Dynamic Response of an Offshore Floating Wind Turbine at Accidental Limit States—Mooring Failure Event

Abstract

:1. Introduction

2. Analytical Modelling

2.1. Governing Equation

2.2. Wind Load

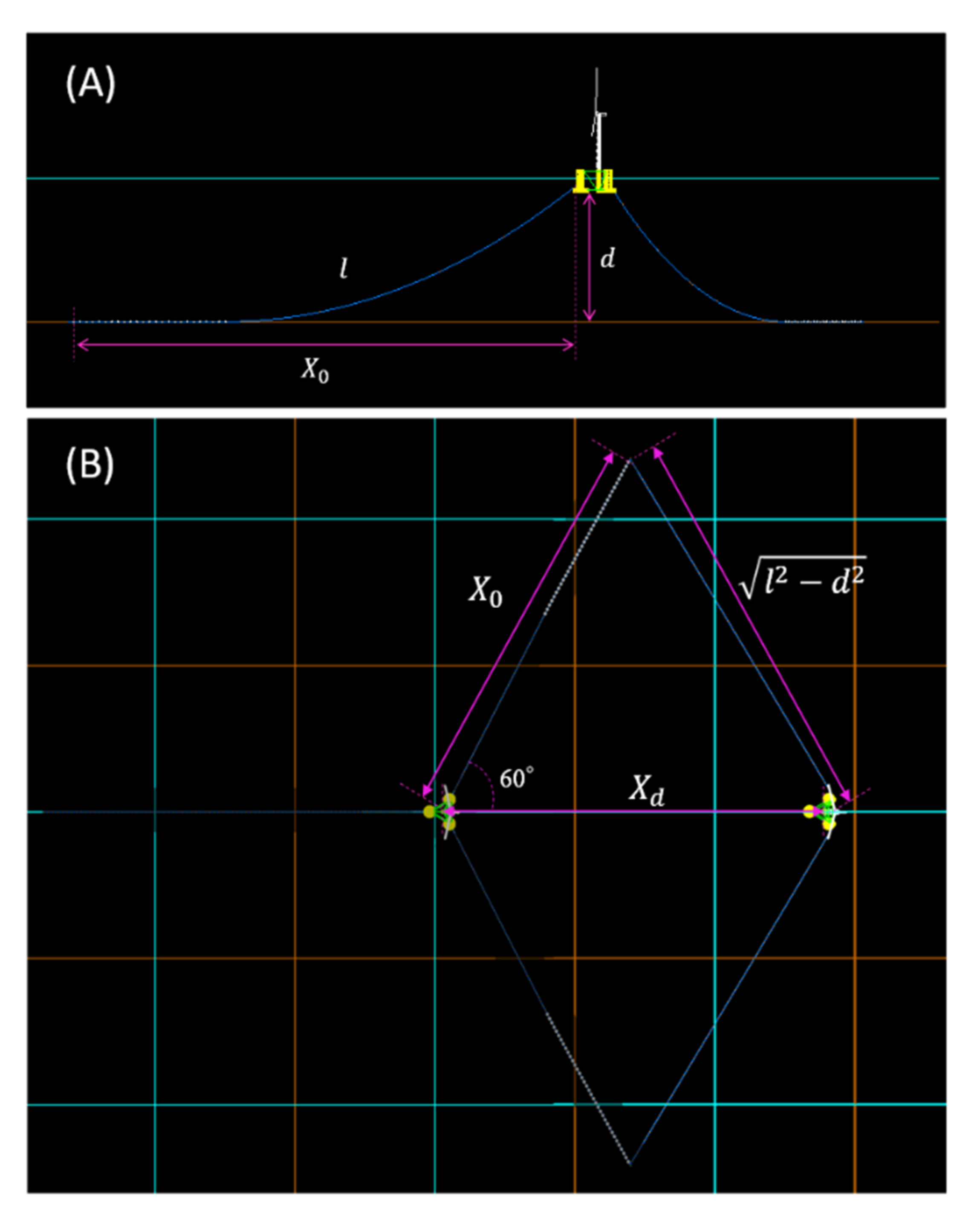

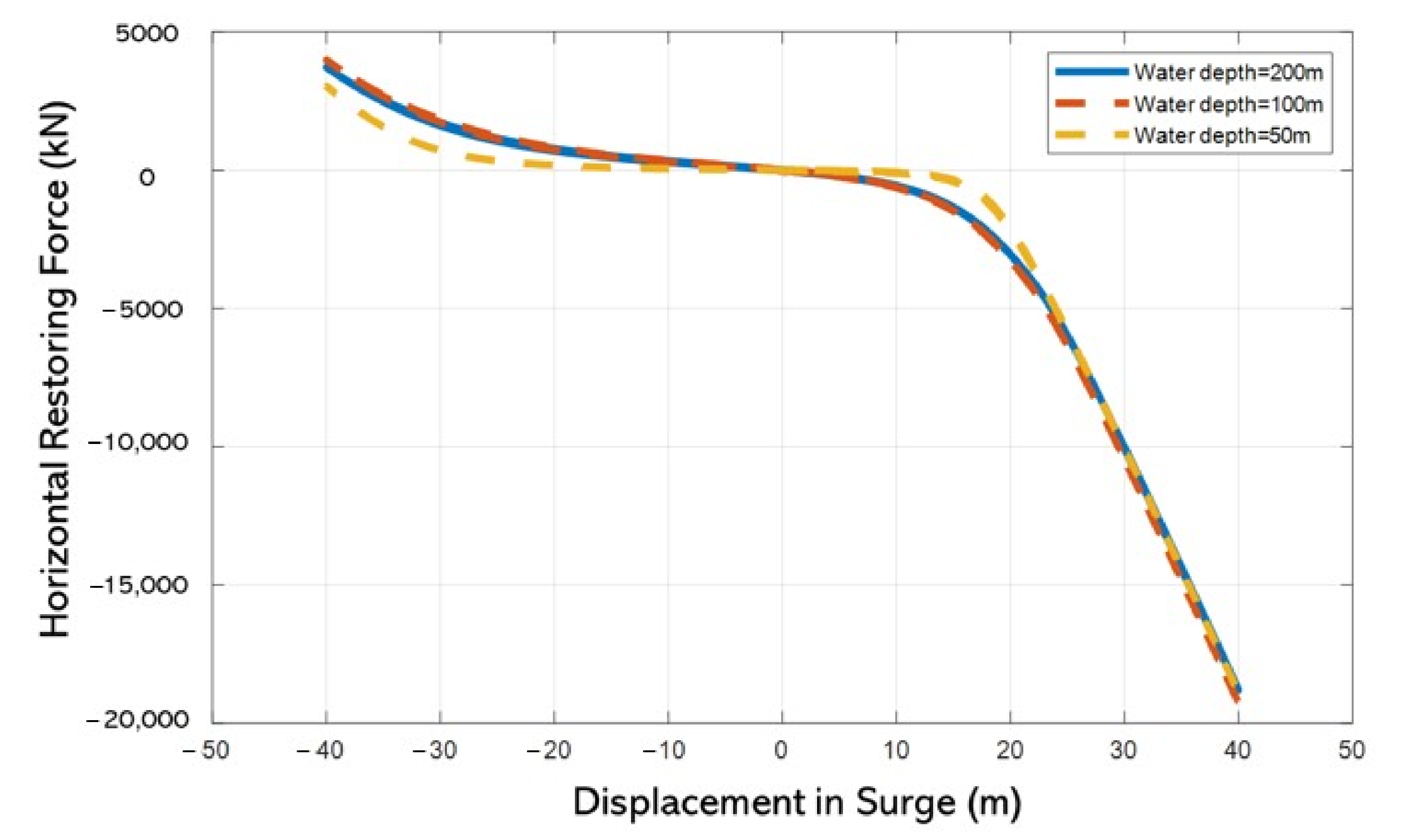

2.3. Mooring Load

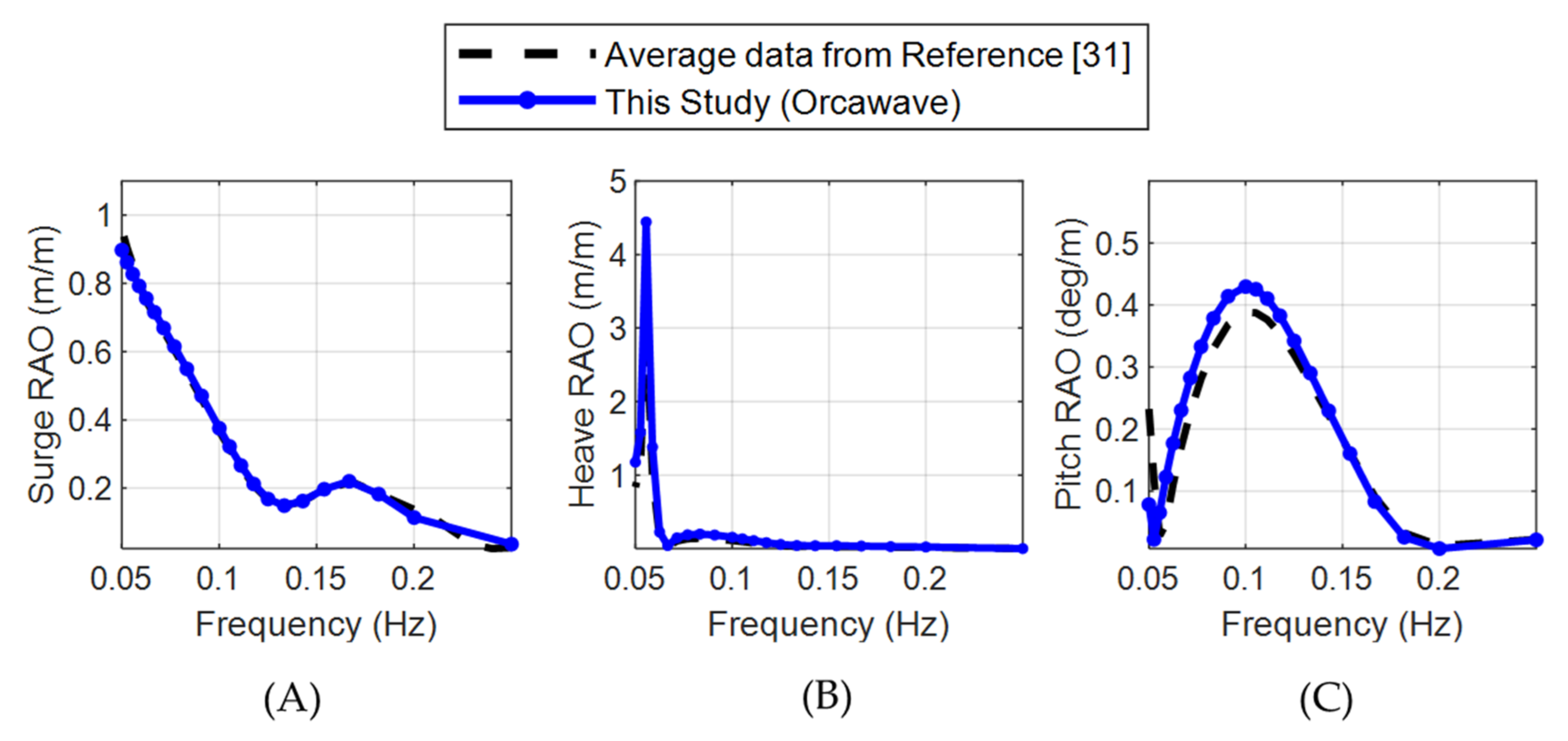

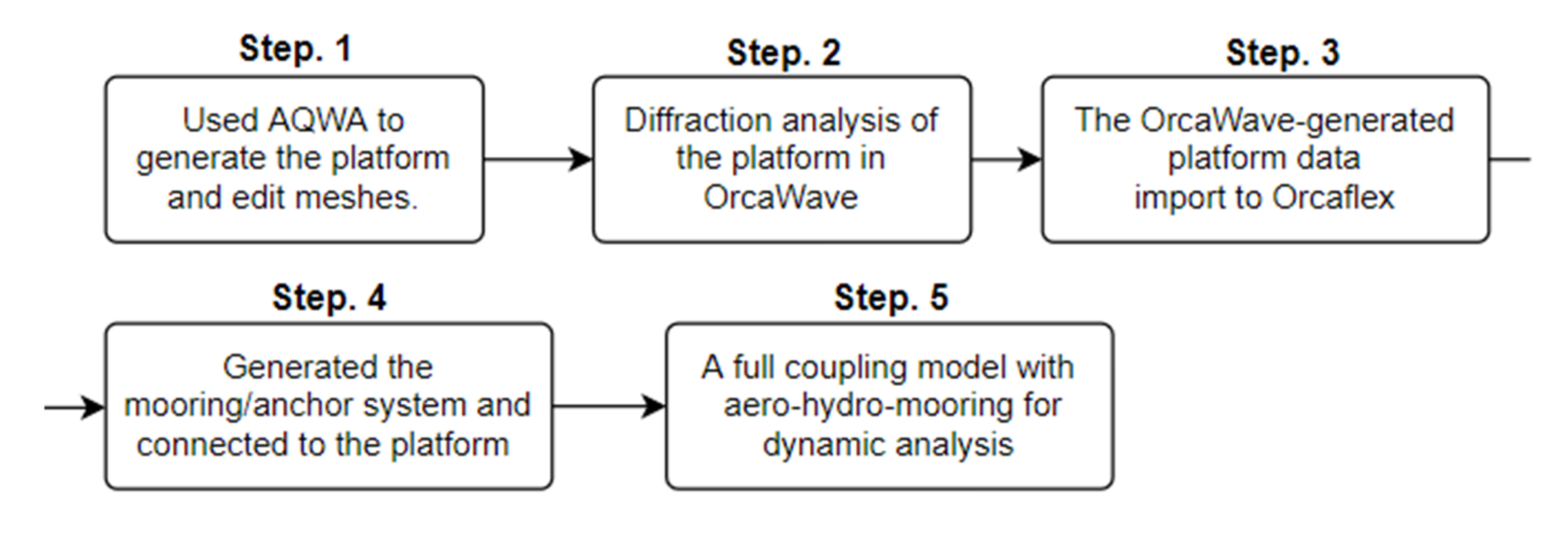

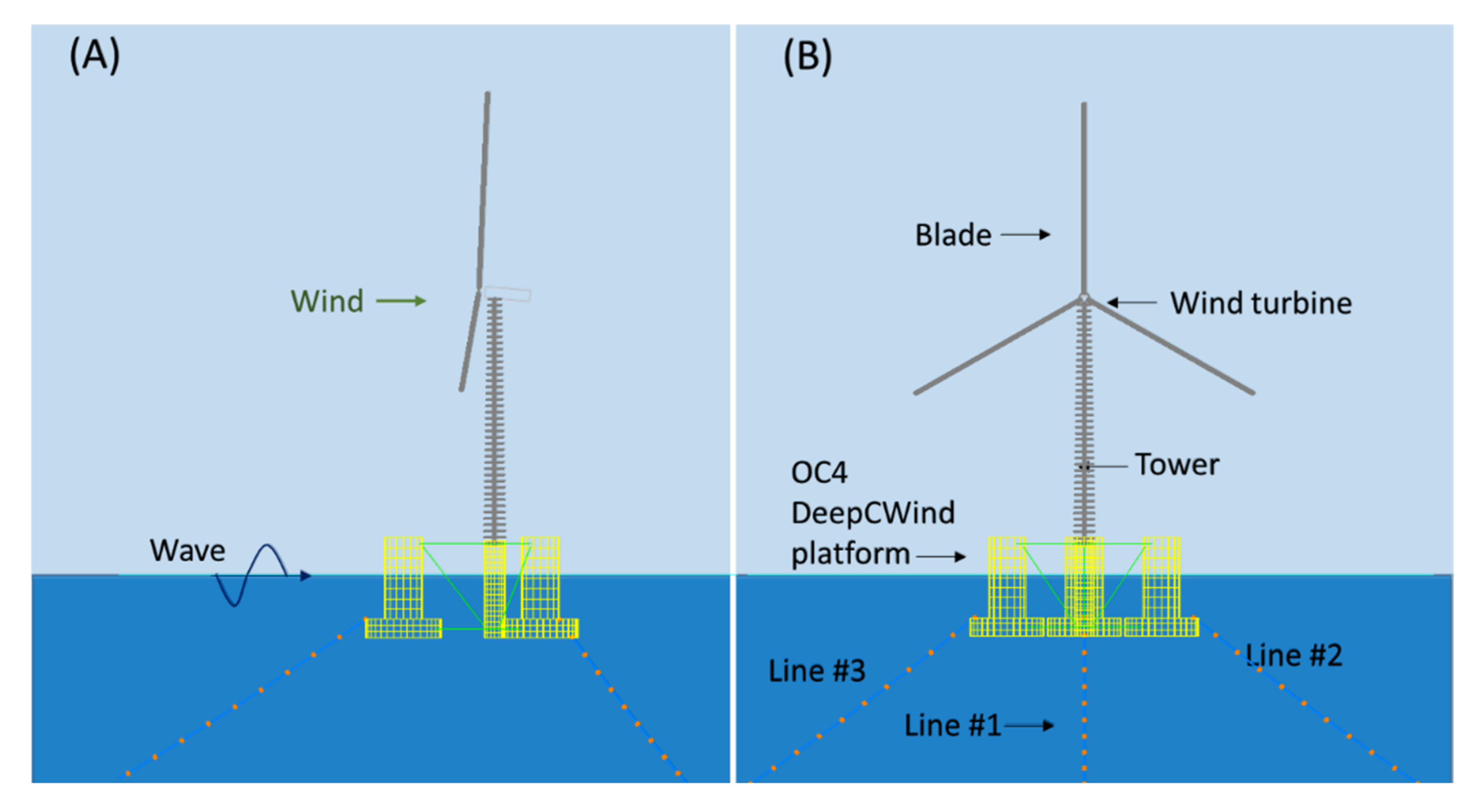

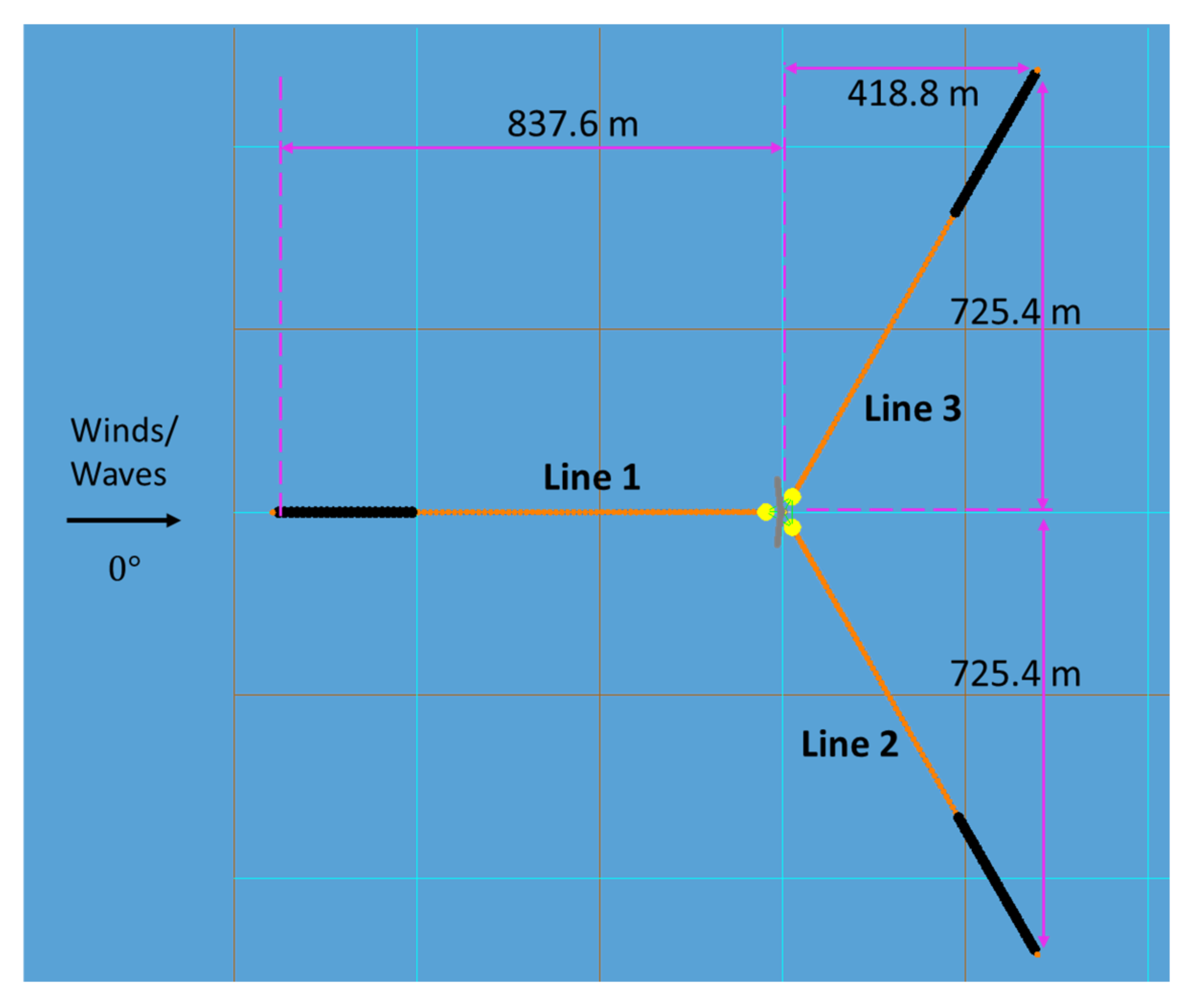

3. Numerical Modelling

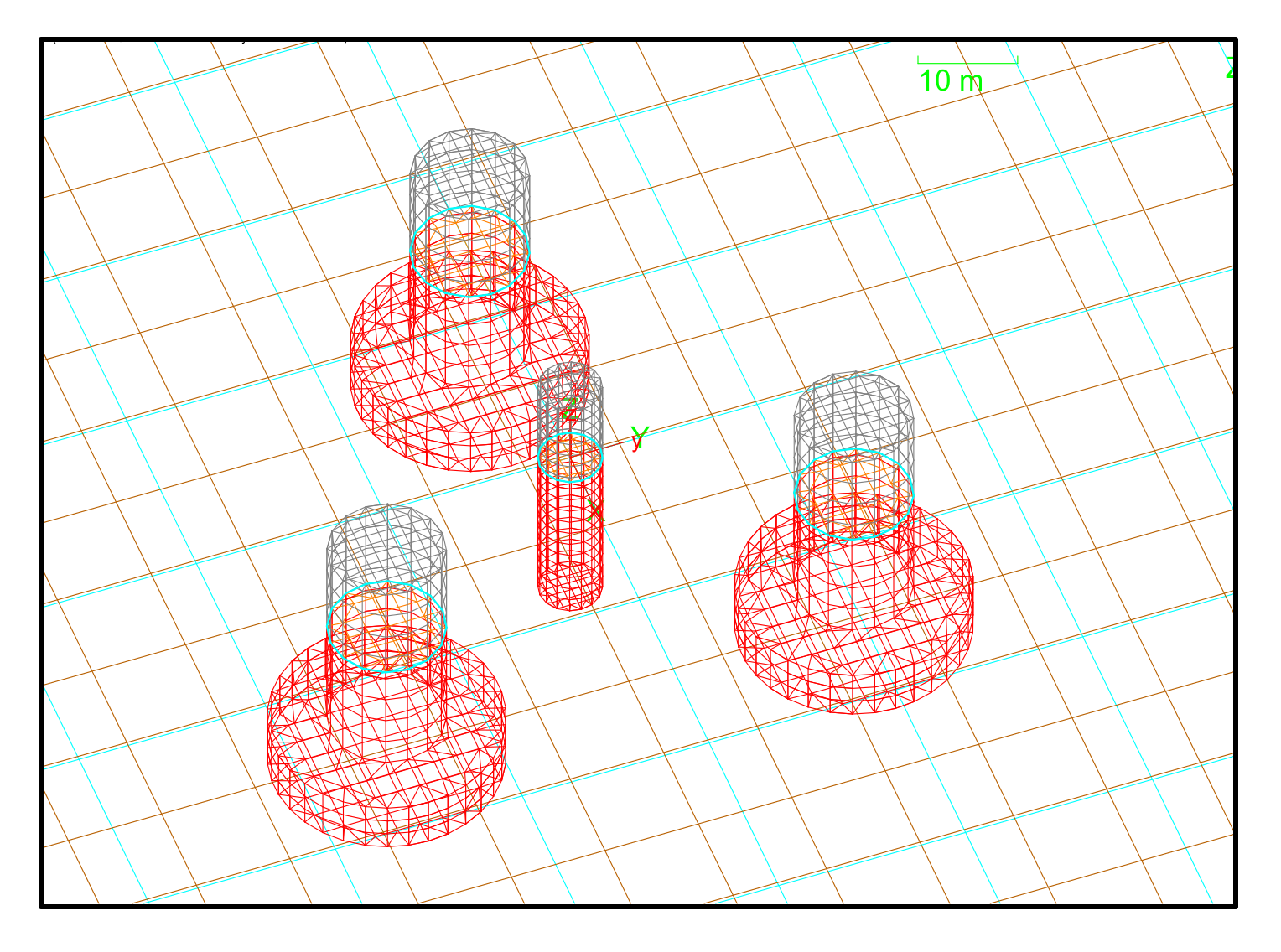

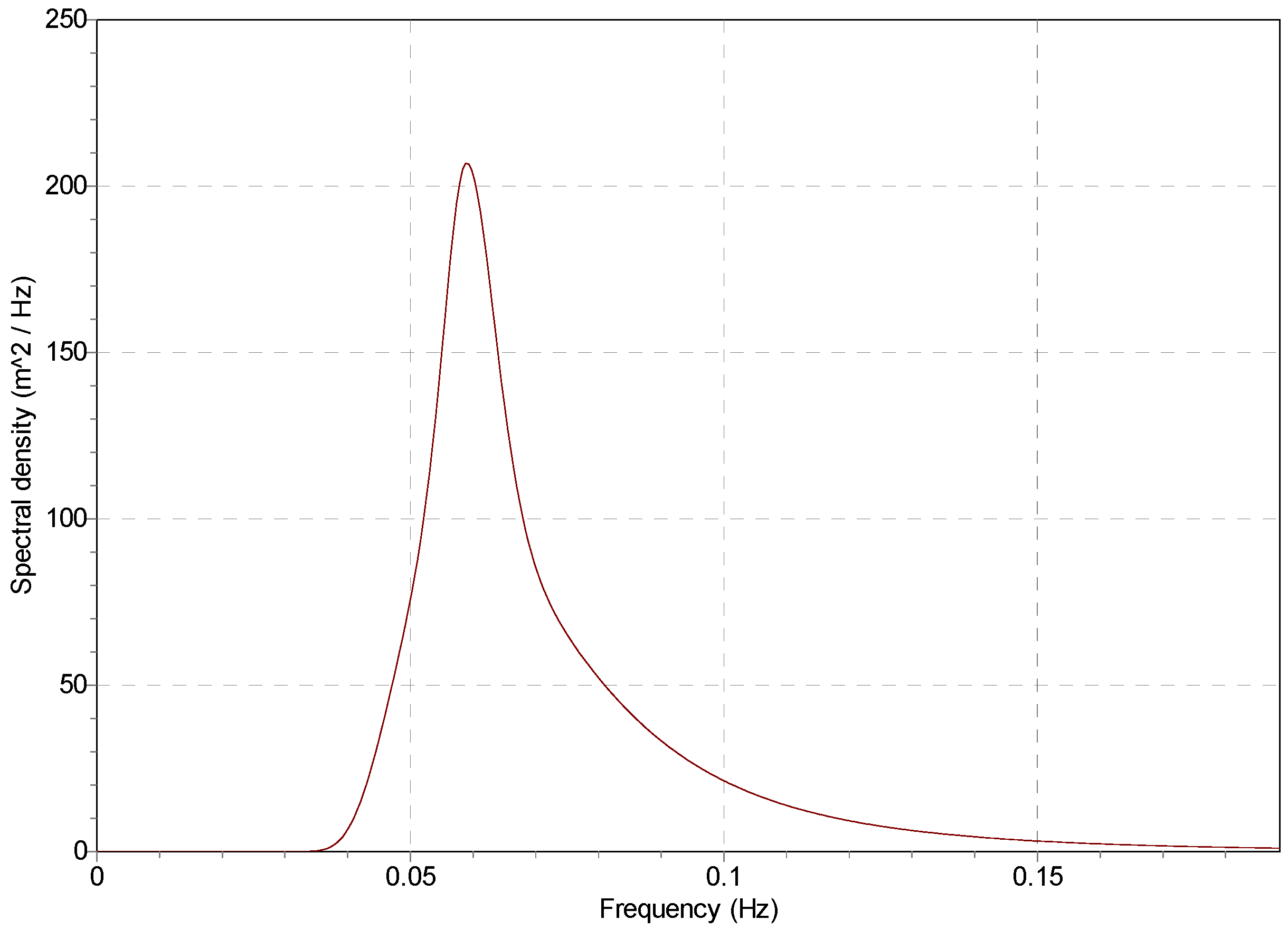

3.1. Model Set-Up

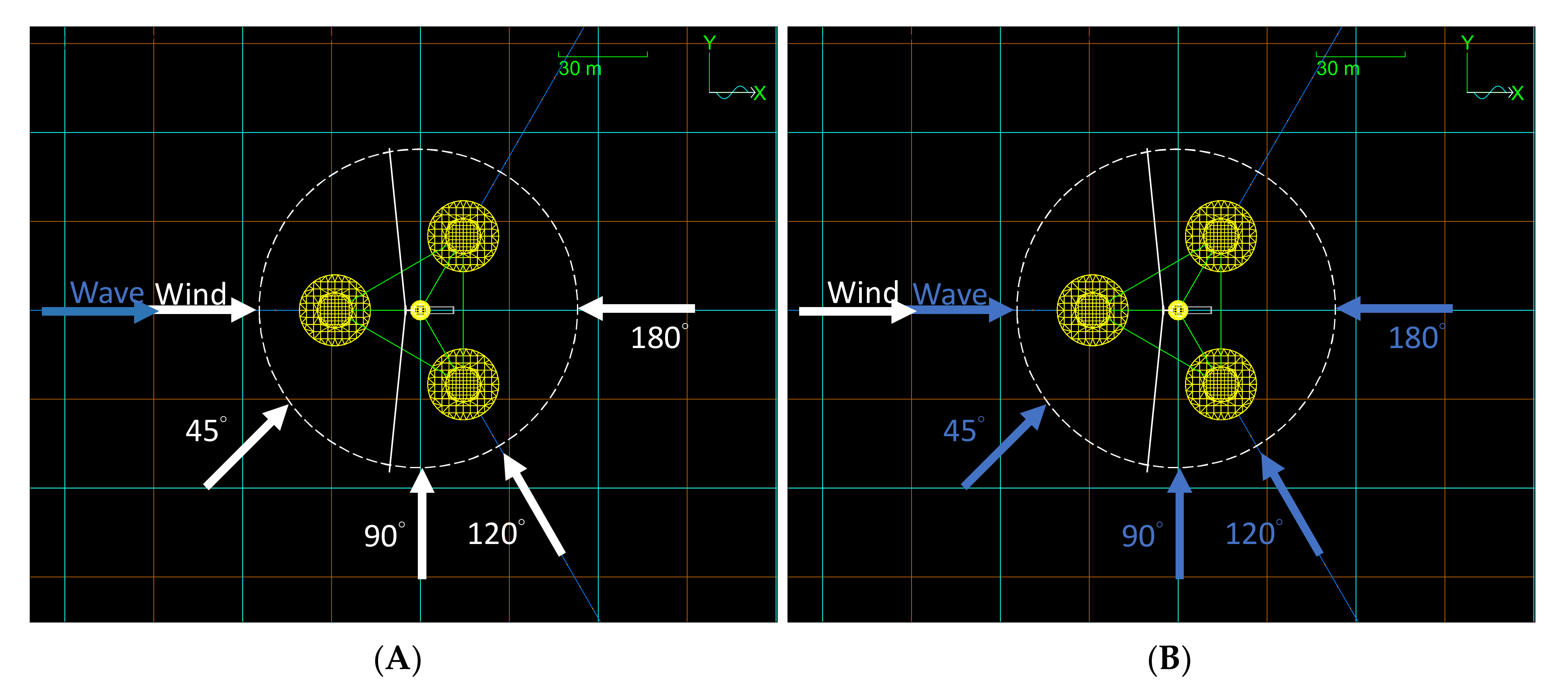

3.2. Load Cases

4. Results

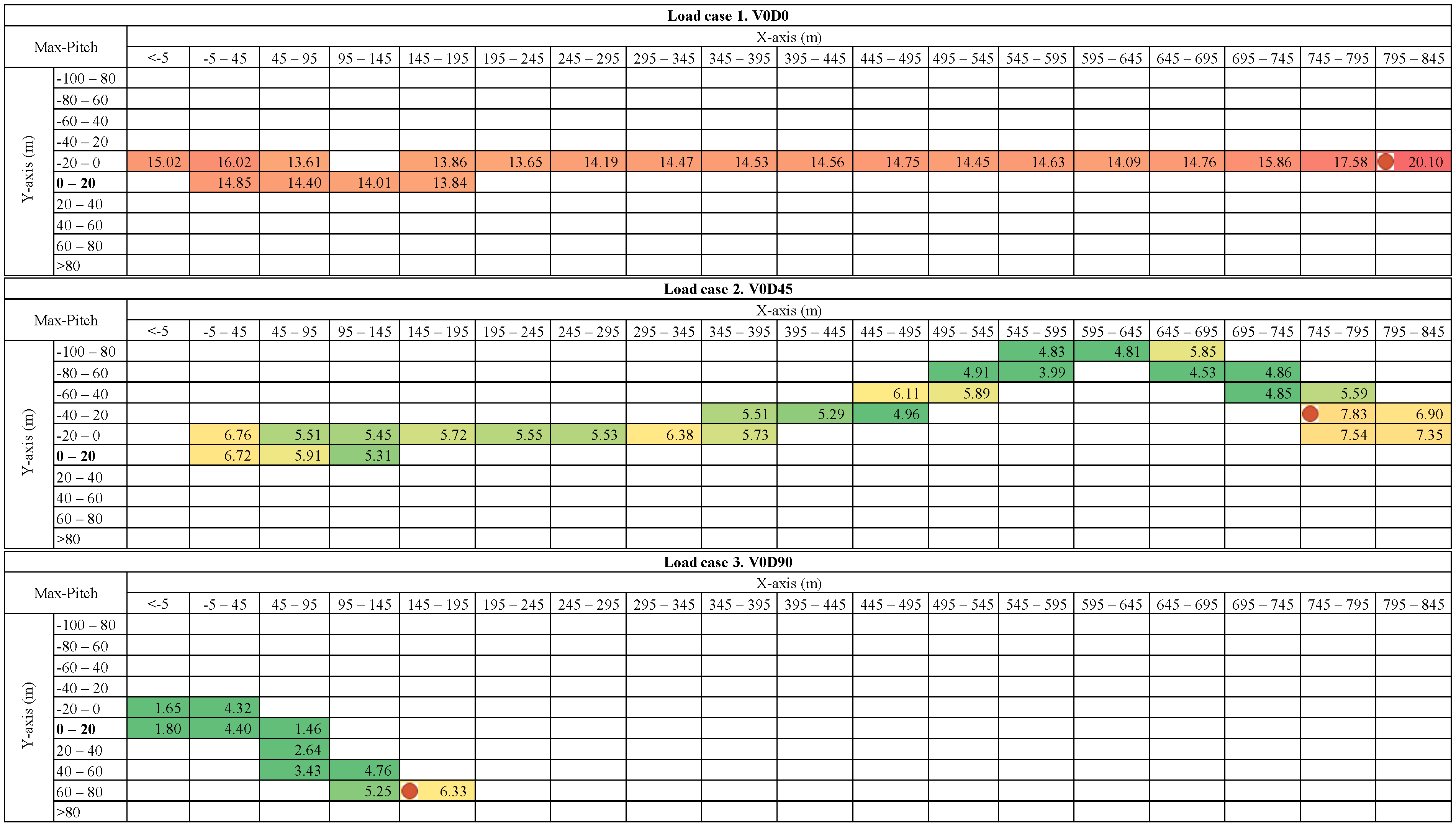

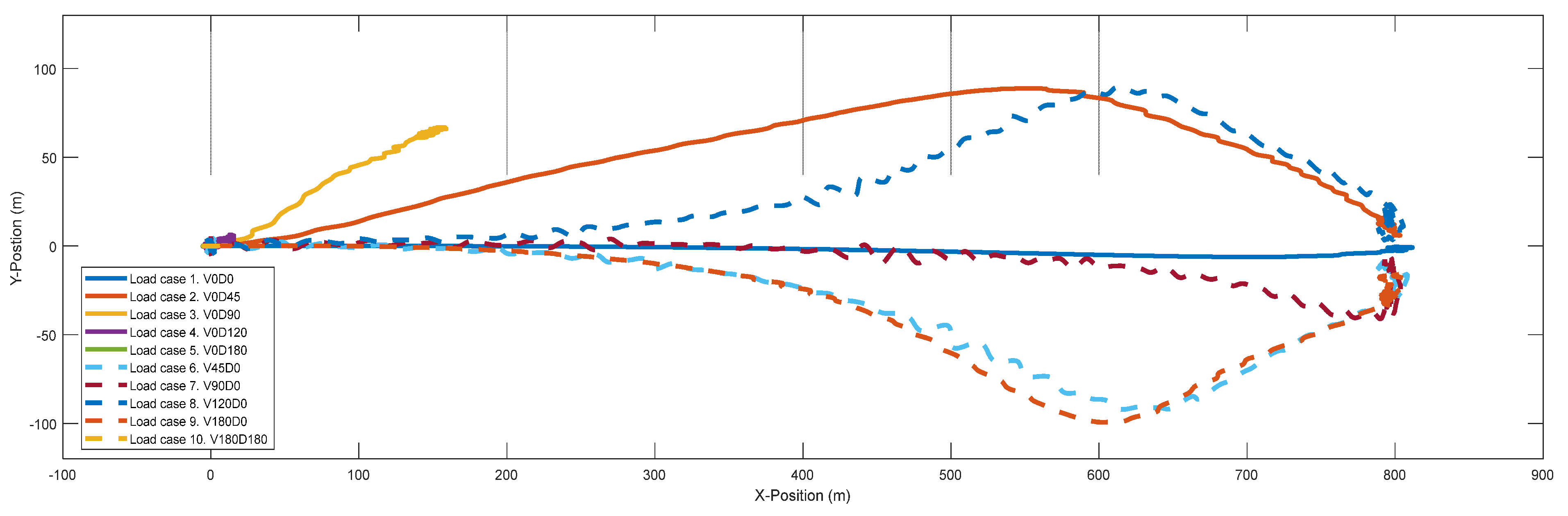

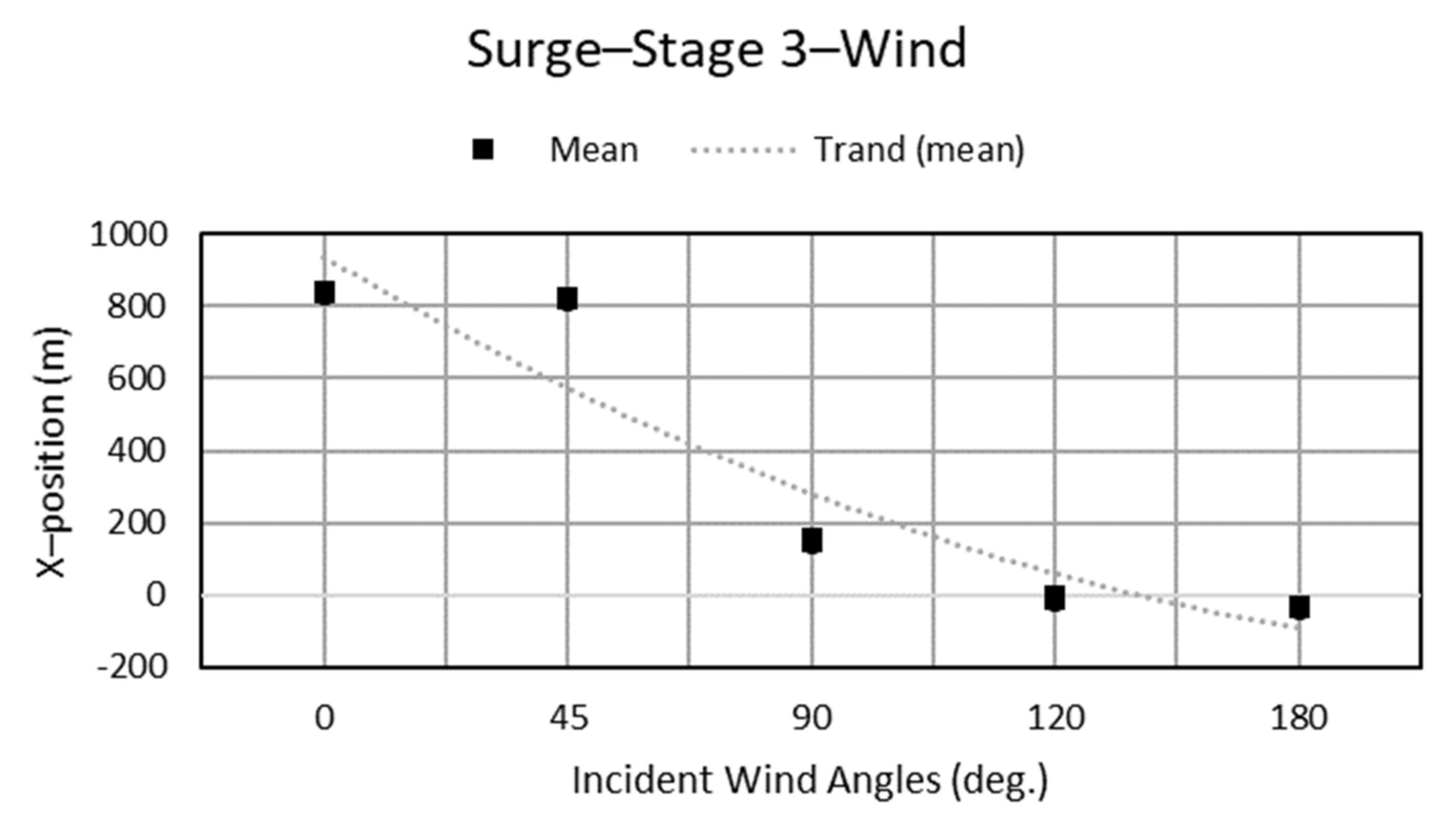

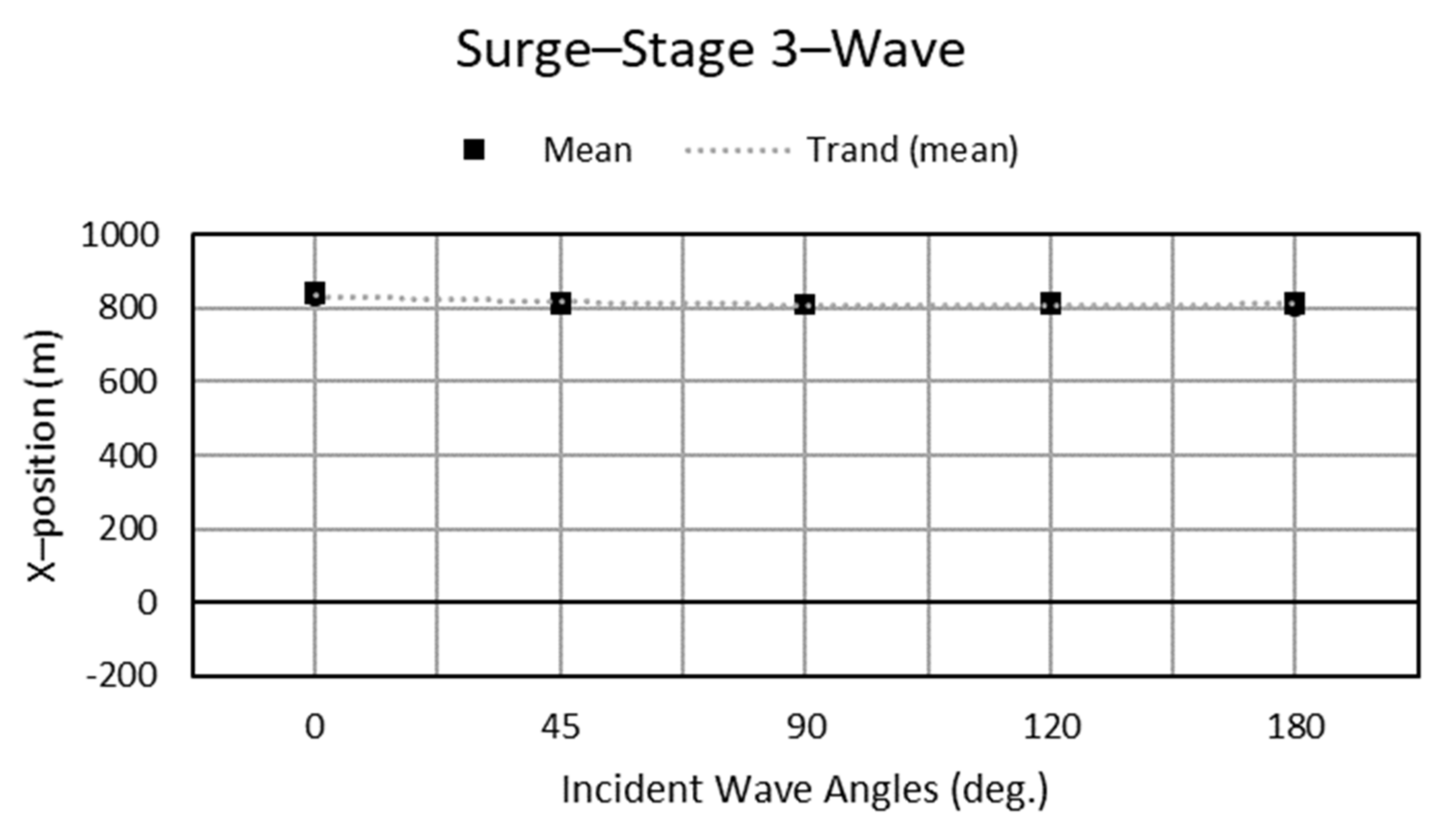

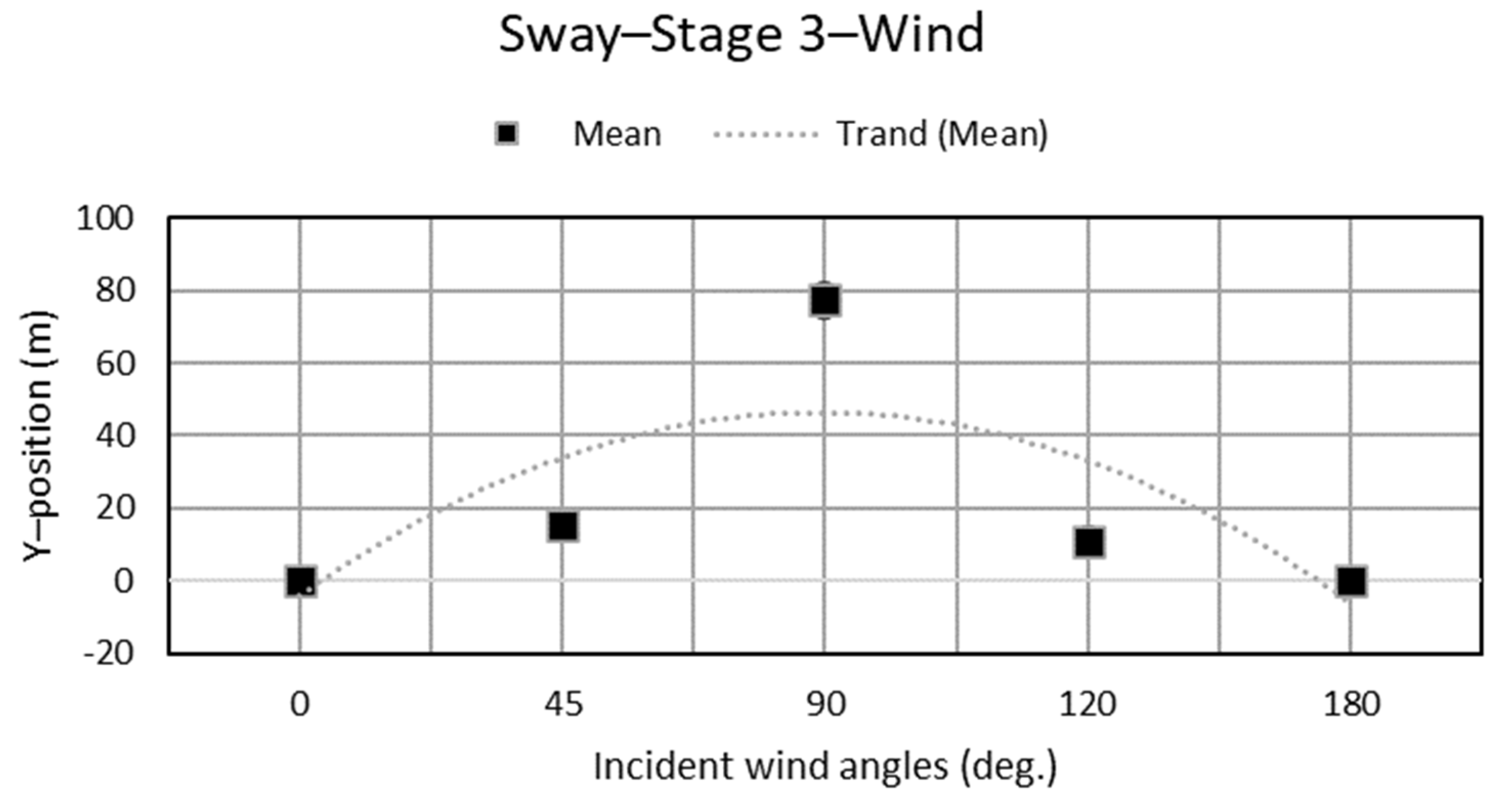

4.1. Drift Area and Velocity of the Platform

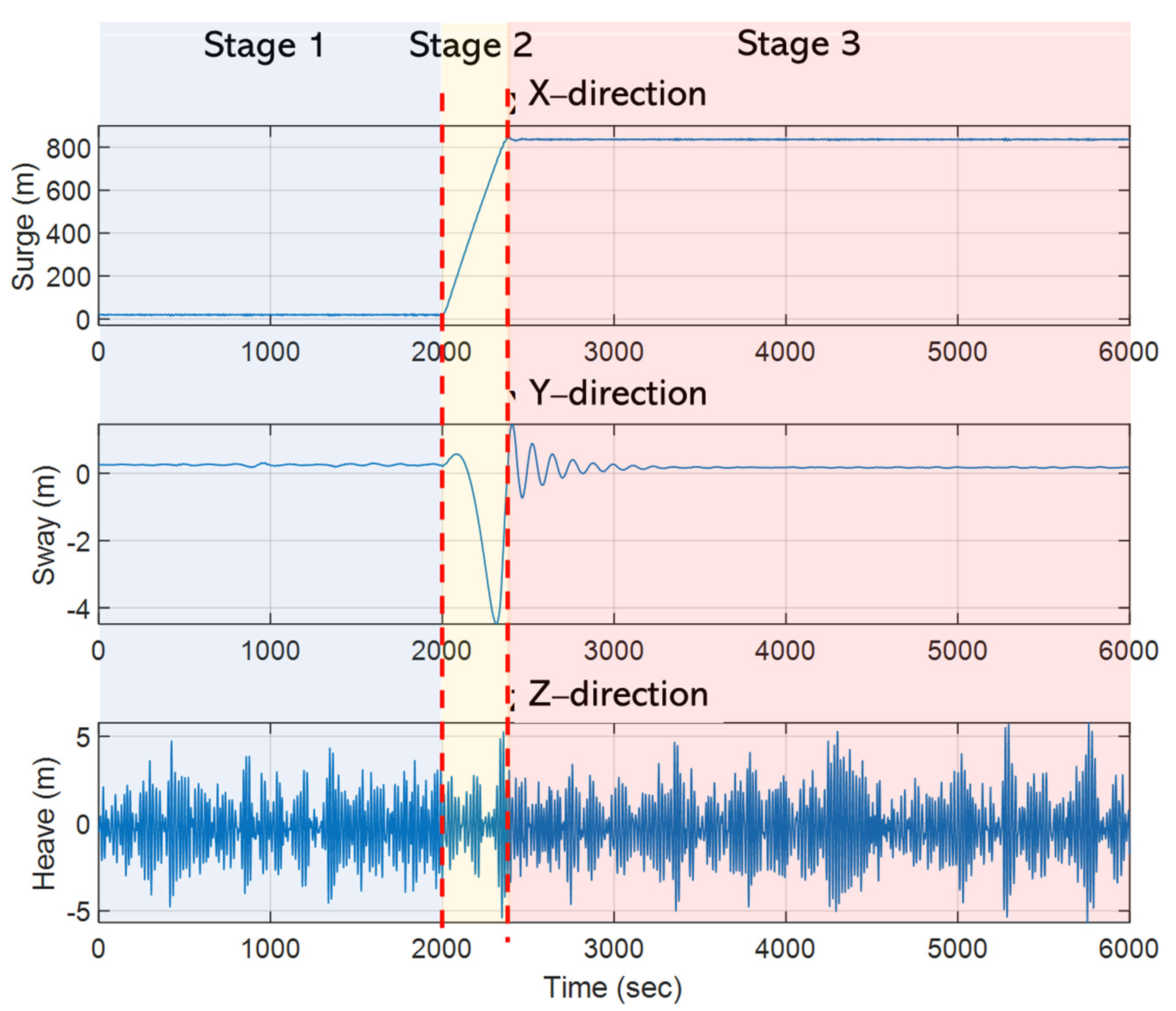

4.2. Floating Platform Dynamic Response

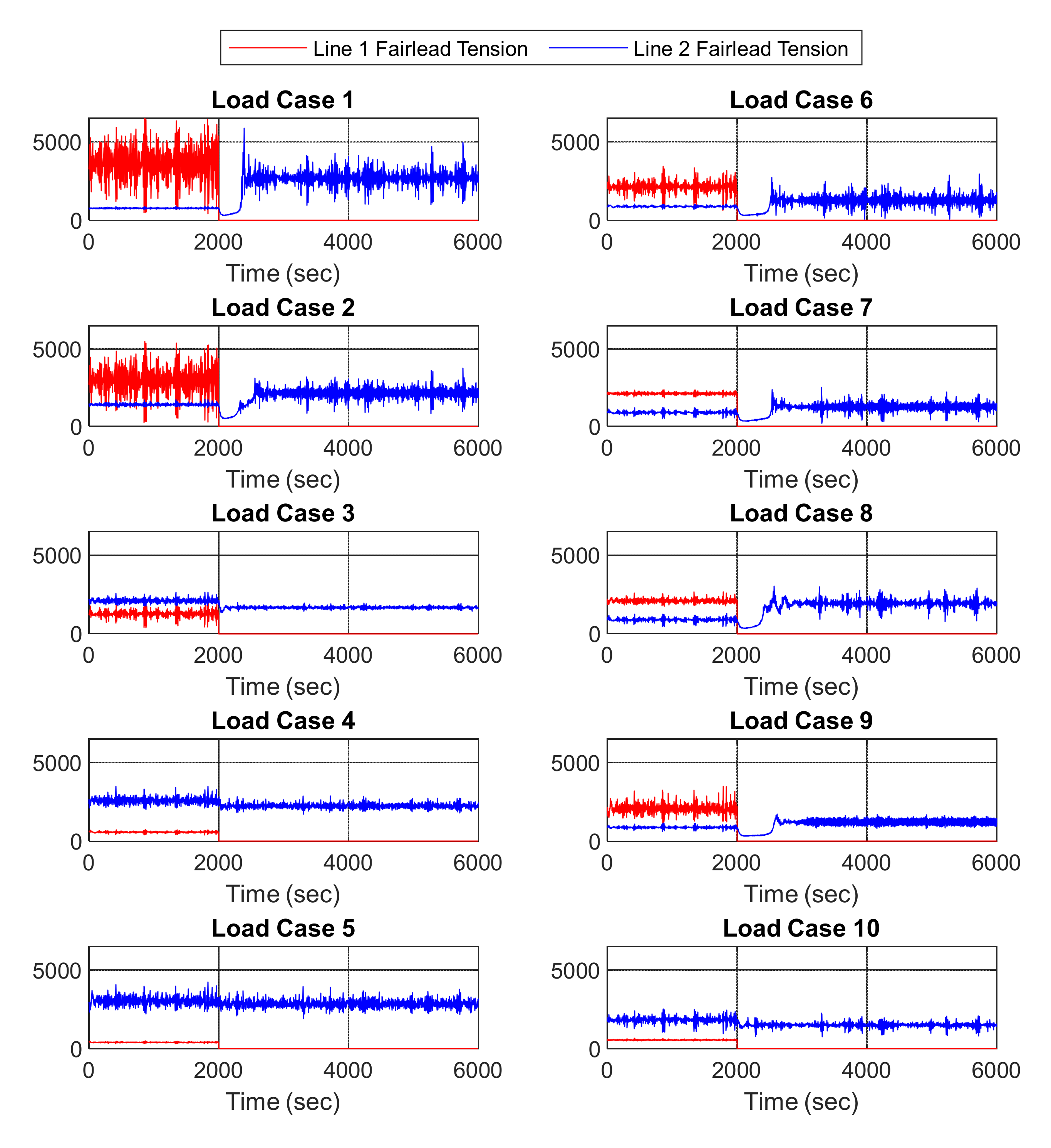

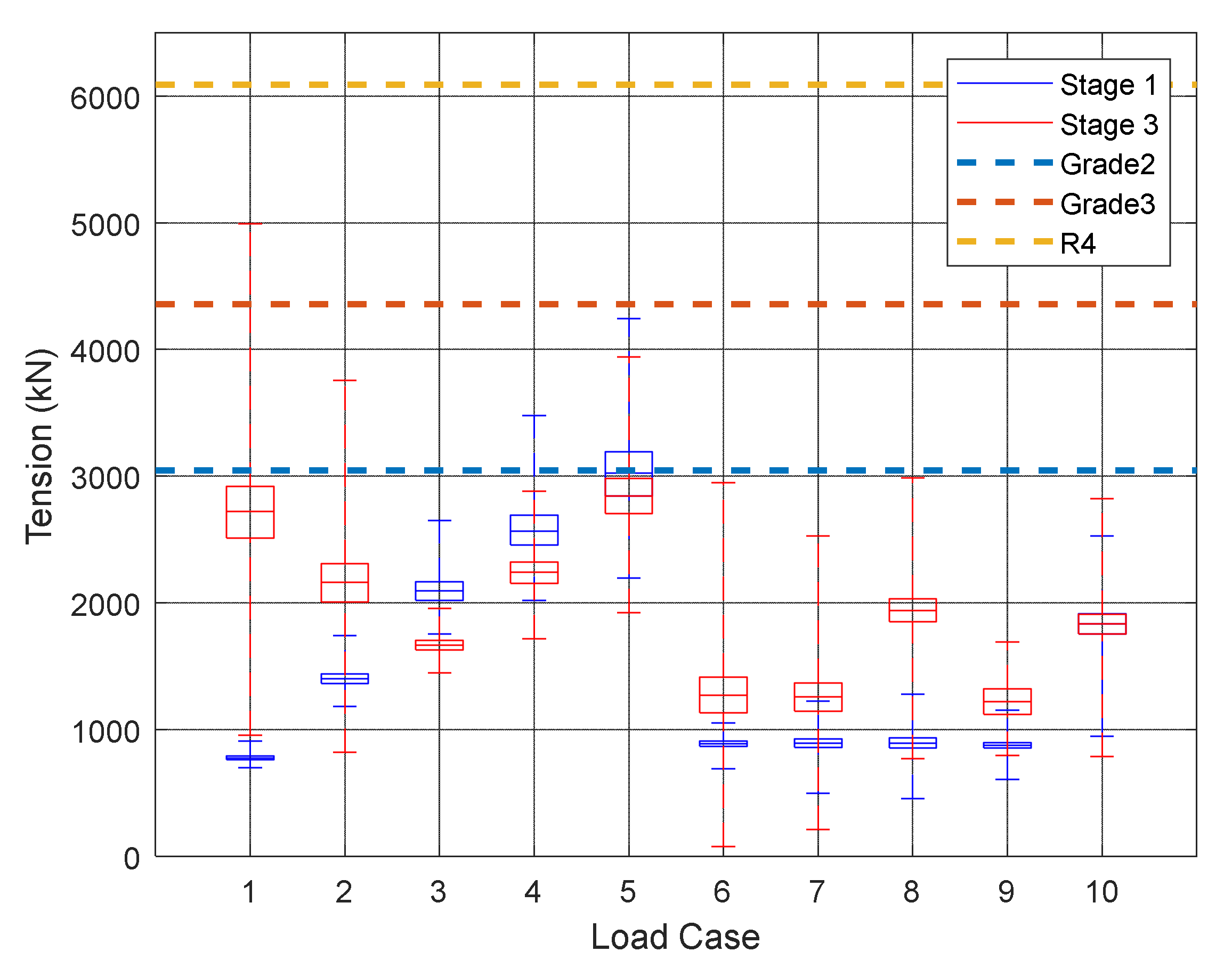

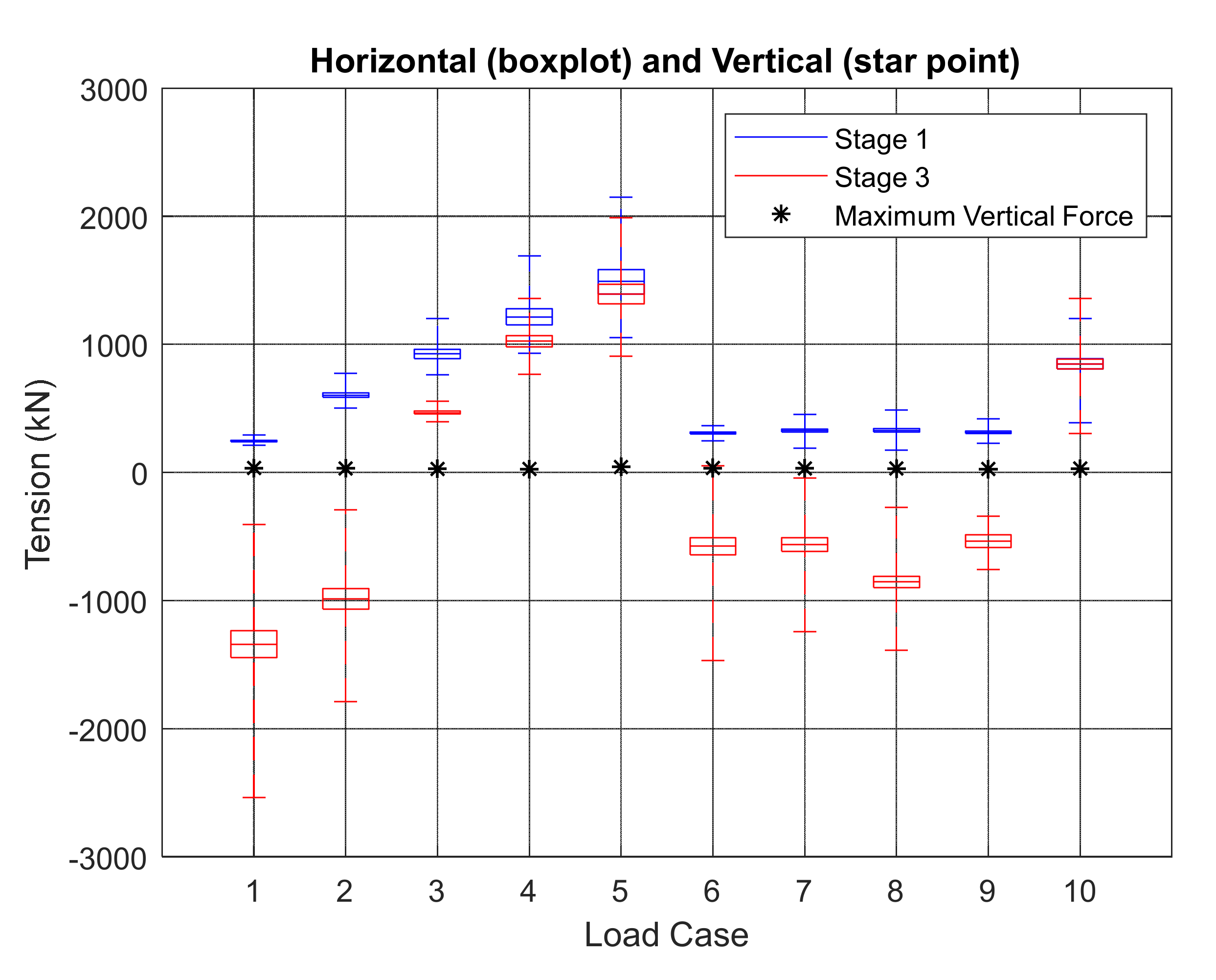

4.3. Mooring Line Tension

4.3.1. Tension on Top End (Fairlead)

- Mode A: line #2 mean tension in stage one lower than stage three.

- Mode B: line #2 mean tension in stage one higher than stage three.

- Mode C: line #2 mean tension in stage one and stage three have no obvious change.

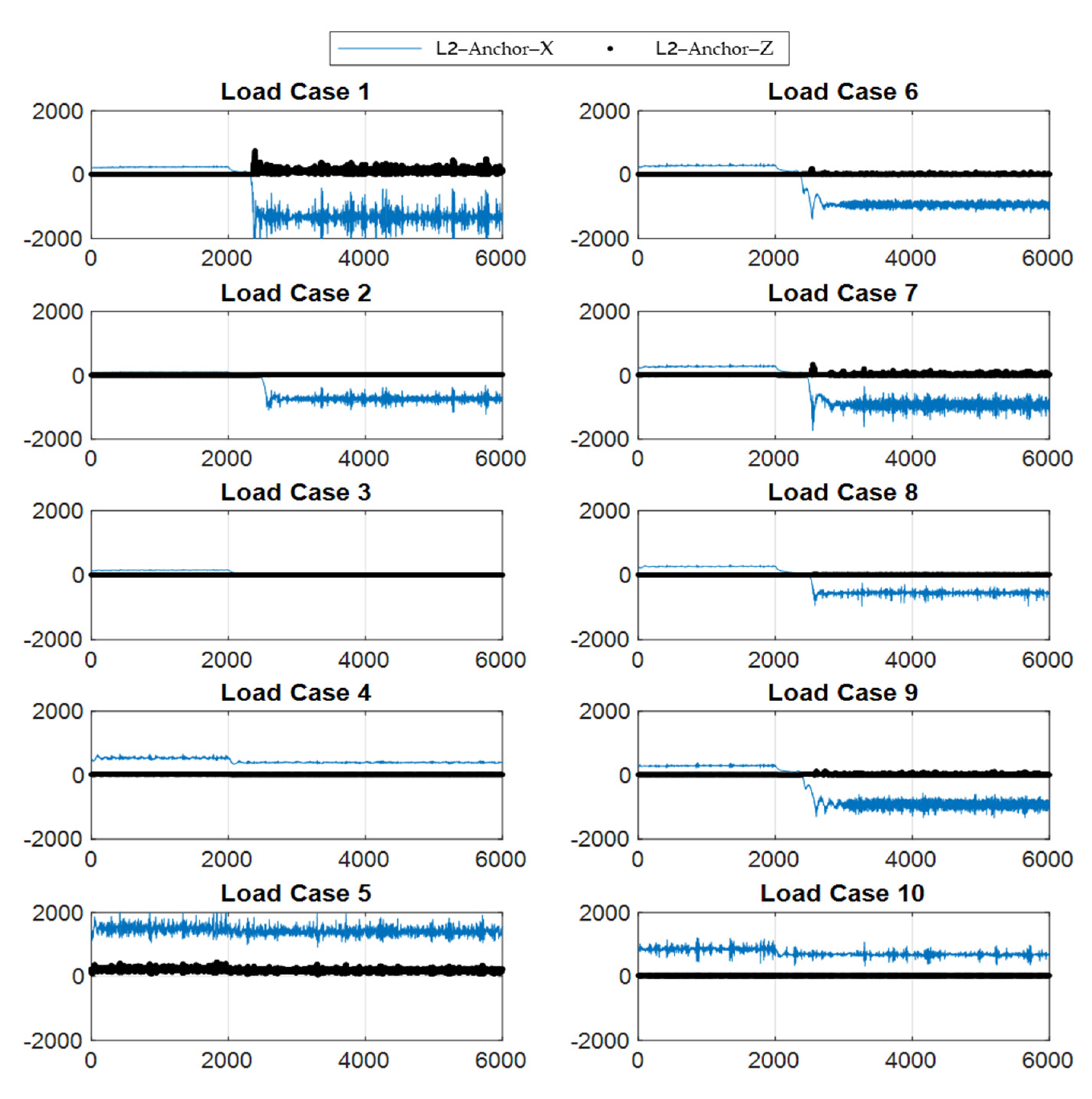

4.3.2. Tension on Bottom End (Anchor)

4.4. Mathematical Method to Maximum Drift Prediction

5. Discussion

5.1. Drift Area and Velocity of the Platform

5.2. Floating Platform Dynamic Response

5.3. Mooring Line Tension

5.4. Mathematical Method for Prediction of Maximum Drift

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Eriksen, E.; Aanestad, O.M.; Eidsvold, M.F. The Future of Offshore Wind Is a Float. Available online: https://www.equinor.com/en/what-we-do/floating-wind.html (accessed on 12 September 2021).

- Spearman, D.K.; Strivens, S.; Matha, D.; Cosack, N.; Macleay, A.; Regelink, J.; Patel, D.; Walsh, T. Floating Wind Joint Industry Project Phase II Summary Report; The Carbon Trust: London, UK, 2020. [Google Scholar]

- Strivens, S.; Northridge, E.; Evans, H.; Harvey, M.; Camp, T.; Terry, N. Floating Wind Joint Industry Project Phase III Summary Report; The Carbon Trust: London, UK, 2021. [Google Scholar]

- Musial, W.; Spitsen, P.; Beiter, P.; Duffy, P.; Marquis, M.; Cooperman, A.; Hammond, R.; Shields, M. Offshore Wind Market Report: 2021 Edition; Department of Energy: Washington, DC, USA, 2021. [Google Scholar]

- Ibrion, M.; Paltrinieri, N.; Nejad, A.R. Learning from failures: Accidents of marine structures on Norwegian continental shelf over 40 years time period. Eng. Fail. Anal. 2020, 111, 104487. [Google Scholar] [CrossRef]

- Ma, K.-t.; Shu, H.; Smedley, P.; L’Hostis, D.; Duggal, A. A historical review on integrity issues of permanent mooring systems. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2013. [Google Scholar]

- Technology, S.S. Advanced Anchoring and Mooring Study; Oregon Wave Energy Trust (OWET): Portland, OR, USA, 2009. [Google Scholar]

- Anchors, V. Anchor Manual. 2010. Available online: http://www.vryhof.com/pdf/anchor_manual.pdf. (accessed on 21 August 2021).

- James, R.; Ros, M.C. Floating offshore wind: Market and technology review. Carbon Trust 2015, 1, 439. [Google Scholar]

- Thomsen, J.B.; Ferri, F.; Kofoed, J.P.; Black, K. Cost optimization of mooring solutions for large floating wave energy converters. Energies 2018, 11, 159. [Google Scholar] [CrossRef] [Green Version]

- Enterprise, S. Mooring and Anchoring Research Report: Mooring and Anchoring Literature Review and Consultation; Xodus Group: Glasgow, UK, 2020. [Google Scholar]

- Leong, M. Japan Awards First Floating Offshore Wind Tender. Available online: https://connect.ihsmarkit.com/upstream-insight/article/phoenix/4011325/japan-awards-first-floating-offshore-wind-tender (accessed on 24 April 2021).

- Durakovic, A. WindFloat Atlantic Fully up and Running. Available online: https://www.offshorewind.biz/2020/07/27/windfloat-atlantic-fully-up-and-running/ (accessed on 1 May 2021).

- Shimada, K.; Shiroeda, T.; Hotta, H.; Phuc, P.V.; Kida, T. Fukushima Offshore Wind Consortium. Available online: http://www.fukushima-forward.jp/english/ (accessed on 1 September 2021).

- Margaronis, S. New England Aqua Ventus will Launch First US Floating Offshore Wind Turbine in 2023/24. Available online: https://ajot.com/insights/full/ai-new-england-aqua-ventus-will-launch-first-us-floating-offshore-wind-turbine-in-2024 (accessed on 2 November 2021).

- Akers, R.H. Why Good Mooring Systems Go Bad. In Proceedings of the Maine Ocean&Wind Industry Initiative, Portland, OR, USA, 16 July 2012. [Google Scholar]

- F-konstruksjonssikkerhet; Kvitrud, A.; Bache, B.T. Anchor line failures—Norwegian Continental Shelf—2010–2014; Petroleumstilsynet: Stavanger, Norwey, 2014; Volume 5, pp. 212–236. [Google Scholar]

- Sekita, K.; Sakai, M. Model tests to establish a design method for TLP-tether systems. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 7–9 May 1984. [Google Scholar]

- Deb, M.K. Statics and Dynamics of a Tension Leg Platform in Intact and Tether Damage Conditions; Memorial University of Newfoundland: St. John’s, NL, Canada, 1986. [Google Scholar]

- Yang, C.K.; Padmanabhan, B.; Murray, J.; Kim, M. The transient effect of tendon disconnection on the global motion of ETLP. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Estoril, Portugal, 15–20 June 2008; pp. 497–507. [Google Scholar]

- Kim, M.H.; Zhang, Z. Transient effects of tendon disconnection on the survivability of a TLP in moderate-strength hurricane conditions. Int. J. Nav. Archit. Ocean Eng. 2009, 1, 13–19. [Google Scholar] [CrossRef] [Green Version]

- Yang, C.K.; Kim, M.-H. Transient effects of tendon disconnection of a TLP by hull–tendon–riser coupled dynamic analysis. Ocean Eng. 2010, 37, 667–677. [Google Scholar] [CrossRef]

- Yu, J.; Hao, S.; Yu, Y.; Chen, B.; Cheng, S.; Wu, J. Mooring analysis for a whole TLP with TTRs under tendon one-time failure and progressive failure. Ocean Eng. 2019, 182, 360–385. [Google Scholar] [CrossRef]

- Bae, Y.; Kim, M.; Kim, H. Performance changes of a floating offshore wind turbine with broken mooring line. Renew. Energy 2017, 101, 364–375. [Google Scholar] [CrossRef]

- Jonkman, J.; Butterfield, S.; Musial, W.; Scott, G. Definition of a 5-MW Reference Wind Turbine for Offshore System Development; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2009. [Google Scholar]

- Robertson, A.; Jonkman, J.; Masciola, M.; Song, H.; Goupee, A.; Coulling, A.; Luan, C. Definition of the Semisubmersible Floating System for Phase II of OC4; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2014. [Google Scholar]

- Faltinsen, O.M. Sea Loads on Ships and Offshore Structures; Cambridge University Press: Cambridge, UK, 1999. [Google Scholar]

- Orcina, L. OrcaWave User Manual: Version 11.1 d. Available online: https://www.orcina.com/webhelp/OrcaFlex/Default.htm (accessed on 2 November 2021).

- Jonkman, J. Definition of the Floating System for Phase IV of OC3 (No. NREL/TP-500-47535; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2010. [Google Scholar]

- Robertson, A.; Jonkman, J.; Vorpahl, F.; Popko, W.; Qvist, J.; Frøyd, L.; Chen, X.; Azcona, J.; Uzunoglu, E.; Guedes Soares, C. Offshore Code Comparison Collaboration Continuation Within IEA Wind Task 30: Phase II Results Regarding a Floating Semisubmersible Wind System Preprint. In Proceedings of the 33rd International Conference on Ocean, Offshore and Arctic Engineering, San Francisco, CA, USA, 8–13 June 2014. [Google Scholar]

- DNV GL. DNV GL-ST-0437: Loads and Site Conditions for Wind Turbines; DNV GL: Oslo, Norway, 2016. [Google Scholar]

- The 2nd River Management Office, Water Resources Agency. Planning Report on Environmental Protection and Construction Plan for the South Coast of Hsinchu Port. 2005. Available online: https://www-ws.wra.gov.tw/Download.ashx?u=LzAwMS9VcGxvYWQvb2xkRmlsZTIvbWVkaWEvMTEyNjAvMTkyMTY4MjUzMy1yb2JvY29weS0zMmFwLXJpdmVyX3dlYi1naXBudWxsLXN5cy1wdWJsaWMtZGF0YS0xNzgxNzE5MTg3MS5wZGY%3D&n=MTc4MTcxOTE4NzEucGRmLnBkZg%3D%3D&icon=.pdf (accessed on 9 December 2021).

- DNV GL. DNVGL-RP-0286: Coupled analysis of floating wind turbines. In Recommend Practice DNVGL-RP-0286; DNV GL: Oslo, Norway, 2019. [Google Scholar]

| Types Item | Catenary Mooring System | Tension-Leg Mooring System | Semi-Taut Mooring System |

|---|---|---|---|

| Platform stability (without mooring system) | relatively high | relatively low | medium |

| Platform performance (with mooring system) | acceptable | relatively stable | acceptable |

| Pre-tension of mooring system | relatively low | relatively high | medium |

| Footprint size of mooring system | relatively large | relatively small | medium |

| Installation of mooring system | relatively simple compared to a tension-leg mooring system | relatively difficult compared to catenary and semi-taut mooring systems | relatively simple compared to a tension-leg mooring system |

| Property | Values | Unit |

|---|---|---|

| Wind turbine capability | 5 | MW |

| Blade quantity | 3 | - |

| Rotor diameter | 126 | m |

| Cut-in, rated, cut-out wind speed | 3, 11.4, 25 | m/s |

| Rotor weight | 110.00 | te |

| Nacelle weight | 240.00 | te |

| Tower weight | 347.46 | te |

| Property | Values | Unit |

|---|---|---|

| Overall Integrated Mass | 347.46 | te |

| CM Location (above GL) | 38.148 | m |

| Material Effective Density | 8.5 | te/m3 |

| Material Young’s Modulus | 210 | Gpa |

| Material Shear Modulus | 80.8 | Gpa |

| Poisson Ratio | 0.3 | - |

| Added Mass Coefficient | 1.0 | - |

| Drag Coefficient | 1.2 | - |

| Property | Values | Unit |

|---|---|---|

| Depth of platform base below SWL (total draft) | 20 | m |

| Elevation of the main column (tower base) above SWL | 10 | m |

| Elevation of offset columns above SWL | 12 | m |

| Spacing between offset columns | 50 | m |

| Length of upper columns | 26 | m |

| Length of base columns | 6 | m |

| Depth to top of base columns below SWL | 14 | m |

| Diameter of the main column | 6.5 | m |

| Diameter of offset (upper) columns | 12 | m |

| Diameter of base columns | 24 | m |

| Diameter of pontoons and cross braces | 1.6 | m |

| Platform mass, including ballast | 1.3473 × 107 | kg |

| CM location below SWL | 13.46 | m |

| Platform roll inertia about CM | 6.827 × 109 | kg-m2 |

| Platform pitch inertia about CM | 6.827 × 109 | kg-m2 |

| Platform yaw inertia about CM | 1.226 × 1010 | kg-m2 |

| Property | Values | Unit |

|---|---|---|

| Number of mooring lines | 3 | - |

| Angle between adjacent lines | 120 | ° |

| Depth to anchors below sea water level | 200 | m |

| Depth to fairleads below sea water level | 14 | m |

| Radius of anchors from platform centreline | 837.60 | m |

| Radius to fairleads from platform centreline | 40.87 | m |

| Unstretched mooring line length | 835.5 | m |

| Mooring line diameter | 0.0766 | m |

| Equivalent mooring line mass in water | 108.63 | kg/m |

| Hydrodynamic drag coefficient for mooring lines | 1.1 | - |

| Hydrodynamic added-mass coefficient for mooring lines | 1.0 | - |

| Structural damping of mooring lines | 2.0 | % |

| Return Period (Year) | 10 | 20 | 50 | |||

|---|---|---|---|---|---|---|

| Wave Directions | Hs (m) | Ts (s) | Hs (m) | Ts (s) | Hs (m) | Ts (s) |

| North-East, NE (33–45 degrees) | 6.6 | 10.8 | 7.7 | 11.7 | 9.1 | 12.7 |

| North-Northeast, NNE (12–33 degrees) | 6.1 | 10.4 | 7.3 | 11.3 | 8.7 | 12.4 |

| North-Northwest, NNW (327–348 degrees) | 4.5 | 8.9 | 5.5 | 9.8 | 6.7 | 10.9 |

| Load Case Symbol | Wave Incident Directions (°) | Wind Incident Directions (°) | Symbol |

|---|---|---|---|

| LC1 | 0 | 0 | V0D0 |

| LC2 | 0 | 45 | V0D45 |

| LC3 | 0 | 90 | V0D90 |

| LC4 | 0 | 120 | V0D120 |

| LC5 | 0 | 180 | V0D180 |

| LC6 | 45 | 0 | V45D0 |

| LC7 | 90 | 0 | V90D0 |

| LC8 | 120 | 0 | V120D0 |

| LC9 | 180 | 0 | V180D0 |

| LC10 | 180 | 180 | V180D180 |

| Load Cases | Wave (°) | Wind (°) | X-Direction (m) | Y-Direction (m) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| All Stages | Stage 1 | Stage 2 | Stage 3 | All Stage | Stage 1 | Stage 2 | Stage 3 | |||

| 1 | 0 | 0 | 814.23 | 8.88 | 814.23 | 10.43 | −6.25 | 0.16 | −6.25 | 0.10 |

| 2 | 0 | 45 | 805.27 | 9.94 | 805.27 | 11.08 | 89.09 | 1.40 | 89.09 | 1.33 |

| 3 | 0 | 90 | 161.23 | 10.54 | 161.23 | 12.46 | 67.39 | 2.84 | 67.39 | 3.10 |

| 4 | 0 | 120 | 18.02 | 12.30 | 18.02 | 11.84 | 7.10 | 3.64 | 7.10 | 2.11 |

| 5 | 0 | 180 | −13.02 | −13.02 | −11.26 | −10.71 | 0.02 | 0.02 | 0.02 | 0.02 |

| 6 | 45 | 0 | 809.95 | 6.91 | 809.95 | 6.98 | −94.49 | 8.95 | −94.49 | 8.90 |

| 7 | 90 | 0 | 804.22 | 0.82 | 804.22 | 1.81 | −45.08 | 10.61 | −45.08 | 10.83 |

| 8 | 120 | 0 | 807.63 | 5.73 | 807.63 | 6.33 | 91.70 | 10.06 | 91.70 | 10.85 |

| 9 | 180 | 0 | 809.49 | 11.19 | 809.49 | 10.66 | −99.49 | 0.20 | −99.49 | 3.71 |

| 10 | 180 | 180 | 10.33 | 10.33 | 10.02 | 9.66 | 0.14 | 0.12 | 0.12 | 0.14 |

| Maximum Range (Highest–Lowest) | 827.25 | 25.32 | 825.50 | 23.17 | 191.19 | 10.59 | 191.19 | 10.83 | ||

| Water Depth (m) | 200 | 100 | 50 | |

|---|---|---|---|---|

| Properties Item | ||||

| Vertical distance from the fairlead to the anchor, d (m) | 186.00 | 86.00 | 36.00 | |

| Radius to fairlead from anchors, X0 (m) | 796.73 | 813.50 | 816.50 | |

| Orcaflex-Surge+ in stage 1 in Orcaflex (m) | 3.30 | 3.37 | 3.54 | |

| Orcaflex-Surge- (m) in stage 1 in Orcaflex (m) | −5.58 | −5.49 | −5.30 | |

| Maximum Surge after line breakage in Orcaflex (m) | 814.23 | 833.76 | 833.62 | |

| Maximum Surge after line breakage from Equataion (10) (m) | 831.24 | 847.58 | 851.83 | |

| Orcaflex/Equation (10) result (%) | 97.95 | 98.37 | 97.86 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, R.-Y.; Chuang, T.-C.; Zhao, C.; Johanning, L. Dynamic Response of an Offshore Floating Wind Turbine at Accidental Limit States—Mooring Failure Event. Appl. Sci. 2022, 12, 1525. https://doi.org/10.3390/app12031525

Yang R-Y, Chuang T-C, Zhao C, Johanning L. Dynamic Response of an Offshore Floating Wind Turbine at Accidental Limit States—Mooring Failure Event. Applied Sciences. 2022; 12(3):1525. https://doi.org/10.3390/app12031525

Chicago/Turabian StyleYang, Ray-Yeng, Tzu-Ching Chuang, Chenyu Zhao, and Lars Johanning. 2022. "Dynamic Response of an Offshore Floating Wind Turbine at Accidental Limit States—Mooring Failure Event" Applied Sciences 12, no. 3: 1525. https://doi.org/10.3390/app12031525

APA StyleYang, R.-Y., Chuang, T.-C., Zhao, C., & Johanning, L. (2022). Dynamic Response of an Offshore Floating Wind Turbine at Accidental Limit States—Mooring Failure Event. Applied Sciences, 12(3), 1525. https://doi.org/10.3390/app12031525