The Dependence of InAs/InAsSb Superlattice Detectors’ Spectral Response on Molecular Beam Epitaxy Growth Temperature

Abstract

:1. Introduction

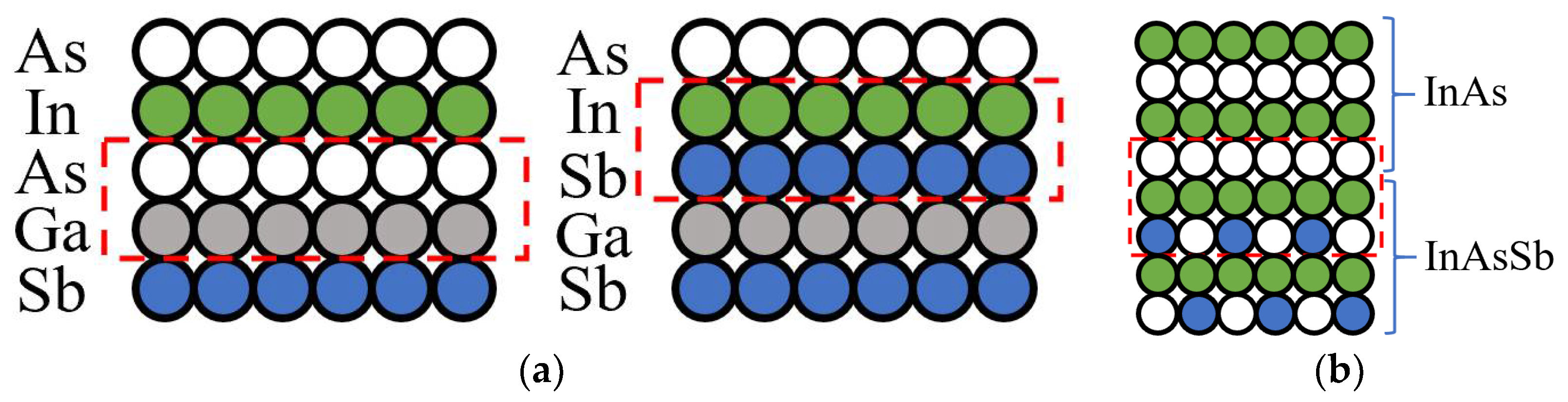

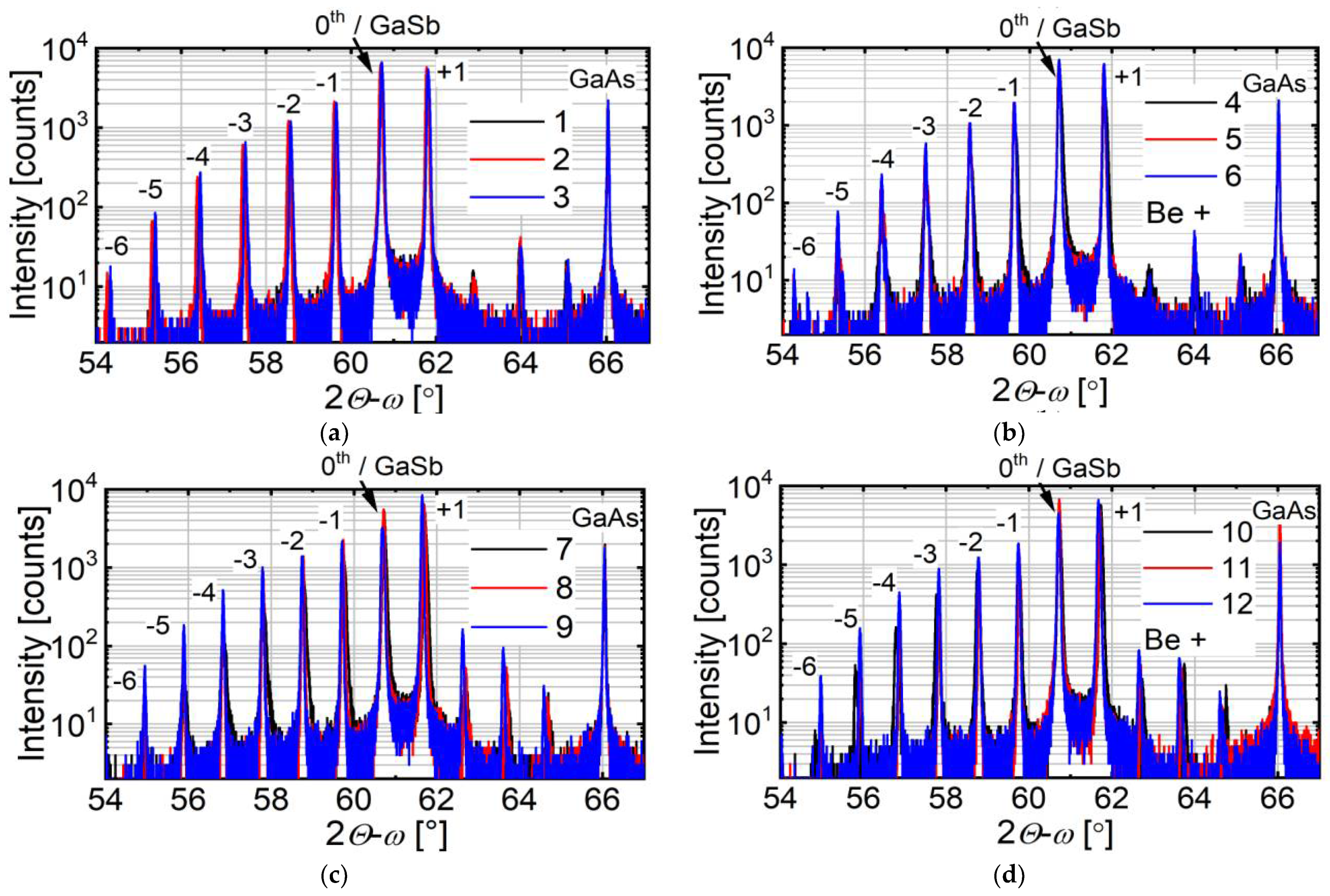

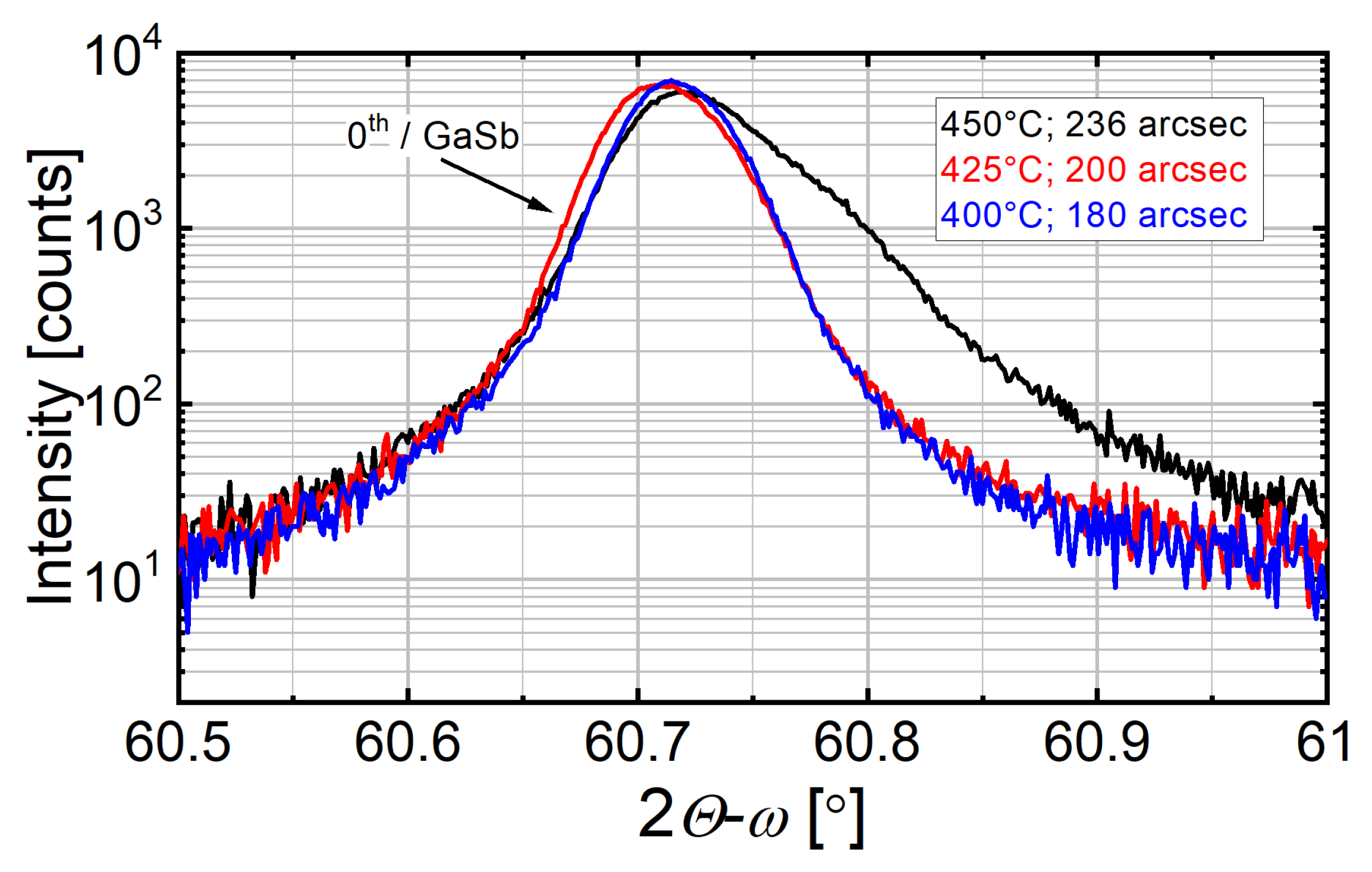

2. Material Growth Procedure

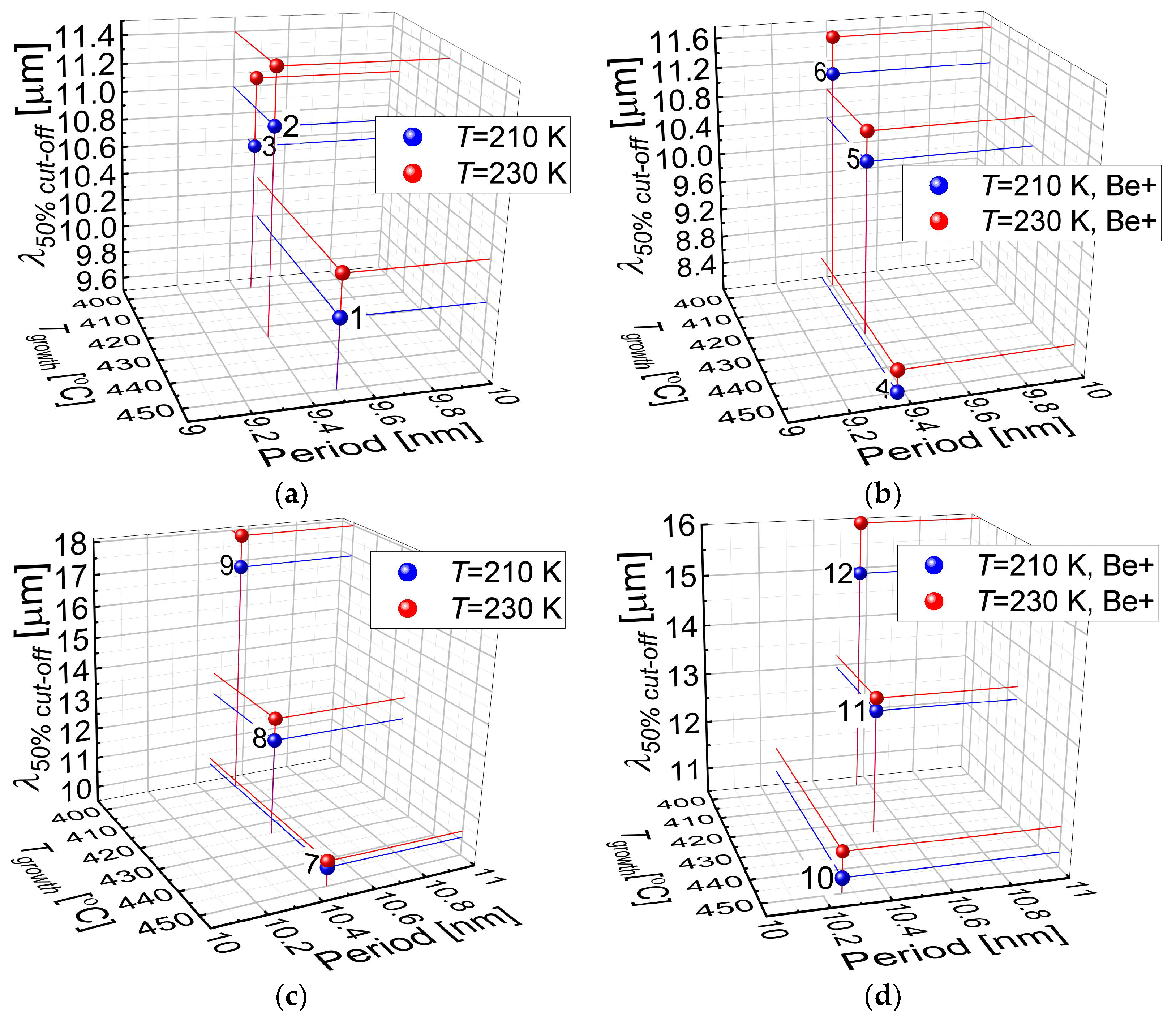

3. Optical Characterization

4. Discussion

- for 0 < z < N;

- for N < z < P.

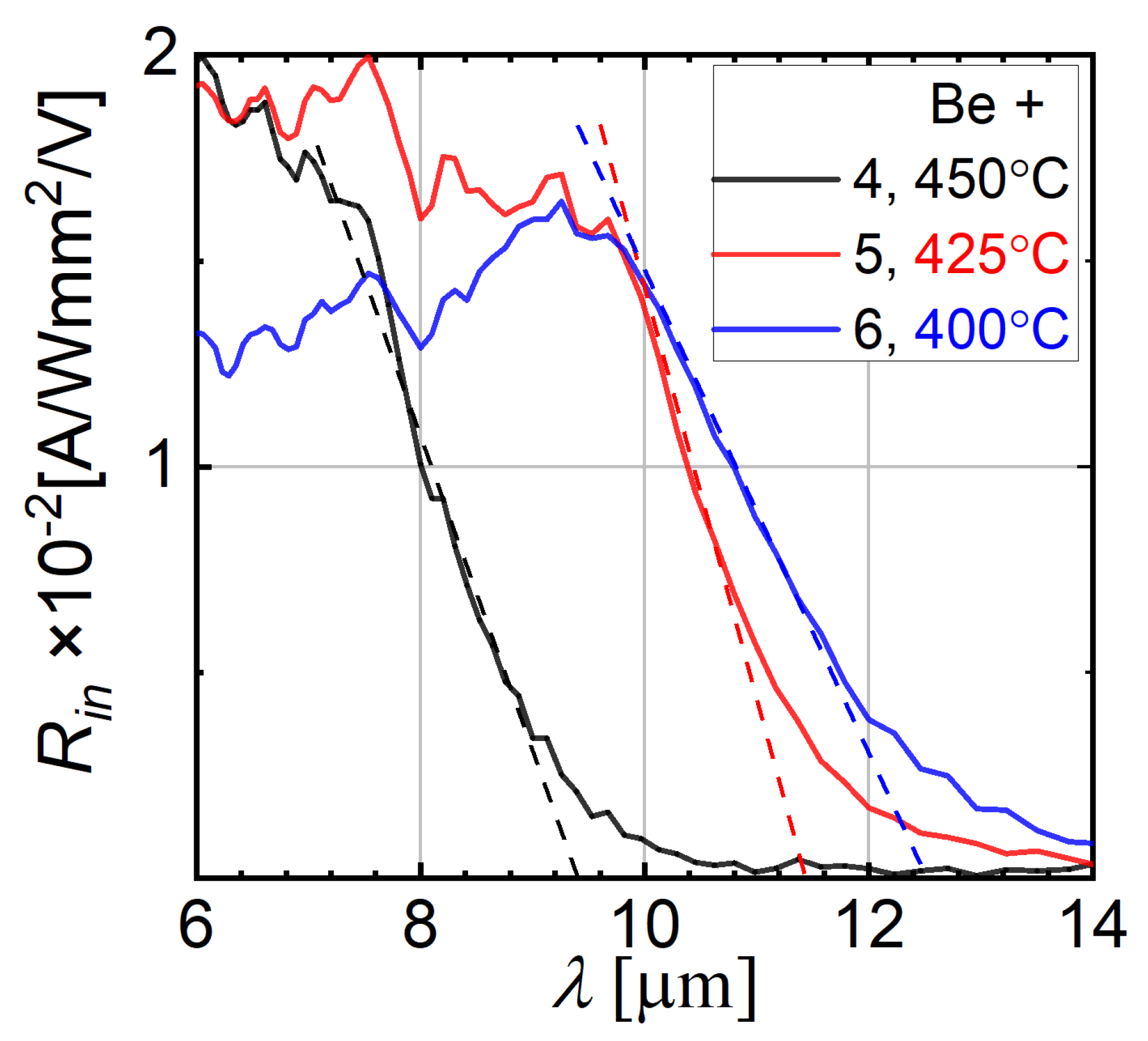

- ~12.3 μm for 1.27%—(measured~12.8 μm);

- ~10.9 μm for 0.6%—(measured~11.5 μm);

- ~9.8 μm for 0.05%—(measured~9.4 μm).

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Leroy, C.; Chorier, P.; Destefanis, G. LWIR and VLWIR MCT technologies and detectors development at SOFRADIR for space applications. In Proceedings of the Infrared Technology and Applications XXXVIII, Baltimore, MA, USA, 23–27 April 2012; Volume 8353. [Google Scholar]

- Sagiv, L.; Rotman, S.R.; Blumberg, D.G. Detection and identification of effluent gases by long wave infrared (LWIR) hyperspectral images. In Proceedings of the 2008 IEEE 25th Convention of Electrical and Electronics Engineers, Eilat, Israel, 3–5 December 2008; pp. 413–417. [Google Scholar]

- Esaki, L.; Tsu, R. Superlattice and Negative Differential Conductivity in Semiconductors. IBM J. Res. Dev. 1970, 14, 61–65. [Google Scholar] [CrossRef]

- Bajaj, J.; Sullivan, G.; Lee, D.; Aifer, E.; Razeghi, M. Comparison of type-II superlattice and HgCdTe infrared detector technologies. In Proceedings of the Infrared Technology and Applications XXXIII, Orlando, FL, USA, 8 June 2007; Volume 6542, p. 65420B. [Google Scholar]

- Benyahia, D.; Kubiszyn, Ł.; Michalczewski, K.; Kębłowski, A.; Martyniuk, P.; Piotrowski, J.; Rogalski, A. Low-temperature growth of GaSb epilayers on GaAs (001) by molecular beam epitaxy. Opto-Electron. Rev. 2016, 24, 40–45. [Google Scholar] [CrossRef]

- Ayers, J.E. Heteroepitaxy of Semiconductors: Theory, Growth, and Characterization; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Kaiser, S.; Jakob, M.; Zweck, J.; Gebhardt, W.; Ambacher, O.; Dimitrov, R.; Schremer, A.T.; Smart, J.; Shealy, J.R. Structural properties of AlGaN/GaN heterostructures on Si(111) substrates suitable for high-electron mobility transistors. J. Vac. Sci. Technol. 2000, 18, 733–740. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, C.; Wang, X.; Wu, J.; Huang, L. Interface investigation of InAs/GaSb type II superlattice for long wavelength infrared photodetectors. Infrared Phys. Technol. 2011, 113, 103573. [Google Scholar] [CrossRef]

- Michalczewski, K.; Kubiszyn, Ł.; Martyniuk, P.; Wu, C.H.; Jureńczyk, J.; Grodecki, K.; Benyahia, D.; Rogalski, A.; Piotrowski, J. Demonstration of HOT LWIR T2SLs InAs/InAsSb photodetectors grown on GaAs substrate. Infrared Phys. Technol. 2018, 95, 222–226. [Google Scholar] [CrossRef]

- Lee, G.S.; Lo, Y.; Lin, Y.F.; Bedair, S.M.; Laidig, W.D. Growth of InAs1−xSbx (0<x<1) and InSb-InAsSb superlattices by molecular beam epitaxy. Appl. Phys. Lett. 1985, 47, 1219–1221. [Google Scholar] [CrossRef]

- Sarney, W.L.; Svensson, S.P. Flux dependent Sb-incorporation during molecular beam epitaxy of InAsSb. J. Vac. Sci. Technol. B 2015, 33, 060604. [Google Scholar] [CrossRef]

- Benyahia, D.; Kubiszyn, Ł.; Michalczewski, K.; Kębłowski, A.; Martyniuk, P.; Piotrowski, J.; Rogalski, A. Interfacial misfit array technique for GaSb growth on GaAs (001) substrate by molecular beam epitaxy. J. Electron. Mater. 2018, 47, 299–304. [Google Scholar] [CrossRef] [Green Version]

- Benyahia, D.; Kubiszyn, Ł.; Michalczewski, K.; Kębłowski, A.; Martyniuk, P.; Piotrowski, J.; Rogalski, A. Optimization of the interfacial misfit array growth mode of GaSb epilayers on GaAs substrate. J. Cryst. Growth 2018, 483, 26–30. [Google Scholar] [CrossRef]

- Benyahia, D.; Kubiszyn, Ł.; Michalczewski, K.; Kębłowski, A.; Martyniuk, P.; Piotrowski, J.; Rogalski, A. p-type doping of GaSb by beryllium grown on GaAs (001) substrate by molecular beam epitaxy. JSTS J. Semicond. Technol. Sci. 2016, 16, 695–701. [Google Scholar] [CrossRef] [Green Version]

- Piotrowski, J. Uncooled operation of IR photodetectors. Opto-Electron. Rev. 2004, 12, 111–122. [Google Scholar]

- Webster, P.T.; Riordan, N.A.; Liu, S.; Steenbergen, E.H.; Synowicki, R.A.; Zhang, Y.H.; Johnson, S.R. Measurement of InAsSb bandgap energy and InAs/InAsSb band edge positions using spectroscopic ellipsometry and photoluminescence spectroscopy. J. Appl. Phys. 2015, 118, 245706. [Google Scholar] [CrossRef] [Green Version]

- Durlin, Q.; Perez, J.P.; Rossignol, R.; Rodriguez, J.B.; Cerutti, L.; Delacourt, B.; Rothman, J.; Cervera, C.; Christol, P. InAs/InAsSb superlattice structure tailored for detection of the full midwave infrared spectral domain. In Proceedings of the Quantum Sensing and Nano Electronics and Photonics XIV, San Francisco, CA, USA, 29 January–2 February 2017; Volume 10111, p. 1011112. [Google Scholar]

- Ting, D.Z.; Soibel, A.; Khoshakhlagh, A.; Keo, S.A.; Rafol, S.B.; Fisher, A.M.; Pepper, B.J.; Luong, E.M.; Hill, C.J.; Gunapala, S.D. Advances in III-V semiconductor infrared absorbers and detectors. Infrared Phys. Technol. 2019, 97, 210–216. [Google Scholar] [CrossRef]

- Liu, S.; Li, H.; Cellek, O.O.; Ding, D.; Shen, X.M.; Lin, Z.Y.; Steenbergen, E.H.; Fan, J.; He, Z.Y.; Lu, J.; et al. Impact of substrate temperature on the structural and optical properties of strain-balanced InAs/InAsSb type-II superlattices grown by molecular beam epitaxy. Appl. Phys. Lett. 2013, 102, 071903. [Google Scholar] [CrossRef]

- Haugan, H.J.; Mahalingam, K.; Szmulowicz, F.; Brown, G.J. Quantitative study of the effect of deposition temperature on antimony segregation in gallium free InAs/InAsSb superlattices. J. Cryst. Growth 2016, 436, 134–137. [Google Scholar] [CrossRef]

- Wood, M.R.; Kanedy, K.; Lopez, F.; Weimer, M.; Klem, J.F.; Hawkins, S.D.; Shaner, E.A.; Kim, J.K. Monolayer-by-monolayer compositional analysis of InAs/InAsSb superlattices with cross-sectional STM. J. Cryst. Growth 2015, 425, 110–114. [Google Scholar] [CrossRef]

- Kim, H.; Meng, Y.; Klem, J.F.; Hawkins, S.D.; Kim, J.K.; Zuo, J.M. Sb-induced strain fluctuations in a strained layer superlattice of InAs/InAsSb. J. Appl. Phys. 2018, 123, 161521. [Google Scholar] [CrossRef]

- Muraki, K.; Fukatsu, S.; Shiraki, Y.; Ito, R. Surface segregation of in atoms during molecular beam epitaxy and its influence on the energy levels in InGaAs/GaAs quantum wells. Appl. Phys. Lett. 1992, 61, 557–559. [Google Scholar] [CrossRef]

- Kotulak, N.A.; Nolde, J.A.; Katz, M.B.; Twigg, M.E.; Knipling, K.E.; Lubyshev, D.; Fastenau, J.M.; Liu, A.W.K.; Aifer, E.H. Three-dimensional visualization of Sb segregation in InAs/InAsSb superlattices using atom probe tomography. J. Appl. Phys. 2020, 128, 015302. [Google Scholar] [CrossRef]

- Lu, J.; Luna, E.; Aoki, T.; Steenbergen, E.H.; Zhang, Y.H.; Smith, D.J. Evaluation of antimony segregation in InAs/InAs1−xSbx type-II superlattices grown by molecular beam epitaxy. J. Appl. Phys. 2016, 119, 095702. [Google Scholar] [CrossRef] [Green Version]

- Ciani, J.; Grein, C.H.; Irick, B.; Miao, M.; Kioussis, N. Molecular dynamics growth modeling of InAs1−xSbx based type-II superlattice. Opt. Eng. 2017, 56, 091609. [Google Scholar] [CrossRef]

- Litvinov, D.; Gerthsen, D.; Rosenauer, A.; Schowalter, M.; Passow, T.; Feinäugle, P.; Hetterich, M. Transmission electron microscopy investigation of segregation and critical floating-layer content of indium for island formation in InxGa1−xAs. Phys. Rev. B 2006, 74, 165306. [Google Scholar] [CrossRef] [Green Version]

- Steenbergen, E.H.; Nunna, K.; Ouyang, L.; Ullrich, B.; Huffaker, D.L.; Smith, D.J.; Zhang, Y.H. Strain-balanced InAs/InAs1-xSbx type-II superlattices grown by molecular beam epitaxy on GaSb substrates. J. Vac. Sci. Technol. 2012, 30, 02B107. [Google Scholar] [CrossRef]

- Steenbergen, E.H. Strain-balanced InAs-InAsSb Type-II Superlattices on GaSb Substrates for Infrared Photodetector Applications. Ph.D. Thesis, Arizona State University, Tempe, AZ, USA, 2012. [Google Scholar]

- Ting, D.Z.; Rafol, S.R.; Khoshakhlagh, A.; Soibel, A.; Keo, S.A.; Fisher, A.M.; Pepper, B.J.; Hill, C.J.; Gunapala, S.D. InAs/InAsSb Type-II Strained-Layer Superlattice Infrared Photodetectors. Micromachines 2020, 11, 958. [Google Scholar] [CrossRef]

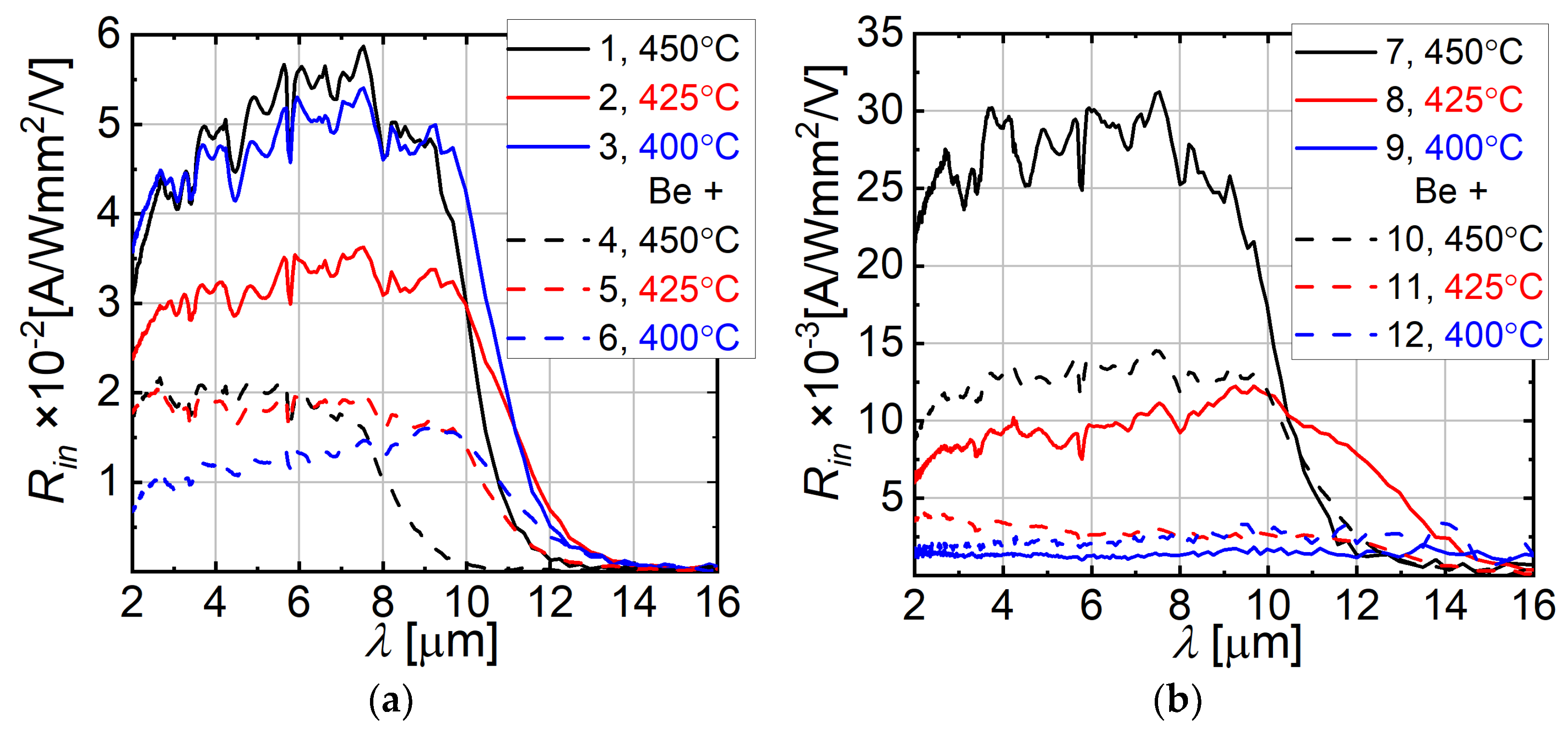

| Tgrowth [°C] | NoBe | P [nm] | xSb | l [µm] | λ50%cut-off [μm] | FWHM 0th/GaSb [arcsec] | ∆a/a GaAs-0th/GaSb [%] | |

|---|---|---|---|---|---|---|---|---|

| 210 K | 230 K | |||||||

| Set I | ||||||||

| 450 | 1- | 9.5 | 0.4 | 3.01 | 10 | 10.3 | 216 | 7.294 |

| 425 | 2- | 9.4 | 0.39 | 2.98 | 11 | 11.4 | 215 | 7.255 |

| 400 | 3- | 9.46 | 0.38 | 3.0 | 10.6 | 11.1 | 196 | 7.267 |

| 450 | 4+ | 9.38 | 0.39 | 2.97 | 8 | 8.3 | 236 | 7.279 |

| 425 | 5+ | 9.4 | 0.39 | 2.98 | 10.4 | 10.8 | 200 | 7.270 |

| 400 | 6+ | 9.4 | 0.39 | 2.98 | 11.1 | 11.6 | 180 | 7.294 |

| Set II | ||||||||

| 450 | 7- | 10.46 | 0.39 | 3.01 | 10.1 | 10.3 | 205 | 7.266 |

| 425 | 8- | 10.47 | 0.39 | 3.02 | 12.6 | 13.3 | 185 | 7.273 |

| 400 | 9- | 10.53 | 0.405 | 3.03 | 17 | 18 | 270 | 7.312 |

| 450 | 10+ | 10.26 | 0.39 | 2.95 | 10.8 | 11.3 | 190 | 7.253 |

| 425 | 11+ | 10.49 | 0.375 | 3.02 | 12.95 | 13.2 | 170 | 7.260 |

| 400 | 12+ | 10.55 | 0.395 | 3.04 | 15 | 16 | 211 | 7.278 |

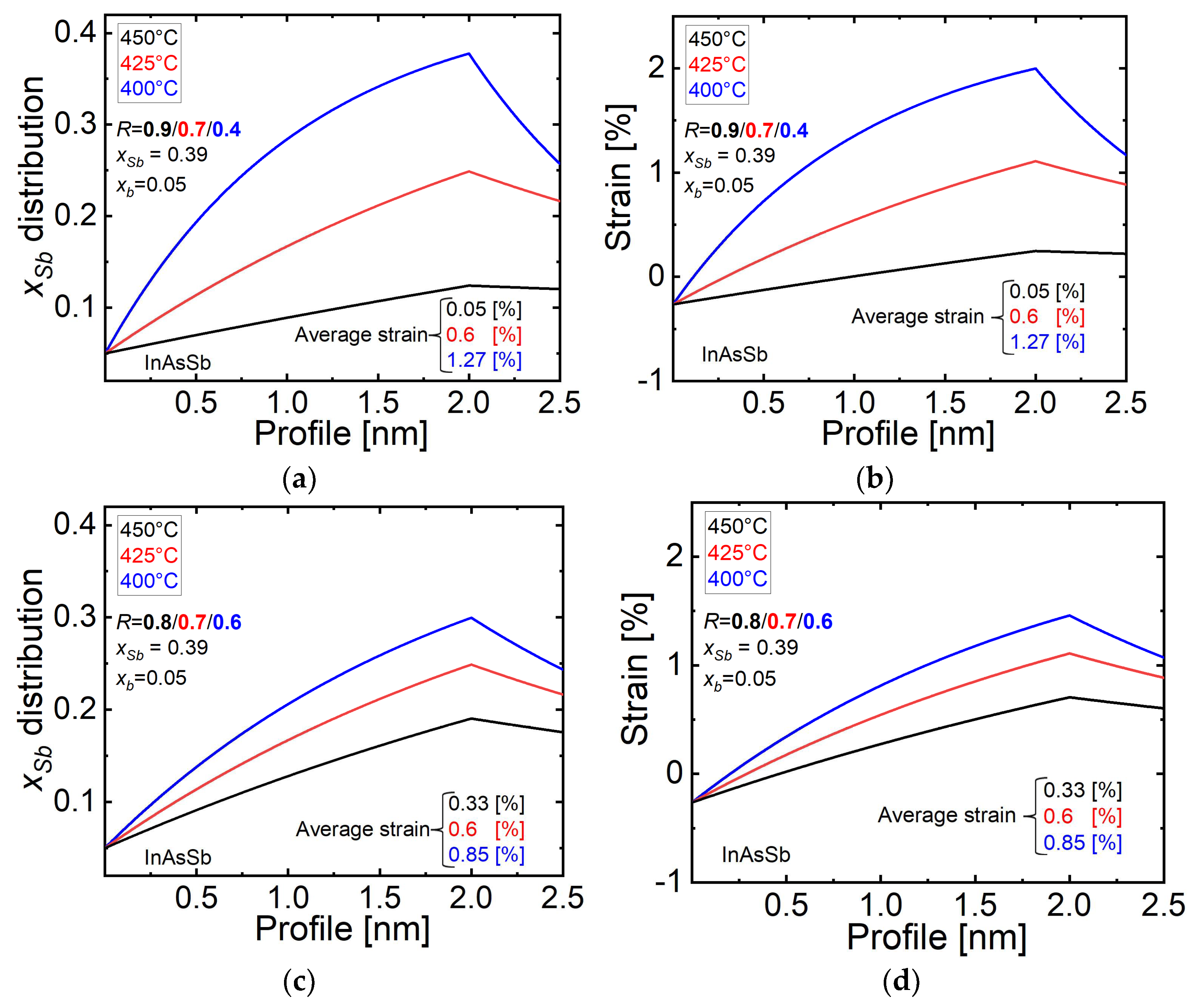

| Parameter | 450 °C | 425 °C | 400 °C |

| Sb background (xb) | ↑5% | 5% (SIMS) [9] | ↓5% |

| R | ↑0.9 | 0.7 [22] | ↓ (0.4) |

| Nominal Sb composition (x0) | 0.39 | ||

| Nominal InAsSb thickness [nm] | 2.49 | ||

| InAsSb thickness (N)-maximum xSb [nm] | 2 | ||

| Period (P) [nm] | 9.4 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Michalczewski, K.; Jureńczyk, J.; Kubiszyn, Ł.; Martyniuk, P. The Dependence of InAs/InAsSb Superlattice Detectors’ Spectral Response on Molecular Beam Epitaxy Growth Temperature. Appl. Sci. 2022, 12, 1368. https://doi.org/10.3390/app12031368

Michalczewski K, Jureńczyk J, Kubiszyn Ł, Martyniuk P. The Dependence of InAs/InAsSb Superlattice Detectors’ Spectral Response on Molecular Beam Epitaxy Growth Temperature. Applied Sciences. 2022; 12(3):1368. https://doi.org/10.3390/app12031368

Chicago/Turabian StyleMichalczewski, Krystian, Jarosław Jureńczyk, Łukasz Kubiszyn, and Piotr Martyniuk. 2022. "The Dependence of InAs/InAsSb Superlattice Detectors’ Spectral Response on Molecular Beam Epitaxy Growth Temperature" Applied Sciences 12, no. 3: 1368. https://doi.org/10.3390/app12031368