Accuracy of 3D-Printed Occlusal Devices of Different Volumes Using a Digital Light Processing Printer

Abstract

:1. Introduction

2. Materials and Methods

2.1. Design of the Occlusal Device

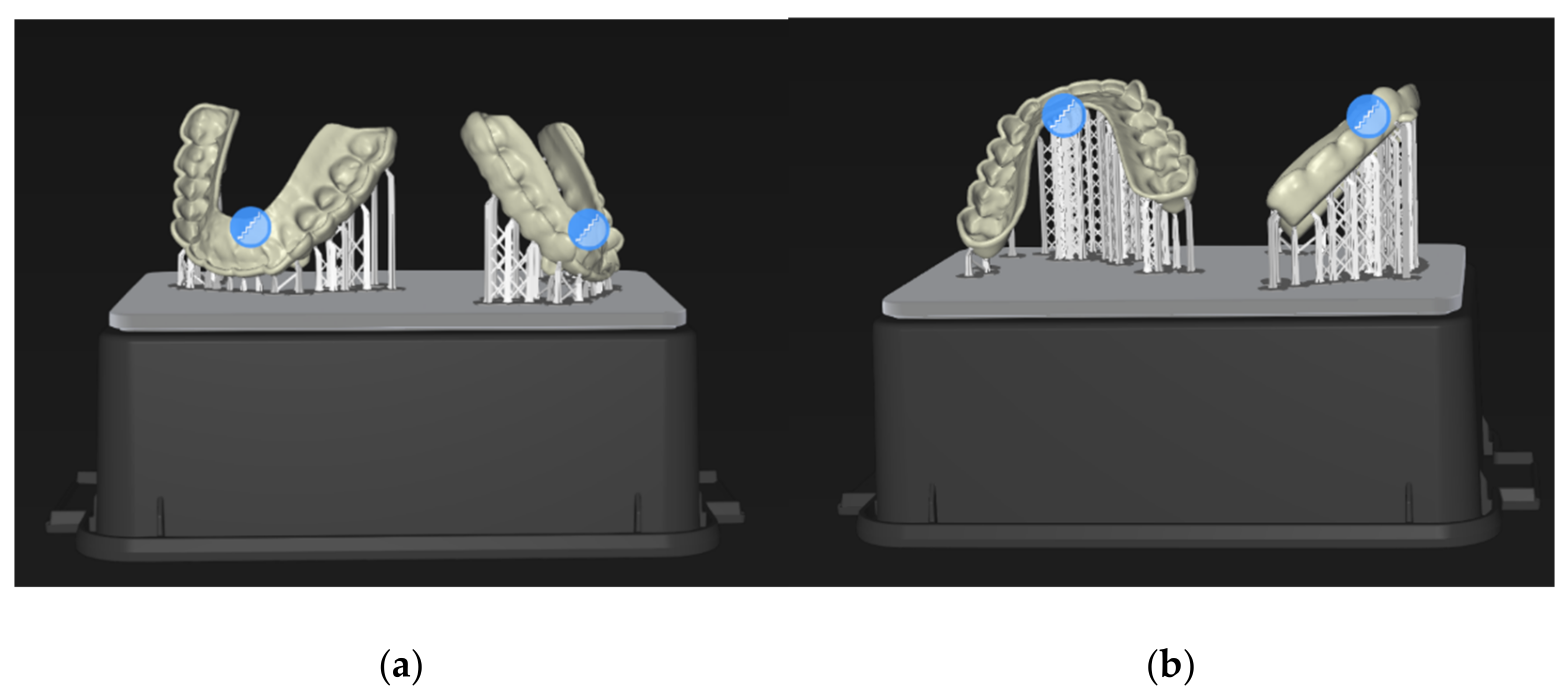

2.2. Additive Manufacturing

2.3. Accuracy Evaluation via Surface Comparison

2.4. Statistics

3. Results

3.1. Evaluation of the Internal Surfaces

3.1.1. Trueness

3.1.2. Precision

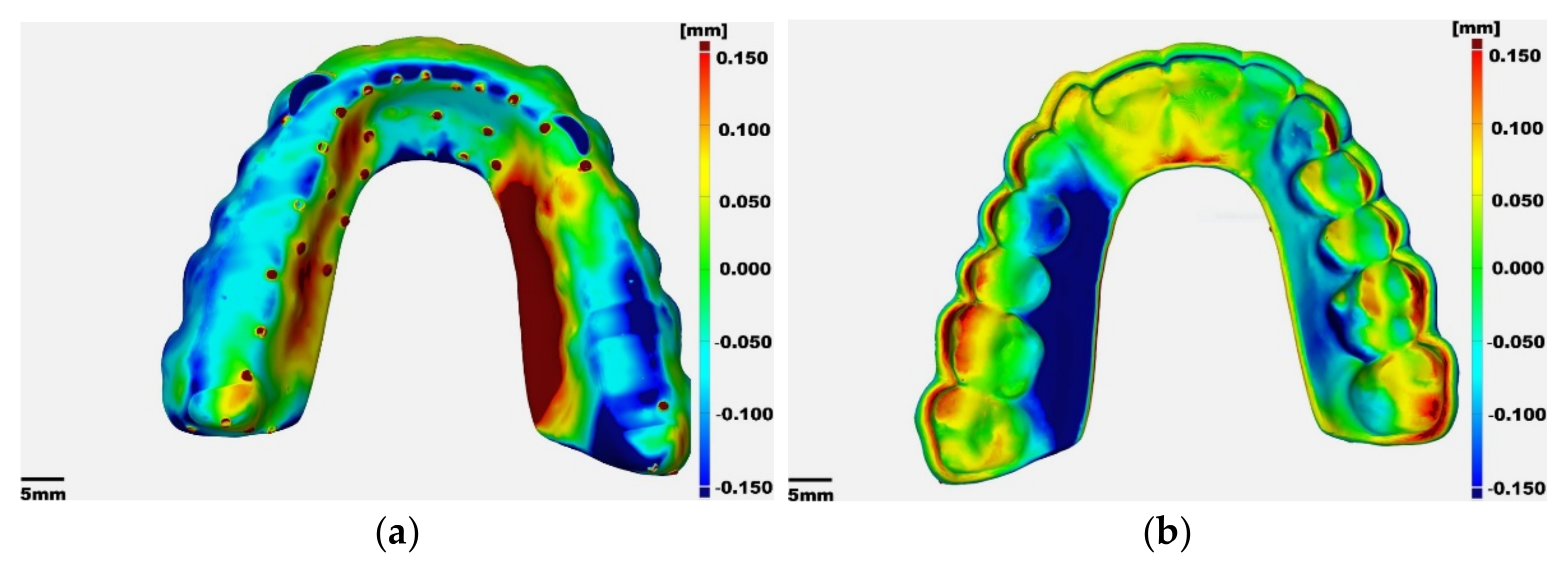

3.2. Evaluation of the Total Surface

3.2.1. Trueness

3.2.2. Precision

3.3. Evaluation of Volume

4. Discussion

Limitations

5. Conclusions

- −

- The printing and post-processing process were accompanied by a minimal shrinkage. The volume of the printed objects was between 2.11% and 2.35% less in comparison to the CAM files, which served as blueprint;

- −

- Within their groups, the [2.5_TOTAL] and [4.5_TOTAL] devices showed identical dimensional deviations in comparison to their corresponding stl references. However, between the two groups different deviation patterns were observed. The [2.5_TOTAL] were wider in the posterior region and compressed in the anterior area. The [4.5_TOTAL] showed a compression of the posterior area;

- −

- These observations confirmed that deviation patterns are not rigidly associated with the specific printer system but with different parameters. The different platform orientations specified by the CAM software for [2.5_TOTAL] and [4.5_TOTAL] and the different volumes could be identified as such influential variables;

- −

- The results revealed a high precision. The absolute mean deviation values were 19 µm for [2.5_TOTAL] and 26 µm for [4.5_TOTAL]. The high precision was underlined to be the more outlier sensitive RMSE value which revealed 34 µm for [2.5_TOTAL] and 42 µm for [4.5_TOTAL];

- −

- The absolute mean trueness was 68 µm for [2.5_TOTAL] and 90 µm for [4.5_TOTAL]. The median RMSE results were 88 µm for [2.5_TOTAL] and 122 µm for [4.5_TOTAL]. Thus, the results were comparable with previously published printer results;

- −

- There were statistically significant differences between [2.5_TOTAL] and [4.5_TOTAL] and between [2.5_INTERNAL] and [4.5_INTERNAL] with respect to trueness and precision values.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Klasser, G.D.; Greene, C.S. Oral appliances in the management of temporomandibular disorders. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endod. 2009, 107, 212–223. [Google Scholar] [CrossRef] [PubMed]

- Fricton, J.; Look, J.O.; Wright, E.; Alencar, F.G., Jr.; Chen, H.; Lang, M.; Ouyang, W.; Velly, A.M. Systematic review and meta-analysis of randomized controlled trials evaluating intraoral orthopedic appliances for temporomandibular disorders. J. Orofac. Pain 2010, 24, 237–254. [Google Scholar] [PubMed]

- Proff, P.; Richter, E.J.; Blens, T.; Fanghanel, J.; Hutzen, D.; Kordass, B.; Gedrange, T.; Rottner, K. A michigan-type occlusal splint with spring-loaded mandibular protrusion functionality for treatment of anterior disk dislocation with reduction. Ann. Anat. 2007, 189, 362–366. [Google Scholar] [CrossRef]

- Schindler, H.J.; Hugger, A.; Kordaß, B.; Türp, J.C. Splint therapy for temporomandibular disorders: Basic principles. J. Craniomandib. Funct. 2014, 6, 207–230. [Google Scholar]

- Leib, A.M. The occlusal bite splint—A noninvasive therapy for occlusal habits and temporomandibular disorders. Compend. Contin. Educ. Dent. 1996, 17, 1081–1084, 1086, 1088. [Google Scholar] [PubMed]

- Turp, J.C.; Komine, F.; Hugger, A. Efficacy of stabilization splints for the management of patients with masticatory muscle pain: A qualitative systematic review. Clin. Oral Investig. 2004, 8, 179–195. [Google Scholar] [CrossRef]

- Reyes-Sevilla, M.; Kuijs, R.H.; Werner, A.; Kleverlaan, C.J.; Lobbezoo, F. Comparison of wear between occlusal splint materials and resin composite materials. J. Oral Rehabil. 2018, 45, 539–544. [Google Scholar] [CrossRef]

- Macedo, C.R.; Silva, A.B.; Machado, M.A.; Saconato, H.; Prado, G.F. Occlusal splints for treating sleep bruxism (tooth grinding). Cochrane Database Syst. Rev. 2007, CD005514. [Google Scholar] [CrossRef]

- Edelhoff, D.; Schweiger, J.; Prandtner, O.; Trimpl, J.; Stimmelmayr, M.; Guth, J.F. CAD/CAM splints for the functional and esthetic evaluation of newly defined occlusal dimensions. Quintessence Int. 2017, 48, 181–191. [Google Scholar] [CrossRef]

- Vayrynen, V.O.; Tanner, J.; Vallittu, P.K. The anisotropicity of the flexural properties of an occlusal device material processed by stereolithography. J. Prosthet. Dent. 2016, 116, 811–817. [Google Scholar] [CrossRef]

- Kass, C.A.; Tregaskes, J.N. Occlusal splint fabrication. J. Prosthet. Dent. 1978, 40, 461–463. [Google Scholar] [CrossRef]

- Becker, C.M.; Kaiser, D.A.; Lemm, R.B. A simplified technique for fabrication fo night guards. J. Prosthet. Dent. 1974, 32, 582–589. [Google Scholar] [CrossRef]

- Bohnenkamp, D.M. Dimensional stability of occlusal splints. J. Prosthet. Dent. 1996, 75, 262–268. [Google Scholar] [CrossRef]

- Grymak, A.; Aarts, J.M.; Ma, S.; Waddell, J.N.; Choi, J.J.E. Wear Behavior of Occlusal Splint Materials Manufactured By Various Methods: A Systematic Review. J. Prosthodont. 2021. [Google Scholar] [CrossRef] [PubMed]

- Huettig, F.; Kustermann, A.; Kuscu, E.; Geis-Gerstorfer, J.; Spintzyk, S. Polishability and wear resistance of splint material for oral appliances produced with conventional, subtractive, and additive manufacturing. J. Mech. Behav. Biomed. Mater. 2017, 75, 175–179. [Google Scholar] [CrossRef] [PubMed]

- Reymus, M.; Stawarczyk, B. In vitro study on the influence of postpolymerization and aging on the Martens parameters of 3D-printed occlusal devices. J. Prosthet. Dent. 2021, 125, 817–823. [Google Scholar] [CrossRef]

- Marcel, R.; Reinhard, H.; Andreas, K. Accuracy of CAD/CAM-fabricated bite splints: Milling vs 3D printing. Clin. Oral Investig. 2020, 24, 4607–4615. [Google Scholar] [CrossRef]

- Berli, C.; Thieringer, F.M.; Sharma, N.; Muller, J.A.; Dedem, P.; Fischer, J.; Rohr, N. Comparing the mechanical properties of pressed, milled, and 3D-printed resins for occlusal devices. J. Prosthet. Dent. 2020, 124, 780–786. [Google Scholar] [CrossRef]

- Wesemann, C.; Spies, B.C.; Sterzenbach, G.; Beuer, F.; Kohal, R.; Wemken, G.; Krugel, M.; Pieralli, S. Polymers for conventional, subtractive, and additive manufacturing of occlusal devices differ in hardness and flexural properties but not in wear resistance. Dent. Mater. 2021, 37, 432–442. [Google Scholar] [CrossRef]

- Kattadiyil, M.T.; Jekki, R.; Goodacre, C.J.; Baba, N.Z. Comparison of treatment outcomes in digital and conventional complete removable dental prosthesis fabrications in a predoctoral setting. J. Prosthet. Dent. 2015, 114, 818–825. [Google Scholar] [CrossRef]

- Pagac, M.; Hajnys, J.; Ma, Q.P.; Jancar, L.; Jansa, J.; Stefek, P.; Mesicek, J. A Review of Vat Photopolymerization Technology: Materials, Applications, Challenges, and Future Trends of 3D Printing. Polymers 2021, 13, 598. [Google Scholar] [CrossRef]

- Hui, J.; Ding, K.; Chan, F. An investigation on energy consumption and part quality of stereolithography apparatus manufactured parts. Rapid Prototyp. J. 2022, 28, 52–67. [Google Scholar] [CrossRef]

- Sim, J.Y.; Jang, Y.; Kim, W.C.; Kim, H.Y.; Lee, D.H.; Kim, J.H. Comparing the accuracy (trueness and precision) of models of fixed dental prostheses fabricated by digital and conventional workflows. J. Prosthodont. Res. 2019, 63, 25–30. [Google Scholar] [CrossRef] [PubMed]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mulhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [Green Version]

- Alifui-Segbaya, F. Biomedical photopolymers in 3D printing. Rapid Prototyp. J. 2019, 26, 437–444. [Google Scholar] [CrossRef]

- Revilla-Leon, M.; Ozcan, M. Additive Manufacturing Technologies Used for Processing Polymers: Current Status and Potential Application in Prosthetic Dentistry. J. Prosthodont. 2019, 28, 146–158. [Google Scholar] [CrossRef] [Green Version]

- Kumar, M.V. Additive manufacturing techniques for the fabrication of tissue engineering scaffolds: A review. Rapid Prototyp. J. 2021, 27, 1230–1272. [Google Scholar] [CrossRef]

- Etemad-Shahidi, Y.; Qallandar, O.B.; Evenden, J.; Alifui-Segbaya, F.; Ahmed, K.E. Accuracy of 3-Dimensionally Printed Full-Arch Dental Models: A Systematic Review. J. Clin. Med. 2020, 9, 3357. [Google Scholar] [CrossRef]

- Tumbleston, J.R.; Shirvanyants, D.; Ermoshkin, N.; Janusziewicz, R.; Johnson, A.R.; Kelly, D.; Chen, K.; Pinschmidt, R.; Rolland, J.P.; Ermoshkin, A.; et al. Additive manufacturing. Continuous liquid interface production of 3D objects. Science 2015, 347, 1349–1352. [Google Scholar] [CrossRef]

- Balkenhol, M. Dentale CAD/CAM-Technologie Thieme; Thieme Verlag: Stuttgart, Germany, 2018. [Google Scholar]

- Stansbury, J.W.; Idacavage, M.J. 3D printing with polymers: Challenges among expanding options and opportunities. Dent. Mater. 2016, 32, 54–64. [Google Scholar] [CrossRef]

- Methani, M.M.; Revilla-Leon, M.; Zandinejad, A. The potential of additive manufacturing technologies and their processing parameters for the fabrication of all-ceramic crowns: A review. J. Esthet. Restor. Dent. 2019, 32, 182–192. [Google Scholar] [CrossRef] [PubMed]

- Pillai, S.; Upadhyay, A.; Khayambashi, P.; Farooq, I.; Sabri, H.; Tarar, M.; Lee, K.T.; Harb, I.; Zhou, S.; Wang, Y.; et al. Dental 3D-Printing: Transferring Art from the Laboratories to the Clinics. Polymers 2021, 13, 157. [Google Scholar] [CrossRef] [PubMed]

- Schlotthauer, T.; Nitsche, J.; Middendorf, P. Evaluation of UV post-curing depth for homogenous cross-linking of stereolithographic parts. Rapid Prototyp. J. 2021, 27, 1910–1916. [Google Scholar] [CrossRef]

- Unkovskiy, A.; Bui, P.H.; Schille, C.; Geis-Gerstorfer, J.; Huettig, F.; Spintzyk, S. Objects build orientation, positioning, and curing influence dimensional accuracy and flexural properties of stereolithographically printed resin. Dent. Mater. 2018, 34, e324–e333. [Google Scholar] [CrossRef] [PubMed]

- Kim, N.; Bhalerao, I.; Han, D.; Yang, C.; Lee, H. Improving Surface Roughness of Additively Manufactured Parts Using a Photopolymerization Model and Multi-Objective Particle Swarm Optimization. Appl. Sci. 2019, 9, 151. [Google Scholar] [CrossRef] [Green Version]

- Wu, X.; Xu, C.; Zhang, Z.; Jin, Z. Tilting separation simulation and theory verification of mask projection stereolithography process. Rapid Prototyp. J. 2021, 27, 851–860. [Google Scholar] [CrossRef]

- Mehl, A.; Reich, S.; Beuer, F.; Güth, J. Accuracy, trueness, and precision–A guideline for evaluation of these basic values in digital dentistry. Int. J. Comput. Dent. (in press). 2021, 24, 1–11. [Google Scholar]

- International Organization for Standardization. ISO 5725-1. Accuracy (Trueness and Precision) of Measuring Methods and Results. Part-I: General Principles and Definitions; Beuth Verlag: Berlin, Germany, 1994. [Google Scholar]

- Passos, L.; Meiga, S.; Brigagao, V.; Street, A. Impact of different scanning strategies on the accuracy of two current intraoral scanning systems in complete-arch impressions: An in vitro study. Int. J. Comput. Dent. 2019, 22, 307–319. [Google Scholar]

- Dold, P.; Bone, M.C.; Flohr, M.; Preuss, R.; Joyce, T.J.; Deehan, D.; Holland, J. Validation of an optical system to measure acetabular shell deformation in cadavers. Proc. Inst. Mech. Eng. H 2014, 228, 781–786. [Google Scholar] [CrossRef]

- Wesemann, C.; Spies, B.C.; Schaefer, D.; Adali, U.; Beuer, F.; Pieralli, S. Accuracy and its impact on fit of injection molded, milled and additively manufactured occlusal splints. J. Mech. Behav. Biomed. Mater. 2021, 114, 104179. [Google Scholar] [CrossRef]

- Yoon, H.I.; Hwang, H.J.; Ohkubo, C.; Han, J.S.; Park, E.J. Evaluation of the trueness and tissue surface adaptation of CAD-CAM mandibular denture bases manufactured using digital light processing. J. Prosthet. Dent. 2018, 120, 919–926. [Google Scholar] [CrossRef] [PubMed]

- Wenbin, H.; Tsui, L.; Haiging, G. A study of the staircase effect induced by material shrinkage in rapid prototyping. Rapid Prototyp. J. 2005, 11, 82–89. [Google Scholar] [CrossRef]

- Park, J.M.; Jeon, J.; Koak, J.Y.; Kim, S.K.; Heo, S.J. Dimensional accuracy and surface characteristics of 3D-printed dental casts. J. Prosthet. Dent. 2021, 126, 427–437. [Google Scholar] [CrossRef] [PubMed]

- Bugeda, G.; Cervera, M.; Lombera, G.; Onate, E. Numerical analysis of stereolithography processes using the finite element method. Rapid Prototyp. J. 1995, 1, 13–23. [Google Scholar] [CrossRef]

| Resin | |

|---|---|

| Flexural Strength [MPa] | >80 |

| Elastic Modulus [MPa] | >2000 |

| Water Absorption [µg/mm3] | <32 |

| Solubility [µg/mm3] | <5 |

| Hardness [Shore D] | >82 |

| Color | clear-transparent |

| Curing Wavelength [nm] | 385 |

| CAM Settings | |

| Printer | |

| DMD projector resolution [pixels] | 1920 × 1024 |

| Spectral Maximum of LED | 385 nm |

| Membrane Type of Material Unit | flexible |

| Support Structures | |

| Distribution | based on object geometry |

| Density | Medium |

| Size | Medium |

| Spherical Support Tip | Yes |

| Occlusal Device | |

| Orientation Strategy | Optimized quality |

| Detail Level (Layer Thickness [µm]) | Very high (50) |

| Post-Processing | |

| Washing Solution | 99.9% isopropyl alcohol |

| n | Absolute Mean Deviation [µm] | RMS Error [µm] | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Minimum | Maximum | Mean ± Standard Deviation | Median | Minimum | Maximum | Mean ± Standard Deviation | Median | ||

| [2.5_INTERNAL] | 10 | 54 | 64 | 59 ± 5 | 59 | 70 | 83 | 77 ± 6 | 77 |

| [4.5_INTERNAL] | 10 | 73 | 98 | 80 ± 9 | 78 | 97 | 130 | 106 ± 12 | 103 |

| n | Precision Based on Absolute Deviation [µm] | Precision Based on RMS Error [µm] | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Minimum | Maximum | Mean ± Standard Deviation | Median | Minimum | Maximum | Mean ± Standard Deviation | Median | ||

| [2.5_INTERNAL] | 10 | 3 | 22 | 14 ± 8 | 20 | 5 | 29 | 19 ± 10 | 27 |

| [4.5_INTERNAL] | 10 | 4 | 40 | 22 ± 11 | 22 | 8 | 52 | 31 ± 13 | 29 |

| n | Absolute Mean Deviation [µm] | RMS Error [µm] | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Minimum | Maximum | Mean ± Standard Deviation | Median | Minimum | Maximum | Mean ± Standard Deviation | Median | ||

| [2.5_TOTAL] | 10 | 65 | 69 | 68 ± 1 | 68 | 83 | 91 | 88 ± 3 | 88 |

| [4.5_TOTAL] | 10 | 82 | 109 | 90 ± 10 | 87 | 113 | 145 | 122 ± 12 | 118 |

| n | Precision Based on Absolute Deviation [µm] | Precision Based on RMS Error [µm] | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Minimum | Maximum | Mean ± Standard Deviation | Median | Minimum | Maximum | Mean ± Standard Deviation | Median | ||

| [2.5_TOTAL] | 10 | 6 | 29 | 19 ± 10 | 26 | 21 | 46 | 34 ± 8 | 37 |

| [4.5_TOTAL] | 10 | 7 | 45 | 26 ± 13 | 25 | 23 | 65 | 42 ± 12 | 41 |

| [2.5_TOTAL] | |

|---|---|

| Reference file | 5682.69 |

| Printed (mean) (N = 10) | 5548.93 |

| Absolute Volume Difference | 133.76 |

| Relative Volume Difference | 2.35% |

| [4.5_TOTAL] | Volume [] |

| Reference file | 6737.55 |

| Printed (mean) (N = 10) | 6595.38 |

| Absolute Volume Difference | 142.17 |

| Relative Volume Difference | 2.11% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reich, S.; Berndt, S.; Kühne, C.; Herstell, H. Accuracy of 3D-Printed Occlusal Devices of Different Volumes Using a Digital Light Processing Printer. Appl. Sci. 2022, 12, 1576. https://doi.org/10.3390/app12031576

Reich S, Berndt S, Kühne C, Herstell H. Accuracy of 3D-Printed Occlusal Devices of Different Volumes Using a Digital Light Processing Printer. Applied Sciences. 2022; 12(3):1576. https://doi.org/10.3390/app12031576

Chicago/Turabian StyleReich, Sven, Saskia Berndt, Christina Kühne, and Hannah Herstell. 2022. "Accuracy of 3D-Printed Occlusal Devices of Different Volumes Using a Digital Light Processing Printer" Applied Sciences 12, no. 3: 1576. https://doi.org/10.3390/app12031576

APA StyleReich, S., Berndt, S., Kühne, C., & Herstell, H. (2022). Accuracy of 3D-Printed Occlusal Devices of Different Volumes Using a Digital Light Processing Printer. Applied Sciences, 12(3), 1576. https://doi.org/10.3390/app12031576