Multivehicle Point-to-Point Network Problem Formulation for UAM Operation Management Used with Dynamic Scheduling

Abstract

:1. Introduction

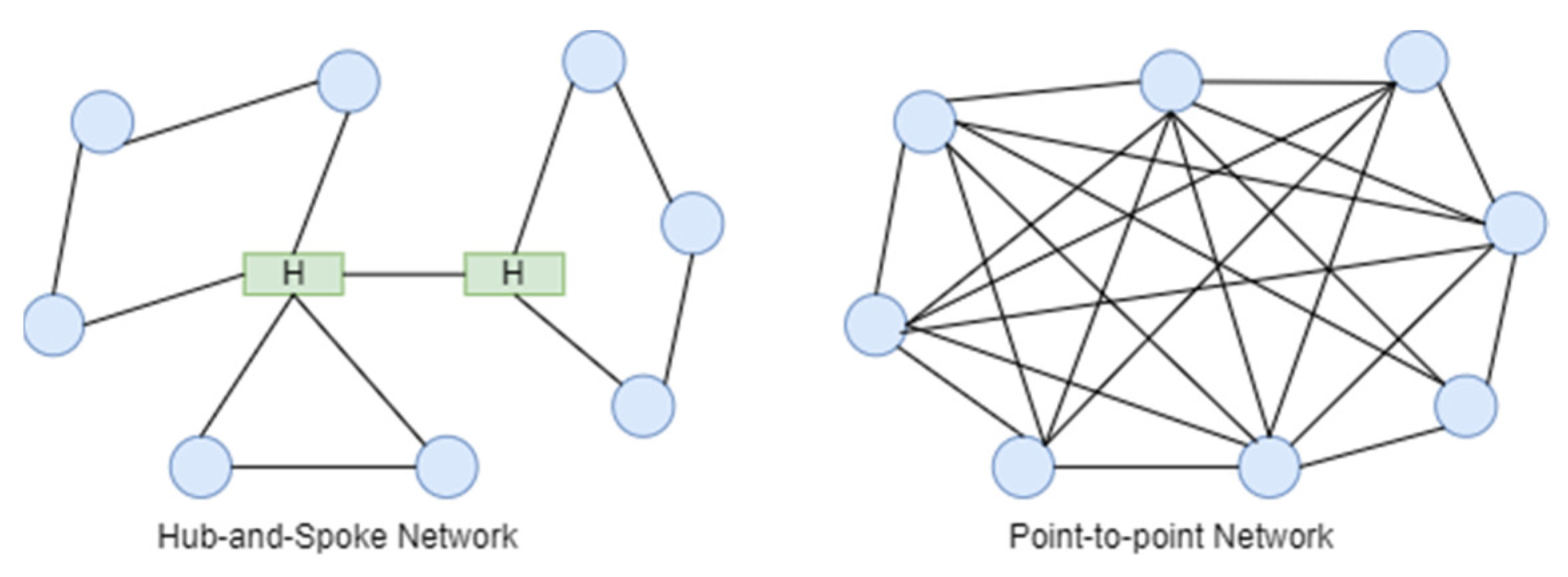

2. Motivation

3. Problem Definitions for the Point-to-Point Network and Dynamic Scheduling

3.1. Problem Definition for Point-to-Point Network

3.2. Multivehicle Point-to-Point Network with Dynamic Scheduling

4. Mathematical Formulation

- Each vehicle must leave from and return to the same vertiport;

- All the vehicles need to travel to others vertiport locations;

- Vehicles in the same vertiports must travel by selecting different routes;

- Vehicles in the same vertiports cannot depart at the same time, meaning that the second vehicle needs to travel after the first vehicle after waiting some time;

- Vehicles cannot arrive at the same time to a vertiport, meaning that the second vehicles need to arrive after the first vehicles after waiting some time; and

- All vehicles can travel at varying speeds defined by vehicle specifications.

- Set and Index:

- Set of vertiports - Index of vertiports - Set of all vehicles - Index of vehicles - Set of vertiports, - Set of vehicles belonging to each vertiport - Variables:

- Binary variable that is equal to one if vehicle travels from to and zero otherwise. - Departure time of vehicle from vertiport , where - Arrival time of vehicle at vertiport , where - Waiting time of vehicle at depot , where - Speed of vehicle , where - Parameters;

- Distance between and , where , - Maximum and minimum speeds of vehicles - Maximum and minimum waiting times - Number of vehicles at each vertiport - Number of vertiports

5. Computational Experiments

6. Case Studies

6.1. Operation Environment and Flight Corridors

6.2. UAM Model and Flight Missions

6.3. Implementaiton of Formulaiton

6.4. Case Studies

7. Results and Discussion

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix A.1. Case Study 1: Optimum Route for Each Vehicle at Each Vertiport and Selected Corridors

Appendix A.2. Case Study 1: Route Selection and Scheduling Results

| Case 1 | Departure | Arrival | Departure Time (mins) | Arrival Time (mins) | Mission Speed (km/h) | Mission Key | Cost (m) |

|---|---|---|---|---|---|---|---|

| UAM1 route | GMP | ICN | 22.05 | 32.02 | 210 | GMP-ICN-6 | 102,708 |

| ICN | JSL | 35.62 | 47.38 | 240 | ICN-JSL-2 | ||

| JSL | SEBT | 48.19 | 49.42 | 240 | JSL-SEBT-2 | ||

| SEBT | YGS | 52.09 | 53.75 | 240 | SEBT-YGS-2 | ||

| YGS | GMP | 55.87 | 60.58 | 240 | YGS-GMP-2 | ||

| UAM2 route | GMP | JSL | 17.05 | 22.97 | 210 | GMP-JSL-6 | 113,474 |

| JSL | ICN | 25.82 | 37.58 | 240 | JSL-ICN-2 | ||

| ICN | YGS | 39.62 | 49.41 | 240 | ICN-YGS-2 | ||

| YGS | SEBT | 51.08 | 52.61 | 240 | YGS-SEBT-2 | ||

| SEBT | GMP | 53.2 | 58.3 | 240 | SEBT-GMP-2 | ||

| UAM3 route | JSL | SEBT | 20.82 | 21.64 | 240 | JSL-SEBT-2 | 102,708 |

| SEBT | YGS | 25.53 | 27.19 | 240 | SEBT-YGS-2 | ||

| YGS | GMP | 29.31 | 34.02 | 240 | YGS-GMP-2 | ||

| GMP | ICN | 36.17 | 46.13 | 210 | GMP-ICN-6 | ||

| ICN | JSL | 49.74 | 63.53 | 240 | ICN-JSL-2 | ||

| UAM4 route | JSL | SEBT | 15.82 | 16.64 | 240 | JSL-SEBT-2 | 108,827 |

| SEBT | GMP | 20.53 | 25.63 | 240 | SEBT-GMP-2 | ||

| GMP | YGS | 27.74 | 32.45 | 240 | GMP-YGS-2 | ||

| YGS | ICN | 34.59 | 46.27 | 240 | YGS-ICN-2 | ||

| ICN | JSL | 49.14 | 60.06 | 240 | ICN-JSL-2 | ||

| UAM5 route | SEBT | GMP | 15.53 | 20.63 | 210 | SEBT-GMP-2 | 110,614 |

| GMP | ICN | 22.74 | 32.71 | 240 | GMP-ICN-6 | ||

| ICN | YGS | 36.32 | 48.15 | 240 | ICN-YGS-2 | ||

| YGS | JSL | 50.11 | 51.34 | 240 | YGS-JSL-2 | ||

| JSL | SEBT | 53.47 | 54.29 | 240 | JSL-SEBT-2 | ||

| UAM6 route | SEBT | YGS | 10.53 | 12.19 | 240 | SEBT-YGS-2 | 112,256 |

| YGS | GMP | 14.31 | 19.02 | 240 | YGS-GMP-2 | ||

| GMP | JSL | 21.17 | 27.08 | 210 | GMP-JSL-6 | ||

| JSL | ICN | 29.94 | 41.7 | 240 | JSL-ICN-2 | ||

| ICN | SEBT | 43.73 | 56.33 | 240 | ICN-SEBT-2 | ||

| UAM7 route | YGS | GMP | 9.31 | 14.02 | 240 | YGS-GMP-2 | 102,708 |

| GMP | ICN | 16.17 | 26.13 | 210 | GMP-ICN-6 | ||

| ICN | JSL | 29.74 | 41.49 | 240 | ICN-JSL-2 | ||

| JSL | SEBT | 42.31 | 43.53 | 240 | JSL-SEBT-2 | ||

| SEBT | YGS | 46.2 | 47.87 | 240 | SEBT-YGS-2 | ||

| UAM8 route | YGS | JSL | 4.66 | 6.61 | 240 | YGS-JSL-2 | 112,152 |

| JSL | ICN | 9.98 | 21.73 | 240 | JSL-ICN-2 | ||

| ICN | SEBT | 23.77 | 33.63 | 240 | ICN-SEBT-2 | ||

| SEBT | GMP | 36.37 | 38.73 | 240 | SEBT-GMP-2 | ||

| GMP | YGS | 40.84 | 45.55 | 240 | GMP-YGS-2 | ||

| UAM9 route | ICN | JSL | 16.73 | 30.53 | 240 | ICN-JSL-2 | 102,708 |

| JSL | SEBT | 28.49 | 29.3 | 240 | JSL-SEBT-2 | ||

| SEBT | YGS | 33.2 | 34.86 | 240 | SEBT-YGS-2 | ||

| YGS | GMP | 36.98 | 41.69 | 240 | YGS-GMP-2 | ||

| GMP | ICN | 43.83 | 53.8 | 210 | GMP-ICN-6 | ||

| UAM10 route | ICN | GMP | 11.73 | 21.7 | 210 | ICN-GMP-6 | 110,328 |

| GMP | YGS | 27.05 | 31.75 | 240 | GMP-YGS-2 | ||

| YGS | SEBT | 33.9 | 35.56 | 240 | YGS-SEBT-2 | ||

| SEBT | JSL | 37.68 | 38.5 | 240 | SEBT-JSL-2 | ||

| JSL | ICN | 42.55 | 56.35 | 240 | JSL-ICN-2 | ||

| TOTAL COST | 1,078,483 | ||||||

Appendix A.3. Case Study 2: Optimum Route for Each Vehicle at Each Vertiport and Selected Corridors

Appendix A.4. Case Study 2: Route Selection and Scheduling Results

| Case-2 | Departure | Arrival | Depart Time (mins) | Arrive Time (mins) | Mission Speed (km/h) | Mission Name | Cost (m) |

|---|---|---|---|---|---|---|---|

| UAM-1-route | GMP | ICN | 19.46 | 29.43 | 210 | GMP-ICN-7 | 110,718 |

| ICN | YGS | 33.03 | 44.87 | 240 | ICN-YGS-1 | ||

| YGS | SEBT | 46.53 | 48.06 | 240 | YGS-SEBT-1 | ||

| SEBT | JSL | 48.65 | 49.47 | 240 | SEBT-JSL-1 | ||

| JSL | GMP | 53.52 | 59.44 | 210 | JSL-GMP-6 | ||

| UAM-2-route | GMP | YGS | 14.46 | 19.16 | 240 | GMP-YGS-1 | 108,827 |

| YGS | ICN | 21.31 | 32.98 | 240 | YGS-ICN-1 | ||

| ICN | JSL | 35.86 | 44.74 | 240 | ICN-JSL-1 | ||

| JSL | SEBT | 45.55 | 46.78 | 240 | JSL-SEBT-1 | ||

| SEBT | GMP | 49.45 | 54.55 | 240 | SEBT-GMP-1 | ||

| UAM-11-route | GMP | JSL | 9.46 | 15.38 | 210 | GMP-JSL-1 | 112,256 |

| JSL | ICN | 18.23 | 29.99 | 240 | JSL-ICN-1 | ||

| ICN | SEBT | 32.03 | 41.88 | 240 | ICN-SEBT-1 | ||

| SEBT | YGS | 43.55 | 44.62 | 240 | SEBT-YGS-1 | ||

| YGS | GMP | 45.67 | 50.37 | 240 | YGS-GMP-1 | ||

| UAM-3-route | JSL | GMP | 13.23 | 19.15 | 210 | JSL-GMP-7 | 110,718 |

| GMP | ICN | 21.84 | 31.81 | 210 | GMP-ICN-7 | ||

| ICN | YGS | 35.42 | 47.25 | 240 | ICN-YGS-1 | ||

| YGS | SEBT | 48.92 | 50.44 | 240 | YGS-SEBT-1 | ||

| SEBT | JSL | 51.04 | 51.85 | 240 | SEBT-JSL-1 | ||

| UAM-4-route | JSL | SEBT | 8.23 | 9.05 | 240 | JSL-SEBT-1 | 108,827 |

| SEBT | GMP | 12.94 | 18.04 | 240 | SEBT-GMP-1 | ||

| GMP | YGS | 20.15 | 24.86 | 240 | GMP-YGS-1 | ||

| YGS | ICN | 27 | 38.68 | 240 | YGS-ICN-1 | ||

| ICN | JSL | 41.55 | 52.47 | 240 | ICN-JSL-1 | ||

| UAM-12-route | JSL | ICN | 4.12 | 15.87 | 240 | JSL-ICN-1 | 112,256 |

| ICN | SEBT | 17.91 | 27.77 | 240 | ICN-SEBT-1 | ||

| SEBT | YGS | 29.43 | 30.5 | 240 | SEBT-YGS-1 | ||

| YGS | GMP | 31.55 | 36.26 | 240 | YGS-GMP-1 | ||

| GMP | JSL | 38.4 | 44.32 | 210 | GMP-JSL-7 | ||

| UAM-5-route | SEBT | GMP | 22.77 | 27.87 | 240 | SEBT-GMP-1 | 110,614 |

| GMP | ICN | 29.98 | 39.95 | 210 | GMP-ICN-7 | ||

| ICN | YGS | 43.55 | 55.39 | 240 | ICN-YGS-1 | ||

| YGS | JSL | 57.34 | 58.58 | 240 | YGS-JSL-1 | ||

| JSL | SEBT | 60.71 | 61.52 | 240 | JSL-SEBT-1 | ||

| UAM-6-route | SEBT | GMP | 17.77 | 22.87 | 240 | SEBT-GMP-1 | 108,827 |

| GMP | YGS | 24.98 | 29.68 | 240 | GMP-YGS-1 | ||

| YGS | ICN | 31.83 | 43.5 | 240 | YGS-ICN-1 | ||

| ICN | JSL | 46.38 | 55.26 | 240 | ICN-JSL-1 | ||

| JSL | SEBT | 56.08 | 57.3 | 240 | JSL-SEBT-1 | ||

| UAM-13-route | SEBT | YGS | 12.77 | 14.43 | 240 | SEBT-YGS-1 | 112,256 |

| YGS | GMP | 16.55 | 21.26 | 240 | YGS-GMP-1 | ||

| GMP | JSL | 23.4 | 29.32 | 210 | GMP-JSL-7 | ||

| JSL | ICN | 32.18 | 43.93 | 240 | JSL-ICN-1 | ||

| ICN | SEBT | 45.97 | 58.56 | 240 | ICN-SEBT-1 | ||

| UAM-7-route | YGS | ICN | 11.55 | 23.23 | 240 | YGS-ICN-1 | 116,937 |

| ICN | GMP | 26.1 | 33.19 | 210 | ICN-GMP-7 | ||

| GMP | SEBT | 38.54 | 43.64 | 240 | GMP-SEBT-1 | ||

| SEBT | JSL | 45.75 | 46.57 | 240 | SEBT-JSL-1 | ||

| JSL | YGS | 50.62 | 52.58 | 240 | JSL-YGS-1 | ||

| UAM-8-route | YGS | GMP | 6.55 | 11.26 | 240 | YGS-GMP-1 | 102,708 |

| GMP | ICN | 13.4 | 23.37 | 210 | GMP-ICN-7 | ||

| ICN | JSL | 26.97 | 38.73 | 240 | ICN-JSL-1 | ||

| JSL | SEBT | 39.55 | 40.77 | 240 | JSL-SEBT-1 | ||

| SEBT | YGS | 43.44 | 45.1 | 240 | SEBT-YGS-1 | ||

| UAM-14-route | YGS | JSL | 3.28 | 5.23 | 240 | YGS-JSL-1 | 112,152 |

| JSL | ICN | 8.6 | 20.35 | 240 | JSL-ICN-1 | ||

| ICN | SEBT | 22.39 | 32.25 | 240 | ICN-SEBT-1 | ||

| SEBT | GMP | 34.98 | 37.35 | 240 | SEBT-GMP-1 | ||

| GMP | YGS | 39.46 | 44.16 | 240 | GMP-YGS-1 | ||

| UAM-9-route | ICN | YGS | 15.35 | 27.19 | 240 | ICN-YGS-1 | 110,718 |

| YGS | SEBT | 28.85 | 30.38 | 240 | YGS-SEBT-1 | ||

| SEBT | JSL | 30.97 | 31.79 | 240 | SEBT-JSL-1 | ||

| JSL | GMP | 35.84 | 41.76 | 210 | JSL-GMP-7 | ||

| GMP | ICN | 44.45 | 54.42 | 210 | GMP-ICN-7 | ||

| UAM-10-route | ICN | JSL | 10.35 | 22.11 | 240 | ICN-JSL-1 | 102,708 |

| JSL | SEBT | 22.92 | 24.15 | 240 | JSL-SEBT-1 | ||

| SEBT | YGS | 26.82 | 28.48 | 240 | SEBT-YGS-1 | ||

| YGS | GMP | 30.6 | 35.31 | 240 | YGS-GMP-1 | ||

| GMP | ICN | 37.45 | 47.42 | 210 | GMP-ICN-7 | ||

| UAM-15-route | ICN | SEBT | 5.35 | 17.25 | 240 | ICN-SEBT-1 | 112,152 |

| SEBT | GMP | 19.98 | 22.35 | 240 | SEBT-GMP-1 | ||

| GMP | YGS | 24.46 | 29.16 | 240 | GMP-YGS-1 | ||

| YGS | JSL | 31.31 | 33.27 | 240 | YGS-JSL-1 | ||

| JSL | ICN | 36.63 | 50.42 | 240 | JSL-ICN-1 | ||

| TOTAL COST | 1,652,674 | ||||||

References

- Urban Air Mobility (UAM). EASA. Available online: https://www.easa.europa.eu/en/domains/urban-air-mobility-uam (accessed on 17 October 2022).

- Urban Air Mobility Concepts of Operations—KADA. Available online: http://kada.konkuk.ac.kr/2021/06/09/urban-air-mobility-concepts-of-operations/ (accessed on 17 October 2022).

- K-UAM ConOps English Version and Related Material: K-UAM Grand Challenge, 18 February 2022. Available online: http://en.kuam-gc.kr/35/?q=YToxOntzOjEyOiJrZXl3b3JkX3R5cGUiO3M6MzoiYWxsIjt9&bmode=view&idx=10439947&t=board (accessed on 17 October 2022).

- UAM_ConOps_v1.0.pdf. Available online: https://nari.arc.nasa.gov/sites/default/files/attachments/UAM_ConOps_v1.0.pdf (accessed on 17 October 2022).

- Berger, R. The High-Flying Industry: Urban Air Mobility Takes Off. Available online: https://www.rolandberger.com/en/Insights/Publications/The-high-flying-industry-Urban-Air-Mobility-takes-off.html (accessed on 3 November 2022).

- Hane, C.A.; Barnhart, C.; Johnson, E.L.; Marsten, R.E.; Nemhauser, G.L.; Sigismondi, G. The fleet assignment problem: Solving a large-scale integer program. Math. Program. 1995, 70, 211–232. [Google Scholar] [CrossRef]

- Al-Sultan, A.T.; Ishioka, F.; Kurihara, K. An airline scheduling model and solution algorithms. Commun. Stat. Appl. Methods 2011, 18, 257–266. [Google Scholar] [CrossRef]

- Zhou, L.; Liang, Z.; Chou, C.-A.; Chaovalitwongse, W.A. Airline planning and scheduling: Models and solution methodologies. Front. Eng. 2020, 7, 1–26. [Google Scholar] [CrossRef]

- Wei, M.; Sun, B.; Wu, W.; Jing, B. A multiple objective optimization model for aircraft arrival and departure scheduling on multiple runways. Math. Biosci. Eng. 2020, 17, 5545–5560. [Google Scholar] [CrossRef] [PubMed]

- Caetano, D.; Gualda, N. A Flight Schedule and Fleet Assignment Model. In Proceedings of the 12th World Conference on Transport Research, Lisboa, Portugal, 11–15 July 2010. [Google Scholar]

- Cheikhrouhou, O.; Khoufi, I. A comprehensive survey on the multiple traveling salesman problem: Applications, approaches and taxonomy. Comput. Sci. Rev. 2021, 40, 100369. [Google Scholar] [CrossRef]

- Herdianti, W.; Gunawan, A.; Komsiyah, S. Distribution cost optimization using pigeon inspired optimization method with reverse learning mechanism. Procedia Comput. Sci. 2021, 179, 920–929. [Google Scholar] [CrossRef]

- Li, J.; Zhou, M.; Sun, Q.; Dai, X.; Yu, X. Colored traveling salesman problem. IEEE Trans. Cybern. 2015, 45, 2390–2401. [Google Scholar] [CrossRef] [PubMed]

- Gribkovskaia, I.; Laporte, G.; Shyshou, A. The single vehicle routing problem with deliveries and selective pickups. Comput. Oper. Res. 2008, 35, 2908–2924. [Google Scholar] [CrossRef]

- Bae, H.; Moon, I. Multi-depot vehicle routing problem with time windows considering delivery and installation vehicles. Appl. Math. Model. 2016, 40, 6536–6549. [Google Scholar] [CrossRef]

- Shuai, Y.; Yunfeng, S.; Kai, Z. An effective method for solving multiple travelling salesman problem based on NSGA-II. Syst. Sci. Control. Eng. 2019, 7, 108–116. [Google Scholar] [CrossRef]

- Li, J.; Li, Y.; Pardalos, P.M. Multi-depot vehicle routing problem with time windows under shared depot resources. J. Comb. Optim. 2016, 31, 515–532. [Google Scholar] [CrossRef]

- Calvet, L.; Wang, D.; Juan, A.; Bové, L. Solving the multidepot vehicle routing problem with limited depot capacity and stochastic demands. Int. Trans. Oper. Res. 2019, 26, 458–484. [Google Scholar] [CrossRef]

- Faye, A. Solving the aircraft landing problem with time discretization approach. Eur. J. Oper. Res. 2015, 242, 1028–1038. [Google Scholar] [CrossRef] [Green Version]

- Farhadi, F.; Ghoniem, A.; Al-Salem, M. Runway capacity management—An empirical study with application to Doha International Airport. Transp. Res. Part E Logist. Transp. Rev. 2014, 68, 53–63. [Google Scholar] [CrossRef]

- Aktürk, M.S.; Atamtürk, A.; Gürel, S. Aircraft rescheduling with cruise speed control. Oper. Res. 2014, 62, 829–845. [Google Scholar] [CrossRef] [Green Version]

- Abdallah, K.S.; Adel, Y. Electric Vehicles Routing Problem with Variable Speed and Time Windows. In Proceedings of the International Conference on Industry, Engineering & Management Systems, Singapore, 15 March 2020; pp. 55–65. [Google Scholar]

- Ramos, T.R.; Gomes, M.I.; Póvoa, A.P. Multi-depot vehicle routing problem: A comparative study of alternative formulations. Int. J. Log. Res. Appl. 2020, 23, 103–120. [Google Scholar] [CrossRef]

- Miller, C.E.; Tucker, A.W.; Zemlin, R.A. Integer programming formulation of traveling salesman problems. J. ACM 1960, 7, 326–329. [Google Scholar] [CrossRef]

- Kohl, N.; Madsen, O.B.G. An optimization algorithm for the vehicle routing problem with time windows based on Lagrangian relaxation. Oper. Res. 1997, 45, 395–406. [Google Scholar] [CrossRef]

- Gurobi—The Fastest Solver. Available online: https://www.gurobi.com/ (accessed on 19 October 2022).

- Lee, Y.; Kwag, T.H.; Jeong, G.M.; Ahn, J.H.; Chung, B.C.; Lee, J.-W. Flight routes establishment through the operational concept analysis of urban air mobility system. J. Korean Soc. Aeronaut. Space Sci. 2020, 48, 1021–1031. [Google Scholar] [CrossRef]

- Lee, Y.; Lee, J.; Lee, J.-W. Holding area conceptual design and validation for various urban air mobility (UAM) operations: A case study in Seoul–GyungIn area. Appl. Sci. 2021, 11, 10707. [Google Scholar] [CrossRef]

- An, J.; Thu, Z.W.; Lee, J.; Lee, Y.; Min, J.; Jang, M.; Na, S.; Lee, J.-W. A Study on Performance Operation Analysis of Hydrogen Fuel Cell Urban Air Transportation. Abstract of the Korean Society for Aeronautical and Space Sciences Conference. pp. 663–664. Available online: https://www.dbpia.co.kr/journal/articleDetail?nodeId=NODE10526236 (accessed on 24 October 2022).

- MIL-STD-3013|Glossary of Definitions, Ground Rules, and Mission Profiles to Define Air Vehicle Performance Capability|Document Center, Inc. Available online: https://www.document-center.com/standards/show/MIL-STD-3013 (accessed on 24 October 2022).

UAM1,

UAM1,  UAM2.

UAM2.

UAM1,

UAM1,  UAM2,

UAM2,  UAM3.

UAM3.

| Problem | Departure Station | Vehicles at Each Departure Station | Network Type | Time Window | ||||

|---|---|---|---|---|---|---|---|---|

| Single | Multiple | Single | Multiple | Hub-and-Spoke | Point-to-Point | Fixed | Variable | |

| TSP | ✓ | ✓ | ✓ | |||||

| mTSP | ✓ | ✓ | ✓ | |||||

| MD-mTSP | ✓ | ✓ | ✓ | ✓ | ||||

| TSPTW | ✓ | ✓ | ✓ | ✓ | ||||

| mTSPTW | ✓ | ✓ | ✓ | ✓ | ||||

| MDmTSPTW | ✓ | ✓ | ✓ | ✓ | ✓ | |||

| VRP | ✓ | ✓ | ✓ | ✓ | ||||

| MDVRP | ✓ | ✓ | ✓ | |||||

| VRPTW | ✓ | ✓ | ✓ | ✓ | ✓ | |||

| MDVRPTW | ✓ | ✓ | ✓ | ✓ | ||||

| Proposed method | ✓ | ✓ | ✓ | ✓ | ✓ | |||

| Case | Problem Size | Total Cost (m) | CPU Time (s) |

|---|---|---|---|

| Case 1 | = 4 | 2607.159 | 0.203 |

| Case 2 | = 6 | 7793.7766 | 3.29 |

| Case 3 | = 5 | 9471.775 | 117.82 |

| Case 4 | = 6 | 12,816.8524 | 4137.32 |

| Case 5 | = 7 | 12,000.48011 | 24,895.83 |

| Case 6 | = 7 | 19,623.4244 | 857,601.56 |

| Name | Longitude (Deg) | Latitude (Deg) |

|---|---|---|

| Gimpo (GMP) | 37.5608 | 126.8031 |

| Yongsan (YGS) | 37.5318 | 126.9680 |

| Bus Express Terminal (SEBT) | 37.5052 | 127.0056 |

| Jamsil (JSL) | 37.5141 | 127.0689 |

| Incheon (ICN) | 37.44556 | 126.45313 |

| Departure | Arrival | Distance (m) |

|---|---|---|

| Gimpo | Yongsan | 15,405.1945 |

| Gimpo | Bus Express Terminal | 16,854.3812 |

| Gimpo | Jamsil | 23,097.4728 |

| Gimpo | Incheon | 42,297.4791 |

| Yongsan | Gimpo | 15,405.3166 |

| Yongsan | Bus Express Terminal | 3141.2371 |

| Yongsan | Jamsil | 9280.9207 |

| Yongsan | Incheon | 34,703.0307 |

| Bus Express Terminal | Gimpo | 16,854.4422 |

| Bus Express Terminal | Jamsil | 7483.5077 |

| Bus Express Terminal | Yongsan | 3141.2984 |

| Bus Express Terminal | Incheon | 36,347.4148 |

| Jamsil | Gimpo | 22,447.0629 |

| Jamsil | Yongsan | 8630.5112 |

| Jamsil | Bus Express Terminal | 6833.0981 |

| Jamsil | Incheon | 35,032.6843 |

| Incheon | Gimpo | 49,267.0353 |

| Incheon | Bus Express Terminal | 35,581.0653 |

| Incheon | Jamisl | 35,032.6843 |

| Incheon | Yongsan | 35,350.0857 |

| UAM Model | |

|---|---|

| Name | KP-1 UAM (In-House Model) |

| MTOW | 1566 kg |

| Length | 7 m |

| Wingspan | 8.6 m |

| Max range | 1025 km |

| Stall speed | 96 km/h |

| Maximum speed | 240 km/h |

| Cruise speed | 200 km/h |

| Power system | Hydrogen fuel cell (110 kW max cont. power) |

| Input | Output | ||

|---|---|---|---|

| Speed | Departure | Arrival | Mission Name (Keys) |

| 240 | Gimpo | Jamsil | GMP-JSL-1 |

| 235 | Gimpo | Jamsil | GMP-JSL-2 |

| 230 | Gimpo | Jamsil | GMP-JSL-3 |

| 225 | Gimpo | Jamsil | GMP-JSL-4 |

| 220 | Gimpo | Jamsil | GMP-JSL-5 |

| 215 | Gimpo | Jamsil | GMP-JSL-6 |

| 210 | Gimpo | Jamsil | GMP-JSL-7 |

| Parameter | Remarks | |

|---|---|---|

| Distance matrix in Table 4 | Distance between each pair of vertiports | |

| 240 km/h | Maximum cruise speed of UAM | |

| 210 km/h | Minimum cruise speed of UAM | |

| 5 min | Maximum waiting time for customer satisfaction | |

| 3 min | Minimum waiting time for customer satisfaction | |

| Variable | ||

| Decision variables for selection route | ||

| Departure time of vehicle at vertiport | ||

| Arrival time of vehicle at vertiport | ||

| Waiting time of vehicle at vertiport | ||

| Speed of UAM travelling from to | ||

| Set and Index | Remarks | ||

|---|---|---|---|

| [GMP, YGS, JSL, SEBT, ICN] | Set of vertiports | ||

| Belongs to set of vertiports | |||

| Case-1 | 10 | Total number of vehicles | |

| 2 | No. of vehicles belonging to this vertiport | ||

| Case-2 | 15 | Total number of vehicles | |

| 3 | No. of vehicles belonging to this vertiport | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thu, Z.W.; Kim, D.; Lee, J.; Won, W.-J.; Lee, H.J.; Ywet, N.L.; Maw, A.A.; Lee, J.-W. Multivehicle Point-to-Point Network Problem Formulation for UAM Operation Management Used with Dynamic Scheduling. Appl. Sci. 2022, 12, 11858. https://doi.org/10.3390/app122211858

Thu ZW, Kim D, Lee J, Won W-J, Lee HJ, Ywet NL, Maw AA, Lee J-W. Multivehicle Point-to-Point Network Problem Formulation for UAM Operation Management Used with Dynamic Scheduling. Applied Sciences. 2022; 12(22):11858. https://doi.org/10.3390/app122211858

Chicago/Turabian StyleThu, Zin Win, Dasom Kim, Junseok Lee, Woon-Jae Won, Hyeon Jun Lee, Nan Lao Ywet, Aye Aye Maw, and Jae-Woo Lee. 2022. "Multivehicle Point-to-Point Network Problem Formulation for UAM Operation Management Used with Dynamic Scheduling" Applied Sciences 12, no. 22: 11858. https://doi.org/10.3390/app122211858

APA StyleThu, Z. W., Kim, D., Lee, J., Won, W.-J., Lee, H. J., Ywet, N. L., Maw, A. A., & Lee, J.-W. (2022). Multivehicle Point-to-Point Network Problem Formulation for UAM Operation Management Used with Dynamic Scheduling. Applied Sciences, 12(22), 11858. https://doi.org/10.3390/app122211858