Probabilistic Model of Drying Process of Leek

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mathematical Modelling of Drying Process

3. Results and Discussion

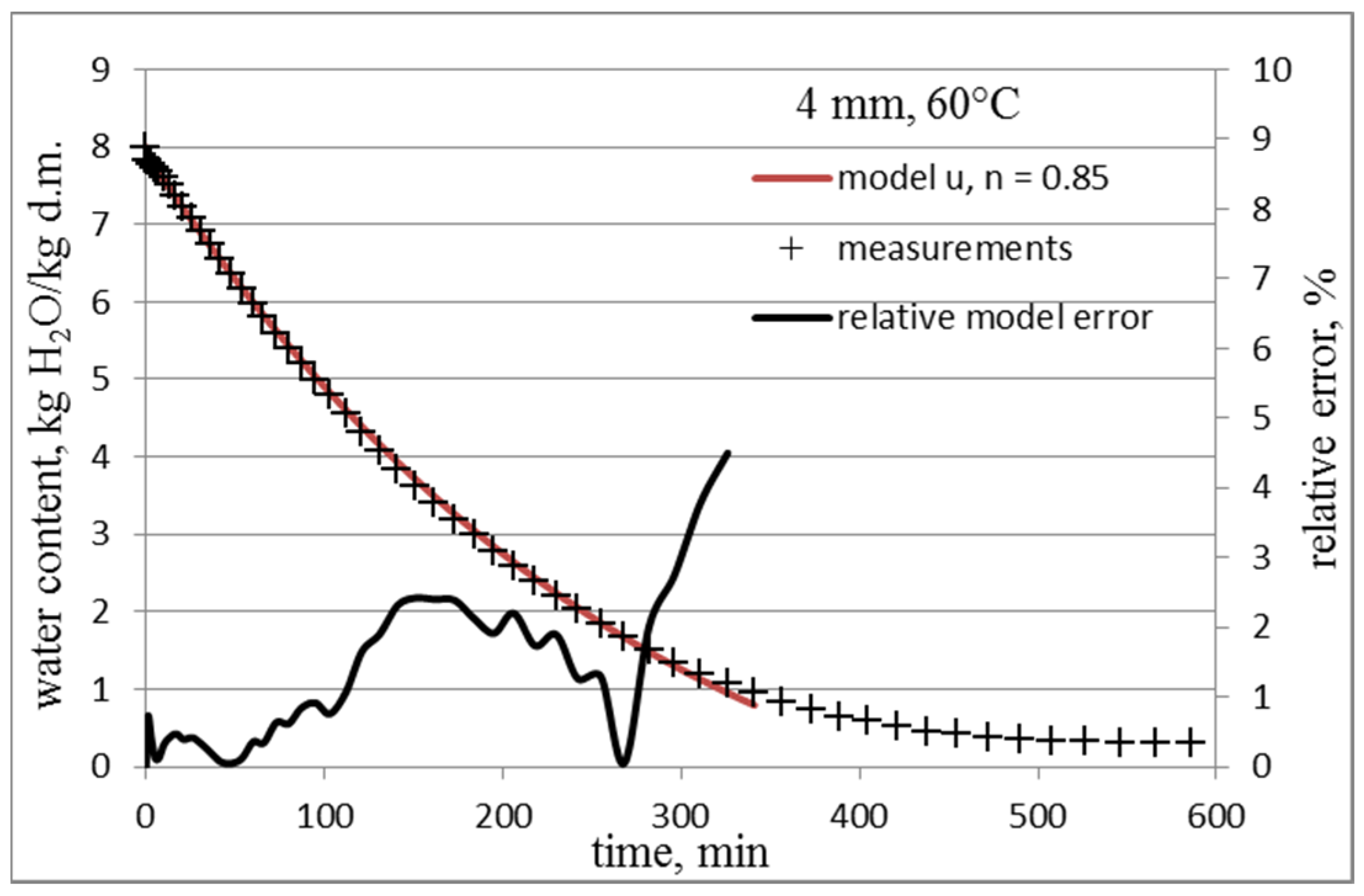

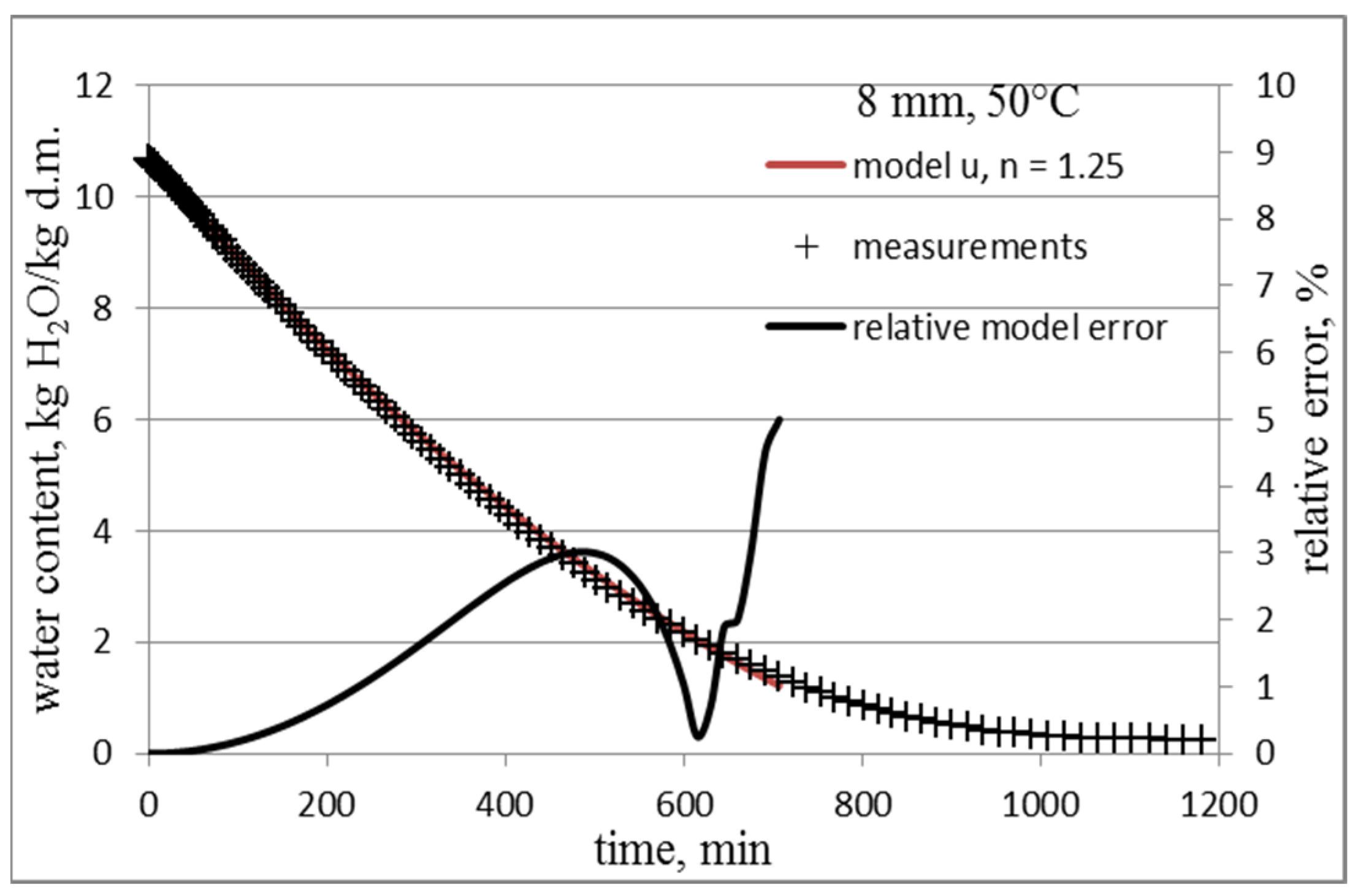

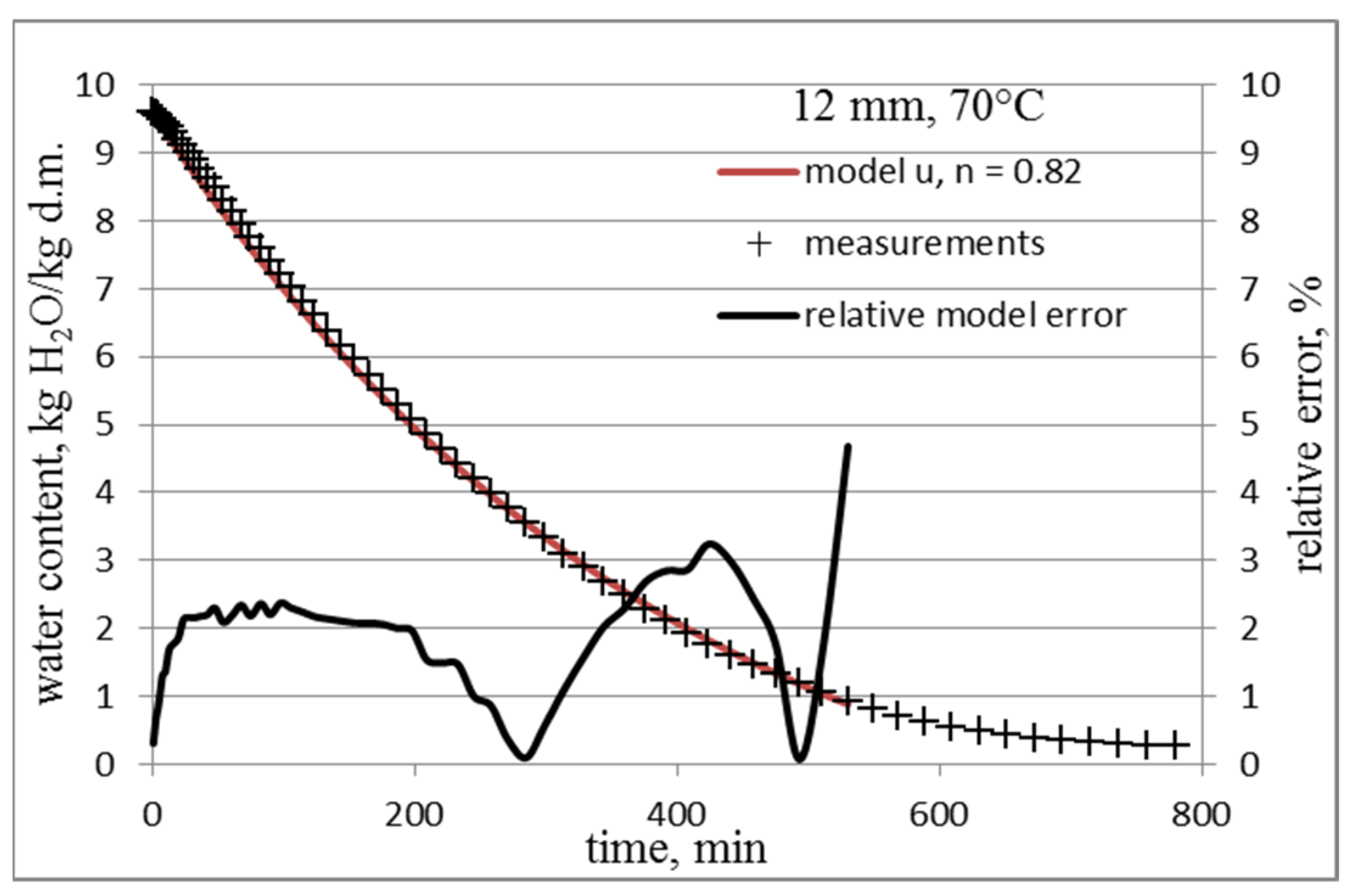

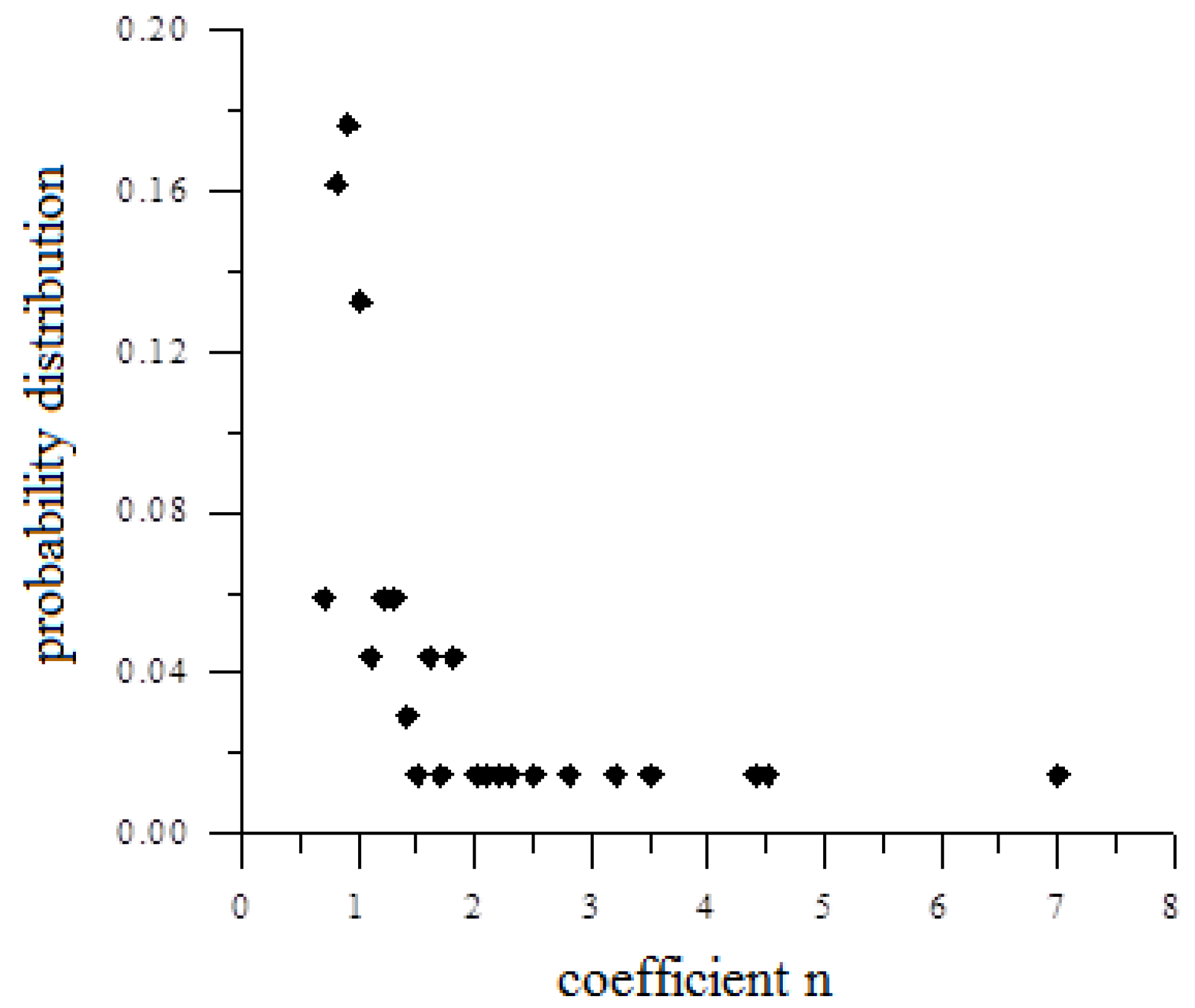

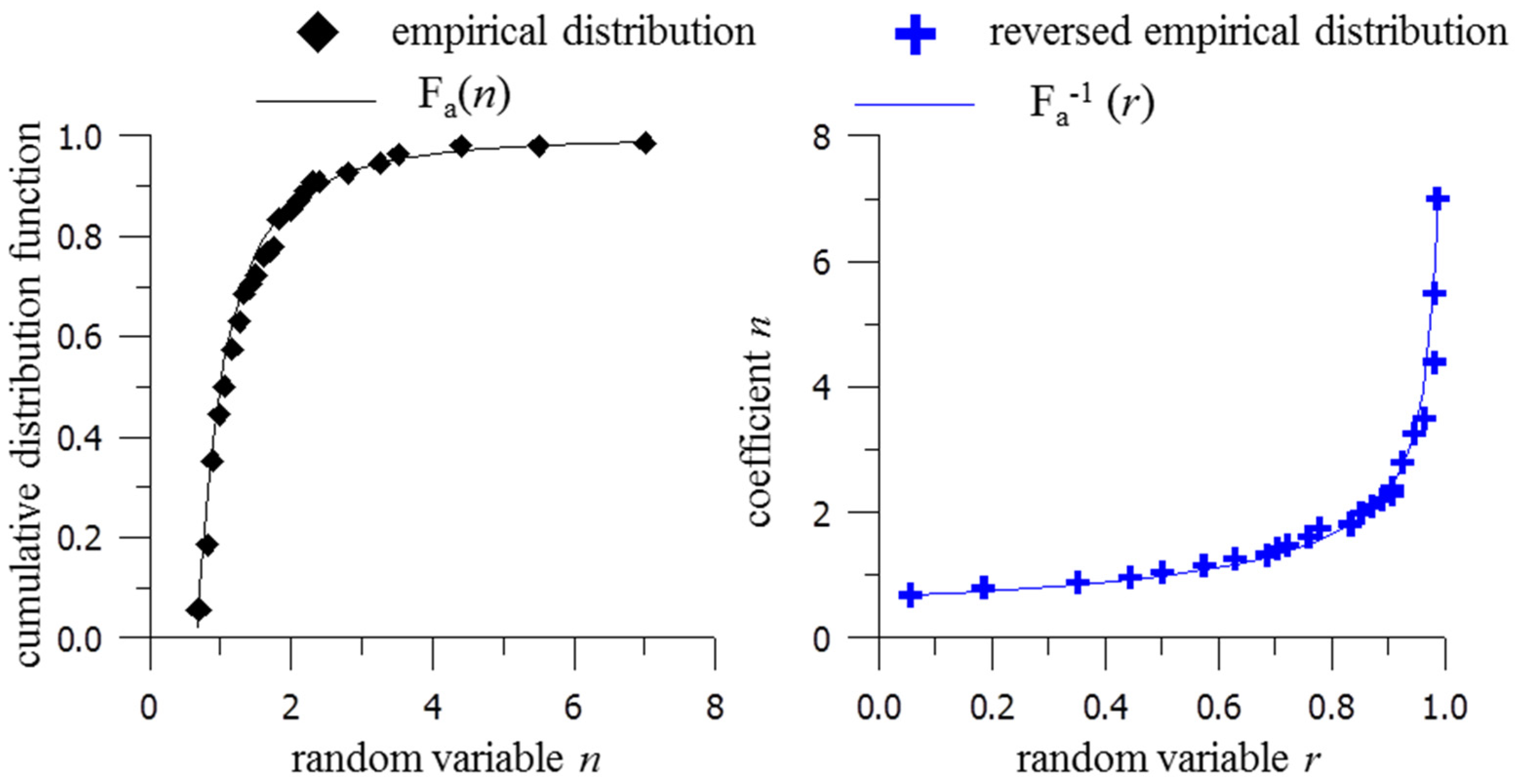

3.1. Determining the Value of the n Coefficient of the Model

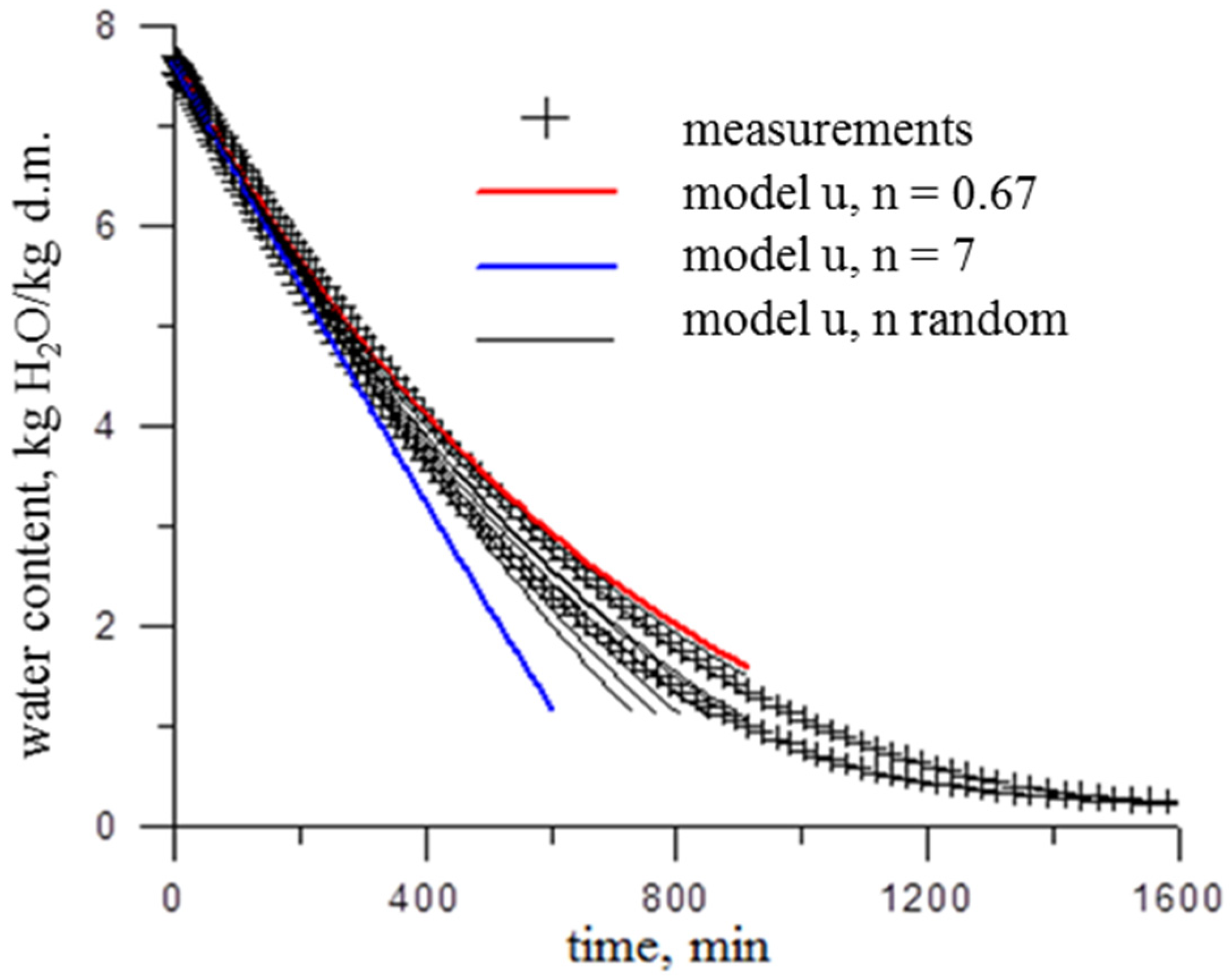

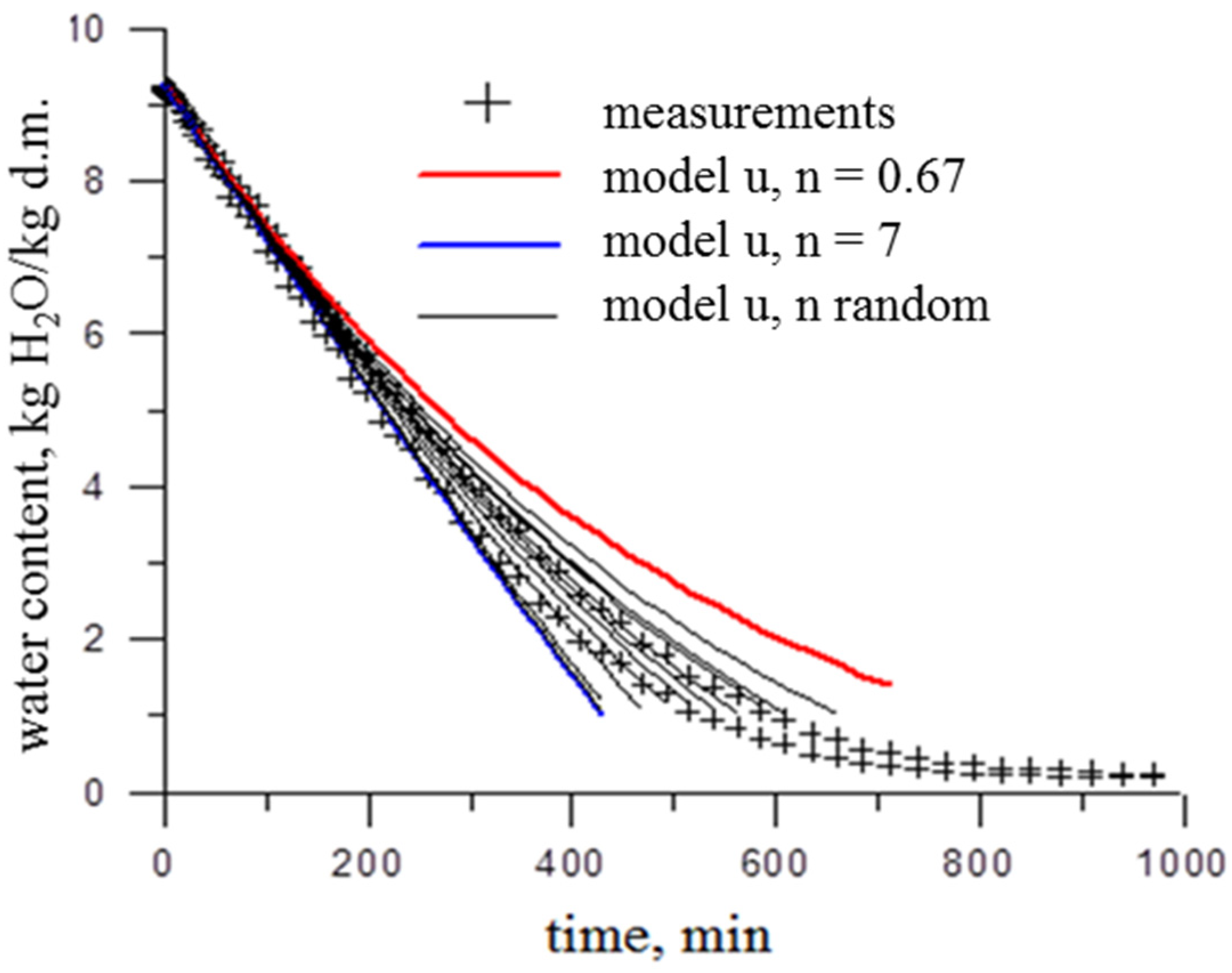

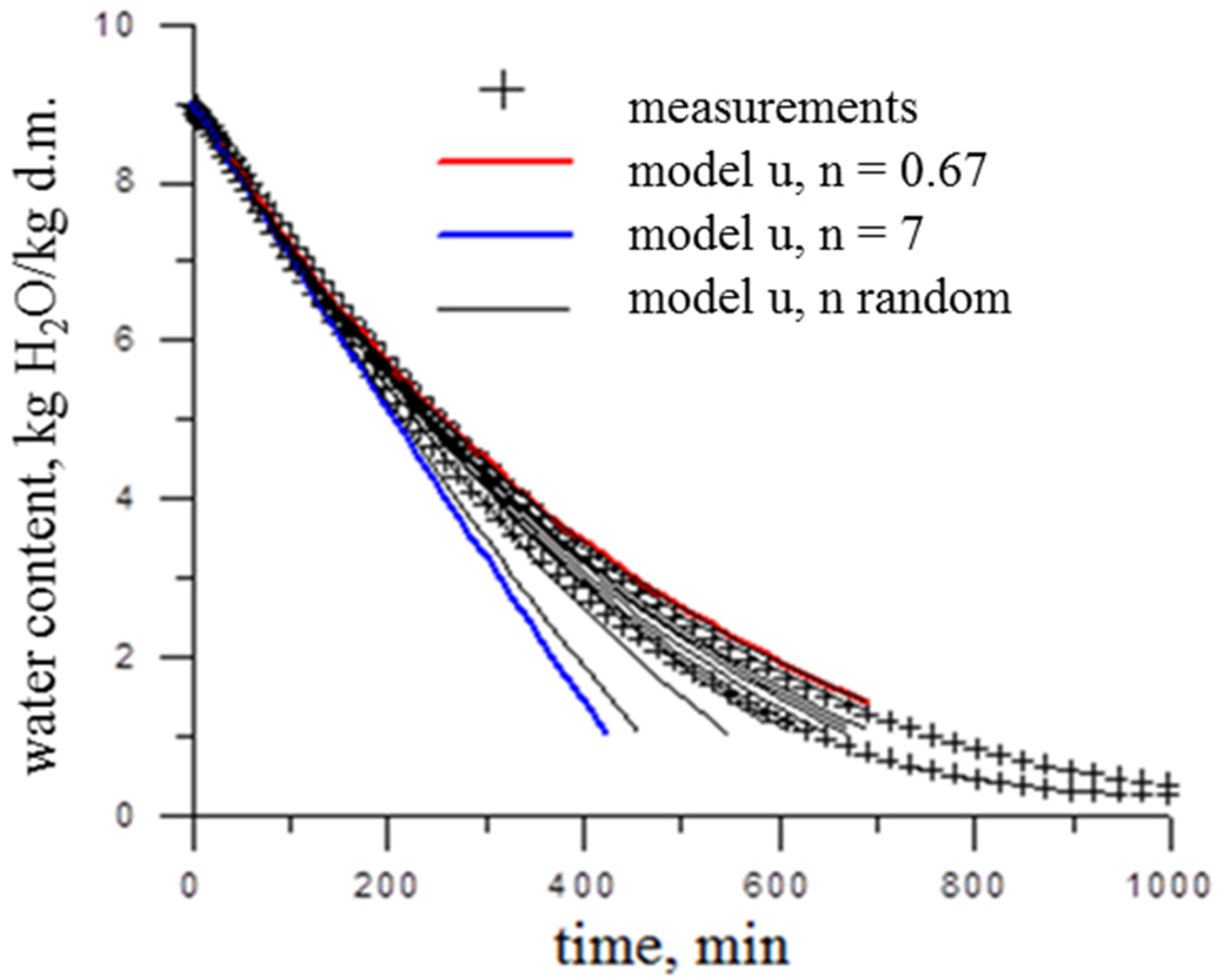

3.2. Models of Water Content Changes with Random Coefficient

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mahapatra, A.; Tripathy, P.P. Modeling and simulation of moisture transfer during solar drying of carrot slices. J. Food Process Eng. 2018, 41, e12909. [Google Scholar] [CrossRef]

- Savas, E. The Modelling of Convective Drying Variables’ Effects on the Functional Properties of Sliced Sweet Potatoes. Foods 2022, 11, 741. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Liu, H.; Liu, H.; Zhang, X.; Hong, Q.; Chen, W.; Zeng, X. Microwave Drying Characteristics and Drying Quality Analysis of Corn in China. Processes 2021, 9, 1511. [Google Scholar] [CrossRef]

- Sánchez-Sáenz, C.M.; de Oliveira, R.A.; Park, K.J. HTST Pre-drying influence on vacuum drying kinetics and carrot slices quality parameters evaluation: Vacuum drying kinetics for carrot slices. J. Food Process. Preserv. 2015, 39, 1636–1646. [Google Scholar] [CrossRef]

- Abbaspour-Gilandeh, Y.; Kaveh, M.; Fatemi, H.; Khalife, E.; Witrowa-Rajchert, D.; Nowacka, M. Effect of Pretreatments on Convective and Infrared Drying Kinetics, Energy Consumption and Quality of Terebinth. Appl. Sci. 2021, 11, 7672. [Google Scholar] [CrossRef]

- Zhang, M.; Chen, H.; Mujumdar, A.S.; Tang, J.; Miao, S.; Wang, Y. Recent developments in high-quality drying of vegetables, fruits, and aquatic products. Crit. Rev. Food Sci. Nutr. 2015, 57, 1239–1255. [Google Scholar] [CrossRef]

- Inyang, U.E.; Oboh, I.O.; Etuk, B.R. Kinetic Models for Drying Techniques—Food Materials. Adv. Chem. Eng. Sci. 2018, 8, 27–48. [Google Scholar] [CrossRef] [Green Version]

- Onwude, D.I.; Hashim, N.; Janius, R.B.; Nawi, N.M.; Abdan, K. Modeling the Thin-Layer Drying of Fruits and Vegetables: A Review. Compr. Rev. Food Sci. Food Saf. 2016, 15, 599–618. [Google Scholar] [CrossRef] [Green Version]

- Kowalski, S.J.; Mierzwa, D. Numerical analysis of drying kinetics for shrinkable products such as fruits and vegetables. J. Food Eng. 2013, 114, 522–529. [Google Scholar] [CrossRef]

- Curcio, S.; Aversa, M. Influence of shrinkage on convective drying of fresh vegetables: A theoretical model. J. Food Eng. 2014, 123, 36–49. [Google Scholar] [CrossRef]

- Strati, I.F.; Kostomitsopoulos, G.; Lytras, F.; Zoumpoulakis, P.; Proestos, C.; Sinanoglou, V.J. Optimization of Polyphenol Extraction from Allium ampeloprasum var. porrum through Response Surface Methodology. Foods 2018, 7, 162. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Biernacka, B.; Dziki, D.; Kozłowska, J.; Kowalska, I.; Soluch, A. Dehydrated at Different Conditions and Powdered Leek as a Concentrate of Biologically Active Substances: Antioxidant Activity and Phenolic Compound Profile. Materials 2021, 14, 6127. [Google Scholar] [CrossRef] [PubMed]

- Fernández-López, J.; Botella-Martínez, C.; Navarro-Rodríguez de Vera, C.; Sayas-Barberá, M.E.; Viuda-Martos, M.; Sánchez-Zapata, E.; Pérez-Álvarez, J.A. Vegetable Soups and Creams: Raw Materials, Processing, Health Benefits, and Innovation Trends. Plants 2020, 9, 1769. [Google Scholar] [CrossRef] [PubMed]

- Soininen, T.H.; Jukarainen, N.; Soininen, P.; Auriola, S.O.K.; Julkunen-Tiitto, R.; Oleszek, W.; Stochmal, A.; Karjalainen, R.O.; Vepsäläinen, J.J. Metabolite Profiling of Leek (Allium porrum L) Cultivars by 1H NMR and HPLC–MS. Phytochem. Anal. 2014, 25, 220–228. [Google Scholar] [CrossRef]

- Kavalcová, P.; Bystrická, J.; Tomáš, J.; Karovičová, J.; Kuchtová, V. Evaluation and comparison of the content of total polyphenols and antioxidant activity in onion, garlic and leek. Potravinarstvo Slovak J. Food Sci. 2014, 8, 272–276. [Google Scholar] [CrossRef] [Green Version]

- Kovarovič, J.; Bystrická, J.; Fehér, A.; Lenková, M. Evaluation and comparison of bioactive substances in selected species of the genus Allium. Potravinarstvo 2017, 11, 702–708. [Google Scholar] [CrossRef] [Green Version]

- Radovanović, B.; Mladenović, J.; Radovanović, A.; Pavlović, R.; Nikolić, V. Phenolic composition, antioxidant, antimicrobial and cytotoxic activites of Allium porrum L. (Serbia) extracts. J. Food Nutr. Res. 2015, 3, 564–569. [Google Scholar]

- Bernaert, N.; De Clercq, H.; Van Bockstaele, E.; De Loose, M.; van Droogenbroeck, B. Antioxidant changes during postharvest processing and storage of leek (Allium ampeloprasum var. porrum). Postharvest Biol. Technol. 2013, 86, 8–16. [Google Scholar] [CrossRef]

- Kovarovič, J.; Bystrická, J.; Micová, M.; Harangozo, Ľ.; Miššík, J.; Hegedűsová, A. The influence of variety on the content of total polyphenols and antioxidant activity in leek (Allium porrum L.). J. Microbiol. Biotechnol. Food Sci. 2019, 8, 1072–1075. [Google Scholar] [CrossRef] [Green Version]

- Kratchanova, M.; Nikolova, M.; Pavlova, E.; Yanakieva, I.; Kussovski, V. Composition and properties of biologically active pectic polysaccharides from leek (Allium porrum). J. Sci. Food Agric. 2010, 90, 2046–2051. [Google Scholar] [CrossRef]

- Asemani, Y.; Zamani, N.; Bayat, M.; Amirghofran, Z. Allium vegetables for possible future of cancer treatment. Phytother. Res. 2019, 33, 3019–3039. [Google Scholar] [CrossRef] [PubMed]

- Itňanová, I.; Ranostajová, S.; Sobotová, H.; Demelová, D.; Pechán, I.; Ďuračková, Z. Antioxidative activity of selected fruits and vegetables. Biologia 2006, 61, 279–284. [Google Scholar] [CrossRef] [Green Version]

- Murcia, M.A.; Jimenez, A.M.; Martinez-Torne, M. Vegetables antioxidant losses during industrial processing and refrigerated storage. Food Res. Int. 2009, 42, 1046–1052. [Google Scholar] [CrossRef]

- Bernaert, N.; Debonne, E.; De Leyn, I.; van Droogenbroeck, B.; van Bockstaele, F. Incorporation of leek powder (Allium ampeloprasum var. porrum) in wheat bread: Technological implications, shelf life and sensory evaluation. LWT 2021, 153, 112517. [Google Scholar] [CrossRef]

- Biernacka, B.; Dziki, D.; Gawlik-Dziki, U. Pasta Enriched with Dried and Powdered Leek: Physicochemical Properties and Changes during Cooking. Molecules 2022, 27, 4495. [Google Scholar] [CrossRef]

- Royen, M.J.; Noori, A.W.; Haydary, J. Experimental Study and Mathematical Modeling of Convective Thin-Layer Drying of Apple Slices. Processes 2020, 8, 1562. [Google Scholar] [CrossRef]

- Rayaguru, K.; Routray, W. Mathematical modeling of thin layer drying kinetics of stone apple slices. Int. Food Res. J. 2012, 19, 1503–1510. [Google Scholar]

- Pinheiro, M.; Madaleno, R.; Castro, L.M. Drying kinetics of two fruits Portuguese cultivars (Bravo de Esmolfe apple and Madeira banana): An experimental study. Heliyon 2022, 8, e09341. [Google Scholar] [CrossRef]

- Bozkir, H. Effects of hot air, vacuum infrared, and vacuum microwave dryers on the drying kinetics and quality characteristics of orange slices. J. Food Process. Eng. 2020, 43, e13485. [Google Scholar] [CrossRef]

- Tan, S.; Miao, Y.; Zhou, C.; Luo, Y.; Lin, Z.; Xie, R.; Li, W. Effects of Hot Air Drying on Drying Kinetics and Anthocyanin Degradation of Blood-Flesh Peach. Foods 2022, 11, 1596. [Google Scholar] [CrossRef]

- Reppich, M.; Jegla, Z.; Grondinger, J.; Azouma, Y.O.; Turek, V. Mathematical Modeling of Drying Processes of Selected Fruits and Vegetables. Chem. Ing. Tech. 2021, 93, 1581–1589. [Google Scholar] [CrossRef]

- Khuwijitjaru, P.; Somkane, S.; Nakagawa, K.; Mahayothee, B. Osmotic Dehydration, Drying Kinetics, and Quality Attributes of Osmotic Hot Air-Dried Mango as Affected by Initial Frozen Storage. Foods 2022, 11, 489. [Google Scholar] [CrossRef] [PubMed]

- Tulej, W.; Głowacki, S. Modeling of the Drying Process of Apple Pomace. Appl. Sci. 2022, 12, 1434. [Google Scholar] [CrossRef]

- Alam, R.; Lyng, J.G.; Frontuto, D.; Marra, F.; Cinquanta, L. Effect of Pulsed Electric Field Pretreatment on Drying Kinetics, Color, and Texture of Parsnip and Carrot. J. Food Sci. 2018, 83, 2159–2166. [Google Scholar] [CrossRef]

- Abbaspour-Gilandeh, Y.; Kaveh, M.; Aziz, M. Ultrasonic-Microwave and Infrared Assisted Convective Drying of Carrot: Drying Kinetic, Quality and Energy Consumption. Appl. Sci. 2020, 10, 6309. [Google Scholar] [CrossRef]

- Sonmete, M.H.; Mengeş, H.O.; Ertekin, C.; Özcan, M.M. Mathematical modeling of thin layer drying of carrot slices by forced convection. J. Food Meas. Charact. 2016, 11, 629–638. [Google Scholar] [CrossRef]

- Górnicki, K.; Kaleta, A.; Choińska, A. Suitable model for thin-layer drying of root vegetables and onion. Int. Agrophys. 2020, 34, 79–86. [Google Scholar] [CrossRef]

- Zcan, M.M.; Arslan, D.; Mengeş, H.O. Evaluation of drying methods with respect to drying kinetics and mineral contents of dill and parsley. Iran. J. Chem. Chem. Eng. (IJCCE) 2018, 37, 237–245. [Google Scholar]

- Jaros, M.; Pabis, S. Theoretical models for fluid bed drying of cut vegetables. Biosyst. Eng. 2006, 93, 45–55. [Google Scholar] [CrossRef]

- Krokida, M.; Karathanos, V.; Maroulis, Z.; Marinos-Kouris, D. Drying kinetics of some vegetables. J. Food Eng. 2003, 59, 391–403. [Google Scholar] [CrossRef]

- Kaleta, A.; Górnicki, K. Some remarks on evaluation of drying models of red beet particles. Energy Convers. Manag. 2010, 51, 2967–2978. [Google Scholar] [CrossRef]

- Szadzińska, J.; Mierzwa, D.; Pawłowski, A.; Musielak, G.; Pashminehazar, R.; Kharaghani, A. Ultrasound- and microwave-assisted intermittent drying of red beetroot. Dry. Technol. 2019, 38, 93–107. [Google Scholar] [CrossRef]

- Azeez, L.; Adebisi, S.A.; Oyedeji, A.; Adetoro, R.O.; Tijani, K.O. Bioactive compounds’ contents, drying kinetics and mathematical modelling of tomato slices influenced by drying temperatures and time. J. Saudi Soc. Agric. Sci. 2019, 18, 120–126. [Google Scholar] [CrossRef]

- Bennamoun, L.; Khama, R.; Léonard, A. Convective drying of a single cherry tomato: Modeling and experimental study. Food Bioprod. Process. 2015, 94, 114–123. [Google Scholar] [CrossRef]

- Abbasi, S.; Mousavi, S.M.; Mohebbi, M. Modeling of moisture ratio and shrinkage of onion slices during hot air drying. In Proceedings of the 6th International Chemical Engineering Congress and Exhibition, ICHEC 2009, Kish Island, Iran, 16–20 November 2009. [Google Scholar]

- Ilter, I.; Akyıl, S.; Devseren, E.; Okut, D.; Koç, M.; Ertekin, F.K. Microwave and hot air drying of garlic puree: Drying kinetics and quality characteristics. Heat Mass Transf. 2018, 54, 2101–2112. [Google Scholar] [CrossRef]

- Rasouli, M.; Seiiedlou, S.; Ghasemzadeh, H.R.; Nalbandi, H. Convective drying of garlic (Allium sativum L.): Part I: Drying kinetics, mathematical modeling and change in color. Aust. J. Crop Sci. 2011, 5, 1707–1714. [Google Scholar]

- Younis, M.; Abdelkarim, D.; El-Abdein, A.Z. Kinetics and mathematical modeling of infrared thin-layer drying of garlic slices. Saudi J. Biol. Sci. 2018, 25, 332–338. [Google Scholar] [CrossRef]

- Benseddik, A.; Azzi, A.; Zidoune, M.; Khanniche, R.; Besombes, C. Empirical and diffusion models of rehydration process of differently dried pumpkin slices. J. Saudi Soc. Agric. Sci. 2019, 18, 401–410. [Google Scholar] [CrossRef]

- Agrawal, S.G.; Methekar, R.N. Mathematical model for heat and mass transfer during convective drying of pumpkin. Food Bioprod. Process. 2017, 101, 68–73. [Google Scholar] [CrossRef]

- Falade, K.O.; Solademi, O.J. Modelling of air drying of fresh and blanched sweet potato slices. Int. J. Food Sci. Technol. 2010, 45, 278–288. [Google Scholar] [CrossRef]

- Doymaz, I. Drying of Leek Slices Using Heated Air. J. Food Process. Eng. 2008, 31, 721–737. [Google Scholar] [CrossRef]

- Doymaz, I. Influence of blanching and slice thickness on drying characteristics of leek slices. Chem. Eng. Process. Process Intensif. 2008, 47, 41–47. [Google Scholar] [CrossRef]

- Dadali, G.; Özbek, B. Microwave heat treatment of leek: Drying kinetic and effective moisture diffusivity. Int. J. Food Sci. Technol. 2008, 43, 1443–1451. [Google Scholar] [CrossRef]

- Zakipour, E.; Hamidi, Z. Vacuum Drying Characteristics of Some Vegetables. Iran. J. Chem. Chem. Eng. (Ijcce) 2011, 30, 97–105. [Google Scholar]

- Kaleta, A.; Górnicki, K.; Winiczenko, R.; Chojnacka, A. Evaluation of drying models of apple (var. Ligol) dried in a fluidized bed dryer. Energy Convers. Manag. 2013, 67, 179–185. [Google Scholar] [CrossRef]

- Kucuk, H.; Midilli, A.; Aydin Kilic, A.; Dincer, I. A Review on Thin-Layer Drying-Curve Equations. Dry. Technol. 2014, 32, 757–773. [Google Scholar] [CrossRef]

- Kaleta, A.; Górnicki, K. Evaluation of drying models of apple (var. McIntosh) dried in a convective dryer. Int. J. Food Sci. Technol. 2010, 45, 891–898. [Google Scholar] [CrossRef]

- Górnicki, K.; Kaleta, A. Drying curve modelling of blanched carrot cubes under natural convection condition. J. Food Eng. 2007, 82, 160–170. [Google Scholar] [CrossRef]

- Pabis, S. The Initial Phase of Convection Drying of Vegetables and Mushrooms and the Effect of Shrinkage. J. Agric. Eng. Res. 1999, 72, 187–195. [Google Scholar] [CrossRef]

- Pabis, S.; Jaros, M. PH—Postharvest Technology: The First Period of Convection Drying of Vegetables and the Effect of Shape-dependent Shrinkage. Bios. Eng. 2002, 81, 201–211. [Google Scholar] [CrossRef]

- Sojak, M.; Glowacki, S. Analysis of giant pumpkin (Cucurbita maxima) drying kinetics in various technologies of convective drying. J. Food Eng. 2010, 99, 323–329. [Google Scholar] [CrossRef]

- Górnicki, K.; Kaleta, A. Modelling convection drying of blanched parsley root slices. Biosyst. Eng. 2007, 97, 51–59. [Google Scholar] [CrossRef]

- Kukiełko, E. Modeling of the Convection Drying Process of Chokeberry Fruit in a Thin Layer. Doctoral Dissertation, Warsaw University of Life Sciences, Warsaw, Poland, 2001. (In Polish). [Google Scholar]

- Matuszak, N. The Monte Carlo method and using in radiotherapy. Zesz. Nauk. WCO Lett. Oncol. Sci. 2019, 16, 50–57. [Google Scholar]

| Drying Temperature [°C] | Slice Thickness [mm] | Type of Slice | Coefficient n * | Coefficient N |

|---|---|---|---|---|

| 40 | 4 | ns | 1.01; 0.97; 1.02 | 2.94; 3.2; 2.89 |

| 8 | ns | 0.85; 1; 0.9 | 4.64; 3; 3.86 | |

| s | 0.8; 0.94; 1 | 6; 3.44; 3 | ||

| 12 | ns | 0.87; 0.95; 1.1 | 4.28; 3.35; 2.54 | |

| 50 | 4 | ns | 1.42; 1.58; 1.65 | 1.88; 1.73; 1.68 |

| 8 | ns | 1.29; 1.2; 1.25 | 2.07; 2.25; 2.14 | |

| s | 0.86; 1.26; 0.91 | 4.45; 2.12; 3.73 | ||

| 12 | ns | 0.7; 0.81; 0.75 | 201; 5.65; 9 | |

| s | 0.74; 0.67; 0.82 | 10.09; 201; 5.35 | ||

| 60 | 4 | ns | 1.31; 0.89; 0.85 | 2.04; 3.99; 4.46 |

| s | 1.81; 0.88. 0.85 | 1.58; 4.13; 4.64 | ||

| 8 | ns | 0.8; 1.49; 1.35 | 6; 1.8; 1.98 | |

| s | 0.83; 1.04; 0.84 | 5.08; 2.79; 4.85 | ||

| 12 | ns | 0.84; 0.93; 1.06 | 4.85; 3.53; 2.79 | |

| s | 0.89; 0.88; 0.77 | 3.99; 4.13; 7.45 | ||

| 70 | 4 | ns | 1.15; 2.8; 1.38 | 2.38; 1.31; 1.93 |

| 8 | ns | 1.33; 1.74; 2.1 | 2.01; 1.62; 1.46 | |

| s | 2; 1.06. 0.9 | 1.5; 2.69; 3.86 | ||

| 12 | ns | 0.87; 0.82; 0.91 | 4.28; 5.35; 3.74 | |

| s | 1.82; 1.15; 1 | 1.58; 2.38; 3 | ||

| 80 | 4 | ns | 2.3; 7; 3.25 | 1.41; 1.11; 1.26 |

| s | 2.2; 1.05; 4.5 | 1.43; 2.74; 1.17 | ||

| 8 | ns | 1.82; 3.51; 4.4 | 1.59; 1.23; 1.18 | |

| s | 1.65; 2.51; 1.13 | 1.68; 1.36; 2.44 | ||

| 12 | ns | 0.89; 1.25; 0.97 | 3.99; 2.14; 3.2 | |

| s | 0.9; 0.94; 0.82 | 3.86; 3.44; 5.35 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Golisz, E.; Wielewska, I.; Roman, K.; Kacprzak, M. Probabilistic Model of Drying Process of Leek. Appl. Sci. 2022, 12, 11761. https://doi.org/10.3390/app122211761

Golisz E, Wielewska I, Roman K, Kacprzak M. Probabilistic Model of Drying Process of Leek. Applied Sciences. 2022; 12(22):11761. https://doi.org/10.3390/app122211761

Chicago/Turabian StyleGolisz, Ewa, Izabela Wielewska, Kamil Roman, and Marzena Kacprzak. 2022. "Probabilistic Model of Drying Process of Leek" Applied Sciences 12, no. 22: 11761. https://doi.org/10.3390/app122211761

APA StyleGolisz, E., Wielewska, I., Roman, K., & Kacprzak, M. (2022). Probabilistic Model of Drying Process of Leek. Applied Sciences, 12(22), 11761. https://doi.org/10.3390/app122211761