Influence of Warm Isostatic Press Process on Mechanical Properties of a Part Fabricated by Metal Material Extrusion Process

Abstract

:1. Introduction

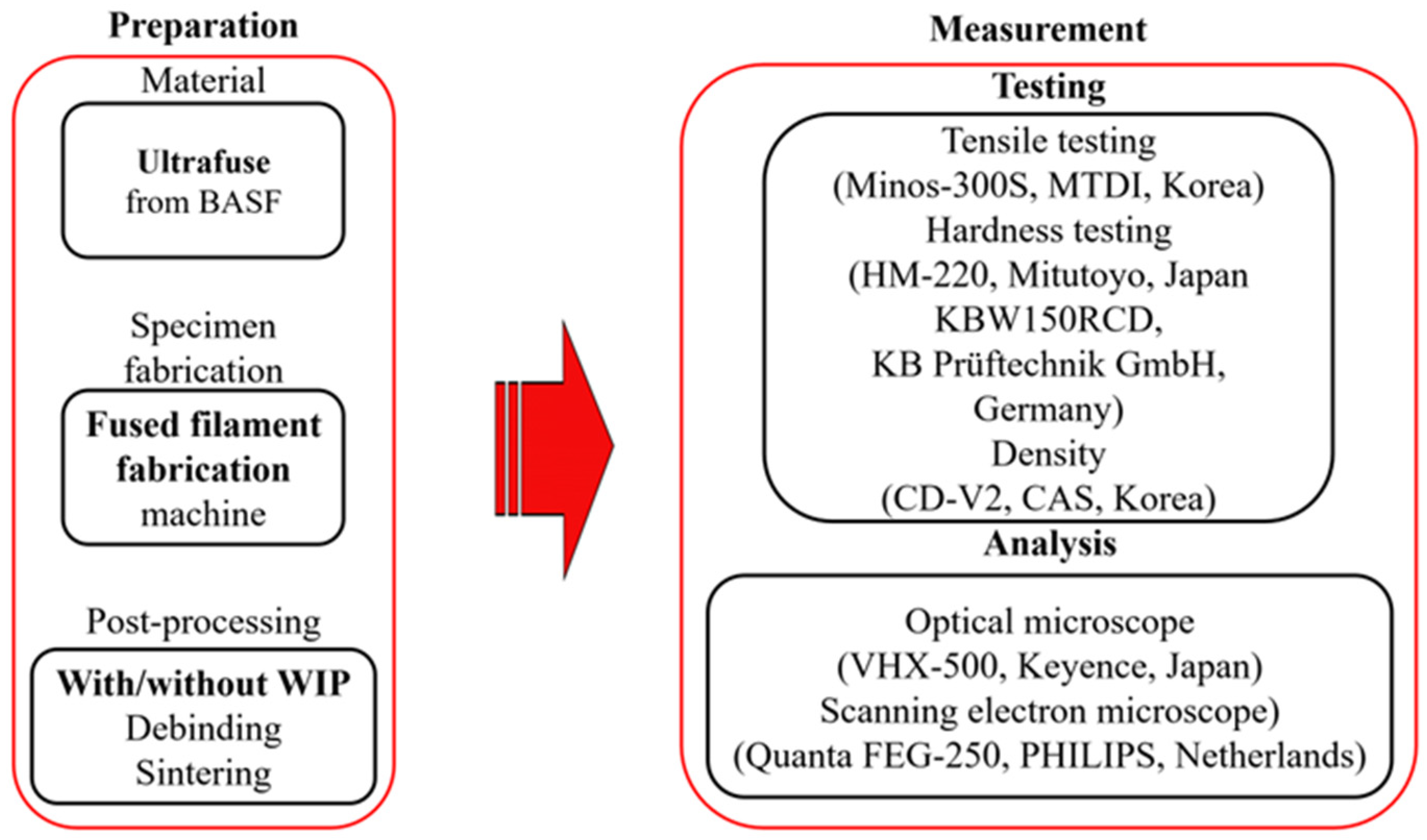

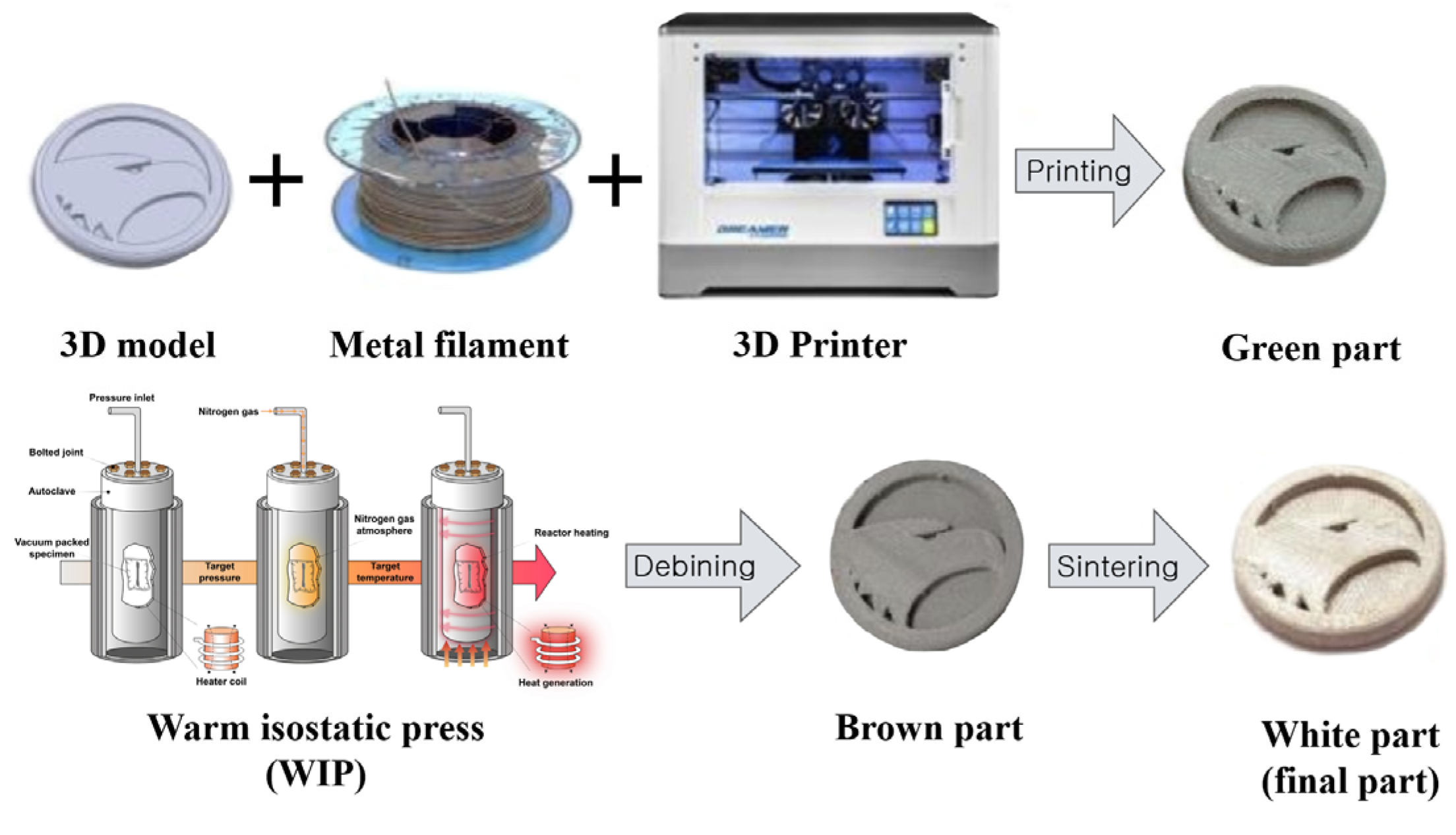

2. Experimental Procedure

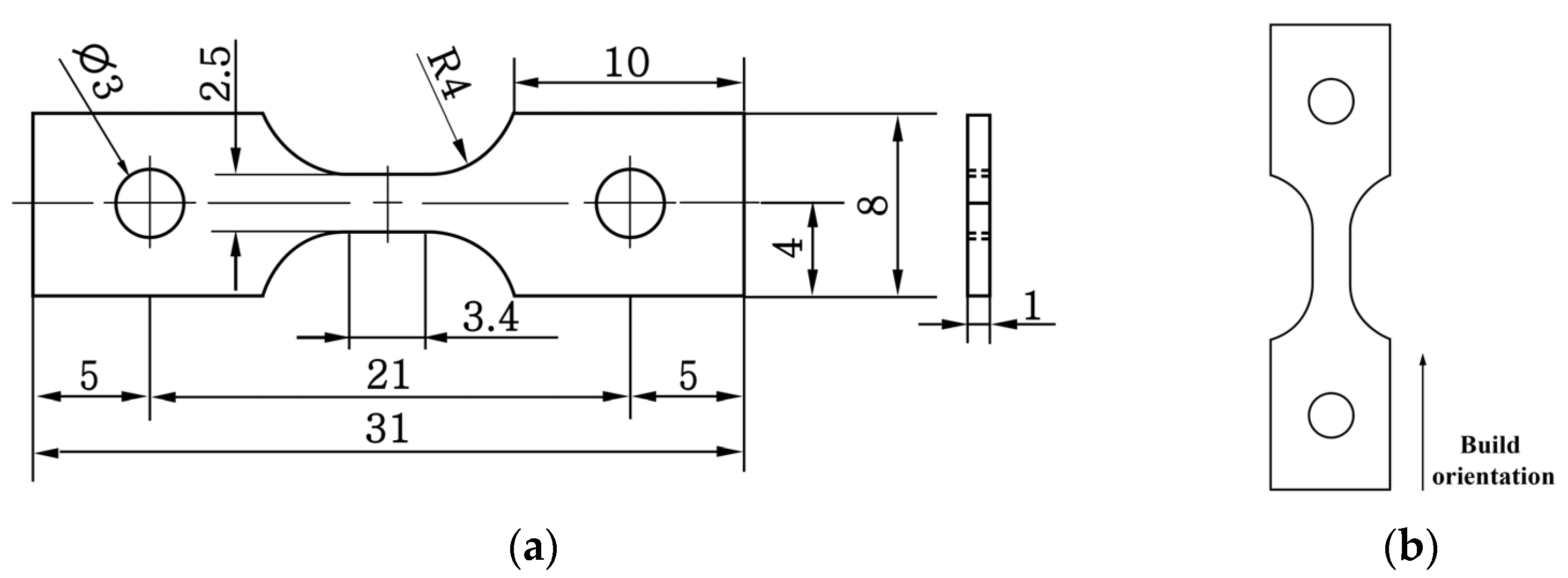

2.1. Fabrications of Specimens

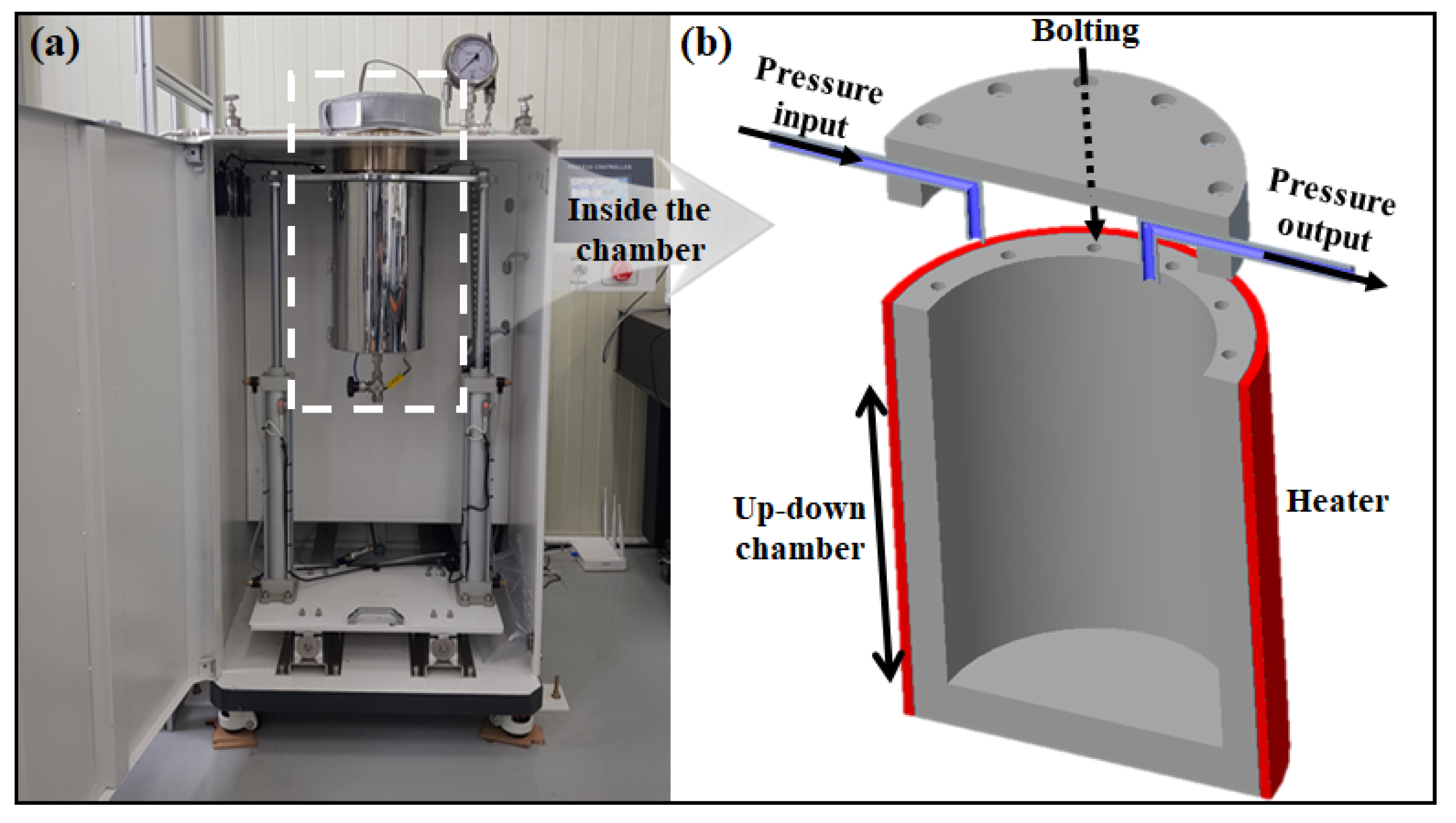

2.2. WIP Equipment and Process Parameters

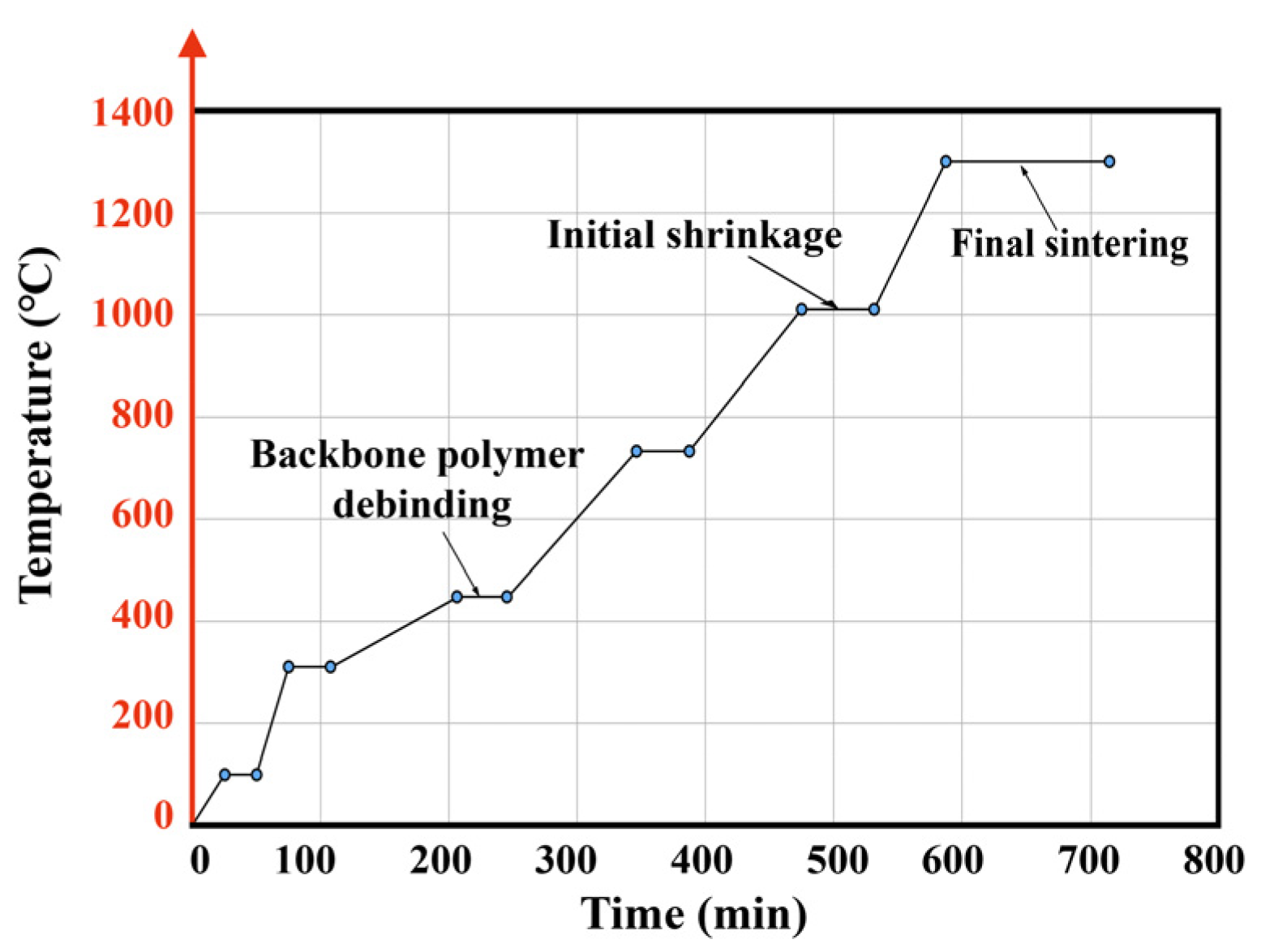

2.3. Debinding and Sintering

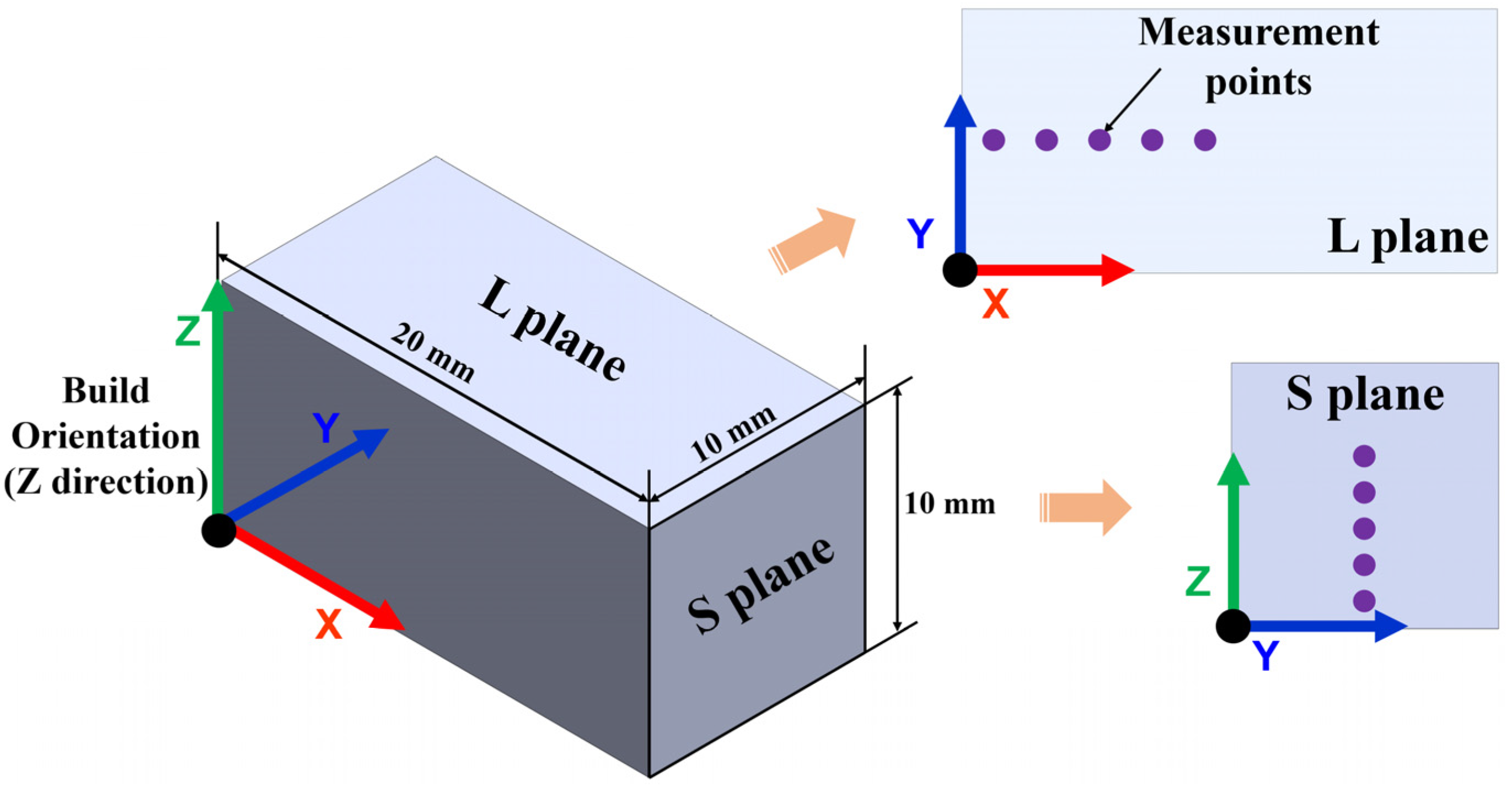

2.4. Measurement of Mechanical Properties

2.5. Microstructural Analysis

3. Results

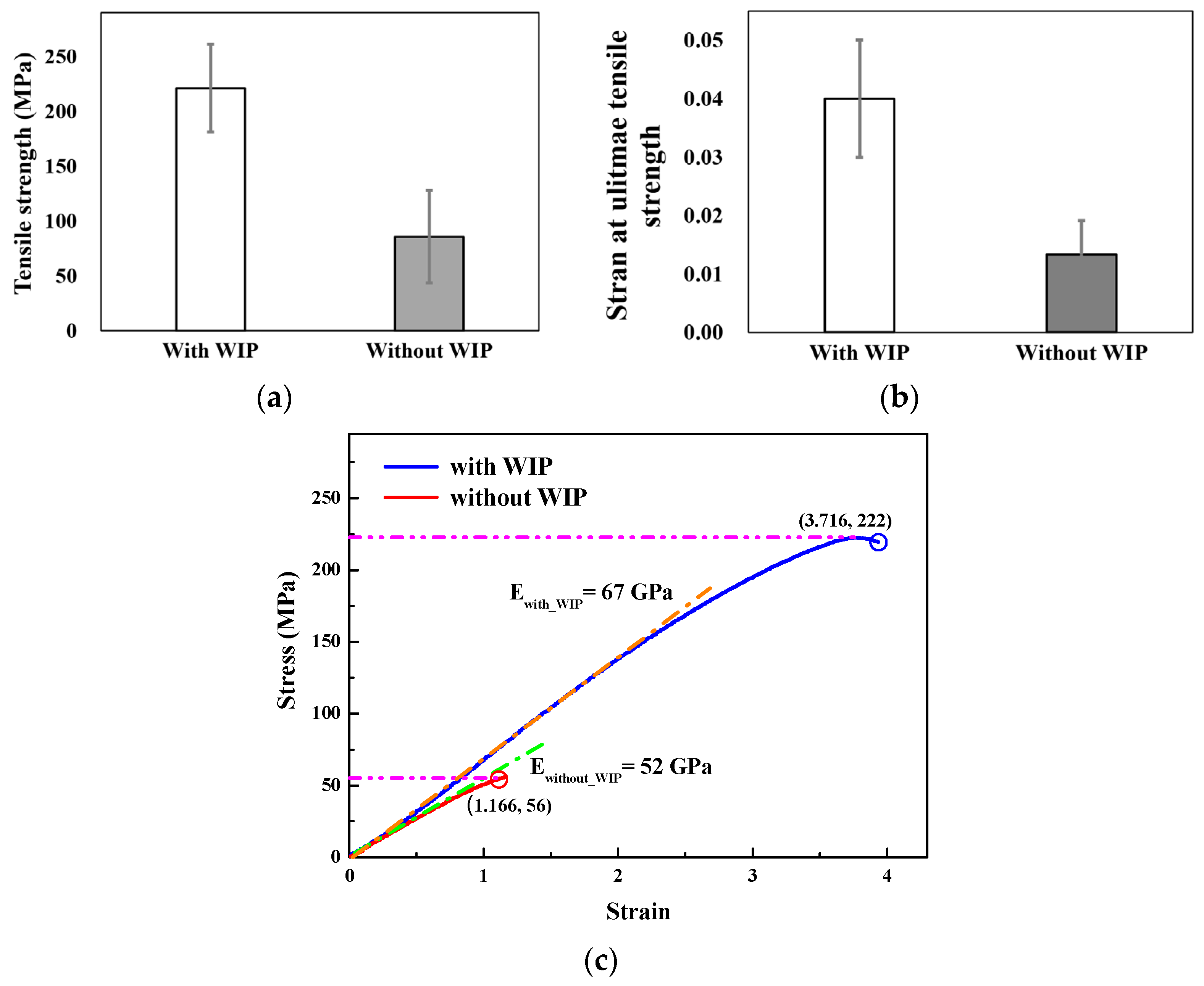

3.1. Tensile Strength

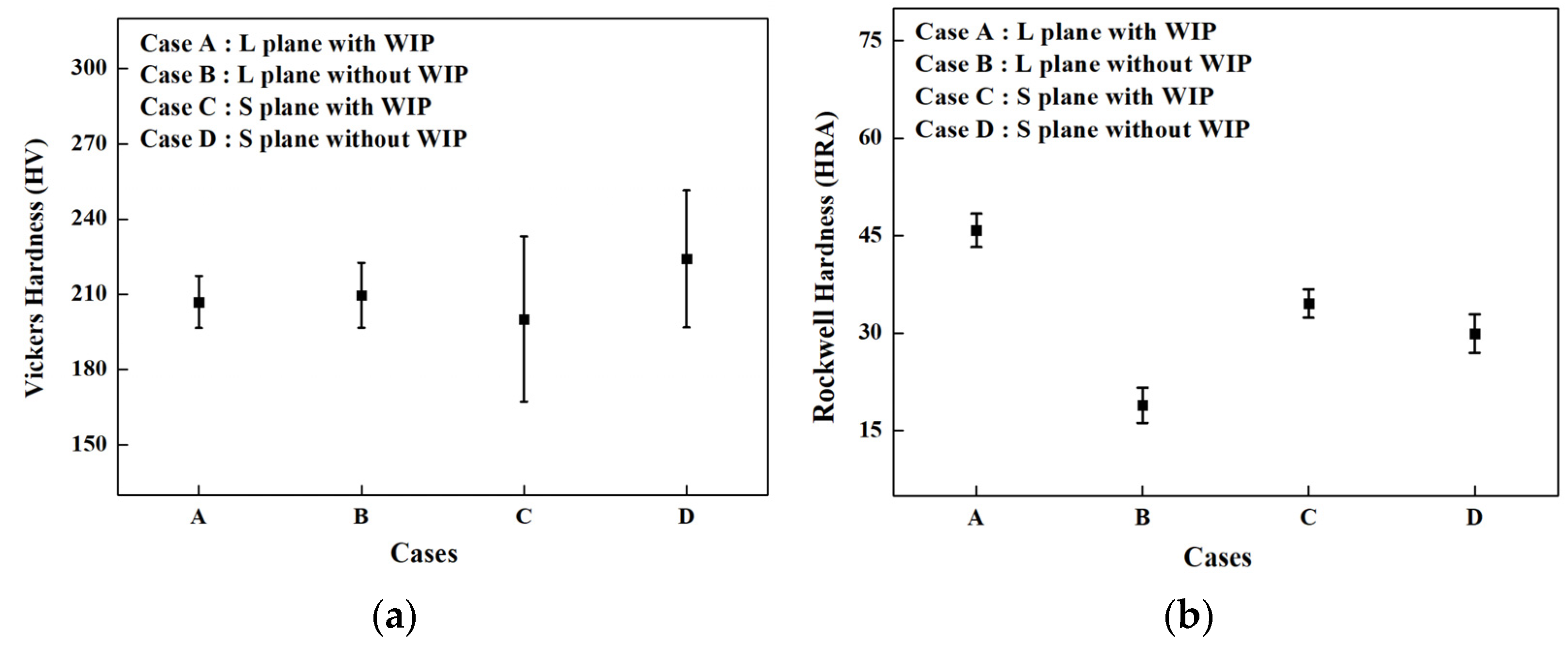

3.2. Hardness

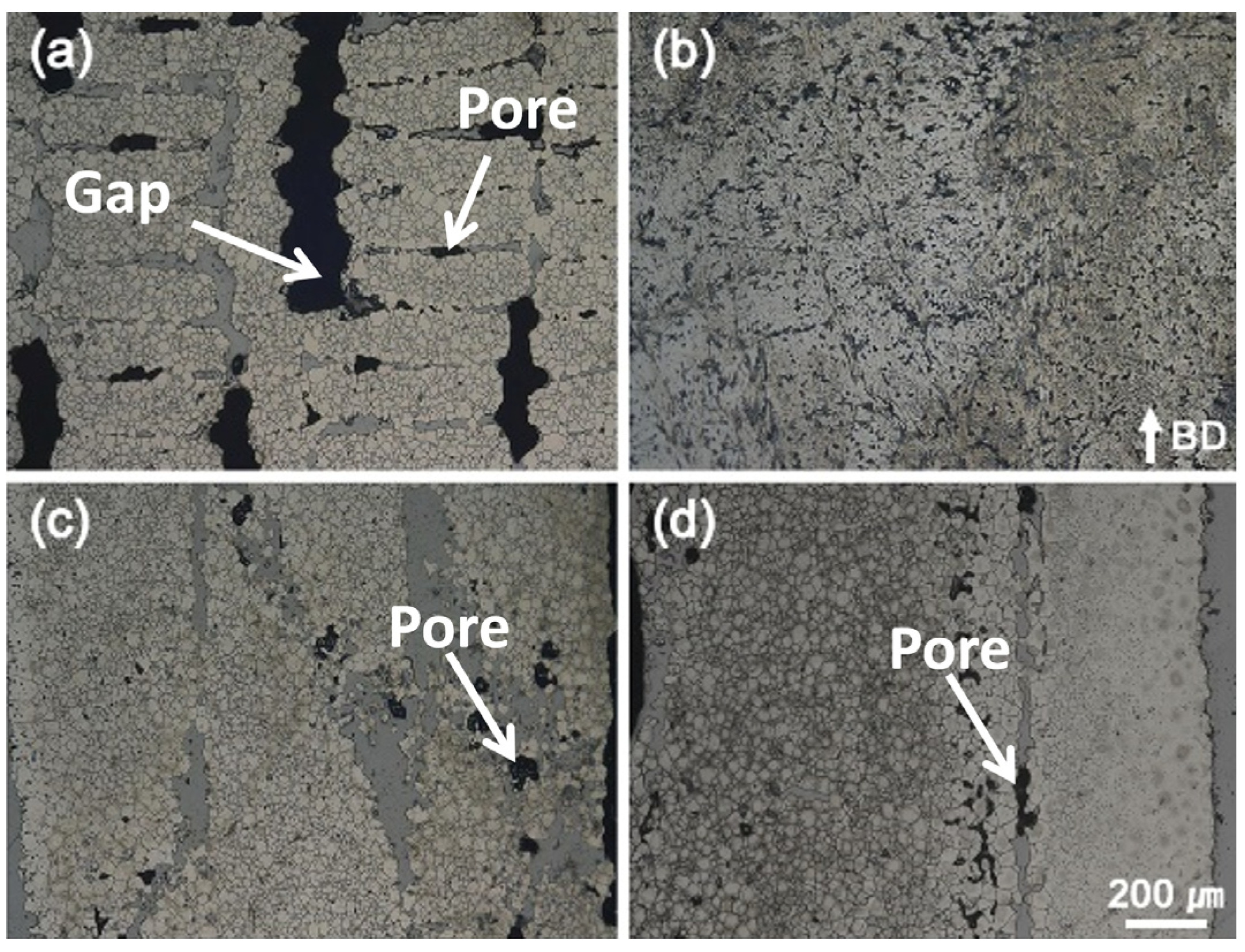

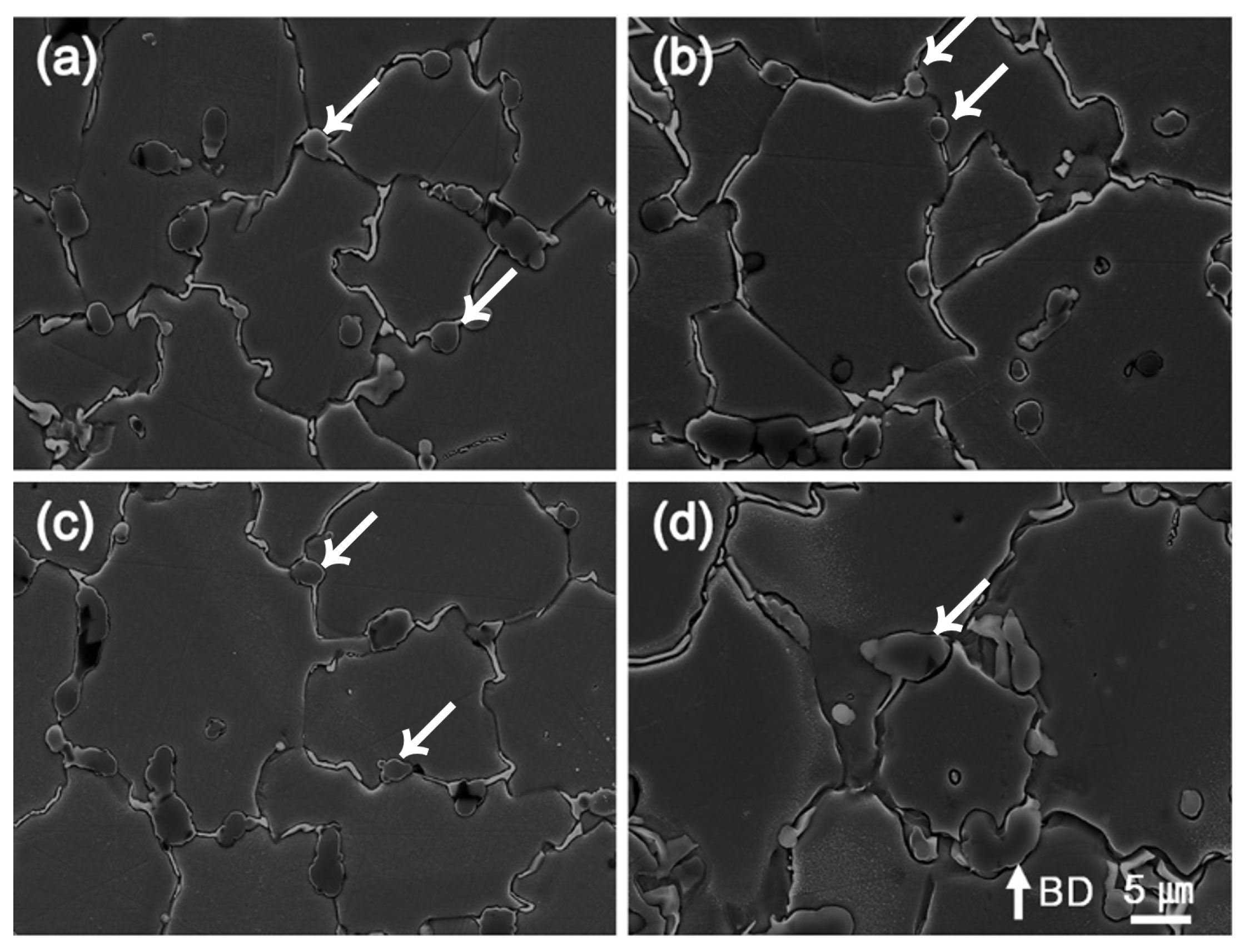

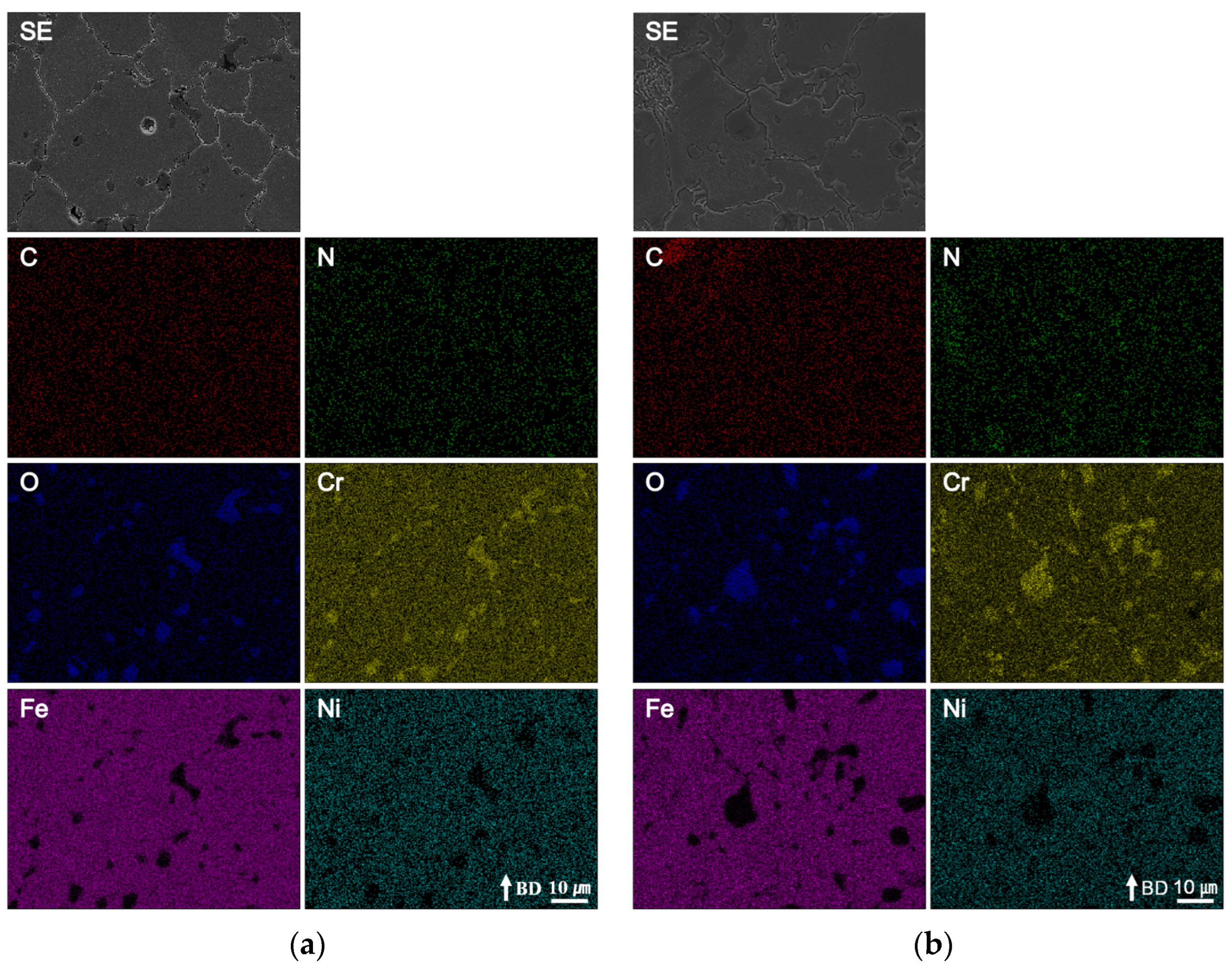

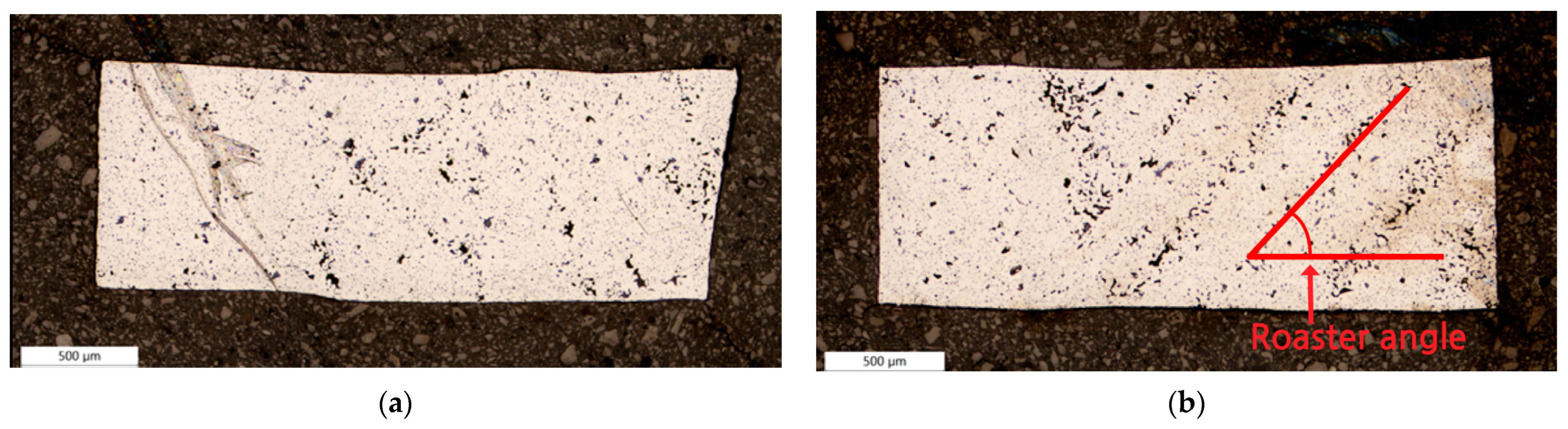

3.3. Microstructural Analysis

4. Discussion

4.1. WIP Effect on Mechanical Properties

4.2. Considerations for the WIP Process Parameters in Metal ME

5. Conclusions

- In the specimens used in this study, the tensile strength increased by a factor of 2.5 with WIP treatment. This shows that the specimen-manufacturing process conditions contribute to increasing the tensile strength, even considering the lack of optimization.

- The strain at ultimate tensile strength also increased fourfold with WIP. This was because, in the absence of WIP treatment, the large number of pores played an important role in crack initiation even at small strain and produced brittle behavior. If the process conditions were optimized, the effect of WIP treatment would be reduced, but not eliminated.

- Two types of hardness tests were performed. The Rockwell (macroscopic) hardness was affected by WIP (probably through pore generation); the Vickers (microscopic) hardness was not, because the WIP process was not performed at a high enough temperature to change of the microstructure of the metal.

- At the grain boundary, there were round secondary-phase particles composed of chrome oxide. Although chrome oxide exists on the surface of a typical SUS material, it seems that in this case, the chrome oxide phase only on the surface of the printed strand was impregnated inside.

Author Contributions

Funding

Conflicts of Interest

References

- Yadav, D.K.; Srivastava, R.; Dev, S. Design & fabrication of ABS part by FDM for automobile application. Mater. Today Proc. 2020, 26, 2089–2093. [Google Scholar] [CrossRef]

- Jiang, J. A novel fabrication strategy for additive manufacturing processes. J. Clean. Prod. 2020, 272, 122916. [Google Scholar] [CrossRef]

- Ali, M.; Sari, R.K.; Sajjad, U.; Sultan, M.; Ali, H.M. Effect of annealing on microstructures and mechanical properties of PA-12 lattice structures proceeded by multi jet fusion technology. Addit. Manuf. 2021, 47, 102285. [Google Scholar] [CrossRef]

- Kim, S.H.; Yeon, S.-M.; Lee, J.H.; Kim, Y.W.; Lee, H.; Park, J.; Lee, N.-K.; Choi, J.P.; Aranas, C., Jr.; Lee, Y.J.; et al. Additive manufacturing of a shift block via laser powder bed fusion: The simultaneous utilisation of optimised topology and a lattice structure. Virtual Phys. Prototyp. 2020, 15, 1–21. [Google Scholar] [CrossRef]

- Park, S.J.; Lee, J.H.; Yang, J.; Heogh, W.; Kang, D.; Yeon, S.M.; Kim, S.H.; Hong, S.; Son, Y.; Park, J. Lightweight injection mold using additively manufactured Ti-6Al-4V lattice structures. J. Manuf. Process. 2022, 79, 759–766. [Google Scholar] [CrossRef]

- Frandsen, C.S.; Nielsen, M.M.; Chaudhuri, A.; Jayaram, J.; Govindan, K. In search for classification and selection of spare parts suitable for additive manufacturing: A literature review. Int. J. Prod. Res. 2019, 58, 970–996. [Google Scholar] [CrossRef]

- Park, S.J.; Lee, J.E.; Park, J.; Lee, N.-K.; Son, Y.; Park, S.-H. High-temperature 3D printing of polyetheretherketone products: Perspective on industrial manufacturing applications of super engineering plastics. Mater. Des. 2021, 211, 110163. [Google Scholar] [CrossRef]

- Park, S.J.; Lee, J.E.; Lee, H.B.; Park, J.; Lee, N.-K.; Son, Y.; Park, S.-H. 3D printing of bio-based polycarbonate and its potential applications in ecofriendly indoor manufacturing. Addit. Manuf. 2019, 31, 100974. [Google Scholar] [CrossRef]

- Peterson, A.M. Review of acrylonitrile butadiene styrene in fused filament fabrication: A plastics engineering-focused perspective. Addit. Manuf. 2019, 27, 363–371. [Google Scholar] [CrossRef]

- Manoj, A.; Bhuyan, M.; Banik, S.R.; Sankar, M.R. Review on particle emissions during fused deposition modeling of acrylonitrile butadiene styrene and polylactic acid polymers. Mater. Today Proc. 2021, 44, 1375–1383. [Google Scholar] [CrossRef]

- Rinaldi, M.; Cecchini, F.; Pigliaru, L.; Ghidini, T.; Lumaca, F.; Nanni, F. Additive Manufacturing of Polyether Ether Ketone (PEEK) for Space Applications: A Nanosat Polymeric Structure. Polymers 2020, 13, 11. [Google Scholar] [CrossRef] [PubMed]

- Çevik, Ü.; Kam, M.; Zare, E.N. A Review Study on Mechanical Properties of Obtained Products by FDM Method and Metal/Polymer Composite Filament Production. J. Nanomater. 2020, 1–9. [Google Scholar] [CrossRef]

- Liu, Z.; Lei, Q.; Xing, S. Mechanical characteristics of wood, ceramic, metal and carbon fiber-based PLA composites fabricated by FDM. J. Mater. Res. Technol. 2019, 8, 3741–3751. [Google Scholar] [CrossRef]

- Tosto, C.; Tirillò, J.; Sarasini, F.; Cicala, G. Hybrid Metal/Polymer Filaments for Fused Filament Fabrication (FFF) to Print Metal Parts. Appl. Sci. 2021, 11, 1444. [Google Scholar] [CrossRef]

- Rosnitschek, T.; Seefeldt, A.; Alber-Laukant, B.; Neumeyer, T.; Altstädt, V.; Tremmel, S. Correlations of Geometry and Infill Degree of Extrusion Additively Manufactured 316L Stainless Steel Components. Materials 2021, 14, 5173. [Google Scholar] [CrossRef]

- Ye, H.; Liu, X.Y.; Hong, H. Fabrication of metal matrix composites by metal injection molding—A review. J. Mater. Process. Technol. 2008, 200, 12–24. [Google Scholar] [CrossRef] [Green Version]

- Safarian, A.; Subaşi, M.; Karataş, Ç. The effect of sintering parameters on diffusion bonding of 316L stainless steel in inserted metal injection molding. Int. J. Adv. Manuf. Technol. 2016, 89, 2165–2173. [Google Scholar] [CrossRef]

- Ye, H.; Liu, X.Y.; Hong, H. Sintering of 17-4PH stainless steel feedstock for metal injection molding. Mater. Lett. 2008, 62, 3334–3336. [Google Scholar] [CrossRef] [Green Version]

- Singh, P.; Balla, V.K.; Gokce, A.; Atre, S.V.; Kate, K.H. Additive manufacturing of Ti-6Al-4V alloy by metal fused filament fabrication (MF3): Producing parts comparable to that of metal injection molding. Prog. Addit. Manuf. 2021, 6, 593–606. [Google Scholar] [CrossRef]

- Yu, P.C.; Li, Q.F.; Fuh, J.Y.H.; Li, T.; Ho, P.W. Micro injection molding of micro gear using nano-sized zirconia powder. Microsyst. Technol. 2008, 15, 401–406. [Google Scholar] [CrossRef]

- Thomas-Vielma, P.; Cervera, A.; Levenfeld, B.; Várez, A. Production of alumina parts by powder injection molding with a binder system based on high density polyethylene. J. Eur. Ceram. Soc. 2008, 28, 763–771. [Google Scholar] [CrossRef]

- Tao, Y.; Kong, F.; Li, Z.; Zhang, J.; Zhao, X.; Yin, Q.; Xing, D.; Li, P. A review on voids of 3D printed parts by fused filament fabrication. J. Mater. Res. Technol. 2021, 15, 4860–4879. [Google Scholar] [CrossRef]

- Solomon, I.J.; Sevvel, P.; Gunasekaran, J. A review on the various processing parameters in FDM. Mater. Today Proc. 2020, 37, 509–514. [Google Scholar] [CrossRef]

- Gao, G.; Xu, F.; Xu, J.; Tang, G.; Liu, Z. A Survey of the Influence of Process Parameters on Mechanical Properties of Fused Deposition Modeling Parts. Micromachines 2022, 13, 553. [Google Scholar] [CrossRef] [PubMed]

- Carneiro, O.S.; Silva, A.F.; Gomes, R. Fused deposition modeling with polypropylene. Mater. Des. 2015, 83, 768–776. [Google Scholar] [CrossRef]

- Kuznetsov, V.E.; Solonin, A.N.; Urzhumtsev, O.D.; Schilling, R.; Tavitov, A.G. Strength of PLA Components Fabricated with Fused Deposition Technology Using a Desktop 3D Printer as a Function of Geometrical Parameters of the Process. Polymers 2018, 10, 313. [Google Scholar] [CrossRef] [Green Version]

- Aloyaydi, B.A.; Sivasankaran, S.; Ammar, H.R. Influence of infill density on microstructure and flexural behavior of 3D printed PLA thermoplastic parts processed by fusion deposition modeling. AIMS Mater. Sci. 2019, 6, 1033–1048. [Google Scholar] [CrossRef]

- Rayegani, F.; Onwubolu, G.C. Fused deposition modelling (FDM) process parameter prediction and optimization using group method for data handling (GMDH) and differential evolution (DE). Int. J. Adv. Manuf. Technol. 2014, 73, 509–519. [Google Scholar] [CrossRef]

- Saniman, M.N.F.; Hashim, M.H.M.; Mohammad, K.A.; Wahid, K.A.A.; Muhamad, W.M.W.; Mohamed, N.H.N. Tensile Characteristics of Low Density Infill Patterns for Mass Reduction of 3D Printed Polylactic Parts. Int. J. Automot. Mech. Eng. 2020, 17, 7927–7934. [Google Scholar] [CrossRef]

- Dezaki, M.L.; Ariffin, M.; Serjouei, A.; Zolfagharian, A.; Hatami, S.; Bodaghi, M. Influence of Infill Patterns Generated by CAD and FDM 3D Printer on Surface Roughness and Tensile Strength Properties. Appl. Sci. 2021, 11, 7272. [Google Scholar] [CrossRef]

- Meng, Q.; Gu, Y.; Luo, L.; Wang, S.; Li, M.; Zhang, Z. Annealing effect on crystalline structure and mechanical properties in long glass fiber reinforced polyamide 66. J. Appl. Polym. Sci. 2017, 134, 44832. [Google Scholar] [CrossRef]

- Wang, J.; Tan, Q.; Wang, K.; Yao, S.; Peng, Y.; Rao, Y. A heat-press-treatment method for 3D printed thin-walled composite structures with improved interfacial and compressive properties. Polym. Compos. 2022, 34, 8471–8482. [Google Scholar] [CrossRef]

- Bhandari, S.; Lopez-Anido, R.A.; Gardner, D.J. Enhancing the interlayer tensile strength of 3D printed short carbon fiber reinforced PETG and PLA composites via annealing. Addit. Manuf. 2019, 30, 100922. [Google Scholar] [CrossRef]

- Park, S.J.; Son, Y.; Ahn, I.H. Influence of warm isostatic press (WIP) process parameters on mechanical properties of additively manufactured acrylonitrile butadiene styrene (ABS) parts. Int. J. Adv. Manuf. Technol. 2022, 122, 3311–3322. [Google Scholar] [CrossRef]

- O’Connor, H.J.; Dowling, D.P. Low-pressure additive manufacturing of continuous fiber-reinforced polymer composites. Polym. Compos. 2019, 40, 4329–4339. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, Y.; Zhou, Y. Novel mechanical models of tensile strength and elastic property of FDM AM PLA materials: Experimental and theoretical analyses. Mater. Des. 2019, 181, 108089. [Google Scholar] [CrossRef]

- Yao, T.; Ye, J.; Deng, Z.; Zhang, K.; Ma, Y.; Ouyang, H. Tensile failure strength and separation angle of FDM 3D printing PLA material: Experimental and theoretical analyses. Compos. Part B Eng. 2020, 188, 107894. [Google Scholar] [CrossRef]

- Wang, W.; Zhao, G.; Wu, X.; Zhai, Z. The effect of high temperature annealing process on crystallization process of polypropylene, mechanical properties, and surface quality of plastic parts. J. Appl. Polym. Sci. 2015, 132, 42773. [Google Scholar] [CrossRef]

- Cherry, J.A.; Davies, H.M.; Mehmood, S.; Lavery, N.P.; Brown, S.G.R.; Sienz, J. Investigation into the effect of process parameters on microstructural and physical properties of 316L stainless steel parts by selective laser melting. Int. J. Adv. Manuf. Technol. 2015, 76, 869–879. [Google Scholar] [CrossRef] [Green Version]

- Wagner, M.A.; Engel, J.; Hadian, A.; Clemens, F.; Rodriguez-Arbaizar, M.; Carreño-Morelli, E.; Wheeler, J.M.; Spolenak, R. Filament extrusion-based additive manufacturing of 316L stainless steel: Effects of sintering conditions on the microstructure and mechanical properties. Addit. Manuf. 2022, 59, 103147. [Google Scholar] [CrossRef]

- Park, S.J.; Son, Y.; Ahn, I.H. Reducing anisotropy of a part fabricated by material extrusion via warm isostatic pressure (WIP) process. Addit. Manuf. 2022, 55, 102841. [Google Scholar] [CrossRef]

- Singh, P.; Balla, V.K.; Atre, S.V.; German, R.M.; Kate, K.H. Factors affecting properties of Ti-6Al-4V alloy additive manufactured by metal fused filament fabrication. Powder Technol. 2021, 386, 9–19. [Google Scholar] [CrossRef]

- Hwang, S.; Reyes, E.I.; Moon, K.-S.; Rumpf, R.C.; Kim, N.S. Thermo-mechanical Characterization of Metal/Polymer Composite Filaments and Printing Parameter Study for Fused Deposition Modeling in the 3D Printing Process. J. Electron. Mater. 2014, 44, 771–777. [Google Scholar] [CrossRef]

| Properties | Values | Units |

|---|---|---|

| Metal load | >80 | Wt% |

| Powder diameter [34] | 20–50 | µm |

| Density | 5 | g/cm3 |

| Properties | Values | Units |

|---|---|---|

| Extruder temperature | 235 | °C |

| Bed temperature | 90 | °C |

| Nozzle diameter | 0.4 | mm |

| Printing speed | 30 | mm/s |

| Layer height | 0.17 | mm |

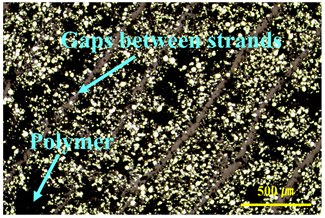

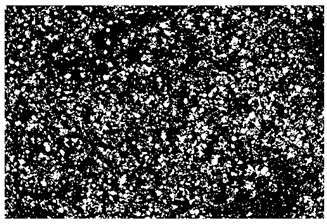

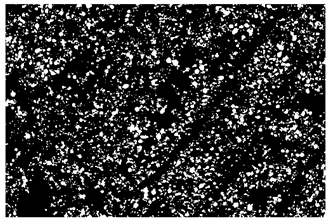

| With WIP | Without WIP | |

|---|---|---|

| Origin Images |  |  |

| 8 bit Images |  |  |

| Area Fraction | 26.62 | 17.16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, B.-Y.; Park, S.-J.; Son, Y.; Han, S.-J.; Kim, H.-G.; Ahn, I.-H.; Choi, W.-C. Influence of Warm Isostatic Press Process on Mechanical Properties of a Part Fabricated by Metal Material Extrusion Process. Appl. Sci. 2022, 12, 12240. https://doi.org/10.3390/app122312240

Choi B-Y, Park S-J, Son Y, Han S-J, Kim H-G, Ahn I-H, Choi W-C. Influence of Warm Isostatic Press Process on Mechanical Properties of a Part Fabricated by Metal Material Extrusion Process. Applied Sciences. 2022; 12(23):12240. https://doi.org/10.3390/app122312240

Chicago/Turabian StyleChoi, Byeong-Yeol, Seong-Je Park, Yong Son, Seung-Jun Han, Hyung-Giun Kim, Il-Hyuk Ahn, and Woo-Chun Choi. 2022. "Influence of Warm Isostatic Press Process on Mechanical Properties of a Part Fabricated by Metal Material Extrusion Process" Applied Sciences 12, no. 23: 12240. https://doi.org/10.3390/app122312240