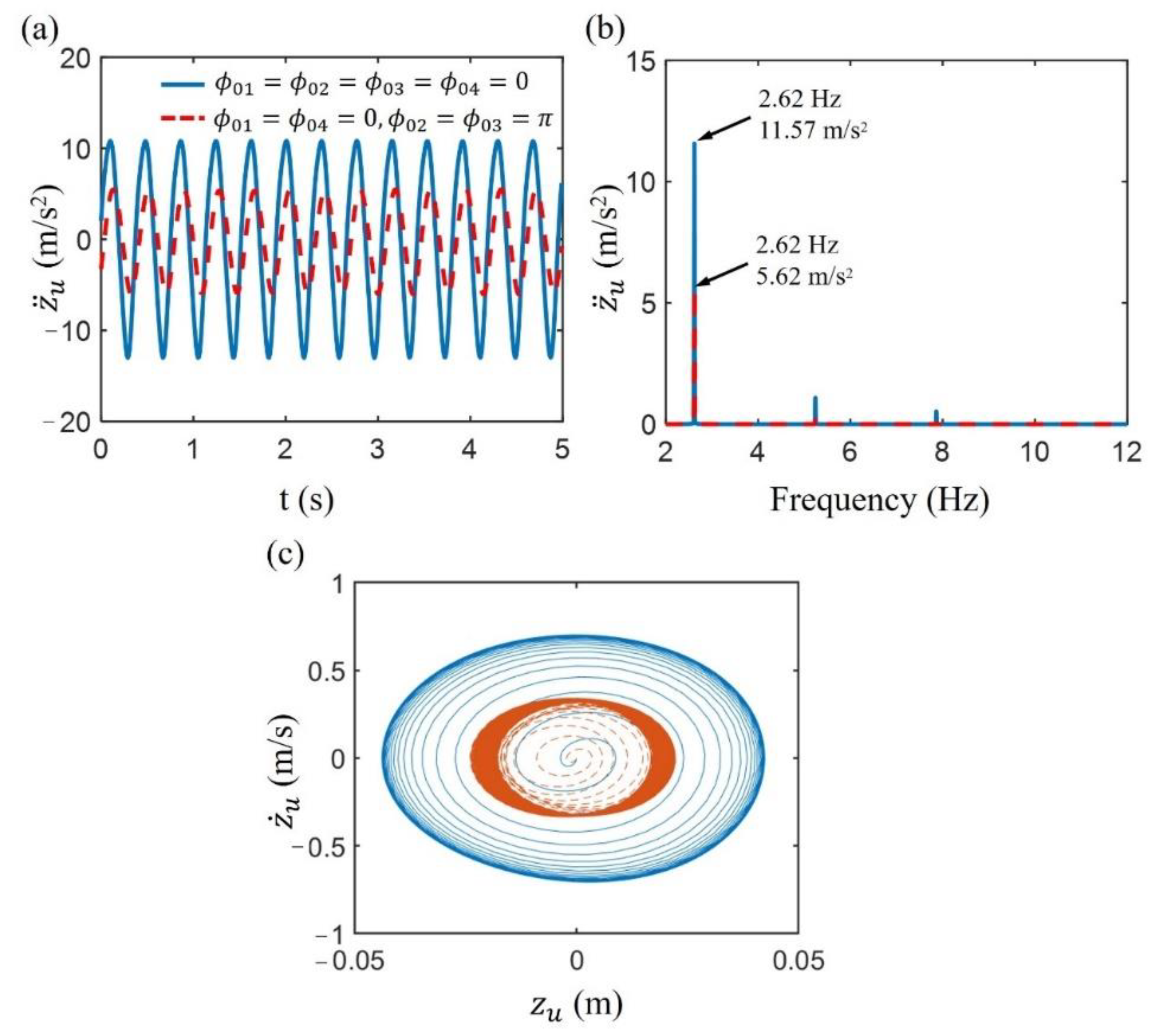

3.3. Performance Comparison

4. Parameter Study

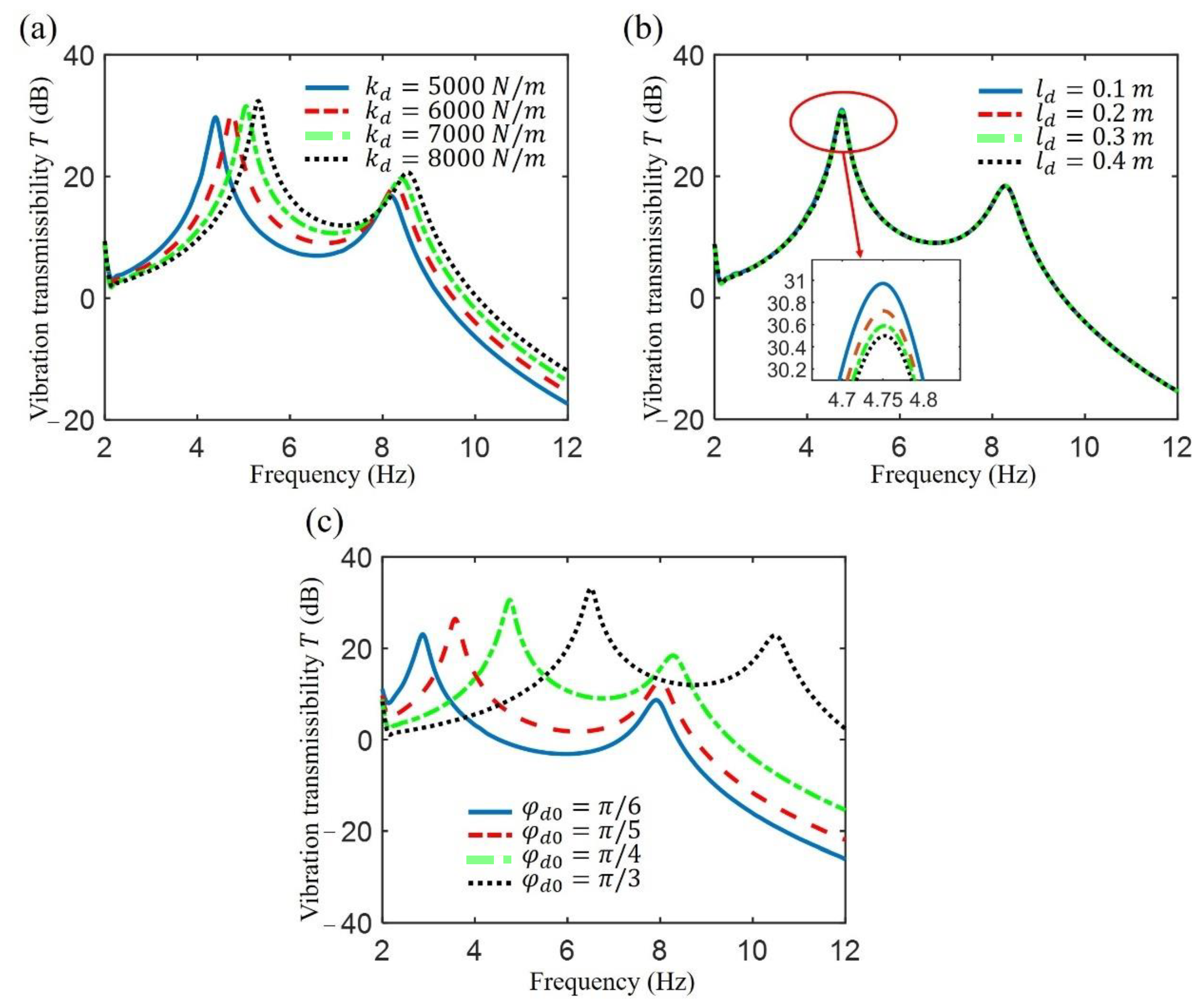

4.1. Influence of the Isolator Parameters on Vibration Isolation Performance

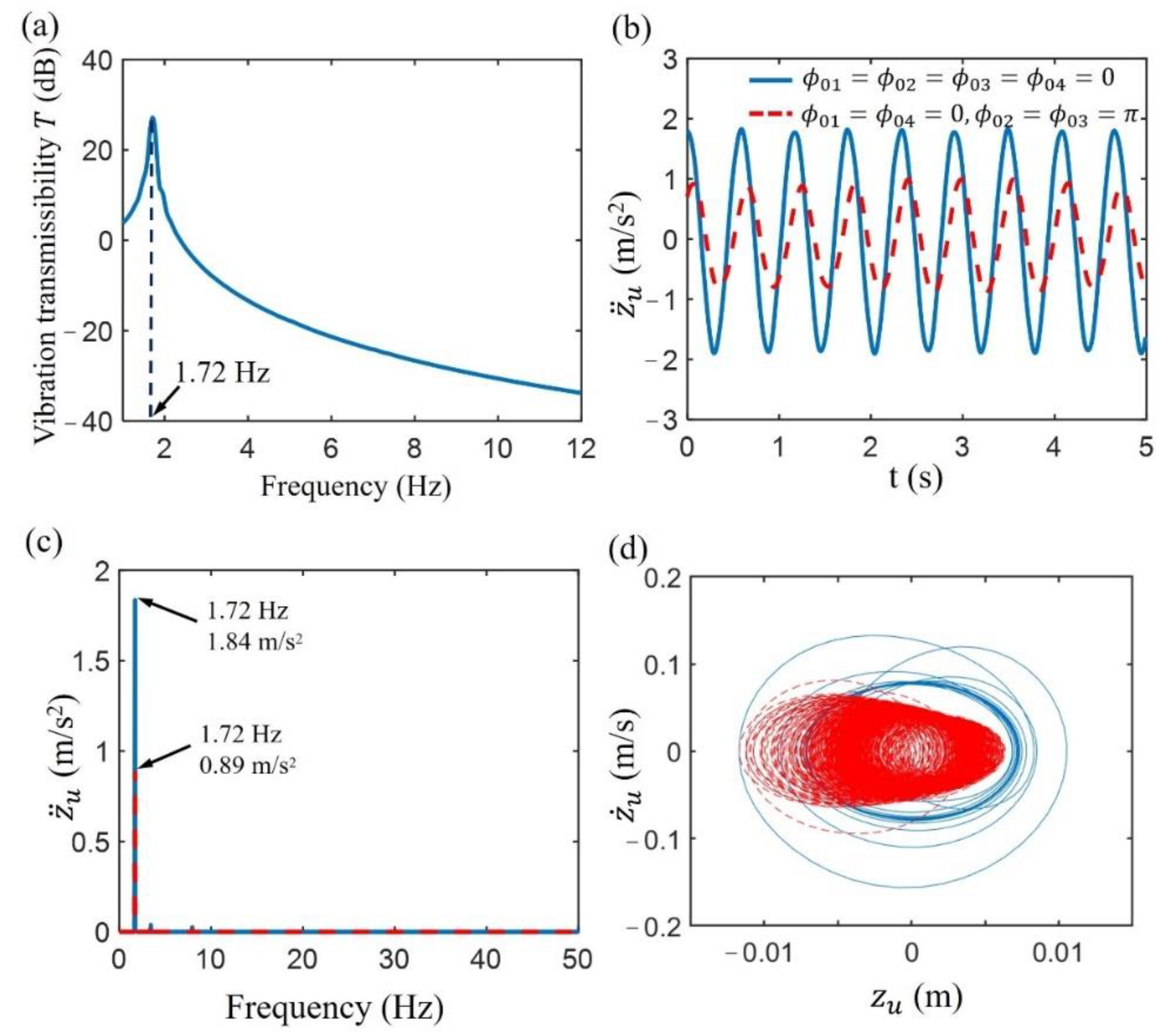

4.2. Influence of the Base Excitation on System Response

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Hou, R.; Xia, Y. Review on the new development of vibration-based damage identification for civil engineering structures: 2010–2019. J. Sound Vib. 2021, 491, 115741. [Google Scholar] [CrossRef]

- Feng, K.; Ji, J.C.; Ni, Q.; Beer, M. A review of vibration-based gear wear monitoring and prediction techniques. Mech. Syst. Signal Process. 2023, 182, 109605. [Google Scholar] [CrossRef]

- Deng, T.; Wen, G.; Ding, H.; Lu, Z.Q.; Chen, L.Q. A bio-inspired isolator based on characteristics of quasi-zero stiffness and bird multi-layer neck. Mech. Syst. Signal Process. 2020, 145, 106967. [Google Scholar] [CrossRef]

- Yan, B.; Wang, Z.; Ma, H.; Bao, H.; Wang, K.; Wu, C. A novel lever-type vibration isolator with eddy current damping. J. Sound Vib. 2021, 494, 115862. [Google Scholar] [CrossRef]

- Hur, D.-J.; Hong, S.-C. Analysis of an Isolation System with Vertical Spring-viscous Dampers in Horizontal and Vertical Ground Motion. Appl. Sci. 2020, 10, 1411. [Google Scholar] [CrossRef]

- Dai, H.; Jing, X.; Wang, Y.; Yue, X.; Yuan, J. Post-capture vibration suppression of spacecraft via a bio-inspired isolation system. Mech. Syst. Signal Process. 2018, 105, 214–240. [Google Scholar] [CrossRef]

- Jing, X.; Zhang, L.; Feng, X.; Sun, B.; Li, Q. A novel bio-inspired anti-vibration structure for operating hand-held jackhammers. Mech. Syst. Signal Process. 2019, 118, 317–339. [Google Scholar] [CrossRef]

- Wang, Y.; Jing, X.; Guo, Y. Nonlinear analysis of a bio-inspired vertically asymmetric isolation system under different structural constraints. Nonlinear Dyn. 2019, 95, 445–464. [Google Scholar] [CrossRef]

- Bian, J.; Jing, X. Superior nonlinear passive damping characteristics of the bio-inspired limb-like or X-shaped structure. Mech. Syst. Signal Process. 2019, 125, 21–51. [Google Scholar] [CrossRef]

- Dai, H.; Jing, X.; Sun, C.; Wang, Y.; Yue, X. Accurate modeling and analysis of a bio-inspired isolation system: With application to on-orbit capture. Mech. Syst. Signal Process. 2018, 109, 111–133. [Google Scholar] [CrossRef]

- Dai, H.; Cao, X.; Jing, X.; Wang, X.; Yue, X. Bio-inspired anti-impact manipulator for capturing non-cooperative spacecraft: Theory and experiment. Mech. Syst. Signal Process. 2020, 142, 106785. [Google Scholar] [CrossRef]

- Wang, Y.; Jing, X. Nonlinear stiffness and dynamical response characteristics of an asymmetric X-shaped structure. Mech. Syst. Signal Process. 2019, 125, 142–169. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, J.; Yin, H.; Zhang, B.; Jing, X. Bio-inspired structure reference model oriented robust full vehicle active suspension system control via constraint-following. Mech. Syst. Signal Process. 2022, 179, 109368. [Google Scholar] [CrossRef]

- Chai, Y.; Jing, X. Low-frequency multi-direction vibration isolation via a new arrangement of the X-shaped linkage mechanism. Nonlinear Dyn. 2022, 109, 2383–2421. [Google Scholar] [CrossRef]

- Yan, G.; Wang, S.; Zou, H.; Zhao, L.; Gao, Q.; Zhang, W. Bio-inspired polygonal skeleton structure for vibration isolation: Design, modelling, and experiment. Sci. China Technol. Sci. 2020, 63, 2617–2630. [Google Scholar] [CrossRef]

- Gatti, G. A K-shaped spring configuration to boost elastic potential energy. Smart Mater. Struct. 2019, 28, 077002. [Google Scholar] [CrossRef]

- Zhao, Y.; Meng, G. A bio-inspired semi-active vibration isolator with variable-stiffness dielectric elastomer: Design and modeling. J. Sound Vib. 2020, 485, 115592. [Google Scholar] [CrossRef]

- Shi, X.; Chen, T.; Zhang, J.; Su, B.; Cong, Q.; Tian, W. A Review of Bioinspired Vibration Control Technology. Appl. Sci. 2021, 11, 10584. [Google Scholar] [CrossRef]

- Chen, S.; Xuan, M.; Xin, J.; Liu, Y.; Gu, S.; Li, J.; Zhang, L. Design and experiment of dual micro-vibration isolation system for optical satellite flywheel. Int. J. Mech. Sci. 2020, 179, 105592. [Google Scholar] [CrossRef]

- Yang, T.; Cao, Q. Modeling and analysis of a novel multi-directional micro-vibration isolator with spring suspension struts. Arch. Appl. Mech. 2022, 92, 801–819. [Google Scholar] [CrossRef]

- Li, L.; Tan, L.; Kong, L.; Wang, D.; Yang, H. The influence of flywheel micro vibration on space camera and vibration suppression. Mech. Syst. Signal Process. 2018, 100, 360–370. [Google Scholar] [CrossRef]

- Wang, X.; Wu, H.; Yang, B. Micro-vibration suppressing using electromagnetic absorber and magnetostrictive isolator combined platform. Mech. Syst. Signal Process. 2020, 139, 106606. [Google Scholar] [CrossRef]

- Hadroug, N.; Hafaifa, A.; Alili, B.; Iratni, A.; Chen, X. Fuzzy Diagnostic Strategy Implementation for Gas Turbine Vibrations Faults Detection: Towards a Characterization of Symptom–fault Correlations. J. Vib. Eng. Technol. 2022, 10, 225–251. [Google Scholar] [CrossRef]

- Qian, Y.; Xie, Y.; Jia, J.; Zhang, L. Development of Active Microvibration Isolation System for Precision Space Payload. Appl. Sci. 2022, 12, 4548. [Google Scholar] [CrossRef]

- Lei, Y.J.; Li, R.J.; Zhang, L.S.; Hu, P.H.; Huang, Q.X. Optical Accelerometers for Detecting Low-Frequency Micro-Vibrations. Appl. Sci. 2022, 12, 3994. [Google Scholar] [CrossRef]

- Wang, Y.; Li, H.X.; Cheng, C.; Ding, H.; Chen, L.Q. A nonlinear stiffness and nonlinear inertial vibration isolator. J. Vib. Control 2020, 27, 1336–1352. [Google Scholar] [CrossRef]

- Yan, B.; Yu, N.; Wu, C. A state-of-the-art review on low-frequency nonlinear vibration isolation with electromagnetic mechanisms. Appl. Math. Mech. 2022, 43, 1045–1062. [Google Scholar] [CrossRef]

- Zhang, F.; Xu, M.; Shao, S.; Xie, S. A new high-static-low-dynamic stiffness vibration isolator based on magnetic negative stiffness mechanism employing variable reluctance stress. J. Sound Vib. 2020, 476, 115322. [Google Scholar] [CrossRef]

- Mofidian, S.M.M.; Bardaweel, H. A dual-purpose vibration isolator energy harvester: Experiment and model. Mech. Syst. Signal Process. 2019, 118, 360–376. [Google Scholar] [CrossRef]

- Yun, H.; Liu, L.; Li, Q.; Yang, H. Investigation on two-stage vibration suppression and precision pointing for space optical payloads. Aerosp. Sci. Technol. 2020, 96, 105543. [Google Scholar] [CrossRef]

- Lu, Z.; Brennan, M.; Ding, H.; Chen, L. High-static-low-dynamic-stiffness vibration isolation enhanced by damping nonlinearity. Sci. China Technol. Sci. 2019, 62, 1103–1110. [Google Scholar] [CrossRef]

- Yang, T.; Wu, L.; Li, X.; Zhu, M.; Brennan, M.J.; Liu, Z. Active Vibration Isolation of a Diesel Generator in a Small Marine Vessel: An Experimental Study. Appl. Sci. 2020, 10, 3025. [Google Scholar] [CrossRef]

- Qin, C.; Xu, Z.; Xia, M.; He, S.; Zhang, J. Design and optimization of the micro-vibration isolation system for large space telescope. J. Sound Vib. 2020, 482, 115461. [Google Scholar] [CrossRef]

- Wang, Z.; Tian, D.; Shi, L.; Liu, J. Multi-Body Dynamics Modeling and Control for Strapdown Inertially Stabilized Platforms Considering Light Base Support Characteristics. Appl. Sci. 2020, 10, 7175. [Google Scholar] [CrossRef]

- Lei, X.; Wu, C.; Wu, H. A novel composite vibration control method using double-decked floating raft isolation system and particle damper. J. Vib. Control 2018, 24, 4407–4418. [Google Scholar] [CrossRef]

- Feng, X.; Chen, H.; Wu, G.; Zhang, A.; Zhao, Z. A New Vibration Controller Design Method Using Reinforcement Learning and FIR Filters: A Numerical and Experimental Study. Appl. Sci. 2022, 12, 9869. [Google Scholar] [CrossRef]

| Parameters | Description | Values |

|---|---|---|

| Control object mass | ||

| Stiffness of the linear isolator | ||

| Damping of the linear isolator | ||

| Intermediate mass | ||

| Damping of the bio-inspired isolator |

| Initial Phase of the Base Excitation | |||||

|---|---|---|---|---|---|

| 0.4 | 5000 | 0.10 | 0.10 | ||

| 0.4 | 5000 | 0.20 | 0.10 | ||

| 0.4 | 5000 | 0.21 | 0.21 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Z.; Shi, X.; Mu, D.; Huang, X.; Tong, W. Performance and Optimization of a Dual-Stage Vibration Isolation System Using Bio-Inspired Vibration Isolators. Appl. Sci. 2022, 12, 11387. https://doi.org/10.3390/app122211387

Huang Z, Shi X, Mu D, Huang X, Tong W. Performance and Optimization of a Dual-Stage Vibration Isolation System Using Bio-Inspired Vibration Isolators. Applied Sciences. 2022; 12(22):11387. https://doi.org/10.3390/app122211387

Chicago/Turabian StyleHuang, Zhou, Xianjie Shi, Dong Mu, Xin Huang, and Weihao Tong. 2022. "Performance and Optimization of a Dual-Stage Vibration Isolation System Using Bio-Inspired Vibration Isolators" Applied Sciences 12, no. 22: 11387. https://doi.org/10.3390/app122211387

APA StyleHuang, Z., Shi, X., Mu, D., Huang, X., & Tong, W. (2022). Performance and Optimization of a Dual-Stage Vibration Isolation System Using Bio-Inspired Vibration Isolators. Applied Sciences, 12(22), 11387. https://doi.org/10.3390/app122211387