Deep Electrochemical Etching of Stainless Steel Using a Deposited Copper Layer

Abstract

:1. Introduction

2. Experimental System

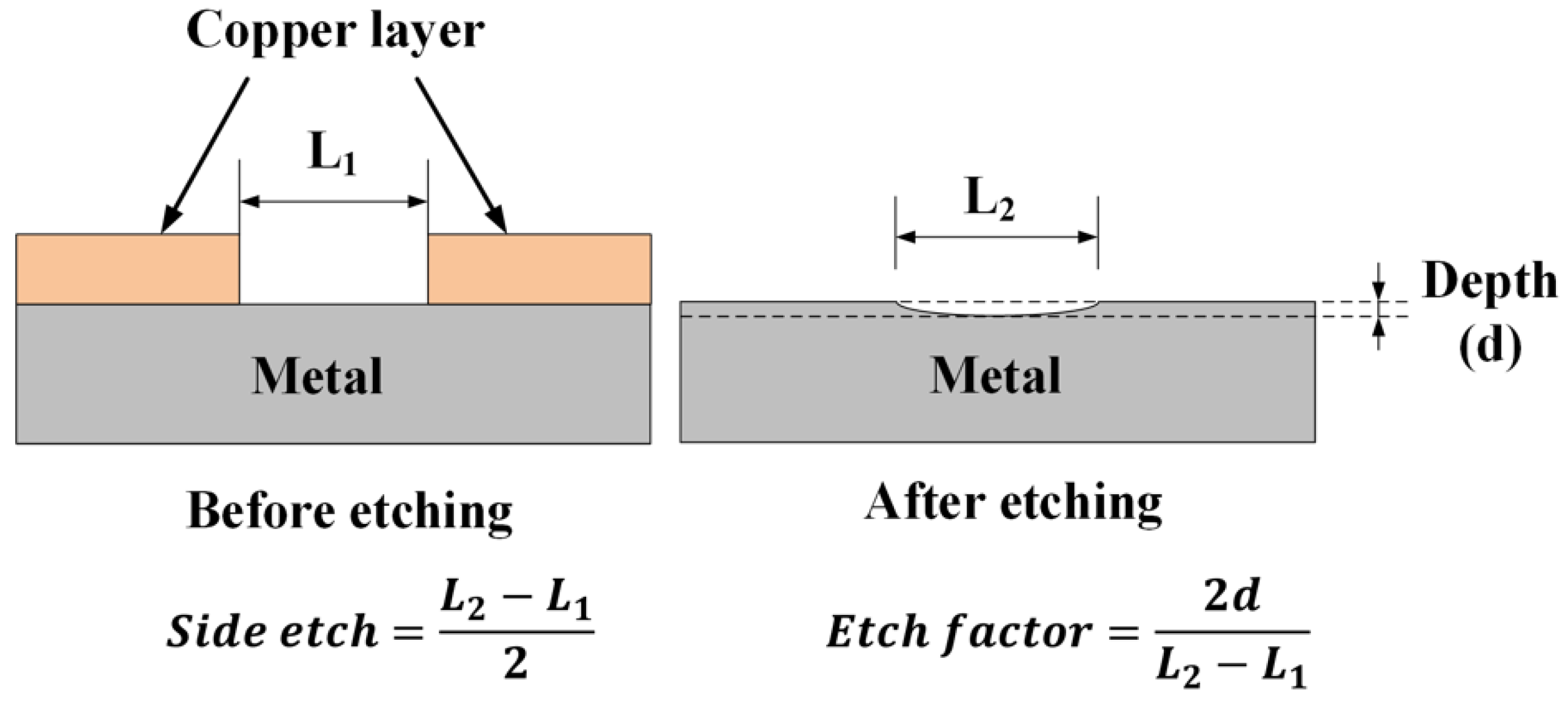

3. Principle of DEE Process

4. Results and Discussion

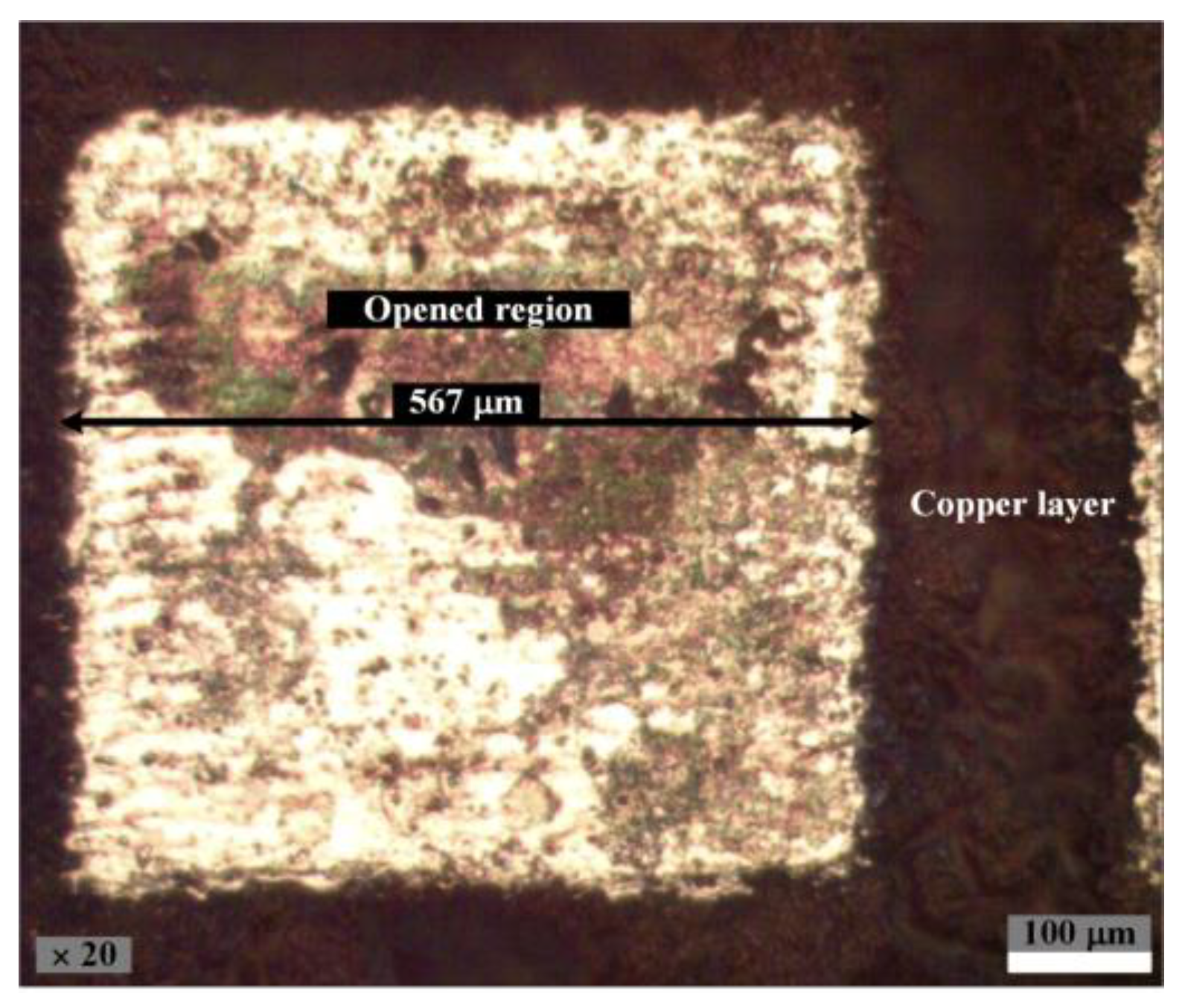

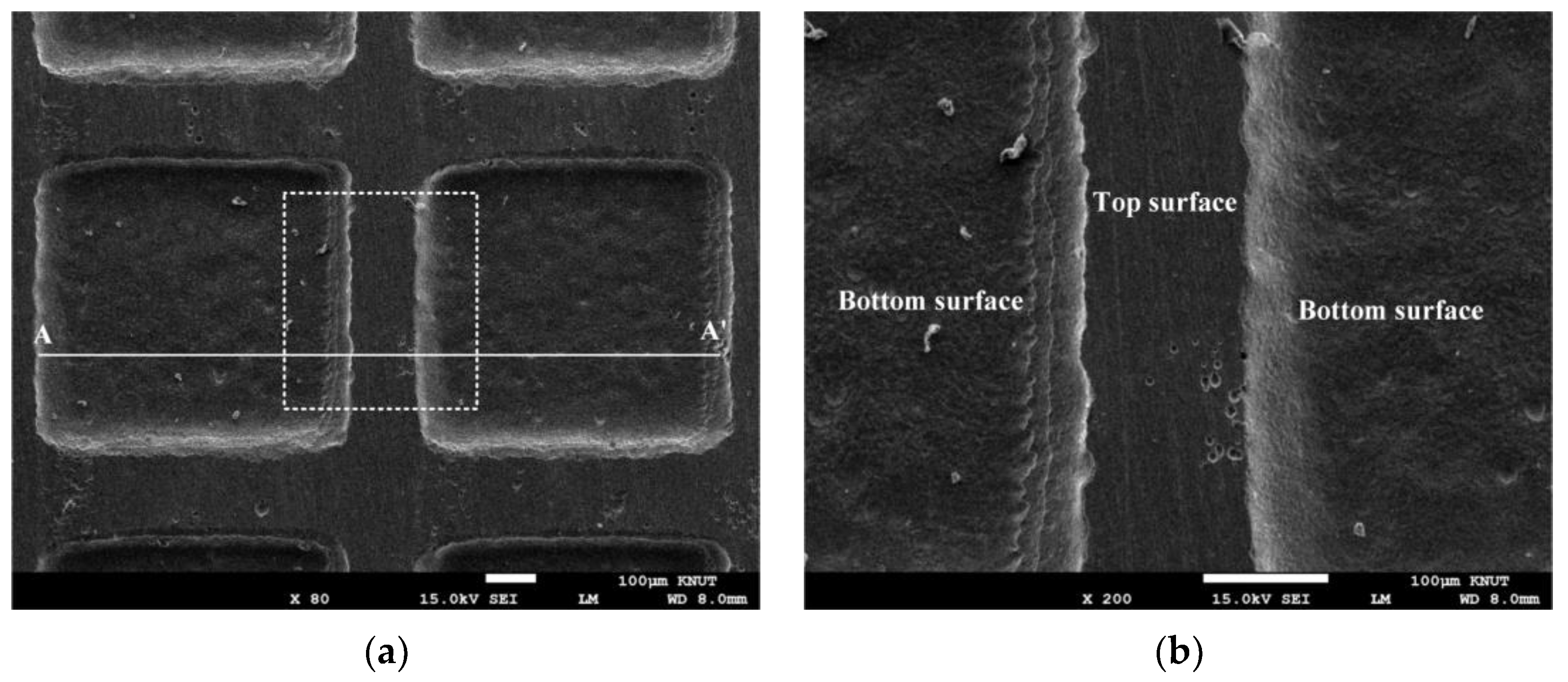

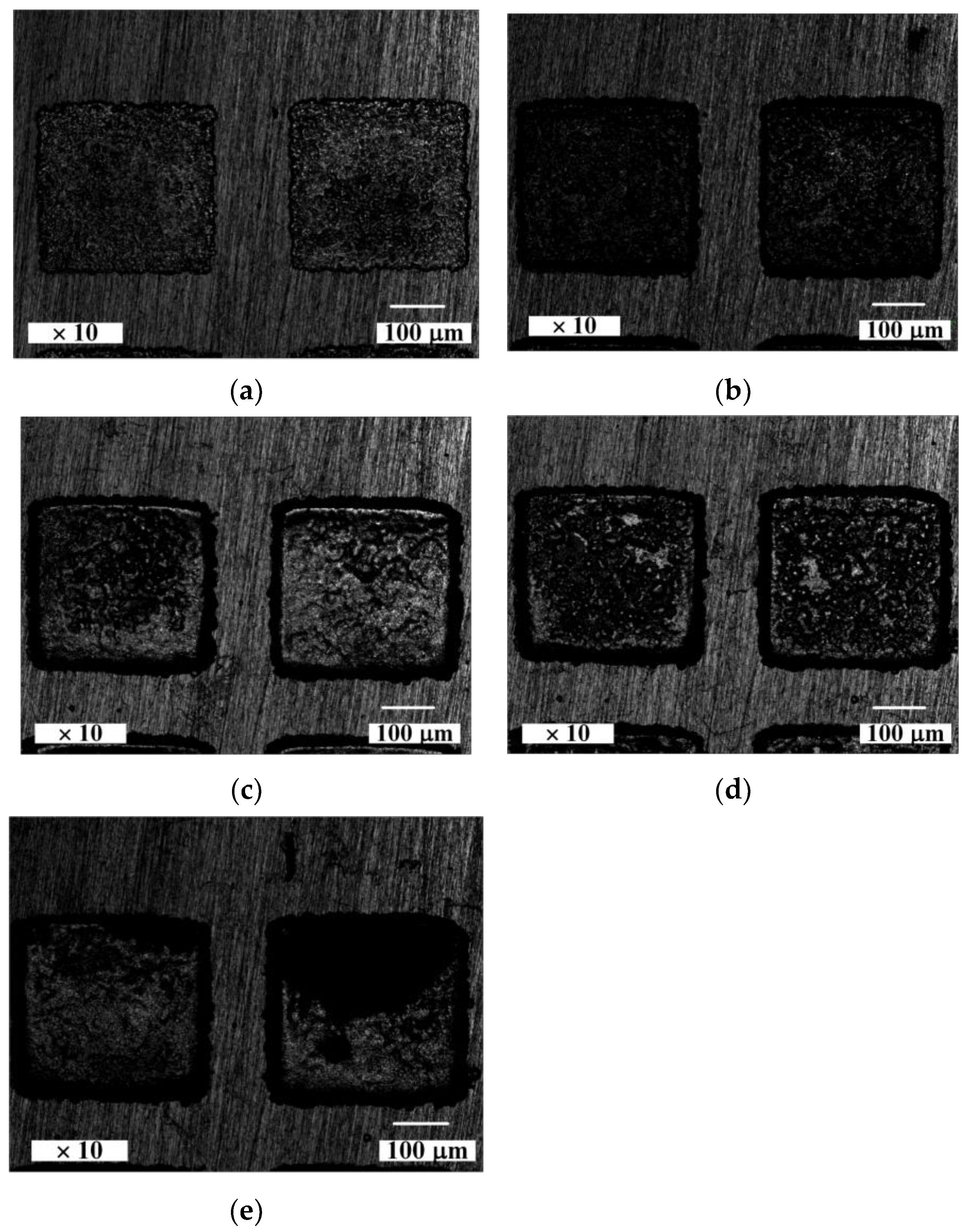

4.1. Shape Evolution of DEE Process Conditions

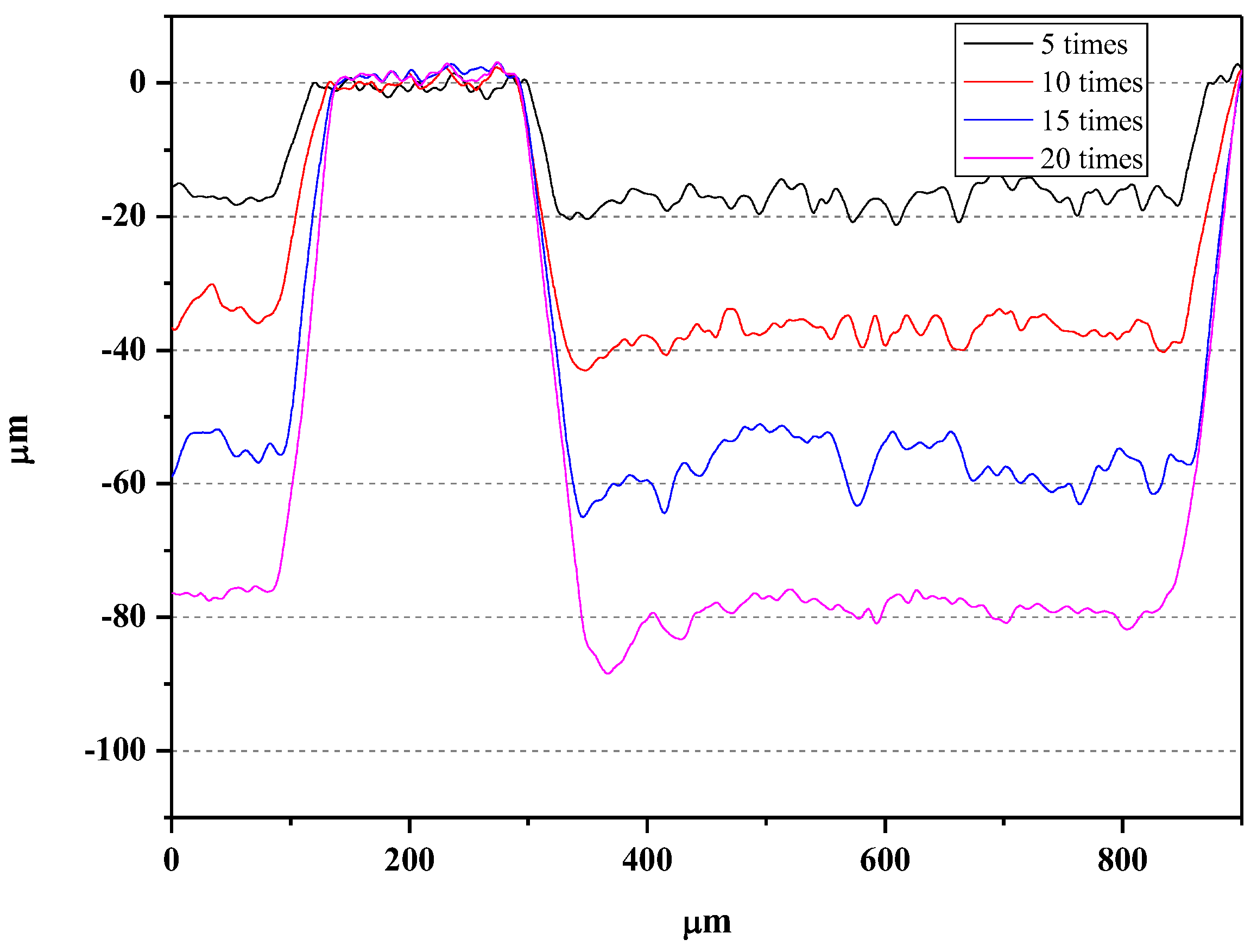

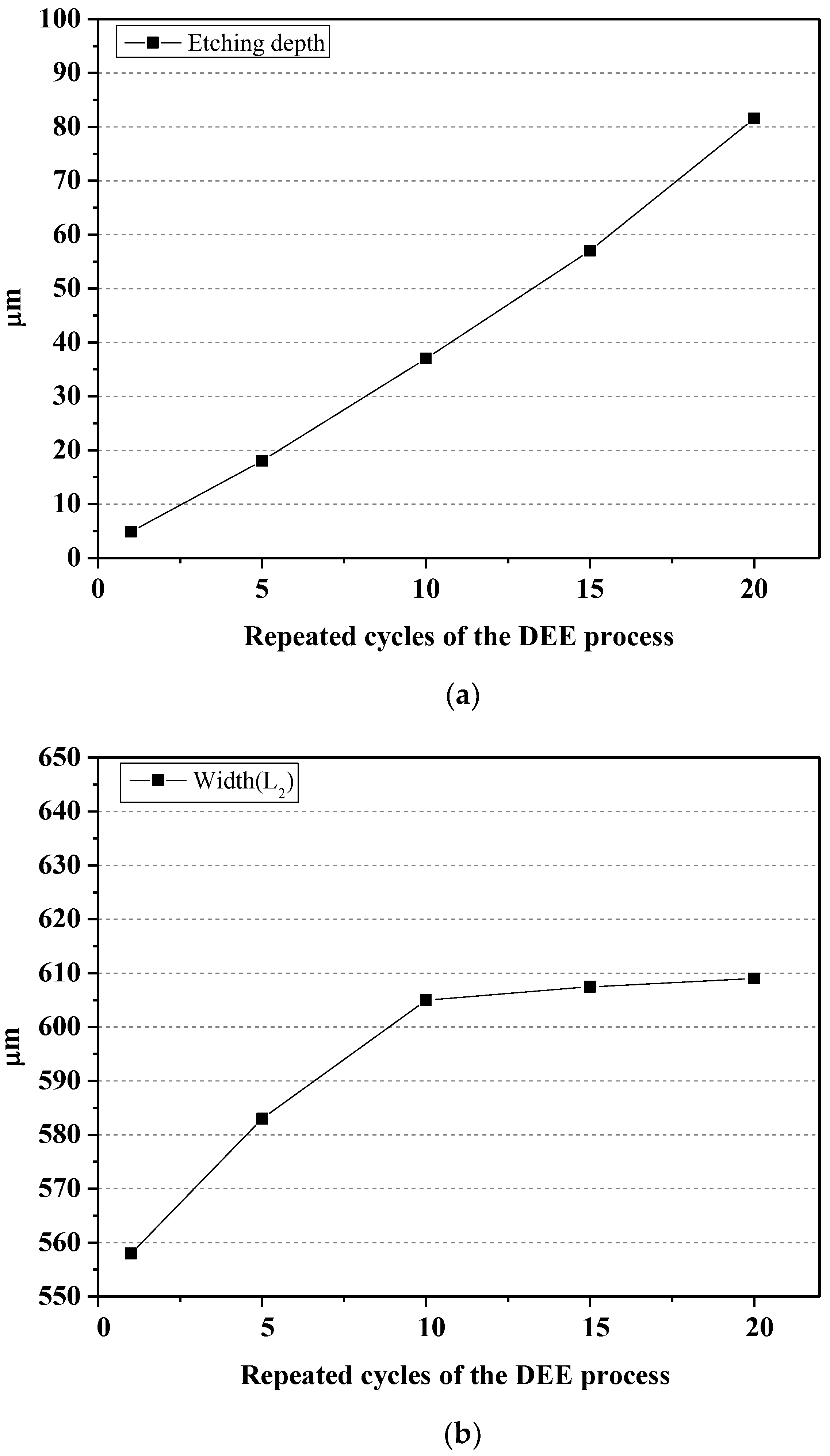

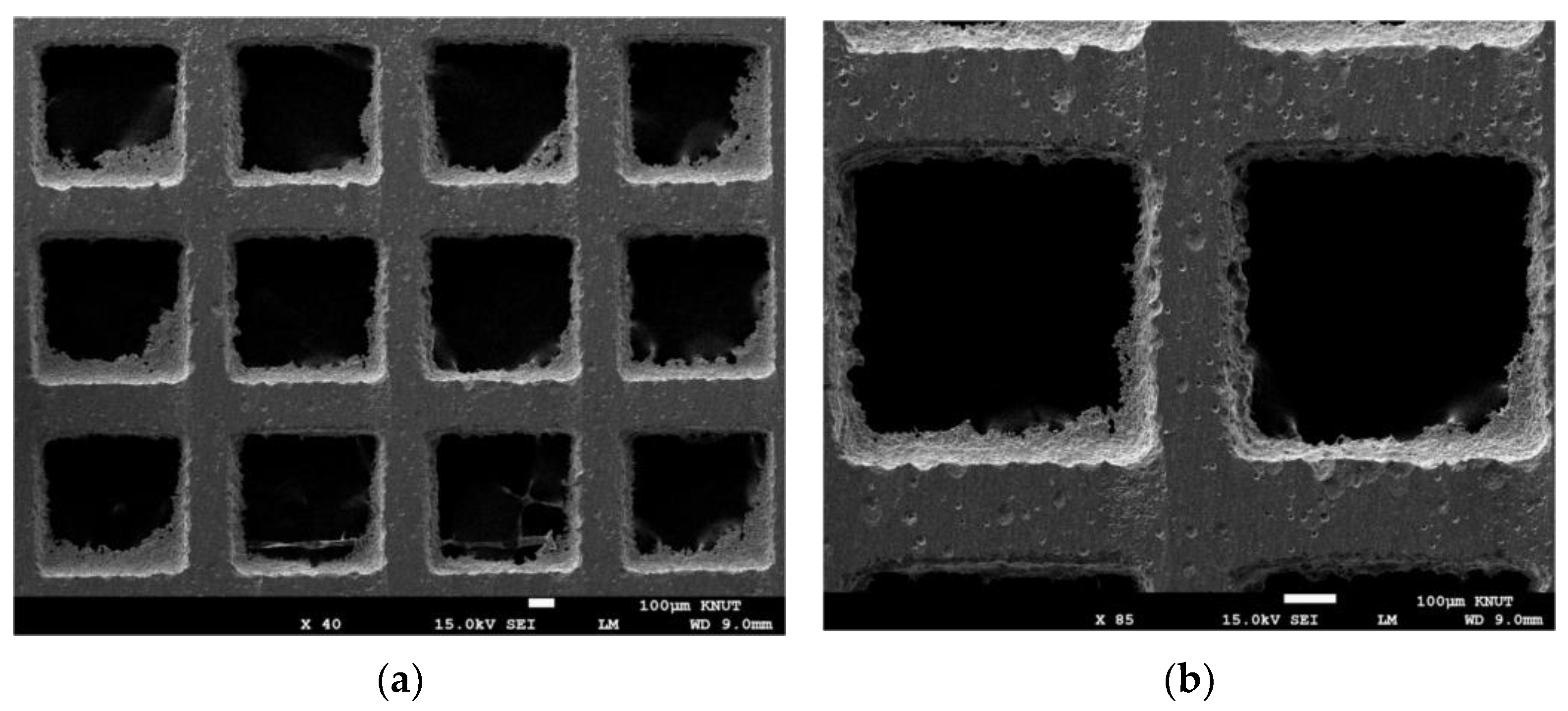

4.2. Deep Etching by the DEE process

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Datta, M.; Landolt, D. Fundamental aspects and applications of electrochemical microfabrication. Electrochim. Acta 2000, 45, 2535–2558. [Google Scholar] [CrossRef]

- Datta, M.; Harris, D. Electrochemical micromachining: An environmentally friendly, high speed processing technology. Electrochim. Acta 1997, 42, 3007–3013. [Google Scholar] [CrossRef]

- Datta, M.; Harris, D. Electrochemical processing technologies in chip fabrication: Challenges and opportunities. Electrochim. Acta 2003, 48, 2975–2985. [Google Scholar] [CrossRef]

- Park, M.S.; Chu, C.N. Micro-electrochemical machining using multiple tool electrodes. J. Micromech. Microeng. 2007, 17, 1451. [Google Scholar] [CrossRef]

- Duan, W.; Mei, X.; Fan, Z.; Li, J.; Wang, K.; Zhang, Y. Electrochemical corrosion assisted laser drilling of micro-hole without recast layer. Optik 2020, 202, 163577. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, J. Laser drilling assisted with jet electrochemical machining for the minimization of recast and spatter. Int. J. Adv. Manuf. Technol. 2012, 62, 1055–1062. [Google Scholar] [CrossRef]

- Zhang, H.; Gao, P.; Xu, J.; Yuan, L. Effect of Electrochemical Dissolving in Laser Drilling Assisted with Jet Electrochemical Machining. Int. J. Electrochem. Sci. 2021, 16, 21056. [Google Scholar] [CrossRef]

- Park, M.S.; Kim, B.S. Fabrication of Glass Microstructure Using Laser-Induced Backside Wet Etching. Trans. KSME A 2014, 38, 967–972. [Google Scholar]

- Shin, H.S.; Chung, D.K.; Park, M.S.; Kim, B.H.; Chu, C.N. Electrochemical etching of stainless steel through laser masking. J. Micromech. Microeng. 2010, 20, 055030. [Google Scholar] [CrossRef]

- Shin, H.S.; Park, M.S.; Chu, C.N. Electrochemical etching using laser masking for multilayered structures on stainless steel. CIRP Ann-Manuf. Technol. 2010, 59, 585–588. [Google Scholar] [CrossRef]

- Chen, X.; Fang, X.L. Reduction of undercutting in electrochemical micro-machining of micro-dimple arrays by utilizing oxygen produced at the anode. Surf. Coat. Technol. 2015, 277, 44–51. [Google Scholar] [CrossRef]

- Parasuraman, J.; Summanwar, A.; Marty, F.; Basset, P.; Angelescue, D.; Bourouina, T. Deep reactive ion etching of sub-micrometer trenches with ultra high aspect ratio. Microelectron. Eng. 2014, 113, 35–39. [Google Scholar] [CrossRef]

- Shin, H.S. E Selective Electrochemical Etching of Stainless Steel Using a Laser-Patterned Copper Layer. Int. J. Precis. Eng. Manuf. 2019, 20, 711–716. [Google Scholar] [CrossRef]

| Characteristics | Value |

|---|---|

| Laser source | ND:YAG |

| Mode of operation | Pulsed |

| Pulse duration | 100 ns |

| Average power | ≤20 W |

| Pulse repetition rate | ≤80 kHz |

| Moving speed of spot | 600 mm/s |

| Central emission wavelength | 1064 nm |

| Spot size | 50 μm |

| Line spacing of beam spot | 10 μm |

| Characteristics | Value |

|---|---|

| Average power | 4 W |

| Pulse repetition rate | 80 kHz |

| Moving speed of spot | 600 mm/s |

| Line spacing of beam spot | 10 μm |

| Number of repeated laser patterning | 3 times |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, H.-S. Deep Electrochemical Etching of Stainless Steel Using a Deposited Copper Layer. Appl. Sci. 2022, 12, 12473. https://doi.org/10.3390/app122312473

Shin H-S. Deep Electrochemical Etching of Stainless Steel Using a Deposited Copper Layer. Applied Sciences. 2022; 12(23):12473. https://doi.org/10.3390/app122312473

Chicago/Turabian StyleShin, Hong-Shik. 2022. "Deep Electrochemical Etching of Stainless Steel Using a Deposited Copper Layer" Applied Sciences 12, no. 23: 12473. https://doi.org/10.3390/app122312473

APA StyleShin, H.-S. (2022). Deep Electrochemical Etching of Stainless Steel Using a Deposited Copper Layer. Applied Sciences, 12(23), 12473. https://doi.org/10.3390/app122312473