The Choice of Optical Flame Detectors for Automatic Explosion Containment Systems Based on the Results of Explosion Radiation Analysis of Methane- and Dust-Air Mixtures

Abstract

:1. Introduction

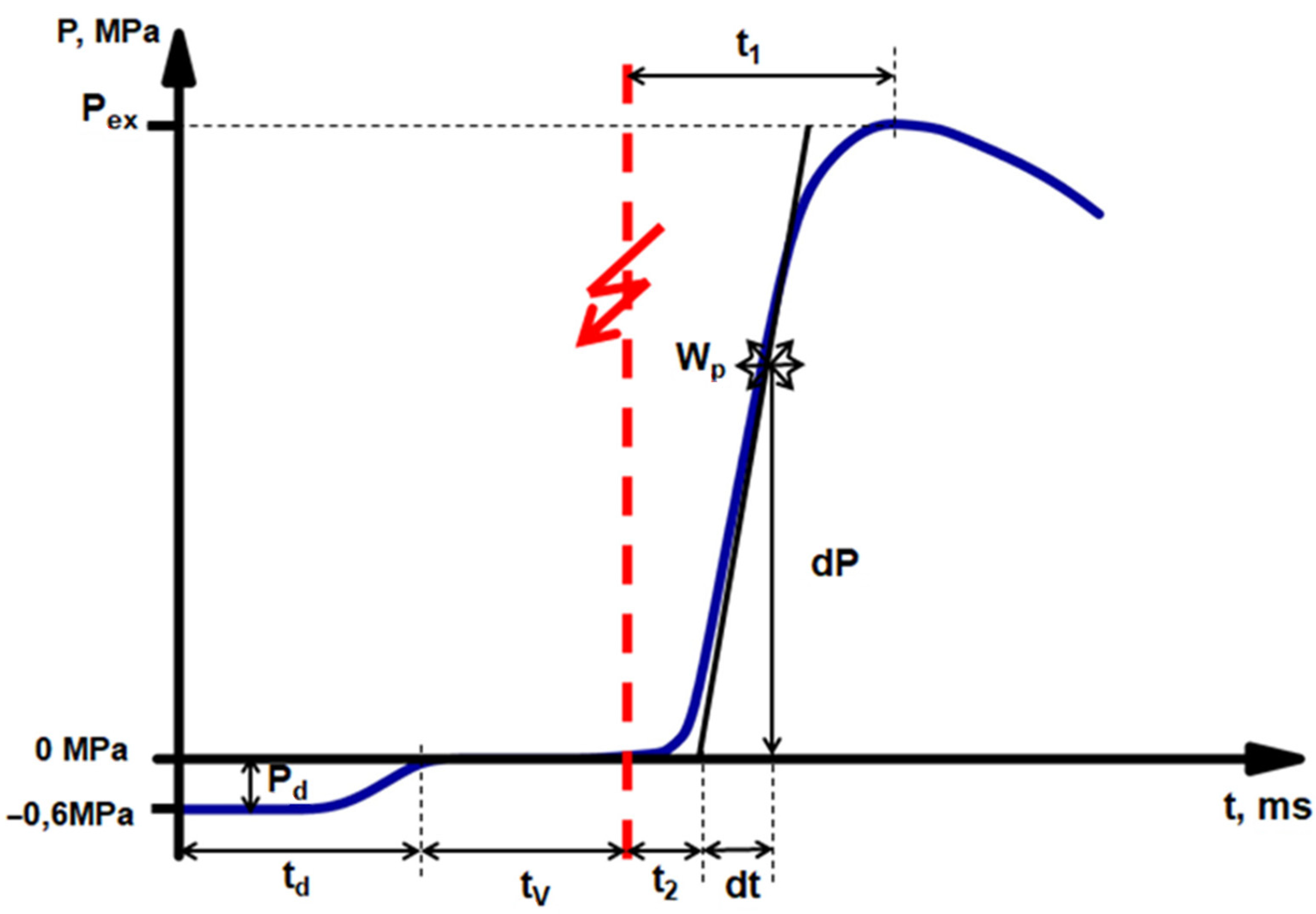

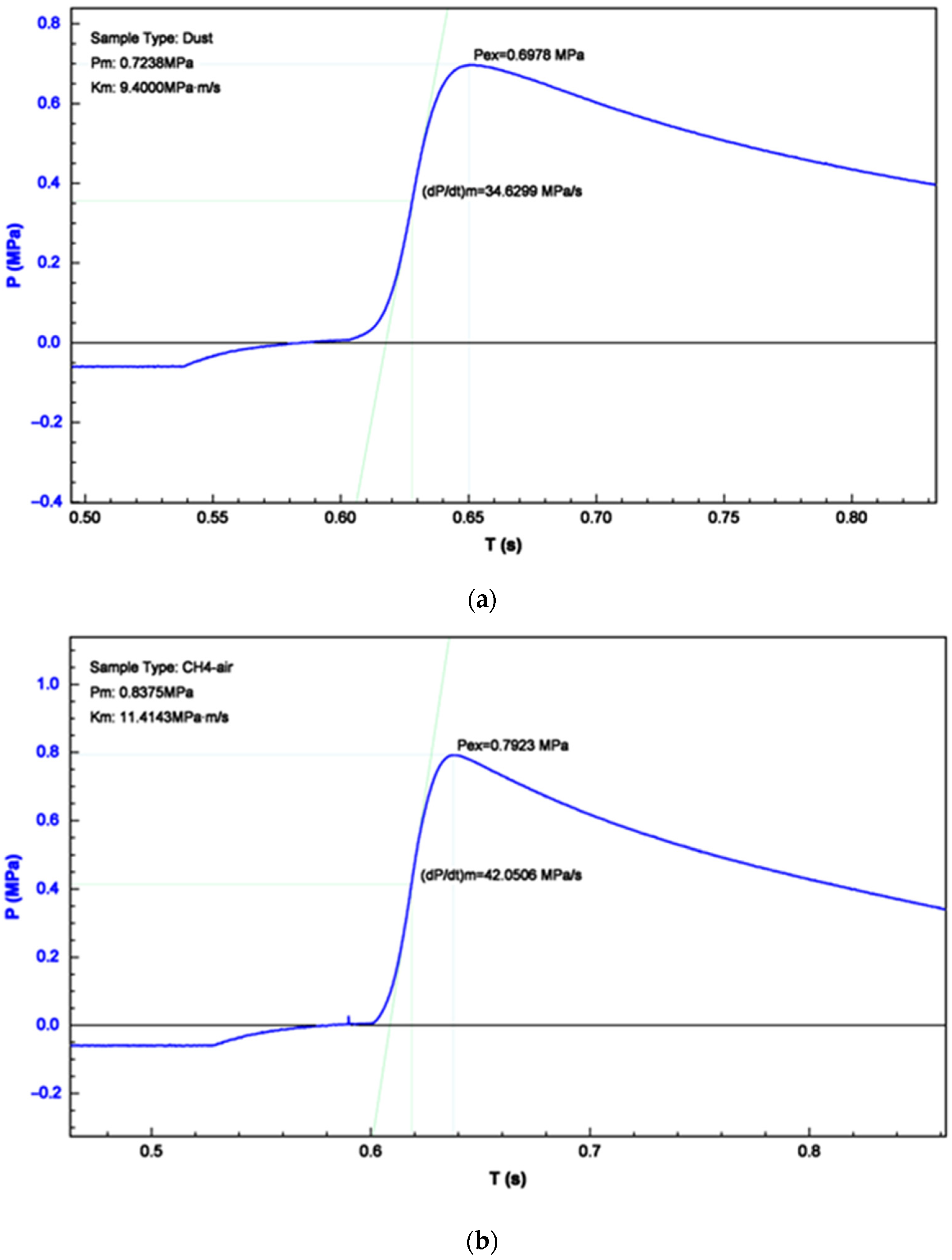

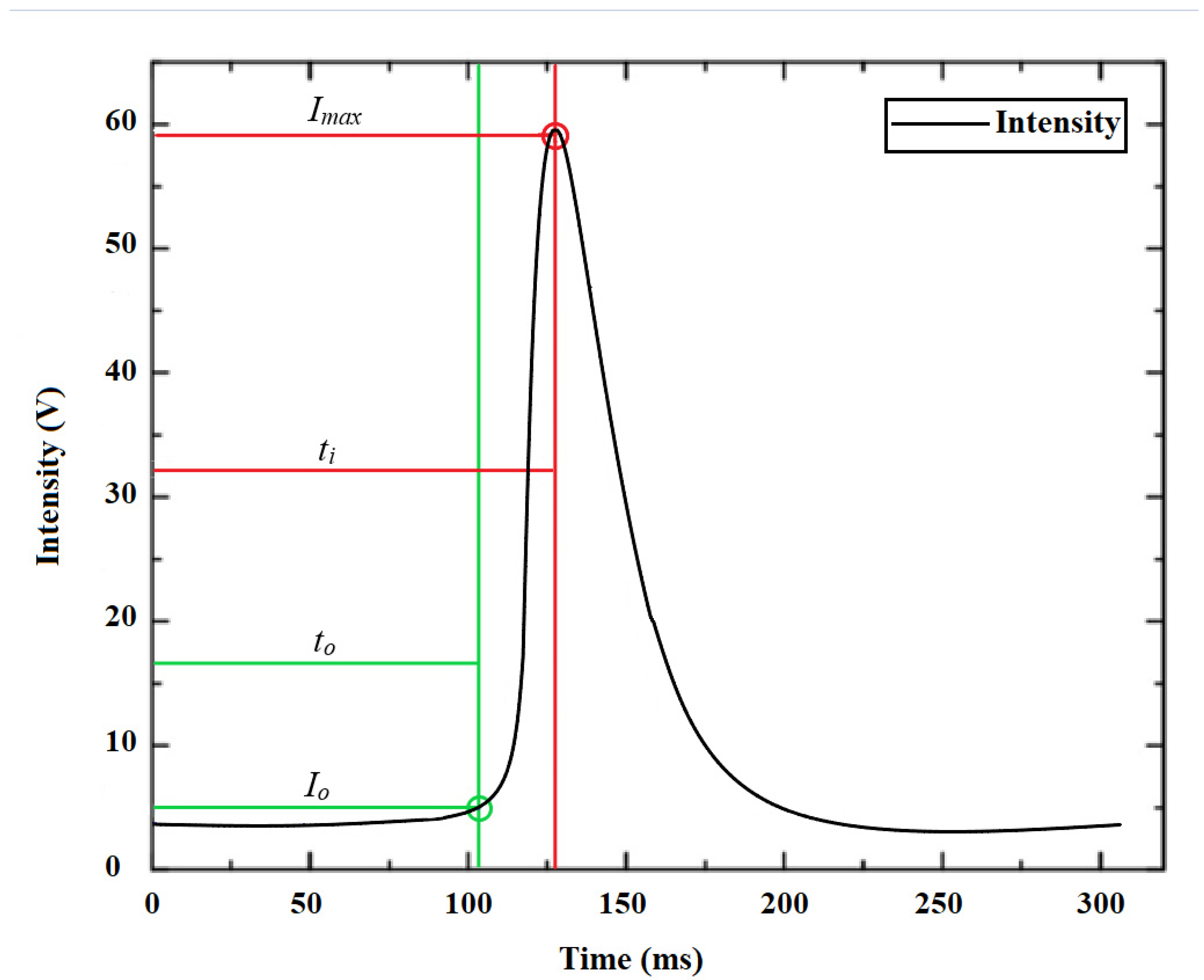

2. Materials and Methods

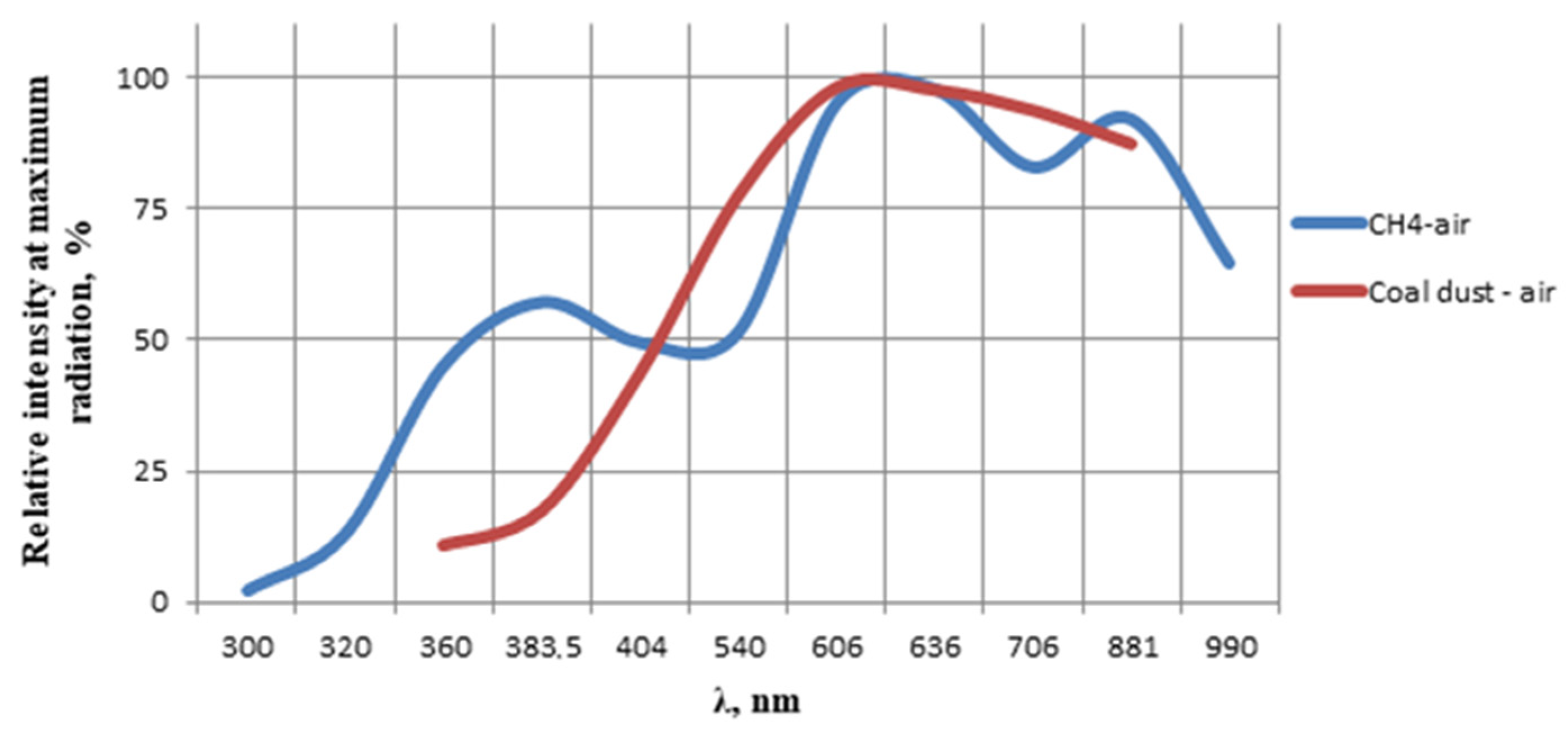

3. Results

4. Conclusions

- -

- Probability of fire detection in the absence of optical interference;

- -

- False alarm probability;

- -

- Probability of fire detection in the presence of external optical interference. The research results will help to improve the decision-making credibility of the device in its direct design.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Goncharov, E.V.; Tsirel′, S.V. Geodynamic methods for assessing methane distribution in bituminous coal deposits and measures to intensify methane fluxes during mine gas drainage. J. Min. Inst. 2016, 222, 803. [Google Scholar] [CrossRef]

- Rodionov, V.A.; Pikhonen, L.V.; Zhiharev, S.Y. Analyzing application methods of thermal analysis for evaluation of explosive properties of Sokolovsky deposit coal. Proc. Tula States Univ.-Sci. Earth 2017, 3, 84–93. [Google Scholar]

- Yutiaev, E.; Meshkov, A.; Popov, A.; Shabarov, A. Allocation of the geo-dynamically hazardous zones during intensive mining of flat-lying coal seams in the mines of SUEK-Kuzbass JSC. E3S Web Conf. 2019, 134, 01022. [Google Scholar] [CrossRef] [Green Version]

- Golubev, D.D. Influence of technological factors on the formation of spontaneous combustion centers in underground mining. In Scientific and Practical Studies of Raw Material Issues; CRC Press: Boca Raton, FL, USA, 2019; pp. 75–81. [Google Scholar] [CrossRef]

- Strizhenok, A.V.; Ivanov, A.V. An Advanced Technology for Stabilizing Dust Producing Surfaces of Built-Up Technogenic Massifs during Their Operation. Power Technol. Eng. 2016, 50, 240–243. [Google Scholar] [CrossRef]

- Meshkov, A.; Kazanin, O.; Sidorenko, A. Methane Emission Control at the High-Productive Longwall Panels of the Yalevsky Coal Mine. E3S Web Conf. 2020, 174, 01040. [Google Scholar] [CrossRef]

- Dmitrievich, M.R.; Alekseevich, R.V.; Borisovich, S.V. Methodological Approach to Issue of Researching Dust-Explosion Protection of Mine Workings of Coal Mines. Int. J. Civ. Eng. Technol. 2019, 10, 1154–1161. [Google Scholar]

- Kabanov, E.I.; Korshunov, G.I.; Magomet, R.D. Quantitative risk assessment of miners injury during explosions of methane-dust-air mixtures in underground workings. J. Appl. Sci. Eng. 2020, 24, 105–110. [Google Scholar]

- Smirnyakov, V.; Smirnyakova, V.; Pekarchuk, D.; Orlov, F. Analysis of methane and dust explosions in modern coal mines in Russia. Int. J. Civ. Eng. Technol. 2019, 10, 1917–1929. [Google Scholar]

- Koteleva, N.; Kuznetsov, V.; Vasilyeva, N. A Simulator for Educating the Digital Technologies Skills in Industry. Part One. Dynamic Simulation of Technological Processes. Appl. Sci. 2021, 11, 10885. [Google Scholar] [CrossRef]

- Shevtsov, N. Vzryvozaschita gornyh vyrabotok: Uchebnoe posobie dlya vuzov. In Explosion Mining: A Manual for Schools, 2nd ed.; Nord-Press: Donetsk, Russian, 2002. [Google Scholar]

- Vasil’ev, A.A. Estimates of the excitation conditions and extinction of blast waves during mine explosions. Bull. Res. Cent. Saf. Coal Ind. 2016, 2, 91–105. [Google Scholar]

- Necepljaev, M.I. Bor’ba so vzryvami ugol’noj pyli v shahtah. In Fighting Coal Dust Explosions in Mines; Nedra: Moscow, Russian, 1992; p. 298. [Google Scholar]

- Sidorenko, A.I. Pyrometric sensor with optical shutters for determining the two-dimensional coordinates of the explosion center. Vestn. Nauchnogo Cent. be-Zopasnosti Rabot Ugol’noj Promyshlennosti 2013, 1, 98–104. [Google Scholar]

- Ajruni, A.T.; Klebanov, F.S.; Smirnov, O.V. Vzryvoopasnost’ ugol’nyh shaht. In Explosive-Ness of Coal Mines; Gornoe delo OOO Kimmerijskij Centr: Moscow, Russian, 2011; p. 264. [Google Scholar]

- Zaharenko, D.M. Problemy rannego obnaruzhenija ochagov pozharov i vzryvov ugol’noj pyli. Problems of early detection of fires and coal dust explosions], Problems of using Kansk-Achinsk coal at power plants: Materials. In Proceedings of the All-Russian Scientific and Practical Conference, Krasnoyarsk, Russian, 21–23 November 2000; pp. 141–149. [Google Scholar]

- Pavlov, A.N. Optiko-jelektronnaja sistema opredelenija trehmernyh koordinat ochaga vzryva v gazodispersnyh sistemah nachal’noj stadia [Optoelectronic system for deter-mining the three-dimensional coordinates of the explosion center in gas-dispersed systems of the initial stage]. Ph.D. Thesis, Biysk Institute of Technology, Biysk, Russian, 2010; p. 134. [Google Scholar]

- Pavlov, A.N.; Sypin, E.V. Optoelectronic system for determination of ignition center three-dimensional coordinates at initial stage. In Proceedings of the 9th International Conference and Seminar on Micro/Nanotechnologies and Electron Devices EDM’2010: Conference Proceedings, NSTU, Novosibirsk, Russian, 30 June–4 July 2010; pp. 417–419. [Google Scholar]

- Hertzberg, M.; Litton, C.D.; Donaldson, W.F.; Burgess, D. The infrared radiance and the optical detection of fires and explosions. Symp. (Int.) Combust. 1975, 15, 137–144. [Google Scholar] [CrossRef]

- Tupikina, N.Y.; Sypin, E.V.; Lisakov, S.A.; Pavlov, A.N.; Leonov, G.V. Two spectral retios optic electronic instrument operational parameters experimental test. Ind. Saf. 2015, 4, 66–72. [Google Scholar]

- Dzhigrin, A.V. Analysis of Explosion Localization Systems Operating in Coal Mines and Evaluation of the Effectiveness of Their Application. Available online: http://asvplv.ru/doc/expert_mvk.pdf (accessed on 19 January 2022).

- Kaledina, N.O.; Malashkina, V.A. Indicator assessment of the reliability of mine ventilation and degassing systems functioning. J. Min. Inst. 2021, 250, 553–561. [Google Scholar] [CrossRef]

- Vasilenko, T.A.; Kirillov, A.K.; Molchanov, A.N.; Pronskii, E.A. An NMR Study of the Ratio between Free and Sorbed Methane in the Pores of Fossil Coals. Solid Fuel Chem. 2018, 52, 361–369. [Google Scholar] [CrossRef]

- Magunov, A.N. Spektral’naja pirometrija objektov s neodnorodnoj temperaturoj. In Spectral Pyrometry of Objects with Inhomogeneous Temperature; FIZMATLIT: Moscow, Russian, 2012; p. 248. [Google Scholar]

- Walker, C.G. Handbook of Spectroscopy; Wiley-VCH GmbH: Stuttgart, Germany, 2005. [Google Scholar]

- Siwek, R. Experimental methods for the determination of explosion characteristics of combustible dust. In Proceedings of the 3-d International Symposium on Lose Prevention and Safety Pro-motion in the Process Industries, Basel, Switzerland, 15–19 September 1980; Volume 3. [Google Scholar]

- Determination of Explosion Characteristics of Dust Clouds. Part 3: Determination of the Lower Explosion Limit LEL of Dust Clouds BS EN 14034-3:2006+A1:2011. Available online: https://www.en-standard.eu/bs-en-14034-3-2006-a1-2011-determination-of-explosion-characteristics-of-dust-clouds-determination-of-the-lower-explosion-limit-lel-of-dust-clouds/ (accessed on 19 January 2022).

- Determination of Explosion Characteristics of Dust Clouds. Part 2: Determination of the Maximum Rate of Explosion Pressure rise (dP/dt)Max of Dust Clouds BS EN 14034-2:2006+A1:2011. Available online: https://www.en-standard.eu/bs-en-14034-2-2006-a1-2011-determination-of-explosion-characteristics-of-dust-clouds-determination-of-the-maximum-rate-of-explosion-pressure-rise-dp-dt-sub-m-sub-ax-of-dust-clouds/ (accessed on 19 January 2022).

- Standard Test Method for Minimum Explosible Concentration of Combustible Dusts ASTM E1515-14. Available online: https://standards.globalspec.com/std/3857038/astm-e1515-14 (accessed on 19 January 2022).

- Rodionov, V.A.; Pihkonen, L.V.; Zhiharev, S.Y. Dispersion of the g-type coal dust of the Vorgashorskoe field and its influence on the thermal destruction process. Perm J. Pet. Min. Eng. 2017, 16, 350–356. [Google Scholar] [CrossRef]

- Li, Q.; Zhai, C.; Wu, H.-J.; Lin, B.-Q.; Zhu, C. Investigation on coal dust explosion characteristics using 20 L explosion sphere vessels. J. China Coal Soc. 2011, 36, 119–124. [Google Scholar]

- Jiang, H.; Bi, M.; Huang, L.; Zhou, Y.; Gao, W. Suppression mechanism of ultrafine water mist containing phosphorus compounds in methane/coal dust explosions. Energy 2022, 239, 121987. [Google Scholar] [CrossRef]

- Konnov, A.A.; Dyakov, I.V.; De Ruyck, J. Measurement of adiabatic burning velocity in ethane–oxygen–nitrogen and in ethane–oxygen–argon mixtures. Exp. Therm. Fluid Sci. 2003, 27, 379–384. [Google Scholar] [CrossRef]

- Chen, C.-F.; Shu, C.-M.; Wu, H.-C.; Ho, H.-H.; Ho, S.-P. Ethylene gas explosion analysis under oxygen-enriched atmospheres in a 20-liter spherical vessel. J. Loss Prev. Process Ind. 2017, 49, 519–524. [Google Scholar] [CrossRef]

- Wang, T.; Luo, Z.; Wen, H.; Zhang, J.; Mao, W.; Cheng, F.; Zhao, J.; Su, B.; Li, R.; Deng, J. Experimental study on the explosion and flame emission behaviors of methane-ethylene-air mixtures. J. Loss Prev. Process Ind. 2019, 60, 183–194. [Google Scholar] [CrossRef]

- Burdjugov, S.I.; Karmanov, V.V.; Halturin, V.G. Vibrational structure of the Swann bands of the electronic spectrum of radical C2. In Chemical Physics and Mesoscopy; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Wu, J.; Yan, Z.; Ye, S.; Yang, X.; Hu, D. Micro-mechanism of carbon generation from benzene’s quick reaction using monochrometer. Acta Opt. Sin. 2007, 27, 1873–1876. [Google Scholar]

- Wang, H.; Sheen, D.A. Combustion kinetic model uncertainty quantification, propagation and minimization. Prog. Energy Combust. Sci. 2015, 47, 1–31. [Google Scholar] [CrossRef] [Green Version]

- Abiev, Z.A.; Rodionov, V.A.; Paramonov, G.P.; Chernobaj, V.I. Methodology for studying the effect of inhibitory and phlegmatizing additives on the flammability and explo-siveness of coal dust. Gorn. Inf.-Analiticheskij Bjulleteń 2018, 5, 26–34. [Google Scholar] [CrossRef]

- Snegirev, A.Y.; Tsoy, A.S. Treatment of local extinction in CFD fire modeling. Proc. Combust. Inst. 2015, 35, 2519–2526. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khokhlov, S.; Abiev, Z.; Makkoev, V. The Choice of Optical Flame Detectors for Automatic Explosion Containment Systems Based on the Results of Explosion Radiation Analysis of Methane- and Dust-Air Mixtures. Appl. Sci. 2022, 12, 1515. https://doi.org/10.3390/app12031515

Khokhlov S, Abiev Z, Makkoev V. The Choice of Optical Flame Detectors for Automatic Explosion Containment Systems Based on the Results of Explosion Radiation Analysis of Methane- and Dust-Air Mixtures. Applied Sciences. 2022; 12(3):1515. https://doi.org/10.3390/app12031515

Chicago/Turabian StyleKhokhlov, Sergey, Zaur Abiev, and Viacheslav Makkoev. 2022. "The Choice of Optical Flame Detectors for Automatic Explosion Containment Systems Based on the Results of Explosion Radiation Analysis of Methane- and Dust-Air Mixtures" Applied Sciences 12, no. 3: 1515. https://doi.org/10.3390/app12031515

APA StyleKhokhlov, S., Abiev, Z., & Makkoev, V. (2022). The Choice of Optical Flame Detectors for Automatic Explosion Containment Systems Based on the Results of Explosion Radiation Analysis of Methane- and Dust-Air Mixtures. Applied Sciences, 12(3), 1515. https://doi.org/10.3390/app12031515