Effect of Using Plastic Waste Bottles on Soil Response above Buried Pipes under Static Loads

Abstract

:1. Introduction

2. Materials and Experimental Setup

2.1. Material Properties

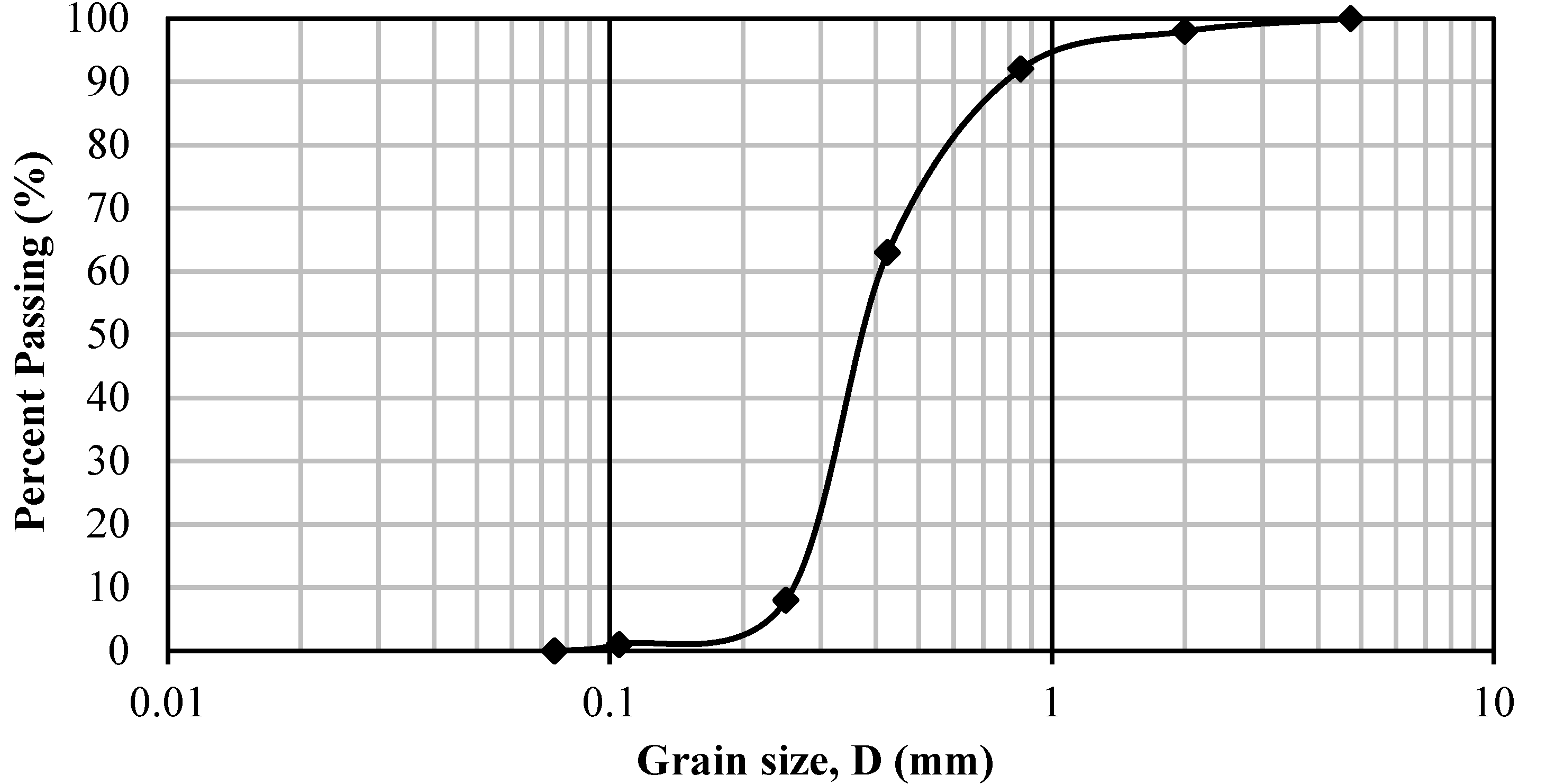

2.1.1. Backfill and Infill Soils

2.1.2. uPVC Pipe

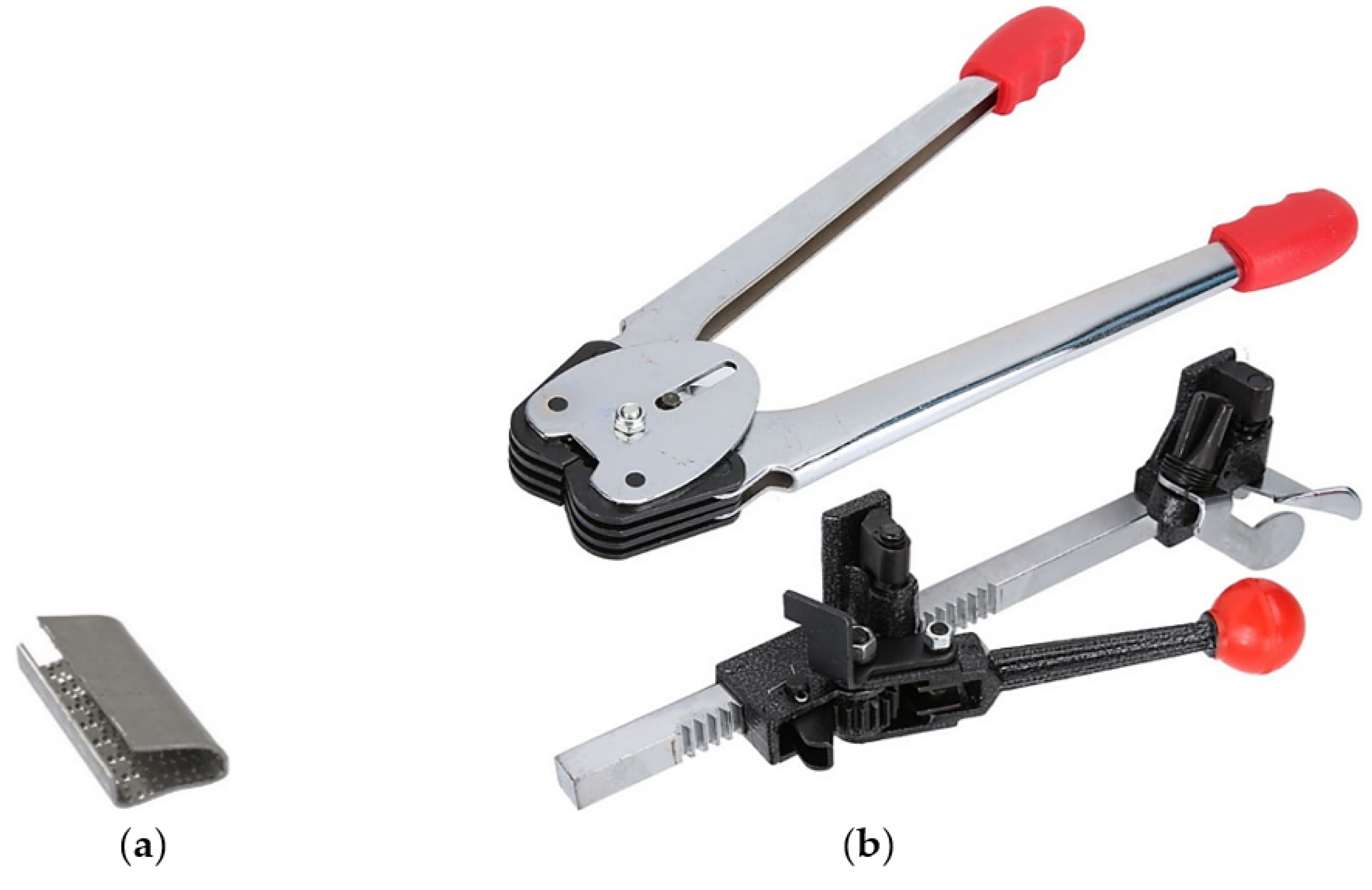

2.1.3. PET (Polyethylene Terephthalate) Bottles

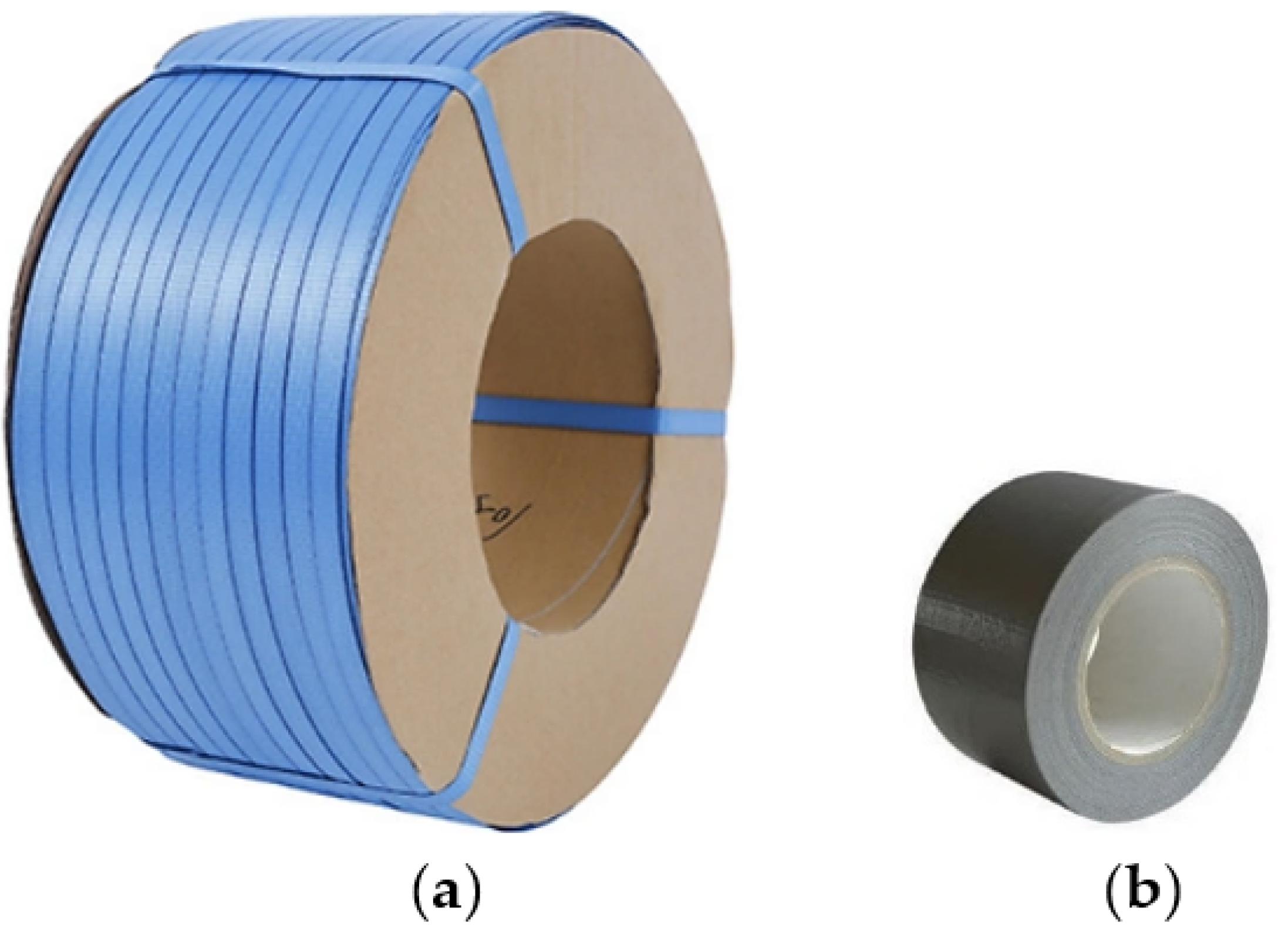

2.1.4. Polypropylene (PP) Strips and Cloth Duct Tape

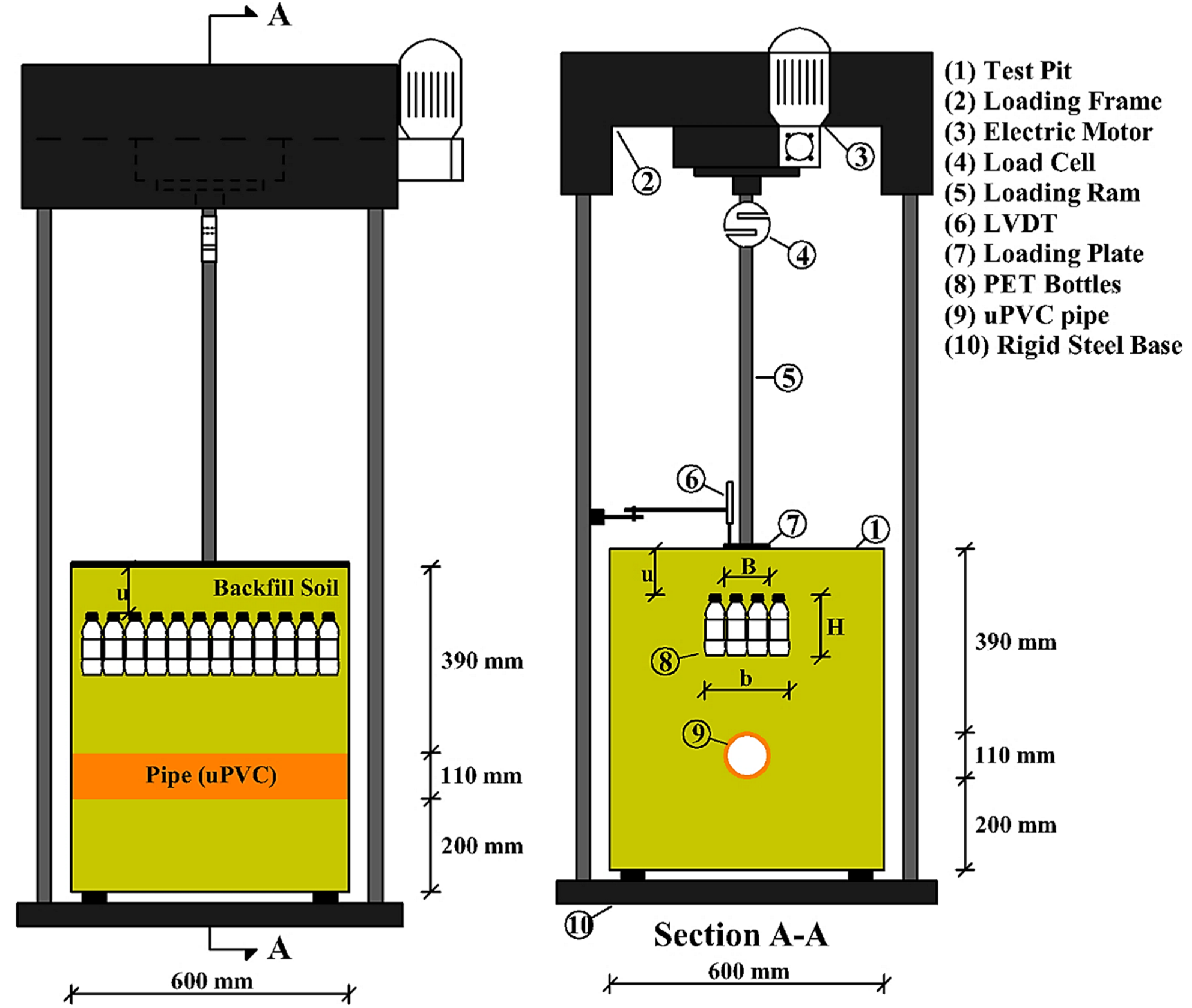

2.2. Experimental Setup

2.3. Test Preparation and Experimental Procedure

2.4. Testing Program

3. Results and Discussion

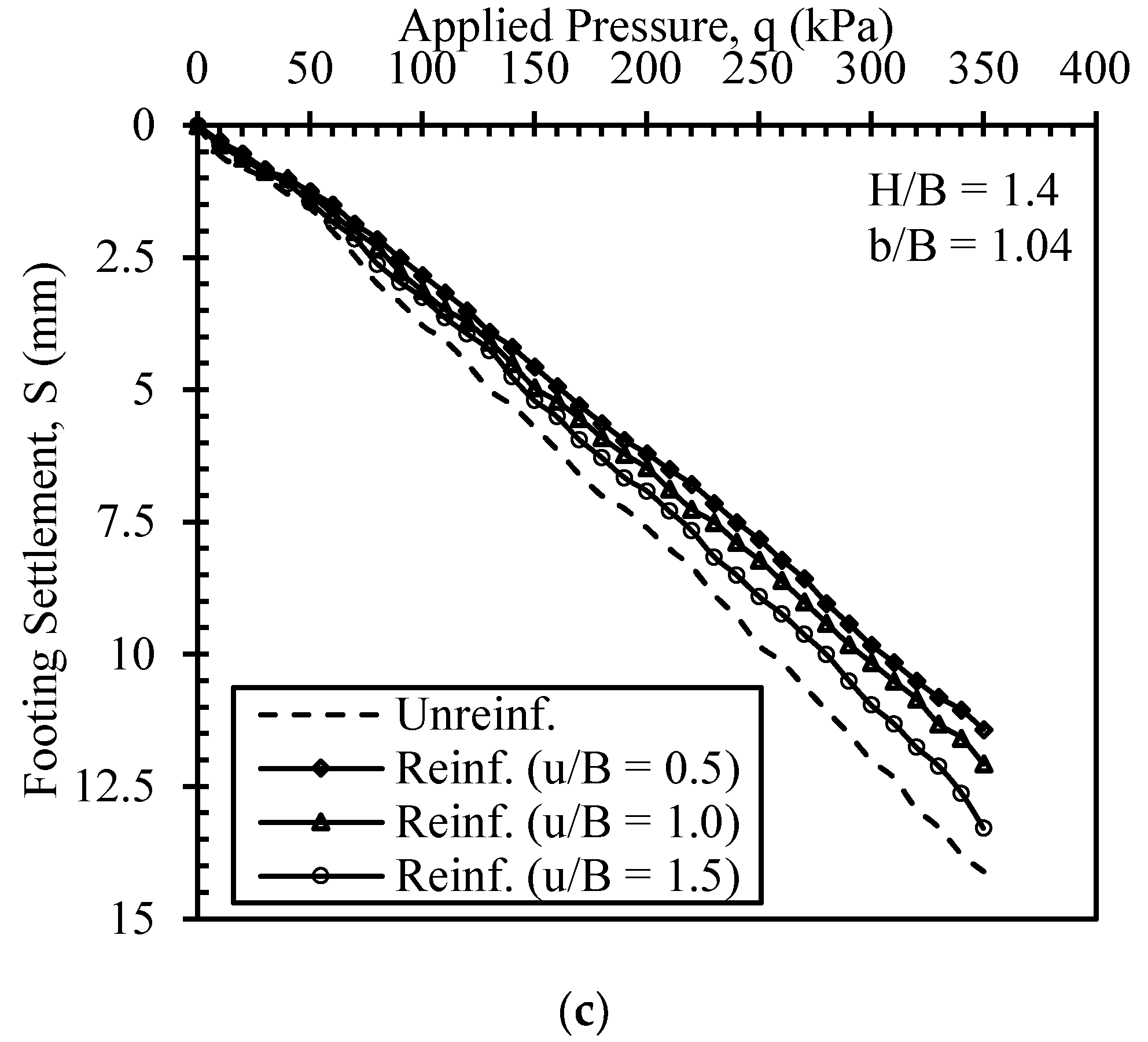

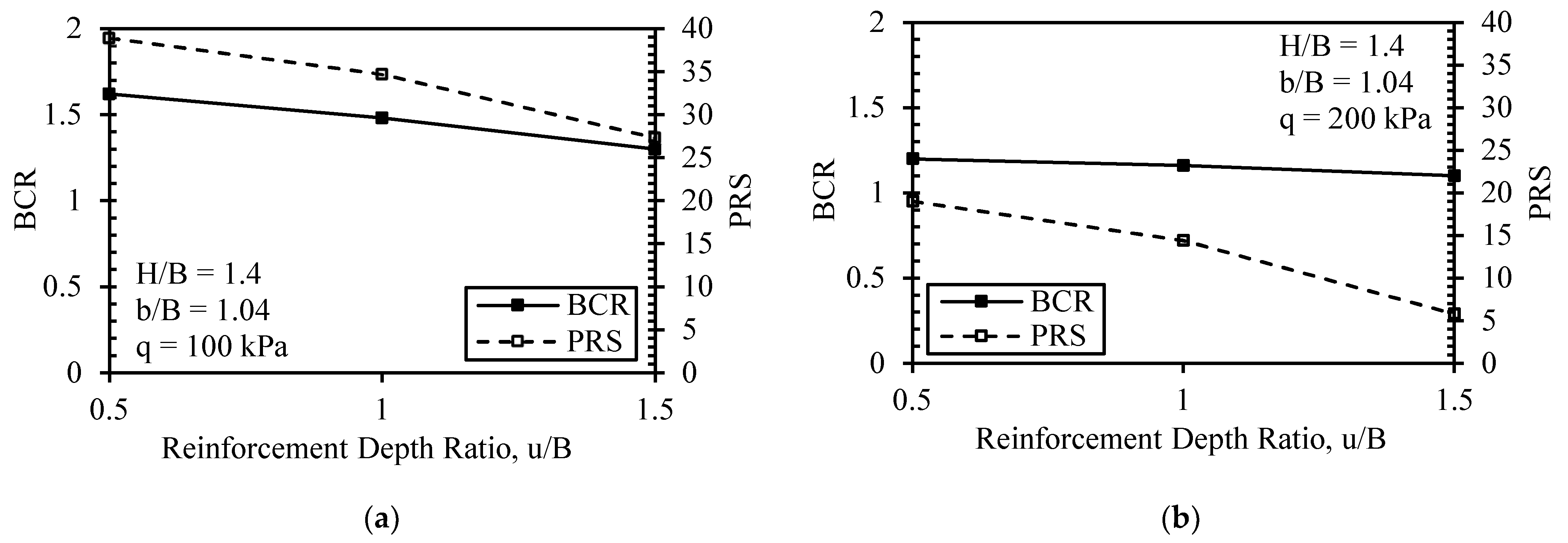

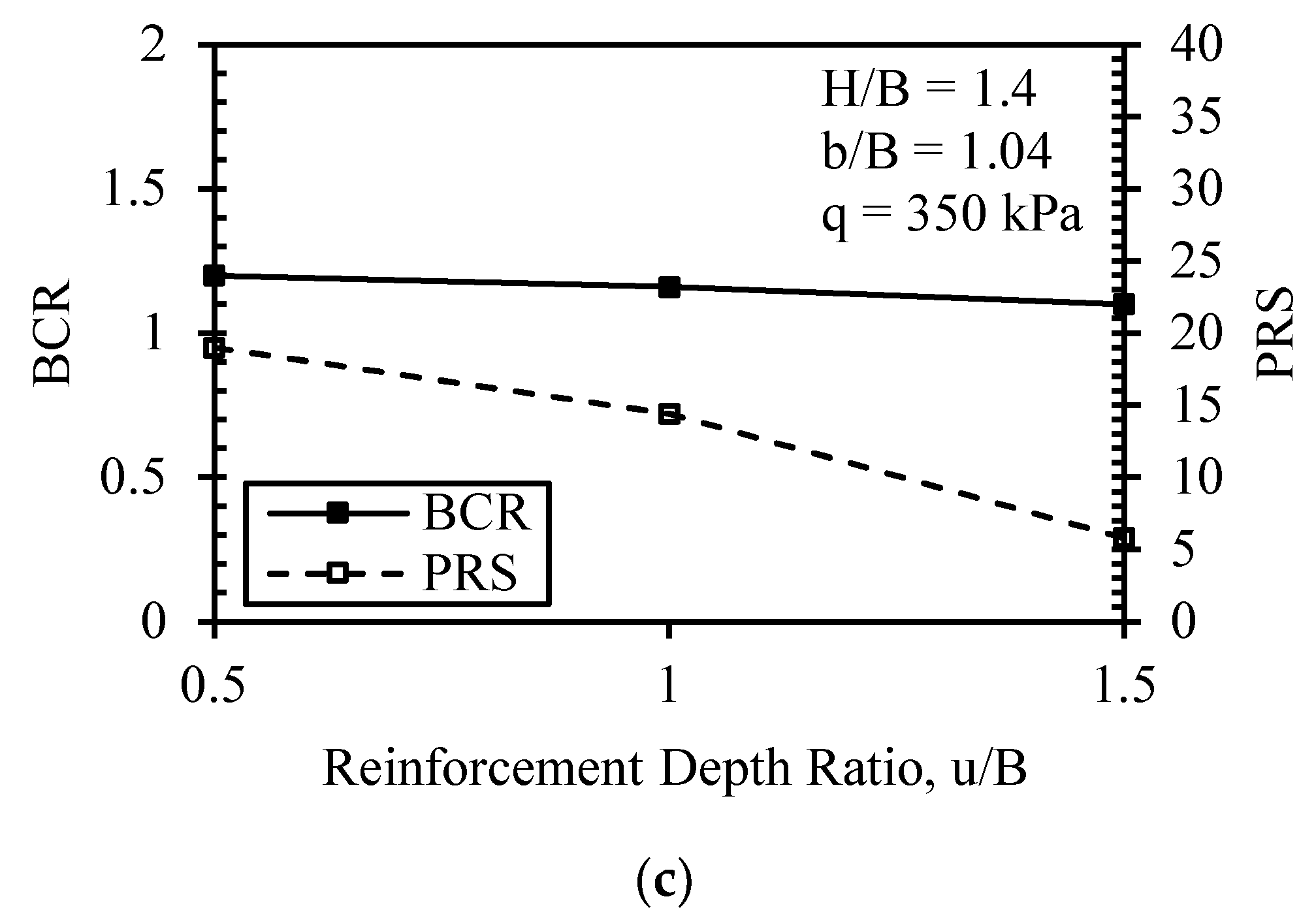

3.1. Bottles-Reinforcement Placement Depth (u/B) Effect

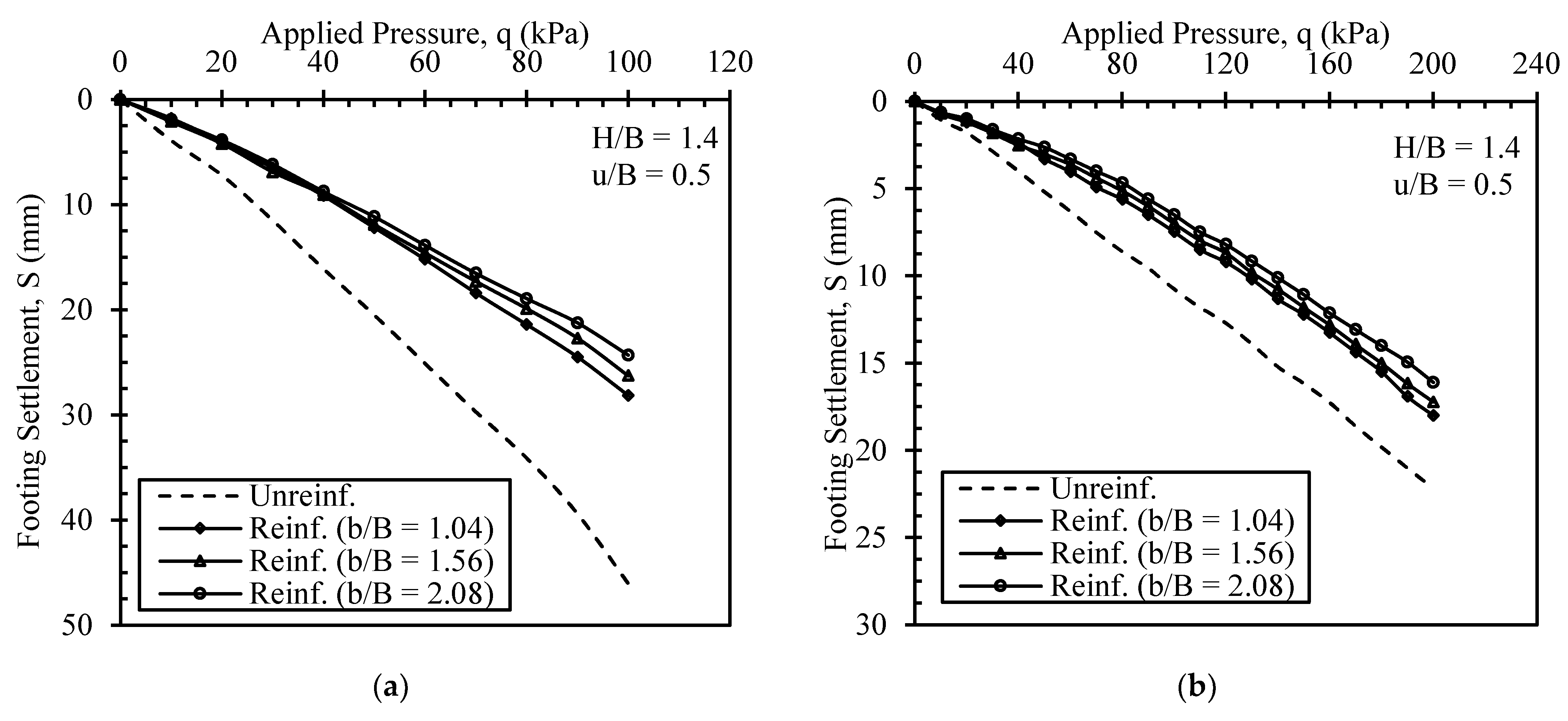

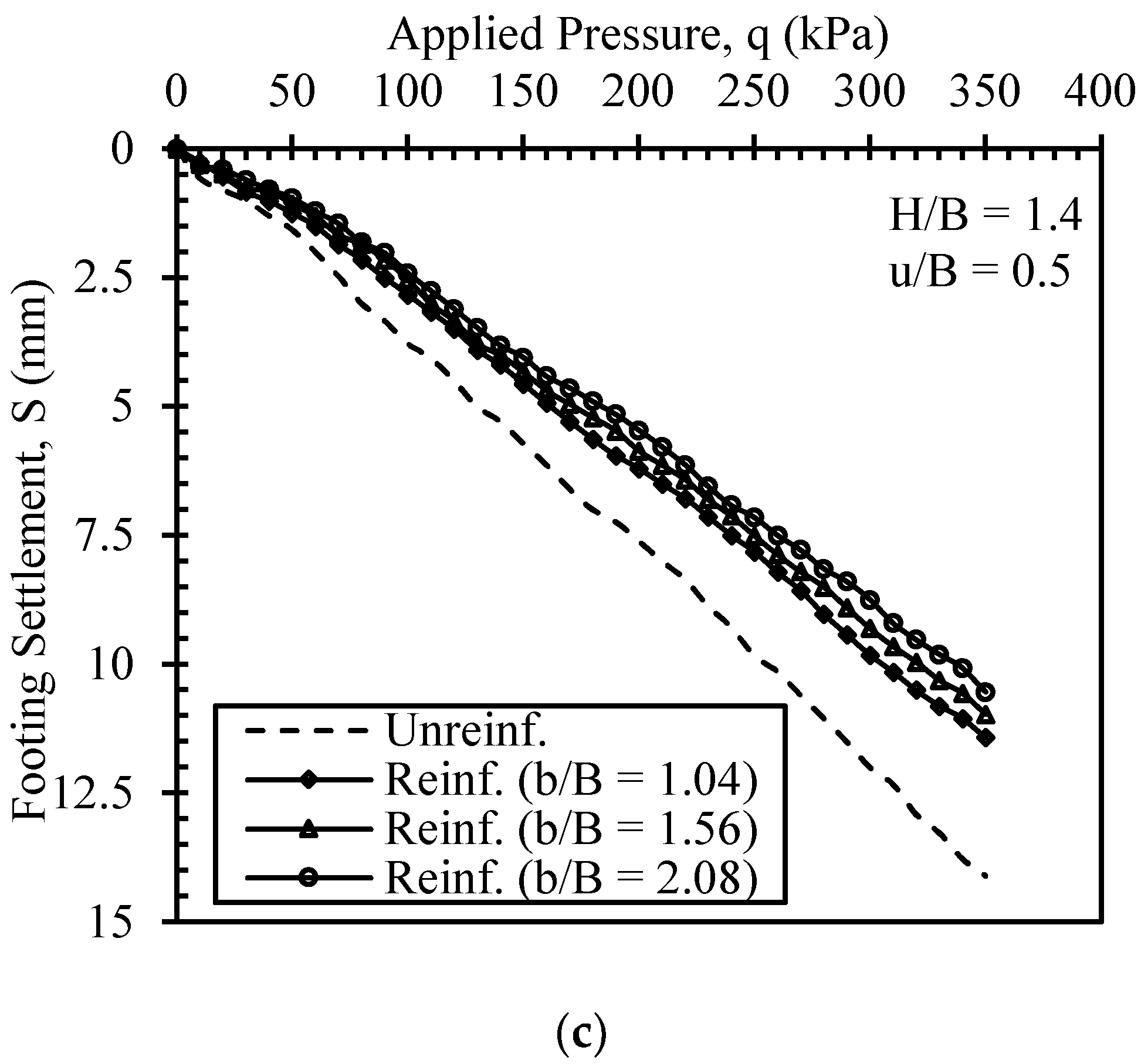

3.2. Bottles-Reinforcement Width (b/B) Effect

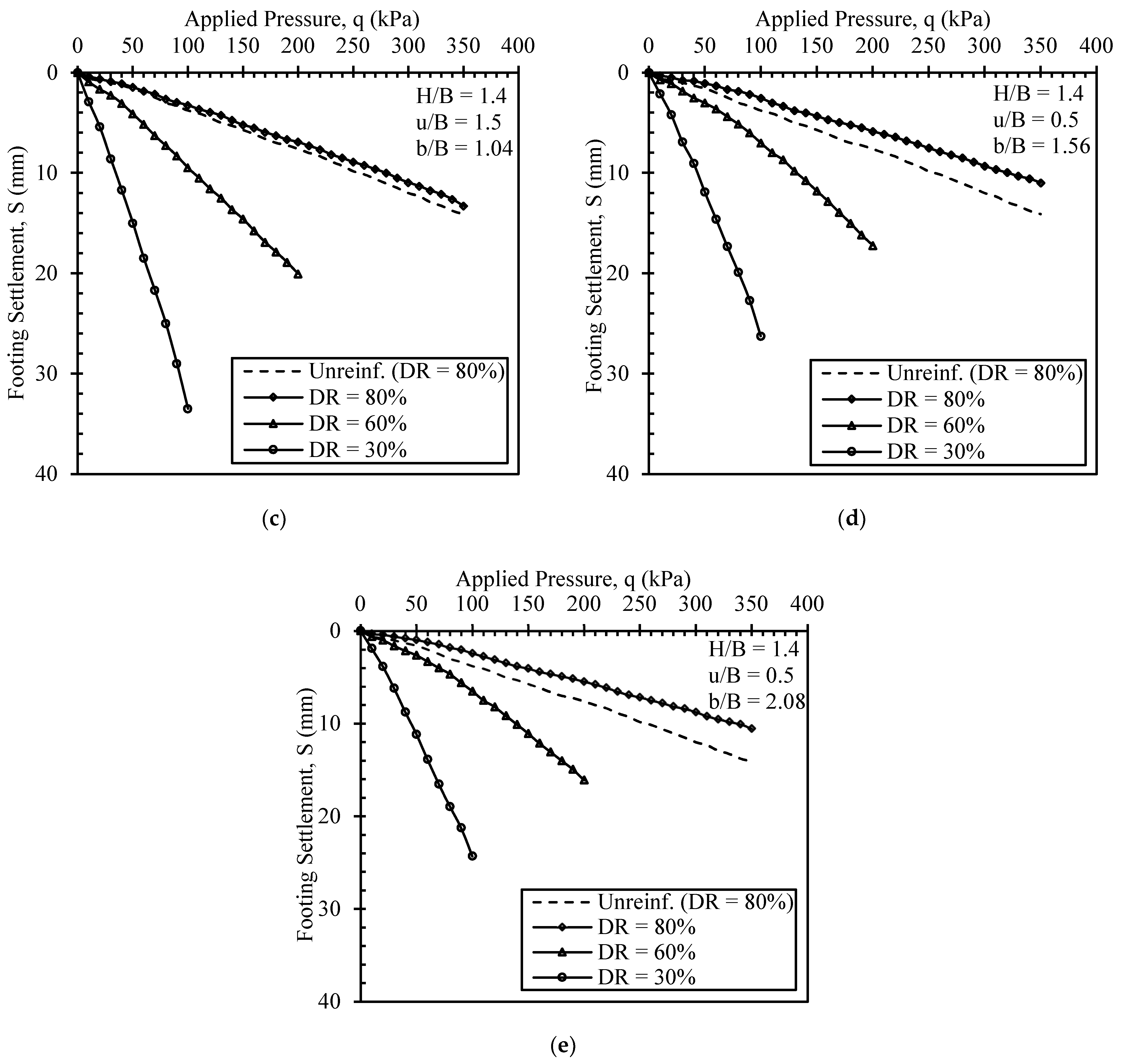

3.3. Relative Density of Backfill Soil (DR) Effect

4. Summary and Conclusions

- ▪

- Tied soil-filled PET bottles perform best when located close to the loading steel plate. The soil bed’s ultimate bearing capacity increases as the bottle’s placement depth decreases.

- ▪

- As the width of the bottle’s reinforcement block increases, the ultimate bearing capacity of the soil slightly increases too. However, the improvement of the ultimate bearing capacity of bottle-reinforced soil’s bed due to increasing the width of bottle reinforcement mattresses is not significant.

- ▪

- The bearing capacity ratio (BCR) of the soil bed was improved by a factor of ~1.71 (resulting in an average 71% improvement in ultimate bearing capacity at RD = 30%), which, in turn, will reduce the surface settlement of backfilled soil and result in a firm soil bed above the buried pipe.

- ▪

- As the relative density of the bottle-reinforced soil bed increases, the bearing pressure increases (and the footing surface settlement decreases) due to the inclusion of a bottle reinforcement mattress. In addition, at a given applied pressure, the footing surface settlement decreases as the relative density of the sand bed increases.

- ▪

- The optimum placement depth and width of the bottle-reinforced mattress were 0.50 and 2.08 B, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Choo, Y.W.; Abdoun, T.H.; O’Rourke, M.J.; Ha, D. Remediation for buried pipeline systems under permanent ground deformation. Soil Dyn. Earthq. Eng. 2007, 27, 1043–1055. [Google Scholar] [CrossRef]

- Tafreshi, S.M.; Dawson, A.R. Comparison of bearing capacity of a strip footing on sand with geocell and with planar forms of geotextile reinforcement. Geotext. Geomembr. 2010, 28, 72–84. [Google Scholar] [CrossRef]

- Moghaddas Tafreshi, S.N.; Khalaj, O.; Halvaee, M.J.G.I. Experimental study of a shallow strip footing on geogrid-reinforced sand bed above a void. Geosynth. Int. 2011, 18, 178–195. [Google Scholar] [CrossRef] [Green Version]

- El Sawwaf, M.A. Behavior of strip footing on geogrid-reinforced sand over a soft clay slope. Geotext. Geomembr. 2007, 25, 50–60. [Google Scholar] [CrossRef]

- Deb, K.; Chandra, S.; Basudhar, P.K. Settlement response of a multilayer geosynthetic-reinforced granular fill–soft soil system. Geosynth. Int. 2005, 12, 288–298. [Google Scholar] [CrossRef]

- Shin, E.C.; Das, B.M. Experimental study of bearing capacity of a strip foundation on geogrid-reinforced sand. Geosynth. Int. 2000, 7, 59–71. [Google Scholar] [CrossRef]

- Wysokowski, A. Influence of single-layer geotextile reinforcement on load capacity of buried steel box structure based on laboratory full-scale tests. Thin-Walled Struct. 2021, 159, 107312. [Google Scholar] [CrossRef]

- Beben, D. Soil-Steel Bridges. In Design, Maintenance and Durability; Springer Nature: Cham, Switzerland, 2020. [Google Scholar]

- Thallak, S.G.; Saride, S.; Dash, S.K. Performance of surface footing on geocell-reinforced soft clay beds. Geotech. Geol. Eng. 2007, 25, 509–524. [Google Scholar] [CrossRef]

- Palmeira, E.M.; Andrade, H.K.P.A. Protection of buried pipes against accidental damage using geosynthetics. Geosynth. Int. 2010, 17, 228–241. [Google Scholar] [CrossRef]

- Alotaibi, E.; Omar, M.; Shanableh, A.; Zeiada, W.; Fattah, M.Y.; Tahmaz, A.; Arab, M.G. Geogrid bridging over existing shallow flexible PVC buried pipe–Experimental study. Tunn. Undergr. Space Technol. 2021, 113, 103945. [Google Scholar] [CrossRef]

- Aattah, M.Y.; Zbar, B.S.; Al-Kalali, H.H.M. Three-dimensional finite element simulation of the buried pipe problem in geogrid reinforced soil. J. Eng. 2016, 22, 60–73. [Google Scholar]

- Fattah, M.Y.; Zbar, B.S.; Al-Kalali, H.H.M. Experimental study on the effect of embedment depth of buried flexible pipe subjected to static load. Glob. J. Eng. Sci. Res. Manag. 2015, 2, 113–122. [Google Scholar]

- Ahmed, A.; Ugai, K.; Kamei, T. Investigation of recycled gypsum in conjunction with waste plastic trays for ground improvement. Constr. Build. Mater. 2011, 25, 208–217. [Google Scholar] [CrossRef]

- Dutta, S.; Mandal, J.N. Feasibility study on waste plastic water bottles as encasements of stone columns for ground improvement. In Proceedings of the International Symposium on Design and Practice of Geosynthetic-Reinforced Soil Structures, Bologna, Italy, 14–16 October 2013; pp. 379–388. [Google Scholar]

- Karmacharya, R.; Acharya, I.P. Reinforcement of Soil Using Recycled Polyethylene Terephthalate (PET) Bottle Strips. In Proceedings of the IOE Graduate Conference, Lalitpur, Nepal, 29–30 December 2017; Volume 5. [Google Scholar]

- Singh, J.; Sonthwal, V.; Rattan, J. Review on improvement of engineering properties of soil using waste plastic bottles strips (Polyethylene terephthalate). Int. J. Emerg. Technol. 2017, 8, 1–4. [Google Scholar]

- Peddaiah, S.; Burman, A.; Sreedeep, S. Experimental study on effect of waste plastic bottle strips in soil improvement. Geotech. Geol. Eng. 2018, 36, 2907–2920. [Google Scholar] [CrossRef]

- Jaya, A.D.; Sunil, A.; Joseph, M.; Varghese, M.; Veena, M. Soil Stabilization Using Raw Plastic Bottles. In Proceedings of the Indian Geotechnical Conference, Kochi, India, 15–17 December 2011; pp. 489–492. [Google Scholar]

- Thakare, S.W.; Sonule, S.K. Performance of plastic bottle reinforced soil. Int. J. Eng. Innov. Res. 2013, 2, 207. [Google Scholar]

- Dutta, S.; Nadaf, M.Á.; Mandal, J.N. An overview on the use of waste plastic bottles and fly ash in civil engineering applications. Procedia Environ. Sci. 2016, 35, 681–691. [Google Scholar] [CrossRef]

- Moghaddas Tafreshi, S.N.; Rafiezadeh Malekshah, A.; Rahimi, M.; Dawson, A.R. (2022). Bearing capacity improvement using soil-filled post-consumer PET bottles. Geosynth. Int. 2022, 29, 205–216. [Google Scholar] [CrossRef]

- Fattah, M.; Mohammed Redha, W.B. Protection of flexible pipes from dynamic surface stresses by Geocell-reinforced sand backfill. Int. J. Min. Geo-Eng. 2022, 56, 61–66. [Google Scholar]

- ASTM Committee D-18 on Soil and Rock. Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer; ASTM International: West Conshohocken, PA, USA, 2006. [Google Scholar]

- ASTM Committee D-18 on Soil and Rock. Standard Test Methods for Maximum Index Density and Unit Weight of Soils Using a Vibratory Table; ASTM International: West Conshohocken, PA, USA, 2006. [Google Scholar]

- American Society for Testing and Materials. Standard Test Methods for Minimum Index Density and Unit Weight of Soils and Calculation of Relative Density; ASTM International: West Conshohocken, PA, USA, 2006. [Google Scholar]

- American Society for Testing and Materials Committee D18 on Soil and Rock. Standard Test Methods for Particle-Size Distribution (Gradation) of Soils Using Sieve Analysis; ASTM International: West Conshohocken, PA, USA, 2004. [Google Scholar]

- ASTM Committee D-18 on Soil and Rock. Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System); ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- D3080/D3080M; Standard Test Method for Direct Shear Test of Soils under Consolidated Drained Conditions. ASTM International: West Conshohocken, PA, USA, 2011.

- Omar, M.T.; Das, B.M.; Puri, V.K.; Yen, S.C. Ultimate bearing capacity of shallow foundations on sand with geogrid reinforcement. Can. Geotech. J. 1993, 30, 545–549. [Google Scholar] [CrossRef]

- Terzaghi, K. Theoretical Soil Mechanics; John Wiley and Sons Inc.: New York, NY, USA, 1943; Volume 314. [Google Scholar]

- Milligan, G.W.E.; Jewell, R.A.; Houlsby, G.T.; Burd, H.J. A new approach to the design of unpaved roads-part 1. Ground Eng. 1989, 22, 25–29. [Google Scholar]

- Fang, H.; Yang, K.; Li, B.; Tan, P.; Wang, F.; Du, X. Experimental and numerical study on mechanical analysis of buried corroded concrete pipes under static traffic loads. Appl. Sci. 2019, 9, 5002. [Google Scholar] [CrossRef] [Green Version]

- Abdelfateh, K.; Mohamed, B.; Fattah, M.Y. Numerical Modeling of the Pipeline Uplift Mechanism in Clay. Arch. Hydro-Eng. Environ. Mech. 2021, 68, 119–135. [Google Scholar] [CrossRef]

- Park, J.; Chung, Y.; Hong, G. Reinforcement Effect of a Concrete Mat to Prevent Ground Collapses Due to Buried Pipe Damage. Appl. Sci. 2020, 10, 5439. [Google Scholar] [CrossRef]

- Tafreshi, S.M.; Khalaj, O. Laboratory tests of small-diameter HDPE pipes buried in reinforced sand under repeated-load. Geotext. Geomembr. 2008, 26, 145–163. [Google Scholar] [CrossRef]

| Property | Value | Method | ||

|---|---|---|---|---|

| Specific gravity, Gs | 2.64 | ASTM D854 [24] | ||

| Maximum dry density, ɣd, max. (kN/m3) | 18.49 | ASTM D4253 [25] | ||

| Minimum void ratio, emin. | 0.390 | |||

| Minimum dry density, ɣd, min. (kN/m3) | 14.45 | ASTM D4254 [26] | ||

| Maximum void ratio, emax. | 0.753 | |||

| Effective particle size, D10 (mm) | 0.27 | ASTM D6913 [27] | ||

| D60 (mm) | 0.41 | |||

| D30 (mm) | 0.32 | |||

| Coefficient of uniformity, Cu | 1.52 | |||

| Coefficient of curvature, Cc | 0.93 | |||

| Soil classification as per USCS | SP | ASTM D2487 [28] | ||

| Relative density, DR (%) | 30 | 60 | 80 | --- |

| Friction angle, Ø (°) | 28.17 | 35.26 | 40.78 | ASTM D3080 [29] |

| Property | Value |

|---|---|

| Outer Diameter (mm) | 110 |

| Thickness (mm) | 4.32 |

| Modulus of Elasticity (GPa) | 3 |

| Tensile Strength (MPa) | 51.2 |

| PP strapping | Size = 12 mm; thickness = 0.6 mm; color: blue; breaking strength = 120 kg |

|---|---|

| Cloth duct tape | Roll width = 48 mm; roll length = 22.86 m (25 yards); tape thickness = 0.23 mm; tensile strength = 438 n/100 mm |

| Test Series | Pipe | Reinforcement Condition | Variables | Constants |

|---|---|---|---|---|

| Series 1: three tests | Yes | Unreinforced | DR = 30, 60, and 80% | --- |

| Series 2: nine tests | Yes | Bottle reinforced | DR = 30, 60, and 80%; u/B = 0.5, 1 and 1.5 | b/B = 1.04 and H/B = 1.4 |

| Series 3: six tests | Yes | Bottle reinforced | DR = 30, 60, and 80%; b/B = 1.56 and 2.08 | u/B = 0.5 and H/B = 1.4 |

| Test No. | Reinforcement Condition | u/B | b/B | H/B | DR (%) | Ultimate Bearing Capacity (kPa) | BCR |

|---|---|---|---|---|---|---|---|

| 1 | Unreinforced | --- | --- | --- | 30 | 26.5 | --- |

| 2 | Bottle reinforced | 0.5 | 1.04 | 1.4 | 42.8 | 1.62 | |

| 3 | 1 | 1.04 | 39.3 | 1.48 | |||

| 4 | 1.5 | 1.04 | 34.5 | 1.30 | |||

| 5 | 0.5 | 1.56 | 43.3 | 1.63 | |||

| 6 | 0.5 | 2.08 | 45.3 | 1.71 | |||

| 7 | Unreinforced | --- | --- | --- | 60 | 93.8 | --- |

| 8 | Bottle reinforced | 0.5 | 1.04 | 1.4 | 128.1 | 1.37 | |

| 9 | 1 | 1.04 | 115.9 | 1.24 | |||

| 10 | 1.5 | 1.04 | 105.2 | 1.12 | |||

| 11 | 0.5 | 1.56 | 132.1 | 1.41 | |||

| 12 | 0.5 | 2.08 | 139.0 | 1.48 | |||

| 13 | Unreinforced | --- | --- | --- | 80 | 255.5 | --- |

| 14 | Bottle reinforced | 0.5 | 1.04 | 1.4 | 305.5 | 1.20 | |

| 15 | 1 | 1.04 | 295.6 | 1.16 | |||

| 16 | 1.5 | 1.04 | 280.0 | 1.10 | |||

| 17 | 0.5 | 1.56 | 321.3 | 1.26 | |||

| 18 | 0.5 | 2.08 | 337.3 | 1.32 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Haddad, S.A.; Al-Ani, F.H.; Fattah, M.Y. Effect of Using Plastic Waste Bottles on Soil Response above Buried Pipes under Static Loads. Appl. Sci. 2022, 12, 12304. https://doi.org/10.3390/app122312304

Al-Haddad SA, Al-Ani FH, Fattah MY. Effect of Using Plastic Waste Bottles on Soil Response above Buried Pipes under Static Loads. Applied Sciences. 2022; 12(23):12304. https://doi.org/10.3390/app122312304

Chicago/Turabian StyleAl-Haddad, Sinan A., Faris H. Al-Ani, and Mohammed Y. Fattah. 2022. "Effect of Using Plastic Waste Bottles on Soil Response above Buried Pipes under Static Loads" Applied Sciences 12, no. 23: 12304. https://doi.org/10.3390/app122312304

APA StyleAl-Haddad, S. A., Al-Ani, F. H., & Fattah, M. Y. (2022). Effect of Using Plastic Waste Bottles on Soil Response above Buried Pipes under Static Loads. Applied Sciences, 12(23), 12304. https://doi.org/10.3390/app122312304