Impact of Rice Husk Ash on the Mechanical Characteristics and Freeze–Thaw Resistance of Recycled Aggregate Concrete

Abstract

:1. Introduction

2. Materials and Methods

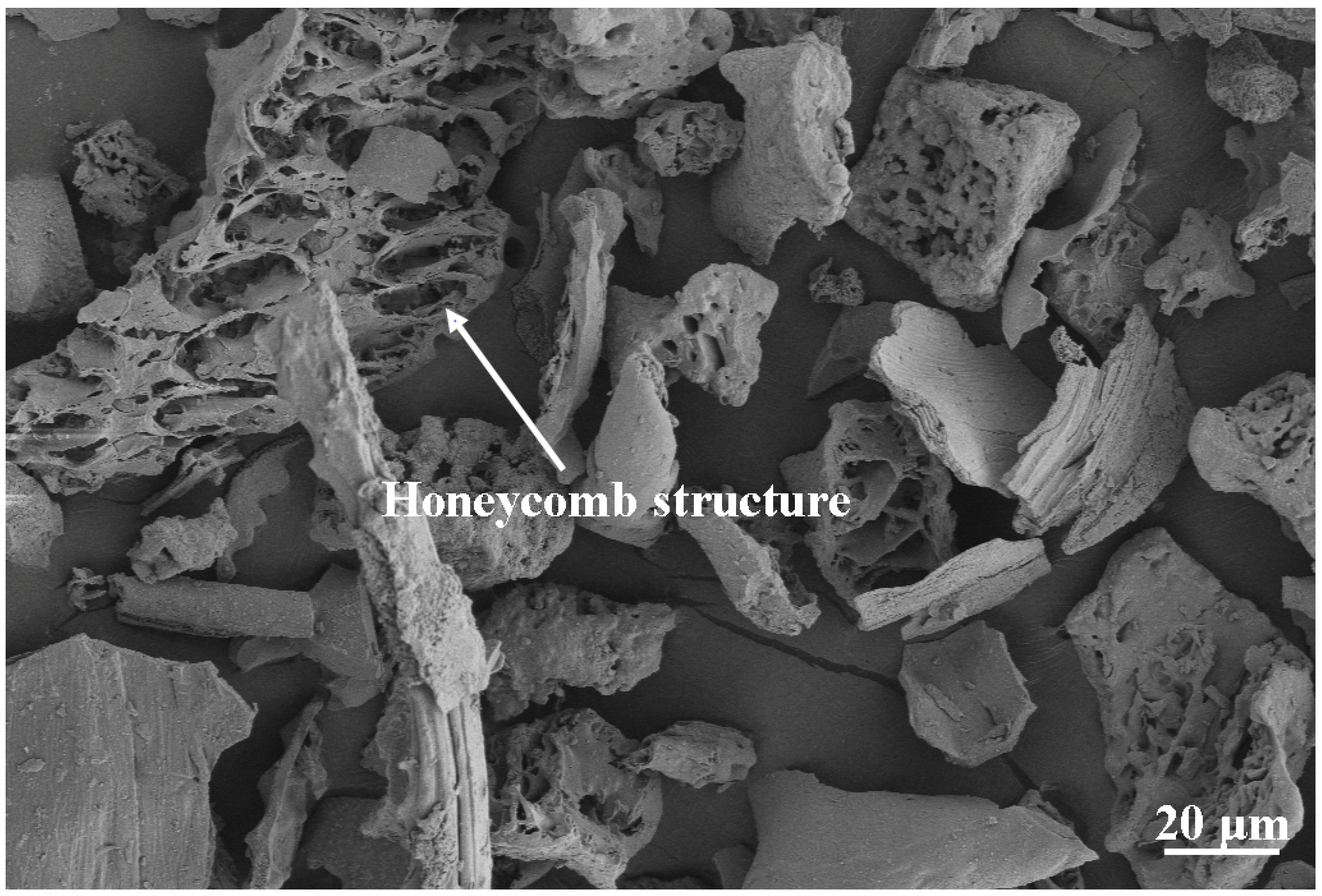

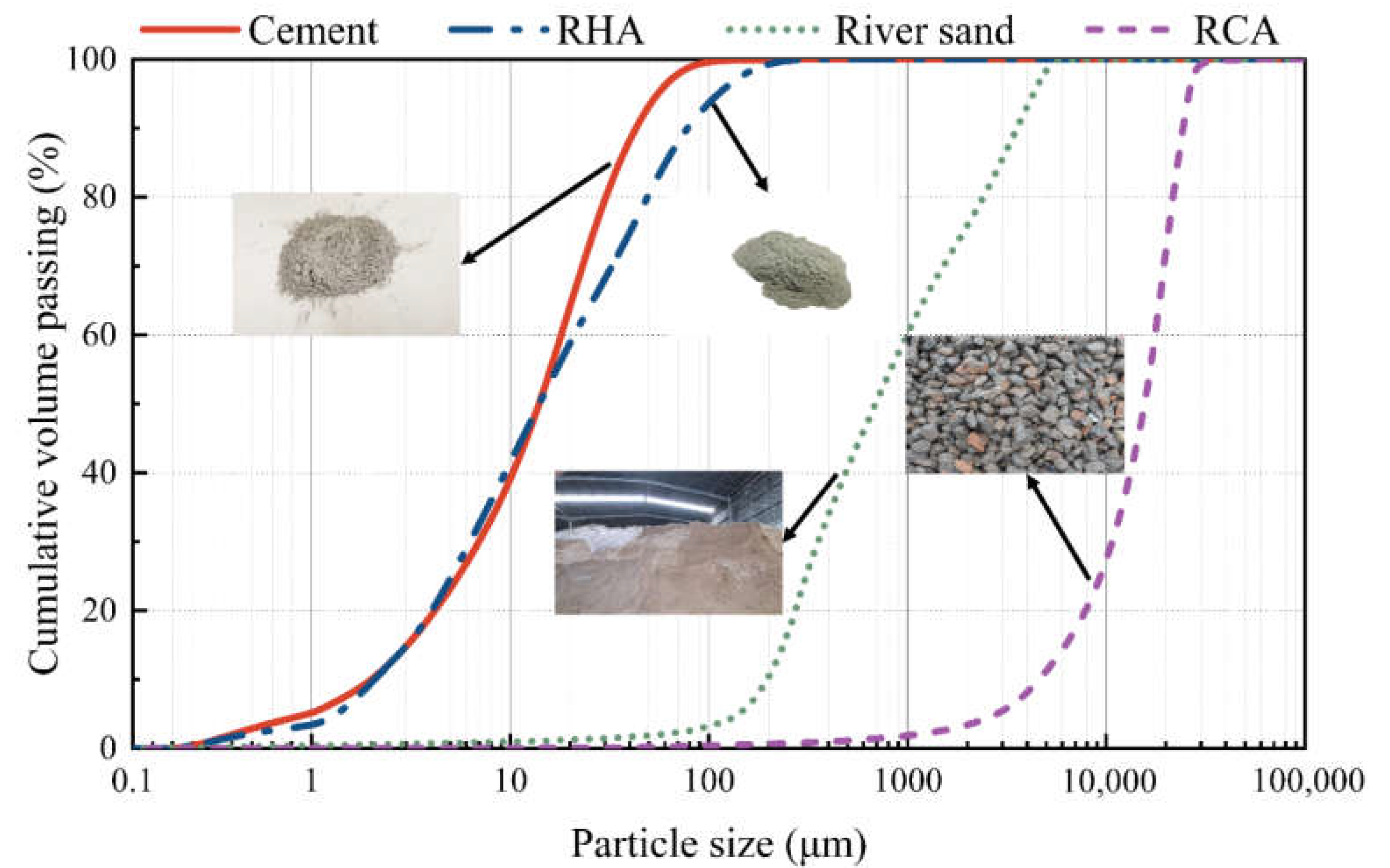

2.1. Raw Materials

2.2. Mixture Proportions and Specimen Preparation

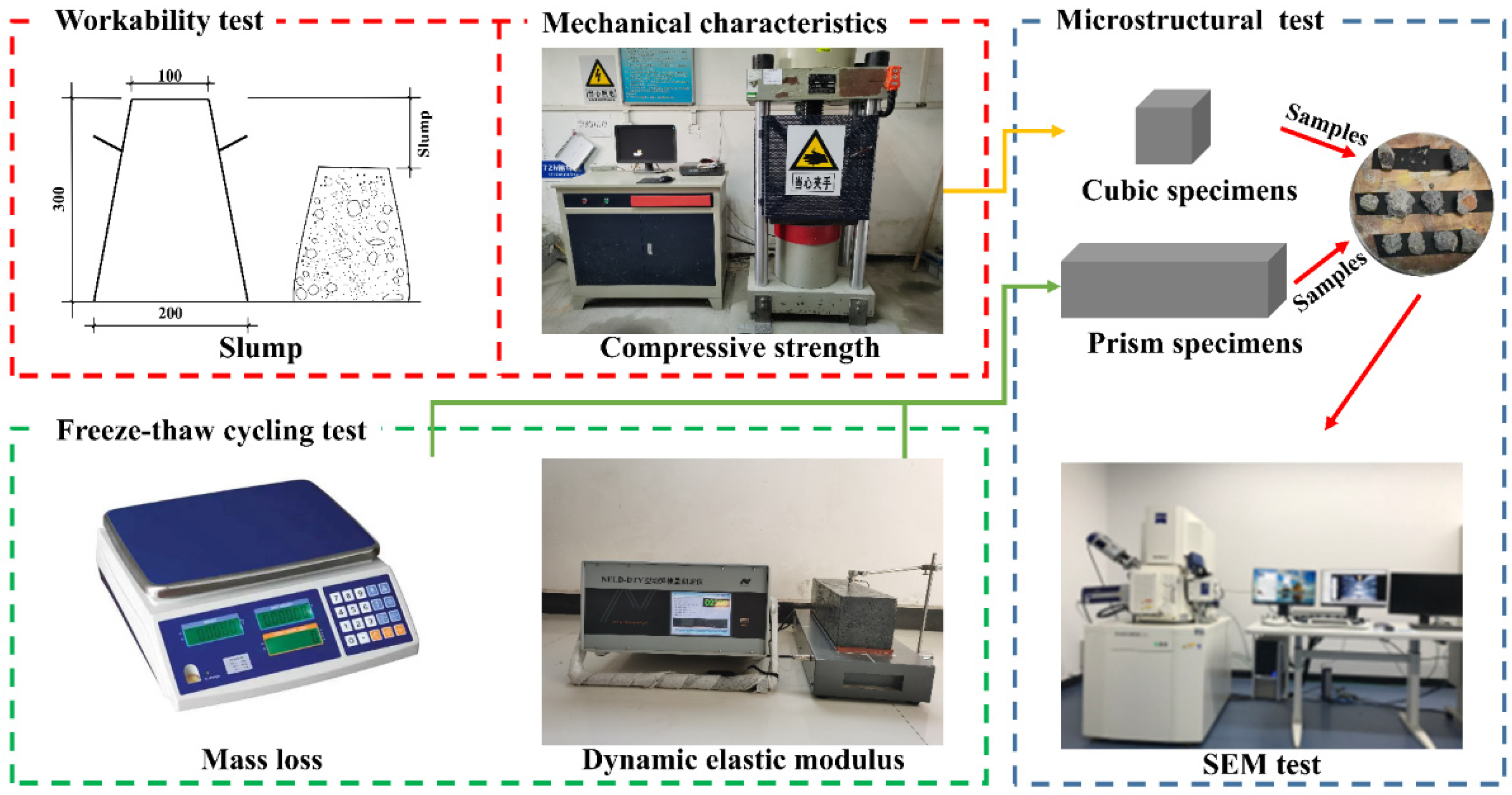

2.3. Experimental Method

2.3.1. Workability

2.3.2. Mechanical Characteristics

2.3.3. Freeze–Thaw Cycling

2.3.4. SEM Test

3. Results and Discussions

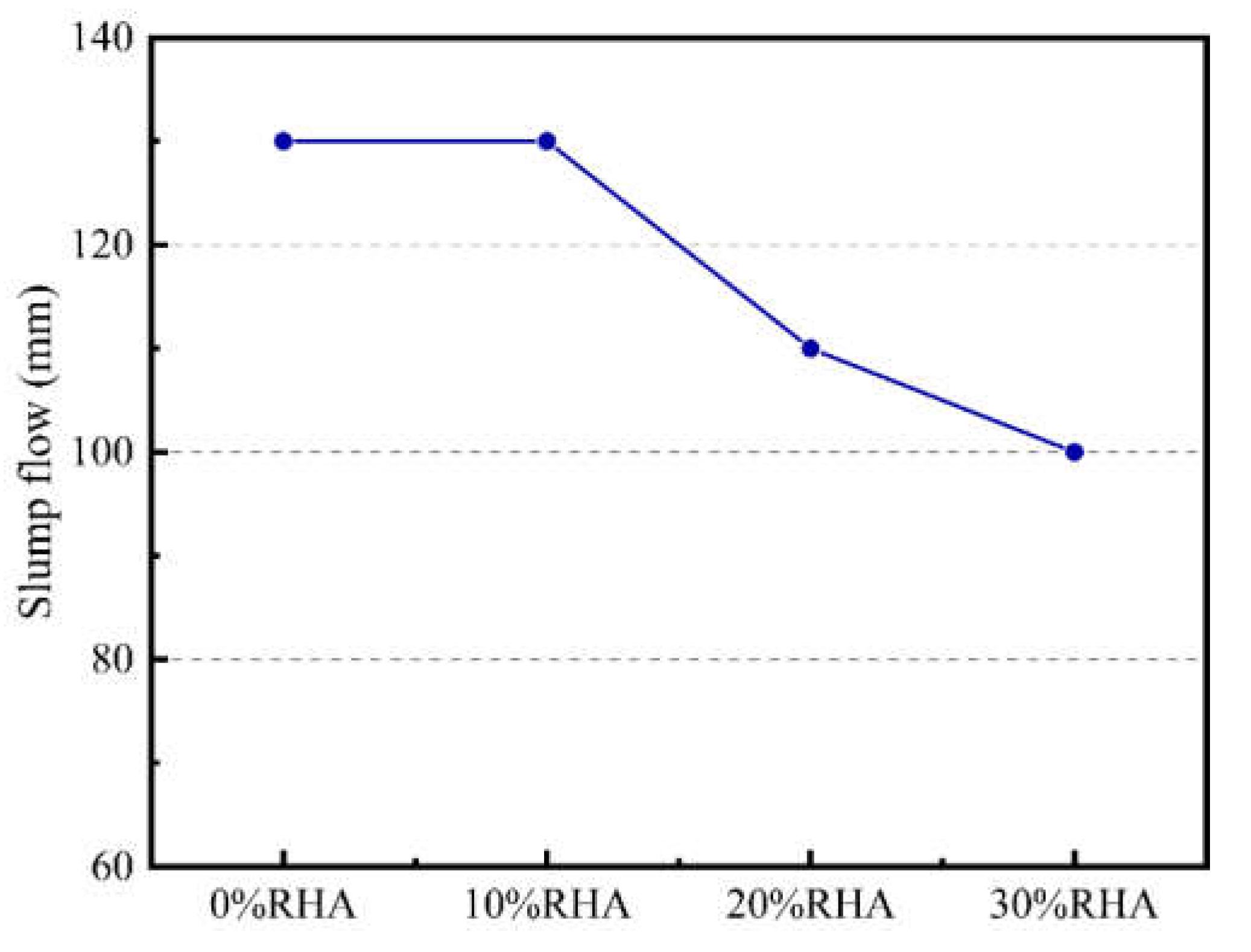

3.1. Workability of RHA Recycled Aggregate Concrete

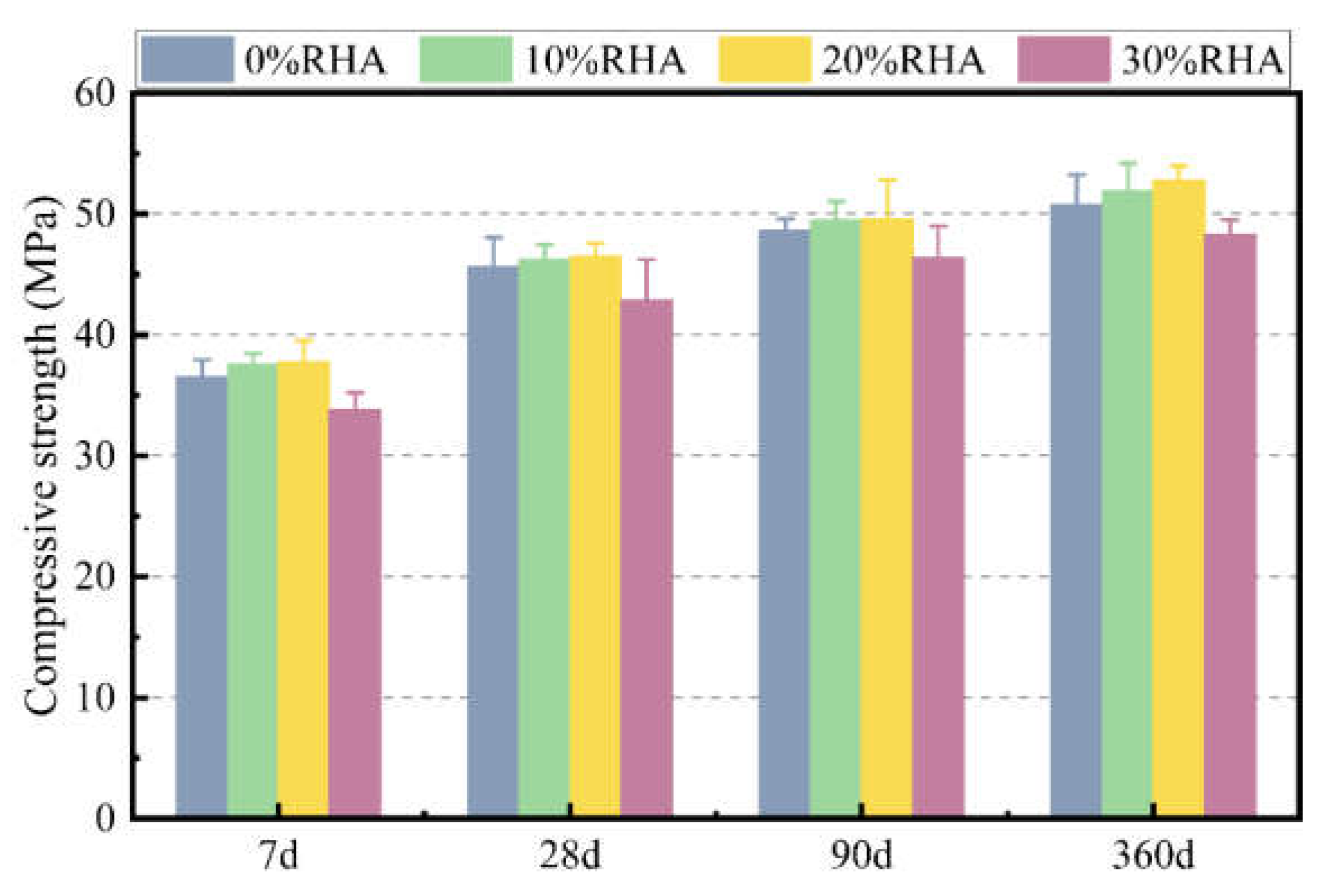

3.2. Compressive Strength of RHA Recycled Aggregate Concrete

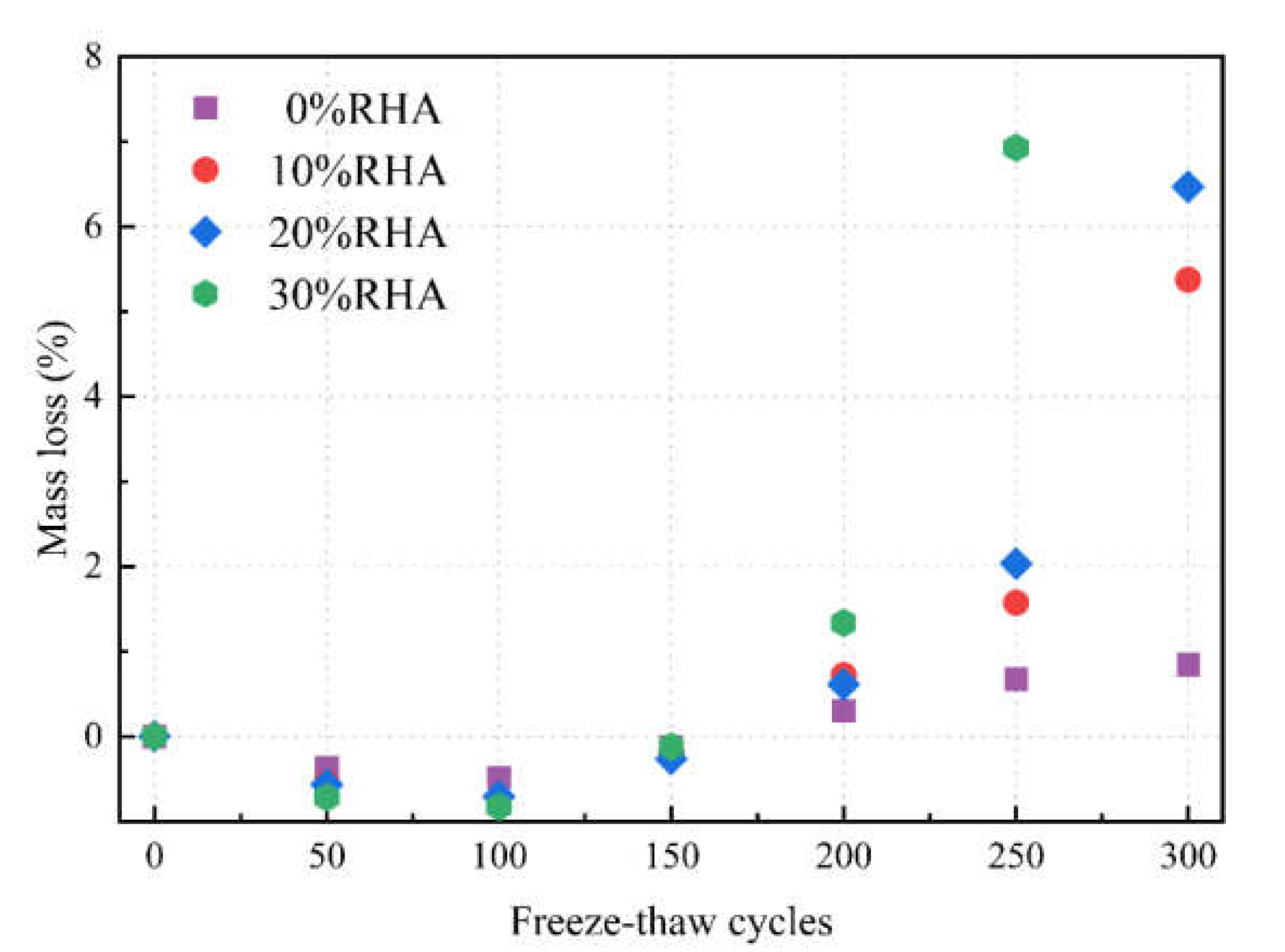

3.3. Mass Loss of RHA Recycled Aggregate Concrete

3.4. Relative Dynamic Elastic Modulus of RHA Recycled Aggregate Concrete

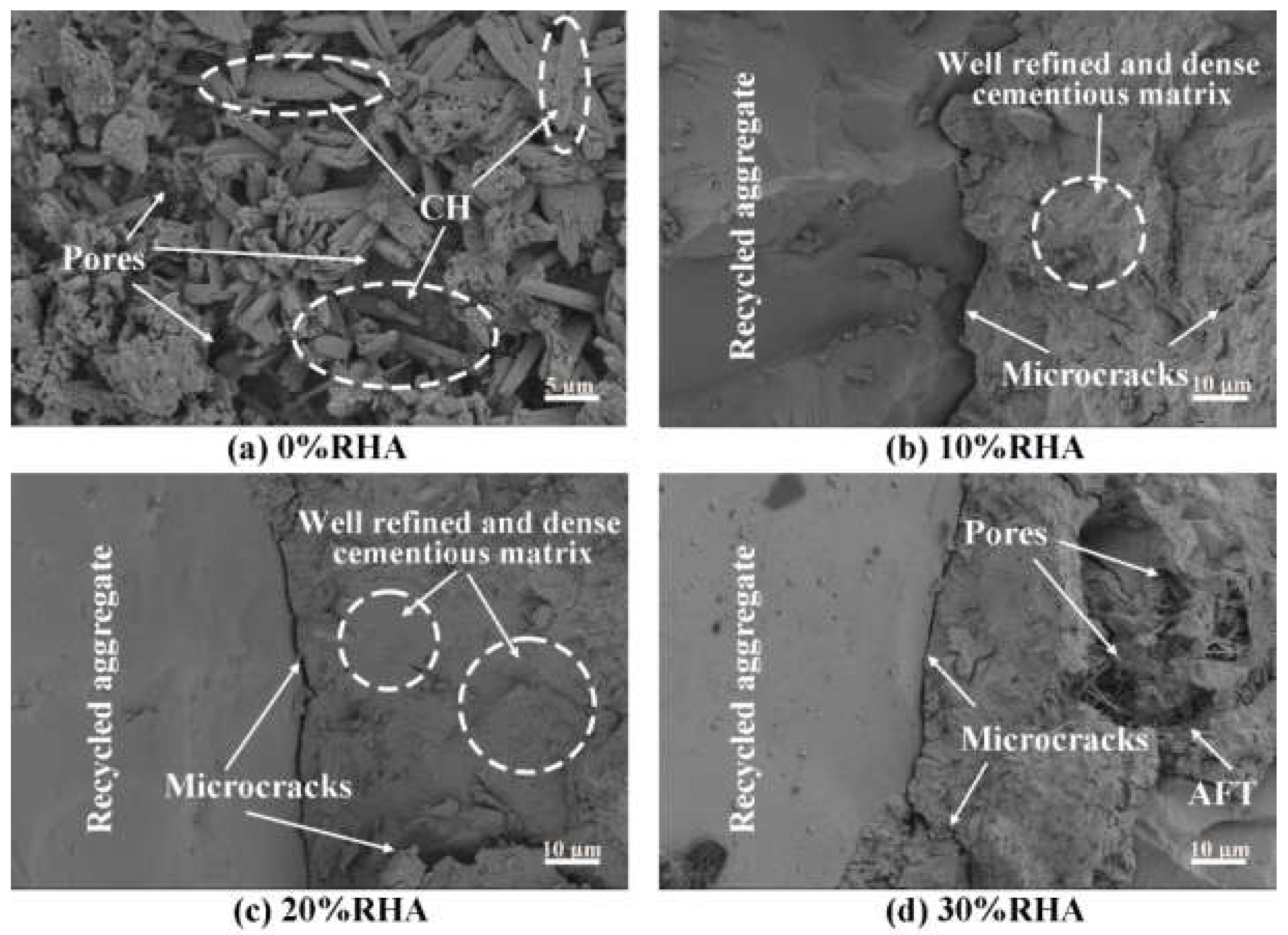

3.5. Mechanistic Analysis of the Influence of RHA on the Microstructure of Recycled Aggregate Concrete

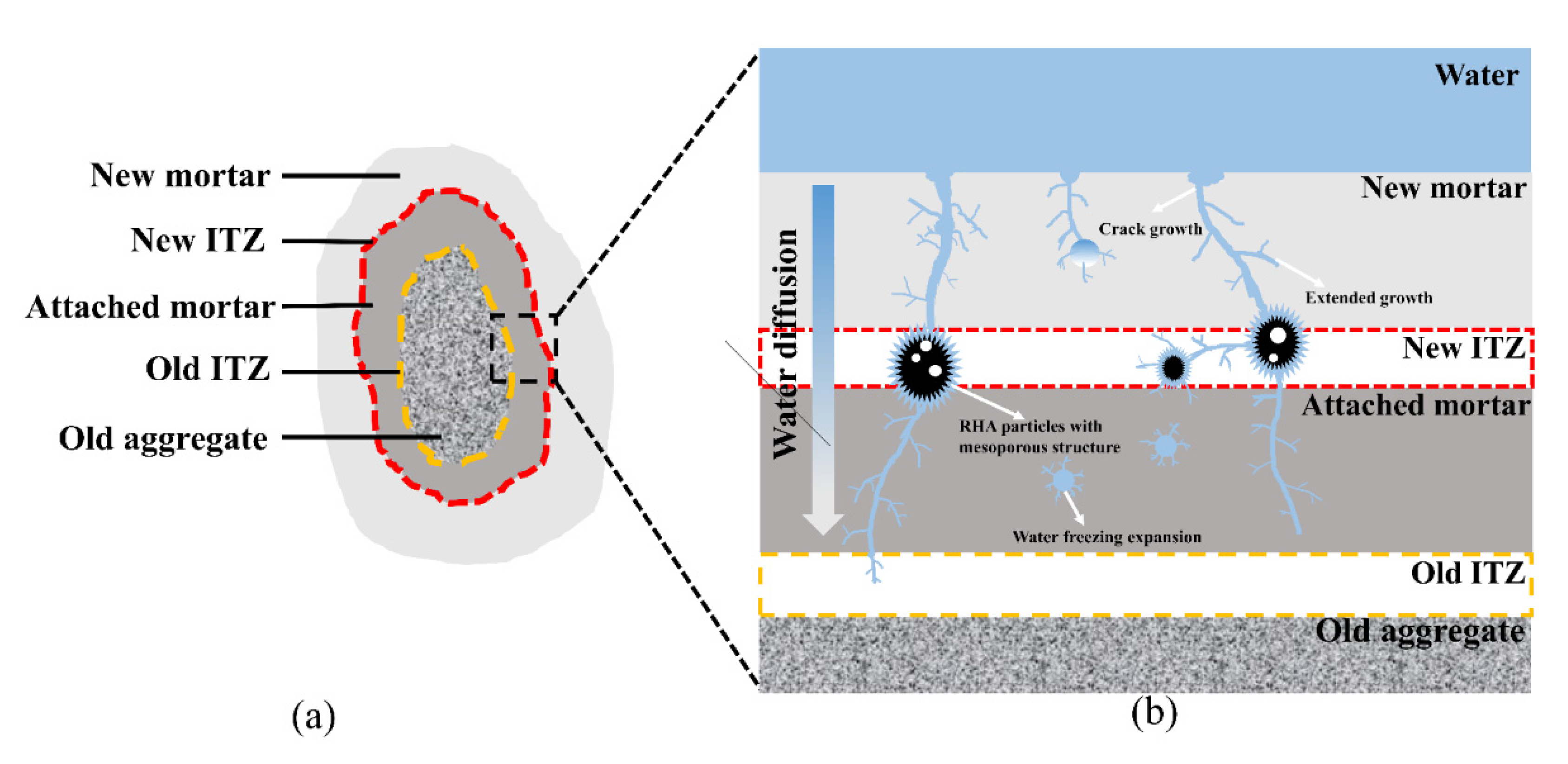

3.6. Mechanistic Analysis of the Influence of RHA on the Mechanical Characteristics and Freeze–Thaw Resistance of Recycled Aggregate Concrete

4. Conclusions

- (1)

- The gradual increase in the RHA replacement ratio increased the cementitious material’s total specific surface area and porosity, which will increase the mixtures’ friction resistance and discourage the flow, which in turn leads to the decrease in the concrete slump and the reduced workability.

- (2)

- With the continuous hydration reaction process, the compressive strength of recycled concrete increased with the growth of the curing age, and the growth rate shows a trend of first being rapid, then slowing down and finally gradually stabilizing. In addition, the optimum compressive strength of recycled concrete is observed with a 20% RHA replacement ratio.

- (3)

- With the gradual increase in the number of freeze–thaw cycles, the mass loss of recycled concrete showed a tendency to first decrease and then increase, while the relative dynamic elastic modulus showed a continuous decreasing trend.

- (4)

- Compared with ordinary concrete (without RHA), the RHA particle’s high specific surface area will promote the cement hydration and the formation of C-S-H gel by providing nucleation positions before the freeze–thaw cycle. During the process of the freeze–thaw cycle, the existence of the recycled aggregate attached mortar’s porous structure will cause a large amount of water absorption. With the continuous accumulation of expansion pressure, the internal pores and microcracks will gradually expand and extend, which will provide a channel for water migration, thus resulting in recycled concrete undergoing more severe freeze–thaw damage, and the degree of freeze–thaw damage deterioration grows as the RHA replacement ratio increases.

- (5)

- In addition, more exploration and experimentation in other durability aspects are needed to expand the application of RHA in recycled aggregate concrete.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yan, K.; Lan, H.; Li, Q.; Ge, D.; Li, Y. Optimum utilization of recycled aggregate and rice husk ash stabilized base material. Constr. Build. Mater. 2022, 348, 128627. [Google Scholar] [CrossRef]

- Benhelal, E.; Zahedi, G.; Hashim, H. A novel design for green and economical cement manufacturing. J. Clean. Prod. 2012, 22, 60–66. [Google Scholar] [CrossRef]

- Andrew, R.M. Global CO2 emissions from cement production. Earth Syst. Sci. Data 2018, 10, 195–217. [Google Scholar] [CrossRef] [Green Version]

- Kurda, R.; de Brito, J.; Silvestre, J.D. Water absorption and electrical resistivity of concrete with recycled concrete aggregates and fly ash. Cem. Concr. Compos. 2019, 95, 169–182. [Google Scholar] [CrossRef]

- Alyousef, R.; Ali, B.; Mohammed, A.; Kurda, R.; Alabduljabbar, H.; Riaz, S. Evaluation of Mechanical and Permeability Characteristics of Microfiber-Reinforced Recycled Aggregate Concrete with Different Potential Waste Mineral Admixtures. Materials 2021, 14, 5933. [Google Scholar] [CrossRef]

- Fu, Q.; Zhang, Z.; Zhao, X.; Xu, W.; Niu, D. Effect of nano calcium carbonate on hydration characteristics and microstructure of cement-based materials: A review. J. Build. Eng. 2022, 50, 104220. [Google Scholar] [CrossRef]

- Wang, J.; Xiao, J.; Zhang, Z.; Han, K.; Hu, X.; Jiang, F. Action mechanism of rice husk ash and the effect on main performances of cement-based materials: A review. Constr. Build. Mater. 2021, 288, 123068. [Google Scholar] [CrossRef]

- Hu, L.; He, Z.; Shao, Y.; Cai, X.; Zhang, S. Microstructure and properties of sustainable cement-based materials using combustion treated rice husk ash. Constr. Build. Mater. 2021, 294, 123482. [Google Scholar] [CrossRef]

- Yao, W.; Bai, M.; Pang, J.; Liu, T. Performance degradation and damage model of rice husk ash concrete under dry–wet cycles of sulfate environment. Environ. Sci. Pollut. Res. 2022, 29, 59173–59189. [Google Scholar] [CrossRef]

- Abolhasani, A.; Samali, B.; Aslani, F. Rice Husk Ash Incorporation in Calcium Aluminate Cement Concrete: Life Cycle Assessment, Hydration and Strength Development. Sustainability 2022, 14, 1012. [Google Scholar] [CrossRef]

- Bie, R.-S.; Song, X.-F.; Liu, Q.-Q.; Ji, X.-Y.; Chen, P. Studies on effects of burning conditions and rice husk ash (RHA) blending amount on the mechanical behavior of cement. Cem. Concr. Compos. 2015, 55, 162–168. [Google Scholar] [CrossRef]

- Chalee, W.; Sasakul, T.; Suwanmaneechot, P.; Jaturapitakkul, C. Utilization of rice husk–bark ash to improve the corrosion resistance of concrete under 5-year exposure in a marine environment. Cem. Concr. Compos. 2013, 37, 47–53. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, W.; Liu, H.; Lin, X.; Zhang, R. A compressive strength prediction model based on the hydration reaction of cement paste by rice husk ash. Constr. Build. Mater. 2022, 340, 127841. [Google Scholar] [CrossRef]

- Vieira, A.P.; Filho, R.D.T.; Tavares, L.; Cordeiro, G.C. Effect of particle size, porous structure and content of rice husk ash on the hydration process and compressive strength evolution of concrete. Constr. Build. Mater. 2020, 236, 117553. [Google Scholar] [CrossRef]

- Amin, M.; Abdelsalam, B.A. Efficiency of rice husk ash and fly ash as reactivity materials in sustainable concrete. Sustain. Environ. Res. 2019, 29, 30. [Google Scholar] [CrossRef] [Green Version]

- Kang, S.-H.; Hong, S.-G.; Moon, J. The use of rice husk ash as reactive filler in ultra-high performance concrete. Cem. Concr. Res. 2019, 115, 389–400. [Google Scholar] [CrossRef]

- Liu, H.; Liu, C.; Bai, G.; Wu, Y.; He, C.; Zhang, R.; Wang, Y. Influence of pore defects on the hardened properties of 3D printed concrete with coarse aggregate. Addit. Manuf. 2022, 55, 102843. [Google Scholar] [CrossRef]

- Liu, H.; Liu, C.; Wu, Y.; Bai, G.; He, C.; Zhang, R.; Wang, Y. Hardened properties of 3D printed concrete with recycled coarse aggregate. Cem. Concr. Res. 2022, 159, 106868. [Google Scholar] [CrossRef]

- Qureshi, L.A.; Ali, B.; Ali, A. Combined effects of supplementary cementitious materials (silica fume, GGBS, fly ash and rice husk ash) and steel fiber on the hardened properties of recycled aggregate concrete. Constr. Build. Mater. 2020, 263, 120636. [Google Scholar] [CrossRef]

- Rattanachu, P.; Toolkasikorn, P.; Tangchirapat, W.; Chindaprasirt, P.; Jaturapitakkul, C. Performance of recycled aggregate concrete with rice husk ash as cement binder. Cem. Concr. Compos. 2020, 108, 103533. [Google Scholar] [CrossRef]

- Nuaklong, P.; Jongvivatsakul, P.; Pothisiri, T.; Sata, V.; Chindaprasirt, P. Influence of rice husk ash on mechanical properties and fire resistance of recycled aggregate high-calcium fly ash geopolymer concrete. J. Clean. Prod. 2020, 252, 119797. [Google Scholar] [CrossRef]

- Padhi, R.S.; Patra, R.K.; Mukharjee, B.B.; Dey, T. Influence of incorporation of rice husk ash and coarse recycled concrete aggregates on properties of concrete. Constr. Build. Mater. 2018, 173, 289–297. [Google Scholar] [CrossRef]

- Koushkbaghi, M.; Kazemi, M.J.; Mosavi, H.; Mohseni, E. Acid resistance and durability properties of steel fiber-reinforced concrete incorporating rice husk ash and recycled aggregate. Constr. Build. Mater. 2019, 202, 266–275. [Google Scholar] [CrossRef]

- Salahuddin, H.; Nawaz, A.; Maqsoom, A.; Mehmood, T.; Zeeshan, B.U.A. Effects of elevated temperature on performance of recycled coarse aggregate concrete. Constr. Build. Mater. 2019, 202, 415–425. [Google Scholar] [CrossRef]

- Alnahhal, M.F.; Alengaram, U.J.; Jumaat, M.Z.; Abutaha, F.; Alqedra, M.A.; Nayaka, R.R. Assessment on engineering properties and CO2 emissions of recycled aggregate concrete incorporating waste products as supplements to Portland cement. J. Clean. Prod. 2018, 203, 822–835. [Google Scholar] [CrossRef]

- GB/T 14685-2011; Pebble and Crushed Stone for Construction. Chinese National Standard: Beijing, China, 2011.

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. Chinese National Standard: Beijing, China, 2019.

- GB/T 50080-2016; Standard for Test Method of Performance on Ordinary Fresh Concrete. Chinese National Standard: Beijing, China, 2016.

- Liu, C.; Zhang, W.; Liu, H.; Zhu, C.; Wu, Y.; He, C.; Wang, Z. Recycled aggregate concrete with the incorporation of rice husk ash: Mechanical properties and microstructure. Constr. Build. Mater. 2022, 351, 128934. [Google Scholar] [CrossRef]

- GB/T 50082-2009; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. Chinese National Standard: Beijing, China, 2009.

- Zhang, W.; Pi, Y.; Kong, W.; Zhang, Y.; Wu, P.; Zeng, W.; Yang, F. Influence of damage degree on the degradation of concrete under freezing-thawing cycles. Constr. Build. Mater. 2020, 260, 119903. [Google Scholar] [CrossRef]

- He, Z.-H.; Li, L.-Y.; Du, S.-G. Creep analysis of concrete containing rice husk ash. Cem. Concr. Compos. 2017, 80, 190–199. [Google Scholar] [CrossRef]

- Antiohos, S.; Papadakis, V.; Tsimas, S. Rice husk ash (RHA) effectiveness in cement and concrete as a function of reactive silica and fineness. Cem. Concr. Res. 2014, 61–62, 20–27. [Google Scholar] [CrossRef]

- Zhang, S.; Cao, K.; Wang, C.; Wang, X.; Deng, G.; Wei, P. Influence of the porosity and pore size on the compressive and splitting strengths of cellular concrete with millimeter-size pores. Constr. Build. Mater. 2020, 235, 117508. [Google Scholar] [CrossRef]

- Msinjili, N.S.; Schmidt, W.; Rogge, A.; Kühne, H.-C. Performance of rice husk ash blended cementitious systems with added superplasticizers. Cem. Concr. Compos. 2017, 83, 202–208. [Google Scholar] [CrossRef]

- Jamil, M.; Khan, M.; Karim, M.; Kaish, A.; Zain, M. Physical and chemical contributions of Rice Husk Ash on the properties of mortar. Constr. Build. Mater. 2016, 128, 185–198. [Google Scholar] [CrossRef]

- Van Tuan, N.; Ye, G.; van Breugel, K.; Copuroglu, O. Hydration and microstructure of ultra high performance concrete incorporating rice husk ash. Cem. Concr. Res. 2011, 41, 1104–1111. [Google Scholar] [CrossRef]

- Salas, A.; Delvasto, S.; DE Gutierrez, R.M.; Lange, D. Comparison of two processes for treating rice husk ash for use in high performance concrete. Cem. Concr. Res. 2009, 39, 773–778. [Google Scholar] [CrossRef]

- Alex, J.; Dhanalakshmi, J.; Ambedkar, B. Experimental investigation on rice husk ash as cement replacement on concrete production. Constr. Build. Mater. 2016, 127, 353–362. [Google Scholar] [CrossRef]

- Venkatanarayanan, H.K.; Rangaraju, P.R. Effect of grinding of low-carbon rice husk ash on the microstructure and performance properties of blended cement concrete. Cem. Concr. Compos. 2015, 55, 348–363. [Google Scholar] [CrossRef]

- Chao-Lung, H.; Le Anh-Tuan, B.; Chun-Tsun, C. Effect of rice husk ash on the strength and durability characteristics of concrete. Constr. Build. Mater. 2011, 25, 3768–3772. [Google Scholar] [CrossRef]

- Kessler, S.; Thiel, C.; Grosse, C.U.; Gehlen, C. Effect of freeze–thaw damage on chloride ingress into concrete. Mater. Struct. 2016, 50, 121. [Google Scholar] [CrossRef]

- del Bosque, I.S.; Heede, P.V.D.; De Belie, N.; de Rojas, M.S.; Medina, C. Freeze-thaw resistance of concrete containing mixed aggregate and construction and demolition waste-additioned cement in water and de-icing salts. Constr. Build. Mater. 2020, 259, 119772. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Gao, X.F.; Tam, C.M. Microstructural analysis of recycled aggregate concrete produced from two-stage mixing approach. Cem. Concr. Res. 2005, 35, 1195–1203. [Google Scholar] [CrossRef]

- Zhan, B.J.; Xuan, D.X.; Poon, C.S.; Scrivener, K.L. Characterization of interfacial transition zone in concrete prepared with carbonated modeled recycled concrete aggregates. Cem. Concr. Res. 2020, 136, 106175. [Google Scholar] [CrossRef]

- Miyandehi, B.M.; Feizbakhsh, A.; Yazdi, M.A.; Liu, Q.-F.; Yang, J.; Alipour, P. Performance and properties of mortar mixed with nano-CuO and rice husk ash. Cem. Concr. Compos. 2016, 74, 225–235. [Google Scholar] [CrossRef]

- Wang, D.; Zhou, X.; Fu, B.; Zhang, L. Chloride ion penetration resistance of concrete containing fly ash and silica fume against combined freezing-thawing and chloride attack. Constr. Build. Mater. 2018, 169, 740–747. [Google Scholar] [CrossRef] [Green Version]

- Gencel, O.; Benli, A.; Bayraktar, O.Y.; Kaplan, G.; Sutcu, M.; Elabade, W.A.T. Effect of waste marble powder and rice husk ash on the microstructural, physico-mechanical and transport properties of foam concretes exposed to high temperatures and freeze–thaw cycles. Constr. Build. Mater. 2021, 291, 123374. [Google Scholar] [CrossRef]

- Pawluczuk, E.; Kalinowska-Wichrowska, K.; Jiménez, J.R.; Fernández-Rodríguez, J.M.; Suescum-Morales, D. Geopolymer concrete with treated recycled aggregates: Macro and microstructural behavior. J. Build. Eng. 2021, 44, 103317. [Google Scholar] [CrossRef]

- Peerzada, M.; Naqash, J.A. Amelioration of freeze thaw damage of concrete with multi-walled carbon nano tubes. World J. Eng. 2020, 18, 58–65. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J.M. Concrete Microstructure, Properties and Materials; McGraw-Hill Education: San Francisco, CA, USA, 2001; pp. 1–239. [Google Scholar]

| Characteristics | Cementitious Materials | |

|---|---|---|

| Cement | RHA | |

| Physical properties | ||

| Mean particle size (μm) | 14.77 | 14.81 |

| Specific surface area (m2/g) | 1.72 | 8.60 |

| Setting time (min) | ||

| Initial time | 202 | - |

| Final time | 258 | - |

| Chemical composition (%) | ||

| Silicon dioxide (SiO2) | 21.07 | 92.08 |

| Ferric oxide (Fe2O3) | 3.78 | 0.05 |

| Aluminium oxide (Al2O3) | 4.91 | 0.11 |

| Potassium oxide (K2O) | 0.59 | 3.50 |

| Magnesium oxide (MgO) | 1.43 | 0.49 |

| Calcium oxide (CaO) | 65.36 | 0.78 |

| Sodium oxide (Na2O) | 0.39 | - |

| Phosphorous oxide (P2O5) | - | 1.35 |

| Sulfur trioxide (SO3) | 2.45 | 0.92 |

| Loss on ignition | 4.52 | 1.83 |

| Aggregate Type | Grading (mm) | Water Absorption (%) | Apparent Density (kg/m3) | Bulk Density (kg/m3) | Crush Index (%) |

|---|---|---|---|---|---|

| RCA | 5–25 | 3.8 | 2458.0 | 1430.0 | 17.0 |

| Specimen | W/B | Mixture Proportion (kg/m3) | ||||||

|---|---|---|---|---|---|---|---|---|

| Cement | RHA | Sand | RCA | Water | AW | SP | ||

| 0% RHA | 0.40 | 410 | - | 825 | 1085 | 164 | 22 | 8.5 |

| 10% RHA | 0.40 | 369 | 41 | 825 | 1085 | 164 | 22 | 9.5 |

| 20% RHA | 0.40 | 328 | 82 | 825 | 1085 | 164 | 22 | 11.5 |

| 30% RHA | 0.40 | 287 | 123 | 825 | 1085 | 164 | 22 | 12.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Liu, H.; Liu, C. Impact of Rice Husk Ash on the Mechanical Characteristics and Freeze–Thaw Resistance of Recycled Aggregate Concrete. Appl. Sci. 2022, 12, 12238. https://doi.org/10.3390/app122312238

Zhang W, Liu H, Liu C. Impact of Rice Husk Ash on the Mechanical Characteristics and Freeze–Thaw Resistance of Recycled Aggregate Concrete. Applied Sciences. 2022; 12(23):12238. https://doi.org/10.3390/app122312238

Chicago/Turabian StyleZhang, Wei, Huawei Liu, and Chao Liu. 2022. "Impact of Rice Husk Ash on the Mechanical Characteristics and Freeze–Thaw Resistance of Recycled Aggregate Concrete" Applied Sciences 12, no. 23: 12238. https://doi.org/10.3390/app122312238

APA StyleZhang, W., Liu, H., & Liu, C. (2022). Impact of Rice Husk Ash on the Mechanical Characteristics and Freeze–Thaw Resistance of Recycled Aggregate Concrete. Applied Sciences, 12(23), 12238. https://doi.org/10.3390/app122312238