Prediction of Compressive Strength Loss of Normal Concrete after Exposure to High Temperature

Abstract

:1. Introduction

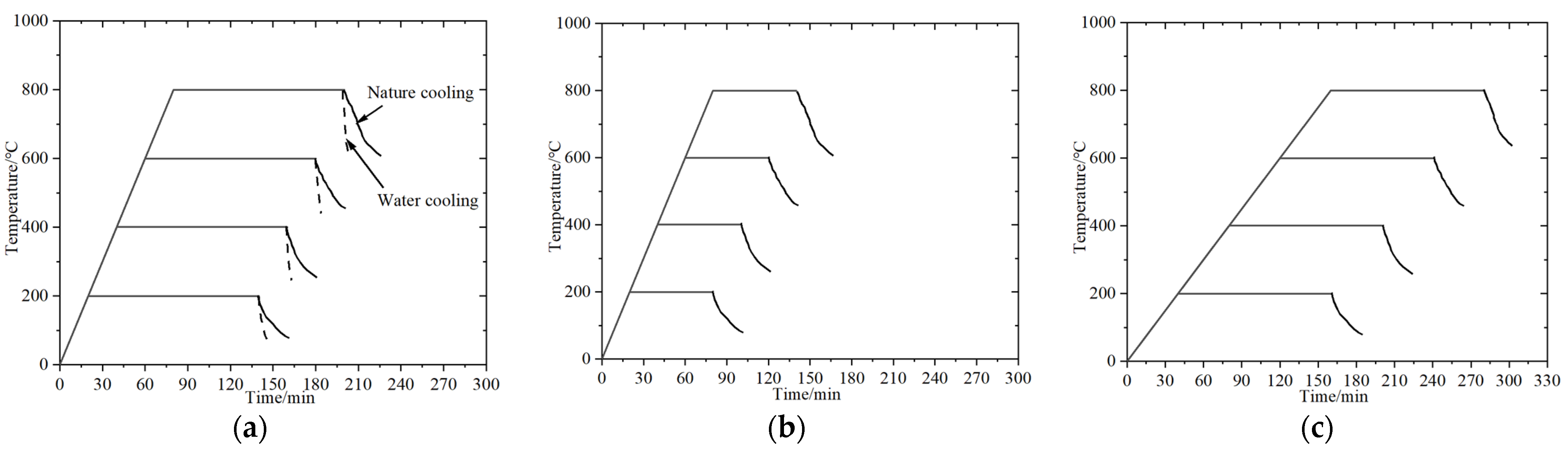

2. Modeling

2.1. Parameter Determination

2.2. Data Collection

2.3. Models

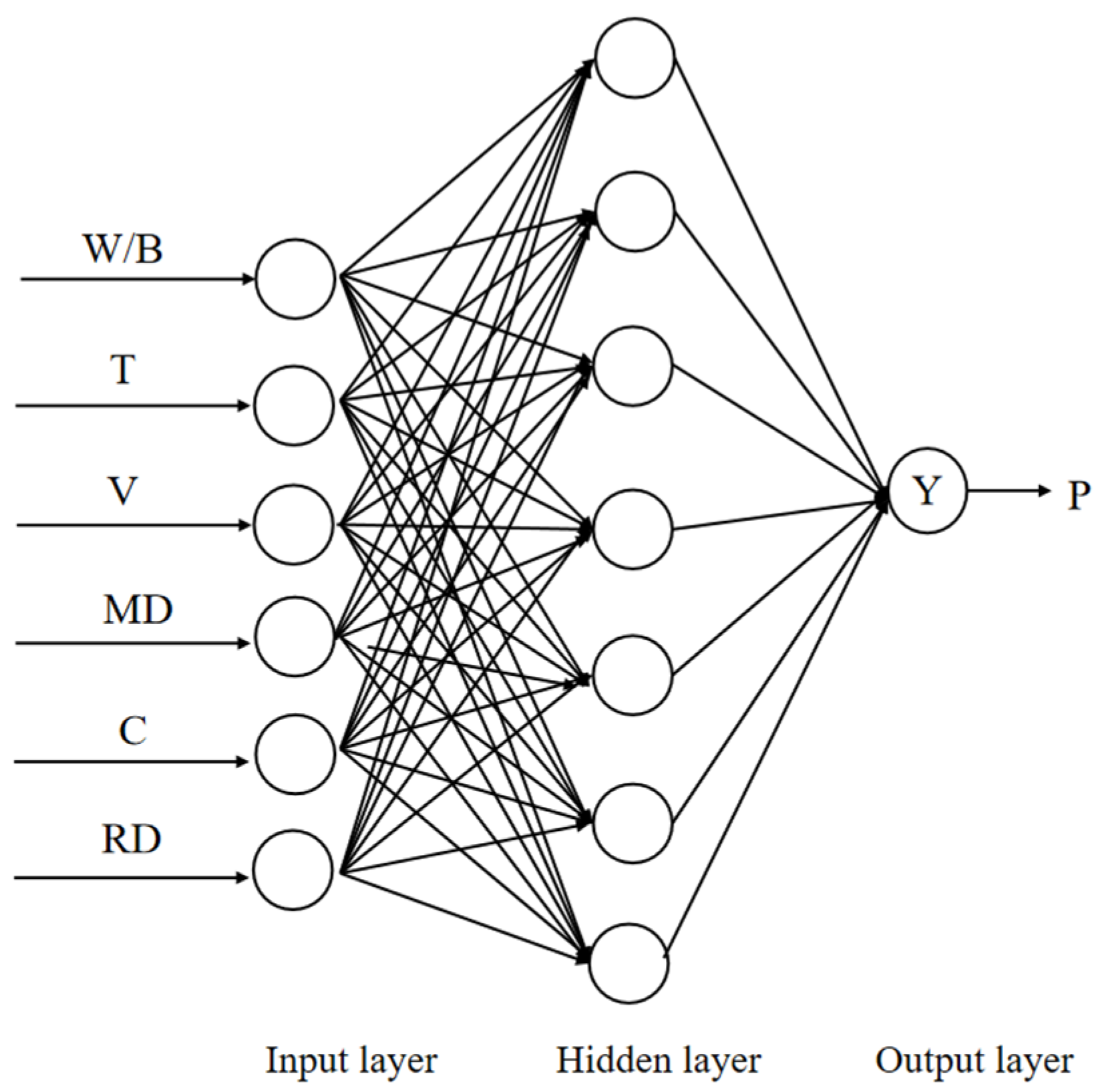

2.3.1. BP Neural Network

2.3.2. PSO-BP Neural Network

- →

- Vi: particle velocity, denoted as (Vi1, Vi2, Vi3......ViA)T;

- →

- Pi: individual extreme value, denoted as (Pi1, Pi2, Pi3......PiA)T;

- →

- Pg: global extreme value, denoted as (Pg1, Pg2, Pg3......PgA)T;

- →

- Xi: particle position, denoted as (Xi1, Xi2, Xi3......XiA)T;

- →

- ω: inertia weights;

- →

- k: number of current iterations;

- →

- c1 and c2: learning factors which are non-negative constants;

- →

- r1 and r2: momentum coefficients which are random numbers between [0,1].

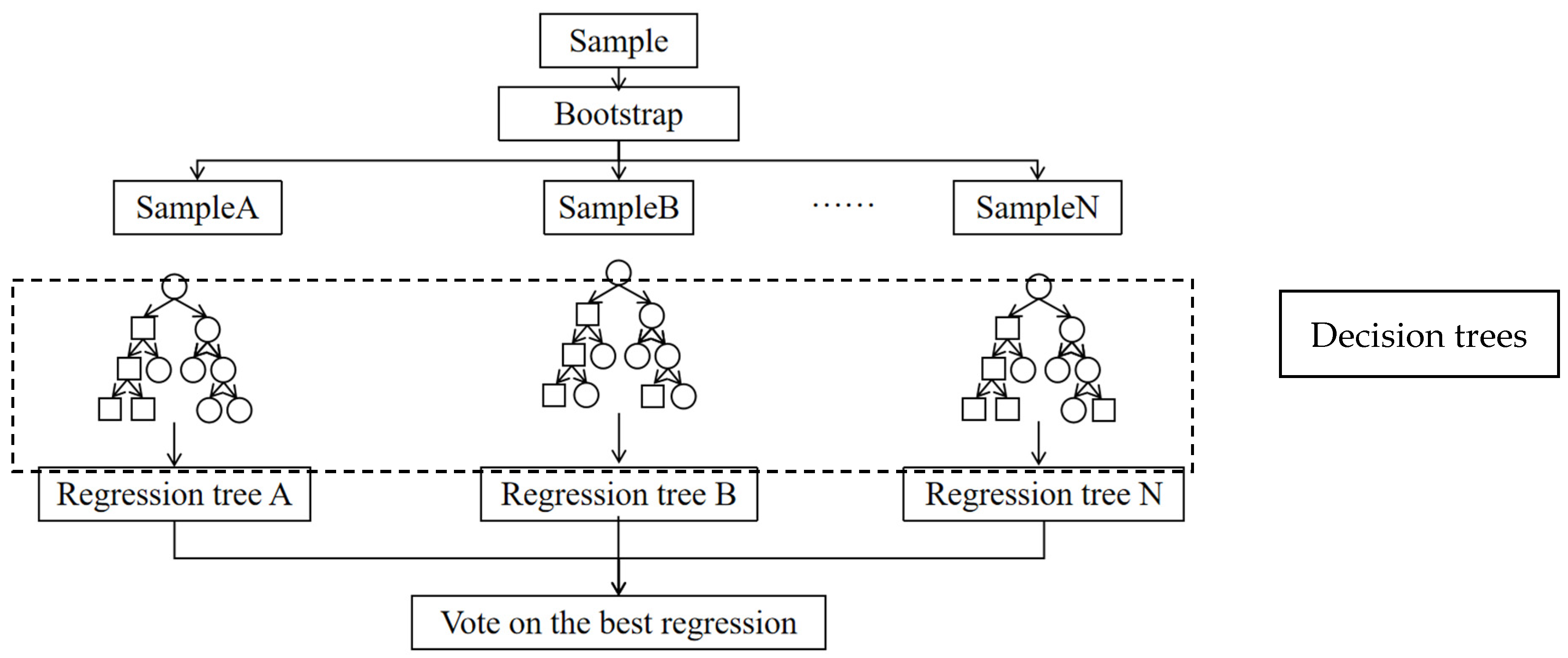

2.3.3. RF

2.4. Error Evaluation

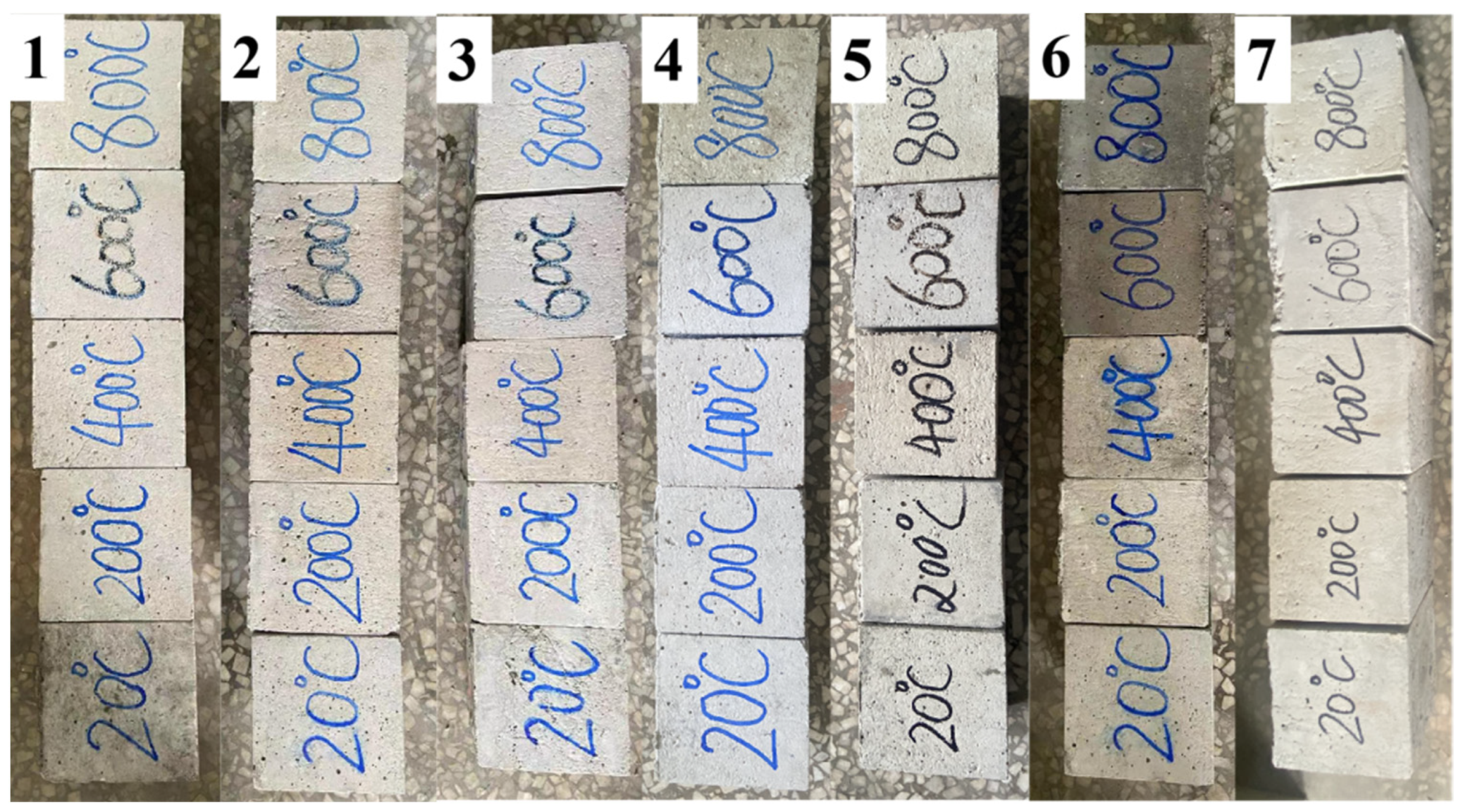

3. Experimental Program

4. Results and Discussion

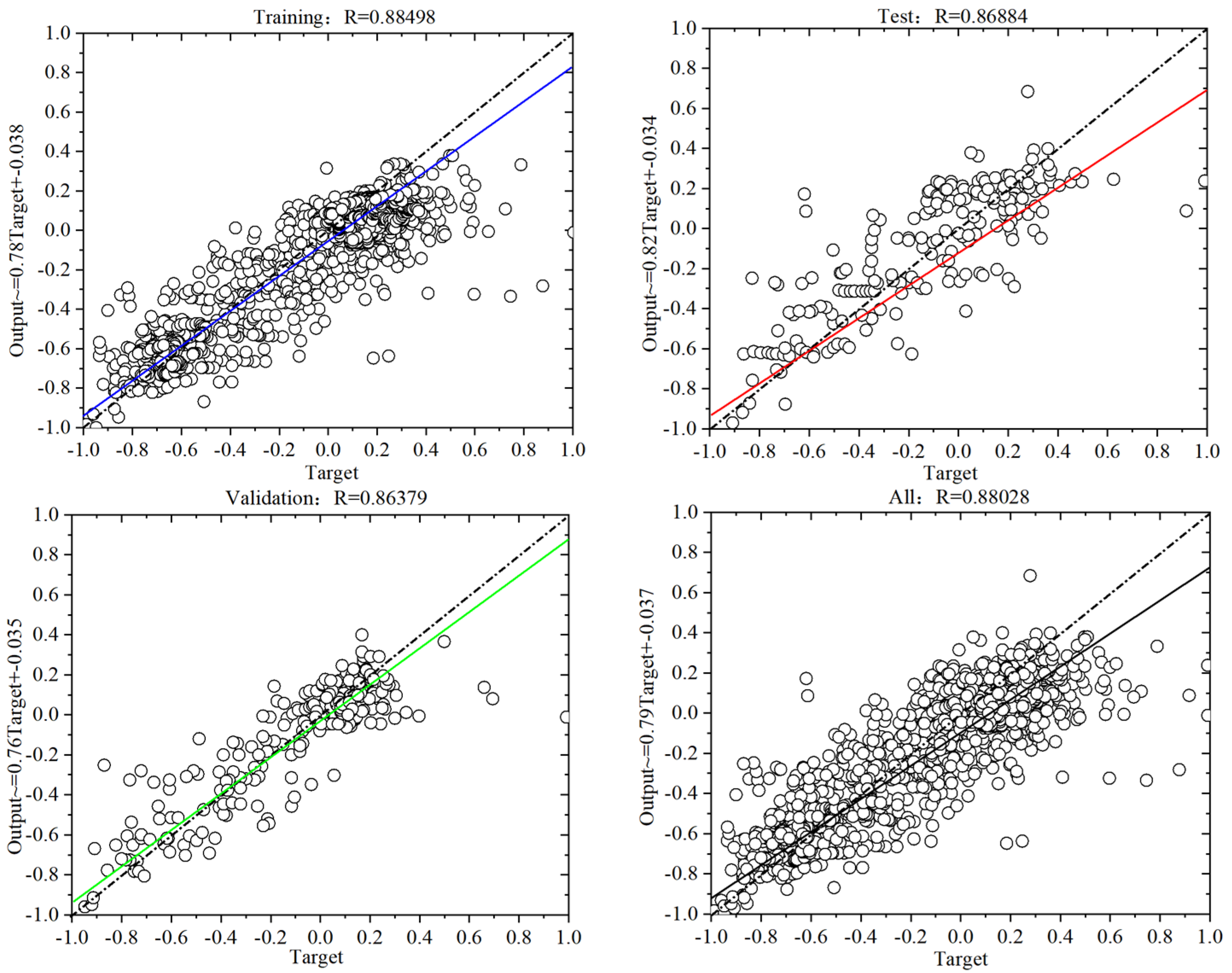

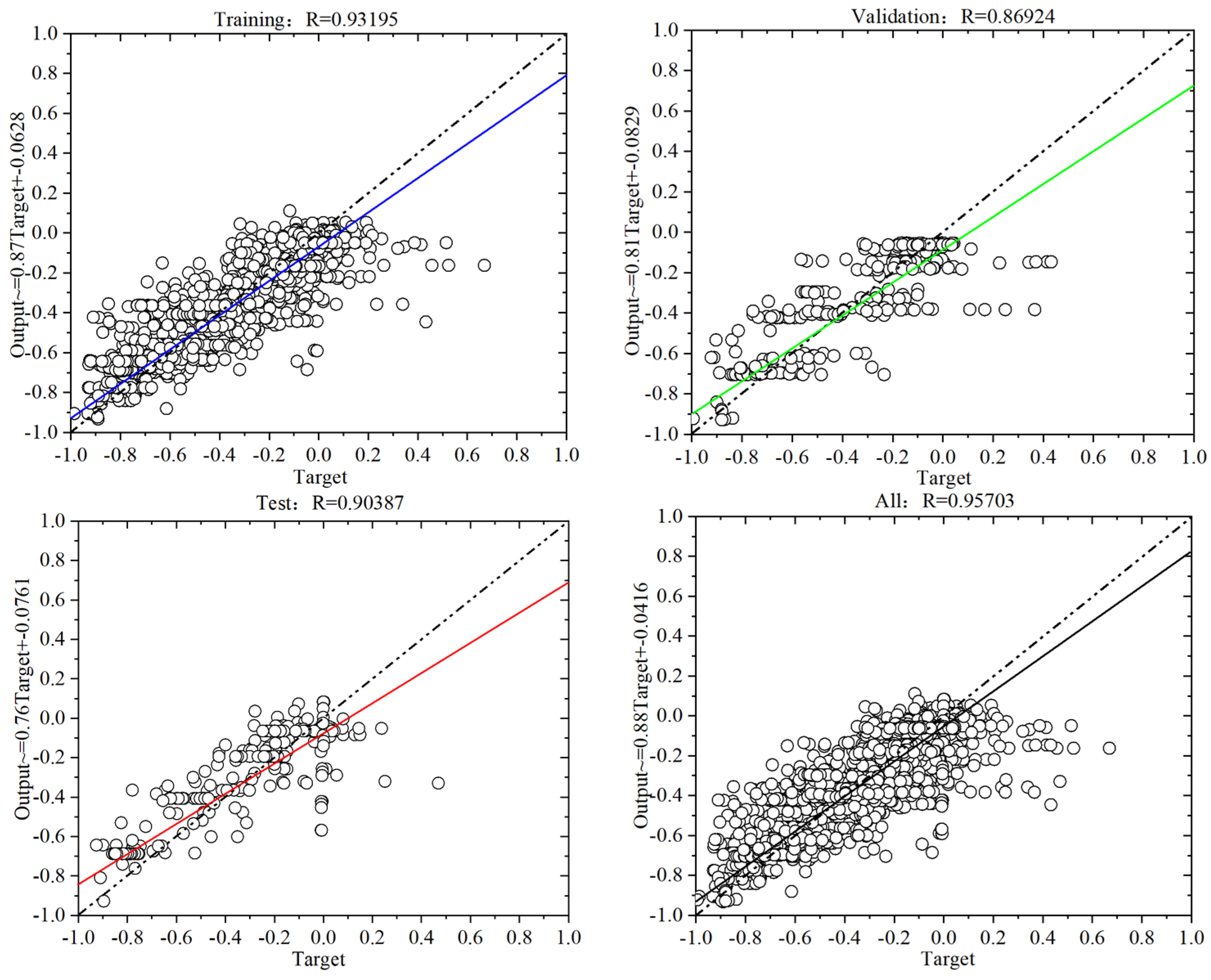

4.1. Modeling

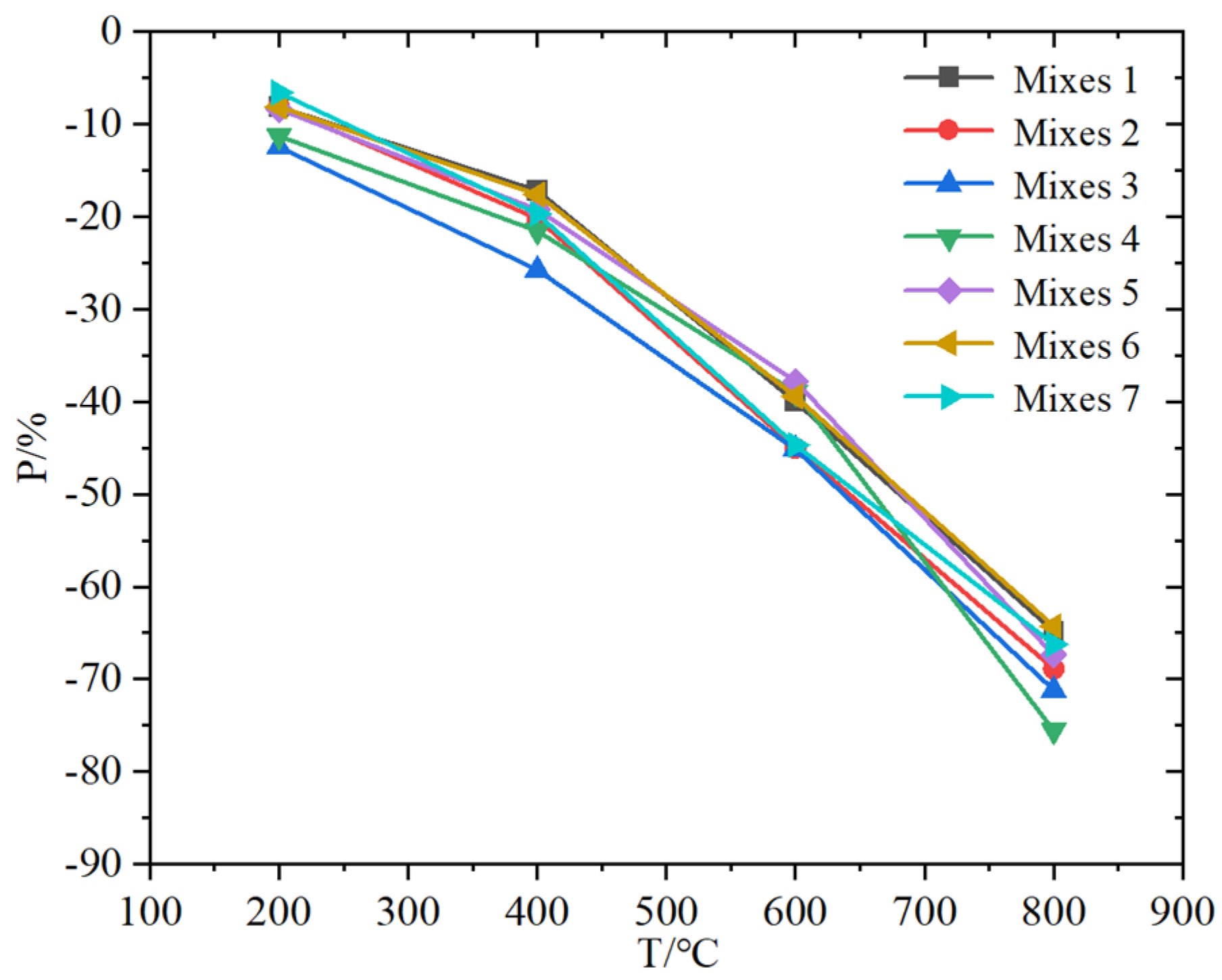

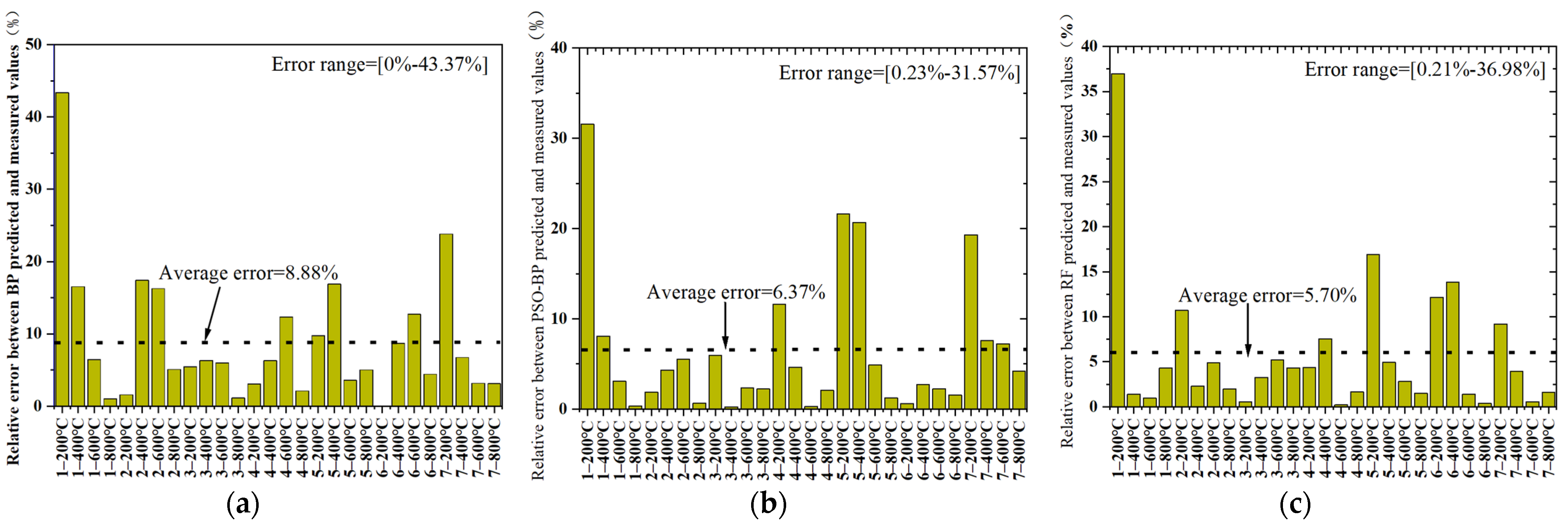

4.2. Experimental Validation

4.3. VIM

5. Conclusions

- (1)

- To establish the models, 1803 sets of data from the publicly published literature were used, W/B, T, V, MD, C and RD were determined as input parameters and P was applied as an output parameter. Based on RMSE and MAE error evaluation, the accuracy of all three models was sufficiently high. Compared to the BP model, both the PSO-BP and the RF models were more accurate.

- (2)

- Parallel experimental work was carried out with modeling prediction using the same parameters. An error value between the results measured and predicted of less than 10% proved that all three models had sufficient feasibility to complement the prediction. Compared to the other two models, RF one was much more feasible.

- (3)

- Based on the RF model, the importance of the input parameters was ranked in the sequence of T > W/B > V > MD > RD > C.

- (4)

- With the continuous expansion of data size, the accuracy of the models could be improved further. Such prediction work has provided a new perspective to assess the post-fire properties of concrete non-destructively and objectively. Additionally, it could be used to guide performance-based design for fire-resistant concrete.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| REF. | Input Parameters | Output Parameters | |||||

|---|---|---|---|---|---|---|---|

| W/B | T (°C) | V (°C/min) | MD (h) | C | RD (day) | P (%) | |

| [5] | 0.49 | 200 | 10 | 2 | 1 | 14 | −4.28 |

| 0.49 | 300 | 10 | 2 | 1 | 14 | 8.06 | |

| 0.49 | 400 | 10 | 2 | 1 | 14 | 11.83 | |

| 0.49 | 500 | 10 | 2 | 1 | 14 | 2.00 | |

| 0.49 | 600 | 10 | 2 | 1 | 14 | −23.50 | |

| 0.49 | 700 | 10 | 2 | 1 | 14 | −50.06 | |

| 0.49 | 800 | 10 | 2 | 1 | 14 | −71.17 | |

| 0.49 | 200 | 10 | 2 | 0 | 14 | −1.33 | |

| 0.49 | 300 | 10 | 2 | 0 | 14 | 0.94 | |

| 0.49 | 400 | 10 | 2 | 0 | 14 | −1.75 | |

| 0.49 | 500 | 10 | 2 | 0 | 14 | 1.81 | |

| 0.49 | 600 | 10 | 2 | 0 | 14 | −17.64 | |

| 0.49 | 700 | 10 | 2 | 0 | 14 | −42.75 | |

| 0.49 | 800 | 10 | 2 | 0 | 14 | −63.03 | |

| [6] | 0.18 | 100 | 2 | 2 | 1 | 3 | −1.05 |

| 0.18 | 200 | 2 | 2 | 1 | 3 | 14.65 | |

| 0.18 | 300 | 2 | 2 | 1 | 3 | 25.42 | |

| 0.18 | 400 | 2 | 2 | 1 | 3 | 34.56 | |

| 0.18 | 500 | 2 | 2 | 1 | 3 | 8.61 | |

| 0.18 | 600 | 2 | 2 | 1 | 3 | 4.22 | |

| 0.18 | 800 | 2 | 2 | 1 | 3 | −68.85 | |

| [7] | 0.52 | 200 | 5 | 6 | 1 | 0 | −1.05 |

| 0.52 | 400 | 5 | 6 | 1 | 0 | −9.41 | |

| 0.52 | 600 | 5 | 6 | 1 | 0 | −27.74 | |

| 0.52 | 800 | 5 | 6 | 1 | 0 | −43.71 | |

| 0.52 | 200 | 5 | 6 | 0 | 2 | 2.09 | |

| 0.52 | 400 | 5 | 6 | 0 | 2 | −11.00 | |

| 0.52 | 600 | 5 | 6 | 0 | 2 | −33.50 | |

| 0.52 | 800 | 5 | 6 | 0 | 2 | −52.36 | |

| [8] | 0.33 | 105 | 10 | 3 | 1 | 1 | −7.06 |

| 0.33 | 200 | 10 | 3 | 1 | 1 | −12.86 | |

| 0.33 | 400 | 10 | 3 | 1 | 1 | −36.64 | |

| 0.33 | 600 | 10 | 3 | 1 | 1 | −63.91 | |

| 0.33 | 800 | 10 | 3 | 1 | 1 | −85.36 | |

| [9] | 0.49 | 105 | 10 | 6 | 1 | 1 | −10.00 |

| 0.49 | 300 | 10 | 6 | 1 | 1 | −2.80 | |

| 0.49 | 500 | 10 | 6 | 1 | 1 | −13.34 | |

| 0.49 | 700 | 10 | 6 | 1 | 1 | −51.94 | |

| 0.6 | 105 | 10 | 6 | 1 | 0 | −11.67 | |

| 0.6 | 300 | 10 | 6 | 1 | 0 | −7.00 | |

| 0.6 | 500 | 10 | 6 | 1 | 0 | −19.63 | |

| 0.6 | 700 | 10 | 6 | 1 | 0 | −44.23 | |

| 0.49 | 105 | 10 | 6 | 1 | 0 | −10.01 | |

| 0.49 | 300 | 10 | 6 | 1 | 0 | −3.42 | |

| 0.49 | 500 | 10 | 6 | 1 | 0 | −14.23 | |

| 0.49 | 700 | 10 | 6 | 1 | 0 | −41.75 | |

| 0.4 | 105 | 10 | 6 | 1 | 0 | −12.74 | |

| 0.4 | 300 | 10 | 6 | 1 | 0 | −9.07 | |

| 0.4 | 500 | 10 | 6 | 1 | 0 | −10.81 | |

| 0.4 | 700 | 10 | 6 | 1 | 0 | −46.70 | |

| [10] | 0.5 | 100 | 10 | 1 | 1 | 1 | −8.28 |

| 0.5 | 100 | 10 | 2 | 1 | 1 | −8.77 | |

| 0.5 | 100 | 10 | 3 | 1 | 1 | −6.16 | |

| 0.5 | 100 | 10 | 1 | 1 | 1 | −6.62 | |

| 0.5 | 100 | 10 | 2 | 1 | 1 | −8.48 | |

| 0.5 | 100 | 10 | 3 | 1 | 1 | −1.86 | |

| 0.5 | 100 | 10 | 1 | 1 | 1 | −6.85 | |

| 0.5 | 100 | 10 | 2 | 1 | 1 | −8.95 | |

| 0.5 | 100 | 10 | 3 | 1 | 1 | −4.09 | |

| 0.5 | 300 | 10 | 1 | 1 | 1 | −7.35 | |

| 0.5 | 300 | 10 | 2 | 1 | 1 | −5.64 | |

| 0.5 | 300 | 10 | 3 | 1 | 1 | −6.67 | |

| 0.5 | 300 | 10 | 1 | 1 | 1 | −4.23 | |

| 0.5 | 300 | 10 | 2 | 1 | 1 | −6.11 | |

| 0.5 | 300 | 10 | 3 | 1 | 1 | −7.73 | |

| 0.5 | 300 | 10 | 1 | 1 | 1 | −3.16 | |

| 0.5 | 300 | 10 | 2 | 1 | 1 | −4.66 | |

| 0.5 | 300 | 10 | 3 | 1 | 1 | −7.77 | |

| 0.5 | 500 | 10 | 1 | 1 | 1 | −38.09 | |

| 0.5 | 500 | 10 | 2 | 1 | 1 | −41.99 | |

| 0.5 | 500 | 10 | 3 | 1 | 1 | −46.16 | |

| 0.5 | 500 | 10 | 1 | 1 | 1 | −36.27 | |

| 0.5 | 500 | 10 | 2 | 1 | 1 | −41.93 | |

| 0.5 | 500 | 10 | 3 | 1 | 1 | −47.90 | |

| 0.5 | 500 | 10 | 1 | 1 | 1 | −39.07 | |

| 0.5 | 500 | 10 | 2 | 1 | 1 | −41.79 | |

| 0.5 | 500 | 10 | 3 | 1 | 1 | −48.22 | |

| 0.5 | 700 | 10 | 1 | 1 | 1 | −62.35 | |

| 0.5 | 700 | 10 | 2 | 1 | 1 | −67.53 | |

| 0.5 | 700 | 10 | 3 | 1 | 1 | −68.91 | |

| 0.5 | 700 | 10 | 1 | 1 | 1 | −63.46 | |

| 0.5 | 700 | 10 | 2 | 1 | 1 | −66.48 | |

| 0.5 | 700 | 10 | 3 | 1 | 1 | −69.65 | |

| 0.5 | 700 | 10 | 1 | 1 | 1 | −66.18 | |

| 0.5 | 700 | 10 | 2 | 1 | 1 | −68.90 | |

| 0.5 | 700 | 10 | 3 | 1 | 1 | −70.65 | |

| [11] | 0.57 | 200 | 16 | 1.5 | 1 | 2 | −6.75 |

| 0.57 | 400 | 10 | 1.5 | 1 | 2 | −13.00 | |

| 0.57 | 600 | 3 | 1.5 | 1 | 2 | −48.75 | |

| 0.57 | 200 | 16 | 1.5 | 0 | 2 | −2.25 | |

| 0.57 | 400 | 10 | 1.5 | 0 | 2 | −20.00 | |

| 0.57 | 600 | 3 | 1.5 | 0 | 2 | −38.50 | |

| 0.57 | 200 | 16 | 1.5 | 1 | 2 | −17.02 | |

| 0.57 | 400 | 10 | 1.5 | 1 | 2 | −26.71 | |

| 0.57 | 600 | 3 | 1.5 | 1 | 2 | −55.79 | |

| 0.57 | 200 | 16 | 1.5 | 0 | 2 | −15.60 | |

| 0.57 | 400 | 10 | 1.5 | 0 | 2 | −29.08 | |

| 0.57 | 600 | 3 | 1.5 | 0 | 2 | −47.04 | |

| 0.57 | 200 | 16 | 1.5 | 1 | 2 | −11.33 | |

| 0.57 | 400 | 10 | 1.5 | 1 | 2 | −23.65 | |

| 0.57 | 600 | 3 | 1.5 | 1 | 2 | −61.08 | |

| 0.57 | 200 | 16 | 1.5 | 0 | 2 | −10.10 | |

| 0.57 | 400 | 10 | 1.5 | 0 | 2 | −32.51 | |

| 0.57 | 600 | 3 | 1.5 | 0 | 2 | −48.77 | |

| 0.57 | 200 | 16 | 1.5 | 1 | 2 | −7.73 | |

| 0.57 | 400 | 10 | 1.5 | 1 | 2 | −27.93 | |

| 0.57 | 600 | 3 | 1.5 | 1 | 2 | −57.61 | |

| 0.57 | 200 | 16 | 1.5 | 0 | 2 | −3.24 | |

| 0.57 | 400 | 10 | 1.5 | 0 | 2 | −32.67 | |

| 0.57 | 600 | 3 | 1.5 | 0 | 2 | −41.15 | |

| 0.57 | 200 | 16 | 1.5 | 1 | 2 | −5.97 | |

| 0.57 | 400 | 10 | 1.5 | 1 | 2 | −28.05 | |

| 0.57 | 600 | 3 | 1.5 | 1 | 2 | −62.08 | |

| 0.57 | 800 | 2.29 | 1.5 | 1 | 2 | −83.64 | |

| 0.57 | 200 | 16 | 1.5 | 0 | 2 | −3.90 | |

| 0.57 | 400 | 10 | 1.5 | 0 | 2 | −37.66 | |

| 0.57 | 600 | 3 | 1.5 | 0 | 2 | −48.05 | |

| 0.57 | 800 | 2.29 | 1.5 | 0 | 2 | −88.31 | |

| [12] | 0.42 | 300 | 30 | 1.5 | 1 | 90 | 1.37 |

| 0.42 | 500 | 25 | 1 | 1 | 90 | 1.31 | |

| 0.42 | 700 | 17.5 | 1 | 1 | 90 | 1.78 | |

| 0.42 | 900 | 11.25 | 1 | 1 | 90 | −1.75 | |

| 0.42 | 300 | 30 | 1.67 | 1 | 90 | 0.03 | |

| 0.42 | 500 | 25 | 1.67 | 1 | 90 | 4.24 | |

| 0.42 | 700 | 17.5 | 1.67 | 1 | 90 | −15.57 | |

| 0.42 | 900 | 11.25 | 1.67 | 1 | 90 | −27.11 | |

| 0.42 | 300 | 30 | 2.33 | 1 | 90 | 2.17 | |

| 0.42 | 500 | 25 | 2.33 | 1 | 90 | −5.90 | |

| 0.42 | 700 | 17.5 | 2.33 | 1 | 90 | −50.55 | |

| 0.42 | 900 | 11.25 | 2.33 | 1 | 90 | −70.10 | |

| 0.42 | 300 | 30 | 3 | 1 | 90 | 4.57 | |

| 0.42 | 500 | 25 | 3 | 1 | 90 | −4.57 | |

| 0.42 | 700 | 17.5 | 3 | 1 | 90 | −58.82 | |

| 0.42 | 900 | 11.25 | 3 | 1 | 90 | −73.57 | |

| 0.42 | 300 | 30 | 1 | 0 | 90 | −2.33 | |

| 0.42 | 500 | 25 | 1 | 0 | 90 | −10.62 | |

| [13] | 0.42 | 700 | 17.5 | 1 | 0 | 90 | −15.43 |

| 0.42 | 900 | 11.25 | 1 | 0 | 90 | −21.31 | |

| 0.42 | 300 | 30 | 1.67 | 0 | 90 | −5.22 | |

| 0.42 | 500 | 25 | 1.67 | 0 | 90 | −1.21 | |

| 0.42 | 700 | 17.5 | 1.67 | 0 | 90 | −13.78 | |

| 0.42 | 900 | 11.25 | 1.67 | 0 | 90 | −47.30 | |

| 0.42 | 300 | 30 | 2.33 | 0 | 90 | −1.42 | |

| 0.42 | 500 | 25 | 2.33 | 0 | 90 | −17.73 | |

| 0.42 | 700 | 17.5 | 2.33 | 0 | 90 | −48.21 | |

| 0.42 | 900 | 11.25 | 2.33 | 0 | 90 | −58.64 | |

| 0.42 | 300 | 30 | 3 | 0 | 90 | 2.91 | |

| 0.42 | 500 | 25 | 3 | 0 | 90 | −9.12 | |

| 0.42 | 700 | 17.5 | 3 | 0 | 90 | −63.13 | |

| 0.42 | 900 | 11.25 | 3 | 0 | 90 | −72.22 | |

| [14] | 0.52 | 200 | 6.67 | 2 | 1 | 2 | −14.58 |

| 0.52 | 200 | 6.67 | 6 | 1 | 2 | −17.17 | |

| 0.52 | 200 | 6.67 | 24 | 1 | 2 | −24.02 | |

| 0.52 | 200 | 6.67 | 48 | 1 | 2 | −26.80 | |

| 0.52 | 400 | 13.33 | 2 | 1 | 2 | −45.23 | |

| 0.52 | 400 | 13.33 | 6 | 1 | 2 | −52.54 | |

| 0.52 | 400 | 13.33 | 24 | 1 | 2 | −57.13 | |

| 0.52 | 400 | 13.33 | 48 | 1 | 2 | −60.30 | |

| 0.52 | 600 | 20 | 2 | 1 | 2 | −85.16 | |

| 0.52 | 600 | 20 | 6 | 1 | 2 | −88.72 | |

| 0.52 | 600 | 20 | 24 | 1 | 2 | −89.46 | |

| 0.52 | 600 | 20 | 48 | 1 | 2 | −90.56 | |

| 0.52 | 800 | 26.67 | 2 | 1 | 2 | −92.43 | |

| 0.52 | 800 | 26.67 | 6 | 1 | 2 | −92.79 | |

| 0.52 | 800 | 26.67 | 24 | 1 | 2 | −93.18 | |

| 0.52 | 800 | 26.67 | 48 | 1 | 2 | −93.95 | |

| [15] | 0.58 | 150 | 150 | 3 | 1 | 27 | −3.25 |

| 0.58 | 150 | 150 | 3 | 1 | 25 | 3.25 | |

| 0.58 | 150 | 150 | 3 | 1 | 21 | −15.52 | |

| 0.58 | 150 | 150 | 3 | 1 | 14 | −17.33 | |

| 0.58 | 150 | 150 | 3 | 1 | 0 | −22.74 | |

| 0.58 | 300 | 300 | 3 | 1 | 27 | −13.36 | |

| 0.58 | 300 | 300 | 3 | 1 | 25 | −8.30 | |

| 0.58 | 300 | 300 | 3 | 1 | 21 | −20.58 | |

| 0.58 | 300 | 300 | 3 | 1 | 14 | −16.35 | |

| 0.58 | 300 | 300 | 3 | 1 | 0 | −29.96 | |

| 0.58 | 400 | 200 | 3 | 1 | 27 | −19.49 | |

| 0.58 | 400 | 200 | 3 | 1 | 25 | −9.75 | |

| 0.58 | 400 | 200 | 3 | 1 | 21 | −13.00 | |

| 0.58 | 400 | 200 | 3 | 1 | 14 | −22.02 | |

| 0.58 | 400 | 200 | 3 | 1 | 0 | −16.97 | |

| 0.58 | 600 | 75 | 3 | 1 | 27 | −37.55 | |

| 0.58 | 600 | 75 | 3 | 1 | 25 | −23.47 | |

| 0.58 | 600 | 75 | 3 | 1 | 21 | −29.97 | |

| 0.58 | 600 | 75 | 3 | 1 | 14 | −47.29 | |

| 0.58 | 600 | 75 | 3 | 1 | 0 | −35.74 | |

| 0.58 | 800 | 35.5 | 3 | 1 | 27 | −62.82 | |

| 0.58 | 800 | 35.5 | 3 | 1 | 25 | −47.29 | |

| 0.58 | 800 | 35.5 | 3 | 1 | 21 | −51.99 | |

| 0.58 | 800 | 35.5 | 3 | 1 | 14 | −73.65 | |

| 0.58 | 800 | 35.5 | 3 | 1 | 0 | −59.93 | |

| 0.58 | 900 | 20.2 | 3 | 1 | 27 | −79.78 | |

| 0.58 | 900 | 20.2 | 3 | 1 | 25 | −69.68 | |

| 0.58 | 900 | 20.2 | 3 | 1 | 21 | −75.09 | |

| 0.58 | 900 | 20.2 | 3 | 1 | 14 | −84.12 | |

| 0.58 | 900 | 20.2 | 3 | 1 | 0 | −75.09 | |

| 0.58 | 150 | 150 | 3 | 0 | 27 | 5.12 | |

| 0.58 | 150 | 150 | 3 | 0 | 25 | 1.89 | |

| 0.58 | 150 | 150 | 3 | 0 | 21 | −1.41 | |

| 0.58 | 150 | 150 | 3 | 0 | 14 | −5.45 | |

| 0.58 | 150 | 150 | 3 | 0 | 0 | −27.17 | |

| 0.58 | 300 | 300 | 3 | 0 | 27 | 10.91 | |

| 0.58 | 300 | 300 | 3 | 0 | 25 | 19.22 | |

| 0.58 | 300 | 300 | 3 | 0 | 21 | 1.89 | |

| 0.58 | 300 | 300 | 3 | 0 | 14 | −9.17 | |

| 0.58 | 300 | 300 | 3 | 0 | 0 | −31.73 | |

| 0.58 | 400 | 200 | 3 | 0 | 27 | 1.81 | |

| 0.58 | 400 | 200 | 3 | 0 | 25 | 6.39 | |

| 0.58 | 400 | 200 | 3 | 0 | 21 | 3.55 | |

| 0.58 | 400 | 200 | 3 | 0 | 14 | −2.55 | |

| 0.58 | 400 | 200 | 3 | 0 | 0 | −18.90 | |

| 0.58 | 600 | 75 | 3 | 0 | 27 | −25.92 | |

| 0.58 | 600 | 75 | 3 | 0 | 25 | −11.40 | |

| 0.58 | 600 | 75 | 3 | 0 | 21 | −24.59 | |

| 0.58 | 600 | 75 | 3 | 0 | 14 | −59.04 | |

| 0.58 | 600 | 75 | 3 | 0 | 0 | −76.83 | |

| 0.58 | 800 | 35.5 | 3 | 0 | 27 | −42.47 | |

| 0.58 | 800 | 35.5 | 3 | 0 | 25 | −30.85 | |

| 0.58 | 800 | 35.5 | 3 | 0 | 21 | −38.24 | |

| 0.58 | 800 | 35.5 | 3 | 0 | 14 | −57.59 | |

| 0.58 | 800 | 35.5 | 3 | 0 | 0 | −76.83 | |

| 0.58 | 900 | 20.2 | 3 | 0 | 27 | −65.64 | |

| 0.58 | 900 | 20.2 | 3 | 0 | 25 | −51.54 | |

| 0.58 | 900 | 20.2 | 3 | 0 | 21 | −56.03 | |

| 0.58 | 900 | 20.2 | 3 | 0 | 14 | −76.21 | |

| 0.58 | 900 | 20.2 | 3 | 0 | 0 | −87.17 | |

| [16] | 0.34 | 200 | 5 | 3 | 1 | 0 | −3.57 |

| 0.34 | 400 | 5 | 3 | 1 | 0 | −27.26 | |

| 0.34 | 600 | 5 | 3 | 1 | 0 | −59.08 | |

| 0.4 | 200 | 5 | 3 | 1 | 0 | −8.24 | |

| 0.4 | 400 | 5 | 3 | 1 | 0 | −28.92 | |

| 0.4 | 600 | 5 | 3 | 1 | 0 | −57.47 | |

| 0.5 | 200 | 5 | 3 | 1 | 0 | −10.54 | |

| 0.5 | 400 | 5 | 3 | 1 | 0 | −23.49 | |

| 0.5 | 600 | 5 | 3 | 1 | 0 | −53.37 | |

| [17] | 0.49 | 200 | 2.5 | 8 | 1 | 0 | 41.30 |

| 0.49 | 400 | 2.5 | 8 | 1 | 0 | 7.60 | |

| 0.49 | 600 | 2.5 | 8 | 1 | 0 | −33.20 | |

| 0.49 | 700 | 2.5 | 8 | 1 | 0 | −46.70 | |

| 0.49 | 800 | 2.5 | 8 | 1 | 0 | −66.30 | |

| 0.49 | 200 | 2.5 | 8 | 1 | 0 | −23.40 | |

| 0.49 | 400 | 2.5 | 8 | 1 | 0 | −46.50 | |

| 0.49 | 600 | 2.5 | 8 | 1 | 0 | −55.50 | |

| 0.49 | 700 | 2.5 | 8 | 1 | 0 | −65.50 | |

| 0.49 | 800 | 2.5 | 8 | 1 | 0 | −67.60 | |

| 0.49 | 900 | 2.5 | 8 | 1 | 0 | −82.50 | |

| [18] | 0.42 | 300 | 10 | 6 | 1 | 0 | −27.00 |

| 0.42 | 500 | 10 | 6 | 1 | 0 | −44.00 | |

| 0.42 | 700 | 10 | 6 | 1 | 0 | −64.00 | |

| 0.42 | 300 | 10 | 6 | 1 | 0 | −14.00 | |

| 0.42 | 500 | 10 | 6 | 1 | 0 | −33.00 | |

| 0.42 | 700 | 10 | 6 | 1 | 0 | −67.00 | |

| [19] | 0.25 | 200 | 90 | 0.5 | 1 | 1 | −4.59 |

| 0.25 | 400 | 90 | 0.5 | 1 | 1 | −13.33 | |

| 0.25 | 600 | 54 | 0.5 | 1 | 1 | −32.43 | |

| 0.25 | 800 | 28.42 | 0.5 | 1 | 1 | −44.40 | |

| 0.3 | 200 | 90 | 0.5 | 1 | 1 | −4.52 | |

| 0.3 | 400 | 90 | 0.5 | 1 | 1 | −12.36 | |

| 0.3 | 600 | 54 | 0.5 | 1 | 1 | −31.62 | |

| 0.3 | 800 | 28.42 | 0.5 | 1 | 1 | −46.36 | |

| [20] | 0.31 | 200 | 10 | 3 | 1 | 0 | 4.63 |

| 0.31 | 400 | 10 | 3 | 1 | 0 | 45.66 | |

| 0.31 | 600 | 10 | 3 | 1 | 0 | 7.07 | |

| 0.31 | 800 | 10 | 3 | 1 | 0 | −56.30 | |

| 0.31 | 200 | 10 | 3 | 1 | 0 | 38.68 | |

| 0.31 | 400 | 10 | 3 | 1 | 0 | 52.44 | |

| 0.31 | 600 | 10 | 3 | 1 | 0 | 23.40 | |

| 0.31 | 800 | 10 | 3 | 1 | 0 | −49.33 | |

| [21] | 0.3 | 200 | 16 | 2 | 1 | 0 | −10.55 |

| 0.3 | 400 | 20.5 | 2 | 1 | 0 | −29.61 | |

| 0.3 | 600 | 17.5 | 2 | 1 | 0 | −47.08 | |

| 0.3 | 800 | 13.4 | 2 | 1 | 0 | −75.64 | |

| 0.3 | 200 | 16 | 2 | 1 | 0 | −12.78 | |

| 0.3 | 400 | 20.5 | 2 | 1 | 0 | −31.86 | |

| 0.3 | 600 | 17.5 | 2 | 1 | 0 | −48.60 | |

| 0.3 | 800 | 13.4 | 2 | 1 | 0 | −78.01 | |

| 0.3 | 200 | 16 | 2 | 1 | 0 | −15.41 | |

| 0.3 | 400 | 20.5 | 2 | 1 | 0 | −37.21 | |

| 0.3 | 600 | 17.5 | 2 | 1 | 0 | −51.17 | |

| 0.3 | 800 | 13.4 | 2 | 1 | 0 | −78.30 | |

| 0.3 | 200 | 16 | 2 | 1 | 0 | −10.35 | |

| 0.3 | 400 | 20.5 | 2 | 1 | 0 | −35.24 | |

| 0.3 | 600 | 17.5 | 2 | 1 | 0 | −49.20 | |

| 0.3 | 800 | 13.4 | 2 | 1 | 0 | −79.57 | |

| [22] | 0.48 | 200 | 10 | 1.5 | 1 | 0 | −16.21 |

| 0.48 | 400 | 10 | 1.5 | 1 | 0 | −10.48 | |

| 0.48 | 800 | 10 | 1.5 | 1 | 0 | −4.68 | |

| 0.48 | 200 | 10 | 1.5 | 1 | 0 | 4.29 | |

| 0.48 | 400 | 10 | 1.5 | 1 | 0 | −69.21 | |

| 0.48 | 800 | 10 | 1.5 | 1 | 0 | −31.90 | |

| [23] | 0.35 | 200 | 12 | 2 | 1 | 0 | −18.16 |

| 0.35 | 300 | 12 | 2 | 1 | 0 | −28.18 | |

| 0.35 | 400 | 12 | 2 | 1 | 0 | −22.24 | |

| 0.35 | 600 | 12 | 2 | 1 | 0 | −41.64 | |

| 0.35 | 800 | 12 | 2 | 1 | 0 | −69.66 | |

| 0.35 | 200 | 12 | 2 | 1 | 0 | −8.54 | |

| 0.35 | 300 | 12 | 2 | 1 | 0 | −17.24 | |

| 0.35 | 400 | 12 | 2 | 1 | 0 | −15.05 | |

| 0.35 | 600 | 12 | 2 | 1 | 0 | −37.74 | |

| 0.35 | 800 | 12 | 2 | 1 | 0 | −72.94 | |

| 0.35 | 200 | 12 | 2 | 1 | 0 | −7.32 | |

| 0.35 | 300 | 12 | 2 | 1 | 0 | −16.47 | |

| 0.35 | 400 | 12 | 2 | 1 | 0 | −14.25 | |

| 0.35 | 600 | 12 | 2 | 1 | 0 | −36.24 | |

| 0.35 | 800 | 12 | 2 | 1 | 0 | −66.57 | |

| 0.35 | 200 | 12 | 2 | 1 | 0 | −14.66 | |

| 0.35 | 300 | 12 | 2 | 1 | 0 | −23.60 | |

| 0.35 | 400 | 12 | 2 | 1 | 0 | −21.76 | |

| 0.35 | 600 | 12 | 2 | 1 | 0 | −41.94 | |

| 0.35 | 800 | 12 | 2 | 1 | 0 | −71.91 | |

| [24] | 0.33 | 200 | 15 | 2 | 1 | 1 | −8.24 |

| 0.33 | 400 | 15 | 2 | 1 | 1 | −19.06 | |

| 0.33 | 600 | 15 | 2 | 1 | 1 | −40.14 | |

| 0.33 | 800 | 15 | 2 | 1 | 1 | −65.84 | |

| 0.33 | 200 | 15 | 2 | 1 | 1 | −5.55 | |

| 0.33 | 400 | 15 | 2 | 1 | 1 | −14.62 | |

| 0.33 | 600 | 15 | 2 | 1 | 1 | −32.71 | |

| 0.33 | 800 | 15 | 2 | 1 | 1 | −44.80 | |

| 0.33 | 200 | 15 | 2 | 1 | 1 | −9.10 | |

| 0.33 | 400 | 15 | 2 | 1 | 1 | −16.28 | |

| 0.33 | 600 | 15 | 2 | 1 | 1 | −32.99 | |

| 0.33 | 800 | 15 | 2 | 1 | 1 | −45.90 | |

| 0.33 | 200 | 15 | 2 | 1 | 1 | −9.07 | |

| 0.33 | 400 | 15 | 2 | 1 | 1 | −20.40 | |

| 0.33 | 600 | 15 | 2 | 1 | 1 | −33.99 | |

| 0.33 | 800 | 15 | 2 | 1 | 1 | −48.03 | |

| [25] | 0.27 | 200 | 10 | 1.5 | 1 | 0 | −0.13 |

| 0.27 | 400 | 10 | 1.5 | 1 | 0 | −7.02 | |

| 0.27 | 600 | 10 | 1.5 | 1 | 0 | −28.61 | |

| 0.27 | 800 | 10 | 1.5 | 1 | 0 | −71.52 | |

| 0.27 | 200 | 10 | 1.5 | 1 | 0 | −19.42 | |

| 0.27 | 400 | 10 | 1.5 | 1 | 0 | −30.87 | |

| 0.27 | 600 | 10 | 1.5 | 1 | 0 | −37.39 | |

| 0.27 | 800 | 10 | 1.5 | 1 | 0 | −70.14 | |

| [26] | 0.49 | 800 | 6 | 1 | 1 | 0 | −74.41 |

| 0.49 | 1100 | 6 | 1 | 1 | 0 | −91.88 | |

| 0.49 | 800 | 6 | 1 | 0 | 0 | −78.62 | |

| 0.49 | 1100 | 6 | 1 | 0 | 0 | −91.57 | |

| 0.49 | 800 | 6 | 1 | 1 | 0 | −65.90 | |

| 0.49 | 1100 | 6 | 1 | 1 | 0 | −87.75 | |

| 0.49 | 800 | 6 | 1 | 0 | 0 | −71.63 | |

| 0.49 | 1100 | 6 | 1 | 0 | 0 | −89.60 | |

| [27] | 0.49 | 250 | 10 | 2 | 0 | 7 | −2.03 |

| 0.49 | 450 | 10 | 2 | 0 | 7 | −3.36 | |

| 0.49 | 250 | 10 | 2 | 0 | 7 | −7.90 | |

| 0.49 | 450 | 10 | 2 | 0 | 7 | −21.94 | |

| 0.49 | 250 | 10 | 2 | 0 | 7 | −17.92 | |

| 0.49 | 450 | 10 | 2 | 0 | 7 | −28.29 | |

| 0.49 | 250 | 10 | 2 | 0 | 7 | −23.79 | |

| 0.49 | 450 | 10 | 2 | 0 | 7 | −31.72 | |

| 0.49 | 550 | 10 | 2 | 0 | 7 | −46.32 | |

| 0.49 | 650 | 10 | 2 | 0 | 7 | −66.78 | |

| [28] | 0.55 | 100 | 5 | 1 | 1 | 2 | −9.01 |

| 0.55 | 300 | 5 | 1 | 1 | 2 | −26.12 | |

| 0.55 | 500 | 5 | 1 | 1 | 2 | −36.94 | |

| 0.55 | 700 | 5 | 1 | 1 | 2 | −47.75 | |

| 0.33 | 100 | 5 | 1 | 1 | 2 | −8.74 | |

| 0.33 | 300 | 5 | 1 | 1 | 2 | −33.01 | |

| 0.33 | 500 | 5 | 1 | 1 | 2 | −45.63 | |

| 0.33 | 700 | 5 | 1 | 1 | 2 | −69.90 | |

| [29] | 0.36 | 200 | 20 | 1.5 | 0 | 2 | −4.30 |

| 0.36 | 300 | 20 | 1.5 | 0 | 2 | −4.70 | |

| 0.36 | 400 | 20 | 2 | 0 | 2 | −15.30 | |

| 0.36 | 500 | 20 | 2 | 0 | 2 | −35.60 | |

| 0.36 | 600 | 20 | 2.5 | 0 | 2 | −40.50 | |

| 0.36 | 700 | 20 | 2.5 | 0 | 2 | −44.20 | |

| 0.36 | 800 | 20 | 2.5 | 0 | 2 | −69.20 | |

| [30] | 0.44 | 100 | 100 | 2 | 1 | 0.25 | 19.38 |

| 0.44 | 100 | 100 | 2 | 1 | 0.25 | 0.32 | |

| 0.44 | 100 | 100 | 2 | 1 | 0.25 | −0.66 | |

| 0.44 | 200 | 200 | 2 | 1 | 0.25 | 1.94 | |

| 0.44 | 200 | 200 | 2 | 1 | 0.25 | −7.05 | |

| 0.44 | 200 | 200 | 2 | 1 | 0.25 | 4.32 | |

| 0.44 | 300 | 300 | 2 | 1 | 0.25 | 6.20 | |

| 0.44 | 300 | 300 | 2 | 1 | 0.25 | −16.99 | |

| 0.44 | 300 | 300 | 2 | 1 | 0.25 | −9.97 | |

| 0.44 | 400 | 400 | 2 | 1 | 0.25 | 1.94 | |

| 0.44 | 400 | 400 | 2 | 1 | 0.25 | −14.10 | |

| 0.44 | 400 | 400 | 2 | 1 | 0.25 | −18.27 | |

| 0.44 | 500 | 500 | 2 | 1 | 0.25 | −7.75 | |

| 0.44 | 500 | 500 | 2 | 1 | 0.25 | −19.87 | |

| 0.44 | 500 | 500 | 2 | 1 | 0.25 | −15.61 | |

| 0.44 | 600 | 2.5 | 1 | 1 | 0.25 | −24.81 | |

| 0.44 | 600 | 2.5 | 1 | 1 | 0.25 | −32.69 | |

| 0.44 | 600 | 2.5 | 1 | 1 | 0.25 | −31.89 | |

| 0.44 | 700 | 2.5 | 1 | 1 | 0.25 | −47.67 | |

| 0.44 | 700 | 2.5 | 1 | 1 | 0.25 | −50.64 | |

| 0.44 | 700 | 2.5 | 1 | 1 | 0.25 | −57.81 | |

| 0.44 | 800 | 2.5 | 1 | 1 | 0.25 | −54.26 | |

| 0.44 | 800 | 2.5 | 1 | 1 | 0.25 | −60.90 | |

| 0.44 | 800 | 2.5 | 1 | 1 | 0.25 | −72.09 | |

| 0.44 | 900 | 2.5 | 1 | 1 | 0.25 | −74.03 | |

| 0.44 | 900 | 2.5 | 1 | 1 | 0.25 | −77.88 | |

| 0.44 | 900 | 2.5 | 1 | 1 | 0.25 | −74.42 | |

| 0.35 | 100 | 100 | 2 | 1 | 0.25 | −1.48 | |

| 0.35 | 100 | 100 | 2 | 1 | 0.25 | 2.08 | |

| 0.35 | 100 | 100 | 2 | 1 | 0.25 | 6.04 | |

| 0.35 | 200 | 200 | 2 | 1 | 0.25 | −8.62 | |

| 0.35 | 200 | 200 | 2 | 1 | 0.25 | −7.79 | |

| 0.35 | 200 | 200 | 2 | 1 | 0.25 | 0.00 | |

| 0.35 | 300 | 300 | 2 | 1 | 0.25 | −12.56 | |

| 0.35 | 300 | 300 | 2 | 1 | 0.25 | −3.64 | |

| 0.35 | 300 | 300 | 2 | 1 | 0.25 | −12.09 | |

| 0.35 | 400 | 400 | 2 | 1 | 0.25 | −20.69 | |

| 0.35 | 400 | 400 | 2 | 1 | 0.25 | −16.88 | |

| 0.35 | 400 | 400 | 2 | 1 | 0.25 | −7.69 | |

| 0.35 | 500 | 500 | 2 | 1 | 0.25 | −26.60 | |

| 0.35 | 500 | 500 | 2 | 1 | 0.25 | −24.68 | |

| 0.35 | 500 | 500 | 2 | 1 | 0.25 | −22.53 | |

| 0.35 | 600 | 2.5 | 1 | 1 | 0.25 | −40.89 | |

| 0.35 | 600 | 2.5 | 1 | 1 | 0.25 | −38.18 | |

| 0.35 | 600 | 2.5 | 1 | 1 | 0.25 | −32.69 | |

| 0.35 | 700 | 2.5 | 1 | 1 | 0.25 | −43.60 | |

| 0.35 | 700 | 2.5 | 1 | 1 | 0.25 | −45.19 | |

| 0.35 | 700 | 2.5 | 1 | 1 | 0.25 | −32.97 | |

| 0.35 | 800 | 2.5 | 1 | 1 | 0.25 | −60.59 | |

| 0.35 | 800 | 2.5 | 1 | 1 | 0.25 | −60.00 | |

| 0.35 | 800 | 2.5 | 1 | 1 | 0.25 | −52.75 | |

| 0.35 | 900 | 2.5 | 1 | 1 | 0.25 | −78.08 | |

| 0.35 | 900 | 2.5 | 1 | 1 | 0.25 | −80.52 | |

| 0.35 | 900 | 2.5 | 1 | 1 | 0.25 | −75.82 | |

| 0.35 | 100 | 100 | 2 | 1 | 0.25 | 2.90 | |

| 0.35 | 100 | 100 | 2 | 1 | 0.25 | 2.31 | |

| 0.35 | 100 | 100 | 2 | 1 | 0.25 | 4.78 | |

| 0.35 | 200 | 200 | 2 | 1 | 0.25 | −9.54 | |

| 0.35 | 200 | 200 | 2 | 1 | 0.25 | −9.64 | |

| 0.35 | 200 | 200 | 2 | 1 | 0.25 | −9.56 | |

| 0.35 | 300 | 300 | 2 | 1 | 0.25 | −16.80 | |

| 0.35 | 300 | 300 | 2 | 1 | 0.25 | −18.03 | |

| 0.35 | 300 | 300 | 2 | 1 | 0.25 | −17.67 | |

| 0.35 | 400 | 400 | 2 | 1 | 0.25 | −18.67 | |

| 0.35 | 400 | 400 | 2 | 1 | 0.25 | −25.37 | |

| 0.35 | 400 | 400 | 2 | 1 | 0.25 | −22.25 | |

| 0.35 | 500 | 500 | 2 | 1 | 0.25 | −27.59 | |

| 0.35 | 500 | 500 | 2 | 1 | 0.25 | −27.67 | |

| 0.35 | 500 | 500 | 2 | 1 | 0.25 | −27.86 | |

| 0.35 | 600 | 2.5 | 1 | 1 | 0.25 | −31.33 | |

| 0.35 | 600 | 2.5 | 1 | 1 | 0.25 | −33.33 | |

| 0.35 | 600 | 2.5 | 1 | 1 | 0.25 | −32.85 | |

| 0.35 | 700 | 2.5 | 1 | 1 | 0.25 | −37.97 | |

| 0.35 | 700 | 2.5 | 1 | 1 | 0.25 | −41.72 | |

| 0.35 | 700 | 2.5 | 1 | 1 | 0.25 | −40.33 | |

| 0.35 | 800 | 2.5 | 1 | 1 | 0.25 | −61.83 | |

| 0.35 | 800 | 2.5 | 1 | 1 | 0.25 | −58.07 | |

| 0.35 | 800 | 2.5 | 1 | 1 | 0.25 | −61.33 | |

| 0.35 | 900 | 2.5 | 1 | 1 | 0.25 | −88.80 | |

| [31] | 0.46 | 100 | 11 | 6 | 1 | 1 | −4.00 |

| 0.46 | 300 | 11 | 6 | 1 | 1 | −15.00 | |

| 0.46 | 500 | 11 | 6 | 1 | 1 | −45.00 | |

| 0.46 | 700 | 11 | 6 | 1 | 1 | −73.00 | |

| 0.46 | 100 | 11 | 6 | 1 | 7 | −14.00 | |

| 0.46 | 300 | 11 | 6 | 1 | 7 | −18.00 | |

| 0.46 | 500 | 11 | 6 | 1 | 7 | −58.00 | |

| 0.46 | 700 | 11 | 6 | 1 | 7 | −79.00 | |

| 0.46 | 100 | 11 | 6 | 1 | 14 | 4.00 | |

| 0.46 | 300 | 11 | 6 | 1 | 14 | −21.00 | |

| 0.46 | 500 | 11 | 6 | 1 | 14 | −60.00 | |

| 0.46 | 700 | 11 | 6 | 1 | 14 | −78.00 | |

| 0.46 | 100 | 11 | 6 | 1 | 28 | 0.00 | |

| 0.46 | 300 | 11 | 6 | 1 | 28 | −23.00 | |

| 0.46 | 500 | 11 | 6 | 1 | 28 | −63.00 | |

| 0.46 | 700 | 11 | 6 | 1 | 28 | −80.00 | |

| 0.46 | 100 | 11 | 6 | 1 | 56 | −9.00 | |

| 0.46 | 300 | 11 | 6 | 1 | 56 | −17.00 | |

| 0.46 | 500 | 11 | 6 | 1 | 56 | −58.00 | |

| 0.46 | 700 | 11 | 6 | 1 | 56 | −75.00 | |

| 0.46 | 100 | 11 | 6 | 1 | 77 | −16.00 | |

| 0.46 | 300 | 11 | 6 | 1 | 77 | −26.00 | |

| 0.46 | 500 | 11 | 6 | 1 | 77 | −52.00 | |

| 0.46 | 700 | 11 | 6 | 1 | 77 | −77.00 | |

| 0.46 | 100 | 11 | 6 | 1 | 112 | −5.00 | |

| 0.46 | 300 | 11 | 6 | 1 | 112 | −23.00 | |

| 0.46 | 500 | 11 | 6 | 1 | 112 | −57.00 | |

| 0.46 | 700 | 11 | 6 | 1 | 112 | −76.00 | |

| [32] | 0.43 | 200 | 20 | 1 | 1 | 0 | −24.30 |

| 0.43 | 300 | 17.5 | 1 | 1 | 0 | −18.66 | |

| 0.43 | 400 | 2.24 | 1 | 1 | 0 | −24.66 | |

| 0.43 | 500 | 1.84 | 1 | 1 | 0 | −28.99 | |

| 0.43 | 600 | 1.16 | 1 | 1 | 0 | −41.69 | |

| 0.43 | 700 | 1.04 | 1 | 1 | 0 | −62.96 | |

| 0.43 | 800 | 1.02 | 1 | 1 | 0 | −70.94 | |

| [33] | 0.56 | 150 | 10 | 1.5 | 1 | 0 | −3.80 |

| 0.56 | 250 | 10 | 1.5 | 1 | 0 | −8.70 | |

| 0.56 | 350 | 10 | 1.5 | 1 | 0 | −13.60 | |

| 0.56 | 450 | 10 | 1.5 | 1 | 0 | −21.50 | |

| 0.56 | 550 | 10 | 1.5 | 1 | 0 | −37.70 | |

| 0.56 | 650 | 10 | 1.5 | 1 | 0 | −53.60 | |

| 0.56 | 150 | 10 | 1.5 | 0 | 0 | −11.30 | |

| 0.56 | 250 | 10 | 1.5 | 0 | 0 | −18.00 | |

| 0.56 | 350 | 10 | 1.5 | 0 | 0 | −22.60 | |

| 0.56 | 450 | 10 | 1.5 | 0 | 0 | −25.70 | |

| 0.56 | 550 | 10 | 1.5 | 0 | 0 | −29.80 | |

| 0.56 | 650 | 10 | 1.5 | 0 | 0 | −35.10 | |

| 0.53 | 150 | 10 | 1.5 | 1 | 0 | −4.20 | |

| 0.53 | 250 | 10 | 1.5 | 1 | 0 | −11.70 | |

| 0.53 | 350 | 10 | 1.5 | 1 | 0 | −15.90 | |

| 0.53 | 450 | 10 | 1.5 | 1 | 0 | −18.40 | |

| 0.53 | 550 | 10 | 1.5 | 1 | 0 | −33.30 | |

| 0.53 | 650 | 10 | 1.5 | 1 | 0 | −51.50 | |

| 0.53 | 150 | 10 | 1.5 | 0 | 0 | −7.40 | |

| 0.53 | 250 | 10 | 1.5 | 0 | 0 | −14.60 | |

| 0.53 | 350 | 10 | 1.5 | 0 | 0 | −21.00 | |

| 0.53 | 450 | 10 | 1.5 | 0 | 0 | −23.00 | |

| 0.53 | 550 | 10 | 1.5 | 0 | 0 | −24.30 | |

| 0.53 | 650 | 10 | 1.5 | 0 | 0 | −31.40 | |

| 0.5 | 150 | 10 | 1.5 | 1 | 0 | −6.10 | |

| 0.5 | 250 | 10 | 1.5 | 1 | 0 | −13.00 | |

| 0.5 | 350 | 10 | 1.5 | 1 | 0 | −18.60 | |

| 0.5 | 450 | 10 | 1.5 | 1 | 0 | −23.50 | |

| 0.5 | 550 | 10 | 1.5 | 1 | 0 | −35.40 | |

| 0.5 | 650 | 10 | 1.5 | 1 | 0 | −56.20 | |

| 0.5 | 150 | 10 | 1.5 | 0 | 0 | −7.80 | |

| 0.5 | 250 | 10 | 1.5 | 0 | 0 | −15.70 | |

| 0.5 | 350 | 10 | 1.5 | 0 | 0 | −21.70 | |

| 0.5 | 450 | 10 | 1.5 | 0 | 0 | −29.00 | |

| 0.5 | 550 | 10 | 1.5 | 0 | 0 | −25.80 | |

| 0.5 | 650 | 10 | 1.5 | 0 | 0 | −31.30 | |

| [34] | 0.77 | 200 | 2.5 | 1 | 1 | 1 | −8.40 |

| 0.77 | 400 | 2.5 | 1 | 1 | 1 | −12.38 | |

| 0.77 | 800 | 2.5 | 1 | 1 | 1 | −84.51 | |

| 0.77 | 200 | 2.5 | 1 | 1 | 1 | −4.23 | |

| 0.77 | 400 | 2.5 | 1 | 1 | 1 | −13.93 | |

| 0.77 | 800 | 2.5 | 1 | 1 | 1 | −70.04 | |

| 0.77 | 200 | 2.5 | 1 | 1 | 1 | −7.01 | |

| 0.77 | 400 | 2.5 | 1 | 1 | 1 | −14.02 | |

| 0.77 | 800 | 2.5 | 1 | 1 | 1 | −68.49 | |

| 0.77 | 200 | 2.5 | 1 | 1 | 1 | −3.59 | |

| 0.77 | 400 | 2.5 | 1 | 1 | 1 | −25.01 | |

| 0.77 | 800 | 2.5 | 1 | 1 | 1 | −77.04 | |

| 0.77 | 200 | 2.5 | 1 | 1 | 1 | −1.51 | |

| 0.77 | 400 | 2.5 | 1 | 1 | 1 | −6.82 | |

| 0.77 | 800 | 2.5 | 1 | 1 | 1 | −64.01 | |

| 0.77 | 200 | 2.5 | 1 | 1 | 1 | −7.97 | |

| 0.77 | 400 | 2.5 | 1 | 1 | 1 | −16.88 | |

| 0.77 | 800 | 2.5 | 1 | 1 | 1 | −56.69 | |

| 0.77 | 200 | 2.5 | 1 | 1 | 1 | −11.30 | |

| 0.77 | 400 | 2.5 | 1 | 1 | 1 | −14.78 | |

| 0.77 | 800 | 2.5 | 1 | 1 | 1 | −56.23 | |

| 0.77 | 200 | 2.5 | 1 | 1 | 1 | −11.69 | |

| 0.77 | 400 | 2.5 | 1 | 1 | 1 | −35.50 | |

| 0.77 | 800 | 2.5 | 1 | 1 | 1 | −56.28 | |

| [35] | 0.29 | 851 | 2 | 4 | 1 | 0 | −78.80 |

| 0.29 | 851 | 10 | 4 | 1 | 0 | −57.60 | |

| 0.29 | 851 | 100 | 4 | 1 | 0 | −8.00 | |

| 0.25 | 851 | 2 | 4 | 1 | 0 | −78.30 | |

| 0.25 | 851 | 10 | 4 | 1 | 0 | −68.90 | |

| 0.25 | 851 | 100 | 4 | 1 | 0 | −16.20 | |

| 0.27 | 851 | 2 | 4 | 1 | 0 | −74.20 | |

| 0.27 | 851 | 10 | 4 | 1 | 0 | −73.70 | |

| 0.27 | 851 | 100 | 4 | 1 | 0 | −7.00 | |

| 0.24 | 851 | 2 | 4 | 1 | 0 | −75.70 | |

| 0.24 | 851 | 10 | 4 | 1 | 0 | −78.00 | |

| 0.24 | 851 | 100 | 4 | 1 | 0 | −11.50 | |

| [36] | 0.43 | 200 | 10 | 6 | 1 | 1 | −0.97 |

| 0.43 | 300 | 10 | 6 | 1 | 1 | 6.31 | |

| 0.43 | 400 | 10 | 6 | 1 | 1 | −13.56 | |

| 0.43 | 500 | 10 | 6 | 1 | 1 | −21.81 | |

| 0.37 | 200 | 10 | 6 | 1 | 1 | −2.46 | |

| 0.37 | 300 | 10 | 6 | 1 | 1 | −18.60 | |

| 0.37 | 400 | 10 | 6 | 1 | 1 | −13.31 | |

| 0.37 | 500 | 10 | 6 | 1 | 1 | −28.04 | |

| [37] | 0.4 | 100 | 3 | 3 | 1 | 0 | −13.32 |

| 0.4 | 200 | 3 | 3 | 1 | 0 | −10.05 | |

| 0.4 | 300 | 3 | 3 | 1 | 0 | −24.80 | |

| 0.4 | 600 | 3 | 3 | 1 | 0 | −66.47 | |

| 0.35 | 100 | 3 | 3 | 1 | 0 | −15.04 | |

| 0.35 | 200 | 3 | 3 | 1 | 0 | −12.75 | |

| 0.35 | 300 | 3 | 3 | 1 | 0 | −23.80 | |

| 0.35 | 600 | 3 | 3 | 1 | 0 | −70.16 | |

| 0.3 | 100 | 3 | 3 | 1 | 0 | −15.52 | |

| 0.3 | 200 | 3 | 3 | 1 | 0 | −14.72 | |

| 0.3 | 300 | 3 | 3 | 1 | 0 | −30.95 | |

| 0.3 | 600 | 3 | 3 | 1 | 0 | −73.35 | |

| 0.3 | 100 | 3 | 3 | 1 | 0 | −14.52 | |

| 0.3 | 200 | 3 | 3 | 1 | 0 | −11.99 | |

| 0.3 | 300 | 3 | 3 | 1 | 0 | −27.48 | |

| 0.3 | 600 | 3 | 3 | 1 | 0 | −69.15 | |

| [38] | 0.29 | 600 | 2.5 | 0 | 1 | 0 | −52.55 |

| 0.29 | 800 | 2.5 | 0 | 1 | 0 | −74.47 | |

| 0.29 | 600 | 2.5 | 0 | 1 | 0 | −45.45 | |

| 0.29 | 800 | 2.5 | 0 | 1 | 0 | −66.67 | |

| 0.29 | 600 | 2.5 | 0 | 1 | 0 | −49.91 | |

| 0.29 | 800 | 2.5 | 0 | 1 | 0 | −75.08 | |

| 0.29 | 600 | 2.5 | 0 | 1 | 0 | −48.00 | |

| 0.29 | 800 | 2.5 | 0 | 1 | 0 | −67.63 | |

| 0.29 | 600 | 2.5 | 0 | 1 | 0 | −61.35 | |

| 0.29 | 800 | 2.5 | 0 | 1 | 0 | −81.70 | |

| 0.29 | 600 | 2.5 | 0 | 1 | 0 | −55.75 | |

| 0.29 | 800 | 2.5 | 0 | 1 | 0 | −75.53 | |

| 0.29 | 600 | 2.5 | 0 | 1 | 0 | −59.23 | |

| 0.29 | 800 | 2.5 | 0 | 1 | 0 | −82.60 | |

| 0.29 | 600 | 2.5 | 0 | 1 | 0 | −62.54 | |

| 0.29 | 800 | 2.5 | 0 | 1 | 0 | −82.87 | |

| 0.29 | 600 | 2.5 | 0 | 1 | 0 | −55.06 | |

| 0.29 | 800 | 2.5 | 0 | 1 | 0 | −79.29 | |

| 0.29 | 600 | 2.5 | 0 | 1 | 0 | −54.30 | |

| 0.29 | 800 | 2.5 | 0 | 1 | 0 | −75.18 | |

| 0.29 | 600 | 2.5 | 0 | 1 | 0 | −53.18 | |

| 0.29 | 800 | 2.5 | 0 | 1 | 0 | −71.97 | |

| 0.29 | 600 | 2.5 | 0 | 1 | 0 | −54.95 | |

| 0.29 | 800 | 2.5 | 0 | 1 | 0 | −80.99 | |

| 0.29 | 600 | 2.5 | 0 | 1 | 0 | −58.42 | |

| 0.29 | 800 | 2.5 | 0 | 1 | 0 | −82.65 | |

| 0.29 | 600 | 2.5 | 0 | 1 | 0 | −54.54 | |

| 0.29 | 800 | 2.5 | 0 | 1 | 0 | −76.78 | |

| [39] | 0.2 | 120 | 4 | 2 | 1 | 3 | 0.04 |

| 0.2 | 200 | 4 | 2 | 1 | 3 | 0.07 | |

| 0.2 | 300 | 4 | 2 | 1 | 3 | 0.14 | |

| 0.2 | 400 | 4 | 2 | 1 | 3 | 0.17 | |

| 0.2 | 500 | 4 | 2 | 1 | 3 | 0.00 | |

| 0.2 | 600 | 4 | 2 | 1 | 3 | −0.16 | |

| 0.2 | 700 | 4 | 2 | 1 | 3 | −0.44 | |

| 0.2 | 800 | 4 | 2 | 1 | 3 | −0.81 | |

| 0.2 | 900 | 4 | 2 | 1 | 3 | −0.80 | |

| 0.2 | 120 | 4 | 2 | 1 | 3 | 0.05 | |

| 0.2 | 200 | 4 | 2 | 1 | 3 | 0.06 | |

| 0.2 | 300 | 4 | 2 | 1 | 3 | 0.12 | |

| 0.2 | 400 | 4 | 2 | 1 | 3 | 0.15 | |

| 0.2 | 500 | 4 | 2 | 1 | 3 | 0.01 | |

| 0.2 | 600 | 4 | 2 | 1 | 3 | −0.20 | |

| 0.2 | 700 | 4 | 2 | 1 | 3 | −0.41 | |

| 0.2 | 800 | 4 | 2 | 1 | 3 | −0.72 | |

| 0.2 | 900 | 4 | 2 | 1 | 3 | −0.69 | |

| 0.2 | 120 | 4 | 2 | 1 | 3 | 0.06 | |

| 0.2 | 200 | 4 | 2 | 1 | 3 | 0.08 | |

| 0.2 | 300 | 4 | 2 | 1 | 3 | 0.13 | |

| 0.2 | 400 | 4 | 2 | 1 | 3 | 0.16 | |

| 0.2 | 500 | 4 | 2 | 1 | 3 | 0.09 | |

| 0.2 | 600 | 4 | 2 | 1 | 3 | −0.15 | |

| 0.2 | 700 | 4 | 2 | 1 | 3 | −0.40 | |

| 0.2 | 800 | 4 | 2 | 1 | 3 | −0.72 | |

| 0.2 | 900 | 4 | 2 | 1 | 3 | −0.68 | |

| [40] | 0.28 | 200 | 5 | 0 | 0 | 0 | −30.95 |

| 0.28 | 400 | 5 | 0 | 0 | 0 | −36.11 | |

| 0.41 | 200 | 5 | 0 | 0 | 0 | −11.29 | |

| 0.41 | 400 | 5 | 0 | 0 | 0 | −9.57 | |

| 0.41 | 200 | 5 | 0 | 0 | 0 | −9.23 | |

| 0.41 | 400 | 5 | 0 | 0 | 0 | −4.62 | |

| 0.41 | 600 | 5 | 0 | 0 | 0 | −33.46 | |

| 0.41 | 800 | 5 | 0 | 0 | 0 | −68.65 | |

| 0.64 | 200 | 5 | 0 | 0 | 0 | −10.41 | |

| 0.64 | 400 | 5 | 0 | 0 | 0 | −19.46 | |

| 0.64 | 600 | 5 | 0 | 0 | 0 | −35.75 | |

| 0.64 | 800 | 5 | 0 | 0 | 0 | −70.14 | |

| 0.64 | 200 | 5 | 0 | 0 | 0 | −16.97 | |

| 0.64 | 400 | 5 | 0 | 0 | 0 | −49.54 | |

| 0.64 | 600 | 5 | 0 | 0 | 0 | −66.51 | |

| 0.64 | 800 | 5 | 0 | 0 | 0 | −76.15 | |

| [41] | 0.34 | 100 | 10 | 3 | 1 | 0 | 2.54 |

| 0.34 | 200 | 9.09 | 3 | 1 | 0 | −11.38 | |

| 0.34 | 300 | 10.89 | 3 | 1 | 0 | −5.84 | |

| 0.34 | 400 | 8.7 | 3 | 1 | 0 | −14.82 | |

| 0.34 | 500 | 9.09 | 3 | 1 | 0 | −23.80 | |

| 0.34 | 600 | 8.82 | 3 | 1 | 0 | −40.42 | |

| 0.34 | 700 | 8.92 | 3 | 1 | 0 | −51.65 | |

| 0.34 | 800 | 8.73 | 3 | 1 | 0 | −67.81 | |

| 0.34 | 900 | 8.91 | 3 | 1 | 0 | −83.83 | |

| 0.3 | 100 | 10 | 3 | 1 | 0 | 10.74 | |

| 0.3 | 200 | 9.09 | 3 | 1 | 0 | −1.67 | |

| 0.3 | 300 | 10.89 | 3 | 1 | 0 | 8.95 | |

| 0.3 | 400 | 8.7 | 3 | 1 | 0 | −7.40 | |

| 0.3 | 600 | 8.82 | 3 | 1 | 0 | −52.03 | |

| 0.3 | 800 | 8.73 | 3 | 1 | 0 | −63.60 | |

| 0.3 | 900 | 8.91 | 3 | 1 | 0 | −76.37 | |

| 0.25 | 100 | 10 | 3 | 1 | 0 | −6.34 | |

| 0.25 | 200 | 9.09 | 3 | 1 | 0 | −9.09 | |

| 0.25 | 300 | 10.89 | 3 | 1 | 0 | −11.85 | |

| 0.25 | 400 | 8.7 | 3 | 1 | 0 | −9.09 | |

| 0.25 | 500 | 9.09 | 3 | 1 | 0 | −30.67 | |

| 0.25 | 600 | 8.82 | 3 | 1 | 0 | −41.23 | |

| 0.25 | 700 | 8.92 | 3 | 1 | 0 | −56.38 | |

| 0.34 | 100 | 10 | 3 | 1 | 0 | −0.15 | |

| 0.34 | 200 | 9.09 | 3 | 1 | 0 | −2.26 | |

| 0.34 | 300 | 10.89 | 3 | 1 | 0 | 3.77 | |

| 0.34 | 400 | 8.7 | 3 | 1 | 0 | −15.51 | |

| 0.34 | 500 | 9.09 | 3 | 1 | 0 | −22.59 | |

| 0.34 | 600 | 8.82 | 3 | 1 | 0 | −39.61 | |

| 0.34 | 700 | 8.92 | 3 | 1 | 0 | −50.75 | |

| 0.34 | 800 | 8.73 | 3 | 1 | 0 | −72.44 | |

| 0.34 | 900 | 8.91 | 3 | 1 | 0 | −81.33 | |

| 0.3 | 100 | 10 | 3 | 1 | 0 | 6.99 | |

| 0.3 | 200 | 9.09 | 3 | 1 | 0 | 10.29 | |

| 0.3 | 300 | 10.89 | 3 | 1 | 0 | 3.96 | |

| 0.3 | 400 | 8.7 | 3 | 1 | 0 | −4.88 | |

| 0.3 | 500 | 9.09 | 3 | 1 | 0 | −21.77 | |

| 0.3 | 600 | 8.82 | 3 | 1 | 0 | −22.96 | |

| 0.3 | 700 | 8.92 | 3 | 1 | 0 | −33.51 | |

| 0.3 | 800 | 8.73 | 3 | 1 | 0 | −61.48 | |

| 0.3 | 900 | 8.91 | 3 | 1 | 0 | −71.24 | |

| 0.25 | 100 | 10 | 3 | 1 | 0 | 0.10 | |

| 0.25 | 200 | 9.09 | 3 | 1 | 0 | −7.86 | |

| 0.25 | 300 | 10.89 | 3 | 1 | 0 | −3.49 | |

| 0.25 | 400 | 8.7 | 3 | 1 | 0 | −0.29 | |

| 0.25 | 500 | 9.09 | 3 | 1 | 0 | −31.81 | |

| 0.25 | 600 | 8.82 | 3 | 1 | 0 | −46.56 | |

| 0.25 | 700 | 8.92 | 3 | 1 | 0 | −64.79 | |

| 0.25 | 800 | 8.73 | 3 | 1 | 0 | −74.01 | |

| 0.25 | 900 | 8.91 | 3 | 1 | 0 | −80.60 | |

| [42] | 0.5 | 400 | 2.5 | 3 | 1 | 7 | −1.77 |

| 0.5 | 600 | 2.5 | 3 | 1 | 7 | −23.92 | |

| 0.5 | 800 | 2.5 | 3 | 1 | 7 | −69.93 | |

| 0.5 | 400 | 2.5 | 3 | 1 | 7 | 2.85 | |

| 0.5 | 600 | 2.5 | 3 | 1 | 7 | −11.71 | |

| 0.5 | 800 | 2.5 | 3 | 1 | 7 | −66.18 | |

| 0.5 | 400 | 2.5 | 3 | 1 | 7 | 17.12 | |

| 0.5 | 600 | 2.5 | 3 | 1 | 7 | −5.30 | |

| 0.5 | 800 | 2.5 | 3 | 1 | 7 | −57.75 | |

| 0.5 | 400 | 2.5 | 3 | 1 | 7 | 7.84 | |

| 0.5 | 600 | 2.5 | 3 | 1 | 7 | −4.73 | |

| 0.5 | 800 | 2.5 | 3 | 1 | 7 | −55.76 | |

| 0.5 | 400 | 2.5 | 3 | 1 | 7 | 12.74 | |

| 0.5 | 600 | 2.5 | 3 | 1 | 7 | −5.75 | |

| 0.5 | 800 | 2.5 | 3 | 1 | 7 | −63.26 | |

| 0.5 | 400 | 2.5 | 3 | 1 | 7 | 20.40 | |

| 0.5 | 600 | 2.5 | 3 | 1 | 7 | −26.41 | |

| 0.5 | 800 | 2.5 | 3 | 1 | 7 | −76.98 | |

| 0.5 | 400 | 2.5 | 3 | 1 | 7 | 4.62 | |

| 0.5 | 600 | 2.5 | 3 | 1 | 7 | −19.48 | |

| 0.5 | 800 | 2.5 | 3 | 1 | 7 | −75.39 | |

| 0.5 | 400 | 2.5 | 3 | 1 | 7 | 2.86 | |

| 0.5 | 600 | 2.5 | 3 | 1 | 7 | −19.80 | |

| 0.5 | 800 | 2.5 | 3 | 1 | 7 | −77.81 | |

| 0.5 | 400 | 2.5 | 3 | 1 | 7 | 3.29 | |

| 0.5 | 600 | 2.5 | 3 | 1 | 7 | −25.48 | |

| 0.5 | 800 | 2.5 | 3 | 1 | 7 | −77.02 | |

| [43] | 0.53 | 50 | 16 | 3 | 0 | 0 | 9.06 |

| 0.53 | 100 | 16 | 3 | 0 | 0 | −3.92 | |

| 0.53 | 150 | 16 | 3 | 0 | 0 | −5.34 | |

| 0.53 | 200 | 16 | 3 | 0 | 0 | −23.00 | |

| 0.53 | 250 | 16 | 3 | 0 | 0 | −26.59 | |

| 0.53 | 300 | 16 | 3 | 0 | 0 | −30.54 | |

| 0.53 | 350 | 16 | 3 | 0 | 0 | −26.90 | |

| 0.53 | 400 | 16 | 3 | 0 | 0 | −57.57 | |

| 0.53 | 450 | 16 | 3 | 0 | 0 | −47.44 | |

| 0.53 | 500 | 16 | 3 | 0 | 0 | −55.71 | |

| 0.53 | 600 | 16 | 3 | 0 | 0 | −59.28 | |

| 0.53 | 700 | 16 | 3 | 0 | 0 | −67.17 | |

| 0.53 | 50 | 16 | 3 | 1 | 0 | 13.39 | |

| 0.53 | 100 | 16 | 3 | 1 | 0 | 20.27 | |

| 0.53 | 150 | 16 | 3 | 1 | 0 | −1.01 | |

| 0.53 | 200 | 16 | 3 | 1 | 0 | −16.14 | |

| 0.53 | 250 | 16 | 3 | 1 | 0 | −19.01 | |

| 0.53 | 300 | 16 | 3 | 1 | 0 | −23.68 | |

| 0.53 | 350 | 16 | 3 | 1 | 0 | −18.60 | |

| 0.53 | 400 | 16 | 3 | 1 | 0 | −30.49 | |

| 0.53 | 450 | 16 | 3 | 1 | 0 | −33.71 | |

| 0.53 | 500 | 16 | 3 | 1 | 0 | −48.13 | |

| 0.53 | 600 | 16 | 3 | 1 | 0 | −49.89 | |

| 0.53 | 700 | 16 | 3 | 1 | 0 | −61.39 | |

| 0.53 | 50 | 16 | 3 | 0 | 0 | −6.01 | |

| 0.53 | 100 | 16 | 3 | 0 | 0 | −13.34 | |

| 0.53 | 150 | 16 | 3 | 0 | 0 | −18.00 | |

| 0.53 | 200 | 16 | 3 | 0 | 0 | −20.66 | |

| 0.53 | 250 | 16 | 3 | 0 | 0 | −32.67 | |

| 0.53 | 300 | 16 | 3 | 0 | 0 | −21.27 | |

| 0.53 | 350 | 16 | 3 | 0 | 0 | −29.95 | |

| 0.53 | 400 | 16 | 3 | 0 | 0 | −42.63 | |

| 0.53 | 450 | 16 | 3 | 0 | 0 | −37.92 | |

| 0.53 | 500 | 16 | 3 | 0 | 0 | −45.59 | |

| 0.53 | 600 | 16 | 3 | 0 | 0 | −62.93 | |

| 0.53 | 700 | 16 | 3 | 0 | 0 | −68.23 | |

| 0.53 | 50 | 16 | 3 | 1 | 0 | −4.01 | |

| 0.53 | 100 | 16 | 3 | 1 | 0 | −9.33 | |

| 0.53 | 150 | 16 | 3 | 1 | 0 | −8.64 | |

| 0.53 | 200 | 16 | 3 | 1 | 0 | −17.98 | |

| 0.53 | 250 | 16 | 3 | 1 | 0 | −19.96 | |

| 0.53 | 300 | 16 | 3 | 1 | 0 | −16.26 | |

| 0.53 | 350 | 16 | 3 | 1 | 0 | −19.24 | |

| 0.53 | 400 | 16 | 3 | 1 | 0 | −20.56 | |

| 0.53 | 450 | 16 | 3 | 1 | 0 | −23.54 | |

| 0.53 | 500 | 16 | 3 | 1 | 0 | −31.88 | |

| 0.53 | 600 | 16 | 3 | 1 | 0 | −42.87 | |

| 0.53 | 700 | 16 | 3 | 1 | 0 | −54.52 | |

| [44] | 0.43 | 100 | 1 | 0 | 1 | 0 | −4.72 |

| 0.43 | 200 | 1 | 0 | 1 | 0 | −25.65 | |

| 0.43 | 400 | 1 | 0 | 1 | 0 | −28.44 | |

| 0.43 | 600 | 1 | 0 | 1 | 0 | −35.62 | |

| 0.43 | 800 | 1 | 0 | 1 | 0 | −56.00 | |

| 0.43 | 100 | 1 | 0 | 1 | 0 | −13.26 | |

| 0.43 | 200 | 1 | 0 | 1 | 0 | −20.74 | |

| 0.43 | 400 | 1 | 0 | 1 | 0 | −20.93 | |

| 0.43 | 600 | 1 | 0 | 1 | 0 | −33.55 | |

| 0.43 | 800 | 1 | 0 | 1 | 0 | −70.24 | |

| 0.43 | 100 | 1 | 0 | 1 | 0 | 1.75 | |

| 0.43 | 200 | 1 | 0 | 1 | 0 | −15.82 | |

| 0.43 | 400 | 1 | 0 | 1 | 0 | −15.24 | |

| 0.43 | 600 | 1 | 0 | 1 | 0 | −32.51 | |

| 0.43 | 800 | 1 | 0 | 1 | 0 | −69.72 | |

| [45] | 0.3 | 200 | 5.5 | 0 | 1 | 0 | −7.41 |

| 0.3 | 400 | 5.5 | 0 | 1 | 0 | −12.12 | |

| 0.3 | 600 | 5.5 | 0 | 1 | 0 | −26.94 | |

| 0.3 | 800 | 5.5 | 0 | 1 | 0 | −46.97 | |

| 0.3 | 1000 | 5.5 | 0 | 1 | 0 | −89.06 | |

| 0.3 | 200 | 5.5 | 0 | 0 | 0 | −27.27 | |

| 0.3 | 400 | 5.5 | 0 | 0 | 0 | −29.12 | |

| 0.3 | 600 | 5.5 | 0 | 0 | 0 | −43.43 | |

| 0.5 | 200 | 6.67 | 0 | 1 | 0 | −31.84 | |

| 0.5 | 400 | 6.67 | 0 | 1 | 0 | −23.15 | |

| 0.5 | 600 | 6.67 | 0 | 1 | 0 | −26.09 | |

| 0.5 | 800 | 6.67 | 0 | 1 | 0 | −51.47 | |

| 0.5 | 1000 | 6.67 | 0 | 1 | 0 | −75.32 | |

| 0.5 | 200 | 6.67 | 0 | 0 | 0 | −32.90 | |

| 0.5 | 400 | 6.67 | 0 | 0 | 0 | −29.38 | |

| 0.5 | 600 | 6.67 | 0 | 0 | 0 | −33.96 | |

| 0.5 | 800 | 6.67 | 0 | 0 | 0 | −55.82 | |

| [46] | 0.43 | 110 | 0.1 | 0.5 | 1 | 0 | −0.82 |

| 0.43 | 210 | 0.1 | 0.5 | 1 | 0 | −7.01 | |

| 0.43 | 310 | 0.1 | 0.5 | 1 | 0 | −34.65 | |

| [47] | 0.5 | 200 | 10 | 2 | 1 | 0 | −16.93 |

| 0.5 | 200 | 10 | 4 | 1 | 0 | −27.46 | |

| 0.5 | 200 | 10 | 6 | 1 | 0 | −34.93 | |

| 0.5 | 400 | 10 | 2 | 1 | 0 | −18.43 | |

| 0.5 | 400 | 10 | 4 | 1 | 0 | −27.09 | |

| 0.5 | 400 | 10 | 6 | 1 | 0 | −33.84 | |

| 0.5 | 600 | 10 | 2 | 1 | 0 | −35.75 | |

| 0.5 | 600 | 10 | 4 | 1 | 0 | −38.31 | |

| 0.5 | 600 | 10 | 6 | 1 | 0 | −41.34 | |

| 0.5 | 200 | 10 | 2 | 1 | 0 | −16.08 | |

| 0.5 | 200 | 10 | 4 | 1 | 0 | −16.08 | |

| 0.5 | 200 | 10 | 6 | 1 | 0 | −8.08 | |

| 0.5 | 400 | 10 | 2 | 1 | 0 | −9.86 | |

| 0.5 | 400 | 10 | 4 | 1 | 0 | −13.11 | |

| 0.5 | 400 | 10 | 6 | 1 | 0 | −17.52 | |

| 0.5 | 600 | 10 | 2 | 1 | 0 | −15.78 | |

| 0.5 | 600 | 10 | 4 | 1 | 0 | −20.41 | |

| 0.5 | 600 | 10 | 6 | 1 | 0 | −19.03 | |

| 0.5 | 200 | 10 | 2 | 1 | 0 | −25.15 | |

| 0.5 | 200 | 10 | 4 | 1 | 0 | −31.57 | |

| 0.5 | 200 | 10 | 6 | 1 | 0 | −28.94 | |

| 0.5 | 400 | 10 | 2 | 1 | 0 | −20.57 | |

| 0.5 | 400 | 10 | 4 | 1 | 0 | −25.76 | |

| 0.5 | 400 | 10 | 6 | 1 | 0 | −34.81 | |

| 0.5 | 600 | 10 | 2 | 1 | 0 | −36.31 | |

| 0.5 | 600 | 10 | 4 | 1 | 0 | −41.71 | |

| 0.5 | 600 | 10 | 6 | 1 | 0 | 43.26 | |

| [48] | 0.5 | 200 | 16.98 | 0 | 1 | 0 | 20.74 |

| 0.5 | 400 | 15.75 | 0 | 1 | 0 | −13.41 | |

| 0.5 | 600 | 12.7 | 0 | 1 | 0 | −45.12 | |

| 0.5 | 800 | 11.28 | 0 | 1 | 0 | −70.73 | |

| 0.5 | 200 | 16.98 | 0 | 0 | 0 | −1.62 | |

| 0.5 | 400 | 15.75 | 0 | 0 | 0 | −27.64 | |

| 0.5 | 600 | 12.7 | 0 | 0 | 0 | −59.35 | |

| 0.5 | 800 | 11.28 | 0 | 0 | 0 | −70.32 | |

| 0.5 | 200 | 16.98 | 0 | 0 | 0 | −13.00 | |

| 0.5 | 400 | 15.75 | 0 | 0 | 0 | −40.65 | |

| 0.5 | 600 | 12.7 | 0 | 0 | 0 | −69.51 | |

| 0.5 | 800 | 11.28 | 0 | 0 | 0 | −85.37 | |

| 0.5 | 200 | 16.98 | 0 | 0 | 0 | −15.04 | |

| 0.5 | 400 | 15.75 | 0 | 0 | 0 | −45.53 | |

| 0.5 | 600 | 12.7 | 0 | 0 | 0 | −67.07 | |

| 0.5 | 800 | 11.28 | 0 | 0 | 0 | −80.89 | |

| 0.5 | 200 | 16.98 | 0 | 0 | 0 | −12.19 | |

| 0.5 | 400 | 15.75 | 0 | 0 | 0 | −33.74 | |

| 0.5 | 600 | 12.7 | 0 | 0 | 0 | −66.26 | |

| 0.5 | 800 | 11.28 | 0 | 0 | 0 | −82.11 | |

| 0.5 | 200 | 16.98 | 0 | 1 | 0 | 8.12 | |

| 0.5 | 400 | 15.75 | 0 | 1 | 0 | −21.40 | |

| 0.5 | 600 | 12.7 | 0 | 1 | 0 | −47.97 | |

| 0.5 | 800 | 11.28 | 0 | 1 | 0 | −72.32 | |

| 0.5 | 200 | 16.98 | 0 | 0 | 0 | 6.64 | |

| 0.5 | 400 | 15.75 | 0 | 0 | 0 | −27.31 | |

| 0.5 | 600 | 12.7 | 0 | 0 | 0 | −53.87 | |

| 0.5 | 800 | 11.28 | 0 | 0 | 0 | −67.53 | |

| 0.5 | 200 | 16.98 | 0 | 0 | 0 | −8.49 | |

| 0.5 | 400 | 15.75 | 0 | 0 | 0 | −42.07 | |

| 0.5 | 600 | 12.7 | 0 | 0 | 0 | −64.21 | |

| 0.5 | 800 | 11.28 | 0 | 0 | 0 | −92.99 | |

| 0.5 | 200 | 16.98 | 0 | 0 | 0 | −10.33 | |

| 0.5 | 400 | 15.75 | 0 | 0 | 0 | −41.33 | |

| 0.5 | 600 | 12.7 | 0 | 0 | 0 | −62.73 | |

| 0.5 | 200 | 16.98 | 0 | 0 | 0 | −6.64 | |

| 0.5 | 400 | 15.75 | 0 | 0 | 0 | −34.32 | |

| 0.5 | 600 | 12.7 | 0 | 0 | 0 | −61.62 | |

| 0.5 | 200 | 16.98 | 0 | 1 | 0 | 9.95 | |

| 0.5 | 400 | 15.75 | 0 | 1 | 0 | −10.38 | |

| 0.5 | 600 | 12.7 | 0 | 1 | 0 | −47.88 | |

| 0.5 | 800 | 11.28 | 0 | 1 | 0 | −84.65 | |

| 0.5 | 200 | 16.98 | 0 | 0 | 0 | 7.10 | |

| 0.5 | 400 | 15.75 | 0 | 0 | 0 | −24.68 | |

| 0.5 | 600 | 12.7 | 0 | 0 | 0 | −60.01 | |

| 0.5 | 800 | 11.28 | 0 | 0 | 0 | −87.14 | |

| 0.5 | 200 | 16.98 | 0 | 0 | 0 | −11.46 | |

| 0.5 | 400 | 15.75 | 0 | 0 | 0 | −34.31 | |

| 0.5 | 600 | 12.7 | 0 | 0 | 0 | −69.66 | |

| 0.5 | 800 | 11.28 | 0 | 0 | 0 | −92.49 | |

| 0.5 | 200 | 16.98 | 0 | 0 | 0 | −13.60 | |

| 0.5 | 400 | 15.75 | 0 | 0 | 0 | −37.16 | |

| 0.5 | 600 | 12.7 | 0 | 0 | 0 | −67.15 | |

| 0.5 | 200 | 16.98 | 0 | 0 | 0 | −8.60 | |

| 0.5 | 400 | 15.75 | 0 | 0 | 0 | −35.37 | |

| 0.5 | 600 | 12.7 | 0 | 0 | 0 | −63.58 | |

| 0.5 | 200 | 16.98 | 0 | 1 | 0 | 31.91 | |

| 0.5 | 400 | 15.75 | 0 | 1 | 0 | −7.44 | |

| 0.5 | 600 | 12.7 | 0 | 1 | 0 | −38.87 | |

| 0.5 | 800 | 11.28 | 0 | 1 | 0 | −74.27 | |

| 0.5 | 200 | 16.98 | 0 | 0 | 0 | 3.20 | |

| 0.5 | 400 | 15.75 | 0 | 0 | 0 | −13.39 | |

| 0.5 | 600 | 12.7 | 0 | 0 | 0 | −48.78 | |

| 0.5 | 800 | 11.28 | 0 | 0 | 0 | −75.75 | |

| 0.5 | 200 | 16.98 | 0 | 0 | 0 | −7.20 | |

| 0.5 | 400 | 15.75 | 0 | 0 | 0 | −32.19 | |

| 0.5 | 600 | 12.7 | 0 | 0 | 0 | −64.61 | |

| 0.5 | 800 | 11.28 | 0 | 0 | 0 | −86.64 | |

| 0.5 | 200 | 16.98 | 0 | 0 | 0 | −4.72 | |

| 0.5 | 400 | 15.75 | 0 | 0 | 0 | −28.23 | |

| 0.5 | 600 | 12.7 | 0 | 0 | 0 | −60.65 | |

| 0.5 | 800 | 11.28 | 0 | 0 | 0 | −85.16 | |

| 0.5 | 200 | 16.98 | 0 | 0 | 0 | −2.74 | |

| 0.5 | 400 | 15.75 | 0 | 0 | 0 | −21.80 | |

| 0.5 | 600 | 12.7 | 0 | 0 | 0 | −51.75 | |

| 0.5 | 800 | 11.28 | 0 | 0 | 0 | −84.17 | |

| 0.5 | 200 | 16.98 | 0 | 1 | 0 | 8.03 | |

| 0.5 | 400 | 15.75 | 0 | 1 | 0 | −23.89 | |

| 0.5 | 600 | 12.7 | 0 | 1 | 0 | −47.18 | |

| 0.5 | 800 | 11.28 | 0 | 1 | 0 | −75.93 | |

| 0.5 | 200 | 16.98 | 0 | 0 | 0 | −6.06 | |

| 0.5 | 400 | 15.75 | 0 | 0 | 0 | −42.98 | |

| 0.5 | 600 | 12.7 | 0 | 0 | 0 | −60.82 | |

| 0.5 | 800 | 11.28 | 0 | 0 | 0 | −78.65 | |

| 0.5 | 200 | 16.98 | 0 | 0 | 0 | −12.87 | |

| 0.5 | 400 | 15.75 | 0 | 0 | 0 | −54.80 | |

| 0.5 | 600 | 12.7 | 0 | 0 | 0 | −71.27 | |

| 0.5 | 800 | 11.28 | 0 | 0 | 0 | −88.65 | |

| 0.5 | 200 | 16.98 | 0 | 0 | 0 | −9.69 | |

| 0.5 | 400 | 15.75 | 0 | 0 | 0 | −49.80 | |

| 0.5 | 600 | 12.7 | 0 | 0 | 0 | −67.63 | |

| 0.5 | 800 | 11.28 | 0 | 0 | 0 | −85.01 | |

| 0.5 | 200 | 16.98 | 0 | 0 | 0 | −7.87 | |

| 0.5 | 400 | 15.75 | 0 | 0 | 0 | −46.62 | |

| 0.5 | 600 | 12.7 | 0 | 0 | 0 | −64.91 | |

| 0.5 | 800 | 11.28 | 0 | 0 | 0 | −85.93 | |

| [49] | 0.5 | 200 | 20 | 2 | 1 | 0.08 | 7.58 |

| 0.5 | 300 | 20 | 2 | 1 | 0.08 | −0.26 | |

| 0.5 | 400 | 20 | 2 | 1 | 0.08 | −3.18 | |

| 0.5 | 500 | 20 | 2 | 1 | 0.08 | −5.45 | |

| 0.5 | 600 | 20 | 2 | 1 | 0.08 | −8.70 | |

| 0.5 | 700 | 20 | 2 | 1 | 0.08 | −25.06 | |

| 0.5 | 800 | 20 | 2 | 1 | 0.08 | −71.92 | |

| 0.5 | 1000 | 20 | 2 | 1 | 0.08 | −86.94 | |

| 0.5 | 1200 | 20 | 2 | 1 | 0.08 | −93.12 | |

| 0.6 | 200 | 20 | 2 | 1 | 0.08 | −2.25 | |

| 0.6 | 400 | 20 | 2 | 1 | 0.08 | −0.56 | |

| 0.6 | 600 | 20 | 2 | 1 | 0.08 | −12.96 | |

| 0.6 | 700 | 20 | 2 | 1 | 0.08 | −27.69 | |

| 0.6 | 800 | 20 | 2 | 1 | 0.08 | −62.41 | |

| 0.6 | 1000 | 20 | 2 | 1 | 0.08 | −85.30 | |

| 0.6 | 1200 | 20 | 2 | 1 | 0.08 | −92.13 | |

| 0.4 | 200 | 20 | 2 | 1 | 0.08 | −4.87 | |

| 0.4 | 400 | 20 | 2 | 1 | 0.08 | −15.97 | |

| 0.4 | 600 | 20 | 2 | 1 | 0.08 | −25.12 | |

| 0.4 | 700 | 20 | 2 | 1 | 0.08 | −49.68 | |

| 0.4 | 800 | 20 | 2 | 1 | 0.08 | −78.81 | |

| 0.4 | 1000 | 20 | 2 | 1 | 0.08 | −89.26 | |

| 0.4 | 1200 | 20 | 2 | 1 | 0.08 | −98.03 | |

| 0.5 | 200 | 20 | 2 | 1 | 0.08 | −0.61 | |

| 0.5 | 400 | 20 | 2 | 1 | 0.08 | −27.77 | |

| 0.5 | 500 | 20 | 2 | 1 | 0.08 | −34.62 | |

| 0.5 | 600 | 20 | 2 | 1 | 0.08 | −56.89 | |

| 0.5 | 700 | 20 | 2 | 1 | 0.08 | −66.69 | |

| 0.5 | 900 | 20 | 2 | 1 | 0.08 | −83.69 | |

| 0.5 | 1200 | 20 | 2 | 1 | 0.08 | −98.69 | |

| [50] | 0.41 | 150 | 5 | 5 | 1 | 0 | −18.56 |

| 0.41 | 300 | 5 | 5 | 1 | 0 | −24.08 | |

| 0.41 | 400 | 5 | 5 | 1 | 0 | −35.49 | |

| 0.41 | 500 | 5 | 5 | 1 | 0 | −39.87 | |

| 0.41 | 600 | 5 | 5 | 1 | 0 | −60.80 | |

| 0.41 | 700 | 5 | 5 | 1 | 0 | −75.40 | |

| 0.41 | 150 | 5 | 5 | 1 | 0 | −17.85 | |

| 0.41 | 300 | 5 | 5 | 1 | 0 | −24.73 | |

| 0.41 | 400 | 5 | 5 | 1 | 0 | −34.56 | |

| 0.41 | 500 | 5 | 5 | 1 | 0 | −37.13 | |

| 0.41 | 600 | 5 | 5 | 1 | 0 | −61.01 | |

| 0.41 | 700 | 5 | 5 | 1 | 0 | −73.10 | |

| 0.41 | 150 | 5 | 5 | 1 | 0 | −18.27 | |

| 0.41 | 300 | 5 | 5 | 1 | 0 | −24.47 | |

| 0.41 | 400 | 5 | 5 | 1 | 0 | −36.56 | |

| 0.41 | 500 | 5 | 5 | 1 | 0 | −55.23 | |

| 0.41 | 600 | 5 | 5 | 1 | 0 | −66.19 | |

| 0.41 | 700 | 5 | 5 | 1 | 0 | −75.55 | |

| 0.41 | 150 | 5 | 5 | 1 | 0 | −18.70 | |

| 0.41 | 300 | 5 | 5 | 1 | 0 | −32.15 | |

| 0.41 | 400 | 5 | 5 | 1 | 0 | −49.91 | |

| 0.41 | 500 | 5 | 5 | 1 | 0 | −58.15 | |

| 0.41 | 600 | 5 | 5 | 1 | 0 | −66.16 | |

| 0.41 | 700 | 5 | 5 | 1 | 0 | −77.80 | |

| [51] | 0.4 | 100 | 3 | 3 | 1 | 0 | −13.70 |

| 0.4 | 200 | 3 | 3 | 1 | 0 | −10.20 | |

| 0.4 | 300 | 3 | 3 | 1 | 0 | −24.70 | |

| 0.4 | 600 | 3 | 3 | 1 | 0 | −66.60 | |

| 0.35 | 100 | 3 | 3 | 1 | 0 | −15.00 | |

| 0.35 | 200 | 3 | 3 | 1 | 0 | −12.50 | |

| 0.35 | 300 | 3 | 3 | 1 | 0 | −23.50 | |

| 0.35 | 600 | 3 | 3 | 1 | 0 | −70.50 | |

| 0.3 | 100 | 3 | 3 | 1 | 0 | −14.60 | |

| 0.3 | 200 | 3 | 3 | 1 | 0 | 11.40 | |

| 0.3 | 300 | 3 | 3 | 1 | 0 | −27.30 | |

| 0.3 | 600 | 3 | 3 | 1 | 0 | −68.80 | |

| 0.3 | 100 | 3 | 3 | 1 | 0 | −15.30 | |

| 0.3 | 200 | 3 | 3 | 1 | 0 | −14.10 | |

| 0.3 | 300 | 3 | 3 | 1 | 0 | −29.60 | |

| 0.3 | 600 | 3 | 3 | 1 | 0 | −70.90 | |

| 0.3 | 100 | 3 | 3 | 1 | 0 | −15.90 | |

| 0.3 | 200 | 3 | 3 | 1 | 0 | −14.80 | |

| 0.3 | 300 | 3 | 3 | 1 | 0 | −31.30 | |

| 0.3 | 600 | 3 | 3 | 1 | 0 | −73.20 | |

| [52] | 0.42 | 105 | 3 | 16 | 1 | 0 | −17.71 |

| 0.42 | 150 | 3 | 4 | 1 | 0 | −14.07 | |

| 0.42 | 150 | 3 | 8 | 1 | 0 | −9.83 | |

| 0.42 | 150 | 3 | 16 | 1 | 0 | −7.71 | |

| 0.42 | 200 | 3 | 4 | 1 | 0 | −0.54 | |

| 0.42 | 200 | 3 | 8 | 1 | 0 | −3.16 | |

| 0.42 | 200 | 3 | 16 | 1 | 0 | −5.05 | |

| 0.42 | 250 | 3 | 4 | 1 | 0 | −1.28 | |

| 0.42 | 250 | 3 | 8 | 1 | 0 | −4.25 | |

| 0.42 | 250 | 3 | 16 | 1 | 0 | −6.29 | |

| 0.42 | 300 | 3 | 4 | 1 | 0 | −4.06 | |

| 0.42 | 300 | 3 | 8 | 1 | 0 | −7.13 | |

| 0.42 | 300 | 3 | 16 | 1 | 0 | −9.21 | |

| 0.42 | 350 | 3 | 4 | 1 | 0 | −7.34 | |

| 0.42 | 350 | 3 | 8 | 1 | 0 | −10.38 | |

| 0.42 | 350 | 3 | 16 | 1 | 0 | −12.33 | |

| 0.42 | 400 | 3 | 4 | 1 | 0 | −11.56 | |

| 0.42 | 400 | 3 | 8 | 1 | 0 | −14.15 | |

| 0.42 | 400 | 3 | 16 | 1 | 0 | −15.86 | |

| 0.42 | 450 | 3 | 4 | 1 | 0 | −16.00 | |

| 0.42 | 450 | 3 | 8 | 1 | 0 | −18.37 | |

| 0.42 | 450 | 3 | 16 | 1 | 0 | −19.86 | |

| [53] | 0.54 | 100 | 15.6 | 0 | 1 | 0 | −3.65 |

| 0.54 | 300 | 15.6 | 0 | 1 | 0 | −21.40 | |

| 0.54 | 500 | 15.6 | 0 | 1 | 0 | −29.07 | |

| 0.54 | 800 | 15.6 | 0 | 1 | 0 | −37.90 | |

| 0.54 | 100 | 15.6 | 0 | 1 | 0 | −5.37 | |

| 0.54 | 300 | 15.6 | 0 | 1 | 0 | −22.55 | |

| 0.54 | 500 | 15.6 | 0 | 1 | 0 | −36.69 | |

| 0.54 | 800 | 15.6 | 0 | 1 | 0 | −50.67 | |

| 0.54 | 100 | 15.6 | 0 | 1 | 0 | −8.42 | |

| 0.54 | 300 | 15.6 | 0 | 1 | 0 | −23.88 | |

| 0.54 | 500 | 15.6 | 0 | 1 | 0 | −37.07 | |

| 0.54 | 800 | 15.6 | 0 | 1 | 0 | −55.24 | |

| 0.54 | 100 | 15.6 | 0 | 1 | 0 | −9.94 | |

| 0.54 | 300 | 15.6 | 0 | 1 | 0 | −23.88 | |

| 0.54 | 500 | 15.6 | 0 | 1 | 0 | −38.21 | |

| 0.54 | 800 | 15.6 | 0 | 1 | 0 | −58.09 | |

| [54] | 0.25 | 200 | 6.67 | 2 | 0 | 0 | 21.61 |

| 0.25 | 400 | 6.67 | 2 | 0 | 0 | 1.26 | |

| 0.25 | 600 | 6.67 | 2 | 0 | 0 | −29.58 | |

| 0.25 | 800 | 6.67 | 2 | 0 | 0 | −70.33 | |

| 0.25 | 1000 | 6.67 | 2 | 0 | 0 | −88.92 | |

| [55] | 0.26 | 400 | 10 | 1 | 1 | 2 | −0.48 |

| 0.26 | 600 | 10 | 1 | 1 | 2 | −21.53 | |

| 0.26 | 800 | 10 | 1 | 1 | 2 | −70.56 | |

| [56] | 0.4 | 200 | 10 | 3 | 1 | 28 | 4.29 |

| 0.4 | 400 | 10 | 3 | 1 | 28 | −15.71 | |

| 0.4 | 600 | 10 | 3 | 1 | 28 | −24.29 | |

| 0.4 | 800 | 10 | 3 | 1 | 28 | −52.86 | |

| 0.4 | 1000 | 10 | 3 | 1 | 28 | −61.43 | |

| 0.4 | 200 | 10 | 3 | 0 | 28 | −1.43 | |

| 0.4 | 400 | 10 | 3 | 0 | 28 | −24.29 | |

| 0.4 | 600 | 10 | 3 | 0 | 28 | −34.29 | |

| 0.4 | 800 | 10 | 3 | 0 | 28 | −57.14 | |

| 0.4 | 1000 | 10 | 3 | 0 | 28 | −74.29 | |

| [57] | 0.62 | 150 | 1 | 0 | 1 | 0 | −2.55 |

| 0.62 | 300 | 1 | 0 | 1 | 0 | −5.71 | |

| 0.62 | 450 | 1 | 0 | 1 | 0 | −42.01 | |

| 0.62 | 600 | 1 | 0 | 1 | 0 | −90.96 | |

| 0.55 | 150 | 1 | 0 | 1 | 0 | −8.44 | |

| 0.55 | 300 | 1 | 0 | 1 | 0 | −0.76 | |

| 0.55 | 450 | 1 | 0 | 1 | 0 | −50.38 | |

| 0.55 | 600 | 1 | 0 | 1 | 0 | −83.85 | |

| 0.44 | 150 | 1 | 0 | 1 | 0 | −9.39 | |

| 0.44 | 300 | 1 | 0 | 1 | 0 | 2.45 | |

| 0.44 | 450 | 1 | 0 | 1 | 0 | −58.29 | |

| 0.44 | 600 | 1 | 0 | 1 | 0 | −87.17 | |

| 0.36 | 150 | 1 | 0 | 1 | 0 | 4.66 | |

| 0.36 | 300 | 1 | 0 | 1 | 0 | 11.67 | |

| 0.36 | 450 | 1 | 0 | 1 | 0 | −47.72 | |

| 0.36 | 600 | 1 | 0 | 1 | 0 | −84.58 | |

| 0.29 | 150 | 1 | 0 | 1 | 0 | −1.72 | |

| 0.29 | 300 | 1 | 0 | 1 | 0 | 7.41 | |

| 0.29 | 350 | 1 | 0 | 1 | 0 | 20.54 | |

| 0.29 | 600 | 1 | 0 | 1 | 0 | −84.87 | |

| [58] | 0.33 | 200 | 1 | 3 | 1 | 0 | 3.86 |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −17.66 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −49.04 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −75.02 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | 3.21 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −15.91 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −49.41 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −76.35 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | −2.29 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −17.49 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −53.97 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −76.66 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | −2.18 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −16.53 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −54.68 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −78.94 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | −0.53 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −18.59 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −57.16 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −77.98 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | 3.58 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −19.79 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −57.00 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −80.14 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | −5.91 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −20.10 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −54.58 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −81.95 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | 1.91 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −23.97 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −50.66 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −76.39 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | −1.37 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −16.77 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −52.98 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −77.25 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | −1.61 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −21.09 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −48.67 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −78.99 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | −3.44 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −22.70 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −51.69 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −80.00 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | 1.10 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −18.71 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −49.54 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −76.41 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | 0.17 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −15.91 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −48.17 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −75.55 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | 3.66 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −18.71 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −47.05 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −77.40 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | −4.54 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −21.01 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −50.58 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −78.00 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | −7.56 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −21.89 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −48.55 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −78.97 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | −8.06 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −20.73 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −47.87 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −80.42 | |

| [59] | 0.56 | 105 | 3 | 16 | 1 | 0 | −17.73 |

| 0.56 | 150 | 3 | 16 | 1 | 0 | −7.75 | |

| 0.56 | 200 | 3 | 16 | 1 | 0 | −5.07 | |

| 0.56 | 250 | 3 | 16 | 1 | 0 | −6.26 | |

| 0.56 | 300 | 3 | 16 | 1 | 0 | −9.24 | |

| 0.56 | 350 | 3 | 16 | 1 | 0 | −12.37 | |

| 0.56 | 400 | 3 | 16 | 1 | 0 | −15.95 | |

| 0.56 | 450 | 3 | 16 | 1 | 0 | −19.82 | |

| [60] | 0.3 | 200 | 2.5 | 1 | 1 | 0 | −3.90 |

| 0.3 | 400 | 2.5 | 1 | 1 | 0 | −12.78 | |

| 0.3 | 600 | 2.5 | 1 | 1 | 0 | −42.78 | |

| 0.3 | 800 | 2.5 | 1 | 1 | 0 | −76.59 | |

| 0.3 | 200 | 2.5 | 1 | 1 | 0 | 6.36 | |

| 0.3 | 400 | 2.5 | 1 | 1 | 0 | −11.03 | |

| 0.3 | 600 | 2.5 | 1 | 1 | 0 | −42.83 | |

| 0.3 | 800 | 2.5 | 1 | 1 | 0 | −75.86 | |

| 0.3 | 200 | 2.5 | 1 | 1 | 0 | 10.81 | |

| 0.3 | 400 | 2.5 | 1 | 1 | 0 | −7.33 | |

| 0.3 | 600 | 2.5 | 1 | 1 | 0 | −39.31 | |

| 0.3 | 800 | 2.5 | 1 | 1 | 0 | −73.22 | |

| 0.3 | 200 | 2.5 | 1 | 1 | 0 | 14.90 | |

| 0.3 | 400 | 2.5 | 1 | 1 | 0 | −6.87 | |

| 0.3 | 600 | 2.5 | 1 | 1 | 0 | −35.44 | |

| 0.3 | 800 | 2.5 | 1 | 1 | 0 | −69.50 | |

| 0.3 | 200 | 2.5 | 1 | 1 | 0 | 19.08 | |

| 0.3 | 400 | 2.5 | 1 | 1 | 0 | 0.14 | |

| 0.3 | 600 | 2.5 | 1 | 1 | 0 | −44.28 | |

| 0.3 | 800 | 2.5 | 1 | 1 | 0 | −71.78 | |

| [61] | 0.31 | 200 | 10 | 3 | 1 | 0 | −11.55 |

| 0.31 | 400 | 10 | 3 | 1 | 0 | 26.27 | |

| 0.31 | 600 | 10 | 3 | 1 | 0 | −5.35 | |

| 0.31 | 800 | 10 | 3 | 1 | 0 | −59.94 | |

| 0.31 | 200 | 10 | 3 | 1 | 0 | 51.47 | |

| 0.31 | 400 | 10 | 3 | 1 | 0 | 66.88 | |

| 0.31 | 600 | 10 | 3 | 1 | 0 | 33.89 | |

| 0.31 | 800 | 10 | 3 | 1 | 0 | −42.68 | |

| [62] | 0.55 | 400 | 7.5 | 1 | 1 | 4 | −18.89 |

| 0.55 | 600 | 7.5 | 1 | 1 | 4 | −20.94 | |

| 0.55 | 800 | 7.5 | 1 | 1 | 4 | −50.72 | |

| 0.55 | 400 | 7.5 | 1 | 1 | 4 | −17.03 | |

| 0.55 | 600 | 7.5 | 1 | 1 | 4 | −21.62 | |

| 0.55 | 800 | 7.5 | 1 | 1 | 4 | −59.19 | |

| 0.55 | 400 | 7.5 | 1 | 1 | 4 | −14.33 | |

| 0.55 | 600 | 7.5 | 1 | 1 | 4 | −21.50 | |

| 0.55 | 800 | 7.5 | 1 | 1 | 4 | −63.48 | |

| 0.55 | 400 | 7.5 | 1 | 1 | 4 | −19.55 | |

| 0.55 | 600 | 7.5 | 1 | 1 | 4 | −27.73 | |

| 0.55 | 800 | 7.5 | 1 | 1 | 4 | −66.82 | |

| [63] | 0.5 | 100 | 6.5 | 1 | 1 | 0 | −6.45 |

| 0.5 | 200 | 6.5 | 1 | 1 | 0 | −1.80 | |

| 0.5 | 300 | 6.5 | 1 | 1 | 0 | −12.15 | |

| 0.5 | 100 | 6.5 | 1 | 1 | 0 | −19.43 | |

| 0.5 | 200 | 6.5 | 1 | 1 | 0 | −2.69 | |

| 0.5 | 300 | 6.5 | 1 | 1 | 0 | −17.59 | |

| 0.5 | 400 | 6.5 | 1 | 1 | 0 | −32.77 | |

| 0.5 | 500 | 6.5 | 1 | 1 | 0 | −37.51 | |

| 0.5 | 600 | 6.5 | 1 | 1 | 0 | −79.81 | |

| 0.5 | 700 | 6.5 | 1 | 1 | 0 | −63.91 | |

| 0.5 | 800 | 5 | 1 | 1 | 0 | −69.21 | |

| 0.5 | 100 | 6.5 | 1 | 1 | 0 | −14.36 | |

| 0.5 | 200 | 6.5 | 1 | 1 | 0 | −0.17 | |

| 0.5 | 300 | 6.5 | 1 | 1 | 0 | −11.14 | |

| 0.5 | 400 | 6.5 | 1 | 1 | 0 | −21.18 | |

| 0.5 | 500 | 6.5 | 1 | 1 | 0 | −37.36 | |

| 0.5 | 600 | 6.5 | 1 | 1 | 0 | −55.38 | |

| 0.5 | 700 | 6.5 | 1 | 1 | 0 | −59.90 | |

| 0.5 | 800 | 5 | 1 | 1 | 0 | −68.10 | |

| 0.5 | 100 | 6.5 | 1 | 1 | 0 | 10.56 | |

| 0.5 | 200 | 6.5 | 1 | 1 | 0 | 0.19 | |

| 0.5 | 300 | 6.5 | 1 | 1 | 0 | 5.54 | |

| 0.5 | 400 | 6.5 | 1 | 1 | 0 | 12.19 | |

| 0.5 | 500 | 6.5 | 1 | 1 | 0 | −27.86 | |

| 0.5 | 600 | 6.5 | 1 | 1 | 0 | −42.16 | |

| 0.5 | 700 | 6.5 | 1 | 1 | 0 | −50.78 | |

| 0.5 | 800 | 5 | 1 | 1 | 0 | −60.71 | |

| [64] | 0.3 | 200 | 2.5 | 1 | 1 | 0 | −3.92 |

| 0.3 | 400 | 2.5 | 1 | 1 | 0 | −10.50 | |

| 0.3 | 600 | 2.5 | 1 | 1 | 0 | −41.64 | |

| 0.3 | 800 | 2.5 | 1 | 1 | 0 | −77.24 | |

| 0.3 | 200 | 2.5 | 1 | 1 | 0 | 0.09 | |

| 0.3 | 400 | 2.5 | 1 | 1 | 0 | −6.35 | |

| 0.3 | 600 | 2.5 | 1 | 1 | 0 | −48.18 | |

| 0.3 | 800 | 2.5 | 1 | 1 | 0 | −78.08 | |

| 0.3 | 200 | 2.5 | 1 | 1 | 0 | −0.25 | |

| 0.3 | 400 | 2.5 | 1 | 1 | 0 | −1.41 | |

| 0.3 | 600 | 2.5 | 1 | 1 | 0 | −5.89 | |

| 0.3 | 800 | 2.5 | 1 | 1 | 0 | −8.73 | |

| 0.3 | 200 | 2.5 | 1 | 1 | 0 | 2.88 | |

| 0.3 | 400 | 2.5 | 1 | 1 | 0 | −6.47 | |

| 0.3 | 600 | 2.5 | 1 | 1 | 0 | −53.59 | |

| 0.3 | 800 | 2.5 | 1 | 1 | 0 | −80.77 | |

| 0.3 | 200 | 2.5 | 1 | 1 | 0 | 7.12 | |

| 0.3 | 400 | 2.5 | 1 | 1 | 0 | −9.14 | |

| 0.3 | 600 | 2.5 | 1 | 1 | 0 | −62.59 | |

| 0.3 | 800 | 2.5 | 1 | 1 | 0 | −86.22 | |

| 0.3 | 200 | 2.5 | 1 | 1 | 0 | 5.20 | |

| 0.3 | 400 | 2.5 | 1 | 1 | 0 | −13.45 | |

| 0.3 | 600 | 2.5 | 1 | 1 | 0 | −68.06 | |

| 0.3 | 800 | 2.5 | 1 | 1 | 0 | −91.24 | |

| 0.3 | 200 | 2.5 | 1 | 1 | 0 | 14.50 | |

| 0.3 | 400 | 2.5 | 1 | 1 | 0 | −3.19 | |

| 0.3 | 600 | 2.5 | 1 | 1 | 0 | −37.83 | |

| 0.3 | 800 | 2.5 | 1 | 1 | 0 | −71.62 | |

| 0.3 | 200 | 2.5 | 1 | 1 | 0 | −5.69 | |

| 0.3 | 400 | 2.5 | 1 | 1 | 0 | −26.14 | |

| 0.3 | 600 | 2.5 | 1 | 1 | 0 | −67.05 | |

| 0.3 | 800 | 2.5 | 1 | 1 | 0 | −92.05 | |

| 0.3 | 200 | 2.5 | 1 | 1 | 0 | −1.92 | |

| 0.3 | 400 | 2.5 | 1 | 1 | 0 | −9.61 | |

| 0.3 | 600 | 2.5 | 1 | 1 | 0 | −67.31 | |

| 0.3 | 800 | 2.5 | 1 | 1 | 0 | −87.50 | |

| 0.3 | 200 | 2.5 | 1 | 1 | 0 | 1.67 | |

| 0.3 | 400 | 2.5 | 1 | 1 | 0 | −14.99 | |

| 0.3 | 600 | 2.5 | 1 | 1 | 0 | −71.66 | |

| 0.3 | 800 | 2.5 | 1 | 1 | 0 | −90.00 | |

| 0.3 | 200 | 2.5 | 1 | 1 | 0 | 3.34 | |

| 0.3 | 400 | 2.5 | 1 | 1 | 0 | −21.33 | |

| 0.3 | 600 | 2.5 | 1 | 1 | 0 | −78.00 | |

| 0.3 | 800 | 2.5 | 1 | 1 | 0 | −92.67 | |

| 0.3 | 200 | 2.5 | 1 | 1 | 0 | 0.91 | |

| 0.3 | 400 | 2.5 | 1 | 1 | 0 | −18.18 | |

| 0.3 | 600 | 2.5 | 1 | 1 | 0 | −64.54 | |

| 0.3 | 800 | 2.5 | 1 | 1 | 0 | −84.55 | |

| [65] | 0.5 | 200 | 1 | 1 | 1 | 0 | 8.04 |

| 0.5 | 400 | 1 | 1 | 1 | 0 | −15.32 | |

| 0.5 | 600 | 1 | 1 | 1 | 0 | −48.90 | |

| 0.5 | 800 | 1 | 1 | 1 | 0 | −69.34 | |

| 0.5 | 200 | 1 | 1 | 1 | 0 | 12.83 | |

| 0.5 | 400 | 1 | 1 | 1 | 0 | −14.87 | |

| 0.5 | 600 | 1 | 1 | 1 | 0 | −46.62 | |

| 0.5 | 800 | 1 | 1 | 1 | 0 | −69.60 | |

| 0.5 | 200 | 1 | 1 | 1 | 0 | 14.91 | |

| 0.5 | 400 | 1 | 1 | 1 | 0 | 1.07 | |

| 0.5 | 600 | 1 | 1 | 1 | 0 | −32.97 | |

| 0.5 | 800 | 1 | 1 | 1 | 0 | −76.59 | |

| 0.3 | 200 | 1 | 1 | 1 | 0 | 7.74 | |

| 0.3 | 400 | 1 | 1 | 1 | 0 | −19.36 | |

| 0.3 | 600 | 1 | 1 | 1 | 0 | −47.42 | |

| 0.3 | 800 | 1 | 1 | 1 | 0 | −77.74 | |

| 0.3 | 200 | 1 | 1 | 1 | 0 | 14.49 | |

| 0.3 | 400 | 1 | 1 | 1 | 0 | −14.84 | |

| 0.3 | 600 | 1 | 1 | 1 | 0 | −44.17 | |

| 0.3 | 800 | 1 | 1 | 1 | 0 | −76.33 | |

| 0.3 | 200 | 1 | 1 | 1 | 0 | 23.76 | |

| 0.3 | 400 | 1 | 1 | 1 | 0 | −0.99 | |

| 0.3 | 600 | 1 | 1 | 1 | 0 | −34.16 | |

| 0.3 | 800 | 1 | 1 | 1 | 0 | −74.75 | |

| [66] | 0.5 | 100 | 10 | 1 | 1 | 0 | −10.42 |

| 0.5 | 300 | 10 | 1 | 1 | 0 | −22.66 | |

| 0.5 | 500 | 10 | 1 | 1 | 0 | −33.41 | |

| 0.5 | 800 | 10 | 1 | 1 | 0 | −78.34 | |

| 0.5 | 100 | 10 | 1 | 0 | 0 | −11.30 | |

| 0.5 | 300 | 10 | 1 | 0 | 0 | −35.71 | |

| 0.5 | 500 | 10 | 1 | 0 | 0 | −44.69 | |

| 0.5 | 800 | 10 | 1 | 0 | 0 | −76.85 | |

| 0.35 | 100 | 10 | 1 | 1 | 0 | −7.57 | |

| 0.35 | 300 | 10 | 1 | 1 | 0 | −3.72 | |

| 0.35 | 500 | 10 | 1 | 1 | 0 | 5.38 | |

| 0.35 | 800 | 10 | 1 | 1 | 0 | −52.45 | |

| 0.35 | 100 | 10 | 1 | 0 | 0 | −7.57 | |

| 0.35 | 300 | 10 | 1 | 0 | 0 | −14.21 | |

| 0.35 | 500 | 10 | 1 | 0 | 0 | −28.07 | |

| 0.35 | 800 | 10 | 1 | 0 | 0 | −64.58 | |

| [67] | 0.6 | 100 | 1.5 | 2 | 1 | 0 | −0.11 |

| 0.6 | 300 | 1.5 | 2 | 1 | 0 | 0.05 | |

| 0.6 | 600 | 1.5 | 2 | 1 | 0 | −0.52 | |

| 0.6 | 750 | 1.5 | 2 | 1 | 0 | −0.75 | |

| 0.6 | 100 | 1.5 | 2 | 1 | 0 | −0.05 | |

| 0.6 | 300 | 1.5 | 2 | 1 | 0 | 0.06 | |

| 0.6 | 600 | 1.5 | 2 | 1 | 0 | −0.50 | |

| 0.6 | 750 | 1.5 | 2 | 1 | 0 | −0.75 | |

| 0.6 | 100 | 1.5 | 2 | 1 | 0 | 0.19 | |

| 0.6 | 300 | 1.5 | 2 | 1 | 0 | 0.32 | |

| 0.6 | 600 | 1.5 | 2 | 1 | 0 | −0.51 | |

| 0.6 | 750 | 1.5 | 2 | 1 | 0 | −0.78 | |

| 0.6 | 100 | 1.5 | 2 | 1 | 0 | 0.13 | |

| 0.6 | 300 | 1.5 | 2 | 1 | 0 | 0.37 | |

| 0.6 | 600 | 1.5 | 2 | 1 | 0 | −0.60 | |

| 0.6 | 750 | 1.5 | 2 | 1 | 0 | −0.85 | |

| 0.6 | 100 | 1.5 | 2 | 1 | 0 | −0.03 | |

| 0.6 | 300 | 1.5 | 2 | 1 | 0 | 0.16 | |

| 0.6 | 600 | 1.5 | 2 | 1 | 0 | −0.68 | |

| 0.6 | 750 | 1.5 | 2 | 1 | 0 | −0.88 | |

| 0.6 | 100 | 1.5 | 2 | 1 | 0 | 0.13 | |

| 0.6 | 300 | 1.5 | 2 | 1 | 0 | 0.39 | |

| 0.6 | 600 | 1.5 | 2 | 1 | 0 | −0.55 | |

| 0.6 | 750 | 1.5 | 2 | 1 | 0 | −0.93 | |

| 0.6 | 100 | 1.5 | 2 | 1 | 0 | 0.24 | |

| 0.6 | 300 | 1.5 | 2 | 1 | 0 | 0.24 | |

| 0.6 | 600 | 1.5 | 2 | 1 | 0 | −0.53 | |

| 0.6 | 750 | 1.5 | 2 | 1 | 0 | −0.75 | |

| 0.6 | 100 | 1.5 | 2 | 1 | 0 | −0.01 | |

| 0.6 | 300 | 1.5 | 2 | 1 | 0 | −0.07 | |

| 0.6 | 600 | 1.5 | 2 | 1 | 0 | −0.48 | |

| 0.6 | 750 | 1.5 | 2 | 1 | 0 | −0.77 | |

| 0.6 | 100 | 1.5 | 2 | 1 | 0 | −0.09 | |

| 0.6 | 300 | 1.5 | 2 | 1 | 0 | −0.08 | |

| 0.6 | 600 | 1.5 | 2 | 1 | 0 | −0.47 | |

| 0.6 | 750 | 1.5 | 2 | 1 | 0 | −0.77 | |

| 0.6 | 100 | 1.5 | 2 | 1 | 0 | −0.05 | |

| 0.6 | 300 | 1.5 | 2 | 1 | 0 | −0.08 | |

| 0.6 | 600 | 1.5 | 2 | 1 | 0 | −0.59 | |

| 0.6 | 750 | 1.5 | 2 | 1 | 0 | −0.81 | |

| 0.6 | 100 | 1.5 | 2 | 1 | 0 | 0.06 | |

| 0.6 | 300 | 1.5 | 2 | 1 | 0 | 0.14 | |

| 0.6 | 600 | 1.5 | 2 | 1 | 0 | −0.56 | |

| 0.6 | 750 | 1.5 | 2 | 1 | 0 | −0.87 | |

| 0.6 | 100 | 1.5 | 2 | 1 | 0 | 0.05 | |

| 0.6 | 300 | 1.5 | 2 | 1 | 0 | 0.06 | |

| 0.6 | 600 | 1.5 | 2 | 1 | 0 | −0.60 | |

| 0.6 | 750 | 1.5 | 2 | 1 | 0 | −0.93 | |

| 0.6 | 100 | 1.5 | 2 | 1 | 0 | 0.08 | |

| 0.6 | 300 | 1.5 | 2 | 1 | 0 | 0.11 | |

| 0.6 | 600 | 1.5 | 2 | 1 | 0 | −0.58 | |

| 0.6 | 750 | 1.5 | 2 | 1 | 0 | −0.85 | |

| 0.6 | 100 | 1.5 | 2 | 1 | 0 | 0.03 | |

| 0.6 | 300 | 1.5 | 2 | 1 | 0 | 0.11 | |

| 0.6 | 600 | 1.5 | 2 | 1 | 0 | −0.66 | |

| 0.6 | 750 | 1.5 | 2 | 1 | 0 | −0.76 | |

| [68] | 0.29 | 200 | 5 | 1 | 1 | 0 | 2.25 |

| 0.29 | 400 | 5 | 1 | 1 | 0 | −29.21 | |

| 0.29 | 500 | 5 | 1 | 1 | 0 | −43.26 | |

| 0.29 | 600 | 5 | 1 | 1 | 0 | −63.48 | |

| 0.45 | 200 | 5 | 1 | 1 | 0 | 2.68 | |

| 0.45 | 400 | 5 | 1 | 1 | 0 | −16.07 | |

| 0.45 | 500 | 5 | 1 | 1 | 0 | −36.61 | |

| 0.45 | 600 | 5 | 1 | 1 | 0 | −59.82 | |

| 0.32 | 200 | 5 | 1 | 1 | 0 | −14.20 | |

| 0.32 | 400 | 5 | 1 | 1 | 0 | −42.61 | |

| 0.32 | 500 | 5 | 1 | 1 | 0 | −48.30 | |

| 0.32 | 600 | 5 | 1 | 1 | 0 | −68.18 | |

| 0.48 | 200 | 5 | 1 | 1 | 0 | −23.97 | |

| 0.48 | 400 | 5 | 1 | 1 | 0 | −19.83 | |

| 0.48 | 500 | 5 | 1 | 1 | 0 | −41.32 | |

| 0.48 | 600 | 5 | 1 | 1 | 0 | −62.81 | |

| [69] | 0.54 | 100 | 5 | 1 | 1 | 0 | −18.74 |

| 0.54 | 300 | 5 | 1 | 1 | 0 | −40.00 | |

| 0.54 | 500 | 5 | 1 | 1 | 0 | −46.25 | |

| 0.54 | 700 | 5 | 1 | 1 | 0 | −72.50 | |

| 0.6 | 100 | 5 | 1 | 1 | 0 | −10.12 | |

| 0.6 | 300 | 5 | 1 | 1 | 0 | −19.10 | |

| 0.6 | 500 | 5 | 1 | 1 | 0 | −29.22 | |

| 0.6 | 700 | 5 | 1 | 1 | 0 | −49.44 | |

| 0.57 | 100 | 5 | 1 | 1 | 0 | −27.91 | |

| 0.57 | 300 | 5 | 1 | 1 | 0 | −27.91 | |

| 0.57 | 500 | 5 | 1 | 1 | 0 | −52.33 | |

| 0.57 | 700 | 5 | 1 | 1 | 0 | −82.56 | |

| 0.57 | 100 | 5 | 1 | 1 | 0 | −11.77 | |

| 0.57 | 300 | 5 | 1 | 1 | 0 | −16.67 | |

| 0.57 | 500 | 5 | 1 | 1 | 0 | −16.67 | |

| 0.57 | 700 | 5 | 1 | 1 | 0 | −31.38 | |

| 0.46 | 100 | 5 | 1 | 1 | 0 | −28.26 | |

| 0.46 | 300 | 5 | 1 | 1 | 0 | −32.81 | |

| 0.46 | 500 | 5 | 1 | 1 | 0 | −39.34 | |

| 0.46 | 700 | 5 | 1 | 1 | 0 | −45.83 | |

| 0.46 | 100 | 5 | 1 | 1 | 0 | −16.14 | |

| 0.46 | 300 | 5 | 1 | 1 | 0 | −23.61 | |

| 0.46 | 500 | 5 | 1 | 1 | 0 | −30.21 | |

| 0.46 | 700 | 5 | 1 | 1 | 0 | −35.07 | |

| 0.43 | 100 | 5 | 1 | 1 | 0 | −18.63 | |

| 0.43 | 300 | 5 | 1 | 1 | 0 | −30.15 | |

| 0.45 | 100 | 5 | 1 | 1 | 0 | −19.47 | |

| 0.45 | 300 | 5 | 1 | 1 | 0 | −29.08 | |

| [70] | 0.5 | 200 | 5 | 2 | 1 | 3 | −4.00 |

| 0.5 | 400 | 5 | 2 | 1 | 3 | −20.00 | |

| 0.5 | 600 | 5 | 2 | 1 | 3 | −36.00 | |

| 0.5 | 800 | 5 | 2 | 1 | 3 | −77.00 | |

| 0.5 | 200 | 5 | 2 | 0 | 3 | −16.00 | |

| 0.5 | 400 | 5 | 2 | 0 | 3 | −37.00 | |

| 0.5 | 600 | 5 | 2 | 0 | 3 | −53.00 | |

| 0.5 | 800 | 5 | 2 | 0 | 3 | −82.00 | |

| [71] | 0.55 | 150 | 10 | 2 | 1 | 0 | 8.05 |

| 0.55 | 500 | 10 | 2 | 1 | 0 | 25.12 | |

| 0.4 | 150 | 10 | 2 | 1 | 0 | 2.30 | |

| 0.4 | 500 | 10 | 2 | 1 | 0 | 46.93 | |

| 0.55 | 150 | 10 | 2 | 1 | 0 | −6.44 | |

| 0.55 | 500 | 10 | 2 | 1 | 0 | −7.92 | |

| 0.55 | 750 | 10 | 2 | 1 | 0 | −57.18 | |

| 0.4 | 150 | 10 | 2 | 1 | 0 | −9.70 | |

| 0.4 | 500 | 10 | 2 | 1 | 0 | −6.84 | |

| 0.4 | 750 | 10 | 2 | 1 | 0 | −65.97 | |

| 0.5 | 150 | 10 | 2 | 1 | 0 | −14.49 | |

| 0.5 | 500 | 10 | 2 | 1 | 0 | −21.74 | |

| 0.5 | 750 | 10 | 2 | 1 | 0 | −77.97 | |

| 0.5 | 1000 | 10 | 2 | 1 | 0 | −91.01 | |

| 0.4 | 150 | 10 | 2 | 1 | 0 | −8.07 | |

| 0.4 | 500 | 10 | 2 | 1 | 0 | −16.14 | |

| 0.4 | 750 | 10 | 2 | 1 | 0 | −67.37 | |

| 0.4 | 1000 | 10 | 2 | 1 | 0 | −89.65 | |

| [72] | 0.33 | 200 | 1 | 3 | 1 | 0 | 4.42 |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −17.33 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −49.08 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −75.24 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | −0.92 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −16.38 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −52.87 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −77.30 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | −1.33 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −21.29 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −48.69 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −79.14 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | −3.56 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −22.85 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −51.80 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −79.68 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | 1.22 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −18.47 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −49.37 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −76.34 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | 0.60 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −15.82 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −47.50 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −75.72 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | 3.57 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −18.66 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −47.10 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −77.03 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | −3.77 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −20.64 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −50.32 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −78.25 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | −7.45 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −21.48 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −48.42 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −78.80 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | −8.13 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −20.35 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −46.98 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −79.88 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | −11.34 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −24.47 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −57.89 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −82.37 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | −21.10 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −30.10 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −59.90 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −80.70 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | −23.19 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −33.41 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −57.96 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −83.53 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | −20.04 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −35.07 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −62.28 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −85.19 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | −16.13 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −23.44 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −56.93 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −84.02 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | −21.02 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −26.56 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −57.50 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −81.73 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | −21.84 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −26.69 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −59.45 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −86.14 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | −17.50 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −24.21 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −59.22 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −84.31 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | −19.78 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −35.83 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −62.77 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −85.42 | |

| 0.33 | 200 | 1 | 3 | 1 | 0 | −24.77 | |

| 0.33 | 400 | 1 | 3 | 1 | 0 | −42.63 | |

| 0.33 | 600 | 1 | 3 | 1 | 0 | −62.38 | |

| 0.33 | 800 | 1 | 3 | 1 | 0 | −84.96 | |

| [73] | 0.61 | 150 | 1 | 1 | 1 | 0 | −0.13 |

| 0.61 | 300 | 1 | 1 | 1 | 0 | −0.17 | |

| 0.61 | 450 | 1 | 1 | 1 | 0 | −0.51 | |

| 0.61 | 600 | 1 | 1 | 1 | 0 | −0.86 | |

| 0.57 | 150 | 1 | 1 | 1 | 0 | −0.09 | |

| 0.57 | 300 | 1 | 1 | 1 | 0 | 0.17 | |

| 0.57 | 450 | 1 | 1 | 1 | 0 | −0.44 | |

| 0.57 | 600 | 1 | 1 | 1 | 0 | −0.80 | |

| 0.54 | 150 | 1 | 1 | 1 | 0 | −0.21 | |

| 0.54 | 300 | 1 | 1 | 1 | 0 | −0.04 | |

| 0.54 | 450 | 1 | 1 | 1 | 0 | −0.55 | |

| 0.54 | 600 | 1 | 1 | 1 | 0 | −0.83 | |

| [74] | 0.35 | 300 | 5 | 4 | 1 | 0 | −19.55 |

| 0.35 | 500 | 5 | 4 | 1 | 0 | −53.22 | |

| 0.35 | 600 | 5 | 4 | 1 | 0 | −65.49 | |

| 0.35 | 800 | 5 | 4 | 1 | 0 | −84.41 | |

| 0.35 | 300 | 5 | 4 | 1 | 0 | −10.25 | |

| 0.35 | 500 | 5 | 4 | 1 | 0 | −49.50 | |

| 0.35 | 600 | 5 | 4 | 1 | 0 | −65.00 | |

| 0.35 | 800 | 5 | 4 | 1 | 0 | −83.50 | |

| 0.35 | 300 | 5 | 4 | 1 | 0 | −15.75 | |

| 0.35 | 500 | 5 | 4 | 1 | 0 | −51.38 | |

| 0.35 | 600 | 5 | 4 | 1 | 0 | −66.58 | |

| 0.35 | 800 | 5 | 4 | 1 | 0 | −82.60 | |

| 0.35 | 300 | 5 | 4 | 1 | 0 | −17.52 | |

| 0.35 | 500 | 5 | 4 | 1 | 0 | −56.32 | |

| 0.35 | 600 | 5 | 4 | 1 | 0 | −66.66 | |

| 0.35 | 800 | 5 | 4 | 1 | 0 | −80.46 | |

| 0.35 | 300 | 5 | 4 | 1 | 0 | −18.60 | |

| 0.35 | 500 | 5 | 4 | 1 | 0 | −54.81 | |

| 0.35 | 600 | 5 | 4 | 1 | 0 | −66.67 | |

| 0.35 | 800 | 5 | 4 | 1 | 0 | −78.53 | |

| 0.35 | 300 | 5 | 4 | 1 | 0 | −7.84 | |

| 0.35 | 500 | 5 | 4 | 1 | 0 | −50.39 | |

| 0.35 | 600 | 5 | 4 | 1 | 0 | −61.88 | |

| 0.35 | 800 | 5 | 4 | 1 | 0 | −80.16 | |

| 0.35 | 300 | 5 | 4 | 1 | 0 | −6.87 | |

| 0.35 | 500 | 5 | 4 | 1 | 0 | −47.39 | |

| 0.35 | 600 | 5 | 4 | 1 | 0 | −59.15 | |

| 0.35 | 800 | 5 | 4 | 1 | 0 | −77.78 | |

| 0.35 | 300 | 5 | 4 | 1 | 0 | −5.08 | |

| 0.35 | 500 | 5 | 4 | 1 | 0 | −46.78 | |