Failure Analysis of Gantry Crane Slewing Bearing Based on Gear Position Accuracy Error

Abstract

:1. Introduction

2. Slewing Bearing Mechanical Analysis and Test

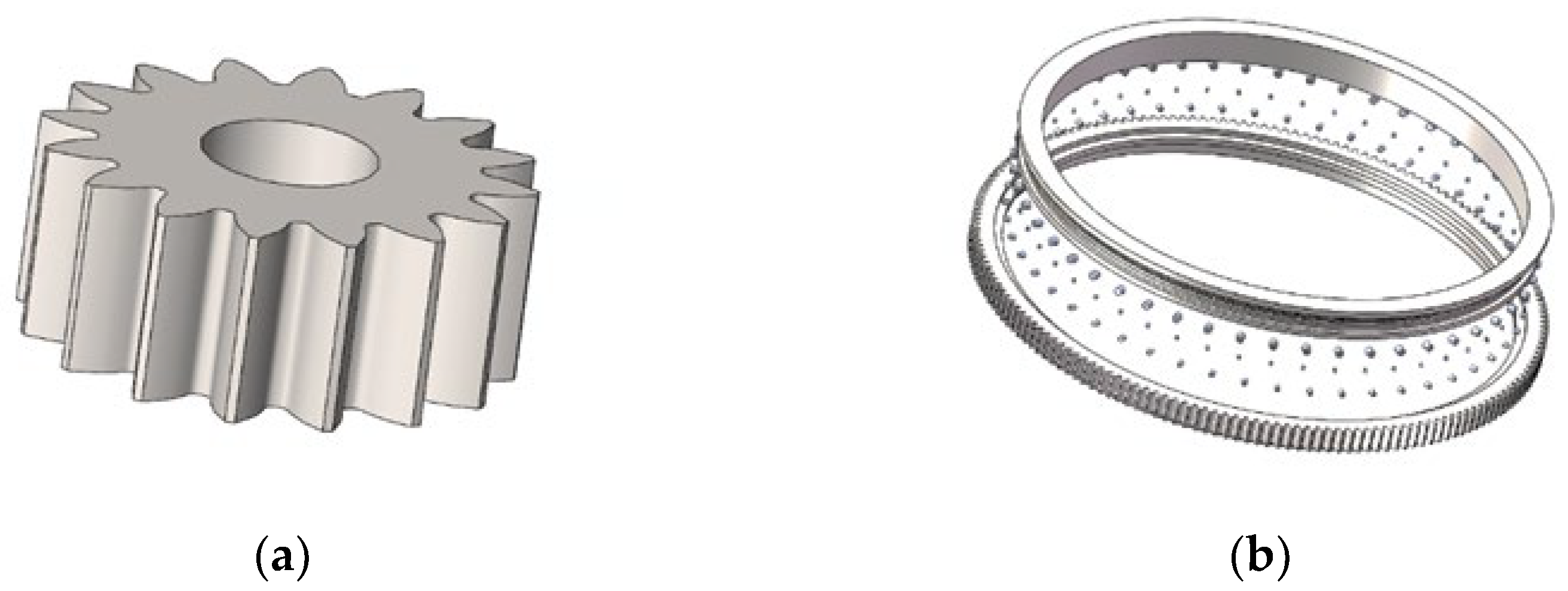

2.1. Model Construction

- Disregarding the influence of components such as cages, seals, retaining bolts, etc., on the analysis process.

- Assuming the pinion is rigidly connected to the turntable structure and ignoring the influence of components in the slewing mechanism.

- Accessories such as stairs and cabs are ignored in the modeling because they have less influence on the main structural forces.

2.2. Pre-Assembly Engagement Mechanical Properties

2.3. Gear Meshing Characteristics after Assembly

2.3.1. Assembly Model Guidance and Grid Generation

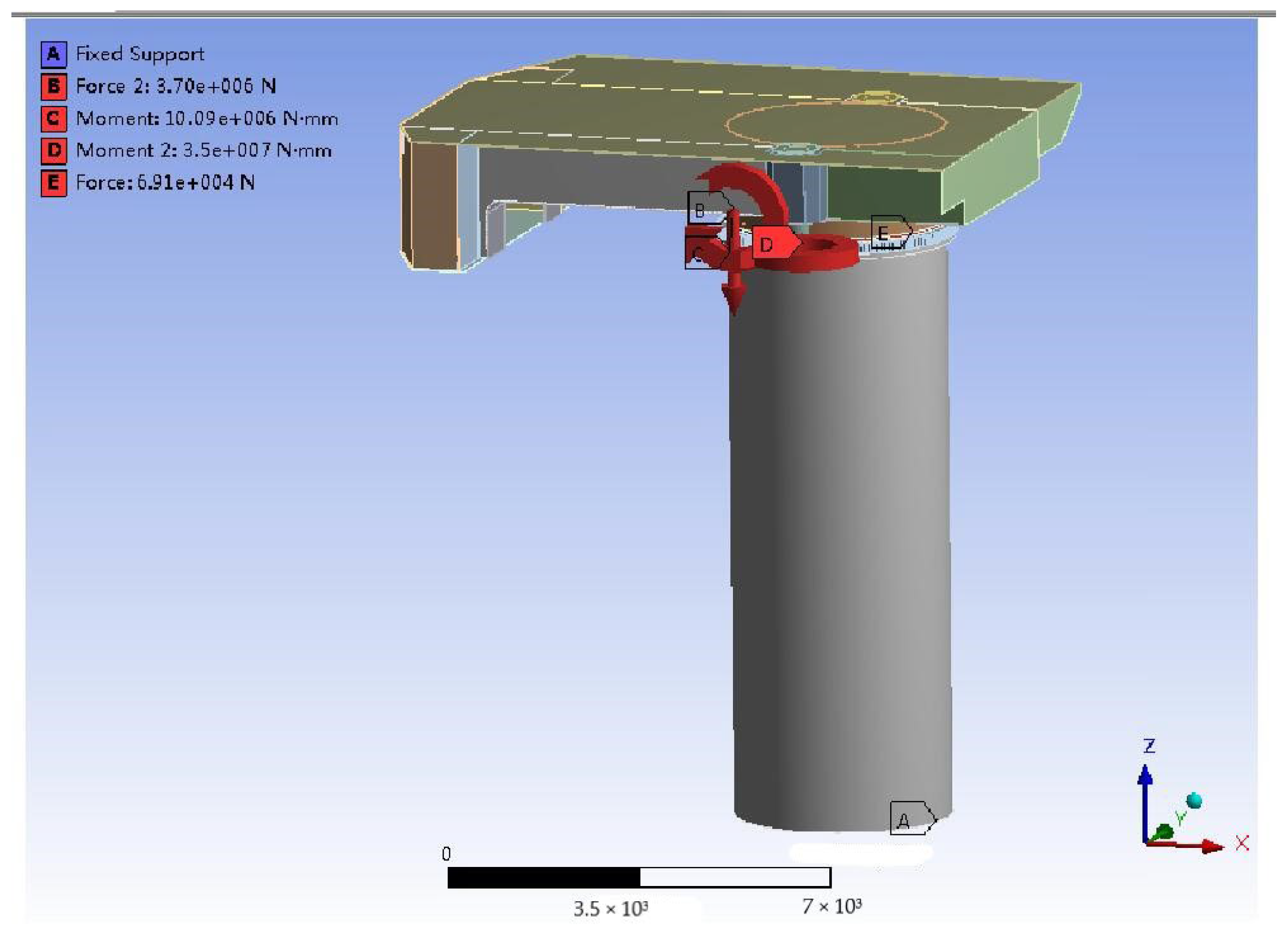

2.3.2. Definition of Contact Parameters and Boundary Conditions

- Axial load calculation

- 2.

- Radial Load Calculation

- 3.

- Calculation of overturning moment

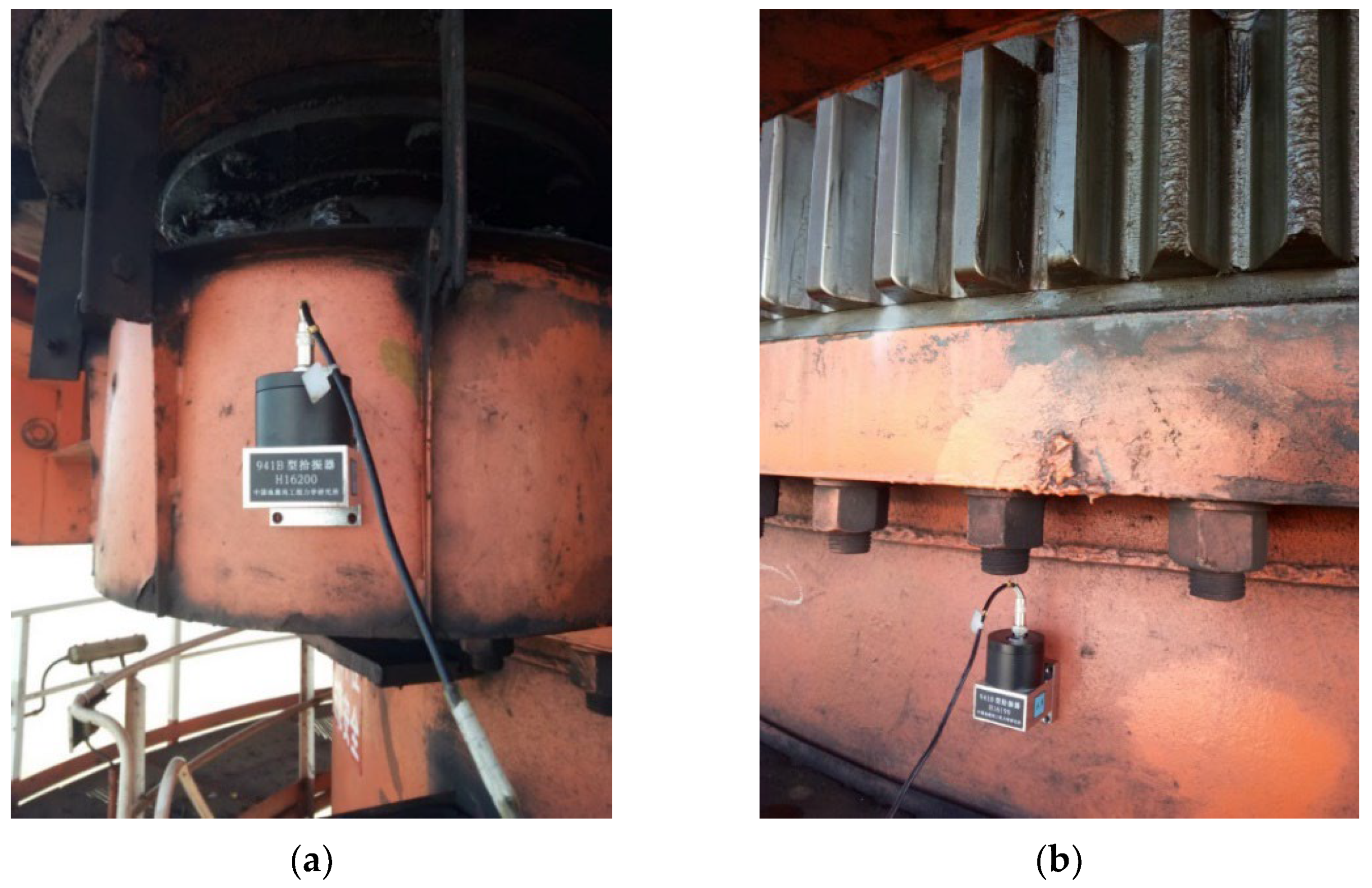

2.4. Test Bench Construction

3. Analysis of Results

3.1. Mechanical Simulation Results

3.1.1. Analysis of Deformation Results

3.1.2. Gear Tooth Meshing Displacement

3.2. Analysis of Experimental Results

3.2.1. Analysis of Displacement Results

3.2.2. Stress Results Analysis

4. Discussion and Conclusions

4.1. Discussion

4.1.1. Characteristics of Gear Position Accuracy Error Method

4.1.2. Analysis of Large Ring Gear Tooth Fracture

- (1)

- This paper takes the MQ4038 type gantry crane as the research object and analyzes the causes of broken teeth of the large gear ring of the slewing bearing. This type of gantry crane has a high cylinder structure and adopts three rows of roller-type slewing bearings. By establishing the finite element model of the rotary table structure, slewing bearing, and cylinder structure assembly, the relative displacement relationship between the pinion and the large gear ring and the forced nature of large gear ring teeth are analyzed. Under the frontal load condition, the relative displacement of the pinion and the large gear ring causes the angle between the two axes, which causes the extrusion of the gear teeth at the large gear ring meshing. Long-term extrusion will accelerate the fatigue of the gear teeth and cause the large gear ring gear teeth to break.

- (2)

- According to the field gear tooth section research, the fatigue crack sprouted from the tooth root and the broken tooth was formed by crack expansion, which can be understood to indicate that the broken tooth type is a fatigue fracture [21]. As the slewing bearing teeth are subjected to additional extrusion stress in addition to the rated torque of the pinion, they are in a bad meshing situation during operation, which leads to fatigue cracking of the tooth root bending. Finally, the broken tooth defect is produced after further expansion of the crack. The dynamic data acquisition instrument and resistance strain gauge were used to test and verify the pinion and large gear ring displacements and cylinder structure stresses, respectively, and the test results were consistent with the finite element analysis results.

4.2. Conclusions

- (1)

- Combined with the large gantry crane slewing bearing universal broken teeth failure, we analyzed the selection of the slewing bearing and slewing mechanism installation process problems. The bearing capacity and fatigue life of the slewing bearing and the gear force were checked, as was the installation quality of the slewing mechanism, and the results met the requirements. The analysis pointed out that when the gantry crane was designed and installed, the relative displacement between the teeth of the slewing bearing was not calculated during operation, which had a large impact on the meshing relationship between the pinion and the large gear ring.

- (2)

- In view of the problems in design and installation, a model of the gantry crane turntable structure, slewing bearing, and cylinder structure was established to analyze the relative displacement of the pinion and large gear ring and the stress of the large gear ring teeth after the assembly of these three parts. It was found that without the influence of adverse factors such as overload and impact, the pinion gear and the large gear ring still produced inconsistent displacement, leading to an angle of 0.48° between the two axes. Meanwhile, the stress in the upper tooth root upon the engagement of the large gear ring increased by 23%, which was five times the value of the lower tooth root stress. The result shows that the gear meshing situation is not ideal, and the upper part of the gear teeth of the large gear ring is subjected to abnormal extrusion and stress concentrations. That is an important reason behind the fatigue fracture of gear teeth.

- (3)

- In order to verify the poor meshing situation between the return gear teeth and the reasonableness of the finite element analysis results, this paper used a dynamic data acquisition instrument and a dynamic resistance strain gauge to analyze the approximate displacements of the pinion and large gear ring and the structural stress of the cylinder, respectively. The difference between the test results and the FEA results is small. The stress analysis results show that even if the design and installation process meet the requirements of use, the pinion and large gear ring will still produce inconsistent displacements, causing fatigue tooth breakage problems.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kania, L. Modelling of rollers in calculation of slewing bearing with the use of finite elements. Mech. Mach. Theory 2006, 41, 1359–1376. [Google Scholar] [CrossRef]

- Cao, G.L.; Jiang, Y. Exploration of load-bearing performance analysis method for spherical bearing. China High-Tech. Enterp. 2016, 85–86. [Google Scholar]

- Xiao, X.; Joshi, S. Automatic toolpath generation for heterogeneous objects manufactured by directed energy deposition additive manufacturing process. J. Manuf. Sci. Eng. 2018, 140, 071005. [Google Scholar] [CrossRef]

- Xiao, X.; Waddell, C.; Hamilton, C.; Xiao, H. Quality Prediction and Control in Wire Arc Additive Manufacturing via Novel Machine Learning Framework. Micromachines 2022, 13, 137. [Google Scholar] [CrossRef] [PubMed]

- Xiao, X.; Roh, B.M.; Hamilton, C. Porosity management and control in powder bed fusion process through process-quality interactions. CIRP J. Manuf. Sci. Technol. 2022, 38, 120–128. [Google Scholar] [CrossRef]

- Xiao, X.; Xiao, H. Autonomous robotic feature-based freeform fabrication approach. Materials 2021, 15, 247. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B. Kinetic Analysis of Rotary Braking Process of Fixed Crane Supporting Cylinder; Wuhan University of Technology: Wuhan, China, 2009. [Google Scholar]

- Ding, B. Repair process of broken teeth of gantry crane slewing bearing. Technol. Innov. Appl. 2017, 185, 124. [Google Scholar]

- Yang, Y.; Wang, J.; Jiao, H.; Zhang, H. Repair process of gantry crane slewing bearing external gear teeth. Constr. Mach. Maint. 2016, 63–64. [Google Scholar] [CrossRef]

- Guo, S.; Zhu, K.; Shandong Province; Heze Traffic Senior Technical School. Repair of crane slewing gear ring. Constr. Mach. Maint. 2008, 167. [Google Scholar] [CrossRef]

- Li, H. Dynamic Simulation Study of Roller-Jacketed Slewing Bearings for Large Marine Cranes; Wuhan University of Technology: Wuhan, China, 2014. [Google Scholar]

- Wang, Y. Finite Element Analysis of Crane Slewing Bearing Contact Problem Based on ANSYS; Southwest Jiaotong University: Chengdu, China, 2011. [Google Scholar]

- Xiao, X.; Joshi, S. Process planning for five-axis support free additive manufacturing. Addit. Manuf. 2020, 36, 101569. [Google Scholar] [CrossRef]

- Xiao, X.; Joshi, S.; Cecil, J. Critical assessment of Shape Retrieval Tools (SRTs). Int. J. Adv. Manuf. Technol. 2021, 116, 3431–3446. [Google Scholar] [CrossRef]

- Zou, S.; Pang, L.; Xu, C.; Xiao, X. Effect of Process Parameters on Distortions Based on the Quantitative Model in the SLM. Process. Appl. Sci. 2022, 12, 1567. [Google Scholar] [CrossRef]

- Liu, C.; Wang, F. A review of current condition monitoring and fault diagnosis methods for low-speed and heavy-load slewing bearings. In Proceedings of the IEEE 2017 9th International Conference on Modelling, Identification and Control (ICMIC), Kunming, China, 10–12 July 2017; pp. 104–109. [Google Scholar]

- Qiu, M.; Van, J.F.; Zhao, B.H.; Chen, L.; Bai, Y.X. A finite-element analysis of the connecting bolts of slewing bearings based on the orthogonal method. J. Mech. Technol. 2012, 26, 883–887. [Google Scholar] [CrossRef]

- Yang, J.; Chen, J.; Jing, R.; Wang, H.; Feng, Y. Research of slew bearing signal de-noising based on multi-scale principal component analysis and EEMD. J. Cent. S. Univ. 2016, 47, 1173–1180. [Google Scholar]

- Wang, F.; Liu, C. A review of current condition monitoring and fault diagnosis methods for slewing bearings. In Innovative Techniques and Applications of Modelling, Identification and Control; Springer: Singapore, 2018; pp. 53–62. [Google Scholar]

- Liu, Z.; Zhang, L. A review of failure modes, condition monitoring and fault diagnosis methods for large-scale wind turbine bearings. Measurement 2020, 149, 107002. [Google Scholar] [CrossRef]

- Caesarendra, W.; Kosasih, B.; Tieu, A.K.; Zhu, H.; Moodie, C.A.; Zhu, Q. Acoustic emission-based condition monitoring methods: Review and application for low speed slew bearing. Mech. Syst. Signal Process. 2016, 72, 134–159. [Google Scholar] [CrossRef]

| Lifting Status Level | |||

|---|---|---|---|

| HC1 | Lifts off the ground smoothly | 0.17 | 1.05 |

| HC2 | Lift off the ground with a slight impact | 0.34 | 1.10 |

| HC3 | Lift off the ground with a moderate impact | 0.51 | 1.13 |

| HC4 | Lift off the ground with a large impact | 0.68 | 1.20 |

| Working Conditions | Axial Load | Horizontal Load | Overturning Moment |

|---|---|---|---|

| Rated load 40 t Max. 38 m | Fa (N) | Fr (N) | M (N-m) |

| 3.70 × 106 | 6.91 × 104 | 10.09 × 106 |

| Maximum Displacement (mm) | Test Value | Finite Element Analysis Value | Deviation |

|---|---|---|---|

| Large gear ring | 8.313 | 12.9531 | 4.6401 |

| Pinion | 11.215 | 15.0023 | 3.7873 |

| Gear displacement deviation | 2.902 | 2.0492 | -- |

| Measurement Point Number | Test Value (MPa) | Finite Element Analysis Value (MPa) | Deviation (MPa) |

|---|---|---|---|

| J1 | −23.9 | −35.2 | 11.3 |

| J2 | +17.2 | +21.4 | 4.2 |

| K1 | −47.9 | −44.8 | 3.1 |

| K2 | +21.4 | +28.0 | 6.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, J.; Wu, Y.; Long, W.; Xu, C. Failure Analysis of Gantry Crane Slewing Bearing Based on Gear Position Accuracy Error. Appl. Sci. 2022, 12, 11907. https://doi.org/10.3390/app122311907

Xiao J, Wu Y, Long W, Xu C. Failure Analysis of Gantry Crane Slewing Bearing Based on Gear Position Accuracy Error. Applied Sciences. 2022; 12(23):11907. https://doi.org/10.3390/app122311907

Chicago/Turabian StyleXiao, Jianbo, Yiming Wu, Wenxing Long, and Chang Xu. 2022. "Failure Analysis of Gantry Crane Slewing Bearing Based on Gear Position Accuracy Error" Applied Sciences 12, no. 23: 11907. https://doi.org/10.3390/app122311907

APA StyleXiao, J., Wu, Y., Long, W., & Xu, C. (2022). Failure Analysis of Gantry Crane Slewing Bearing Based on Gear Position Accuracy Error. Applied Sciences, 12(23), 11907. https://doi.org/10.3390/app122311907