Study of Behaviour of Short Concrete Columns Confined with PVC Tube under Uniaxial Load

Abstract

1. Introduction

2. Experimental Programs

2.1. Specimens Preparation

| D/mm | H/mm | t/mm |

|---|---|---|

| 110 | 330 | 10 |

| 160 | 480 | 10 |

| 220 | 660 | 10 |

| 250 | 750 | 10 |

2.2. Material Properties

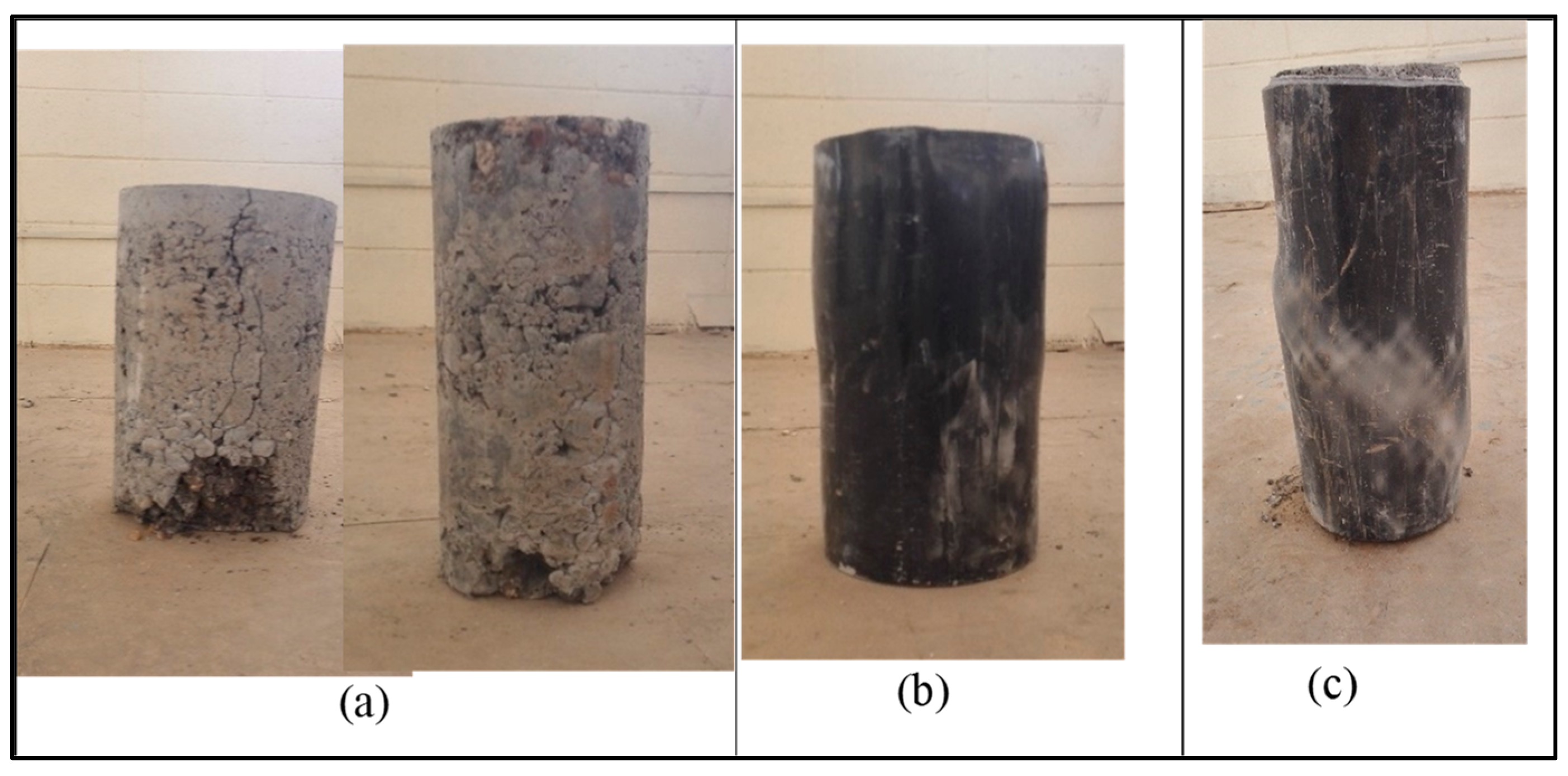

2.3. Specimens

3. Experimental Results

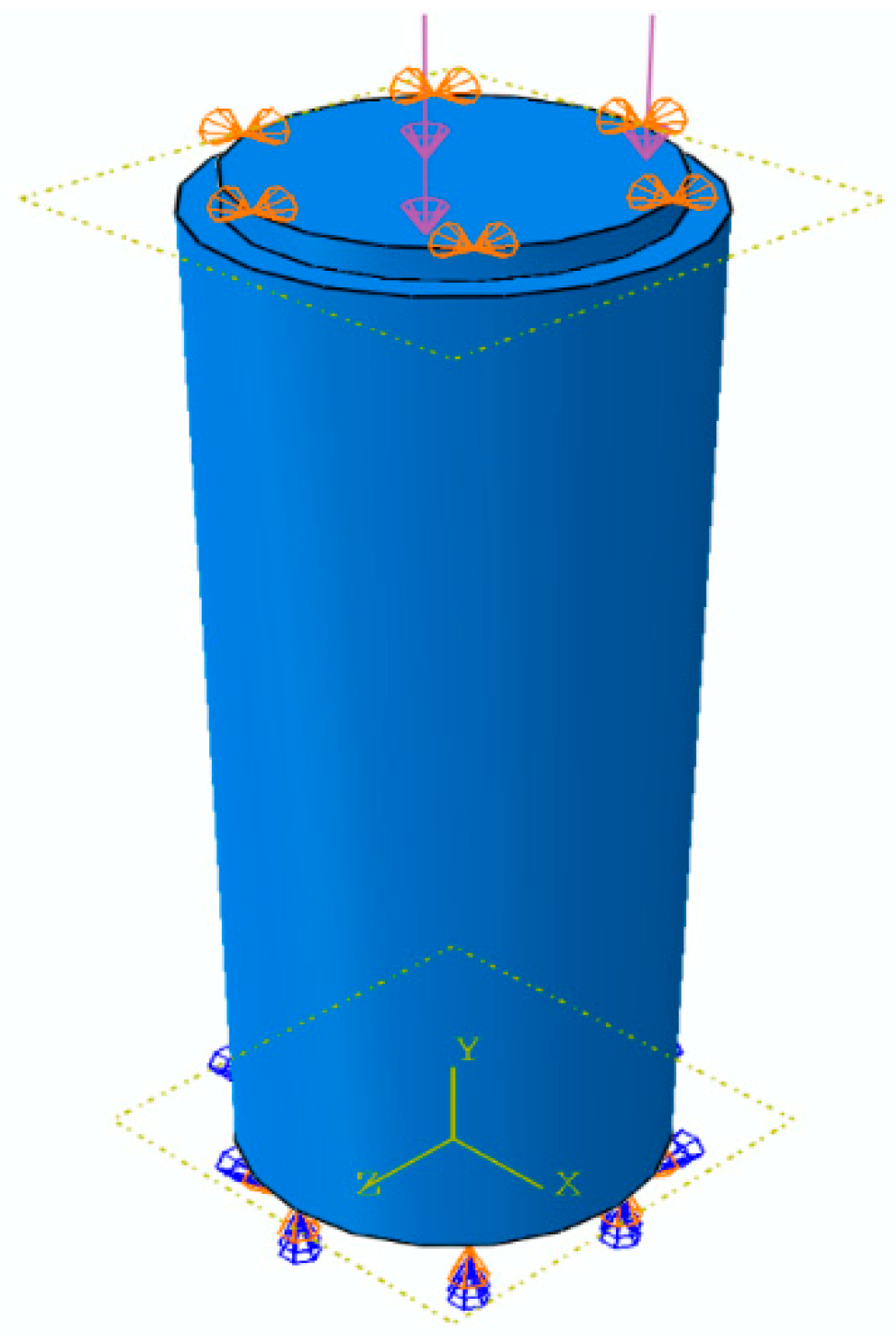

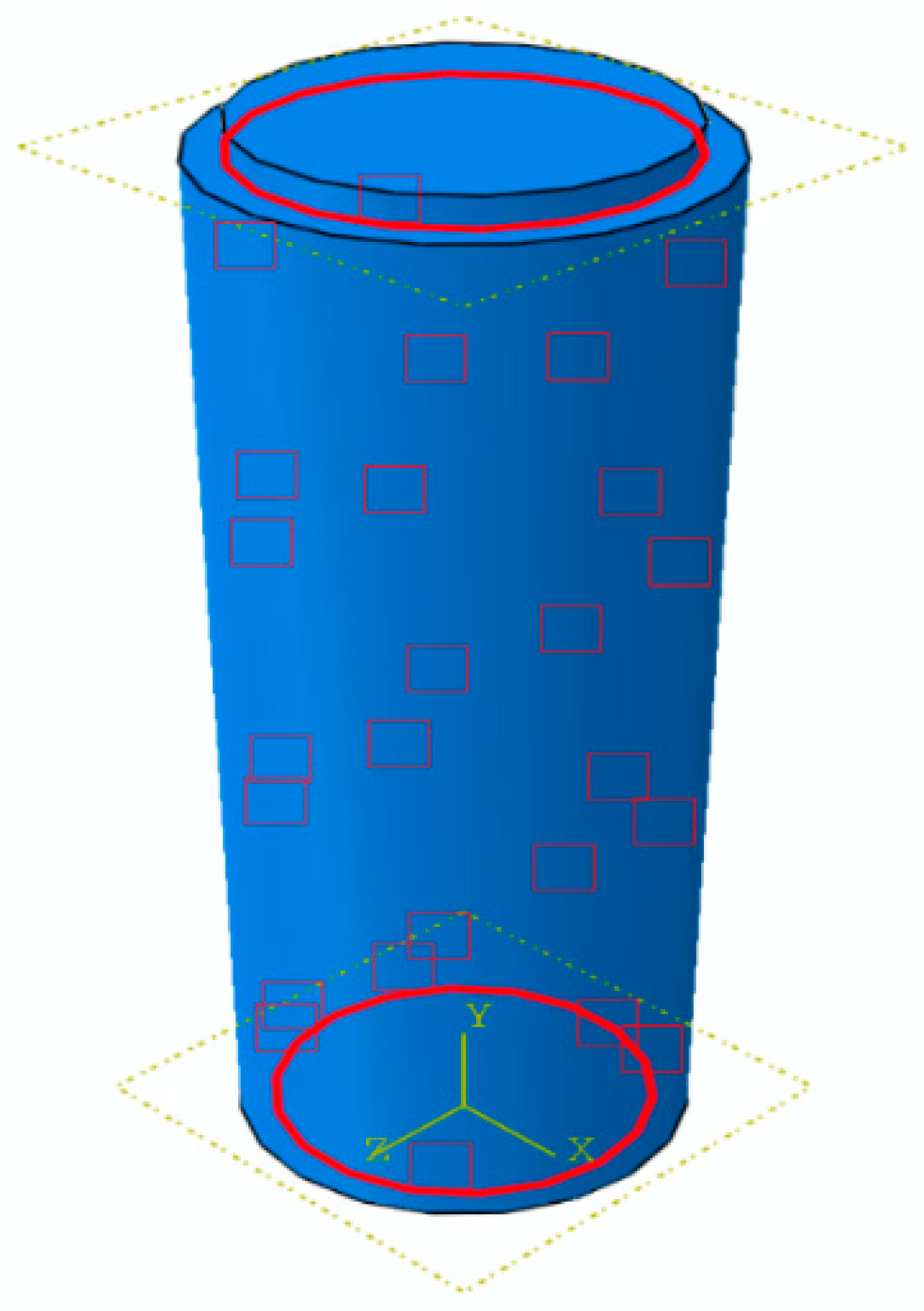

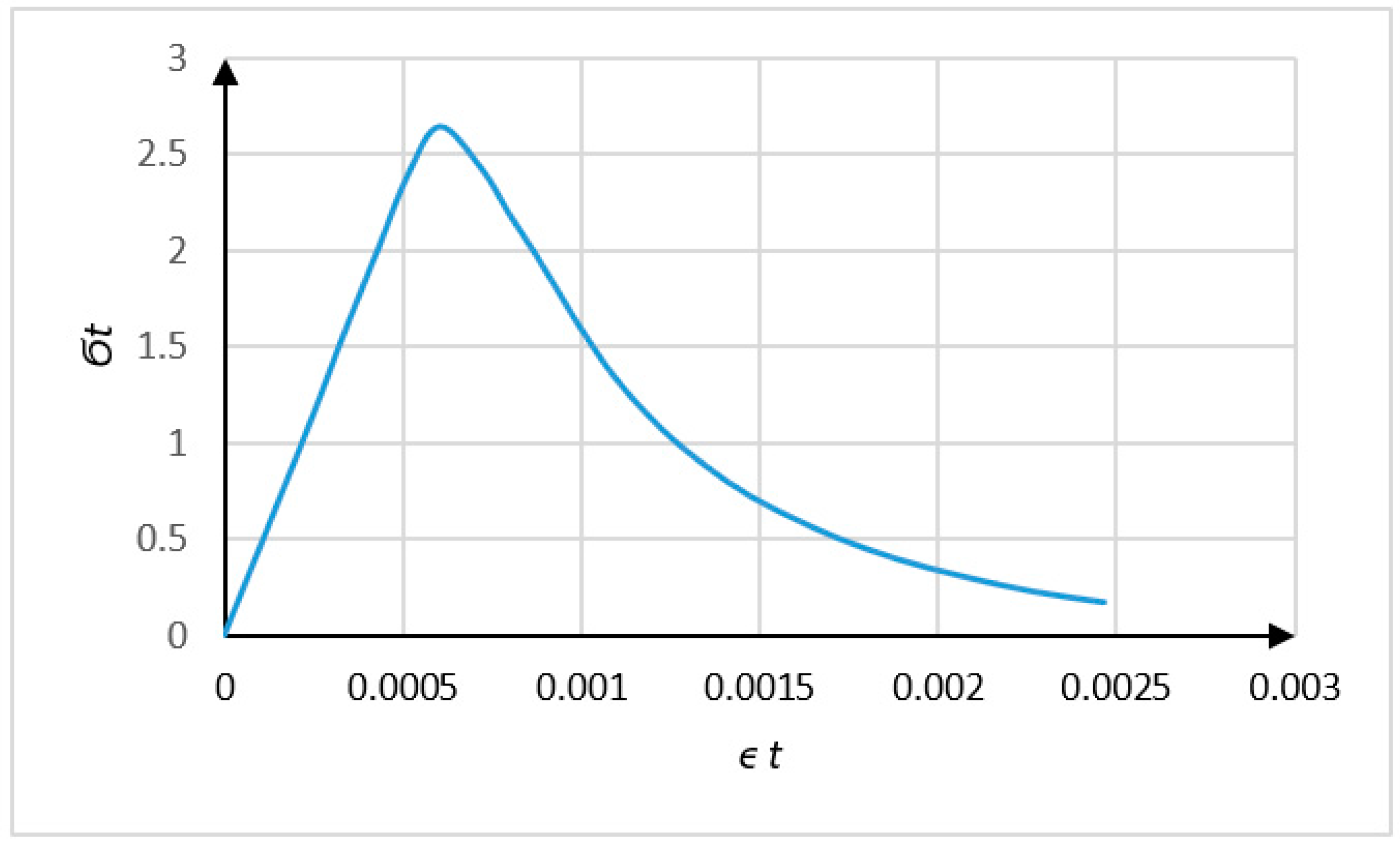

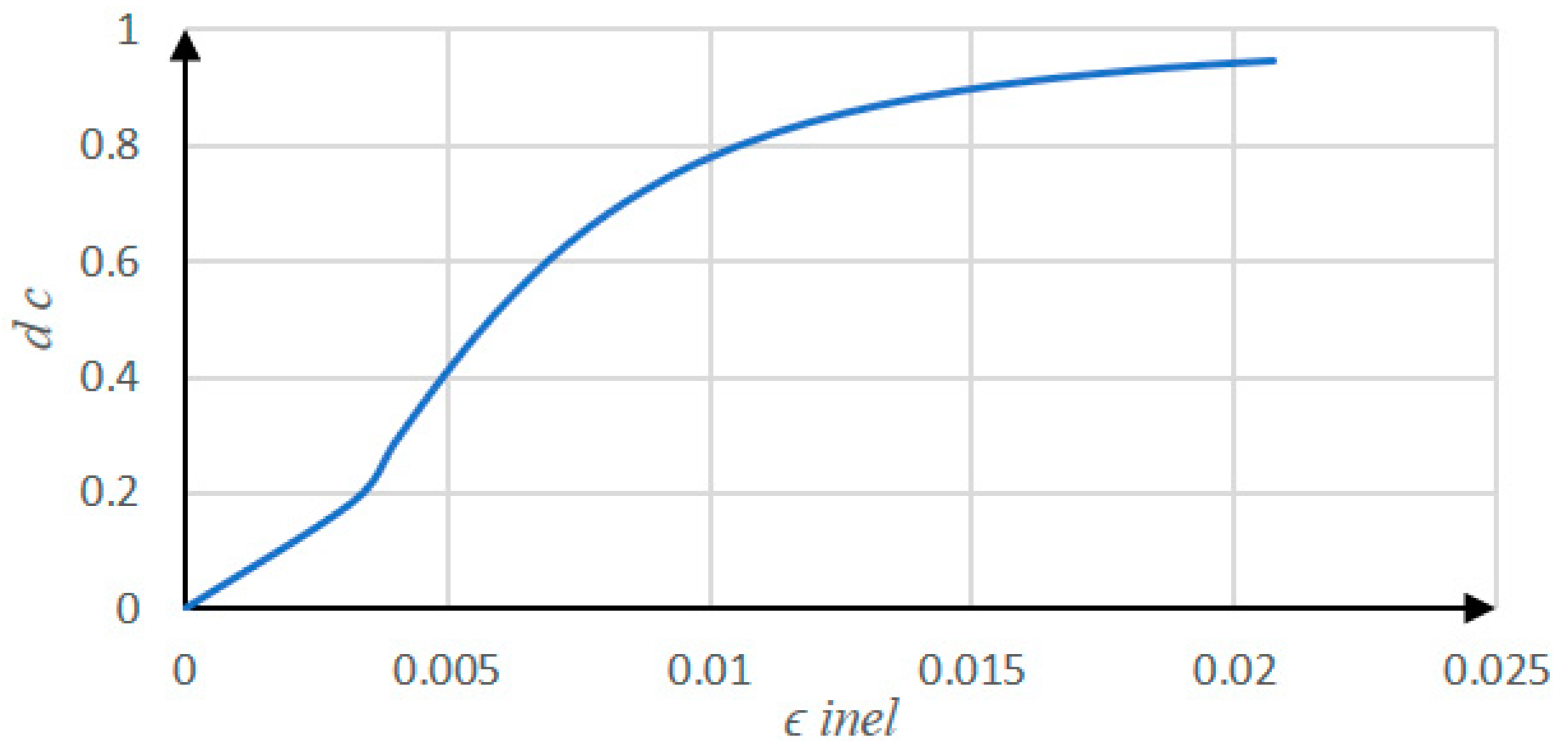

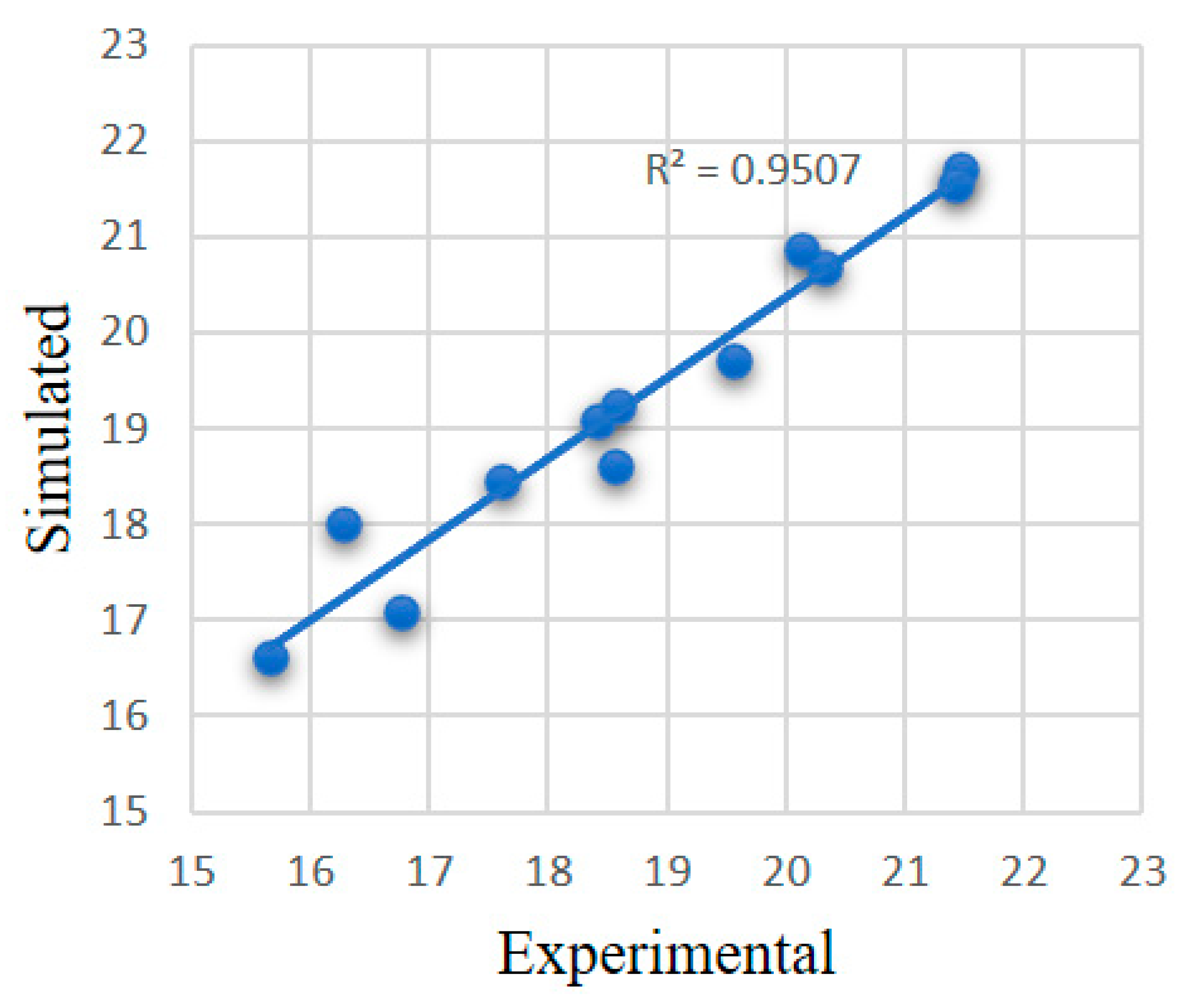

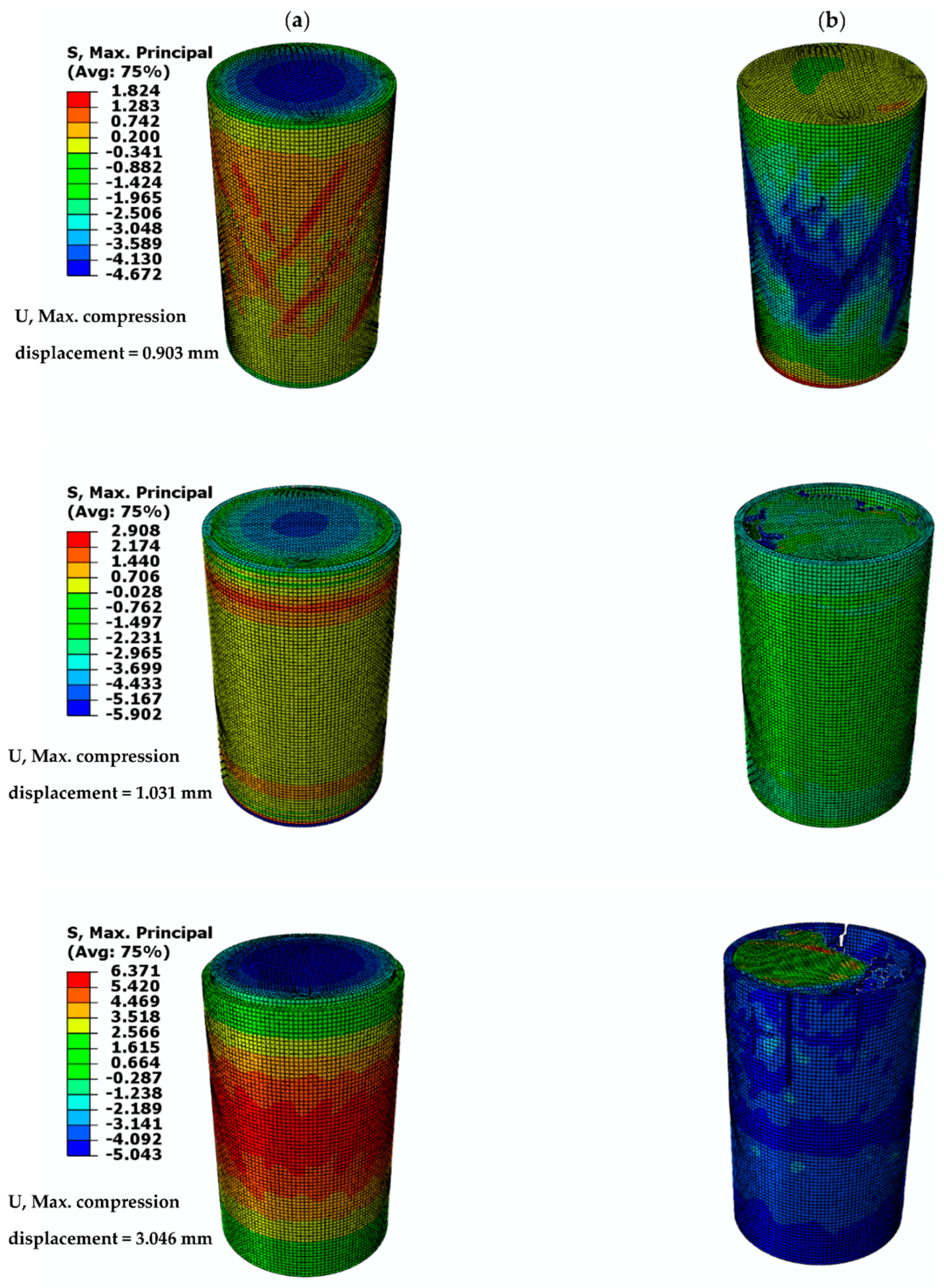

4. Numerical Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, L.; Yang, Z.; Cui, Y.; Wei, B.; Xu, S.; Sheng, J.; Wang, M.; Zhu, Y.; Fei, W. Graphene-copper composite with micro-layered grains and ultrahigh strength. Sci. Rep. 2017, 7, 41896. [Google Scholar] [CrossRef] [PubMed]

- Bazli, M.; Zhao, X.-L.; Raman, R.K.S.; Bai, Y.; Al-Saadi, S. Bond performance between FRP tubes and seawater sea sand concrete after exposure to seawater condition. Constr. Build. Mater. 2020, 265, 120342. [Google Scholar] [CrossRef]

- Yuan, W.; Yang, J. Experimental and numerical studies of short concrete-filled double skin composite tube columns under axially compressive loads. J. Constr. Steel Res. 2013, 80, 23–31. [Google Scholar] [CrossRef]

- Schneider, S.P. Axially loaded concrete-filled steel tubes. J. Struct. Eng. 1998, 124, 1125–1138. [Google Scholar] [CrossRef]

- Al-Gemeel, A.N.; Zhuge, Y. Using textile reinforced engineered cementitious composite for concrete columns confinement. Compos. Struct. 2019, 210, 695–706. [Google Scholar] [CrossRef]

- Shan, B.; Gui, F.C.; Monti, G.; Xiao, Y. Effectiveness of CFRP confinement and compressive strength of square concrete columns. J. Compos. Constr. 2019, 23, 4019043. [Google Scholar] [CrossRef]

- Faleschini, F.; Zanini, M.A.; Hofer, L.; Toska, K.; De Domenico, D.; Pellegrino, C. Confinement of reinforced concrete columns with glass fiber reinforced cementitious matrix jackets. Eng. Struct. 2020, 218, 110847. [Google Scholar] [CrossRef]

- Feng, C.; Yu, F.; Fang, Y. Mechanical behavior of PVC tube confined concrete and PVC-FRP confined concrete: A review. Structures 2021, 31, 613–635. [Google Scholar] [CrossRef]

- Yu, F.; Li, D.; Niu, D.; Zhu, D.; Kong, Z.; Zhang, N.; Fang, Y. A model for ultimate bearing capacity of PVC-CFRP confined concrete column with reinforced concrete beam joint under axial compression. Constr. Build. Mater. 2019, 214, 668–676. [Google Scholar] [CrossRef]

- Roeder, C.W.; Cameron, B.; Brown, C.B. Composite action in concrete filled tubes. J. Struct. Eng. 1999, 125, 477–484. [Google Scholar] [CrossRef]

- Fam, A.Z.; Rizkalla, S.H. Behavior of axially loaded concrete-filled circular fiber-reinforced polymer tubes. Struct. J. 2001, 98, 280–289. [Google Scholar]

- Mao, X.Y.; Xiao, Y. Seismic behavior of confined square CFT columns. Eng. Struct. 2006, 28, 1378–1386. [Google Scholar] [CrossRef]

- Abed, F.; AlHamaydeh, M.; Abdalla, S. Experimental and numerical investigations of the compressive behavior of concrete filled steel tubes (CFSTs). J. Constr. Steel Res. 2013, 80, 429–439. [Google Scholar] [CrossRef]

- Chen, Z.; Xu, J.; Chen, Y.; Lui, E.M. Recycling and reuse of construction and demolition waste in concrete-filled steel tubes: A review. Constr. Build. Mater. 2016, 126, 641–660. [Google Scholar] [CrossRef]

- Boumarafi, A.; Abouzied, A.; Masmoudi, R. Harsh environments effects on the axial behaviour of circular concrete-filled fibre reinforced-polymer (FRP) tubes. Compos. Part B Eng. 2015, 83, 81–87. [Google Scholar] [CrossRef]

- Fam, A.; Pando, M.; Filz, G.; Rizkalla, S. Precast piles for Route 40 bridge in Virginia using concrete filled FRP tubes. PCI J. 2003, 48, 32–45. [Google Scholar] [CrossRef]

- Zhou, A.; Qin, R.; Chow, C.L.; Lau, D. Structural performance of FRP confined seawater concrete columns under chloride environment. Compos. Struct. 2019, 216, 12–19. [Google Scholar] [CrossRef]

- Mahgub, M.; Ashour, A.; Lam, D.; Dai, X. Tests of self-compacting concrete filled elliptical steel tube columns. Thin-Walled Struct. 2017, 110, 27–34. [Google Scholar] [CrossRef]

- Naderpour, H.; Nagai, K.; Fakharian, P.; Haji, M. Innovative models for prediction of compressive strength of FRP-confined circular reinforced concrete columns using soft computing methods. Compos. Struct. 2019, 215, 69–84. [Google Scholar] [CrossRef]

- Jiang, C.; Wu, Y.-F. Axial strength of eccentrically loaded FRP-confined short concrete columns. Polymers 2020, 12, 1261. [Google Scholar] [CrossRef]

- Siddika, A.; Al Mamun, M.A.; Alyousef, R.; Amran, Y.H.M. Strengthening of reinforced concrete beams by using fiber-reinforced polymer composites: A review. J. Build. Eng. 2019, 25, 100798. [Google Scholar] [CrossRef]

- Csuka, B.; Kollár, L.P. Analysis of FRP confined columns under eccentric loading. Compos. Struct. 2012, 94, 1106–1116. [Google Scholar] [CrossRef]

- Hadi, M.N.S.; Widiarsa, I.B.R. Axial and flexural performance of square RC columns wrapped with CFRP under eccentric loading. J. Compos. Constr. 2012, 16, 640–649. [Google Scholar] [CrossRef]

- y Basalo, F.J.D.C.; Matta, F.; Nanni, A. Fiber reinforced cement-based composite system for concrete confinement. Constr. Build. Mater. 2012, 32, 55–65. [Google Scholar] [CrossRef]

- Triantafillou, T.C.; Papanicolaou, C.G.; Zissimopoulos, P.; Laourdekis, T. Concrete confinement with textile-reinforced mortar jackets. ACI Struct. J. 2006, 103, 28. [Google Scholar]

- Bournas, D.A.; Lontou, P.V.; Papanicolaou, C.G.; Triantafillou, T.C. Textile-reinforced mortar versus fiber-reinforced polymer confinement in reinforced concrete columns. ACI Struct. J. 2007, 104, 740. [Google Scholar]

- Marzouck, M.; Sennah, K. Concrete-filled PVC tubes as compression members. In Proceedings of the Composite Materials in Concrete Construction: Proceedings of the International Seminar, Scotland, UK, 5–6 September 2002; Thomas Telford Publishing: London, UK, 2002; pp. 31–37. [Google Scholar]

- Whittle, A.J.; Tennakoon, J. Predicting the residual life of PVC sewer pipes. Plast. Rubber Compos. 2005, 34, 311–317. [Google Scholar] [CrossRef]

- Boersma, A.; Breen, J. Long term performance prediction of existing PVC water distribution systems. In Proceedings of the 9th International Conference PVC, Rhodes Island, Greece, 1–3 September 2005. [Google Scholar]

- Gupta, P.K. Confinement of concrete columns with unplasticized Poly-vinyl chloride tubes. Int. J. Adv. Struct. Eng. 2013, 5, 19. [Google Scholar] [CrossRef]

- Oyawa, W.O.; Githimba, N.K.; Mang’urio, G.N. Structural response of composite concrete filled plastic tubes in compression. Steel Compos. Struct. 2016, 21, 589–604. [Google Scholar] [CrossRef]

- Askari, S.M.; Khaloo, A.; Borhani, M.H.; Masoule, M.S.T. Performance of polypropylene fiber reinforced concrete-filled UPVC tube columns under axial compression. Constr. Build. Mater. 2020, 231, 117049. [Google Scholar] [CrossRef]

- ASTM D1785-06; Standard Specification for Polyvinyl Chloride (PVC) Plastic Pipe, Schedules 40, 80, and 120. ASTM International: West Conshohocken, PA, USA, 2006.

- Carreira, D.J.; Chu, K.-H. Stress-strain relationship for plain concrete in compression. J. Proc. 1985, 82, 797–804. [Google Scholar]

- Chaudhari, S.V.; Chakrabarti, M.A. Modeling of concrete for nonlinear analysis using finite element code ABAQUS. Int. J. Comput. Appl. 2012, 44, 14–18. [Google Scholar]

| Type of Test | Property | Iraqi Specification Limit IQS5/1984 |

|---|---|---|

| Initial setting time (minutes) | 149 min | Not less than 45 min |

| Final setting time (minutes) | 245 min | Not more than 600 min |

| Fineness (cm2/gm) by Blain | 2600 | Not less than 2500 |

| Compressive strength at 3 days | 16 MPa | Not less than 15 (MPa) |

| Compressive strength at 7 days | 28 MPa | Not less than 23 (MPa) |

| Properties/Diameter (mm) | 0.15 | 0.3 | 0.6 | 1.18 | 2.36 | 4.75 | 10 |

|---|---|---|---|---|---|---|---|

| Used sand (passing %) | 2 | 18 | 59 | 72 | 86 | 91 | 100 |

| Upper limits (passing %) | 10 | 30 | 59 | 90 | 100 | 100 | 100 |

| Lower limits (passing %) | 0 | 8 | 35 | 55 | 75 | 90 | 100 |

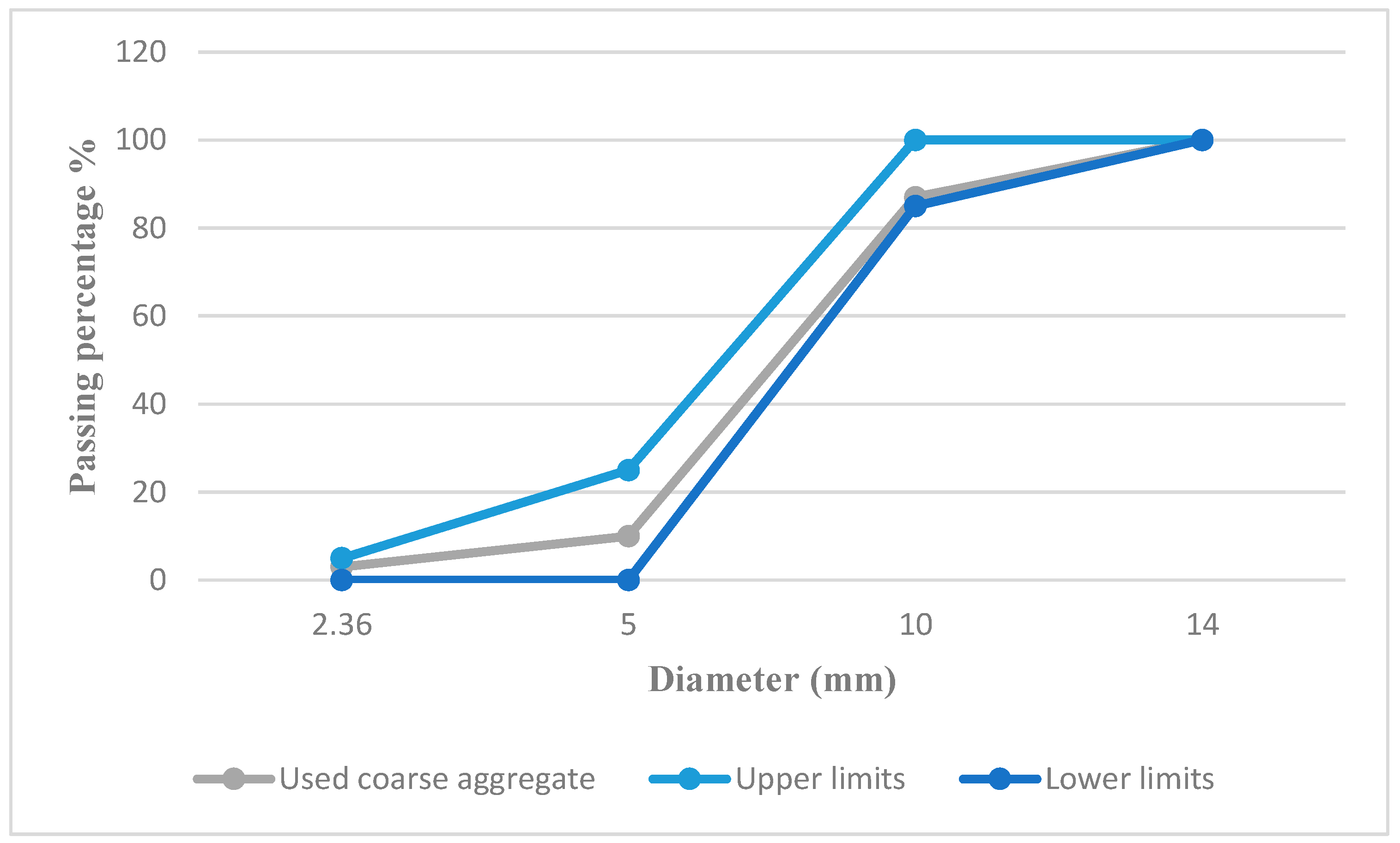

| Properties/Diameter (mm) | 2.36 | 5 | 10 | 14 |

|---|---|---|---|---|

| Used coarse aggregate (passing %) | 3 | 10 | 87 | 100 |

| Upper limits (passing %) | 5 | 25 | 100 | 100 |

| Lower limits (passing %) | 0 | 0 | 85 | 100 |

| Properties | Values |

|---|---|

| Density | 1.35 × 10−5 N/mm3 |

| Young Modulus | 3000 N/mm2 |

| Poisson’s ratio | 0.4 |

| Hydrostatic cutoff stress | 4.62 |

| Sample’s Radius (mm) | Unconfined Sample (Cu) | Fully Confined Sample (Cc) | Confined with End Cutting Sample (CCC) | |||

|---|---|---|---|---|---|---|

| 7 Days | 28 Days | 7 Days | 28 Days | 7 Days | 28 Days | |

| 110 | 3 | 3 | 3 | 3 | 3 | 3 |

| 160 | 3 | 3 | 3 | 3 | 3 | 3 |

| 220 | 3 | 3 | 3 | 3 | 3 | 3 |

| 250 | 3 | 3 | 3 | 3 | 3 | 3 |

| Sample’s Radius (mm) | Strength of Cu (MPa) | Strength of Cc (MPa) | Strength of Ccc (MPa) |

|---|---|---|---|

| 110 | 10.8 | 11.7 | 12.41 |

| 160 | 11.1 | 12 | 12.5 |

| 220 | 12.09 | 12.81 | 13.56 |

| 250 | 13.44 | 14.11 | 14 |

| Sample’s Radius (mm) | Improvement Using Cc % | Improvement Using Ccc% |

|---|---|---|

| 110 | 8.3 | 15 |

| 160 | 8.1 | 12.61 |

| 220 | 6 | 12.16 |

| 250 | 5 | 4.16 |

| Sample’s Radius (mm) | Strength of Cu (MPa) | Strength of Cc (MPa) | Strength of Ccc (MPa) |

|---|---|---|---|

| 110 | 16.62 | 18 | 19.09 |

| 160 | 17.08 | 18.46 | 19.23 |

| 220 | 18.60 | 19.71 | 20.86 |

| 250 | 20.68 | 21.71 | 21.54 |

| Sample’s Radius (mm) | Improvement Using Cc % | Improvement Using Ccc |

|---|---|---|

| 110 | 8.3 | 14.9 |

| 160 | 8.1 | 12.6 |

| 220 | 6.0 | 12.2 |

| 250 | 5.0 | 4.2 |

| Sample’s Radius (mm) | Strength of Cu (MPa) | Strength of Cc (MPa) | Strength of Ccc (MPa) |

|---|---|---|---|

| 110 | 15.66 | 16.27 | 18.42 |

| 160 | 16.77 | 17.61 | 18.58 |

| 220 | 18.57 | 19.56 | 20.14 |

| 250 | 20.33 | 21.47 | 21.42 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hammadi, A.A.; Khaleel, F.; Afan, H.A.; Khan, M.M.H.; Sulaibi, A.A.H. Study of Behaviour of Short Concrete Columns Confined with PVC Tube under Uniaxial Load. Appl. Sci. 2022, 12, 11427. https://doi.org/10.3390/app122211427

Hammadi AA, Khaleel F, Afan HA, Khan MMH, Sulaibi AAH. Study of Behaviour of Short Concrete Columns Confined with PVC Tube under Uniaxial Load. Applied Sciences. 2022; 12(22):11427. https://doi.org/10.3390/app122211427

Chicago/Turabian StyleHammadi, Ammar A., Faidhalrahman Khaleel, Haitham Abdulmohsin Afan, Md Munir Hayet Khan, and Ayad Abdul Hammed Sulaibi. 2022. "Study of Behaviour of Short Concrete Columns Confined with PVC Tube under Uniaxial Load" Applied Sciences 12, no. 22: 11427. https://doi.org/10.3390/app122211427

APA StyleHammadi, A. A., Khaleel, F., Afan, H. A., Khan, M. M. H., & Sulaibi, A. A. H. (2022). Study of Behaviour of Short Concrete Columns Confined with PVC Tube under Uniaxial Load. Applied Sciences, 12(22), 11427. https://doi.org/10.3390/app122211427